#ASME standards

Explore tagged Tumblr posts

Text

Little P.Eng. for ASME B31.1 Power Piping Calculation Services: A Beacon of Expertise and Innovation

Power piping systems serve as the lifeblood of many industrial operations, providing crucial transportation of fluids under high pressure and temperature. These systems demand high standards of safety, reliability, and efficiency, which are delivered by the American Society of Mechanical Engineers (ASME) B31.1 Power Piping Code. One name stands out in offering these precise and complex ASME B31.1 Power Piping Calculation Services - Little P.Eng.

A leading engineering consulting firm, Little P.Eng., combines experience, innovation, and cutting-edge technology to provide unrivaled solutions for power piping systems. In this article, we examine Little P.Eng.'s impact on ASME B31.1 Power Piping Calculation Services and how they excel in this specialized domain.

Deciphering ASME B31.1 Power Piping Code:

ASME B31.1 Power Piping Code is a robust regulatory framework that stipulates design, fabrication, installation, and testing regulations for power piping systems. With its technical intricacies, this code is an engineer's playbook for ensuring the safety and efficacy of power piping systems, and no one plays this game better than Little P.Eng.

Little P.Eng.: Your Trustworthy Ally for Power Piping Calculations:

In the field of ASME B31.1 power piping calculation services, Little P.Eng. has carved a distinctive niche for itself. Their team of seasoned engineers, with a comprehensive understanding of ASME standards, employ the best practices to provide highly accurate and reliable solutions, making them a trusted ally for all power piping needs.

Little P.Eng.'s Extensive Calculation Services:

Little P.Eng.'s expertise spans a wide spectrum of calculation services. From wall thickness calculations to expansion joint pressure thrust calculations, Little P.Eng.'s solutions are renowned for their precision and adherence to ASME B31.1 standards. The firm's exhaustive understanding of power piping systems equips them to handle complex calculations with ease and precision.

Harnessing the Power of Technology:

At Little P.Eng., the latest technology and software tools are harnessed to ensure their ASME B31.1 Power Piping Calculation Services meet the highest industry standards. By using advanced simulation techniques and design validation, they create power piping systems that are safe, reliable, and efficient.

Prioritizing Client Satisfaction:

Little P.Eng. places a strong emphasis on client satisfaction, ensuring each project is tailored to the specific needs of the client. Their commitment to quality, paired with their industry knowledge, delivers solutions that not only meet ASME B31.1 standards but also align seamlessly with the client's requirements.

let's delve into the specific types of pressure design calculations that Little P.Eng. offers under the ASME B31.1 Power Piping Calculation Services:

Minimum Pipe Wall Thickness Calculations: Ensuring the pipe wall is thick enough to contain the internal pressure is a fundamental aspect of pressure design. Little P.Eng. uses state-of-the-art software to calculate the required wall thickness, considering factors like operating pressure, material strength, temperature, and pipe diameter.

Flange Pressure-Temperature Ratings Calculations: Little P.Eng. adeptly handles the calculation of flange ratings under different temperature and pressure conditions. These calculations are crucial for specifying the appropriate flanges that will ensure a leak-free performance of the power piping system.

Branch Reinforcement Calculations: Branch connections, if not properly reinforced, can be potential weak points in a piping system. Little P.Eng. carries out detailed calculations to determine the necessary reinforcements, ensuring the structural integrity and safety of the piping system.

Expansion Joint Pressure Thrust Calculations: Expansion joints in power piping systems need to withstand the pressure thrust exerted upon them. Little P.Eng. uses sophisticated tools and techniques to accurately calculate this pressure thrust, helping to design expansion joints that can safely absorb these forces.

Safety Valve Reaction Force Calculations: When safety valves open in response to excessive pressure, they exert a reaction force that must be taken into account. Little P.Eng.'s team expertly performs these calculations, ensuring safety valves can operate efficiently and safely.

Pipe Support Load Calculations: The load on pipe supports must be accurately calculated to ensure they can sustain the weight of the pipe, the fluid it carries, and any additional loads due to thermal expansion or other forces. Little P.Eng. performs these calculations meticulously, considering various factors such as pipe size, material, and temperature.

High-Pressure Piping Design Calculations: High-pressure piping systems pose unique design challenges. Little P.Eng. offers specialized calculation services to address these, considering factors such as material selection, joint design, and testing procedures.

Conclusion:

ASME B31.1 Power Piping Calculation Services form the backbone of power piping design, ensuring systems can safely and efficiently transport fluids under high-pressure conditions. Little P.Eng., with its mastery of these calculations and unwavering dedication to quality, stands as a beacon of expertise and innovation in this field.

The team at Little P.Eng. continuously adapts to evolving industry standards and market needs, ensuring their clients receive top-tier, cutting-edge services. Their commitment to using the latest technology and best practices positions them as not just a service provider but as a key contributor in shaping the future of the power piping industry.

Keywords: Minimum Pipe Wall Thickness Calculations, Flange Pressure-Temperature Ratings Calculations, Branch Reinforcement Calculations, Expansion Joint Pressure Thrust Calculations, Safety Valve Reaction Force Calculations, Pipe Support Load Calculations, High-Pressure Piping Design Calculations, ASME B31.1 Power Piping Calculation Services, Little P.Eng., power piping systems, engineering consulting, ASME standards, wall thickness calculations, expansion joint pressure thrust calculations, client satisfaction, technological advancements.

Tags:

Meena Rezkallah

Little P.Eng.

engineering consulting

ASME standards

Expansion Joint Pressure Thrust Calculations

Safety Valve Reaction Force Calculations

High-Pressure Piping Design Calculations

client satisfaction

Minimum Pipe Wall Thickness Calculations

Flange Pressure-Temperature Ratings Calculations

Branch Reinforcement Calculations

Pipe Support Load Calculations

ASME B31.1 Power Piping Calculation Services

power piping systems

wall thickness calculations

expansion joint pressure thrust calculations

technological advancements

Engineering Services

Pipe Stress Analysis Services

Piping Design

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Meena Rezkallah#Little P.Eng.#engineering consulting#ASME standards#Expansion Joint Pressure Thrust Calculations#Safety Valve Reaction Force Calculations#High-Pressure Piping Design Calculations#client satisfaction#Minimum Pipe Wall Thickness Calculations#Flange Pressure-Temperature Ratings Calculations#Branch Reinforcement Calculations#Pipe Support Load Calculations#ASME B31.1 Power Piping Calculation Services#power piping systems#wall thickness calculations#expansion joint pressure thrust calculations#technological advancements

0 notes

Text

pipe thickness asme b31.8 design

pipeline thickness formula pipeline design pressure asme b31.8 pipe design pipeline stress analysis https://3d-labs.com/product/pipe-thickness-asme-b-31-8-design/ Pipe Thickness ASME B 31.8 Design involves determining the appropriate wall thickness of pipes for gas transmission systems, ensuring safety, structural integrity, and compliance with ASME standards.

#pipe wall thickness calculation asme#pipeline wall thickness calculation#pipeline engineering standards

0 notes

Text

Material: A105 Caliber: DN500 Pressure: 600 pounds Process: Type III forged flange Precision machined flange Saudi Arabia customized sample list 45 years of professional carbon steel, stainless steel, alloy steel pipe fittings and flanges manufacturers and suppliers

#pipe fittings#flanges#asme#stainless steel pipe fittings#pipe elbow#pipe tee#elbow band#elbow brace#elbow#flange#plate flange#carbon steel plate flange#orifice plate flange#plate flange pictures#slip plate flange#plate flange standard

1 note

·

View note

Text

“Will, can I tell you something?”

“You can tell me anything.” He glances up from his clipboard, grinning wide and wry and sparkling. “Especially if it’s that you’ve got food.”

Nico knows his best friend, so he does have food; a pack of twizzlers the size of his face that he tosses, deliberately quickly, at his face, smiling to himself when he misses and dives down to grab it anyway. His clipboard clatters to the ground, pen bouncing after it, as he tears into it, inhaling at least ten twisty candies in half as many seconds.

“Gods, I love you,” he groans, mouth open like the disgusting mannerless loser he is.

Nico coughs. “Funny you should say.”

He’s spared from having to jump clear through the nearest window and landing right on his neck by the honestly uncomfortable noises Will continues to make — by the gods if he finds out it’s been another twenty three hours since William has eaten he is going to kill him and resurrect his skeleton for permanent manual labour — and instead worries himself with the first random task he sees unfinished. Do the kiddie Band-Aids actually need to be emptied from their boxes and sorted by size and vibe? No. But Will won’t stop him. And Nico needs, like, twenty minutes of recovery. So.

“What did you want to ask me, by the way?”

His mouth is still — somehow — full, so it sounds closer to whaa joo wanna asme. Nico, brave veteran that he is, feigns confusion.

“Hm?”

“Question,” Will swallows, an actual, audible gulp, gods, where have Nico’s standards gone, “that you had.” There’s the sound of joints cracking and a deep sigh, then quick footsteps, and then Will is in front of him, eyes squinted, mouth wide and crooked, leaning on the counter. He has been up before the sun and working the entire time, people pouring in and out like ants to an anthill, and Nico knows he has not rested, but energy still sparks all over his skin. He bounces, almost, from his frizzy ringlet curls to the balls of his feet, humming, twitching, moving.

“I.” Nico’s throat is dry, and his eyes move from the bandages, to Will, to the bandages. “Well.”

When Nico was a kid he would stutter over his words. He was a shit speaker. Bianca spoke four languages by the time she was six, and Nico could barely ever manage the one; he knew what he was trying to say, and he would say it, only somewhere along the way his brain sent the wrong sparks or maybe his tongue got twisted or maybe his mouth made the wrong shapes. Or he blended them all together, like ice sleet on helicopter blades, and everything left his mouth just fine but got smashed to bits in the air outside of him, never reaching his audience quite right. And then he was ten and everything he cared about was smashed to dust and he stopped caring about where the words got twisted and stopped relying on them at all, and stared, instead; glowered, let his face speak for him, even if they weren’t saying the same thing. It annoys everyone around him. It frustrated his mother and pisses off his father and annoys or frightens every other person around him, and everyone guesses, fills in the blanks, deciphers what he is going to say to make his presence just a little easier to bear.

But Will waits, rocking, as he always does, eyes flicking around the infirmary, a handwidth of space between them. Fingers, drumming on the curve of his thigh, too-big front teeth gnawing on his chapped bottom lip. Waiting. For the words, for the time, for the courage.

“I missed you today,” Nico blurts, and it isn’t what he meant to say, not by a long shot, but it’s an approximation and it will count. And Will is suddenly smiling, huge, too big for his face; beaming, brightly, beautifully. “I hate it when you work too long.”

“Yeah?”

Nico exhales, cheekbones ruddy. “Yeah.”

“That’s not a question, Neeks.”

“Oh, stuff it.”

Will laughs, then, and the room gets brighter, and Nico gets warmer, braver, and takes his hand. He walks even both out of the infirmary and Will goes willingly, even though there is work too be done, swinging their hands, and he talks, and talks and talks and talks, and then he waits, quietly, humming to himself, and Nico says nothing, although he thinks things, and Will acts like he has said them. And his palm is still rough and warm against his, and the sun is setting, and Will smells like artificial strawberry and lavender body wash, and Nico thinks, You can tell me anything, and he vows that he will. And he holds his hand, and squeezes it around his, and smiles, and waits, easily, contentedly.

#i love them and the way they are so suited for each other#pjo#percy jackson and the olympians#hoo#heroes of olympus#pjo hoo toa#nico di angelo#will solace#nico di angelo/will solace#nico di angelo & will solace#nico/will#will/nico#solangelo#fluff#100 ways#100 ways to say i love you#my writing#fic#longpost

375 notes

·

View notes

Text

Sepsis is a life-threatening infection complication and accounts for 1.7 million hospitalizations and 350,000 deaths annually in the U.S. Fast and accurate diagnosis is critical, as mortality risk increases up to 8% every hour without effective treatment. However, the current diagnostic standard is reliant on culture growth, which typically takes two to three days. Doctors may choose to administer broad-spectrum antibiotics until more information is available for an accurate diagnosis, but these can have limited efficacy and potential toxicity to the patient. In a study presented at ASM Microbe, a team from Day Zero Diagnostics unveiled a novel approach to antimicrobial susceptibility testing using artificial intelligence (AI).

Continue Reading.

#Science#Medicine#Biology#Microbiology#Antibiotics#Sepsis#AI#Artificial Intelligence#Machine Learning

105 notes

·

View notes

Text

hellooo!

my name is asme. i’m 28, hisuian (pearl clan), she and her pronouns. :)

i’m a warden, and i look after my lovely lady of the bogs! i also have one pokemon of my own: an espeon named fuzz.

i found this device in the lady’s arena a few days ago, and i got it working. this “rotomblr” place popped up when i touched one of the little pictures, and since it seems to be a place to talk to others, well, i had to sign up!

ooc info: likes/follows come from @movedto-mementomoreeyes + rotomblr hub is @soupspkmncorner <3 hiii its soup (it/they+23) again with another oc from my big fucken oc family!! this blog is related to both @mimikinyuu and @cornerstonefriend , neither of them are able to see this blog though. the time will come theres a plot in mind blah blah blah. the gif above is made by cuntryhuman (didnt want to tag out of the blue, gif source works on mobile)!!

whats allowed in the inbox?

- canon characters, antagonists/grunts, ocs, fallers, anyone really! i will note: asme has never interacted with a sapient pokemon and doesnt know what an eeby/sleeby is. she may think that sapients/eebies/sleebies are just pretending at first, but this stance is changeable.

- pelipper mail/mystery gift

- musharna mail/malice

- magic!anons (SELECTIVE + TEMPORARY)

what isnt allowed in the inbox?

- nsfw. the most nsfw this blog (as well as my other rotomblr blogs) will get are silly middle-school jokes, ie KUNG POW PENIS

- union circle. this may change later, but as of right now, im disallowing it for in-universe reasons

- pelipper unmail/malice

- ic or ooc hate

- ic or ooc bigotry (INSTANT block for this)

- dont tell her about legion/soups accounts and dont tell legion/soup that shes on rotomblr. they will eventually connect but not yet.

final notes!

- this blog will discuss pokemon death, hunting/eating pokemon, human death, and similar topics. pokemon hunting/eating will be tagged as #pokemon hunting cw, all other triggers will be tagged similarly as #(x) cw. these topics will not be the blogs main focus.

- this blog takes place about 20 years after the events of legends: arceus. in this universe, asme is the last surviving warden. she knows of the other wardens, but in her universe, they are all retired or passed on.

- in case it isnt obvious asmes noble is a luxray. she is currently a standard luxray, but this may change (i have ideas for a hisuian luxray variant)

- also in case it isnt obvious, asme is not tech-savvy. i am trying so fucken hard to make her feel like shes never seen a phone before. you are allowed to send her fake scams and other things of that nature if that makes you giggle

this post will be updated as needed.

last updated: 29/01/25

22 notes

·

View notes

Note

i think that orka did a great job with the safavid dynasty so far , one of the best "foreign country" representation -but , good god , making bayezid , the foreign country king , the eastern looking man a "sexist" was not a good move (personally) ? - yes , the whole noble community and the church are sexist but when it comes to bayezid n its an annoying stereotype. but let's see how it goes , i think he'll turn out to be a good father at least. orka never fails her readers

That's fair for you to think so. It's certainly a common stereotype that'll leave a bad taste in your mouth. I can't speak for how others may feel but-

Personally, I'm not too mad at it. Given how the characters in the Empire (Richelieu, The Cardinal) are also huge sexists, it tells us that Spice&Kitty/ORKA's decision to make Bayezid a sexist was probably not a racially motivated decision.

"All believers must be silent in the ways of the Church and learn from their husbands. [Shuri] is not a gentle woman."

-Richelieu to Prince Theo

Misogyny is one of the major themes in ASM and a driving force for the religious conflict that makes up the entire series. It's also the reason why we have such strong female characters that are actively working to fight against these bigoted standards. Bayezid could've been written as The Nice Guy, but Halima's character and accomplishments would be far less worthy in comparison.

In literature, we kinda need the bad in order to have the good. Shuri is vocal and motivated against the Church who demands her silence. Rachel is boisterous and boyish against the standards of what a lady should be, as defined by the noble mothers of the empire. And Halima is independent and adventurous, a 180 from the traditional standards of her father and the Safavid Kingdom's beliefs.

Instead, I'd like to see how Halima and Ali are represented in the future. Especially Halima. She's a but of a morally grey character as of yet and I'd love to see how her story advances.

#a stepmother's marchen#the fantasie of a stepmother#stepyapping#bayezid pasha#halima pasha#askstepmarchen

18 notes

·

View notes

Text

Hey, so uhhhh-

At first was excited to see the new dragon because I'm Mexican, love the mythology of my culture, and even recently got a book to help me learn Nahuatl, so it was a fun timing and gave me a boost to my enthusi asm.

When I came here expecting the standard "gene error" and "design goofy" posts, I kinda felt a big chunk of my soul die instead

I loved the design, but reading the original lore and the connotations of it? It's pretty bad. But I don't know if I'm supposed to hate just the lore, lore + the design, or if even the inspiration is apparently a bad thing?

With all the controversy surrounding it, I don't know what I'm supposed to be feeling, I just know that I'm really sad about it. I don't know if I was supposed to be upset about the dragon from the moment I saw it, and I don't know if getting excited makes me ignorant or stupid or something. Idk

This post is pretty late, but I've been wanting to write it for a while, but was too afraid of people either ignoring me, talking/fighting over my words, or deciding that my words are nothing more than an opinion. I hope I'm not too late to give input, and I hope I'm not like, idk, berated? for this. Just in case I'm in the wrong here, I'm incredibly sorry in advance.

25 notes

·

View notes

Text

The ADNOC APPROVAL Misery

هالة فقدان الشغف هنا ف البلد دي مخلياني حقيقي علي اخري.

مش مشكلة بس اهم حاجة بس ال Approval الرخم ده.

النهاردة حد في Title اعلي دخل انترفيو ال Approval في اتسال سؤال خاص ب ال Asme Standards و معرفش يجاوبه. ف انا جاوبته عليه ف لقيته استغرب و بيغلطني. روحت فتحت ال standard ال 1000 و حاجة صفحة و جبتهاله وهنا استغرب اني عارف ال Standard ده كله.

الفكره اني محتاج اجهز. و ان شاء الله هحاول الخميس اللي مش بكره ده يكون معايا ال Approval ده.

ودلوقتي يلا نسترجع زمان و نعمل اقوي ساعتين عشان الحق اريح ساعة قبل الفجر.

6 notes

·

View notes

Text

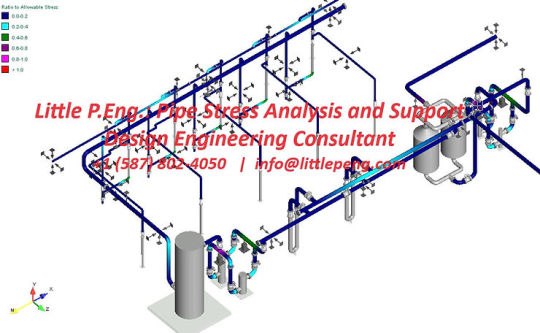

Little P.Eng.: Pipe Stress Analysis and Support Design Engineering Consultant

In the world of engineering, precision and safety are paramount, especially when it comes to piping systems. Any miscalculation or oversight can have severe consequences, ranging from safety hazards to costly downtime. This is where Little P.Eng. Engineering steps in as a trusted partner, providing expert pipe stress analysis and support design services to ensure the structural integrity and efficiency of piping systems across various industries.

With a reputation for excellence and a commitment to delivering tailored solutions, Little P.Eng. Engineering has established itself as a go-to engineering consultant for those seeking to optimize their piping systems.

Expertise in Pipe Stress Analysis

At the core of Little P.Eng.'s services is their expertise in pipe stress analysis. This crucial engineering discipline involves assessing the forces, stresses, and displacements acting on piping systems to ensure they operate safely and efficiently. Whether it's static stress analysis, dynamic stress analysis, thermal analysis, or seismic analysis, Little P.Eng. Engineering has a team of highly skilled engineers who are well-versed in these complex assessments.

Static stress analysis, for example, is employed to evaluate the stresses in stationary piping systems, ensuring they can withstand the pressures and loads they are subjected to during normal operation. Dynamic stress analysis, on the other hand, deals with transient conditions such as startup, shutdown, and water hammer, which can place additional stress on the system.

Ensuring Compliance with Standards

One of the hallmarks of Little P.Eng.'s services is their unwavering commitment to compliance with industry standards and codes. Piping systems must adhere to strict safety and regulatory guidelines, and Little P.Eng. Engineering ensures that all their analyses and designs meet or exceed these standards. Whether it's ASME, ANSI, API, ASTM, or local building codes, clients can trust that their projects are in full compliance.

Customized Solutions for Unique Needs

No two piping systems are identical, and Little P.Eng. Engineering understands this well. They excel in providing customized solutions that align with the specific needs and challenges of each project. Whether it's an oil refinery, a pharmaceutical facility, or a power plant, Little P.Eng.'s team tailors their services to ensure optimal results.

Support Design Expertise

In addition to pipe stress analysis, Little P.Eng. Engineering offers support design services that play a critical role in the stability and longevity of piping systems. Proper support design involves creating structures and supports that hold piping systems in place, preventing excessive movement, vibrations, and stress.

Little P.Eng. Engineering's support design services encompass a range of aspects, including pipe support design, structural analysis, material selection, and installation guidance. These services are crucial in preventing issues like excessive stress, vibrations, misalignment, and premature wear in piping systems.

Commitment to Safety and Quality

Safety is Little P.Eng.'s top priority. Their pipe stress analysis and support design services are driven by a deep commitment to ensuring the safety of people, the environment, and assets. They meticulously evaluate every aspect of a piping system to identify potential safety hazards and implement measures to mitigate them.

Quality assurance is woven into the fabric of Little P.Eng.'s services. They maintain rigorous quality control processes throughout the project lifecycle, from initial analysis to final implementation. This dedication to quality results in reliable and durable piping systems.

Client-Centric Approach

Little P.Eng. Engineering takes a client-centric approach, focusing on understanding the unique needs and goals of each client. They engage in open communication and collaboration, ensuring that clients are actively involved in the decision-making process. This approach fosters trust and transparency, key elements in successful engineering projects.

Timely and Efficient Service

In the world of engineering, time is often of the essence. Little P.Eng. Engineering understands the importance of meeting project timelines. Their streamlined processes and experienced team allow them to deliver timely and efficient services without compromising quality. This ensures that clients can rely on them to meet their project deadlines and objectives.

Continuous Improvement

In an ever-evolving field like engineering, staying current with the latest advancements is crucial. Little P.Eng. Engineering is committed to continuous improvement and invests in ongoing training and development for their team members. This dedication to staying at the forefront of technological advancements allows them to provide cutting-edge solutions to their clients.

Little P.Eng.: Pipe Stress Analysis and Support Design Engineering Consultant

A Pipe Stress Analysis and Support Design engineering consultant offers a range of services to ensure the structural integrity, safety, and efficiency of piping systems in various industries. These services may include:

1. Pipe Stress Analysis:

Static Stress Analysis: Evaluating stresses, forces, and displacements in stationary piping systems.

Dynamic Stress Analysis: Assessing the effects of transient conditions, such as startup, shutdown, and water hammer.

Thermal Stress Analysis: Analyzing the impact of temperature variations on piping materials and components.

Seismic Analysis: Evaluating the response of piping systems to seismic forces and designing for earthquake resistance.

Fatigue Analysis: Predicting the fatigue life of components subjected to cyclic loading.

2. Support Design Services:

Pipe Support Design: Designing supports, hangers, and restraints to prevent excessive movement and stress in piping systems.

Structural Analysis: Evaluating the structural integrity of support structures and ensuring compliance with safety codes.

Material Selection: Recommending suitable materials for support components based on factors like load-bearing capacity and corrosion resistance.

Installation Guidance: Providing recommendations and specifications for the proper installation of supports.

3. Compliance with Standards and Codes:

Ensuring that all designs and analyses meet relevant industry standards, codes, and regulations, such as ASME, ANSI, API, ASTM, and local building codes.

Assisting clients in obtaining necessary permits and approvals for piping system installations or modifications.

4. Customized Solutions:

Tailoring pipe stress analysis and support design services to the specific needs and requirements of each project.

Developing unique solutions for complex or challenging piping system configurations.

5. Failure Analysis and Troubleshooting:

Investigating and diagnosing issues related to piping system failures, leaks, or performance problems.

Recommending corrective actions and retrofits to address identified problems.

6. Hygienic Piping Design (in industries like pharmaceuticals and food production):

Designing piping systems that comply with stringent sanitary and hygiene standards to prevent contamination.

Implementing design solutions that minimize dead legs, reduce the risk of bacterial growth, and facilitate cleaning and sterilization.

7. Stress Testing and Simulation:

Conducting computer simulations and modeling to predict stress and strain behavior under different operating conditions.

Performing load testing to validate the performance of pipe supports and restraints.

8. Energy Efficiency Optimization:

Identifying opportunities to improve energy efficiency by optimizing piping system configurations and insulation.

Recommending modifications to reduce heat loss or improve heat transfer.

9. Retrofit and Upgrade Design:

Developing plans and designs for the retrofit or upgrade of existing piping systems to meet current safety and performance standards.

Incorporating advanced technologies and materials for improved reliability and efficiency.

10. Documentation and Reporting:

Generating comprehensive reports, including stress analysis reports, design drawings, specifications, and installation instructions.

Maintaining accurate records of all analyses, designs, and project documentation.

11. Consulting and Expert Witness Services:

Providing expert consulting services for legal matters, including expert witness testimony in cases involving piping system failures or disputes.

12. Project Management and Coordination:

Overseeing and coordinating the implementation of recommended design changes or support installations to ensure proper execution.

Pipe Stress Analysis and Support Design engineering consultants play a crucial role in ensuring the safe and efficient operation of piping systems across various industries, and their services are vital for preventing failures, reducing downtime, and maintaining regulatory compliance.

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Little P.Eng.

ASME standards

Engineering expertise

Thermal expansion

Structural integrity

Regulatory compliance

Pipe stress analysis

Documentation

Industrial processes

Engineering consultant

Advanced software

Pressure changes

API standards

Maintenance costs

Optimization

ISO standards

Seismic events

Oil and gas industry

Custom support systems

Inspection readiness

Load-bearing capacities

Compliance standards

Piping systems

Power generation

Fluid dynamics

Petrochemical industry

Support design engineering

Troubleshooting

Temperature fluctuations

Safety analysis

Pipe Stress Analysis Services

Engineering Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Little P.Eng.#ASME standards#Engineering expertise#Thermal expansion#Structural integrity#Regulatory compliance#Pipe stress analysis#Documentation#Industrial processes#Engineering consultant#Advanced software#Pressure changes#API standards#Maintenance costs#Optimization#ISO standards#Seismic events#Oil and gas industry#Custom support systems#Inspection readiness#Load-bearing capacities#Compliance standards#Piping systems#Power generation#Fluid dynamics#Petrochemical industry#Support design engineering#Troubleshooting#Temperature fluctuations

0 notes

Note

is it gay to be gay, because when you're gay, you're essentially subscribing to the homosexual agenda where you like men while being a man, which is considered "homosexual" by societal standards? is it gay to love another man romantically or sexually, because that perfectly aligns with what means to be homosexual? homosexuality is often termed as the romantic / sexual attraction towards someone of the same sex, and that is the exact behavior being displayed when you like another male person. is it gay? i think it is. i can't believe no one has ever pointed how gay it is is to be gay. you are practically a member of the RAINBOW MAFIA where they're all having sex with each other despite being of the same gender. it's actually insane how nobody has ever pointed this out in centuries. this is the average homosexual interaction as observed by gay-studying scientists: (allegedly straight male): hi !! (allegedly straight male #2): hi !! (allegedly straight male #1): *becomes infatuated with asm #2) now, naturally, they both fall in love with each other due to the radioactive waves of homosexuality that generally occur during such so-called "straight male" interactions. it's the same case with women. you will never find a woman who hasn't questioned her sexuality at times due to the superfluity of baddies in today's generation, that typically influence the straight female to "act up." for example: chappell roan. most of her listeners are either lesbians or quote-unquote self-identifying "straight females." bisexuals are even worse. they like everybody. hell, there's no winning with bisexual people. they like you, your mom, your dad, your sister, your brother, your whole family, at the same time, because they're biologically wired to like everybody. they can't pick a team and are quite indecisive. so indecisive that they have the gall to say, "i like men AND women." okay??? and after stating such, they'll pick a side (after bouncing from vagina to dick to vagina to dick to vagina to vagina to dick to dick). In conclusion: bush did 9/11. (the voices are getting louder they're winning please help)

This is gonna make numbers on X.

2 notes

·

View notes

Text

Stainless Steel 317/317L Seamless Tubes Exporters In India

Introduction :

Metinox Overseas is a renowned manufacturer, supplier, and stockist of SS 317L Seamless Tubes. The SS 317L alloy is distinguished by its molybdenum-bearing austenitic stainless steel composition, featuring lower carbon content compared to alloy 317. These Stainless Steel ASTM A213 TP 317L Seamless Tubes not only offer impressive tensile and stress-to-rupture strength but also exhibit enhanced creep resistance at elevated temperatures.

Product Overview :

With high chromium content, Stainless Steel 317L Seamless Square Tubes demonstrate excellent oxidation resistance; however, they are susceptible to embrittlement beyond temperatures of approximately 350 degrees Celsius, thus their application is limited to lower temperature environments. Both martensitic and precipitation hardening families of Stainless Steel 317L Rectangular Tubes boast high strengths achievable through thermal treatments.

Stainless Steel 317/317L Tubes Standard Specifications :

Specifications :ASTM A213 / ASME SA213

Outside Diameter :1/8″ OD TO 2″OD 3MM OD TO 38 MM OD

Thickness :1MM TO 3 MM 0.028 TO 0.156 IN, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS

Size :1/2″ NB — 24″ NB

Type :Seamless / Capillary Tubes

Form :Round Tubes, Square Tubes, Rectangular Tubes.

Length :Single Random, Double Random & Required Length

End :Plain End, Beveled End, Treaded

Finish :Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Application of Stainless Steel 317/317L Seamless Tubes :

1. Chemical and Petrochemical Industry

· Used for handling corrosive chemicals, acids, and solvents.

· Common in heat exchangers, condensers, and piping systems.

2. Pharmaceutical and Food Processing

· Ideal for cleanroom applications and processing environments due to hygienic and non-reactive properties.

3. Marine and Coastal Structures

· Suitable for seawater and saline environments due to enhanced resistance to chloride corrosion.

Conclusion :

Stainless Steel 317/317L seamless tubes offer a superior combination of corrosion resistance, mechanical strength, and durability, making them a reliable choice for demanding applications across various industries

#Stainless Steel 317/317L Seamless Tubes#Stainless Steel 317/317L Seamless Tubes Manufacturers#Stainless Steel 317/317L Seamless Tubes Suppliers#Stainless Steel 317/317L Seamless Tubes Stockists#Stainless Steel 317/317L Seamless Tubes Exporters#Stainless Steel 317/317L Seamless Tubes Manufacturers In India#Stainless Steel 317/317L Seamless Tubes Suppliers In India#Stainless Steel 317/317L Seamless Tubes Stockists In India#Stainless Steel 317/317L Seamless Tubes Exporters In India

2 notes

·

View notes

Text

Buy SS 304 Blind Flange | Lowest Price in India

SS 304 Blind Flanges are a vital component for industrial piping systems, known for their durability, corrosion resistance, and strength. These flanges, made from stainless steel grade 304, are designed to seal the ends of pipes or valves, making them ideal for industries such as oil and gas, chemical processing, water treatment, and more. For businesses in India, finding SS 304 Blind Flanges at the lowest price is essential for minimizing operational costs while ensuring high-quality performance. With a wide range of suppliers offering competitive pricing, it's easier than ever to source these flanges at the best rates.

What is SS 304 Blind Flange?

SS 304 Blind Flanges are flat, circular components used to close off the ends of pipelines, valves, or pressure vessels. Unlike other flanges, the blind flange does not have a central bore, meaning it completely blocks the flow of liquid or gas through the pipe. This makes it useful for isolating sections of a piping system for maintenance, testing, or system shutdowns.

The material used in these flanges—stainless steel grade 304—is an austenitic alloy with high chromium (18%) and nickel (8%) content. This composition gives SS 304 its excellent corrosion resistance, making it a perfect choice for harsh industrial environments where chemicals, moisture, and high temperatures are present.

Benefits of SS 304 Blind Flange

1. Outstanding Corrosion Resistance: The SS 304 Blind Flange’s high chromium content allows it to form a passive layer of chromium oxide on its surface, which prevents rust and corrosion. This makes it ideal for use in chemical processing, oil refineries, water treatment plants, and other industries that deal with corrosive environments.

2. High Strength and Durability: SS 304 Blind Flanges are designed to withstand extreme pressures and temperatures. This makes them suitable for high-pressure applications, including oil and gas pipelines, steam systems, and heavy-duty processing plants. Their durability ensures long-term performance without frequent replacements, reducing maintenance costs.

3. Low Maintenance: Due to its superior resistance to corrosion and wear, SS 304 Blind Flanges require minimal maintenance compared to other materials. This makes them a cost-effective choice for industries where reliable performance and low upkeep are critical.

4. Versatile Applications: SS 304 Blind Flanges are used across a wide range of industries. They are suitable for temporarily sealing off pipelines during repairs or permanently closing off systems. Their versatility makes them valuable in oil and gas, petrochemical, marine, pharmaceutical, food processing, and water treatment industries.

Why Buy SS 304 Blind Flanges in India?

India is home to a vast array of suppliers and manufacturers offering SS 304 Blind Flanges at competitive prices. Buying locally ensures that you have access to high-quality products that meet Indian and international standards, such as ASTM or ASME certifications. Here are a few reasons why purchasing SS 304 Blind Flanges in India makes sense:

1. Cost-Effective Pricing: Indian suppliers offer some of the most competitive prices in the global market for SS 304 Blind Flanges. Whether you're looking to buy in small quantities or bulk, Indian manufacturers provide quality products at reasonable rates, often with the option to negotiate prices for large orders.

2. Fast Delivery and Local Availability: When you buy from Indian suppliers, you benefit from faster delivery times and lower shipping costs, especially for domestic orders. Many suppliers have stock readily available, ensuring that you can meet your project deadlines without delays.

3. Industry-Standard Certifications: SS 304 Blind Flanges manufactured in India often adhere to industry standards such as ASTM, ASME, or DIN. These certifications guarantee that the flanges meet the required quality and performance specifications, ensuring safety and reliability in industrial applications.

4. Bulk Discounts: Many suppliers in India offer discounts on bulk orders, making it more affordable for businesses that need large quantities of SS 304 Blind Flanges. Bulk purchasing not only reduces the unit price but can also lead to savings on transportation and logistics.

Applications of SS 304 Blind Flange

SS 304 Blind Flanges are used in various industrial settings due to their robust and corrosion-resistant properties. Common applications include:

Oil and Gas Industry: SS 304 Blind Flanges are used to close off pipeline sections during repairs or testing, especially in environments where corrosion is a concern.

Chemical Processing: In chemical plants, these flanges are used to block pipes that carry corrosive fluids, ensuring the system remains secure and sealed.

Water Treatment Plants: SS 304 Blind Flanges help in sealing off sections of water pipelines, providing a rust-resistant solution for water treatment facilities.

Marine Applications: Due to their resistance to seawater corrosion, SS 304 Blind Flanges are used in marine environments, including shipbuilding and offshore drilling operations.

Pharmaceutical and Food Industry: The non-reactive and hygienic properties of SS 304 make it an excellent choice for industries that require clean and sterile processing, such as pharmaceuticals and food manufacturing.

Tips for Finding SS 304 Blind Flanges at the Lowest Price in India

1. Compare Multiple Suppliers: When purchasing SS 304 Blind Flanges in India, it’s important to compare prices from several suppliers. This will allow you to find the most competitive pricing while ensuring the quality of the product.

2. Look for Bulk Discounts: If your project requires a large quantity of flanges, ask suppliers about bulk pricing. Many manufacturers offer substantial discounts for large orders, helping you reduce the cost per unit.

3. Check for Certifications: Make sure the supplier offers SS 304 Blind Flanges that meet industry standards like ASTM, ASME, or DIN. Certified products provide assurance that the flange will perform under the required conditions.

4. Negotiate for Better Pricing: Negotiation is common in the industrial supply market. If you’re placing a large order or planning a long-term partnership, don’t hesitate to ask for better terms or discounts.

5. Look for Seasonal or Promotional Offers: Some suppliers may offer seasonal discounts or promotional deals on SS 304 Blind Flanges. Stay on the lookout for such opportunities to get the best value for your money.

#SS304BlindFlange#BuySS304Flange#StainlessSteelFlange#IndustrialFlange#CorrosionResistantFlange#LowestPriceInIndia#PipelineSolutions#OilAndGasFlange#MarineFlange#WaterTreatmentFlange#BuyNow#IndiaFlangeDeals

5 notes

·

View notes

Text

In conventional MS-DOS 8086 ASM, you display a single character by loading a value into AX and calling interrupt 0x10 so like

MOV AH,0Eh ;tells int 10h to do teletype output MOV AL,"H" ;character to print INT 10h

now, AH and AL here are two 8-bit halves of the 16bit register AX (the high byte and low byte respectively) which means that this display method means conventional MS-DOS can only use up to 256 characters-- and don't forget that this includes control characters like say, line feed, carriage return, escape, so on... not just printed characters. To display a newline in 8086 MS-DOS ASM you can do:

MOV AX,0E0Ah INT 10h MOV AL,0Dh INT 10h

(i shortened the first command compared to the original snippet because you now understand the relationship between AX, AH, and AL, dear reader. This saves a few CPU clocks :)

So you're pretty limited on the number of characters you can display.... and that's why PC-98 MS-DOS is not binary compatible with standard flavor MS-DOS XD

Like, you can display 65536 characters if you use an entire 16-bit register for the character code and use another register to call the print operation, but first you need to have a reason to do this and to actually do it.

#pc 98#ms dos#8086#asm#this is a thing that is intuitive on its own i think if you know much about old computers#this is meant as an illustration

6 notes

·

View notes

Text

Super Duplex S32760 Flanges Manufacturers in India

The manufacturer and supplier of Very Duplex Steel Flanges made their products in a variety of sizes and forms for the customer in response to interest. The manufacturer, stockist, and supplier of the entire stainless steel item, including this, is Sankalp Alloys Overseas. They provide everything and deliver the product while maintaining excellent quality and price as well.

Super Duplex Steel Flanges are regarded as the best in the series of steel Flanges based on their characteristics and strong points. The austenitic toughened steel is offered in Very Choice with a few components like copper, zinc, and chromium. The majority of businesses use a lot of Duplex steel products since they provide high strength when they come into touch.

There are many kinds of Flanges accessible, for example, Welding Neck Wall It is by and large utilized in low-temperature and high-pressure applications since they required the unhindered liquid stream conveyed by the line framework. Long welding Neck-They is equivalent to a weld neck just contrast in a lengthy welding neck the tightened center point (neck) is expanded and performs like an exhausting expansion. Slip-on Spine It is appended to the fittings or the line by two filet welds, one external the hole and the other one executed inside the rib. They are handily perceived by their minimal and thin shape.

Strung Rib This is attached by screwing the line into the spine rather than using a crease weld. They are typically used in small, low-temperature, low-stress applications like utility and water management. They are legally required in dangerous areas like petrol stations and industries. Since welding associations could be dangerous in this type of environment. Spine Attachment Weld To connect this type of rib to the lines, a single fillet weld is performed on the exterior of the rib. Joint-joint ribs This spine frequently uses an alloy with a stub end and a component with a level spacing. Dark Spine Due to the necessary catapulting forces and the structure pressure, these Flanges reduce outstanding mechanical forces.

A few other exceptional sorts of rib are Nipo rib, Weldo rib, Turn Rib, Elbo Rib, Lactro Rib, Growing spine, and Lessening Rib.

Specification of Super Duplex Stainless Steel S32750/S32760 Flanges

Super Duplex Stainless Steel Flanges Specification: ASTM A182 / ASME SA182 Dimension Standard : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. Size: 1/2" (15 NB) to 48" (1200NB) Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. Flange Face Type: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) DIN Flanges : DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. JIS Flanges : JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K BS Flanges: BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

12 notes

·

View notes

Note

Okay same venom 2003 anon again. I dont have anything else to add to what ur saying as again i didnt read venom 2003 So im just nodding respectfully and wisely to everything your saying but re ur tags is the artist you mean Humberto Ramos? Bc if it is if it helps he's a pretty unpopular artist amongst people (though usually for criticisms about his art being “too cartoony” instead of anything meaningful like the objectification of women which i personally despise when people do that. No more realism sexy super models i want hyper stylisation ONLY in my comic books just to piss those people off). I also personally do not care about him as an artist no hate nor respect towards him but again the bar is so low 😭 ive seen so many genuinely boring deeply misogynistic artists who treat women the exact same awful objectifying way but who get passes in comic book spaces because their art is more Conventionally Likeable. Like if im gonna be forced to see a woman be drawn as only one body type and face and breasting boobily id much rather take the uglier style or the more stylised style just to have something Interesting To Look At then Another Boring Generic Guy Drawing Semi Realism with Soft Shading Based off 1950s Pin ups but thats just me personally as a lifelong comic book guy

YES HUMBERTO RAMOS. i hate the venom 2003 art but in the past two hours i've come to realize that humberto ramos is my real enemy here and the only real fault of venom 2003 is its resemblance of ramos's art (of course in addition to its own home brewed sexism).

i really love stylized art and i hate realistic styles. i love the classic ASM look because it struck a nice balance between the two: the 1960s-80s need to depict the human form in a standardized, realistic way (likely due to toy sales, at least if its caused by the same phenomenon of 80s cartoons, a la he-man, having that same look to them), but the flat colors, limited color palette, and cell shading were so so wonderfully simple and sleek in a really fun way. gave such a distinct Look to the comic, and the simplicity of the colors also made the realistic lineart not too realistic. it just felt very intentional, very careful, very creative with their technological limitations, and it's such a timeless look that has aged so well even still to the 2020s

so while i love the classique look, i also love when comic styles go even further to really break the mold and stylize further!! herrera in venom 2003, and ramos's whole *gestures broadly* COULD be good, if only they were done a little bit more purposefully, and yknow, minus the outrageous sexism

and yes sexism is overall so entrenched in marvel comics and i wouldn't be surprised if it also infected literally all other comic companies out there, considering We Live In A Society. anyone who dares to argue that misogyny doesn't exist needs to go become a comic geek and read hundreds of marvel comics and see

1. how utterly shallow women are characterized compared to their male counterparts

2. how female characters so rarely get to exist on their own outside of a male character; ie. female characters who are only side characters for a male hero, or superheroines who are literaly just "female version of xyz popular male character!", etc etc etc

3. the way women are visually depicted compared to men. men, especially the superheroes, are still subject to white patriarchal standards of beauty of course, but the huge muscles they're drawn with are a form of power, a "look how cool i am." you will never get that with a female character. they are only ever depicted with the same fucking face, the same fucking body type, the same fucking curves and tasteful cleavage and pouty lips and cat eye makeup.

4. and while the men have these like insane muscles that do not exist irl, they at least get to POSE in ways that are not sexualized. the women characters, even if their designs are not objectifying, will still be posed so that their butts face the camera, they have a pretty side profile to show off the silhouette of their breasts, etc. if you really pay careful attention to the way women are placed in comic panels compared to men it's so insane. so fucking insane

but yknow, all of those things tend to manifest in subtle ways, ways that you really can only pick up when you've read so many comics over a decent amount of time, and when you're otherwise prepared to read for and pick up on sexist elements. so i guess i REALLY draw my line and get pissed the fuck off beyond belief when comic writers and/or artists then begin to just be, blatantly, fucking sexist. a la those terrible panels from ASM spider island. a la that one she-hulk issue. a la spider-man/red sonja. when it's blatant it means you give NO fucks, it means you don't even believe women are people because you don't expect them to be engaging your works and thus you don't expect any sort of audience outcry from your blatant sexism, it means you literally only see women as objects for your male audience to oogle over, it's beyond frustrating

2 notes

·

View notes