#NDT Level 2 Certification Courses

Explore tagged Tumblr posts

Text

The Value of Advanced NDT Techniques in Tube Inspection

Ensuring the optimal performance and safety of industrial equipment is a top priority across various sectors. One critical aspect of maintaining such performance is through Tube Inspection Services from RVS QUALITY CERTIFICATIONS PVT LTD. These services are indispensable for industries that rely on the efficient functioning of tubes, such as in heat exchangers, boilers, and condensers. Here, we explore the importance of Inspection Services and how they contribute to the overall health of industrial systems.

Preventive Maintenance e Precision

Inspection Services are fundamental to preventive maintenance strategies. By regularly inspecting tubes, potential issues can be identified before they lead to significant failures or costly downtime. This proactive approach not only enhances the longevity of the equipment but also ensures that it operates at peak efficiency. Regular inspections help detect early signs of wear and tear, corrosion, and other forms of degradation, allowing for timely interventions that can prevent more severe damage.

Advanced Inspection Techniques

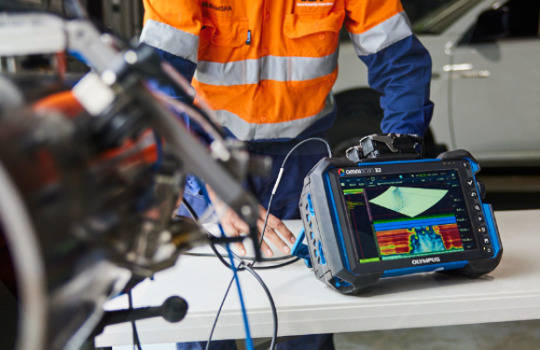

The effectiveness of Inspection Services is greatly enhanced by advanced non-destructive testing (NDT) methods. Techniques such as eddy current testing, ultrasonic testing, and remote visual inspection are commonly employed to assess the condition of tubes without causing any damage. Inspectors with NDT Level 2 Certification Courses from RVS QUALITY CERTIFICATIONS PVT LTD are trained to use these advanced methods to accurately identify defects, including cracks, pitting, and wall thinning. This high level of precision ensures that even the smallest issues are detected, enabling precise maintenance planning and execution.

Optimizing System Efficiency

The performance of systems that rely on tubes, such as heat exchangers and boilers, directly impacts the overall efficiency of industrial operations. Any compromise in the integrity of these tubes can lead to reduced heat transfer efficiency, increased energy consumption, and higher operational costs. By employing comprehensive Inspection Services, organizations can maintain optimal system performance. These inspections help ensure that the tubes are free from blockages, corrosion, and other issues that could impede their functionality, thereby sustaining efficient and cost-effective operations.

Safety and Compliance

Ensuring the safety of industrial operations is paramount, and Inspection Services play a crucial role in this regard. Faulty tubes can lead to catastrophic failures, posing serious risks to personnel and equipment. Regular inspections help mitigate these risks by identifying and addressing potential issues before they escalate. Furthermore, industries are often required to comply with stringent safety and regulatory standards. Third-party Third-Party Inspection Services from RVS QUALITY CERTIFICATIONS PVT LTD provide an additional layer of assurance, validating that the equipment meets all necessary compliance requirements. This external validation not only enhances safety but also boosts the organization's credibility and reliability.

Cost-Effective Maintenance

While some may view Inspection Services as an added expense, they are, in fact, a cost-effective maintenance strategy. Early detection of issues through regular inspections can prevent costly repairs, extensive downtime, and loss of productivity. The ability to plan maintenance activities based on accurate inspection data allows organizations to allocate resources more efficiently and avoid unexpected breakdowns. In the long run, the investment in Inspection Services pays off by reducing the total cost of ownership and maximizing the return on investment for industrial equipment.

Training and Expertise

The effectiveness of Inspection Services is highly dependent on the expertise of the inspectors. Professionals trained through NDT Certification Courses possess the necessary skills and knowledge to perform thorough and accurate inspections. Their expertise ensures that all potential issues are identified and appropriately addressed. Continuous training and certification updates are essential to keep inspectors abreast of the latest advancements in inspection technologies and methodologies, thereby maintaining high standards of service quality.

In conclusion, Inspection Services are essential for ensuring the optimal performance, safety, and efficiency of industrial systems. By incorporating advanced non-destructive testing techniques and leveraging the expertise of certified professionals, organizations can proactively manage the health of their equipment. Regular inspections help prevent costly failures, ensure compliance with safety standards, and enhance overall operational efficiency. For industries striving to maintain high-performance standards and minimize risks, investing in Inspection Services is a prudent and necessary decision.

0 notes

Text

Top Mechanical QA/QC Courses in Trivandrum to Boost Your Career and Enhance Your Professional Growth

In today's competitive job market, professionals in the mechanical engineering field must stay ahead by continually upgrading their skills. One way to achieve this is by pursuing specialized training in Quality Assurance (QA) and Quality Control (QC). These disciplines ensure that engineering projects meet the required standards and regulations, making them critical in sectors like manufacturing, construction, and oil & gas. This blog will explore some of the top mechanical QA/QC courses in Trivandrum that can significantly boost your career prospects. We will also discuss how these courses can equip you with the essential skills needed for success in the field.

1. Understanding the Importance of Mechanical QA/QC Courses in Trivandrum

Quality Assurance (QA) and Quality Control (QC) are vital components of any mechanical engineering project. QA involves the systematic process of determining whether a product or service meets specified requirements, while QC is focused on identifying defects in the finished products. The mechanical QA QC courses in Trivandrum provide an in-depth understanding of these processes, ensuring that professionals can implement effective QA/QC strategies in their work.

These courses are designed to equip engineers with the knowledge and skills needed to ensure that projects adhere to the highest quality standards. By enrolling in a QA QC course in Trivandrum, you will learn how to apply various QA/QC techniques, manage quality-related issues, and enhance the overall quality of engineering projects.

2. Key Topics Covered in Mechanical QA/QC Courses in Trivandrum

The mechanical QA QC courses in Trivandrum typically cover a wide range of topics essential for any aspiring QA/QC engineer. These topics include:

- Quality Management Systems (QMS): Understanding the fundamentals of QMS, including ISO standards, is crucial for implementing effective quality control measures.

- Inspection and Testing Techniques: Learn various methods used to inspect and test materials, components, and systems to ensure they meet the required specifications.

- Non-Destructive Testing (NDT): Gain expertise in NDT methods like ultrasonic testing, radiographic testing, and magnetic particle testing, which are vital for detecting defects without damaging the material.

- Documentation and Reporting: Develop skills in creating detailed reports and maintaining accurate records, which are essential for ensuring compliance with quality standards.

- Project Quality Planning: Learn how to develop and implement a quality plan for engineering projects, ensuring that all quality objectives are met.

These topics are covered in-depth in a QA QC course in Trivandrum, providing you with a comprehensive understanding of quality assurance and control in the mechanical engineering field.

3. Benefits of Enrolling in Mechanical QA/QC Courses in Trivandrum

Enrolling in mechanical QA QC courses in Trivandrum offers numerous benefits that can enhance your career prospects. Some of the key advantages include:

- Increased Employability: With industries placing a strong emphasis on quality, professionals with QA/QC skills are in high demand. Completing a QA QC course in Trivandrum can make you a more attractive candidate to potential employers.

- Career Advancement: QA/QC certification can open doors to higher-level positions, such as Quality Manager, Quality Engineer, or Project Manager, allowing you to advance in your career.

- Improved Technical Skills: The courses provide hands-on training in various inspection and testing techniques, enhancing your technical skills and making you more proficient in your job.

- Enhanced Problem-Solving Abilities: QA/QC professionals are often required to identify and solve quality-related issues. These courses teach you how to analyze problems effectively and implement solutions.

- Networking Opportunities: Enrolling in a QA QC course in Trivandrum allows you to connect with industry professionals, which can lead to valuable networking opportunities and career growth.

4. How to Choose the Right Mechanical QA/QC Course in Trivandrum

When selecting a mechanical QA QC course in Trivandrum, it's essential to consider several factors to ensure you choose the right program. Here are some tips to help you make an informed decision:

- Accreditation: Ensure that the course is accredited by a recognized body, as this will add value to your certification.

- Course Content: Review the curriculum to ensure it covers all the essential topics relevant to your career goals.

- Instructor Expertise: Choose a course taught by experienced professionals with a strong background in QA/QC.

- Practical Training: Opt for a course that offers hands-on training and real-world applications to enhance your learning experience.

- Flexibility: Consider the course's schedule and format, especially if you are a working professional, to ensure it fits your lifestyle.

By considering these factors, you can select a QA QC course in Trivandrum that aligns with your career objectives and provides the skills you need to succeed.

5. Future Career Prospects After Completing a Mechanical QA/QC Course in Trivandrum

Completing a mechanical QA QC course in Trivandrum can significantly enhance your career prospects in various industries. Some potential career paths include:

- Quality Assurance Engineer: Responsible for ensuring that products meet quality standards and regulations.

- Quality Control Inspector: Focused on inspecting and testing products to identify defects and ensure compliance.

- Project Quality Manager: Overseeing the quality management process for engineering projects, ensuring that all quality objectives are met.

- Non-Destructive Testing Technician: Specializing in NDT techniques to detect material defects without causing damage.

- Supplier Quality Engineer: Ensuring that suppliers meet the required quality standards for materials and components.

These roles offer excellent growth opportunities, competitive salaries, and the chance to work on exciting projects in the mechanical engineering field.

Conclusion

In conclusion, enrolling in mechanical QA QC courses in Trivandrum is a strategic move for any mechanical engineer looking to advance their career. These courses provide the essential knowledge and skills needed to excel in quality assurance and control, making you a valuable asset to any organization. By choosing the right QA QC course in Trivandrum and staying committed to continuous learning, you can unlock numerous career opportunities and achieve long-term success in your profession.

0 notes

Text

On Successful Completion of Scaffold training Learner will be awarded an online verified Certificate, The scaffolding Inspection training program will help participants learn and improve upon the basic skills, techniques and record keeping of scaffolding inspections.

Module 1: Introduction to Scaffolding

Understanding the importance of scaffold safety

Types of scaffolding and their applications

Scaffold components and terminology

Legal and regulatory requirements for scaffold inspection

Module 2: Scaffold Design and Planning

Reading scaffold drawings and specifications

Calculating load capacities and weight distribution

Identifying suitable scaffold types for specific projects

Evaluating ground conditions and environmental factors

Module 3: Scaffold Assembly and Dismantling

Step-by-step scaffold erection procedures

Proper use of scaffold fittings and connections

Safe dismantling practices and potential risks

Hands-on demonstrations of scaffold assembly and disassembly

Module 4: Scaffold Inspection Guidelines

Understanding the roles and responsibilities of a scaffold inspector

Pre-inspection preparation and safety checks

Inspection frequency and documentation requirements

Identifying common scaffold defects and hazards

Module 5: Inspection Techniques and Tools

Conducting visual inspections effectively

Use of specialized inspection equipment (e.g., plumb bobs, spirit levels)

Non-destructive testing (NDT) methods for advanced inspections

Reporting and recording inspection findings accurately

Module 6: Scaffold Safety Regulations and Standards

Familiarization with national and international scaffold safety standards

OSHA (Occupational Safety and Health Administration) regulations

ANSI (American National Standards Institute) guidelines

Local codes and best practices

Module 7: Case Studies and Practical Exercises

Analyzing real-life scaffold incidents and accidents

Problem-solving exercises to identify potential hazards

Conducting mock scaffold inspections in a controlled environment

Collaborative group activities for hands-on learning

Certification and Assessment:

To receive the Certified Scaffold Inspector designation, participants must successfully complete the following requirements:

Attendance: Attend all course modules and practical sessions.

Assessments: Pass quizzes and evaluations at the end of each module.

Practical Evaluation: Demonstrate competence in conducting scaffold inspections.

Final Examination: Successfully complete a comprehensive written examination.

Who Should Attend:

Construction site supervisors and managers

Safety officers and inspectors

Engineers and architects involved in scaffold design and implementation

Occupational health and safety professionals

Anyone interested in improving scaffold safety knowledge and skills

Course Benefits:

Acquire essential knowledge and skills to inspect scaffolding structures effectively.

Enhance workplace safety and reduce the risk of scaffold-related accidents.

Meet legal and regulatory requirements for scaffold safety compliance.

Gain a competitive edge in the job market with a recognized certification.

Contribute to a safer work environment and protect the well-being of workers.

Course Duration:

The Certified Scaffold Inspector Course is typically conducted over 3 days. This includes a combination of classroom lectures, practical exercises, and assessments to ensure a comprehensive learning experience.

Instructors:

Our instructors are experienced professionals with extensive expertise in scaffolding, safety regulations, and inspection practices. They are committed to providing high-quality training and supporting participants throughout the learning journey.

Enrollment:

To enroll in the Certified Scaffold Inspector Course, please fill out the registration form on our website or contact our training coordinator at Call +91 9494441108. Limited seats are available for each session, so early registration is recommended.

Note: Course content and schedule are subject to change to enhance the learning experience and meet industry standards.

Join us in becoming a Certified Scaffold Inspector and play a crucial role in ensuring the safety of scaffolding systems on construction sites

0 notes

Text

NDT Level 2 Course in Hyderabad

NDT Level 2 refers to a certification level in Non-Destructive Testing (NDT). NDT is a method of inspecting materials and components for defects or deviations from their intended properties without causing damage to the item being tested. The certification level of NDT Level 2 indicates that the individual holding the certification has the knowledge, skills and abilities to perform NDT inspections and evaluations under the direct supervision of a Level 3 NDT professional. It also indicates that the individual has demonstrated their proficiency in the specific NDT method they are certified in, through a combination of classroom training, practical experience, and successful completion of a written and practical examination.

For more details, visit: -

0 notes

Text

NDT Level 2 Radiographic Testing Film Interpretation Course

https://www.stceducation.org/courses-dubai/ndt-level-2-course-radiographic-testing/

Description

NDT Level 2 Radiographic Testing Film Interpretation Course

Course Code:NDT Level 2 RT Year:2021

Dates: |17-21 Jan | 21-25 Mar | 18-22 April | |23-27 May| 20-24 June|25-29 July |22-26 Aug|19- 23 Sept|24-28 Oct|21-25 Nov|12-16 Dec |Duration: 5 Days| Dubai.

Course Objective:

NDT Course Level 2 Radiographic Testing Certification for welding examination and interpretation on Radiographic film welding test sample. Training focus on NDT Radiographic Testing, Calibration and Interpretation of Test result. Radiographic Testing for welding test method based on ASME Sec V Codes and Standard and acceptance criteria to perform welding evaluation. Evaluating and interpretation of welding discontinuity in Radiographic film for the welding defects using non-destructive testing RT Method.

Who should attend?

NDT Level 1 Technicians/Engineers, Oil and Gas Engineers, Mechanical Engineers, Electrical Engineers, QC assistant, QC Engineers, Quality Control professional and who is interested in QC welding inspector

Learning Outcome:

· Radiographic Testing NDT method

· ASME Sec V Codes and Standard for NDE Inspection for RT

· Learn NDT RT Setup procedure

· Radiographic Testing Calibration

· Understand NDT RT Welding examination

· Evaluate welding defects and reporting

· Interpretation of Radiographic Film welding samples.

· Role of NDT Radiographic Testing Inspector

· NDE Radiographic Testing ASME Codes and Standards

· Acceptance Criteria for RT

· RT Equipment and Materials

· Calibration for Radiographic Testing

· Visual Examination

· Post Weld Welding Inspection

· Evaluating Welding discontinuities

· Interpretation of Radiographic Testing film samples

Calibration, Examination and Interpretations

· Calibration of Radiographic Equipment

· Radiographic Film Interpretation

· Sample Test Report Format

· Examination videos

Training covers NDT Level 2 RT examination required by SNT-TC-1A General Examination

Specific Examination Practical Examination

Keywords:

NDT Level 2 Radiographic Testing, NDT Course Level 2, Radiographic Testing Film Interpretation, NDT Radiographic Testing, non-destructive testing RT Method

1 note

·

View note

Text

We offer Mag particle testing training to help you reach the zenith of your career. Mag particle testing is one of the most used NDT techniques in the industry. Go through basic and advanced modules and training to obtain your level 1 and 2 certificates in NDT mag particle testing. Our course is suitable for technicians, welders, NDT specialists, inspectors, and other industry professionals. Visit our site to learn more about our courses and services.

0 notes

Text

Seeing the Unseen: How Infrared Thermography Services Can Save You Time and Money

In the modern world, maintaining efficiency and reducing costs are paramount for businesses across various industries. One powerful tool that has emerged to help achieve these goals is infrared thermography. Infrared Thermography Services are revolutionizing how companies manage maintenance, detect issues, and ensure safety. At RVS Quality Certifications Pvt Ltd., we understand the value of advanced diagnostic tools and offer comprehensive training and consultancy services to help you harness these technologies.

Understanding Infrared Thermography

Infrared thermography is a non-invasive, non-contact method of detecting heat patterns and temperatures on surfaces. By using infrared cameras, technicians can visualize and measure thermal energy emitted by objects. This technology allows for the identification of anomalies that might indicate underlying problems, such as electrical faults, mechanical failures, or insulation deficiencies.

Employing Infrared Thermography provides significant advantages over traditional inspection methods. It enables the detection of issues before they become critical, allowing for preventive maintenance and reducing the likelihood of unexpected downtime. This proactive approach can save businesses substantial amounts of time and money by avoiding costly repairs and ensuring optimal operational efficiency.

Applications Across Industries

Infrared thermography is versatile and applicable in various industries, including manufacturing, construction, energy, and automotive. In manufacturing, it helps in monitoring equipment conditions, detecting overheating components, and ensuring the integrity of electrical systems. In construction, it is used for inspecting building envelopes, identifying moisture intrusion, and verifying insulation performance.

For energy companies, infrared thermography is essential in monitoring power lines, transformers, and substations. It aids in detecting hot spots that could indicate potential failures, thereby preventing power outages. In the automotive industry, it is used for quality control and ensuring the safety of electrical systems in vehicles.

Training and Certification

To effectively utilize infrared thermography, proper training and certification are crucial. At RVS Quality Certifications Pvt Ltd., we offer NDT Level 2 Certification Courses that equip professionals with the necessary skills and knowledge to perform accurate and reliable thermographic inspections. Our courses cover the principles of thermography, equipment handling, data analysis, and report generation.

Achieving NDT Level 2 certification signifies a high level of competence in non-destructive testing methods, including infrared thermography. This certification not only enhances the skill set of professionals but also increases their value in the job market. Companies benefit from having certified personnel who can conduct thorough inspections and contribute to improved maintenance strategies.

Enhancing Safety and Reliability

One of the primary benefits of infrared thermography is its contribution to safety. By identifying potential issues early, businesses can mitigate risks and prevent accidents. For example, detecting overheating electrical components can prevent fires, while identifying structural weaknesses can avoid catastrophic failures in buildings and machinery.

RVS Quality Certifications Pvt Ltd. emphasizes the importance of Non Destructive Testing Services in maintaining safety and reliability. Our comprehensive training ensures that professionals are equipped to perform accurate assessments, thereby contributing to safer work environments and more reliable operations.

Cost Savings and Efficiency

Implementing infrared thermography can lead to significant cost savings. By identifying problems before they escalate, businesses can plan maintenance activities more effectively, reduce unplanned downtime, and extend the lifespan of equipment. This proactive approach minimizes the need for emergency repairs, which are often more expensive and disruptive.

For industries that rely heavily on the integrity of their equipment, such as energy and manufacturing, the cost savings from avoiding major failures are substantial. Additionally, by optimizing maintenance schedules and reducing downtime, companies can enhance their overall productivity and operational efficiency.

Specialized Services for Specific Needs

In addition to general applications, infrared thermography is also valuable for specialized inspections. For instance, Tube Inspection Services utilize infrared technology to assess the condition of tubes in boilers, heat exchangers, and other critical equipment. This type of inspection can detect issues such as blockages, corrosion, and leaks, which can significantly impact the performance and safety of the equipment.

#Infrared Thermography Services#NDT Level 2 Certification Courses#Non Destructive Testing Services#Tube Inspection Services

0 notes

Text

Get trained under 10 experience trainer ndt online course at just RS 15000/- in Nigeria

0 notes

Text

Best Practises Of QA/QC Course in India

We believe in doing what you preach in the Training of QA/QC Course in India, therefore each candidate is encouraged to conduct each topic that is presented for a better knowledge of the real-world scenarios QA / QC. Quality assurance is the process of assessing if a product meets required standards and meets consumer expectations (QA). Quality assurance (QA) is a goal-setting and process-driven strategy for product design, development, and production. Quality control (QC) is a method used by businesses to ensure that product quality is maintained or improved while minimising or eliminating errors.

QA/QC Course in India practise of comprehensive training helps students to successfully learn all ideas and abilities and subsequently apply them to their field of work by receiving entire information and training on QA/QC Course in India. We are one of the finest QA/QC Course in India training schools, with excellent placement support. We provide well-structured modules and QA/QC Course in India training programmes for both students and working professionals. Training for the QA/QC Course in India is provided over five days, with additional courses held on weekends. It is also possible to organise and schedule. We also provide fast track training programmes for students and professionals who want to improve their skills quickly.

The fundamental aim of QA is to track and resolve flaws before product release. Measurability is the key to a successful QA/QC course in India. QA may necessitate several revisions and result in production delays. Quality control necessitates that the company foster an atmosphere in which both management and employees strive for perfection. This is accomplished by educating employees in the QA/QC Course in India, developing product quality benchmarks, and evaluating goods for statistically significant differences. The QA strategy of a company typically focuses on management, knowledge, skills, personal integrity, confidence, quality connections, and infrastructure.

The goal of Quality Control is to guarantee that the product and its manufacture are not only consistent but also meet the needs of the client. When new QA/QC Course in India procedures are implemented, consultants may be employed if appropriate experience and skills are not existing inside a company. Contracted experts use a mix of procedural documentation and quality function deployment, capability maturity model integration, and Six Sigma, among other things.

A QA/QC engineer's involvement in the training of a QA/QC Course in India is critical and unavoidable for any reputable engineering firm. Those who enrol in the QA/QC Course in India receive in-depth information in piping, welding, and NDT procedures, as well as level 2 NDT certification signed by a level 3 professional following successful completion of training following ASNT (American Society for Nondestructive Testing) standards. Students are also given hands-on exposure to various NDT methods with full-fledged lab facilities outfitted with contemporary equipment and guided by our well-trained and certified QA/QC Course in India experts. Any student who completes the three-month short-term curriculum in QA/QC Course in India will be granted a certificate of merit.

Eliciting testing expectations aids both the quality assurance team and the client in determining the likelihood of meeting the customer's goals with testing help on the QA/QC Course in India. As a consequence, the client should not have unrealistic expectations and should be happy with the end outcomes of the testing process. Understanding the client's objectives and goals enables engineers to produce the outcomes that the customer expects and is satisfied with. This also aids the QA/QC Course in India testing team in developing a good and feasible testing strategy.

To assure the overall quality and efficiency of the QA/QC Course in India environmental review process, a Quality Assurance/Quality Control Plan (QA/QC Plan) is used. This Quality Assurance and Quality Control Plan outlines Quality Assurance and Quality Control procedures and processes, QA/QC review documentation, document review procedures, quality document creation guidelines, and the people responsible for executing tasks and confirming compliance. The QA/QC Course in India also includes templates and resources for properly implementing this QA/QC Plan.

Individual projects and project files are evaluated regularly as part of the QA/QC Course in India to ensure that project-specific quality control procedures such as document verification and technical reviews are fulfilled. QA offers input to those creating papers and technical studies through these methods of the QA/QC Coursein India to ensure continual development.

A useful method for documenting data checking and review (also known as Quality Assurance, Quality Control, or QA/QC in QA/QC Course in India) is to list the actions taken to evaluate the data, how decisions about problem resolution were made, and what actions were taken to resolve the problems at each stage of the data life cycle.

0 notes

Text

We offer Mag particle testing training to help you reach the zenith of your career. Mag particle testing is one of the most used NDT techniques in the industry. Go through basic and advanced modules and training to obtain your level 1 and 2 certificates in NDT mag particle testing. Our course is suitable for technicians, welders, NDT specialists, inspectors, and other industry professionals. Visit our site to learn more about our courses and services.

0 notes

Text

MSMK Training - Welding Consultancy

Tender for new sectors with confidence as you draw from MSMK Training's industry expertise

Numbers of different Welding Standards and Codes like BS EN 15614-1/2, AWS D1.1, ASME 9, GL, NORSOK, EEMUA 158 , MOD 03-34, TOTAL , BP, SHELL available for fabrication and welding of different products in different industries And we can review them all, suggest the best Welding Procedure and Welding method for your requirement, prepare all welding documentation for your project.

Qualify all necessary Welding procedures, create a Weld Maps and Weld Register Database, perform all types of Destructive and Nondestructive testing to satisfy your client.

Estimate the Welding time and consumables usage. If your company does not have a Welding Management system in place, we can do it for you.

We can resolve your issues with welding, perform failure investigation, offer the best solution with welding defects or welder skills.

It is mandatory requirements to have Responsible Welding Coordinator within your business if you aiming to achieve ISO 1090 / BS EN 3834 / BS EN 15085 Accreditation and move your business to the next quality and credibility level . With our Certified European Welding Engineer we can help you to get your company accredited, improve welding quality in you company.

We understand the pressures of stringent quality criteria and the disharmony this can create between departments. As your welding consultancy partner we can deliver tailored training packages to promote effective communication regarding welding faults and their causes. Contact us about our Welding Theory Course for managers and quality professionals.

We offer on-site assessments of welder capability, environmental factors and equipment suitability. Contact us to discuss any issues you may be facing or opportunities on the horizon and we will help you prepare your business to achieve your quality management ambitions.

MSMK Training is authorized by the UK Accreditation Services (UKAS) to conduct welder test examinations and offer certification for competent individuals who meet or exceed the standards required.

More information on the MSMK Welder Certification Scheme can be found here.

UKAS Accredited Testing

Operating from our UKAS Accredited testing laboratory in Sheffield, MSMK Training operatives are fully qualified to perform Destructive and Nondestructive testing in accordance with ISO 17025:2017, to internationally recognized quality standards.

Coded Welder Qualification

MSMK Training offers independent testing of welding procedures and welding qualification in accordance with BS EN 15614-1, BS EN 15614-2, AWS D1.1 & ASME 9. Welding procedures are reviewed by our PCN level 3 qualified engineer, followed by destructive and non-destructive tests.

Coded Welder Qualification Tests can be performed to BS EN ISO 9606-1, BS EN ISO 9606-2, ISO 14732, AWS D.1.1 or ASME 9. After performing destructive and nondestructive testing, welder will be issued a Welder Certificate with plastic Welder Identity Card.

Guaranteed Feedback

We believe a vital component of welder testing is the feedback we give. For every evaluation we deliver insights and observations. Where a weld fails to meet the required standard, MSMK Training guarantees photographic evidence to support our analysis.

For more details on our products and services, please feel free to visit us at: Weld Inspection, Welder code, NDT, WPQR, Welding procedure.

0 notes

Text

Top 5 Benefits Of Non Destructive Testing

In the realm of non-destructive testing (NDT), technological advancements continue to revolutionize inspection methodologies, paving the way for superior results and enhanced efficiency. Among these innovations, Phased Array Ultrasonic Testing stands out as a game-changer, offering unparalleled benefits for various industrial applications. As a leading authority in ISO certification and quality assurance, RVS Quality Certifications Pvt Ltd., one of the prominent Non Destructive Testing Services providers, is committed to highlighting the advantages of PAUT for businesses seeking excellence in inspection processes. Let's explore the top five benefits of Such testing:

Enhanced Inspection Capabilities: Such testing represents a significant leap forward in inspection capabilities, allowing for comprehensive assessment of materials and components with precision and accuracy. Unlike conventional ultrasonic testing methods, which utilize single-element transducers, PAUT employs multiple elements that can be electronically controlled to steer and focus the ultrasonic beam. This dynamic beam control enables inspectors to tailor the inspection angle, focal depth, and beam size, facilitating thorough examination of complex geometries, curved surfaces, and composite materials.

Improved Detection of Defects: One of the primary advantages of Such testing is its superior defect detection capabilities. By manipulating the ultrasonic beam's characteristics, such as angle, focal depth, and frequency, inspectors can optimize the inspection process to detect defects of varying sizes, orientations, and depths within the material. Whether conducting tube inspections, weld examinations, or structural integrity assessments, PAUT enhances flaw detection sensitivity, thereby minimizing the risk of undetected defects and ensuring the integrity of critical components. We also offer Infrared Thermography Services and NDT Level 2 Certification Courses which are important for organizations in a variety of sectors, assisting with the maintenance of buildings and equipment by identifying abnormalities that may suggest possible problems.

Time and Cost Savings: PAUT offers significant time and cost savings compared to traditional ultrasonic testing methods. The ability to perform multiple scans simultaneously and in real-time streamlines the inspection process, reducing downtime and expediting decision-making. Moreover, the versatility of PAUT allows inspectors to inspect larger areas or multiple components in a single scan, eliminating the need for repetitive testing and minimizing labor and equipment costs. As a result, businesses can achieve greater operational efficiency and cost-effectiveness while maintaining high standards of quality and safety.

Versatile Applications and Training Opportunities: PAUT's versatility extends beyond traditional inspection applications, encompassing a wide range of industries and sectors, including aerospace, automotive, energy, and manufacturing. As the demand for PAUT expertise continues to grow, there is a corresponding need for comprehensive Phased Array and TOFD Training programs to equip professionals with the necessary skills and knowledge. RVS Quality Certifications Pvt Ltd. offers industry-leading training courses in Phased Array and TOFD, designed to empower inspectors, engineers, and technicians with proficiency in advanced ultrasonic testing techniques, ensuring compliance with industry standards and regulations.

Enhanced Data Visualization and Analysis: Such testing provides enhanced data visualization and analysis capabilities, empowering inspectors to extract valuable insights from inspection data with unprecedented clarity and detail. Advanced imaging techniques, such as sectorial scanning, C-scan imaging, and 3D visualization, allow for comprehensive mapping of defects and material properties in real-time. This wealth of information enables stakeholders to make informed decisions regarding asset integrity, maintenance strategies, and risk mitigation measures, ultimately enhancing operational reliability and performance.

In conclusion,

Such testing represents a paradigm shift in non-destructive testing methodologies, offering unparalleled benefits in terms of inspection capabilities, defect detection, efficiency, and data analysis. As a trusted provider of Tube Inspection Services, Ultrasonic Testing Services and ISO certification training and consultancy, RVS Quality Certifications Pvt Ltd. recognizes the transformative potential of PAUT in enhancing quality assurance and asset integrity across diverse industries. Embrace the future of inspection technology with Such testing and elevate your organization's commitment to excellence and reliability.

0 notes

Text

NDT Inspection Services Training & Certification | Rite Academy

Rite Academy NDT is the fastest growing NDT and Welding services company in India. Also, the best institute for NDT, Welding training, and certification courses. RITE Academy is a Nondestructive Testing Laboratory. Also, ISO 9001:2015 certified organization started by Professional Engineers with more than a decade of experience in training and Engineering Services. Established in 2018 in Hyderabad, India, we celebrate two decades of our NDT inspection services. That is to say, we are now more experienced in serving India.

In view of maintaining safety and integrity, it is vital to carry out NDT testing of aerospace components and structures. Also, aerospace testing labs should have approvals to carry NDT testing. Further, skilled and certified Level II will do NDT inspection on aircraft structures. NDT Level 2 certification.

Contact Us:

Call: +91 9169215999

Visit: https://www.riteacademy.co.in/

#NDT Inspection Services Training & Certification#Best ndt training institute in Hyderabad#Best Ndt Training Course#best ndt training in hyderabad#Best Ndt Training Institutes In Hyderabad#best ndt training#NDT TRAINING#NDT course#rite academy in hyderabad#rite academy courses#Hyderabad rite academy#Rite Academy

0 notes

Text

EVERYTHING YOU NEEDED TO KNOW ABOUT JOB-ORIENTED COURSES

The short-term courses that are specially designed for students who are suffering to find a specific career path from or to find a job quickly can be called as job-oriented courses. And probably to step up in the career too.

SEO specialist or affiliate marketer is much more specific of broad and wide profession inside the digital marketing. Another example is doctors are getting specialized in one area. Ortho pediatrics, cardiologist, pediatrician, gynecologist urology, ENT...are different specializations for doctors. We can easily say that by profession, doctor is very large and broad profession. The doctor example is only for ease of understanding, but it cannot be fully said that, these are job-oriented courses.

This can be seen in every profession, specialized to one single area of wide sector or the industry. Also, you get more thorough knowledge in one special sector.

This will always help you to easily climb up in the career.

To get one directional in career, a job-oriented courses in the desired industry can help you a lot.

It is difficult to state that, the Graduation is a specific career path. But it helps you to stand out from lot of industries in the world to one big sector. Because a graduation subjects are always a broad topic. You can split a graduation topic into many sub topics, you can select job sector

Full-stack Developer, python Developer, back-end developer … are different types of website developing programs. A Computer science-based student (or who Know web development) can take anyone from above as career.

Like that, Oil and Gas, NDT, MEP, QA QC, Automobile… are different sectors, also career paths For Mechanical engineering-based students.

Logistics and supply chain management, Digital Marketing, interior designing... are some of the common choices for students who wants a career in It. There are many institutions providing these courses for students in Kerala.

the reason behind why I should go for Job-oriented Courses?

Graduation in one or more subjects is considering as a good educational qualification in India. But, Graduation in any subject couldn’t give you the necessary practical knowledge.

At the time of seeking jobs, when we compare ourselves with others who have practical experience, but undergraduate. they still would have the upper hand in the industry. Because they are experienced.

To Compete with other experienced candidates in the industry, we can go for a job-oriented course related to the sector. The proper course will give the industrial wisdom that is capable of overcome their experience of one or two years.

In addition to that, job-oriented courses help you to satisfy the job provider’s needs. Ie; you should have multiple skills for the particular industry in-order to do the works. Ad also, to compete with others who have experience, a job-oriented course in the specific sector will help you.

Most of the job-oriented courses are always designed to meet the industrial skills and needs for the industry and the jobs that you are going to seek. Also, you will get wisdom for facing the problems during the job.

Job-oriented courses are always designed and developed by the industry experts from their wisdom to meet the requirements of the sector.

Benefits you will get after job-oriented courses

professional certification of the industry

The course Provides the Technical, industrial Skills and Knowledge

Helps to get job in the desired industry

You get a boost for the succuss in the career.

You get an upper hand in the industry

The first questions that blow in your mind after completing a diploma/degree is may be, "how to get a job”, “what is should I do next?” “Which industry would be better for me”? Make up your mind with any Job-oriented course for quick and better answers.

Eligibility criteria for job-oriented courses?

Those who have a qualification of +2 (pass/ Fail)/ ITI/ diploma/ degree can Join in all most all the courses. job-oriented courses are usually short-term of 3–6 Months.

Adi Institute of Quality Engineers Is One of the most reputed, famous and well-experienced institute in Kerala for Job-oriented Courses and short- term courses. These are some selected courses for any candidates who are looking for immediate job.

Diploma in Oil and Gas

The oil and gas industry are one of the biggest industries in India and also in the world.

Oil and gas industry is capable of impacting one country's GDP. Its rise and fall are always immediately impacted on GDP of country like India.

Oil and gas industry is creating job opportunities on daily basis. New job-opportunities are always emerging in oil and gas industry.

You can get a job and build a career in this industry through a job-oriented course.

The Adi Institute is offering Diploma in Oil and Gas Engineering course is for candidates interested finding job or to get career growth in the oil and gas industry.

MEP course

MEP stands for Mechanical Electrical Plumbing. As its name means, these are 3 aspects of any type of building.

The M-Mechanical; deals heating, ventilation and air conditioning circuits and other thigs related to it.

E-Electrical; is related to electrical wiring circuits and the equipment related to it.

And P-Plumbing; water plumbing circuits and water treatments.

MEP Course (Mechanical, Electrical, Plumbing) is making capable of you to design these 3 aspects without any problems. Adi institute’s MEP course covers all the topics; planning, documentation, cost estimation, operations and maintenance.

NDT course

Non-Destructive Testing is a course which is most preferred for students in quality checking and quality control sector and a mechanical stream background. 8 types of testing methods are covered in the course. qualified as level 2 NDT Inspector when you complete the course.

HVAC certification course

HVAC means Heating Ventilation and Air Conditioning. Normally it’s subtopic of MEP. While MEP deals with the designing and documentation section and HVAC is working practically on it. HVAC is dealing with designing, maintenance and conditioning of air duct circuits, air conditions (AC) in a building for better and ideal working temperature.

HVAC is important in any type of building. Such as hotels restaurants malls shopping complexes, flats....

The course is designed and developed by Adi institute. This course is covering all the basic fundamentals in HVAC designs, and technicality of HVAC.

Interior designing course

Interior Designing Course covers autocad2d 3d, 3dsmax, Revit architecture, photoshop, V-ray, google sketch up, … The course is specially designed by industry experts of Adi Institute of quality engineers. the experts will deliver the designing knowledge and practical wisdom in interior designing.

Logistics and Supply chain management course

Logistics is being developing since the arrival of e-commerce industry. And the growth rate is just amazing. industry experts and pundits said that, there will be 2.3 M jobs opportunities in logistics and supply chain industry by 2023

The Adi Institute is one of the best and reputed institute in Kerala, South India for Diploma in Logistics and Supply Chain Management course.

after the course, you will get an international certification in logistics and supply chain management. This course is designed by experienced faculties who are also industry experts to expose students to the challenges of managing supply networks and enable them to understand inter-frame and intra-frame technology.

QA/QC Inspector Course

Quality assurance is one of the most important section of any industry/sector. Because, Quality one of the primary and mandatory aspects for any product/ service. It is very difficult to maintain or improve the quality. A QC inspector’s help will always need in any companies.

The main duties of QC inspector are following;

maintain the quality of one product/service

Maintain a good working atmosphere for workers by inspecting the quality of tools and equipment inside the workspace

Maintain the workspaces and tools in a good condition.

Assuring the quality of product / service.

Adi institute’s QA/QC inspector course is a short-term job-oriented course for the students trying to become a QC inspector. Basic qualification needed for the course is any diploma or B.Tech

AC Technician and refrigeration (HVAC Technician) course

AC Technician course is ideal after the pre graduation studies (+2, ITI, Diploma).

The course available in Adi institute of Quality engineers. You will be qualified as AC technician or HVAC technician after the course

#course#courses#certification courses#diploma#diploma courses#mep#QA QC#oilandgas#qaqc#hvac#actechnician

0 notes

Text

Eligibility Criteria You Must Meet Before Enrolling for an NDT Course

As the demand for NDT engineers continues to rise, it’s no surprise to see more and more graduates opting for Non-destructive testing (NDT) training. With this training, the road to becoming an NDT engineer is half traveled as it prepares students beforehand and helps them gain hands-on experience and skill sets.

If you endeavor to become an NDT engineer for a fulfilling career with six figures income and career stability, here is the eligibility criterion you must meet for NDT courses:

Educational Qualifications

A candidate willing to undergo NDT training must meet one of the following eligibility criteria:

● He/she must be graduated with a degree in engineering or science from a minimum four-year college or university curriculum.

● He/she must be an undergraduate with 3 or 4 years of diploma in any field of engineering.

● He/she must have finished a minimum two full academic years of engineering with passing grades or a physical science study at any university, technical school or college. Those with 1 year of experience in NDT testing in an assignment equivalent to Level II in the applicable test method, as mentioned in the American Society for Nondestructive Testing’s (ASNT) Recommended Practice No. SNT-TC-1A can also apply.

● He/she must have completed High School/Higher Secondary School with passing grades as well as those who have completed Industrial Training with 3 years of experience in an assignment equivalent to Level II in the applicable test method, as specified in ASNT’s Recommended Practice No. SNT-TC-1A.

Near Vision Acuity

Students appearing for Non-destructive testing (NDT) training must have corrected near-distance acuity in both or at least one eye so that they are able to read a minimum of Jaeger Number 2 or similar type of size letter from a distance specified on the chart but not less than 305 mm designated on a standard Jaeger test chart. Those with the ability to recognize an Ortho-Rater minimum of 8 or matching test pattern can also undergo NDT courses.

Color Contrast Differentiation

The candidates planning to undergo Non-destructive testing (NDT) training for radiographic film interpretation or radiographic testing and penetrate testing must be capable of differentiating and distinguishing contrast among shades of gray and colors respectively.

Note: Color Contrast Differentiation and Near Vision Acuity tests certificate can be acquired from ophthalmologist/optometrist, physician, RN, employer’s NDT level III with the help of the form Vision Requirements.

In a nutshell

If you plan to embark on the journey to become an NDT engineer or technician, it’s important that you meet the eligibility criteria for NDT courses and obtain Non-Destructive Testing Certification from a reputable training center.

Author’s bio: The author is a blogger and this article is about Non-Destructive Testing training eligibility.

0 notes