#Infrared mechanical inspection

Explore tagged Tumblr posts

Text

#Certified Infrared Thermographer#Commercial infrared inspection#Electrical infrared analysis#Electrical inspection#Energy loss scan#Heat loss scan#Industrial infrared inspection#Infrared building inspection#Infrared electrical inspection#Infrared inspection near me#Infrared mechanical inspection#Infrared roof inspection#Infrared testing#Infrared thermal imaging#Predictive maintenance#Preventive maintenance#Residential infrared inspection#Roof moisture scan#Thermal imaging#Thermal imaging companies near me

1 note

·

View note

Text

Infrared Thermographic Inspection Services by Thermo Elite: Ensuring Safety & Efficiency

In today’s world, maintaining the safety and efficiency of electrical, mechanical, and structural systems is more critical than ever. One of the most effective ways to achieve this is through infrared thermographic inspection. Thermo Elite specializes in this cutting-edge technology, using high-resolution infrared imaging to identify issues that are invisible to the naked eye. This non-invasive inspection method detects temperature variations that can signal underlying problems, enabling proactive solutions.

What is Infrared Thermographic Inspection?

Infrared thermographic inspection involves capturing heat patterns using specialized infrared cameras. By detecting areas of abnormal heat or temperature differences, this technique can identify problems such as overheating electrical components, moisture intrusion, insulation deficiencies, or mechanical failures. Thermo Elite’s experienced thermographers use this technology to provide comprehensive insights into the health of your systems, making it an essential part of predictive and preventive maintenance.

Why Choose Thermo Elite for Infrared Thermographic Inspection?

Thermo Elite offers expert infrared thermographic inspections designed to ensure optimal performance and safety. Here’s why we’re the trusted choice for businesses and homeowners:

Certified Thermographers: Our team is trained and certified in advanced thermographic techniques, ensuring accurate, reliable results.

State-of-the-Art Technology: Thermo Elite utilizes high-resolution infrared cameras and industry-leading tools to capture detailed thermal images.

Detailed Analysis & Reports: After each inspection, we provide detailed reports with thermal images, findings, and recommended corrective actions to address any issues.

Custom Inspection Plans: We tailor our inspections to your specific needs, offering one-time assessments, regular maintenance checks, or custom solutions for unique systems.

Non-Disruptive Services: Our inspections are quick, non-invasive, and performed without disrupting your operations or daily activities.

Benefits of Infrared Thermographic Inspection

Early Problem Detection: Thermography allows you to detect issues like overheating circuits, loose electrical connections, and structural inefficiencies before they escalate.

Reduced Downtime: By addressing small issues early, you can prevent equipment failures and reduce costly downtime.

Fire Hazard Prevention: Excess heat within electrical systems is a significant fire risk; thermography helps pinpoint and eliminate these dangers.

Improved Energy Efficiency: Identify areas of energy loss or inefficiency to optimize system performance and reduce costs.

Compliance & Safety: Many industries require routine inspections for safety compliance, and thermography is a key part of meeting those standards.

Applications of Infrared Thermographic Inspection

Thermo Elite’s services have broad applications across various industries and environments, including:

Electrical Systems: Detecting loose connections, overloaded circuits, and equipment failures.

Building Inspections: Identifying heat loss, moisture intrusion, and insulation issues.

Mechanical Equipment: Locating wear, misalignment, or excessive friction in moving parts.

Data Centers: Ensuring proper cooling and preventing overheating of critical infrastructure.

Industrial Facilities: Maintaining production equipment and ensuring operational safety.

Thermo Elite’s Inspection Process

Thermo Elite’s infrared thermographic inspections are comprehensive and designed for accuracy. Our certified thermographers use state-of-the-art infrared cameras to capture thermal images of your systems. These images reveal temperature anomalies that could indicate potential problems. After completing the inspection, we provide a detailed report outlining the findings, thermal images, and specific recommendations for corrective actions.

#Infrared thermographic inspection#thermal imaging services#Thermo Elite#electrical safety inspection#energy efficiency testing#preventative maintenance#heat detection technology#building thermography#mechanical equipment inspections

0 notes

Note

How long was Mikey trapped in the EPF facility? And how fast acting were the mutations? It kinda sounds like the scientists put him through several rounds of injections over a period of time.

Are there multiple facilities? Did Mikey get moved to a different location or stay in the one he was captured at?

Mikey’s bros had to be losing their minds looking for him, or planning a foolproof strategy to break in and rescue him from the place they knew he disappeared.

Love the double mutated Mikey updates but GIRL! SLEEP!

So Mikey was trapped in the EPF building for one week, if I remember right. Maybe less... The mutations began the very night as he was captured. They were near instantaneous changes in his body, but they were spaced out. So one day he would get injections for a specific species, the next day he got a different species, etc. But the mutation operations mostly ended on day four or five.

In addition to the species mutations, they also added their own formulas and mixtures to try and enhance certain aspects of the species, such as a reptile's brumation and infrared vision, super hearing, how he can weaponize his tails and create exoskeleton armor or quills with his scales, the ability to make his bones be triple-jointed and flexible as a snake or rigid and immovable as iron, etc. I'm pretty sure that they reverse-engineered Draxum's ooze from a mosquito sample and used that on him as well as Krang DNA. Mikey has a lot of abilities now, some are obvious, others have yet to reveal themselves... I'm really excited to share one in particular.

There are probably a bunch of EPF hidden bases, but Mikey stayed at one lab, the one he broke into. He was in one of three rooms for the entire time he was there -- either the open labs where he was in a cage, the operating room where he was mutated, or what I'm calling "the Interaction room", which was an empty room with some strange devices and security cameras where the doctors could watch him "interact" with some of the vicious mutations they created. The purpose of the room was to see if any of the experiments could be trained or controlled, and see their new abilities in action. The machines in the room were weapons and mechanical training simulators, they would fire at Mikey and shoot darts and pellets and stuff at him to see his agility and strength and problem-solving skills. Sometimes drones or robotic arms would be placed in the room as well. (This is why Mikey often inspects the machines in the lair to see if they are "evil".) All the other experiments he met were incredibly savage and prone to insanity, so Mikey was forced to fight them to stay alive. Basically it was an evil scientist's version of a gladiator arena.

Mikey's bros would have probably gone in the very night he was captured, but knew that they needed a plan. Donnie spent the week researching, Leo spent it making strategies and contingency plans, Raph spent it stress-training and crying, April and Cass and CJ spent it scouting the place out.

@boots-with-the-fur-club

#rottmnt#rise of the teenage mutant ninja turtles#rottmnt mikey#double mutation mikey#double mutated mikey#double mutation#double mutated#rottmnt fanfiction#rottmnt fanfic#rottmnt fanfic recs#fanfic rec#tumblr asks#fanfic writer#tumblr writers

30 notes

·

View notes

Text

Boost Industrial Washer-Extractor Efficiency for Laundry Operations

Boost Industrial Washer-Extractor Efficiency for Laundry Operations

Understand the Basics of Washer-Extractor Operations To achieve efficient operation of industrial washer-extractors, we must first deeply understand the principles behind them. The laws of mechanical operation, water temperature control, and the right chemical ratios are interrelated and affect each other. When placing clothes in the machine, operators must be extremely careful and set the load accurately according to the characteristics of different fabrics. After all, heavy linens and light fabrics have different requirements when washing, and the corresponding settings must be different. This is where water level sensors and programmable logic controllers (PLCs) are like right-hand men, who can help operators make precise adjustments so that the machine can effectively remove dirt from fabrics while minimizing resource consumption. In commercial laundry facilities, in order to ensure accuracy and consistency of operation, it is necessary to develop a standard list of wash cycle settings to effectively avoid the trouble caused by operator errors.Get more news about Washer-Extractor,you can vist our website!

Optimize the dehydration stage to save energy In the actual process of commercial laundry operation, it is not difficult to find that the high-speed dehydration stage of the washing machine dehydrator is an important part of energy consumption, and the energy consumed by it accounts for between 18% and 23% of the total energy. In order to achieve the dual goals of energy saving and machine protection, we cannot let the machine run at full speed at the beginning, but should gradually increase the speed. The advantage of doing so is that it can avoid excessive pressure on the motor and bearings in an instant, thereby extending their service life. Operators can use infrared sensors to detect the moisture content of the clothes after dehydration, so that batches with poor dehydration effects can be discovered in time. During the dehydration process, the centrifugal force should be cleverly balanced within the range that the clothes can withstand, so that the water in the clothes can be removed as much as possible without causing damage to the clothes. Once the moisture content of the clothes is reduced, the time and energy required for subsequent drying will naturally be reduced accordingly, which is of great significance for improving laundry efficiency and reducing costs.

Preventive maintenance program to extend service life Regular inspection and maintenance are essential to keep the washing machine and dehydrator in good working condition and working stably for a long time. In particular, it is important to carefully check the condition of the drum bearings and shock absorbers every week, which is particularly important when the machine often handles heavy loads. The frequency of lubricating the machine needs to be determined according to the actual use. If a place has a daily laundry volume of 10 tons or more, it is more appropriate to lubricate it once every two weeks; if the laundry volume is relatively small, it is enough to lubricate it once a month. According to the results of industry research, the use of digital maintenance logs with automatic reminders can effectively reduce equipment downtime by 37%, which undoubtedly provides a strong guarantee for the normal operation of the equipment.

Troubleshooting common performance problems Sometimes, you will encounter some performance problems when using a washing machine and dehydrator. For example, if you find that the machine shakes violently when dehydrating, generally speaking, it may be due to uneven placement of clothes or wear of some stable parts of the machine. Therefore, operators must carefully check the placement of clothes to ensure that they are correct before starting the high-speed spin. If the drainage is not smooth, it is usually because the drain pipe is blocked or the drain valve is damaged. In order to ensure smooth drainage, it is necessary to remove these parts and clean them every month, which generally restores the water flow to normal. When the machine has an error code, it requires professional technicians with their rich experience and expertise to determine whether it is a sensor failure or a mechanical problem, so as to avoid unnecessary parts replacement and save repair costs.

Implementing water recycling strategies Today, some advanced laundry facilities have realized the importance of water resources and have adopted effective water recycling strategies. By adopting a multi-stage filtration system, these facilities can recycle 65% - 80% of the wash water. After being treated with a reverse osmosis device combined with ultraviolet disinfection, the recycled water can be used again in the pre-wash stage. Taking a medium-sized laundry facility as an example, this method can save about 12,000 gallons of fresh water per week, which is a considerable number for water conservation. In addition, installing a heat exchanger can also collect heat from the drain water and use this heat to preheat the incoming cold water by 15-20°F, thereby reducing the load on the boiler. These environmentally friendly practices not only help save water and electricity bills and reduce operating costs, but also help laundry facilities obtain environmental compliance certification and improve their social image.

Improving operator safety in heavy-duty environments In heavy-duty laundry environments, operator safety always comes first. To ensure personnel safety, when performing maintenance on the machine, it is necessary to strictly follow the operating procedures and turn off the power first to prevent accidental injuries caused by accidental start-up of the machine. In places with large laundry volumes, it is very necessary to lay non-slip floors and set up ergonomic loading platforms, which can effectively prevent musculoskeletal injuries caused by long working hours for operators. The application of automatic dosing systems can reduce the opportunity for workers to come into contact with detergents and reduce potential threats to workers' health. And steam detection sensors can provide early warning of the accumulation of harmful gases, allowing operators to take timely measures to avoid danger. Regular safety inspections and timely updating of personal protective equipment (PPE) specifications can help laundry facilities strictly comply with the U.S. Occupational Safety and Health Administration (OSHA) 1910.212 machine guarding standard and create a safe and reliable working environment for operators.

0 notes

Text

For unmatched volume production and zero-compromise quality in semiconductor devices, choose Handlers and Testers from Cohu®

Semiconductor devices have pervaded industries and human needs today. From System on Chip (SoC) and Micro-Electro-Mechanical System (MEMS) to Printed Circuit Board (PCB), the exhaustive range of device types calls for more functionality even with smaller form factors. Volume production of zero-defect devices is required to handle the increasing demand. Enhanced speed of test is paramount while testing a semiconductor device.

To meet this demand, MELSS brings you handling and Testing solutions from Cohu® – the technology leader in test, automation, inspection and metrology products and services for the semiconductor industry.

Cohu’s product portfolio includes a wide range of pick-and-place, thermal and gravity test handlers for MEMS, sensor and turret test and scan applications, a broad spectrum of interface solutions for automotive and power, 5G wireless, artificial intelligence, and data processing applications. Also including probes and contactors, it enables optimised yield and productivity and accelerates customers’ manufacturing time-to-market.

Gravity Test Handlers

Capable of handling extremely small to very large packages over a very wide temperature range, they are ideal for high throughput octal site and quad site testing.

Cohu is the market leader in gravity test handlers with an installed base of 6,000 gravity systems today.

Turret Test and Scan

Turret Handlers are high-speed, high-accuracy devices that handle, inspect and test semiconductor components.

Turret platforms from Cohu for semiconductor testing, inspection and packaging provide:

Highest Throughput for Fragile Devices

Highest Processes Integration Capabilities

Flexible Test and Scan Solution for FFC Devices

Market Leading Inspection Yield with High Throughput

Pick-and-Place Test Handlers

Cohu pick-and-place test handlers automate the movement of semiconductor devices, control temperature during testing, and offer vision inspection capabilities to ensure quality and optimise yield in volume production, with models like the Delta MATRiX, Delta Eclipse, and MT9510 XP/x16.

Features such as the automated movement of semiconductor devices such as ICs – from input to test sockets and then to output – ensure efficient and reliable handling.

These handlers provide high-speed testing. While the Delta Eclipse is capable of testing up to 16 ICs in parallel and achieving throughputs of up to 12,000 UPH, the MATRiX handler’s highly flexible test site configuration makes it suitable for a wide range of test applications.

Many Cohu handlers, such as the MT9510 XP/x16, offer tri-temperature control, allowing for testing in cold, hot, or ambient conditions.

The MATRiX handler incorporates Cohu’s T-Core active thermal control (ATC) technology, which dynamically removes heat from devices during testing, minimising test time and yield loss. The MT9510 XP/x16 test handler provides full temperature control during testing in extreme environmental conditions from -55°C to +175°C.

Cohu offers a broad range of IC pick-and-place test handling solutions with thermal, vision and factory 4.0 automation options for the automotive, mobile, and computing markets.

Cohu’s NV-Core inspection system also provides advanced inspection capabilities such as 3D topographic inspection, sidewall micro-crack detection, and infrared inspection for sub-surface defect detection. Devices are inspected for dimensional or cosmetic defects, lead irregularities, pad bridging, or contamination. The vision system can verify the expected presence/absence of components on input/output units, inside sockets, and on pickups to prevent jams. It also scans all devices in input, identifying each DUT by 2D code reading and storing the data in the handler database for MES integration.

MEMS and Sensor Test

MEMS are micro-scale systems that integrate mechanical components (like sensors, actuators, and micro-structures) with electronic circuits on a single chip.

These are capable of not only integrating complex functions in very small devices but also integrating with other semiconductor components, leading to smaller, more efficient, and more powerful systems. To be capable of performing a wide range of functions such as sensing (e.g., acceleration, pressure, temperature), actuation (e.g., controlling fluids, moving parts), and microfluidics, their handling and testing is crucial.

Cohu MEMS solutions combine the advantages of well-established and production-proven tri-temp test handling equipment with innovative concepts to meet the special requirements of the MEMS market.

Interface Solutions

To complement the aforementioned solutions, Cohu also offers the requisite interface solutions for many industries:

Automotive and power

Artificial intelligence

Virtual and augmented reality

5G infrastructure

Cloud computing

Wearables and Internet of Things

Sensors and actuators

Radio Frequency devices

Cohu is the only company with expertise in the entire test cell and inspection needs of the semiconductor manufacturing industry.

The exhaustive range of solutions from Cohu – a global pioneer among automated test equipment manufacturers – is brought to you by MELSS as part of its comprehensive offerings for the semiconductor manufacturing industry.

0 notes

Text

A Thermal Imager is a non-contact device that captures and displays infrared radiation (heat) emitted by objects, converting it into a visual image known as a thermogram. Widely used in electrical inspections, mechanical diagnostics, building maintenance, HVAC system analysis, and preventive maintenance, this device allows users to detect heat variations, identify overheating components, locate air leaks, moisture intrusion, and insulation issues with ease. Buy : https://vegabazaar.com/category/Thermal-Imagers/ #thermalimager #thermalimagingcamera #infraredthermalcamera #thermalscannercamera

0 notes

Text

Sun, Skin, Safety: What You Need to Know About UV Protection

Let’s get real for a moment…

No, sunbeds are not safe. They emit the same harmful UV rays as the sun, increasing your risk of long-term skin damage and cancer.

Yes, sunscreen is necessary even on cloudy days. UVA rays can pass through clouds and glass.

Yes, your skin needs daily protection – no matter the weather, no excuses.

Why Is Sun Protection So Critical?

Skin cancer is the most common cancer in the UK, with malignant melanoma being the deadliest form. It’s particularly alarming that it’s also one of the most common cancers among young adults (ages 15-34). Roughly 86% of skin cancers are caused by UV radiation damage – a sobering reminder of how vital sun protection is.

Understanding UV Rays

The sun emits three types of ultraviolet rays, each with its own effects:

UVA – The Ageing Ray

Think A for Ageing and Allergies. UVA rays penetrate deep into the skin, accelerating premature aging and contributing to allergic skin conditions. They can even pass through windows and clouds, so daily protection is a must.

UVB – The Burning Ray

B for Burning. UVB rays are stronger in direct sunlight and cause tanning and sunburn. The skin tans as a defense mechanism when it senses UVB-related damage. These rays are most intense between 11 AM and 3 PM.

UVC – Currently Blocked by the Ozone

UVC rays are highly dangerous but fortunately, they’re blocked by the ozone layer — for now.

How to Protect Your Skin

Choose a broad-spectrum SPF that shields you from both UVA and UVB rays. Look for a sunscreen with a visible UVA logo inside a circle, indicating approved UVA protection.

Your best bet? A formula with both physical and chemical protection:

Physical filters like zinc oxide and titanium dioxide reflect UV rays off your skin.

Chemical filters like Tinosorb and Octocrylene absorb UV rays and convert them into harmless energy.

What About Blue Light and Visible Light?

The sun also emits visible light (HEV), including blue light and infrared rays. While these rays aren’t directly linked to skin cancer, they generate free radicals that damage the skin over time, accelerating aging and inflammation.

To combat this, use a powerful antioxidant serum under your sunscreen. Ingredients like Vitamin C help neutralize free radicals and reduce oxidative stress.

Product Tip to Strengthen Protection

Try:

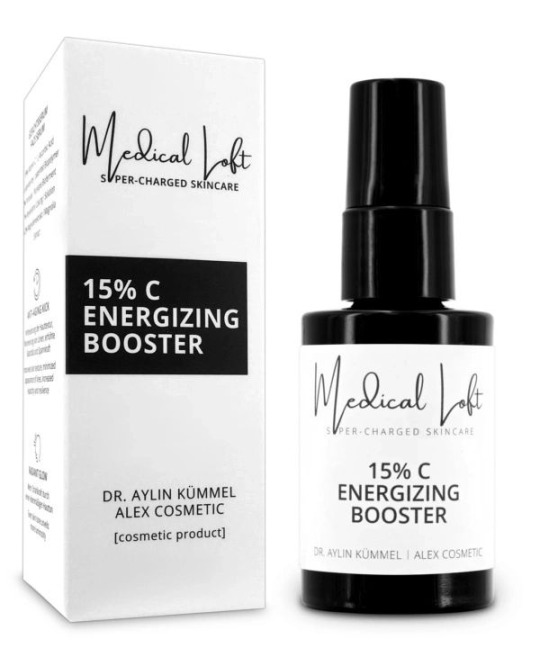

Medical Loft 15% Energizing Booster – A potent Vitamin C serum that helps energize the skin while providing excellent antioxidant protection. Ideal for layering under your sunscreen.

Daily Sun Safety Habits

Apply sunscreen every day, regardless of the weather or whether you’re indoors.

Choose SPF with broad-spectrum UVA/UVB protection.

Layer with a good antioxidant serum for visible light defense.

Reapply sunscreen every two hours when exposed to the sun.

Use protective accessories like hats and sunglasses, especially during peak hours (11 AM – 3 PM).

Remove sunscreen thoroughly at the end of the day.

Sun damage affects all skin tones – no one is exempt.

Check the UV index regularly. When it reaches 3 or higher, protection is essential.

Watch Your Skin Closely

Regularly inspect your skin using the ABCDE rule to spot early signs of melanoma:

A – Asymmetry

B – Border irregularity

C – Colour variations

D – Diameter greater than 6mm

E – Evolving shape, size, or color

See a doctor if you notice anything unusual.

Conclusion

Protecting your skin from the sun is not just a beauty ritual — it’s a health essential. With the right products and habits, you can significantly reduce your risk of sun-related skin issues. Consistent use of broad-spectrum SPF, antioxidants, and protective gear goes a long way in keeping your skin healthy and radiant.

If you’re dealing with concerns like sun spots, hyperpigmentation, melasma, dark marks, or age spots, Alex Cosmetic offers highly effective skincare solutions. Explore the Brighten range tailored to help restore clarity and even tone to your skin.

All Alex Cosmetic products mentioned are available through Biokosmetikoftexas USA — your trusted destination for advanced skin care.

#sun protection#UV rays#UVA and UVB#sunscreen tips#daily SPF#sun safety#broad-spectrum sunscreen#antioxidant serum#vitamin C serum#skin cancer prevention#skincare routine#visible light protection#blue light skincare#HEV light damage#anti-aging skincare#sun damage#hyperpigmentation#melasma care#dark spots#Alex Cosmetic#brighten skincare#Biokosmetikoftexas#skincare education#healthy skin tips#skincare for all skin tones#skin health awareness#summer skincare#radiant skin

1 note

·

View note

Text

10 Things you need to know about thermal imagers

Whether you choose a simple point-and-shoot model or a high-end Thermal Imagers Camera with all the bells and whistles, here are some key features and specs you should consider:

1. Resolution:-

⦁ The number of detector pixels on the camera is indicated by the detector resolution. Higher resolution is indicated by more pixels.

⦁ The region the imager views at any given time is defined by the combination of the field of view (FOV) specification and detector pixels, which form the basis of spatial resolution. The smallest item size that can be detected can be defined with the aid of spatial resolution. Better detail and image quality are associated with a lower spatial resolution value.

2. Focus:-

When choosing a focus type, it is essential to consider both your skill level and the application, given the range of focus mechanisms available. The typical focus mechanisms are as follows:

a. Fixed: Point and shoot simplicity

b. Manual: Precise incremental focus

c. Auto focus: Automatically focuses on a target but may require manual adjustment.

d. Laser-assisted auto focus: Uses a built-in laser distance meter to calculate distance to the target.

e. Multifocal: Captures and stores multiple images of the target from varying focal distances and uses software to blend them into one image with ultra-sharp depth of field detail. Fluke Corp., for example, calls its implementation of this technology MultiSharp™ Focus.

3. Temperature Range:-

⦁ The temperature range required from your thermal imager is defined by the highest and lowest temperatures you observe during your inspection. Alternatively, choose a camera that has a broad temperature range and either automatically adjusts the range according to your scene or enables you to select the temperature range manually.

4. Lens Options:-

⦁ With a camera that allows for lens changes, your versatility is enhanced, enabling you to examine a wider variety of equipment and circumstances. A wide variety of options are available for various applications — standard, wide angle, telephoto, and macro.

5. Saving Images and Additional Data:-

⦁ Speichern Sie digitale und Infrarotbilder sowie in einigen Fällen Sprachnotizen im internen Speicher, auf einem USB-Stick oder auf einer SD-Karte, die entfernt werden kann. Having the option to save images and extra related data to various media for backup or sharing is crucial.

6. Color Palettes:-

⦁ A monochromatic palette, like grayscale or amber, makes it easier to spot slight differences. It can be easier to quickly find obvious anomalies with high-contrast palettes. The camera or the software should allow you to change the palette.

7. Color Alarms:-

⦁ Use these to quickly highlight areas outside your normal temperature ranges.

8. Emissivity and Reflected Temperatures:-

⦁ Surfaces with low emissivity, like shiny metals, can reflect infrared energy from surrounding objects, which may distort your image and affect the precision of your measurements. Therefore, when selecting an imager, seek out the option to modify parameters.

9. Spot Markers:-

⦁ Indicate specific temperatures on your image to compare simultaneous temperatures from various points on the same image.

10. Battery type and Life:-

⦁ Seek a battery that includes practical features, like a charge level indicator. It is extremely bad to begin an inspection without knowing the battery status. Take into account the long battery life and fast charging capability as well.

0 notes

Text

Best Condition Monitoring Services Tabuk

Industries in Tabuk rely on high-performance machinery to maintain productivity and efficiency. To avoid unexpected failures and costly downtimes, businesses must adopt a proactive maintenance strategy. This is where Best Condition Monitoring Services Tabuk come into play, helping industries detect potential issues before they escalate into critical failures.

What is Condition Monitoring?

Condition monitoring is a predictive maintenance technique that involves tracking the performance and health of machinery in real time. By using Best Condition Monitoring Services Tabuk, industries can identify mechanical, electrical, and thermal issues before they lead to major breakdowns. This approach helps in optimizing maintenance schedules and improving overall reliability.

Key Techniques Used in Condition Monitoring

The effectiveness of condition monitoring depends on advanced diagnostic methods that help detect faults early. These include:

Vibration Analysis – Identifies misalignment, imbalance, and mechanical looseness in rotating equipment.

Thermal Imaging – Uses infrared technology to detect overheating components, preventing electrical failures.

Oil and Lubricant Analysis – Examines oil samples to assess contamination and wear, ensuring smooth machinery operation.

Ultrasonic Testing – Detects leaks, cracks, and friction abnormalities that may not be visible during regular inspections.

Motor Current Analysis – Assesses motor performance, identifying electrical imbalances or mechanical inefficiencies.

Advantages of the Best Condition Monitoring Services in Tabuk

Investing in Best Condition Monitoring Services Tabuk provides numerous benefits, including:

Reduced Downtime – Early fault detection prevents unexpected failures, ensuring smooth operations.

Cost Savings – Proactive maintenance helps avoid costly emergency repairs and equipment replacements.

Enhanced Equipment Lifespan – Regular condition monitoring extends the life of machinery by preventing excessive wear and tear.

Improved Safety – Identifying potential issues early minimizes the risk of workplace accidents.

Energy Efficiency – Well-maintained equipment operates with optimal efficiency, reducing energy costs.

Why Choose Bafco Reliability for Condition Monitoring in Tabuk?

Bafco Reliability is a leader in Best Condition Monitoring Services Tabuk, offering industry-specific solutions tailored to your business needs. Our services include:

Cutting-edge diagnostic tools for precise monitoring.

Highly trained technicians with expertise in predictive maintenance.

Real-time data analysis to optimize equipment performance.

Custom maintenance plans designed to reduce downtime and maximize efficiency.

24/7 support for critical machinery monitoring and emergency services.

#ConditionMonitoringTabuk#IndustrialMaintenance#BafcoReliability#PredictiveMaintenance#MachineEfficiency

0 notes

Text

Thermography Non Destructive Testing

Thermography is a cutting-edge non-destructive testing (NDT) technique that uses infrared imaging to detect temperature variations in materials and structures. It helps identify hidden defects, such as cracks, voids, or delamination, without causing damage. Widely used in industries like aerospace, manufacturing, and construction, thermographic NDT enhances safety, reduces downtime, and ensures structural integrity. By capturing heat signatures, this method provides valuable insights for preventive maintenance and quality control. Whether for electrical inspections or mechanical assessments, thermography is an efficient, cost-effective solution for early defect detection. Stay ahead with advanced NDT techniques to protect your assets and operations!

0 notes

Text

The Role of Advanced Safety Sensors in Modern Garage Doors

Garage doors have come a long way from their early manual versions. Today, modern garage doors are equipped with advanced safety sensors that ensure smooth operation and prevent accidents. These sensors are essential for protecting people, pets, and property while also enhancing security. At Roadrunner Garage Doors, we emphasize the importance of keeping these sensors in optimal condition as part of routine garage door repair and maintenance.

In this blog, we’ll explore the role of advanced safety sensors, their benefits, how they work, and why it’s essential to have a reliable garage door company handle their maintenance and repair.

Understanding Garage Door Safety Sensors

Garage door safety sensors are an integral part of modern garage door systems. They prevent the door from closing if an object or person is detected in its path. These sensors are typically installed a few inches from the ground on either side of the door opening. They use infrared technology to communicate with each other, ensuring the garage door only closes when the path is clear.

How Safety Sensors Work

The safety sensors on modern garage doors function through a simple yet effective mechanism:

Infrared Signal Transmission – One sensor emits an invisible infrared beam across the garage door opening.

Signal Reception – The other sensor receives this beam, ensuring that the path is clear.

Interruption Detection – If the beam is blocked by an object, the sensors trigger the garage door opener to stop closing and reverse direction.

These sensors significantly reduce the risk of accidents, making them a crucial feature in any garage door system.

Benefits of Advanced Safety Sensors in Garage Doors

1. Enhanced Safety for Family and Pets

One of the biggest advantages of advanced safety sensors is accident prevention. Whether you have children running around or pets roaming near the garage, these sensors ensure that the garage door won’t close on them.

2. Property Protection

Imagine your car halfway inside the garage when the door starts closing. Without safety sensors, this could lead to costly damages. The sensors detect any obstruction, preventing the door from causing damage to your vehicle or other belongings.

3. Improved Security

Modern garage doors equipped with safety sensors enhance home security. Some models can send alerts to homeowners if unauthorized attempts to manipulate the garage door are detected, providing an added layer of security.

4. Compliance with Safety Regulations

In many regions, federal and state regulations require garage doors to be equipped with safety sensors. Ensuring your sensors are functional keeps you compliant with these safety standards, avoiding legal complications.

5. Convenience and Peace of Mind

With safety sensors in place, you no longer have to worry about checking if something is in the way before closing your garage door. This feature provides peace of mind, knowing that your garage door will operate safely every time.

Common Issues with Garage Door Sensors

Even though advanced garage door safety sensors are highly reliable, they may occasionally experience issues. Here are some common problems that require professional garage door repair:

1. Misalignment

If the sensors are not aligned properly, they won’t be able to communicate, causing the garage door to stop closing. This is a frequent issue that a professional garage door company can quickly resolve.

2. Dirt and Debris Accumulation

Dust, dirt, and cobwebs can obstruct the infrared beam, making the sensors malfunction. Regular cleaning can help prevent this issue.

3. Electrical Interference

Wiring issues or electrical interference from nearby devices can disrupt sensor function. If your garage door sensors stop working unexpectedly, a professional inspection is necessary.

4. Faulty Wiring or Sensor Damage

Over time, wear and tear can cause sensor wires to become loose or damaged. If your garage door sensors aren’t functioning properly, it might be time to replace them.

5. Sunlight Interference

Direct sunlight can sometimes interfere with the infrared signal, preventing the sensors from working correctly. Installing shades or adjusting the sensor angle can help mitigate this issue.

Maintaining and Repairing Garage Door Safety Sensors

To ensure that your garage door safety sensors function optimally, follow these maintenance tips:

1. Regular Cleaning

Dirt and grime can obstruct the infrared beam, so it’s important to clean the sensors with a soft cloth regularly.

2. Check for Proper Alignment

If the garage door won’t close properly, check the sensors’ alignment. If they appear misaligned, adjust them until they face each other directly.

3. Inspect Wiring for Damage

Look for any frayed or loose wires that may be affecting the sensor’s performance. If you notice any issues, contact a garage door repair professional immediately.

4. Test the Sensors Periodically

A simple way to test your safety sensors is to place an object in the door’s path while closing it. If the door doesn’t reverse, your sensors might need professional attention.

5. Seek Professional Help When Needed

If your garage door sensors are malfunctioning and basic troubleshooting doesn’t fix the problem, it’s best to call a professional garage door company like Roadrunner Garage Doors.

Why Choose Roadrunner Garage Doors for Sensor Repairs?

At Roadrunner Garage Doors, we specialize in garage door repair, including sensor troubleshooting and replacement. Here’s why homeowners trust us:

Expert Technicians – Our team has extensive experience diagnosing and fixing garage door sensor issues.

Fast and Reliable Service – We offer prompt repairs to ensure your garage door remains safe and functional.

High-Quality Parts – We use top-tier replacement parts to ensure long-lasting results.

Affordable Pricing – We offer competitive pricing without compromising on quality.

Customer Satisfaction Guaranteed – Our goal is to keep your garage door operating safely and smoothly.

Conclusion

Advanced safety sensors play a vital role in ensuring the safety, security, and efficiency of modern garage doors. From preventing accidents to enhancing security, these sensors are an indispensable feature in any garage door system.

However, like any component, they require regular maintenance and occasional repairs. If you’re experiencing issues with your garage door safety sensors, don’t wait—contact Roadrunner Garage Doors, your trusted garage door company, for expert service today!

1 note

·

View note

Text

Infrared Inspection: The Key to Preventative Maintenance & Safety | Thermo Elite

What is Infrared Inspection?

Thermal imaging inspection, or infrared inspection, is one of the modern advents of technology that employs infrared cameras to observe heat detectable variations in electrical, mechanical, and structural systems non-destructively. These systems often have flaws such as overheating, moisture intrusion, eet insulation failing, and electrical faults that are not readily visible to the naked eye.

At Thermo Elite, we provide reliable and accurate assessments infrared technology for industrial, commercial, and residential applications. With unmatched, years of experience, we guarantee the execution of high infrared precision inspections that aid businesses and property owners identify potential hidden problems before they develop into costly failures.

How Does Infrared Inspection Work?

The window of an infrared camera acts as a detector of emitted thermal energy and transforms it into a visible representation of a thermogram. These photographs show distinctive heat patterns and anomalies that need careful analysis. By analyzing these images, we can effortlessly detect electrical faults, energy inadequacies, mechanical failures, and even water damage without any physical disturbance to the structure.

Why is Infrared Inspection Important?

Many structural and mechanical issues

Most structural and mechanical problems remain unseen at first, only to become expensive to fix later. Conducting regular infrared assessments helps detect issues early to minimize expensive repairs, improve safety, and enhance overall energy efficiency.

Some advantages of infrared inspection are enumerated below:

✅ Early Problem Detection

✅ Hidden Problems—Find issues before they inflict serious damage.

✅ Non-Destructive Testing

✅ No walls or machinery part need opening to diagnose problems.

✅ Cost Savings

✅ Eliminate unforeseen breakdowns and lower repair expense.

✅ Energy Efficiency

✅ Asses for gaps in insulation, air leaks, and poor HVAC.

✅ Improved Safety

✅ Find potential fire risks, electrical overloads, and structural frailties.

#InfraredInspection#ThermalImaging#InfraredThermography#BuildingInspection#ElectricalInspection#ThermographicInspection#EnergyEfficiency#PreventativeMaintenance#MoistureDetection#HVACInspection#IndustrialMaintenance#StructuralAssessment#ThermoElite#NonDestructiveTesting#FirePrevention

0 notes

Text

Phased Array Ultrasonic Testing: Benefits and Applications

Phased Array Ultrasonic Testing (PAUT) is an advanced non-destructive testing (NDT) technique that utilizes multiple ultrasonic elements and electronic time delays to create a focused beam of sound waves. This innovative technology allows for precise control over the angle, focal point, and depth of the inspection, resulting in highly detailed images. Such precision is crucial for identifying defects like cracks, voids, and inclusions within materials, ensuring the integrity and safety of critical components.

Comprehensive Inspection Capabilities

Phased Array Ultrasonic Testing excels in inspecting complex geometries and materials, making it invaluable in industries such as aerospace, oil and gas, and power generation. It is commonly employed for weld inspections, corrosion mapping, and flaw detection in metals and composites. The ability to generate real-time images enables inspectors to make immediate assessments, enhancing the efficiency of the inspection process.

Original Source: https://www.rvsglobe.com/phased-array-ultrasonic-testing-see-beyond-the-surface-benefits-and-applications-120

Integration with Other NDT Methods

For optimal results, PAUT is often integrated with other NDT methods. Combining PAUT with Time of Flight Diffraction (TOFD), for instance, offers a more comprehensive evaluation of material integrity. This integrated approach provides a robust framework for detecting and sizing defects, ensuring the highest standards of safety and reliability.

Cost-Effectiveness and Efficiency

While the initial setup cost for Phased Array Ultrasonic Testing equipment may be higher than traditional methods, the long-term benefits make it a cost-effective solution. The ability to perform thorough inspections quickly reduces downtime, which is crucial for industries where time is of the essence. Moreover, the detailed imaging capabilities minimize the need for multiple inspections, saving both time and resources. The efficiency of PAUT makes it an attractive option for industries looking to optimize their maintenance schedules and extend the lifespan of their assets.

Applications Across Various Industries

The applications of PAUT are vast and varied, extending across multiple industries. In the oil and gas sector, PAUT is utilized to assess the condition of pipelines and pressure vessels, ensuring their safe operation. The aerospace industry employs PAUT for the inspection of aircraft components, where even the smallest defect can have significant consequences. Additionally, the power generation industry uses PAUT to monitor the condition of turbines and other critical equipment, preventing catastrophic failures.

Enhanced Accuracy and Versatility

Phased Array Ultrasonic Testing stands out for its exceptional accuracy and versatility. Unlike conventional ultrasonic testing, PAUT uses multiple ultrasonic elements and electronic time delays to create a focused beam of sound waves. This method allows for precise control over the angle, focal point, and depth of the inspection, resulting in highly detailed images. This level of precision is crucial for identifying defects that might be missed by other testing methods, such as cracks, voids, and inclusions within a material.

Complementary NDT Techniques

In addition to PAUT, various complementary NDT services provide a holistic approach to material inspection. For instance, Infrared Thermography Services are used to detect surface and subsurface anomalies by measuring temperature variations. This non-contact method is particularly useful for identifying electrical and mechanical issues in a wide range of applications. When combined with PAUT, infrared thermography provides a comprehensive understanding of material integrity, ensuring the highest level of safety and performance.

Conclusion

Phased Array Ultrasonic Testing is a powerful tool in the field of non-destructive testing, offering unparalleled accuracy and versatility. The ability to inspect complex geometries and integrate with other NDT methods makes PAUT an essential technique for various industries. By adopting advanced inspection technologies like PAUT, industries can maintain high standards of quality and safety, ensuring the longevity and reliability of their critical assets.

0 notes

Text

What should I do if the organic fertilizer equipment gets damp

If the organic fertilizer equipment is damp, the following measures can be taken for treatment and prevention:

1. Equipment drying treatment Natural drying: If the equipment is not seriously damp, it can be placed in a well-ventilated, dry place to dry naturally.

2. Artificial drying: For the equipment that is seriously damp, you can use a dehumidifier or desiccant for drying.

3. Heating and drying: For some large equipment, you can use infrared bulbs or heating devices to bake during shutdown, but pay attention to control the temperature to avoid overheating and damage to the equipment.

4. Equipment inspection and maintenance: moisture may cause the insulation performance of electrical equipment to decline, so it is necessary to conduct a comprehensive inspection of the electrical system, including wires, plugs, switches, etc., to ensure that there is no short circuit or leakage phenomenon.

5. Check the mechanical parts: check the mechanical parts of the equipment, such as bearings, chains, gears, etc., whether there is corrosion or damage, timely lubrication and replacement.

6. Moisture-proof measures: Seal the interfaces and jacks of the device with sealing materials, such as moisture-proof tape or gaskets, to prevent moisture from invading again.

7. Regular maintenance inspection: Even if the organic fertilizer production line is idle for a long time, regular inspection and maintenance should be carried out to ensure that the equipment is in good condition.

8. Lubrication and maintenance: Regularly lubricate and maintain the equipment, especially for bearing, chain, gear and other easily worn parts.

Through the above measures, we can effectively deal with and prevent the moisture problem of organic fertilizer equipment, extend the service life of the equipment, and ensure its long-term stable operation.

0 notes

Text

The Ultimate Guide to Garage Door Safety Features

Your garage door is one of the largest moving parts in your home — and while it provides security and convenience, it can also pose safety risks if not properly equipped and maintained. Fortunately, modern garage doors come with advanced safety features designed to protect your family, pets, and property from potential accidents.

At Brentwood Door Co Inc, we understand the importance of keeping your garage door safe and reliable. As a trusted garage door company, we’ve helped homeowners throughout the community upgrade their doors and perform essential garage door repairs to ensure safety features are functioning as they should. Let’s walk through the essential safety features every garage door should have and why they matter.

1. Auto-Reverse Mechanism

The auto-reverse feature is one of the most critical safety components on a garage door. If the door detects an object or obstruction in its path, it automatically reverses direction to prevent injury or damage.

This feature is typically powered by two systems:

Mechanical Sensors: When the door hits an obstacle, the force triggers the door to reverse.

Photoelectric Sensors: Infrared sensors placed near the bottom of the door detect movement or obstructions, signaling the door to reverse.

If your door isn’t reversing when it should, it may be time to call Brentwood Door Co Inc for a thorough inspection and garage door repair.

2. Photo Eye Sensors

Photo eye sensors are small devices installed on either side of your garage door, a few inches above the ground. They send an invisible beam across the door’s threshold — if anything interrupts the beam while the door is closing, it immediately stops and reverses.

Over time, sensors can become misaligned or dirty, causing them to malfunction. A quick cleaning or realignment can often solve the issue, but if the sensors are damaged, Brentwood Door Co Inc can replace them and recalibrate your system to keep your door safe.

3. Manual Release Handle

In case of a power outage or motor failure, a manual release handle allows you to disengage the garage door opener and operate the door by hand. This feature is especially important during emergencies when you may need to quickly exit your home.

Make sure the handle is easily accessible and test it periodically to ensure it works properly. If you experience difficulty using the manual release, a garage door repair service can help troubleshoot the problem.

4. Rolling Code Technology

Older garage doors used fixed codes for remote controls, which made them vulnerable to hacking. Rolling code technology changes the access code each time the remote is used, making it nearly impossible for potential intruders to gain unauthorized access.

If your garage door opener doesn’t use rolling codes, upgrading to a newer system is a smart move for added security. Brentwood Door Co Inc can recommend and install modern openers with this essential safety feature.

5. Motion Detection Lighting

A well-lit garage is a safer garage. Motion detection lights automatically turn on when they sense movement, helping you navigate your garage safely at night and deterring potential intruders.

If your garage lacks this feature, adding motion-activated lights is an easy upgrade that can enhance both safety and security. And if your current lights are malfunctioning, a quick call to Brentwood Door Co Inc can get them back in working order.

6. Pinch-Resistant Panels

Garage doors with pinch-resistant panels are designed to push fingers out of the way as the door closes, reducing the risk of painful injuries — especially for children who may unknowingly place their hands near the door’s seams.

If your current door lacks this feature, upgrading to a pinch-resistant model is worth considering. A garage door company like Brentwood Door Co Inc can walk you through the available options and handle the installation with precision.

7. Properly Balanced Springs

Garage door springs are under immense tension and are responsible for lifting and lowering the heavy door. If a spring breaks or is improperly balanced, the door can slam shut unexpectedly, posing a serious safety hazard.

Regular spring inspections are crucial for preventing accidents. If you notice your door feels heavy, makes unusual noises, or doesn’t stay in place when partially open, it’s time to schedule a garage door repair with Brentwood Door Co Inc.

8. Garage Door Seals and Weather Stripping

While not directly related to safety, garage door seals and weather stripping help keep out pests, debris, and moisture that can cause slip hazards or damage to your belongings. Proper sealing also improves insulation, contributing to overall home comfort and energy efficiency.

If your seals are cracked or worn, replacing them is a quick and affordable fix. Brentwood Door Co Inc offers fast, reliable service to ensure your garage door is properly sealed and secure.

9. Regular Maintenance and Safety Inspections

The best way to ensure all your garage door safety features are working properly is to schedule regular maintenance with a professional garage door company. Routine inspections can catch small issues before they turn into dangerous problems, giving you peace of mind that your family is protected.

During a maintenance visit, Brentwood Door Co Inc will:

Test auto-reverse and photo eye sensors

Lubricate moving parts to prevent wear and tear

Check spring tension and balance

Inspect cables, rollers, and tracks for damage

Why Trust Brentwood Door Co Inc?

When it comes to your family’s safety, you want to work with experts who genuinely care. Brentwood Door Co Inc has years of experience providing top-notch garage door repair, maintenance, and installation services. We stay up to date on the latest safety features and best practices, ensuring your garage door remains as safe and secure as possible.

If you suspect your garage door’s safety features need attention — or if you’re considering upgrading to a safer, more efficient system — we’re here to help every step of the way.

Final Thoughts: Prioritize Garage Door Safety

Your garage door is a convenient entry point to your home, but it should never compromise your safety. With the right features in place and regular maintenance from a trusted garage door company, you can protect your loved ones and enjoy peace of mind.

Ready to ensure your garage door is as safe as possible? Contact Brentwood Door Co Inc today for a comprehensive safety inspection or expert garage door repair. We’ll help you keep your home secure, your door functioning smoothly, and your family safe year-round!

0 notes