#regulatory standards

Explore tagged Tumblr posts

Text

Certified Biomedical Technicians are vital to the smooth operation of healthcare facilities, ensuring that critical medical equipment is functional and safe. However, their responsibilities come with unique challenges. Here are some of the most common obstacles they face:

0 notes

Text

Autonomous Vehicle | UK, Germany | Law & Regulatory | Safety

#artificialintelligence#automotive#automated#self driving vehicles#regulatory standards#certification

0 notes

Text

The Essential Guide to Legal Compliance in Multifamily Signage serves as a comprehensive resource for property managers, developers, and legal professionals navigating the complex landscape of signage regulations within multifamily housing environments.

Source : The Essential Guide to Legal Compliance in Multifamily Signage

#Legal Compliance#Multifamily Signage#signage company#Signage Guidelines#Regulatory Standards#Signage Best Practices

0 notes

Text

Drug screening is a critical process in ensuring workplace safety and compliance. At our medical laboratory in Holiday, Florida, we understand the importance of accurate and timely drug testing for various purposes, including pre-employment screening, routine checks, and compliance with regulatory standards. Our commitment to precision and confidentiality ensures that our clients receive reliable results they can trust.

0 notes

Text

Enhancing Healthcare Compliance: The Role of Microlearning in Mitigating Legal and Reputational Risks

In the dynamic landscape of healthcare, maintaining compliance and safeguarding reputation are paramount. The industry faces stringent regulatory standards and ethical obligations, making it imperative for organizations to ensure that their workforce is well-informed and compliant. One powerful tool in this endeavor is microlearning—a modern, efficient approach to training that can significantly enhance healthcare compliance and integrity.

The Complexity of Healthcare Compliance

Healthcare organizations operate under a complex web of regulations, including the Health Insurance Portability and Accountability Act (HIPAA), the Affordable Care Act (ACA), and various state-specific laws. Compliance is not just about avoiding fines and legal action; it's about protecting patient privacy, ensuring data security, and maintaining trust. Non-compliance can lead to severe legal consequences and tarnish an organization’s reputation, potentially resulting in loss of business and public trust.

The Traditional Training Challenges

Traditional compliance training methods, such as lengthy seminars and extensive manuals, often fall short in today’s fast-paced environment. These methods can be overwhelming, time-consuming, and difficult to retain. Employees may struggle to stay engaged, leading to gaps in knowledge and understanding. Additionally, the ever-evolving nature of healthcare regulations necessitates continuous learning, which traditional methods may not effectively support.

Microlearning: A Modern Solution

Microlearning addresses these challenges by breaking down complex information into bite-sized, easily digestible modules. This approach aligns with the way modern learners consume information, making it ideal for healthcare compliance training. Here’s how microlearning can fortify healthcare integrity and mitigate legal and reputational risks:

1. Engaging and Retentive Learning

Microlearning leverages various multimedia elements such as videos, infographics, and interactive quizzes to create engaging content. This not only captures the learners’ attention but also aids in better retention of information. By presenting compliance regulations and ethical guidelines in a visually appealing and interactive manner, employees are more likely to understand and remember key concepts.

2. Just-in-Time Training

One of the significant advantages of microlearning is its flexibility. Healthcare professionals can access training modules anytime, anywhere, allowing for just-in-time learning. This is particularly useful in a fast-paced environment where immediate access to critical information is essential. For example, a nurse can quickly review patient confidentiality protocols right before handling sensitive patient information, ensuring compliance in real-time.

3. Continuous Learning and Updates

Microlearning supports continuous education by providing regular updates and refresher courses. Given the frequent changes in healthcare regulations, this is crucial. Instead of waiting for annual training sessions, employees can receive timely updates on new laws and best practices, ensuring they remain compliant throughout the year. This proactive approach helps organizations stay ahead of regulatory changes and reduces the risk of non-compliance.

4. Personalized Learning Experience

Microlearning allows for personalized learning experiences tailored to individual roles and responsibilities. In a healthcare setting, different departments may have unique compliance requirements. Microlearning modules can be customized to address specific needs, ensuring that each employee receives relevant and targeted training. This targeted approach enhances the effectiveness of the training and ensures that all compliance areas are adequately covered.

Legal and Reputational Safeguards

1. Mitigating Legal Risks

Microlearning’s ability to provide timely, relevant, and easily accessible training helps mitigate legal risks. Employees are more likely to stay informed about compliance requirements, reducing the likelihood of violations. In the event of a legal audit or investigation, organizations can demonstrate their commitment to compliance through detailed records of microlearning activities, showcasing the proactive measures taken to educate their workforce.

2. Enhancing Reputation and Trust

A strong compliance program bolstered by microlearning not only protects against legal scrutiny but also enhances an organization’s reputation. Patients and stakeholders are more likely to trust an organization that prioritizes ethical practices and regulatory compliance. This trust is invaluable in the healthcare industry, where the stakes are high, and reputational damage can have long-lasting consequences.

Implementing Microlearning in Healthcare

To effectively implement microlearning in a healthcare setting, organizations should consider the following steps:

1. Identify Key Compliance Areas

Determine the critical compliance areas that need to be addressed through microlearning. This could include patient privacy, data security, clinical protocols, and ethical standards. Prioritize topics based on regulatory requirements and potential risks.

2. Develop Engaging Content

Create engaging and interactive microlearning modules that cater to different learning styles. Use multimedia elements to make the content visually appealing and easy to understand. Incorporate real-life scenarios and case studies to illustrate the practical application of compliance principles.

3. Leverage Technology

Utilize a robust learning management system (LMS) to deliver and track microlearning modules. An LMS can help monitor employee progress, provide automated updates, and generate reports for compliance audits. Ensure the platform is user-friendly and accessible on various devices.

4. Foster a Culture of Continuous Learning

Encourage a culture of continuous learning and improvement within the organization. Emphasize the importance of compliance and provide incentives for employees who actively engage in microlearning. Regularly update and refresh the content to keep it relevant and aligned with current regulations.

5. Evaluate and Improve

Regularly assess the effectiveness of the microlearning program through feedback and performance metrics. Identify areas for improvement and make necessary adjustments to enhance the learning experience. Continuous evaluation ensures that the program remains effective and impactful.

Conclusion

In the ever-evolving healthcare industry, maintaining compliance and protecting reputation are critical for success. Microlearning offers a strategic solution to these challenges by providing engaging, flexible, and up-to-date training that aligns with modern learning preferences. By incorporating microlearning into their compliance programs, healthcare organizations can fortify their integrity, mitigate legal risks, and build trust with patients and stakeholders. Embracing this innovative approach to training is not just a compliance measure—it’s a strategic advantage in today’s complex healthcare landscape.

#Healthcare compliance#Microlearning#Legal risks#Reputational hazards#Training#Regulatory standards#Ethical obligations#Workforce development#Healthcare integrity#Compliance training

0 notes

Text

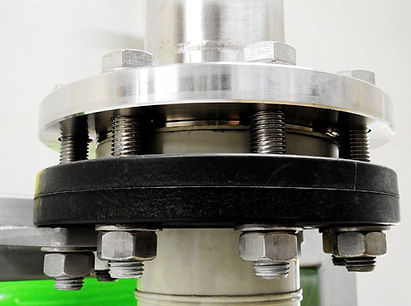

Little P.Eng.: Delivering Expert Flange Design Services as per ASME Sec. VIII Div. 1, Appendix 2

Flange design plays a critical role in ensuring the safety and integrity of pressure vessels and piping systems. When it comes to designing flanges as per ASME (American Society of Mechanical Engineers) Sec. VIII Div. 1, Appendix 2 for ABSA (Alberta Boilers Safety Association) submission, it is crucial to rely on the expertise of a trusted engineering firm. Little P.Eng. is a renowned engineering consultancy that specializes in providing comprehensive flange design services. With their deep understanding of ASME codes and regulations, they are well-equipped to assist clients in meeting ABSA requirements with precision and efficiency.

Expertise in ASME Sec. VIII Div. 1, Appendix 2:

Little P.Eng. prides itself on its extensive knowledge and experience in working with ASME codes, specifically Section VIII Division 1. Appendix 2 of this section provides detailed guidelines for flange design, including bolt loads, gasket constants, and allowable flange stresses. Compliance with these specifications is crucial for ensuring the safety and reliability of pressure vessels. The team at Little P.Eng. possesses a deep understanding of this appendix and keeps up-to-date with the latest revisions, ensuring their designs meet the most current standards.

Accurate and Reliable Flange Design:

When it comes to flange design, precision is paramount. Little P.Eng. employs highly skilled engineers who utilize advanced design software and tools to accurately calculate critical parameters such as bolt loads, gasket constants, and flange stresses. By leveraging their expertise and cutting-edge technology, they deliver robust and reliable designs that are tailored to each client's specific requirements. The team ensures that the design complies with the ASME code, meeting the stringent ABSA submission criteria.

Compliance with ABSA Requirements:

ABSA, as the regulatory authority in Alberta, Canada, mandates strict adherence to safety standards for pressure vessels and piping systems. Little P.Eng. understands the ABSA submission process and the specific requirements that need to be met. Their flange design services are customized to comply with ABSA regulations, enabling clients to obtain necessary approvals for their projects. By engaging Little P.Eng., clients can rest assured that their flange designs will undergo a thorough review process, meeting all ABSA requirements.

Collaborative Approach and Client Satisfaction:

Conclusion:

When it comes to flange design services as per ASME Sec. VIII Div. 1, Appendix 2 for ABSA submission, Little P.Eng. stands out as a reliable and experienced engineering firm. Their deep understanding of ASME codes, expertise in flange design, and commitment to compliance with ABSA requirements make them the go-to choice for clients seeking precision and reliability. By partnering with Little P.Eng., clients can ensure the safety and integrity of their pressure vessels and piping systems, while also meeting the necessary regulatory standards.

Keywords:

Flange design, ASME Sec. VIII Div. 1, Appendix 2, ABSA submission, Little P.Eng., pressure vessels, piping systems, compliance, design calculation, bolt loads, gasket constants, flange stresses, safety, engineering firm, precision, reliability, regulatory standards, ABSA requirements, client satisfaction.

Tags:

Meena Rezkallah

Little P.Eng.

safety

piping systems

engineering firm

reliability

client satisfaction

pressure vessels

Flange design

ASME Sec. VIII Div. 1

Appendix 2

ABSA submission

compliance

design calculation

bolt loads

gasket constants

flange stresses

precision

regulatory standards

ABSA requirements

Engineering Services

Pipe Stress Analysis Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Meena Rezkallah#Little P.Eng.#safety#piping systems#engineering firm#reliability#client satisfaction#pressure vessels#Flange design#ASME Sec. VIII Div. 1#Appendix 2#ABSA submission#compliance#design calculation#bolt loads#gasket constants#flange stresses#precision#regulatory standards#ABSA requirements

1 note

·

View note

Text

Vulnerable children are in many parts of the world. Child sponsorship programs have emerged as a powerful tool to uplift vulnerable children and communities around the world.

0 notes

Text

Renewing your cannabis certificate is essential for uninterrupted access to medical cannabis. With the ever-evolving legal landscape, staying compliant and ensuring your certification remains valid is crucial. With cannabis certificate renewal in Virginia, you can continue to benefit from the therapeutic properties of medical cannabis.

0 notes

Text

Constant Current LED Lighting Power Supply Market Report, Growth and Status Explored in a New Research Report 2032

Overview: The Constant Current LED Lighting Power Supply Market refers to the market for power supply devices specifically designed to provide a stable and regulated current to LED lighting systems. LED lighting technology has gained significant popularity due to its energy efficiency, longer lifespan, and versatility. Constant current LED lighting power supplies ensure that LEDs receive a consistent and controlled current, allowing them to operate optimally. Here is an overview, key trends, demand factors, and market segmentation by platform related to the Constant Current LED Lighting Power Supply Market:

Key Trends:

1. Transition to LED Lighting: The global lighting industry is undergoing a transition from traditional lighting sources to LED lighting technology. LED lighting offers numerous benefits such as energy efficiency, longer lifespan, reduced maintenance costs, and enhanced lighting quality. This transition is driving the demand for constant current LED lighting power supplies.

2. Growing Demand for Energy Efficiency: Energy efficiency is a key driver in the adoption of LED lighting solutions. Constant current LED lighting power supplies are designed to maximize the energy efficiency of LED lighting systems by providing an optimized current output, minimizing energy wastage.

3. Integration of Smart Lighting Solutions: The integration of smart lighting systems and IoT (Internet of Things) technology is a significant trend in the lighting industry. Constant current LED lighting power supplies are increasingly being equipped with smart features such as dimming capabilities, color control, and wireless connectivity to enable advanced lighting control and automation.

4. Demand for Compact and High-Efficiency Power Supplies: With the increasing miniaturization of LED lighting fixtures and the need for space-saving solutions, there is a growing demand for compact and high-efficiency constant current LED lighting power supplies. Manufacturers are focusing on developing power supplies with smaller form factors, high power density, and improved heat dissipation.

Demand Factors:

1. LED Lighting Adoption: The increasing adoption of LED lighting across residential, commercial, and industrial sectors is driving the demand for constant current LED lighting power supplies. The need for reliable power supply devices to ensure the optimal performance of LED lighting systems is a significant demand factor.

2. Retrofitting and Upgrades: Retrofitting existing lighting installations with LED lighting technology is a common practice to enhance energy efficiency and lighting quality. As a result, there is a demand for constant current LED lighting power supplies for retrofit projects and upgrades of traditional lighting systems.

3. Energy Efficiency Requirements: Energy efficiency regulations and sustainability goals set by governments and organizations are fueling the demand for energy-efficient lighting solutions. Constant current LED lighting power supplies play a crucial role in achieving high energy efficiency and meeting regulatory requirements.

Market Segmentation by Platform:

The Constant Current LED Lighting Power Supply Market can be segmented based on the platform or application where the power supplies are deployed. Some common platform segments include:

• Residential LED Lighting Power Supplies

• Commercial LED Lighting Power Supplies

• Industrial LED Lighting Power Supplies

• Outdoor LED Lighting Power Supplies

• Architectural and Decorative LED Lighting Power Supplies

• Automotive LED Lighting Power Supplies

• Horticultural LED Lighting Power Supplies

• Signage and Display LED Lighting Power Supplies

Each platform segment may have specific requirements and considerations, such as power capacity, form factor, environmental ruggedness, and compatibility with lighting control systems.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/constant-current-led-lighting-power-supply-market/6947/

Market Segmentations:

Type:

a. Constant Current LED Drivers: These power supplies are specifically designed to provide a steady and regulated current output to LED lighting systems. They ensure that LEDs receive a consistent current level, allowing for optimal performance and longevity.

Application:

a. Residential LED Lighting Power Supplies: Power supplies tailored for LED lighting applications in residential settings, such as homes and apartments.

b. Commercial LED Lighting Power Supplies: Power supplies designed for LED lighting installations in commercial spaces, including offices, retail stores, hotels, and restaurants.

c. Industrial LED Lighting Power Supplies: Power supplies optimized for LED lighting in industrial environments, such as factories, warehouses, and manufacturing facilities.

d. Outdoor LED Lighting Power Supplies: Power supplies built to withstand outdoor conditions and provide reliable power for LED lighting in applications like street lighting, parking lots, and sports stadiums.

e. Architectural and Decorative LED Lighting Power Supplies: Power supplies specifically for architectural and decorative lighting applications, including lighting for buildings, monuments, and art installations.

f. Automotive LED Lighting Power Supplies: Power supplies designed for LED lighting systems in automotive applications, such as headlights, taillights, and interior lighting.

g. Horticultural LED Lighting Power Supplies: Power supplies optimized for LED lighting used in indoor farming, greenhouse cultivation, and horticultural applications.

h. Signage and Display LED Lighting Power Supplies: Power supplies tailored for LED lighting in signage, billboards, electronic displays, and digital screens.

Power Capacity:

a. Low Power Constant Current LED Power Supplies: Power supplies with lower power ratings suitable for small-scale LED lighting installations or applications with lower power requirements.

b. Medium Power Constant Current LED Power Supplies: Power supplies with moderate power ratings suitable for a wide range of LED lighting applications in various settings.

c. High Power Constant Current LED Power Supplies: Power supplies with higher power ratings designed for demanding LED lighting installations or applications with higher power requirements.

Dimming and Control:

a. Non-Dimmable Constant Current LED Power Supplies: Power supplies without dimming capabilities, providing a fixed and steady current output to LED lighting systems.

b. Dimmable Constant Current LED Power Supplies: Power supplies equipped with dimming features, allowing for adjustable brightness and control of LED lighting intensity.

Connectivity and Smart Features:

a. Standard Constant Current LED Power Supplies: Power supplies without additional connectivity or smart features.

b. Smart Constant Current LED Power Supplies: Power supplies with integrated smart technology, enabling wireless connectivity, remote control, and advanced lighting control features.

Global Constant Current LED Lighting Power Supply Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Constant Current LED Lighting Power Supply market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/constant-current-led-lighting-power-supply-market/6947/

Reasons to Purchase Constant Current LED Lighting Power Supply Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

• To make well-informed business decisions: These research reports give companies data-driven insights that they may use to plan their strategy, develop new products, and devise marketing and advertising plans.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#systems#Electronic devices#Lighting control#Dimmable LED drivers#Retrofit lighting solutions#Industrial lighting#Commercial lighting#Residential lighting#Smart lighting#Power electronics#Energy-saving solutions#Regulatory standards

0 notes

Text

fuck me, SCOTUS overturned chevron

25 notes

·

View notes

Note

hey bb bless your drive but I think your job is slowly killing you and it's time to find a position where you feel like you're thriving

YES. This is true. My rough plan is to try to stay here for another year. But I realized I dont necessarily have all the skills I am supposed to have at my current level so I have two goals 1) get those skills while I still can and 2) prove that since I have all these skills I need a promotion at the 5 year point aka next fall aka when I can leave the company. But I forgot how rough the end of the year is. They do this every year and its always awful but its ESPECIALLY awful right now because they are trying to give me extra experience (because I asked for it). But they are basically asking me to let have 3 different people micromanage me when all I wanted was to become a more competent worker and I am definitely starting to experience burnout. I'm trying to figure out how to reverse it and chill out, but everyday feels worse somehow. Do you have any advice?

#anon#ask#so I work in biotech which means we follow FDA and other regulatory body standards#which means some skills transfer to ANY company and thats what I am trying to learn this year

2 notes

·

View notes

Text

Most stimulants exert their activating effects by enhancing catecholamine neurotransmission. Catecholamine neurotransmitters are employed in regulatory pathways implicated in attention, arousal, motivation, task salience and reward anticipation.

seems to follow that if you have trouble with any of those things (and who amongst us doesn't lmao), stims might provide you with therapeutic benefits rather than just being fun to take

#truly is all about dosage at the end of the day.#a therapeutic dose is different from a recreational dose#i should have just started with that bc that is something else that people don't ever mention#getting drugs on the street means variable dosing (esp if you don't have a scale etc). getting medication means very clear dosing#which means greater control in effects. this was hilariously clear once i got access to legal weed with its regulatory standards

4 notes

·

View notes

Text

One for the Kiwis: Whether one is Maori or not, the Regulatory Standards Bill is an egregious power grab of massive extent, designed to permanently cripple the sovereignty of NZ (either Maori or Pakeha, whether the Treaty or Parliament) in favour of entrenched capital and foreign capital, without effective regulatory oversight. In short, part of the global attempt at doing an end run around participatory democracy and installing Oligarchy.

Some supporting text from Emily Writes:

And direct link to the online signatures form:

1 note

·

View note

Text

Sewage Treatment Plant (STP) Kolhapur |Renovation Services Near Me

Why Choose Ecocivic Solutions for STP in Kolhapur?

1. Expert STP Design and Installation Our team specializes in designing and installing customized STPs that meet local environmental standards and effectively treat wastewater. We ensure that the system operates efficiently, reducing the environmental impact and improving water quality.

2. STP Renovation Services If your existing STP is outdated or underperforming, Ecocivic Solutions offers expert renovation services. We modernize old systems, replace faulty components, and ensure that the plant meets current regulatory standards, improving efficiency and reducing operational costs.

3. Sustainable Practices At Ecocivic Solutions, we focus on sustainability. Our STP systems are designed to minimize waste, reduce energy consumption, and optimize the use of resources, contributing to a cleaner environment in Kolhapur.

Benefits of Our Sewage Treatment Plants

Improved Water Quality: Reduces pollution and enhances water safety.

Environmental Protection: Minimizes harmful wastewater discharge into local water bodies.

Cost Efficiency: Our systems are designed to be low-maintenance and cost-effective.

Renovation Services Near You

For existing STPs that require upgrades or repairs, Ecocivic Solutions provides timely and cost-effective renovation services. We enhance the performance of outdated treatment plants, ensuring they continue to operate efficiently and comply with environmental standards.

Serving Kolhapur and Beyond As a trusted name in Kolhapur for sewage treatment and environmental engineering, Ecocivic Solutions is committed to providing high-quality STP services, whether you’re building a new system or renovating an old one.

Get in Touch If you need expert STP installation or renovation services, contact Ecocivic Solutions today. We’re here to help you achieve a cleaner, greener future with sustainable wastewater management solutions.

Get in touch with : https://ecocivicsolutions.com/

#EnvironmentalEngineering #ConsultancyServices #SustainableSolutions #EcoFriendly #GreenConsulting #EnvironmentalImpact #WasteManagement #Sustainability #CleanTech #ClimateAction #ResourceConservation #InnovationInEngineering #ProfessionalConsultants #EnvironmentalAwareness #EngineeringSolutions #EcosystemHealth #RenewableEnergy #ConsultingExperts #FutureOfEngineering

#sustainable solutions tailored to your needs.#Sewage Treatment Plant (STP) Kolhapur |Renovation Services Near Me#Why Choose Ecocivic Solutions for STP in Kolhapur?#1. Expert STP Design and Installation#reducing the environmental impact and improving water quality.#2. STP Renovation Services#If your existing STP is outdated or underperforming#replace faulty components#and ensure that the plant meets current regulatory standards#improving efficiency and reducing operational costs.#3. Sustainable Practices#At Ecocivic Solutions#reduce energy consumption#and optimize the use of resources#contributing to a cleaner environment in Kolhapur.#Benefits of Our Sewage Treatment Plants#Renovation Services Near You#For existing STPs that require upgrades or repairs#Serving Kolhapur and Beyond#Get in Touch#If you need expert STP installation or renovation services#Get in touch with : https://ecocivicsolutions.com/#EnvironmentalEngineering#ConsultancyServices#SustainableSolutions#EcoFriendly#GreenConsulting#EnvironmentalImpact#WasteManagement#Sustainability

0 notes

Text

Little P.Eng. Engineering for Piping Stress Analysis Using AutoPIPE across Canada and USA

Piping systems are the lifelines of industrial plants, carrying fluids and gases to various components and ensuring the smooth operation of critical processes. However, the design and analysis of piping systems require meticulous attention to detail to prevent catastrophic failures that can lead to safety hazards and costly downtime. In Canada and the USA, engineers and professionals turn to tools like AutoPIPE for piping stress analysis, and Little P.Eng. Engineering has emerged as a trusted name in providing expert services for this critical task.

Little P.Eng. Engineering for Piping Stress Analysis Using AutoPIPE across Canada and USA

The Significance of Piping Stress Analysis

Piping systems in industrial plants, refineries, power plants, and chemical facilities are subjected to a wide range of stresses during their operational lifespan. These stresses can result from various sources, including temperature fluctuations, pressure changes, seismic activity, and the weight of the piping itself. Piping stress analysis is the process of evaluating and predicting how these stresses affect the integrity and safety of the piping system.

Here are some key reasons why piping stress analysis is of paramount importance:

Safety: Ensuring the safety of personnel and assets is the primary concern in any industrial setting. Piping failures can lead to leaks, ruptures, and even explosions, posing a significant risk to human lives and the environment.

Compliance: Regulatory bodies in Canada and the USA have strict standards and codes governing the design and operation of piping systems. Compliance with these standards is mandatory to avoid legal issues and penalties.

Reliability: Reliable piping systems are essential for continuous production and minimal downtime. Stress analysis helps identify potential weaknesses and areas of concern, allowing for proactive maintenance and improvements.

Cost Savings: Early detection of piping issues through stress analysis can prevent costly repairs, replacements, and unplanned shutdowns.

AutoPIPE: A Powerful Piping Stress Analysis Tool

AutoPIPE is a state-of-the-art software solution designed for the analysis and design of piping systems. Developed by Bentley Systems, it offers a comprehensive set of tools and features for performing piping stress analysis with precision and efficiency. AutoPIPE is widely used in the engineering and construction industry across Canada and the USA due to its versatility and reliability.

Key capabilities of AutoPIPE include:

Stress Analysis: AutoPIPE can calculate stresses, displacements, and forces within piping systems under various load conditions, including thermal expansion, pressure, and external loads. It considers complex interactions between different components and materials.

Code Compliance: The software is equipped with a vast library of international piping codes and standards, ensuring that the analysis results align with industry regulations in Canada and the USA. Engineers can easily select the appropriate code for their projects.

Advanced Modeling: AutoPIPE allows for the creation of detailed 3D models of piping systems, including components such as elbows, tees, and flanges. This level of detail is crucial for accurate analysis.

Material Database: Users can access a comprehensive material database, which includes a wide range of materials commonly used in piping systems. This simplifies the process of specifying material properties.

Post-Processing and Reporting: AutoPIPE generates detailed reports and graphical representations of analysis results, making it easier for engineers to communicate findings and make informed decisions.

Little P.Eng. Engineering: Your Trusted Partner

While AutoPIPE is a powerful tool for piping stress analysis, it requires expertise and experience to harness its full potential effectively. This is where Little P.Eng. Engineering steps in as a trusted partner for clients across Canada and the USA. With a team of highly skilled and certified engineers, Little P.Eng. Engineering offers a range of services that complement and enhance the capabilities of AutoPIPE.

Let's explore the key aspects that make Little P.Eng. Engineering a reliable choice for piping stress analysis:

Expertise: The engineers at Little P.Eng. Engineering have years of experience in the field of piping stress analysis. They possess in-depth knowledge of industry codes and standards, ensuring that all analyses are compliant and accurate.

Customized Solutions: Every project is unique, and Little P.Eng. Engineering tailors its services to meet the specific needs of clients. Whether it's a complex refinery system or a simple water distribution network, the team can handle it all.

Seamless Integration: Little P.Eng. Engineering seamlessly integrates AutoPIPE into its workflow, ensuring that clients receive the full benefits of this powerful software. The combination of software and expert analysis enhances the quality and reliability of results.

Cost-Effective Solutions: By detecting and addressing potential issues early in the design phase, Little P.Eng. Engineering helps clients avoid costly rework and repairs during construction or operation. This proactive approach results in significant cost savings.

Timely Delivery: In the fast-paced world of engineering and construction, timing is critical. Little P.Eng. Engineering is known for its commitment to meeting deadlines and delivering results on schedule, helping clients stay on track with their projects.

Case Studies: Little P.Eng. Engineering in Action

To better understand the real-world impact of Little P.Eng. Engineering's services using AutoPIPE, let's examine a couple of case studies from projects conducted in both Canada and the USA:

Case Study 1: Canadian Refinery Expansion

A major refinery in Canada was planning a significant expansion project to increase its production capacity. Little P.Eng. Engineering was contracted to perform a comprehensive piping stress analysis using AutoPIPE. The project involved intricate piping networks, including high-temperature lines, complex fittings, and multiple load scenarios.

The engineers at Little P.Eng. Engineering utilized AutoPIPE's advanced modeling capabilities to create a detailed 3D representation of the refinery's piping system. They then conducted a thorough stress analysis, considering factors such as thermal expansion, pressure variations, and seismic loads.

The analysis identified critical areas where piping stresses exceeded acceptable limits, allowing for proactive design modifications. By addressing these issues early in the project, costly delays and potential safety risks were avoided. The refinery expansion project was completed on schedule, and the client praised Little P.Eng. Engineering for its expertise and contribution to the project's success.

Case Study 2: USA Power Plant Retrofit

In the USA, a power plant undergoing a retrofit faced the challenge of integrating new piping systems into the existing infrastructure. The client turned to Little P.Eng. Engineering for its expertise in piping stress analysis using AutoPIPE.

Little P.Eng. Engineering's team began by conducting a site assessment and a thorough review of the plant's existing piping systems. They then used AutoPIPE to model the proposed modifications and analyze the stress implications. The analysis revealed potential conflicts with existing structures and equipment that could lead to operational issues and safety concerns.

Working closely with the client, Little P.Eng. Engineering provided recommendations for design changes and rerouting of piping to mitigate stress-related problems. The collaborative approach ensured that the retrofit project progressed smoothly, with minimal disruptions to plant operations.

Conclusion

Piping stress analysis is a critical component of ensuring the safety, reliability, and compliance of industrial piping systems in Canada and the USA. AutoPIPE, a powerful software solution, plays a pivotal role in this process by providing advanced analytical capabilities. However, to maximize the benefits of AutoPIPE, the expertise of professionals like Little P.Eng. Engineering is indispensable.

Little P.Eng. Engineering's commitment to excellence, combined with their extensive experience and seamless integration of AutoPIPE, makes them the go-to partner for clients seeking top-notch piping stress analysis services. Through case studies, we have seen how their expertise has contributed to the success of projects in both Canada and the USA, saving clients time and money while ensuring the integrity of their piping systems.

As industries in Canada and the USA continue to evolve and expand, the demand for reliable piping stress analysis services remains high. Little P.Eng. Engineering stands ready to meet this demand, providing innovative solutions that contribute to the growth and success of various industries across North America. With a dedication to safety, compliance, and cost-effective solutions, they are a driving force behind the reliability and efficiency of piping systems in the region.

Pipe Stress Analysis Program AutoPIPE: Unlocking Its Capabilities

Piping systems are the arteries of industrial plants and facilities, ensuring the smooth flow of fluids and gases critical to various processes. The integrity and reliability of these systems are paramount, as any failure can lead to catastrophic consequences, including safety hazards and costly downtime. To safeguard these systems, engineers and professionals across the globe rely on advanced pipe stress analysis programs like AutoPIPE. In this comprehensive article, we will delve deep into the capabilities of AutoPIPE, covering static and dynamic analysis, a range of international codes and standards, and additional features that make it an indispensable tool in the world of piping engineering.

Introduction to AutoPIPE

AutoPIPE, developed by Bentley Systems, is a state-of-the-art software solution designed for the analysis and design of piping systems. Its versatility, accuracy, and compliance with industry standards have made it a trusted choice among engineers and organizations worldwide. AutoPIPE empowers engineers to assess the behavior of piping systems under various conditions, ensuring they meet safety standards, code requirements, and operational needs.

Static Analysis with AutoPIPE

Linear Analysis

Linear analysis is the foundation of pipe stress analysis, and AutoPIPE excels in this fundamental aspect. It performs linear static analysis to calculate stresses, strains, and deflections in piping systems under a variety of loads, including gravity, temperature, pressure, static earthquake, wind, and snow. Let's delve into each of these static loadings:

Gravity: AutoPIPE accounts for the weight of the piping system and its components, ensuring that stress due to gravity is properly considered.

Temperature: Temperature changes can cause significant stress in piping systems due to thermal expansion or contraction. AutoPIPE accurately predicts these effects.

Pressure: Pressure variations within the system, such as startup and shutdown, are analyzed to assess their impact on pipe stress.

Static Earthquake: In regions prone to seismic activity, the software performs seismic analysis according to the relevant seismic code, assessing the system's response to ground motion.

Wind and Snow: AutoPIPE evaluates the stresses induced by wind loads and the weight of accumulated snow, crucial in structures exposed to harsh environmental conditions.

Non-Linear Analysis

While linear analysis covers a wide range of scenarios, there are instances where non-linear behavior must be considered. AutoPIPE supports non-linear analysis, enabling engineers to assess situations such as plastic deformation, large deflections, and material non-linearities. This capability is particularly valuable in extreme loading conditions or when dealing with materials with nonlinear stress-strain behavior.

Dynamic Analysis with AutoPIPE

In addition to static analysis, AutoPIPE offers advanced capabilities for dynamic analysis, crucial for assessing the behavior of piping systems under time-varying loads. Here are some of the dynamic analysis features provided by AutoPIPE:

Modal Analysis

Modal analysis helps identify the natural frequencies and mode shapes of the piping system. This information is crucial for understanding the system's dynamic behavior and resonance frequencies.

Response Spectra Analysis

For seismic events and seismic anchor movement, AutoPIPE can perform response spectra analysis. This method assesses the system's response to ground motion, allowing engineers to design piping systems that can withstand seismic forces.

Time History Analysis

In scenarios involving fast-acting loads like slugs, fast-acting valves, or hammers, AutoPIPE conducts time history analysis. This analysis method considers the time-dependent nature of the loads to predict the system's response accurately.

Harmonic Analysis

Vibrations caused by oscillating loads can lead to fatigue and structural issues. AutoPIPE can conduct harmonic analysis to evaluate the effects of these vibrations on the piping system, helping engineers make necessary design modifications.

International Codes and Standards

AutoPIPE supports a wide range of international piping codes and standards, ensuring that analyses are conducted in compliance with industry regulations. Here is a list of some of the prominent codes and standards that AutoPIPE accommodates:

ASME B31.1: Power Piping

ASME B31.3: Process Piping

ASME B31.4: Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids

ASME B31.8: Gas Transmission and Distribution Piping Systems

ASME B31.12: Hydrogen Piping and Pipelines

EN 13480: European Standard for Metallic Industrial Piping

CSA-Z662: Canadian Standard for Oil and Gas Pipeline Systems

ISO14692: International Standard for Petroleum and Natural Gas Industries - Glass Reinforced Plastics (GRP) Piping

DNV F101: Design of Offshore Steel Structures, General (LRFD Method)

European Piping Codes: Including Sweden SPC, Norway TBKS 6, Russian SNIP, France SNCT & RCC-M, and United Kingdom BS 806

Additional Code Features

AutoPIPE offers a range of additional features to enhance compliance with codes and standards. Some of these features include:

ASME B31J Flexibilities

This feature allows engineers to assess the flexibility factors of piping components, ensuring that they meet the requirements of ASME B31J, a code used for evaluating the flexibility and stress intensification factors of pipe fittings.

Code Case N755 for HDPE

AutoPIPE incorporates Code Case N755, enabling engineers to perform stress analysis on High-Density Polyethylene (HDPE) piping systems as per ASME B31.3 and B31.1.

Basic Static Loading and Analysis

AutoPIPE handles a variety of basic static loading scenarios:

Gravity

It considers the weight of the piping and its components.

Temperature

AutoPIPE accurately predicts the effects of thermal expansion or contraction due to temperature changes.

Pressure

Pressure variations within the system are analyzed to assess their impact on pipe stress.

Static Earthquake

For regions prone to seismic activity, the software conducts seismic analysis according to the relevant seismic code.

Wind

AutoPIPE evaluates the stresses induced by wind loads, ensuring compliance with design requirements.

Snow

It accounts for the weight of accumulated snow, particularly important for structures in snowy regions.

Dynamic Loads

AutoPIPE's capabilities extend to dynamic loads, enabling engineers to assess complex scenarios:

Modal Analysis

This feature helps identify natural frequencies and mode shapes, providing critical insights into dynamic behavior.

Response Spectra for Seismic Events and Seismic Anchor Movement

AutoPIPE performs response spectra analysis, assessing the system's response to ground motion during seismic events.

Time History Analysis for Fast Acting Loads

Fast-acting loads, such as slugs and fast-acting valves, are accurately analyzed using time history analysis.

Harmonic Analysis of Vibrations

Vibrations caused by oscillating loads are evaluated through harmonic analysis to prevent fatigue and structural issues.

Buried Piping

For buried piping systems, AutoPIPE offers specialized features:

Soil Stiffness Calculator

Engineers can calculate soil stiffness to assess the interaction between buried pipes and the surrounding soil.

Soil Overburden Loads

The software considers the weight of soil overburden when analyzing buried piping.

Seismic Wave

AutoPIPE accounts for seismic waves that can affect buried piping systems.

Building Settlement

Settlement of nearby structures can impact buried piping, and AutoPIPE incorporates this consideration.

Upheaval Buckling

To prevent upheaval buckling in buried piping, AutoPIPE provides the necessary tools for analysis and design.

Offshore

AutoPIPE addresses the unique challenges of offshore piping systems:

Buoyancy

The software evaluates buoyancy forces, a critical factor in offshore piping design.

Wave Loading

AutoPIPE accounts for wave-induced loads on offshore structures.

Nuclear

In nuclear applications, AutoPIPE ensures compliance with stringent requirements:

ASME III Class 1, 2, and 3

It supports ASME III codes for nuclear piping, including Class 1 (NB), Class 2 (NC), and Class 3 (ND).

ASME Fatigue Analysis

AutoPIPE provides tools for ASME fatigue analysis, crucial for nuclear piping integrity.

QA Program and Compliance

The software's QA program has been in place since 1989 and complies with class 1, 2, 3, plus ASME NQA-1, NB, NC, ND codes, and ISO 9001.

Flange Design and Analysis

AutoPIPE supports flange design and analysis, ensuring that flanged connections meet the required standards and safety margins. It covers:

ANSI

ASME VIII Div 1 and 2

ASME III Appendix XI

Additional Loadings

AutoPIPE accommodates various additional loadings to provide a comprehensive analysis:

Hydrotest

It assesses stresses during hydrostatic testing, which is crucial to verify the integrity of the piping system.

Force Spectrum

The software can handle force spectra analysis, particularly relevant in systems subjected to varying loads.

Thermal Bowing

AutoPIPE predicts thermal bowing, helping engineers address potential issues due to temperature differentials.

Thermal Transient Analysis

In cases where temperature changes occur over time, thermal transient analysis is conducted to ensure accurate stress predictions.

Additional Features

AutoPIPE includes several additional features that streamline the pipe stress analysis process:

Spring Hanger Analysis

Engineers can analyze spring hanger supports, crucial for managing pipe movement and vibration.

Automatic Support Optimizer

AutoPIPE offers an automatic support optimizer to help engineers identify optimal support locations, minimizing stress and ensuring system integrity.

Creation of Digital, Customizable Stress Isometrics

The software allows for the creation of digital stress isometrics, aiding in communication and documentation of analysis results.

Interoperability

AutoPIPE seamlessly integrates with other engineering software and platforms:

Structural with STAAD and SACS

It can interface with structural analysis software like STAAD and SACS for comprehensive structural-piping interaction analysis.

Import from 3D CAD

AutoPIPE supports importing from various 3D CAD platforms, including OpenPlant, AutoPLANT, PlantSpace, SP3D, Plant 3D, PDS, PDMS, and Revit, simplifying the modeling process.

Nozzle Loads to AutoPIPE Vessel

For vessels connected to piping systems, AutoPIPE can calculate and transfer nozzle loads to AutoPIPE Vessel for vessel analysis.

Importing Time History FRC File

Time history data can be imported into AutoPIPE from external sources to perform dynamic analysis accurately.

Conclusion

AutoPIPE is a comprehensive and versatile pipe stress analysis program that caters to the diverse needs of engineers and organizations across the globe. With its robust static and dynamic analysis capabilities, support for a multitude of international codes and standards, and additional features that streamline the analysis process, AutoPIPE has established itself as an indispensable tool in the field of piping engineering. As industries continue to evolve and face new challenges, AutoPIPE remains at the forefront, empowering engineers to design, analyze, and optimize piping systems with confidence, ensuring the safety, reliability, and efficiency of critical infrastructure.

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Canada

USA

Little P.Eng. Engineering

Compliance

Safety

3D modeling

Piping stress analysis

Thermal expansion

Regulatory standards

AutoPIPE

Retrofit

Material properties

Infrastructure

Industrial piping

Reliability

Cost savings

Refinery

Power plant

Chemical facilities

Seismic analysis

Engineering codes

Expertise

Proactive maintenance

Site assessment

Design modifications

Analytical capabilities

Project success

Compliance with industry regulations

Risk mitigation

Timely delivery

Pipe Stress Analysis Services

Engineering Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Canada#USA#Little P.Eng. Engineering#Compliance#Safety#3D modeling#Piping stress analysis#Thermal expansion#Regulatory standards#AutoPIPE#Retrofit#Material properties#Infrastructure#Industrial piping#Reliability#Cost savings#Refinery#Power plant#Chemical facilities#Seismic analysis#Engineering codes#Expertise#Proactive maintenance#Site assessment#Design modifications#Analytical capabilities#Project success#Compliance with industry regulations#Risk mitigation#Timely delivery

0 notes

Text

As FDA tobacco regulations continue to change, maintaining compliance is becoming increasingly challenging for manufacturers, importers, and distributors. Whether you’re introducing new tobacco products or overseeing an existing lineup, grasping the latest FDA mandates is vital for registering tobacco products in the U.S. market. This guide will outline essential regulatory requirements, clarify how these updates impact the industry, and detail how Freyr can aid global businesses in achieving U.S. tobacco product compliance. **Navigating FDA Tobacco Regulations** The FDA supervises the sale, marketing, and distribution of tobacco products through the Center for Tobacco Products (CTP), enforcing strict compliance standards. Below is a summary of the core regulatory obligations for tobacco product manufacturers and importers in the U.S. **Establishment Registration and Product Listing Rules** All U.S. tobacco product manufacturers, importers, and distributors must register their establishments with the FDA and provide product listings. This requirement includes all types of tobacco products, such as cigarettes, cigars, e-cigarettes, and new nicotine variants. **Annual Re-Registration Obligations** Registered establishments are required to re-register each year by December 31 and refresh their tobacco product listings as needed. Failing to comply may lead to penalties or restricted access to the U.S. market. **Reporting Modifications** Manufacturers and importers must report any significant modifications to their product offerings. This involves: **Registering Tobacco Products in the U.S.: A Comprehensive Guide** Updated product listings must be submitted to the FDA during this reporting. **Tobacco Product Master Files (TPMF)** The FDA has updated its compliance policies concerning various tobacco products, including:

#Tobacco Regulations#FDA Compliance#Tobacco Industry#Market Entry#Nicotine Products#Regulatory challenges#Tobacco Compliance#public health#Product Safety Standards

0 notes