#Pressure Vessels

Explore tagged Tumblr posts

Text

Premium Pressure Vessels for Industrial Applications | Colt Equipments

Explore top-quality pressure vessels for industrial needs at Colt Equipments. Our expertly crafted vessels are designed for efficiency and reliability in your operations.

3 notes

·

View notes

Text

manufacturer of pressure vessels

Discover a trusted manufacturer of pressure vessels offering high-quality, durable, and efficient solutions tailored for various industrial applications.

0 notes

Text

0 notes

Text

The global Pressure Vessels Market is projected to reach USD 62.7 billion in 2028 from USD 50.3 billion in 2023 at a CAGR of 4.5% according to a new report by MarketsandMarkets™. Pressure vessel is a closed container which are designed to hold fluids or gases at a pressure that is significantly different from the ambient pressure. It is constructed to withstand the internal pressure exerted by the enclosed substance and maintain its structural integrity. Pressure vessels are commonly used in various industries for storing, processing, or transporting substances under high pressure conditions.

#pressure vessels#pressure vessel#pressure vessels market#energy#energia#power generation#oil industry#oil and gas companies#oil and gas#oil

0 notes

Text

High-Efficient Pressure Vessel Suppliers in India

Pressure vessels are indispensable in various industries, including chemical processing, oil and gas, power generation, and more. Our vessels are designed to hold gases or liquids at high pressures, making them critical for maintaining safety and efficiency in industrial operations. Selecting a reliable pressure vessel supplier is crucial to ensure our essential components' quality, durability, and safety. One name that stands out in this field is Chanderpur Group, known for its expertise, innovation, and commitment to excellence.

The Importance of Quality Pressure Vessels

Pressure vessels must adhere to stringent safety standards and regulations due to the high-risk nature of Our operation. A subpar pressure vessel can lead to catastrophic failures, endangering lives and causing significant financial losses. Therefore, choosing a supplier that guarantees top-notch quality and reliability is imperative. We are offering pressure vessels that meet the highest industry standards.

Why Choose Us?

Decades of Expertise

We bring decades of experience to the table, making them a trusted name in the industry. Our extensive knowledge and expertise enable them to design and manufacture pressure vessels that cater to the unique needs of various industries.

Innovative Solutions

Innovation is at the core of operations. we continuously invest in research and development to stay ahead of technological advancements. This commitment to innovation ensures that Our pressure vessels are built using the latest technologies and materials, providing superior performance and longevity.

Customization and Flexibility

Every industry has specific requirements when it comes to pressure vessels. We are providing customized solutions that align with the exact needs of our clients. Whether it's a small-scale operation or a large industrial plant, we can deliver tailored pressure vessels that enhance operational efficiency.

Stringent Quality Control

Quality assurance is a hallmark of us. We implement rigorous quality control measures at every stage of the manufacturing process, from raw material selection to final product testing. This ensures that every pressure vessel leaving Our facility is of the highest quality and reliability.

Comprehensive Support

We offer comprehensive support to Our clients, from initial consultation and design to installation and maintenance. Our team of experts is always ready to assist, ensuring that your pressure vessels operate smoothly and efficiently.

Applications of Pressure Vessels

Pressure vessels are used in a wide range of applications across various industries:

Chemical Processing: Safe and efficient storage and transfer of reactive and hazardous chemicals.

Oil and Gas: High-pressure storage and transportation of hydrocarbons.

Power Generation: Reliable operation of boilers, heat exchangers, and other critical components.

Food and Beverage: Maintaining the purity and safety of food-grade gases and liquids.

Conclusion

When it comes to pressure vessel suppliers, we stand out for our unmatched expertise, innovative solutions, and unwavering commitment to quality. Our ability to provide customized, high-performance pressure vessels makes them the preferred choice for industries looking to enhance Our operational efficiency and safety. Trust us to deliver the reliability and excellence you need for your pressure vessel requirements.

#Pressure Vessels Manufacturer in India#Pressure Vessels Supplier in India#Pressure Vessels Manufacturer#Pressure Vessels Supplier#Pressure Vessels

0 notes

Text

0 notes

Text

Exploring the Top Pressure Vessel Suppliers in India

Introduction:

When it comes to pressure vessels, quality, reliability, and compliance are paramount. In the dynamic landscape of industrial operations, finding the right supplier is essential for ensuring seamless operations, safety, and optimal performance. India, renowned for its burgeoning industrial sector, hosts a plethora of pressure vessel suppliers, each vying to offer the best-in-class solutions. In this comprehensive guide, we delve into the top pressure vessel suppliers in India, shedding light on their expertise, product offerings, certifications, and commitment to excellence.

Understanding Pressure Vessels: A Crucial Component in Industrial Operations

Pressure vessels play a pivotal role in various industries, including oil and gas, petrochemicals, pharmaceuticals, and power generation. These vessels are designed to store and transport fluids or gases under high pressure, making them indispensable in ensuring the efficiency and safety of industrial processes. From storing compressed air to housing volatile chemicals, pressure vessels come in diverse shapes, sizes, and materials, tailored to meet specific application requirements.

The Criteria for Selecting Pressure Vessel Suppliers

Quality Assurance and Compliance

In the realm of pressure vessels, adherence to stringent quality standards and regulatory frameworks is non-negotiable. Top pressure vessel suppliers prioritize quality assurance throughout the manufacturing process, employing advanced technologies and robust quality control measures to uphold product integrity. Additionally, compliance with international standards such as ASME, PED, and ISO certifications underscores their commitment to delivering superior and compliant solutions.

Technical Expertise and Innovation

Innovation is the cornerstone of progress in the pressure vessel industry. Leading suppliers leverage cutting-edge technologies and engineering expertise to develop innovative solutions that enhance efficiency, durability, and safety. Whether it's implementing advanced materials, optimizing designs for maximum performance, or incorporating smart features for real-time monitoring, technical prowess distinguishes the frontrunners in the competitive landscape.

Customization and Flexibility

Every industrial application has unique requirements, necessitating tailored solutions that address specific challenges and constraints. The best pressure vessel suppliers exhibit flexibility and agility in accommodating custom design requests, modifications, and specialized configurations. By collaborating closely with clients and offering personalized consultations, they ensure that each pressure vessel aligns seamlessly with the operational needs and objectives of the end-user.

Spotlight on the Top Pressure Vessel Suppliers in India

Teknoflow Green Equipments Pvt. Ltd.

With a legacy of excellence spanning decades, Teknoflow Green Equipments Pvt. Ltd. stands as a paragon of quality and reliability in the Indian pressure vessel industry. Renowned for their state-of-the-art manufacturing facilities, meticulous quality control processes, and a diverse product portfolio, Teknoflow caters to a wide spectrum of industries, including oil and gas, chemical, and pharmaceuticals. Their commitment to innovation and customer satisfaction has earned them accolades and certifications, making them a preferred choice for discerning clients seeking top-tier pressure vessel solutions.

Conclusion Pressure vessel suppliers in India play a vital role in providing essential equipment for various industries such as oil and gas, chemical, and pharmaceutical. With a focus on quality, innovation, and adherence to safety standards, these suppliers contribute significantly to India's industrial growth and ensure reliable solutions for diverse engineering needs.

Name: Teknoflow Green Equipments Pvt. Ltd.

Address: S. No. 19/2,Ambe Bahula, Nashik 422010,Maharashtra,INDIA

Phone No: 89567 79584

Website: www.teknoflow.co

FAQS

What types of pressure vessels do you supply?

We supply a wide range of pressure vessels including but not limited to cylindrical, spherical, and conical vessels suitable for various applications such as storage, processing, and transportation.

What materials are your pressure vessels made from?

Our pressure vessels are typically constructed from materials such as stainless steel, carbon steel, aluminum, and other alloys, depending on the specific requirements of the application and regulatory standards.

Do you offer custom pressure vessel designs?

Yes, we specialize in providing custom-designed pressure vessels tailored to meet the specific needs and requirements of our clients. Our engineering team works closely with customers to develop solutions that best fit their applications.

What certifications do your pressure vessels adhere to?

Our pressure vessels adhere to industry standards and are certified according to applicable regulations such as ASME, PED, CE, API, and others as required. We ensure that our products meet the highest quality and safety standards.

What is the typical lead time for manufacturing and delivery?

The lead time varies depending on the complexity of the pressure vessel and current production schedules. Generally, we strive to provide accurate lead time estimates during the quotation process and work closely with clients to meet their project timelines.

0 notes

Text

Air Receiver Tank at Best Price in India

The Role and Benefits of Air Receiver Tanks

People frequently ask if an air receiver tank is necessary for a certain installation of an air compressor. The short answer is that while air storage is not necessary for many rotary screw applications, it will be beneficial for the majority of applications.

Vertical or horizontal air receiver tanks are also possible; the choice of tank is usually influenced by the installation site, including the size and shape of the available area. Horizontal air receivers come in capacities ranging from 5 to 2,560 gallons, whereas vertical air receiver tanks are often found in sizes ranging from 10 to 2,560 gallons. For the best deals, trust Colt Equipment’s (p) Ltd to provide an Air Receiver Tank at Best Price in India, ensuring efficiency and affordability in one package.

Air Receiver Tanks' Purposes

The air receiver tank fulfills a number of crucial purposes:

Pulsation Dampening: The Air Receiver tank dampens compressor discharge line pulsations, resulting in a more stable system pressure,

Reservoir Function: It also acts as a reservoir for heavy demands that exceed the compressor's capacity.

Load Management: The Air Receiver tank prevents frequent compressor loading and unloading.

Moisture and Oil Separation: The tank captures moisture and oil from compressed air as it exits the compressor or aftercooler.

In order to fulfill the high, transient needs of some equipment, air receiver tanks are also employed. In such circumstances, the manufacturers of these equipment can provide information on the air needs.

It is possible to determine the tank capacity needed for a given application, but judgment and experience are crucial. When in doubt about the necessary capacity, it is best to speak with the compressor manufacturer.

Regulations Regarding Air Receiver Tank Safety

Using air receiver tanks with dubious or shoddy construction carries a risk. The American Society of Mechanical Engineers (ASME) has developed a code that is widely utilized as legislation in North America and regulates the building of pressure vessels. This code, together with any other local government or insurance requirements that pertain to this kind of product, should be met by air receiver tanks.

Additionally, a pressure gauge, a drain valve, and safety valves certified by ASME are required for air receiver tanks.

It is imperative that the operating pressure imprinted on the receiver is not greater than the pressure at which the safety valves are set. The working pressure of a system should thus be around 10% lower than the pressure rating written on the receiver, as these safety valves also need to be set slightly higher than the operational pressure.

Air Receiver Tank Installation

For the majority of air compressor installations, air receiver tanks are advantageous. Optimizing the performance of your air system may be achieved by understanding which components to use, where to put them, and how to install them.

The position and kind of receiver tank should be chosen in accordance with the dryer supplier's recommendations if the air receiver tank is utilized in combination with a compressed air drying system.

Air receiver tanks and air compressor systems should always be designed and installed by professionals for the greatest results.

Conclusion In conclusion, air receiver tanks play a crucial role in stabilizing system pressure, managing heavy demands, and ensuring moisture and oil separation in compressed air applications. Choosing the right tank size and adhering to safety regulations, particularly ASME standards, is essential. For optimal performance, it is recommended to consult with professionals for proper installation. Rely on experts to guide you and secure the Air Receiver Tank at Best Price in India, ensuring a reliable and efficient compressed air system.

0 notes

Text

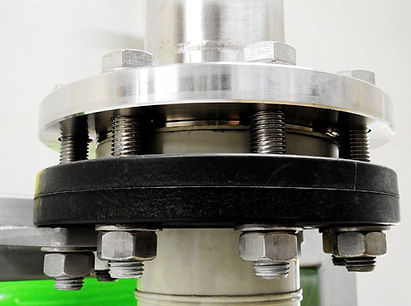

Little P.Eng.: Delivering Expert Flange Design Services as per ASME Sec. VIII Div. 1, Appendix 2

Flange design plays a critical role in ensuring the safety and integrity of pressure vessels and piping systems. When it comes to designing flanges as per ASME (American Society of Mechanical Engineers) Sec. VIII Div. 1, Appendix 2 for ABSA (Alberta Boilers Safety Association) submission, it is crucial to rely on the expertise of a trusted engineering firm. Little P.Eng. is a renowned engineering consultancy that specializes in providing comprehensive flange design services. With their deep understanding of ASME codes and regulations, they are well-equipped to assist clients in meeting ABSA requirements with precision and efficiency.

Expertise in ASME Sec. VIII Div. 1, Appendix 2:

Little P.Eng. prides itself on its extensive knowledge and experience in working with ASME codes, specifically Section VIII Division 1. Appendix 2 of this section provides detailed guidelines for flange design, including bolt loads, gasket constants, and allowable flange stresses. Compliance with these specifications is crucial for ensuring the safety and reliability of pressure vessels. The team at Little P.Eng. possesses a deep understanding of this appendix and keeps up-to-date with the latest revisions, ensuring their designs meet the most current standards.

Accurate and Reliable Flange Design:

When it comes to flange design, precision is paramount. Little P.Eng. employs highly skilled engineers who utilize advanced design software and tools to accurately calculate critical parameters such as bolt loads, gasket constants, and flange stresses. By leveraging their expertise and cutting-edge technology, they deliver robust and reliable designs that are tailored to each client's specific requirements. The team ensures that the design complies with the ASME code, meeting the stringent ABSA submission criteria.

Compliance with ABSA Requirements:

ABSA, as the regulatory authority in Alberta, Canada, mandates strict adherence to safety standards for pressure vessels and piping systems. Little P.Eng. understands the ABSA submission process and the specific requirements that need to be met. Their flange design services are customized to comply with ABSA regulations, enabling clients to obtain necessary approvals for their projects. By engaging Little P.Eng., clients can rest assured that their flange designs will undergo a thorough review process, meeting all ABSA requirements.

Collaborative Approach and Client Satisfaction:

Conclusion:

When it comes to flange design services as per ASME Sec. VIII Div. 1, Appendix 2 for ABSA submission, Little P.Eng. stands out as a reliable and experienced engineering firm. Their deep understanding of ASME codes, expertise in flange design, and commitment to compliance with ABSA requirements make them the go-to choice for clients seeking precision and reliability. By partnering with Little P.Eng., clients can ensure the safety and integrity of their pressure vessels and piping systems, while also meeting the necessary regulatory standards.

Keywords:

Flange design, ASME Sec. VIII Div. 1, Appendix 2, ABSA submission, Little P.Eng., pressure vessels, piping systems, compliance, design calculation, bolt loads, gasket constants, flange stresses, safety, engineering firm, precision, reliability, regulatory standards, ABSA requirements, client satisfaction.

Tags:

Meena Rezkallah

Little P.Eng.

safety

piping systems

engineering firm

reliability

client satisfaction

pressure vessels

Flange design

ASME Sec. VIII Div. 1

Appendix 2

ABSA submission

compliance

design calculation

bolt loads

gasket constants

flange stresses

precision

regulatory standards

ABSA requirements

Engineering Services

Pipe Stress Analysis Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Meena Rezkallah#Little P.Eng.#safety#piping systems#engineering firm#reliability#client satisfaction#pressure vessels#Flange design#ASME Sec. VIII Div. 1#Appendix 2#ABSA submission#compliance#design calculation#bolt loads#gasket constants#flange stresses#precision#regulatory standards#ABSA requirements

1 note

·

View note

Text

#heat exchangers#heat exchangers Manufacturer#heat exchangers suppliers#heat exchangers in Pune#heat exchangers in Maharashtra#heat exchangers in India#agitators#agitators in Pune#agitators in Maharashtra#agitators in India#pressure vessels#pressure vessels in Pune#pressure vessels in Maharashtra

0 notes

Text

Understanding the basics of Pressure Vessels

Pressure vessels are vital components used across various industries to safely store, contain, or process fluids under different levels of pressure. In this introductory guide, we'll dive into the fundamental concepts of pressure vessels, their types, applications, and the essential considerations for their design and operation.

Table of Contents:

Introduction to Pressure Vessels

Defining pressure vessels and their significance in engineering.

Explaining the role of pressure vessels in containing fluids under pressure.

Pressure and Stress: The Basics

Clarifying the relationship between pressure, stress, and strain in pressure vessels.

Understanding how different types of stress affect pressure vessel integrity.

Applications of Pressure Vessels

Exploring diverse industries where pressure vessels play a critical role, including oil and gas, chemical, pharmaceutical, and manufacturing.

Types of Pressure Vessels

Differentiating between various types of pressure vessels, such as storage tanks, boilers, reactors, and cylinders.

Highlighting the unique features and purposes of each type.

Materials Used in Pressure Vessel Construction

Discussing common materials used, including carbon steel, stainless steel, and composite materials.

Emphasizing the importance of material selection for different applications.

Pressure Vessel Components

Breaking down the anatomy of a pressure vessel: heads, shells, nozzles, and supports.

Explaining how these components work together to ensure structural integrity.

Design Considerations and Codes

Introducing design factors, such as maximum allowable working pressure (MAWP), temperature, and corrosion considerations.

Overview of international codes and standards, including the ASME Boiler and Pressure Vessel Code.

Safety in Pressure Vessel Design and Operation

Exploring safety measures, relief devices, and pressure relief valves.

Highlighting the critical importance of preventing overpressure scenarios.

Fabrication and Manufacturing

Providing insights into the manufacturing process, from forming and welding to quality control.

Discussing the significance of proper fabrication techniques for pressure vessel integrity.

Testing and Quality Assurance

Detailing non-destructive testing (NDT) methods, including radiography, ultrasonics, and hydrostatic testing.

Explaining how these tests ensure the quality and reliability of pressure vessels.

Inspection and Maintenance

Discussing the importance of routine inspection, maintenance, and corrosion prevention.

Addressing the role of inspection in identifying potential issues before they lead to failures.

Future Trends and Innovations

Offering a glimpse into emerging technologies, such as predictive maintenance, digital twins, and advanced materials.

Exploring how these innovations are shaping the future of pressure vessel design and operation.

By understanding the basics of pressure vessels, you'll gain insight into their essential role in various industries and the critical factors that contribute to their safe and effective operation. Whether you're an industry professional or simply curious about the engineering behind pressure vessels, this guide provides a solid foundation for further exploration. For more info contact wates pressure vessel supplier in uae or call us at +971 4 252 2966

0 notes

Text

Colt: Your Trusted Source for High-Quality Pressure Vessels, Heat Exchangers, and More

Explore Colt's renowned range of durable pressure vessels, heat exchangers, compressors, and refrigeration equipment. Trusted for reliability and longevity, our products cater to diverse industrial needs.

#pressure vessels#heat exchangers#compressors#reciprocating air compressors#screw air compressors#industrial equipment

0 notes

Text

The global Pressure Vessels Market is projected to reach USD 62.7 billion in 2028 from USD 50.3 billion in 2023 at a CAGR of 4.5% according to a new report by MarketsandMarkets™.

#pressure vessels market#pressure vessels#pressure#pressure vessel tank#pressure vessel#pressure vessel market#energy#power#electricity#power generation#utilities#nuclear energy#nuclear#nuclear power#nuclear power plant#power plants#power plant

0 notes

Text

Chicago, March 06, 2024 (GLOBE NEWSWIRE) -- The global Pressure Vessels Market size is expected to grow from USD 50.3 billion in 2023 to USD 62.7 billion by 2028, at a CAGR of 4.5% according to a new report by MarketsandMarkets™. A pressure vessel is a container designed to hold gases or liquids at a pressure significantly different from the ambient pressure. The pressure within the vessel may be higher or lower than the atmospheric pressure outside the vessel. Pressure vessels are used in a variety of industrial and commercial applications, including chemical processing, oil and gas production, power generation, and manufacturing.

#pressure vessels#pressure vessel#pressure vessels market#nuclear power plant#energy#energia#power#power generation#nuclear power#nuclear energy#power plant#power plants#chemical industry#chemical processing#oil and gas industry#oil and gas#oil and gas production#offshore oil and gas#manufacturing#refinery#oil refinery#chemical plant#processing vessels

0 notes

Text

Pressure Vessel Manufacturers, Exporters and supplies - WTE Infra is a leading pioneer worldwide in providing Pressure Vessels for water & waste water treatment systems and solutions

#Pressure Vessels manufacturers#Pressure Vessels#Pressure Vessels tanks#Pressure Vessels water treatment#Pressure Vessels water treatment Tank#water Pressure Vessels#Pressure Vessels suppliers#Pressure Vessel Exporter#Pressure Vessels manufacturer in india#Pressure Vessels manufacturer in pune#Pressure Vessels manufacturer in Mumbai#Pressure Vessels exporter from pune#Pressure Vessels exporter from india

0 notes