Enviro Solutions, a leading gas analyzer manufacturer, is at the forefront of environmental innovation.

Last active 4 hours ago

Don't wanna be here? Send us removal request.

Text

From Orchard to Market: How Ethylene and CO₂ Sensors Perfect Fruit Ripening

Why Smart Gas Monitoring is the Secret to Fresher, Longer-Lasting Fruits

Ripening Is a Science—Not a Guess

If you think fruit ripening is just about time and temperature, think again. Behind every perfectly ripened mango or banana is a delicate balance of Ethylene and carbon dioxide (CO₂) levels. And when that balance is off? Overripe, uneven, or wasted produce becomes the costly reality.

Enter ESEGAS Ethylene and CO₂ sensors—the intelligent way to monitor, control, and optimize fruit ripening chambers.

Ethylene: The Ripening Accelerator

Ethylene (C₂H₄) is a natural plant hormone that tells your fruit: “It’s time to ripen.” But too much or too little ethylene? That’s a recipe for disaster. + Uneven ripening + Color mismatch + Texture breakdown

ESEGAS ethylene sensors use cutting-edge photoacoustic and electrochemical tech to measure even the tiniest gas fluctuations—down to 0.1 ppm. That means your fruits ripen uniformly, on schedule, and ready for the shelf.

CO₂: The Unsung Hero of Storage

CO₂ doesn’t just hang around—it regulates the ripening speed and prevents spoilage. With levels typically controlled between 1–5%, CO₂ helps you: ✔ Delay ripening for better logistics ✔ Inhibit mold and microbes ✔ Prevent flavor and texture loss

Using ESEGAS CO₂ analyzers with NDIR technology, you can monitor and respond to gas shifts in real time, keeping your fruit in perfect condition.

Real-Time Monitoring = Less Waste

Manual gas checks are outdated. With ESEGAS, you get: ✅ Continuous live readings ✅ Threshold alarms via SMS/email ✅ Seamless integration with control systems ✅ Long-life, humidity-resistant sensor builds

This means less manual guesswork and more data-driven ripening decisions.

Smarter Installation, Better Results

Want to make the most of your sensors? Here’s how: * Place sensors at fruit crate level—not near fans or vents * Clean filters and calibrate monthly or quarterly * Use multiple sensors for large chambers * Choose sensors that withstand 12–20°C and high humidity

ESEGAS sensors are made for exactly this environment, with robust enclosures, moisture protection, and smart diagnostics.

Why It Matters

✔ Reduce post-harvest losses ✔ Extend fruit shelf life ✔ Meet market demands with consistent quality ✔ Make smarter inventory decisions ✔ Cut down on energy and manual labor costs

Whether you’re ripening avocados in India or bananas in South America, ESEGAS sensors help you take control of the invisible forces that shape your fruit quality.

Choose ESEGAS. Choose Quality.

Fruit ripening is both art and science—and with ESEGAS ethylene and CO₂ monitoring systems, you're empowered to master both.

Want to upgrade your ripening chambers?

Need better consistency in your supply chain?

Ready to say goodbye to spoilage?

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes

Text

Protect Your Pipeline: Why the ESE-LASER-600 H₂S Analyzer Is a Must for Sour Gas Monitoring

Ensure Safety, Cut Costs, and Stay Compliant with Real-Time Hydrogen Sulfide Detection

When dealing with sour gas, precision isn’t optional—it’s critical. Hydrogen sulfide (H₂S) is toxic, corrosive, and a constant threat to both human safety and pipeline integrity. That’s why smart operators across the natural gas value chain are turning to one of the most trusted technologies on the market: the ESEGAS ESE-LASER-600 H₂S Analyzer.

This isn’t just a monitoring device—it’s your first line of defense.

Why H₂S Detection Can’t Be an Afterthought

H₂S causes corrosion, damages catalysts, and poses serious safety risks. Even trace levels can compromise product quality and trigger compliance failures. In environments like:

Sour gas pipelines

Amine gas sweetening units

Natural gas processing plants

LNG facilities

…reliable H₂S monitoring isn’t optional. It’s a requirement.

What Makes the ESE-LASER-600 Stand Out?

Powered by Tunable Diode Laser Absorption Spectroscopy (TDLAS), this analyzer delivers unmatched precision, even in harsh environments. Key benefits include:

✅ Dual-range detection: 0–500 ppm or up to 30% ✅ Ultra-low detection limits (ppb range) ✅ High selectivity to H₂S—ignores CH₄, CO₂, and H₂O ✅ No consumables and only 2 calibrations per year ✅ Custom coatings to reduce gas adsorption

That means less downtime, fewer false alarms, and consistent data—even under fluctuating gas conditions.

Where It Fits in the Natural Gas Chain

From wellhead to storage tank, the ESE-LASER-600 ensures precise monitoring at every stage:

Upstream: Real-time decisions during gas extraction Sweetening units: Post-treatment checks to meet sales specs Transport: Prevent corrosion and pipeline leaks Storage & processing: Protect your catalysts and compliance

Easy Integration, Maximum Reliability

Installing the analyzer is straightforward, with step-by-step system guidance:

Sample conditioning (filters, probes, etc.)

Integration with DCS/SCADA

Auto-calibration and diagnostics

Surface-coating options for sticky gas environments

Invest in Safety—and Savings

Lower OPEX: Minimal maintenance Avoid Shutdowns: Instant alerts prevent major failures Better Compliance: Stay aligned with OSHA and environmental norms Peace of Mind: Data-backed decisions, always

✅ Ready to Level Up Your H₂S Monitoring?

If you’re serious about sour gas safety, the ESE-LASER-600 is the upgrade you need. Fast, accurate, and built for industrial reality—it’s more than a sensor. It’s your safeguard against corrosion, leaks, and costly downtime.

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes

Text

"How Gas Analyzers Are Saving Lives Across Industries — And Why ESEGAS Leads the Way"

Invisible Threats, Visible Solutions

Gas leaks don’t just mean lost resources—they mean danger. From oil platforms to food factories, toxic and combustible gases can silently build up, risking explosions, poisoning workers, and halting operations. But thanks to advanced gas analyzers like those from ESEGAS, industries now have a real-time, reliable way to stay ahead of disaster.

Why the Oil & Gas Industry Can’t Operate Without Gas Analyzers

In the oil and gas sector, flammable gases like methane and propane are always present. One unnoticed leak? It could ignite into catastrophe. That’s why ESEGAS gas analyzers are built for rugged, high-risk environments like offshore rigs and refineries. ✅ Detect H₂S, CO₂, methane and more in real-time ✅ Withstand extreme temperatures and humidity ✅ Integrate seamlessly into SCADA/DCS systems

ESEGAS analyzers don’t just monitor—they actively prevent disasters and regulatory violations.

In Chemical Plants, Safety Starts with Detection

Chemical plants are volatile by nature. Toxic gases like chlorine or ammonia can leak through valves or tanks. Without proper detection, these leaks could result in workplace injuries or complete shutdowns. 1. ESEGAS analyzers detect multiple gases at once 2. Built with corrosion-resistant housings for harsh atmospheres 3. Feature zero-drift sensors for long-term accuracy

For chemical operators, ESEGAS ensures peace of mind—day after day.

Wastewater Treatment: Don’t Let Silent Gases Build Up

Most people don’t realize how dangerous wastewater treatment can be. Gases like methane, hydrogen sulfide, and ammonia accumulate during sludge handling and digestion. a) ESEGAS fixed and portable analyzers detect gas threats in confined spaces, tanks, and biogas lines. b) IP-rated and corrosion-proof designs ensure durability in humid, acidic conditions.

When every second counts, ESEGAS alerts the team before it’s too late.

Food & Beverage: When Inert Gases Become Deadly

CO₂ and nitrogen are staples in food processing—but if they leak, they can silently displace oxygen in closed environments. 1. ESEGAS sensors detect oxygen deficiency and gas leaks during packaging, fermentation, or chilling. 2. Clean, hygienic IP67 designs fit food-grade requirements.

Protect your team, your process, and your products with smart leak detection.

Power Generation & Labs: Where Precision Equals Protection

Whether it’s hydrogen in cooling systems or ethylene oxide in sterilization chambers, precision matters. ESEGAS analyzers are designed for high-EMI environments and lab-grade sensitivity. Sub-ppm detection ensures even the tiniest leaks are spotted before they escalate.

Conclusion:

Gas Leak Detection Isn’t Optional—It’s Essential Every industry using gas needs one thing—trustworthy gas analysis. That’s why ESEGAS is setting the standard with smart, rugged, and reliable analyzers for every environment.

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes

Text

Why Every Sewage and Biogas Plant Needs a Portable Biogas Analyzer—Before It's Too Late"

Detect Invisible Dangers Before They Harm

In the world of sewage treatment and biogas generation, danger doesn’t always come with warning signs. Deadly gases like hydrogen sulfide (H₂S), methane (CH₄), and carbon dioxide (CO₂) often go unnoticed—until it’s too late. These gases accumulate in digesters, manholes, and sludge pits, silently threatening lives and operations.

That’s where the ESEGAS UV-DOAS-500P Portable Biogas Analyzer makes a life-saving difference. This rugged device is a field-ready gas detection powerhouse that delivers real-time data in the most challenging environments.

Why Are Confined Spaces So Risky?

Confined spaces in sewage systems—like wet wells, pipes, and digesters—are prone to low oxygen, toxic gas buildup, and flammable atmospheres. Just 10 ppm of H₂S affects health; 100 ppm can be fatal. Methane becomes explosive at just 5%. And when oxygen drops below 19.5%, you risk losing consciousness within minutes.

The ESEGAS Portable Biogas Analyzer prevents these tragedies. It provides on-the-spot, multi-gas analysis, helping environmental health and safety (EHS) teams decide whether it’s safe to enter a space—before putting lives at risk.

Built for Harsh Conditions, Engineered for Speed

Unlike traditional electrochemical sensors, the UV-DOAS-500P uses ultraviolet differential optical absorption spectroscopy (UV-DOAS). This means no sensor drift, no sensor swaps, and no false alarms—even in humid, corrosive environments.

Key features include:

Multi-gas detection in under 60 seconds

Real-time data for H₂S, NH₃, SO₂, NOx, and more

IP65-rated casing for moisture and dust protection

Chemical-resistant internal components

Battery-powered portability with touchscreen control

It’s not just durable—it’s dependable when every second counts.

Beyond Safety: Boost Efficiency and Cut Downtime

Safety is just the start. Portable biogas analyzers also help optimize biogas production. Use them to:

Detect leaks in digesters or piping

Evaluate gas yield for fermentation process control

Prevent desulfurizer media overload

Generate compliance-ready data for audits

In short, you’re getting a mobile lab in your hands—saving lives and improving plant performance at once.

Turn Safety Into a Culture, Not a Checklist

ESEGAS doesn’t just build analyzers—it empowers teams. The UV–DOAS–500P fits seamlessly into your EHS workflows. With proper training, SOPs, and team roles, this tool shifts your approach from reactive to proactive safety.

Whether you're a plant manager, safety officer, or technician, this analyzer gives you the confidence and data you need to act fast and act smart.

Conclusion:

One Tool, Infinite Protection Don’t let invisible dangers decide your fate. In high-risk zones like sewage and biogas plants, the ESEGAS UV–DOAS–500P isn’t optional—it’s essential.

✅ Protect your team ✅ Optimize your operation ✅ Stay compliant and audit-ready

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes

Text

Refine Smarter: How Process Gas Analyzers Are Transforming Oil Refineries

Unlock Higher Efficiency, Quality, and Safety with Real-Time Gas Monitoring

In today’s ultra-competitive refining industry, staying ahead means doing more than just producing fuel. It means optimizing every process for efficiency, safety, and compliance. That’s where process gas analyzers step in—bringing real-time intelligence to every corner of the refinery.

What Exactly is a Process Gas Analyzer?

A process gas analyzer is an advanced tool used to monitor and measure gas concentrations in refining operations. It offers continuous, real-time readings of critical gases such as O₂, CO, CO₂, H₂, H₂S, and CH₄, helping engineers control combustion, prevent contamination, and stay compliant with environmental standards.

Unlike traditional lab analysis or manual sampling—which can take hours—modern gas analyzers provide instant feedback. This makes them essential for maintaining control over complex refinery reactions like hydrotreating, cracking, reforming, and sulfur recovery.

Why Refining Needs Real-Time Gas Monitoring

Refineries operate under extreme conditions—heat, pressure, and ever-changing feedstocks. A minor fluctuation in gas composition can affect product quality, damage expensive catalysts, or even pose safety risks. With process gas analyzers, you get early warnings before problems escalate.

Key benefits include:

Combustion control in boilers and furnaces to reduce fuel waste

Hydrogen monitoring in reformers for protecting catalysts

H₂S and CO₂ tracking in amine units for corrosion prevention

SO₂ and NOₓ detection for emission compliance

Where Are Process Gas Analyzers Used?

These analyzers play a vital role in units such as:

Fired heaters: O₂ and CO sensors help optimize air-to-fuel ratios

Hydrotreaters: H₂ analyzers ensure purity for cleaner fuel

Sulfur recovery units (SRUs): Track H₂S and O₂ for maximum conversion

FCC regenerators: Maintain clean combustion with NDIR CO/O₂ sensors

Whether it's tuning burner settings or fine-tuning hydrogen flow, these tools provide precision control at every step.

Powerful Technologies Behind the Scenes

Modern analyzers are powered by high-tech sensing solutions:

TDLAS (Tunable Diode Laser Absorption Spectroscopy) for H₂S and moisture—ultra-sensitive and fast

NDIR (Non-Dispersive Infrared) sensors for CO, CO₂, and CH₄—reliable and rugged

TCD (Thermal Conductivity Detectors) for H₂ purity

Electrochemical and paramagnetic sensors for O₂

Each technology is tailored to the gas type and application, giving you maximum accuracy with minimal maintenance.

The Result? Better Performance Across the Board

✅ Higher Efficiency: Save fuel, reduce waste ✅ Improved Product Quality: Real-time feedback avoids off-spec products ✅ Stronger Equipment Protection: Prevent catalyst damage and corrosion ✅ Compliance Made Easy: Always stay within emission limits

Final Word

A process gas analyzer isn’t just a sensor—it’s a smart decision. It helps refineries become safer, cleaner, and more efficient. Whether you're in charge of operations, compliance, or maintenance, this is the tool that takes your plant to the next level.

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes

Text

Stack Emissions Got You Stressed? Discover How Industrial Gas Analyzers from ESEGAS Can Help You Breathe Easy!

Your Ultimate Guide to Real-Time Stack Emission Monitoring with ESEGAS Industrial Gas Analyzers

Modern industries can’t afford to fall behind when it comes to emission monitoring. With strict environmental laws, costly penalties, and pressure for transparency, your stack emissions can make or break your compliance efforts.

That’s where ESEGAS Industrial Gas Analyzers step in—bringing precision, real-time data, and peace of mind.

Why Worry About Stack Emissions?

Industrial stack gases are loaded with pollutants like NOx, SO₂, CO, CO₂, NH₃, VOCs, and even fine particulate matter. These gases not only harm the environment but also affect public health—and your bottom line if left unchecked.

ESEGAS analyzers provide real-time, automated monitoring of these invisible threats, helping you take control before regulators do.

What Makes ESEGAS Gas Analyzers So Effective?

Not all analyzers are created equal. ESEGAS uses advanced sensing technologies including:

NDIR (Non-Dispersive Infrared) for CO and CO₂

Electrochemical cells for NOx and O₂

FTIR for multi-gas detection

Paramagnetic sensors for high-accuracy O₂ measurement

Each analyzer is calibrated for continuous, 24/7 monitoring—with built-in self-diagnostics, auto-calibration, and cloud-based alerts.

Extractive or In-Situ? Choose Smart with ESEGAS

Every facility is unique. That’s why ESEGAS offers both:

✅ Extractive Analyzers: Ideal for complex emission profiles and high-precision labs. They pull gas samples, condition them, and analyze them in a controlled cabinet.

✅ In-Situ Analyzers: Perfect for real-time control and low maintenance. These are installed directly on the stack and deliver instant measurements with no delays.

Whether you're running a cement kiln, power plant, or chemical facility, ESEGAS helps you choose the right configuration for reliable performance.

Long-Term Accuracy: Built-In, Not Bolted On

Worried about sensor drift or harsh environments?

ESEGAS analyzers feature:

Scheduled calibration with certified reference gases

Self-diagnostic alerts before faults occur

Advanced sample conditioning systems

Remote access dashboards and notifications

Maintenance kits and support for smooth operation

This means less downtime, fewer surprises, and more accurate reporting—all the time.

✅ Stay Compliant. Stay Confident. Stay Ahead.

With environmental scrutiny at an all-time high, don’t leave compliance to chance. ESEGAS Industrial Gas Analyzers give you the tools to:

Monitor real-time emissions Reduce your environmental footprint Avoid regulatory penalties Optimize combustion efficiency

Ready to level up your emission monitoring?

Visit esegas.com and explore the next generation of stack gas analyzers—engineered for accuracy, built for durability, and designed with your industry in mind.

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes

Text

Unlocking Precision: Why TDLAS HCl Gas Analyzers Are a Must-Have for Industrial Safety and Compliance

Struggling to Monitor HCl Gas Accurately? Here’s the Game-Changing Solution

Hydrogen chloride (HCl) is an invisible but dangerous threat in many industries—waste incineration, chemical production, and cement kilns to name a few. Left unchecked, HCl emissions can corrode equipment, endanger workers, and result in serious environmental penalties. So how do you keep it under control?

Enter: TDLAS-Based HCl Gas Analyzers.

These laser-powered systems are transforming how industries detect and manage HCl. With real-time, highly accurate measurements, they don’t just meet compliance—they redefine operational safety and efficiency.

Why Is Monitoring HCl Gas So Important?

Hydrogen chloride is no ordinary gas. It forms hydrochloric acid on contact with moisture, damaging flue gas ducts, control systems, and sensor units. Exposure can lead to respiratory distress for workers and severe process disruptions.

Government regulations like the Industrial Emissions Directive (IED) mandate strict limits on HCl emissions. Failing to comply? Think heavy fines, shutdowns, and reputational loss.

The takeaway: Monitoring isn’t optional—it’s essential.

TDLAS Technology: Precision You Can Count On

So what makes Tunable Diode Laser Absorption Spectroscopy (TDLAS) such a big deal?

High Selectivity: Targets only HCl without interference from other gases

Fast Response: Instantaneous readings in dynamic environments

Low Maintenance: No moving parts or chemical consumables

In Situ or Extractive: Flexible for all industrial setups

Using TDLAS, ESEGAS HCl analyzers give you ppm to ppb-level sensitivity—ideal for both high-output factories and ultra-clean environments.

Find Your Ideal HCl Analyzer Model from ESEGAS

1. ESE-LASER-HCL-200 – Best for industrial online monitoring 2. ESE-LASER-HCL-200P – Portable, ideal for inspections and audits 3. ESE-LASER-HCL-500 – Built for extreme conditions and higher accuracy 4. ESE-LASER-HCL-700 – Detects trace amounts in ultra-clean environments

Whether you're monitoring emissions in a cement kiln or verifying leaks in a semiconductor lab, there's a tailor-made solution for you.

Why Industries Trust ESEGAS

At ESEGAS, it’s not just about the sensor—it’s about protecting your operation, your workforce, and the environment. Their laser-based systems are engineered for durability, accuracy, and seamless integration into existing control systems like SCADA and DCS.

⚙️ Real-time control 🌍 Emissions compliance 🔒 Enhanced safety

Final Word: Upgrade Before It’s Too Late

If your facility still relies on outdated or slow-response gas detectors, it’s time to rethink your strategy. Modern industrial challenges require modern solutions—and TDLAS HCl gas analyzers from ESEGAS are the cutting edge.

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes

Text

How to Choose the Right Process Gas Analyzer: A Smart Guide for Safer, Smarter Industries

Don’t Let the Wrong Analyzer Cost You Big—Know the Right Way to Select Yours

When it comes to industrial safety, precision, and compliance, choosing the right process gas analyzer is a game-changer. One wrong selection and you’re risking product quality, environmental fines, or even safety disasters. But don’t worry—this guide breaks it all down for you, making complex decisions easy.

Why the Right Analyzer is Critical

Imagine using the wrong analyzer for a toxic gas. Data becomes inaccurate, leading to flawed control decisions, energy inefficiency, or worse—safety violations. Whether it’s a power plant, chemical factory, or waste incinerator, choosing an analyzer isn’t just a technical task—it’s a strategic one.

That’s why experts at ESEGAS recommend starting with the basics: ✔️ What gas are you measuring? ✔️ Under what pressure, temperature, and flow conditions? ✔️ Is the environment corrosive, explosive, or exposed to vibrations?

✅ Key Factors You Must Consider

1. Type of Gas and Technology Compatibility Different gases need different sensing methods. CO₂ or CH₄? Go for NDIR. Oxygen? Consider paramagnetic or electrochemical. Toxic VOCs? You might need a flame ionization detector or laser-based tech.

2. Concentration Levels Low ppm levels require high-sensitivity analyzers. Bulk concentration monitoring? Opt for wider range models. Select an analyzer that’s most accurate around your typical measurement point.

3. Process Conditions If your gas is hot, pressurized, or part of a fast-moving stream, don’t forget:

Temperature affects sensor stability

Pressure changes affect gas density

Sample conditioning might be essential

4. Environmental Challenges Installing analyzers in harsh zones? Dust, corrosion, or flammable gases present real risks. Use corrosion-resistant housings, ATEX-certified explosion-proof designs, or IP-rated enclosures.

5. Sampling Method In-situ analyzers are great for fast response. Extractive analyzers suit controlled sampling. The right method ensures stable readings and manageable maintenance.

How ESEGAS Makes It Simple

ESEGAS doesn’t just provide instruments—they offer tailored gas analysis systems for real-world conditions.

You can choose from:

Online analyzers for continuous monitoring

Portable analyzers for spot checks

Extraction systems for dirty or hot gases

TDL analyzers for high-precision, low-maintenance performance

These come with rugged housings, real-time data output, DCS/PLC integration, and long-term calibration support.

Your Environment Matters More Than You Think

Whether indoors or outdoors, on a reactor or beside a turbine, installation environment can make or break analyzer life. Select enclosures based on IP rating, vibration-proof mounts, or explosion-proof housing based on your zone.

Conclusion:

The right process gas analyzer isn’t just a purchase—it’s a process investment. With proper selection, you’ll gain efficiency, avoid downtime, and meet emission regulations stress-free. Choose smart. Choose ESEGAS.

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes

Text

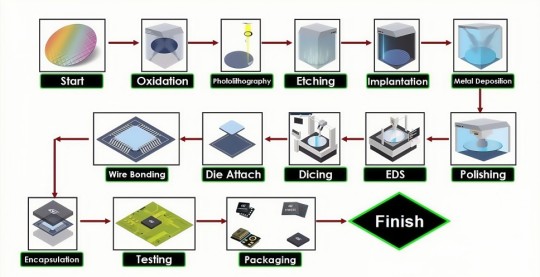

Invisible Risks, Powerful Protection: Why Process Gas Analyzers Are Essential in Electronics Manufacturing

In the fast-paced world of electronics, where semiconductors and battery packs shape our tech future, one invisible danger lurks silently: gas leaks. From toxic HF to explosive SiH₄ and oxygen-sensitive cleanrooms, safety can't be an afterthought. Enter the process gas analyzer—your smart guardian for a safer, smarter factory floor.

Why the Electronics Industry Can't Afford to Ignore Gas Safety

Modern electronics manufacturing—from semiconductor fabrication to PCB assembly—relies heavily on gases. Some are flammable, some toxic, and others need to remain ultra-pure. Whether it’s OLED deposition or battery abuse testing, one tiny leak can halt production or cause real harm.

That’s why process gas analyzers are more than tools—they’re life-saving systems. These analyzers constantly monitor gas levels in real time and integrate with ventilation, alarms, and shutdown protocols to protect workers and assets before a crisis unfolds.

Where Are Process Gas Analyzers Used in Electronics?

Let’s break it down:

Semiconductor Fabrication Processes like etching and doping use dangerous gases (e.g., HF, NH₃, SiH₄). A leak can ruin wafers—or worse, endanger lives.

OLED & Display Production Organic vapors must be kept under control. Analyzers ensure a clean, inert atmosphere to maintain quality and prevent contamination.

PCB Soldering & Assembly Reflow soldering releases VOCs and fumes. Gas analyzers protect both electronics and personnel by keeping indoor air quality in check.

Battery Testing During thermal runaway, batteries emit CO, HF, and methane. Early detection via gas analyzers ensures engineers can react before it escalates.

How Do Process Gas Analyzers Improve Safety?

Here’s how they work:

✅ Continuous Monitoring: Never stop watching. Gas analyzers work 24/7, even when people can’t.

✅ Early Warning: If gas levels rise, they sound alarms, activate fans, or shut systems down—automatically.

✅ SIS Integration: Feed data into Safety Instrumented Systems to meet IEC SIL standards.

✅ Regulatory Compliance: Meet OSHA, EPA, and ISO 14644 standards with ease, complete with audit-ready data logs.

What Gases Do They Detect?

Toxic & Reactive: HF, HCl, NH₃, VOCs, SiH₄

Flammable: Methane, PFCs

Oxygen & Moisture: For cleanrooms

CO/CO₂: Especially in battery and soldering zones

Different tech like FTIR, TDLAS, NDIR, and electrochemical sensors are used depending on the gas and application.

💡Real Benefits That Go Beyond Safety

Enhanced Worker Safety

Reduced Downtime & Product Waste

Data-Driven Process Control

Lower Insurance & Maintenance Costs

Ready to Power Up Your Plant’s Safety?

In a world where gas risks hide in plain sight, process gas analyzers deliver peace of mind. Whether you're building the next-gen microchip or testing EV batteries, ESEGAS solutions give you the confidence to innovate—safely.

0 notes

Text

Cracking the Code: How Gas Analyzers Boost Hydrogen Fuel Cell Innovation

Explore how real-time gas monitoring transforms catalyst evaluation in hydrogen fuel reforming—with smarter insights, faster breakthroughs, and cleaner energy.

Why Catalyst Evaluation Needs More Than Just Voltage Readings

In the world of Hydrogen fuel cell research, understanding catalyst performance isn’t just about measuring electrical output. It's about digging into the actual chemistry of gas reactions. That’s where real-time gas analyzers like the IR-GAS-600 from ESEGAS become game changers.

During steam methane reforming (SMR), CH₄ and H₂O react to produce hydrogen. But without precise monitoring of gases like CO, CO₂, CH₄, and H₂, it’s hard to judge how efficiently a catalyst is really working—or if it's slowly degrading.

The Hidden Signs of Catalyst Wear and Tear

Catalyst deactivation is sneaky. Before your system fails, small shifts in gas ratios start to happen:

Rising CH₄ levels? Possible incomplete reforming.

Increasing CO/CO₂ ratio? Catalyst selectivity might be shifting.

Decreasing H₂ yield? Time to inspect the catalyst structure.

These subtle trends aren’t visible to the eye—or even to basic instruments. Only real-time gas analysis can catch them early.

Real-Time Data = Real Catalyst Insights

The IR-GAS-600 Online Syngas Analyzer delivers continuous, high-resolution data so researchers can evaluate:

✅ Catalyst stability under temperature stress ✅ Real-time reaction dynamics ✅ Gas shifts during feed changes or ramp-ups ✅ Early signs of sintering, fouling, or poisoning

It supports simultaneous detection of CH₄, CO, CO₂, O₂, and H₂—providing the complete picture of SMR performance. And thanks to temperature-compensated sensors, the data is stable, accurate, and fast.

Catalyst Testing in Action: What the Gas Trends Reveal

Imagine testing a new catalyst. With the IR-GAS-600, you might notice:

➡️ CH₄ levels rising slowly across cycles → surface area loss ➡️ CO increasing despite stable feed → reverse reactions taking over ➡️ CO₂ drops while H₂ holds steady → water-gas shift activity decline

Each of these signals tells a story—of aging, stress, or performance loss. With a gas analyzer, you're not just watching it happen—you’re understanding why.

Perfect Fit for Research & Industry

Whether you're working in a research lab or scaling to industrial SMR, ESEGAS analyzers fit the bill:

🔹 High-temp catalyst testing 🔹 Biomass and coal gasification 🔹 Steelmaking processes 🔹 Blast furnaces and syngas production

Built for durability, precision, and easy integration, the IR-GAS-600 makes advanced gas monitoring accessible for everyone serious about hydrogen.

Cleaner Hydrogen Starts with Smarter Tools

Want to unlock cleaner energy with better catalysts? Start with better insights.

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes

Text

How Laser Gas Analyzers Enhance Efficiency & Safety in the Steel Industry

Modern steel production is a high-stakes environment where efficiency, precision, and safety must align perfectly. Laser gas analyzers have emerged as essential tools, offering real-time monitoring and control for gas-related processes across all stages of steelmaking.

Optimizing Blast Furnace Monitoring with Laser Technology

Blast furnaces generate large volumes of gas—including CO, CO₂, H₂, and CH₄—that require constant supervision. Traditional analyzers can’t keep up with process fluctuations, leading to inefficiencies and risks.

Laser gas analyzers, particularly those using Tunable Diode Laser Absorption Spectroscopy (TDLAS), offer non-contact, real-time measurements that stabilize combustion, reduce coke usage, and minimize downtime. They are installed directly on flue ducts and deliver high-speed, ppm-level accuracy.

“The key to reliable blast furnace operation is real-time gas analysis. Laser systems make that possible with unmatched precision.”

Improving Oxygen Control in BOF Steelmaking

In Basic Oxygen Furnace (BOF) operations, maintaining optimal oxygen levels is critical. Over-oxidation can waste valuable metals; under-oxidation affects steel quality.

Laser gas analyzers track CO and O₂ levels in the off-gas, enabling precise endpoint detection and oxygen control. This enhances steel quality, reduces reblows, and ensures tighter process regulation.

“With laser gas monitoring, steelmakers can optimize every oxygen blow, saving both time and material.”

Boosting Combustion Efficiency in Reheating Furnaces

Reheating furnaces demand uniform temperatures for shaping semi-finished steel. Poor combustion control results in energy loss, temperature imbalance, and elevated emissions.

Laser gas analyzers measure O₂ and CO directly within furnace gases, allowing operators to fine-tune air-fuel ratios. Benefits include:

Lower fuel consumption

Reduced NOx and CO emissions

Stable thermal profiles

Minimal maintenance downtime

Enhancing Safety Through Real-Time Gas Monitoring

Steel plants operate with extreme heat, confined spaces, and flammable gases. A leak or combustion failure can have catastrophic results.

Laser gas analyzers help prevent accidents by providing continuous, fast-response detection of hazardous gases like CO and CH₄. Key advantages:

Early leak detection

Abnormal combustion alerts

Safer maintenance access

Compliance with OSHA & EPA standards

Featured Product: ESE-IR-100 CO₂ Analyzer

The ESE-IR-100 is a high-precision, NDIR-based analyzer ideal for emission monitoring. With fast response times and ±2%FS accuracy, it’s perfect for industrial and environmental CO₂ detection needs.

Key specs:

Measuring Range: 0–10,000 μmol/mol

Response Time: ≤60s

Analog & RS485 Output

Conclusion: Smarter Steelmaking Starts with Laser Insights

Laser gas analyzers empower the steel industry with real-time, precise gas measurement—improving operational efficiency, reducing emissions, and enhancing safety. Whether monitoring a blast furnace or controlling oxygen in BOF, this technology is essential for meeting today’s industrial demands.

For More Information Visit our article here.

0 notes

Text

Why Every Landfill Needs a Smart Gas Analyzer – The ESEGAS Advantage

Methane Isn’t Just a Gas – It’s a Risk

Landfills naturally emit gases like methane (CH₄), carbon dioxide (CO₂), and volatile organic compounds (VOCs). But without monitoring, these gases can silently build up to dangerous or non-compliant levels. Methane is not just a greenhouse gas—it's highly flammable. That’s why a reliable gas analyzer is essential for every landfill.

Meet ESEGAS – Smarter, Safer, Stronger Monitoring

If you’re in charge of a landfill site, ESEGAS gas analyzers can change the game. These devices are built to monitor multiple gases—CH₄, CO₂, H₂S, O₂, NH₃, and VOCs—in real time. No more waiting for lab results. ESEGAS uses advanced NDIR and electrochemical sensors for precise, stable readings, even in tough landfill conditions.

Real-Time Data = Real-Time Decisions

Old-school methods of landfill monitoring? Too slow, too risky. With ESEGAS analyzers, you get live data, remote access, data logging, and automated alerts. That means you can detect dangerous gas spikes or system failures before they turn into disasters. Plus, automated reports make regulatory compliance a breeze.

Engineered for the Harshest Conditions

Landfill environments are rough—think corrosive gases, fluctuating temperatures, and high humidity. ESEGAS analyzers are made for this. With corrosion-resistant enclosures, auto-calibration, and low maintenance, they keep running where other systems fail. Whether portable or fixed, they deliver reliability you can count on.

Stay Compliant, Stay Ahead

Regulations from the EPA, EEA, and other global agencies require precise monitoring of landfill gases. ESEGAS analyzers meet and exceed those standards, helping sites stay compliant and even qualify for carbon credits or energy recovery initiatives. It’s not just about following rules—it’s about protecting communities and maximizing landfill value.

Tailored Solutions for Every Site

Every landfill is different. Whether you're operating a small waste facility or a large industrial site, ESEGAS offers tailored analyzer solutions that fit your needs. From sensor type to gas range and connectivity, ESEGAS specialists can help match the perfect analyzer to your site’s specific monitoring requirements.

Conclusion: Breathe Easy with ESEGAS

When safety, compliance, and environmental impact are on the line, you need the best tools available. ESEGAS landfill gas analyzers combine rugged engineering with cutting-edge technology to give you full control over what’s happening underground and in the air.

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes

Text

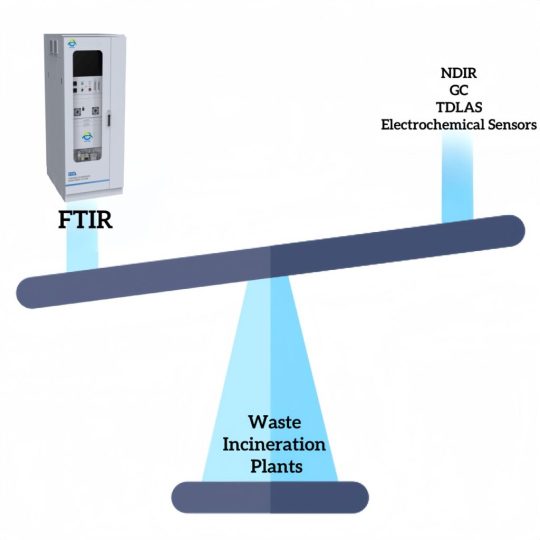

Why FTIR Gas Analyzers Are a Game-Changer for Waste Incineration Emission Monitoring

The Hidden Dangers of Waste Incineration Emissions

Waste incineration plants are essential for reducing landfill usage and generating energy from waste. But there’s a catch—they emit harmful gases like CO, NOx, SO₂, HCl, HF, VOCs, and even dioxins. These pollutants can harm air quality, human health, and the environment if left unchecked. That's why emission monitoring in these plants isn’t just regulatory—it’s critical.

Traditional gas analyzers often fall short. Many can only detect a single gas, require complex setups, and have slower response times. That means you might miss dangerous spikes or spend more on maintenance and compliance issues. Enter a new solution: FTIR gas analyzers.

What Makes FTIR the Smarter Choice?

FTIR (Fourier Transform Infrared) technology changes the game. It identifies gases based on how their molecules absorb infrared light—each gas leaves a unique “fingerprint.” Instead of using multiple analyzers, FTIR monitors dozens of gases at once. Real-time. Accurate. Efficient.

Here’s why FTIR is ideal for waste incineration:

✅ Multi-gas detection: Monitor CO, NOx, SO₂, NH₃, VOCs, and more—all at once.

✅ Real-time data: Immediate alerts help prevent violations and enable faster corrective action.

✅ Low detection limits: Even trace gases at parts-per-billion levels are picked up with precision.

✅ Low maintenance: Minimal sample prep and advanced optics reduce downtime.

Meet the ESE-FTIR-100: Precision Redefined

When it comes to reliable, plant-ready FTIR analyzers, the ESE-FTIR-100 from ESEGAS leads the way. It’s engineered for harsh industrial environments, offering:

Modular design with a stable optical interferometer

Integrated high-temperature gas tracing

Minimal drift thanks to White cell technology

Continuous emission data ready for CEMS reporting

Optional integration with DCS/SCADA systems

This isn’t just a device—it’s a full-spectrum environmental control solution.

Beyond Monitoring: Smarter, Cleaner, Safer Plants

FTIR analyzers do more than meet emissions standards—they give operators insight. You’ll know exactly what’s happening in combustion chambers, flue gas lines, and emission stacks. It becomes easier to optimize fuel use, lower reagent consumption, and reduce your carbon footprint.

Pair this tech with trained operators and smart data integration, and you get a plant that not only meets regulations—but leads the way in sustainability.

Final Word: Future-Proof Your Facility

With regulations tightening and public scrutiny growing, emission monitoring isn’t optional. It's your reputation, your permit, and your planet on the line.

The ESE-FTIR-100 makes it easy to stay compliant, cut emissions, and gain full control over your plant’s environmental impact. Ready to upgrade your monitoring system? The future is FTIR.

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes

Text

How Infrared Gas Analyzers Are Revolutionizing Sintering in Steel Manufacturing

From Efficiency to Emissions—Why Real-Time Gas Monitoring is the Backbone of Smarter Steelmaking

Why Should Steel Plants Care About Gas Monitoring?

In steel manufacturing, especially in the sintering process, invisible gases could be draining profits, harming the environment, and risking compliance. Infrared gas analyzers offer a cutting-edge solution—turning uncertainty into precision, and inefficiency into optimized control.

Whether you're aiming for fuel savings, environmental compliance, or better sinter quality, these tools are the key to intelligent process control.

What Exactly Do Infrared Gas Analyzers Monitor?

Infrared (IR) gas analyzers use Non-Dispersive Infrared (NDIR) technology to measure gases by detecting their unique light absorption properties. In sintering, they continuously track:

CO (Carbon Monoxide): Detects incomplete combustion

CO₂ (Carbon Dioxide): Indicates complete combustion

NOx (Nitrogen Oxides): Helps control regulated emissions

SO₂ (Sulfur Dioxide): Monitors sulfur emissions from raw materials

Hydrocarbons & Water Vapor: Indicate unburned fuel or process inefficiencies

Each gas tells a story about combustion health, energy use, and emission levels—critical for plant performance and compliance.

How Infrared Analyzers Improve Energy Efficiency

Fuel inefficiencies often hide in plain sight. With infrared gas analyzers, steel plants get real-time visibility into combustion conditions. This allows for dynamic control of burner settings, airflow, and fuel feed—resulting in:

✅ Lower specific fuel consumption ✅ Balanced temperature zones ✅ Optimized fuel-to-air ratio

These improvements not only save energy but also enhance sinter bed stability and reduce scrap material.

Real-Time Monitoring = Real Savings

Gone are the days of delayed lab reports. With ESEGAS infrared analyzers, you receive instant alerts for spikes in CO, SO₂, or NOx—giving operators the ability to act before something breaks or becomes non-compliant. This proactive approach:

Prevents costly shutdowns

2. Enables predictive maintenance

3. Keeps production running smoothly

Stay Ahead of Regulations, Not Behind Them

Regulatory frameworks like the EU IED or US EPA’s CFR Part 60 demand round-the-clock emissions monitoring. ESEGAS infrared gas analyzers meet global compliance standards and deliver:

Automated data reporting

Timestamped audit logs

Instant exceedance alerts

Whether it’s your next audit or ESG report, you'll be ready with accurate, traceable data.

The ROI That Goes Beyond Compliance

Infrared gas analyzers are more than environmental tools—they’re operational game-changers. With multi-gas capability and integration into SCADA/DCS systems, they support: ✅ Emissions reduction ✅ Quality control ✅ Energy optimization

One device, multiple wins—making it one of the smartest investments in steel plant modernization.

Conclusion: Smarter Steel Starts with Smarter Sintering

In a world where steel plants must produce more with less—less energy, fewer emissions, and lower cost—infrared gas analyzers are no longer optional. They’re essential. ESEGAS brings steelmakers the tools to run cleaner, safer, and more profitably.

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes

Text

Invisible But Vital: Why Gas Analyzers Are the Smartest Upgrade to Your HVAC System

Is Your HVAC System Truly Efficient and Safe? Gas Analyzers Know the Truth

When your HVAC system is working, it’s easy to assume all is well—until comfort fades, energy bills spike, or worse, safety risks emerge. Gas analyzers reveal what your eyes can't see—carbon monoxide, carbon dioxide, oxygen levels, and more—all of which affect performance, air quality, and regulatory compliance.

ESEGAS's advanced gas analyzers are engineered to make HVAC systems smarter, safer, and more efficient. If you’ve been ignoring the “invisible” part of your HVAC system, now is the time to change that.

What Gases Are You Breathing? It’s Time to Know

Indoor air may look clean—but CO, CO₂, and O₂ levels tell a different story. Gas analyzers track these gases with precision:

CO (Carbon Monoxide) – Highly toxic; undetectable without sensors

CO₂ (Carbon Dioxide) – Indicates air quality and ventilation efficiency

O₂ (Oxygen) – Reveals combustion performance and energy balance

NOₓ & SO₂ – Important in commercial/industrial setups for emission control

ESEGAS analyzers offer multi-gas, real-time monitoring with pinpoint accuracy, helping you maintain healthy indoor air while optimizing HVAC combustion and performance.

Cut Energy Waste With Real-Time Combustion Feedback

What you don’t monitor, you can’t optimize. Fuel-heavy HVAC systems rely on balanced air-to-fuel ratios for efficient operation. Gas analyzers provide real-time readings of CO, CO₂, and O₂—letting you fine-tune combustion on the fly. The result? Less fuel waste, lower emissions, and consistent comfort.

ESEGAS analyzers support automation-ready output—perfect for smart control systems or Building Management Systems (BMS) that want to maintain performance without manual intervention.

Gas Analyzers Save Lives—And Your Reputation

Gas leaks, especially CO, are silent killers. ESEGAS analyzers act like 24/7 safety guards, continuously monitoring your HVAC setup for unsafe gas levels. Whether it’s carbon monoxide, propane, or methane—your system will alert, shut down, or ventilate before anyone is in danger.

Built-in diagnostics, auto-calibration, and fail-safe operation mean you’re covered without guesswork. This makes ESEGAS solutions ideal for homes, hospitals, schools, and industrial HVAC applications.

Smart HVAC Systems Start With Smarter Sensors

Gas analyzers are the sensory nerves of a modern HVAC brain. Whether you're managing a home or a commercial building, ESEGAS analyzers feed real-time data into your BMS or IoT ecosystem. That means ventilation can adapt dynamically, energy use can self-regulate, and air quality can respond to occupancy levels instantly.

From Modbus to cloud integration, ESEGAS is ready to future-proof your building—today.

Conclusion: Gas analyzers might be hidden, but their impact is anything but.

With advanced sensing technology from ESEGAS, you gain full control over what matters most: air quality, energy efficiency, and safety. Whether you’re upgrading a home system or managing a large HVAC network, trust the sensors that power intelligent, reliable climate control.

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes

Text

Why Every Brewery Needs a CO₂ Gas Analyzer — And How It Can Transform Your Brew

Breathe Easy, Brew Better: The Hidden Power of CO₂ Monitoring in Breweries Carbon dioxide plays a central role in brewing—but when left unchecked, it can ruin flavor, compromise safety, and cause costly compliance violations. That’s where a CO₂ gas analyzer in breweries becomes an essential tool—not just for measuring gas, but for maintaining your product quality and worker protection.

What Does a CO₂ Gas Analyzer Do in Breweries?

CO₂ is both a friend and a foe in the brewery. Produced during fermentation, it gives beer its fizz. But excess or inconsistent CO₂ can lead to over-carbonation, under-carbonation, or dangerous working conditions.

A CO₂ gas analyzer in breweries tracks CO₂ levels in real time using Non-Dispersive Infrared (NDIR) technology. These high-precision instruments (like the ESE-IR-100 from ESEGAS) detect CO₂ using light absorption—providing consistent readings without interfering with the brewing process.

Why CO₂ Monitoring Matters More Than You Think

Accurate CO₂ levels mean more than better beer—they mean a safer workplace. Because CO₂ is heavier than air, it settles in cellars and tanks, displacing oxygen and increasing suffocation risks. A CO₂ gas analyzer in breweries ensures OSHA-compliant conditions, alerts staff before buildup becomes hazardous, and keeps your operations secure.

Key Applications in the Brewing Process

✅ Fermentation – Monitor CO₂ generation to control pressure and track yeast activity. ✅ Conditioning & Storage – Prevent over-pressurization and ensure consistent carbonation. ✅ Packaging Lines – Optimize dosing, avoid flat or over-carbonated beers, and improve shelf life. ✅ Cellars & Confined Spaces – Safeguard workers from oxygen-deficient environments. ✅ CO₂ Recovery Systems – Maintain clean gas capture and avoid costly equipment damage.

With tools like ESEGAS CO₂ analyzers, breweries gain the ability to manage gas flow intelligently across each phase.

Improve Efficiency, Lower Costs, and Stay Compliant

With a CO₂ gas analyzer, breweries gain more than measurements—they unlock efficiency. ESEGAS analyzers help detect leaks, optimize gas usage, and reduce waste. This leads to better margins, fewer rejected batches, and easier maintenance of your CO₂ recovery systems.

At the same time, these systems support your compliance with workplace safety standards and environmental regulations. From analog 4–20 mA output to RS485 digital communication, ESEGAS analyzers integrate seamlessly into your plant’s automation infrastructure.

The ESEGAS Advantage

The ESE-IR-100 CO₂ analyzer is engineered for real-world brewery conditions—compact, stainless steel, moisture-resistant, and calibration-stable. It’s built for harsh environments and long-term accuracy. Whether mounted permanently on a fermenter or used as a handheld spot-checker, it delivers the data you need to brew with confidence.

Conclusion:

Don't Gamble with CO₂—Control It Your beer depends on balance—and so does your brewery. From taste to tank pressure, CO₂ must be monitored constantly. A CO₂ gas analyzer in breweries ensures product consistency, protects your people, and helps you meet every regulatory demand.

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes

Text

Smarter Heat-Treating Starts Here: How Process Gas Analyzers Transform Metallurgical Furnaces

Discover how ESEGAS's advanced analyzers ensure quality, efficiency, and safety in every heat-treatment cycle.

In metallurgical heat treatment, atmosphere control isn’t optional—it’s essential. One misstep in gas composition, and your entire batch risks surface defects, incorrect hardness, or even safety violations. Enter the process gas analyzer, a smart tool that turns raw gas data into real-time insights—helping you maintain precise conditions, automate control, and avoid costly mistakes.

Why Do Furnace Atmospheres Matter?

In the world of heat treatment, the furnace atmosphere is more than just hot air—it’s the invisible force that determines the final quality of your metal parts. Whether you’re carburizing steel, annealing stainless, or nitriding components, maintaining the right gas composition is essential for success.

For example:

Too little CO₂? Under-carburization.

Too much O₂? Surface oxidation.

Moisture or H₂ imbalance? Incomplete reduction or scale formation.

That’s why continuous gas analysis is a game-changer for heat-treatment plants.

Real-Time Precision with ESEGAS Process Gas Analyzer

ESEGAS’s Heat Treating Analyzer tracks up to five key gases—CO, CO₂, CH₄, O₂, and H₂—using a mix of NDIR, electrochemical, and thermal conductivity sensors. This sensor fusion creates a full atmospheric snapshot, giving operators the ability to fine-tune parameters on the fly.

Imagine your system auto-adjusting gas flows based on current carbon potential. That’s not just monitoring—that’s smart control.

Four Big Benefits for Metallurgical Plants

Better Product Quality Stay within the optimal furnace atmosphere window—no guesswork. The analyzer alerts operators when key gases deviate from spec, ensuring proper hardness and surface chemistry every time.

Higher Efficiency By linking gas data to the control system, furnaces optimize fuel-to-air ratios and gas usage. CO/CO₂ ratios even help auto-calculate carbon potential for carburizing processes. More precision = less waste.

Emission Control & Safety Methane spikes? O₂ creeping in? The analyzer detects it before it becomes a safety hazard. Plus, by keeping CO and CH₄ in check, emissions stay compliant with industry and environmental standards.

Predictive Maintenance Track long-term gas trends. If O₂ suddenly rises, maybe a seal is failing. If CO readings drift, burner wear could be the issue. Fix problems before they break things.

Seamless Integration, Smarter Plants

ESEGAS analyzers aren’t just plug-and-play—they’re plug-and-optimize. With Modbus, 4–20 mA, and local displays, they integrate into any modern control system. Automated sampling, built-in diagnostics, and remote access features mean less downtime and more uptime.

Ready for Industry 4.0?

These systems don’t just give numbers—they deliver insight. Whether you're reducing your carbon footprint or training new technicians, process gas analyzers offer unmatched value across operations, safety, quality, and sustainability.

Conclusion: If your heat-treating process still relies on manual gas checks or single-point instruments, it’s time for an upgrade. With ESEGAS’s Heat Treating Process Gas Analyzer, you get a reliable, real-time partner that turns furnaces into precision tools. More control. Less waste. Smarter metallurgy.

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes