#Indian Steel Industry

Explore tagged Tumblr posts

Text

Tata Steel Cautions Against Job Fraud, Uncovers Multi-State Recruitment Scam

Fraudsters Demand Money for Fake Job Offers, Company Warns Public Key Points: • Tata Steel exposes large-scale fake recruitment scam across multiple states • Company files FIR against identified scammers, warns public to stay vigilant • Only @tatasteel.com email domain used for official communication, firm states JAMSHEDPUR – Tata Steel has uncovered a multi-state recruitment scam, urging the…

#बिजनेस#business#Corporate Security#Employment Scam#HR Fraud#Indian Steel Industry#Jamshedpur#job fraud#Recruitment Scam#Tata Steel

0 notes

Text

Imagine Studio at the Trees, Mumbai - Studio Lotus

#Studio Lotus#architecture#design#building#modern architecture#interiors#contemporary architecture#adaptive reuse#renovation#industrial#factory#studio#offices#artists#steel#copper#mumbai#indian architecture#india#cool architecture

72 notes

·

View notes

Text

Steel Structures & Metal Buildings (SSMB) Magazine - Advancing Steel Construction in India SSMB is India's premier magazine promoting steel in construction, offering insights, trends, and technical advancements. Reach 50,000+ professionals and boost your brand in the fast-growing steel construction sector.

#Steel Structures#Metal Buildings#SSMB Magazine#Indian construction#steel construction#Build with Steel#industry trends#construction magazine#steel industry India

0 notes

Text

Steel Stocks Surge as India Imposes 12% Import Duty to Curb Cheap Steel Influx

In a significant move to protect its domestic steel industry, the Indian government has imposed a 12% provisional safeguard duty on certain steel imports. This decision, effective from April 21, 2025, aims to counter the surge of inexpensive steel imports, primarily from China, South Korea, and Japan, which have been impacting local manufacturers.

Background: Rising Imports and Domestic Challenges

India, the world’s second-largest crude steel producer, has faced a substantial increase in steel imports over the past year. In the fiscal year 2024/25, finished steel imports reached a nine-year high of 9.5 million metric tons, marking the second consecutive year where imports outpaced exports. This influx, especially of low-cost steel, has pressured domestic producers, leading some smaller mills to scale down operations and consider job cuts.

Government’s Response: Safeguard Duty Implementation

Responding to these challenges, the Directorate General of Trade Remedies (DGTR) recommended a 12% safeguard duty on specific steel products for 200 days. The Ministry of Finance acted on this recommendation, implementing the duty to provide immediate relief to domestic producers. The duty targets various steel products, including hot-rolled coils, sheets, plates, cold-rolled coils, and color-coated sheets. Notably, imports priced above certain thresholds are exempt to ensure fair competition.

Market Reaction: Steel Stocks on the Rise

The stock market responded positively to the announcement. Major steel companies saw their shares surge in early trading on April 22: • Tata Steel: Up by 2.6% to ₹142.85 (Latest in Tata Steel stock news: investors see renewed confidence following the safeguard duty.) • SAIL: Increased by 2.5% (SAIL share price reflects strong investor sentiment amid government support.) • Jindal Stainless: Rose by 2.5% • Jindal Steel and Power: Gained 1.9% (JSPL stock update: bullish trend driven by hopes of reduced import competition.) • NALCO: Advanced by 1.6% to ₹163.90

The Nifty Metal index also climbed, marking its sixth consecutive gain, reflecting investor confidence in the sector’s prospects following the duty imposition.

Industry Perspectives: Support and Concerns

Industry leaders have welcomed the government’s decision. T. V. Narendran, CEO & MD of Tata Steel, stated, “Unchecked imports threaten domestic manufacturing, employment, and future investments. This decision will help restore fair competition and ensure the industry’s long-term sustainability.”

However, some concerns have been raised by downstream industries. MSME exporters in the engineering sector fear that increased raw material costs due to the duty could impact their competitiveness in international markets.

Looking Ahead: Balancing Protection and Growth

The safeguard duty is a strategic move to bolster India’s steel industry against unfair trade practices. While it offers immediate relief to domestic producers, the government must also address the concerns of downstream industries to ensure a balanced approach that promotes both protection and growth.

Sources: • Reuters, “India to put 12% temporary tariff on steel to curb cheap China imports,” April 21, 2025. • Economic Times, “Metal stocks surge up to 3% as India imposes 12% safeguard duty on steel imports for 200 days,” April 22, 2025. • S&P Global, “India imposes 12% safeguard duty on flat steel imports for 200 days,” April 21, 2025. • Moneycontrol, “India imposes 12% safeguard duty on some steel products to curb cheap China imports,” April 21, 2025. • Livemint, “From Tata Steel, SAIL to JSW Steel— metal stocks rise 1-2%. Here’s why,” April 22, 2025.

Note: This article is for informational purposes only and does not constitute investment advice.

For more information, visit https://www.indiratrade.com/

#steel import duty India#Tata Steel stock news#SAIL share price#India steel industry news#JSPL stock update#Nifty Metal index#steel import from China#domestic steel manufacturers India#Indian government steel policy#India steel import duty 2025#Nifty Metal index performance#Indian steel industry news

0 notes

Text

IBR Flanges: Ensuring Safety and Reliability with Tubefit Industries

IBR Flanges: A Comprehensive Guide by Tubefit Industries

IBR flanges are necessary element used in industries requiring high-pressure applications, such as power plants, refineries, and chemical plants. The term "IBR" stands for Indian Boiler Regulations, a set of standards established to ensure the safety, reliability, and efficiency of boiler systems. These flanges are designed and manufactured to meet stringent specifications set by IBR, ensuring they can withstand the most demanding environments.

At Tubefit Industries, we specialize in producing high-quality IBR flanges that cater to various industrial needs. Our IBR flanges are manufactured from superior-grade materials, offering exceptional durability, corrosion resistance, and long-term performance. Whether you're working with steam, water, or other high-pressure fluids, Tubefit Industries provides flanges that comply with IBR standards, ensuring the safety and operational integrity of your system.

Key Features of IBR Flanges by Tubefit Industries:

Compliance with IBR Standards: All flanges are manufactured in strict adherence to the Indian Boiler Regulations, ensuring high safety and quality standards.

Wide Range of Materials: Available in materials like carbon steel, stainless steel, and alloy steel, suitable for various industrial applications.

Precision Engineering: Our flanges are crafted using advanced technology, ensuring precise dimensions and a perfect fit for reliable and leak-proof connections.

Corrosion Resistance: Tubefit Industries' IBR flanges are designed to resist corrosion and maintain their strength even in harsh environments.

Customizable Options: We offer customized IBR flanges based on client specifications, ensuring compatibility with specific system requirements.

If you need top-notch IBR flanges for your high-pressure systems, Tubefit Industries is your trusted partner. Our Dictionary to quality, reliability, and customer contentment ensures that you get the best product for your industrial applications.

Contact us at:

Phone: 9999622266, 9999010233

Email: [email protected]

Website: https://www.tubefitindustries.in/ibr-flanges/

Add: Kila Number 20-21 Pali Nekpur Road Pali Faridabad-121004

#IBR Flanges#IBR Tees#IBR Elbow#IBR Syphon#IBR Reducers#IBR Pipe Fittings Manufacturer in India#IBR Fittings#IBR Pipe Spools#IBR Forgings#IBR Steam Headers Manufacturer#Indian Manufacturers#Industrial Pipe Fittings#IBR Fittings India#Precision Pipe Fittings#Tube Fit Industries#Flanges Manufacturers#Pipe Fittings India#Industria lPipe Components#IBR Standards#Quality Pipe Fittings#Pipe Fitting Solutions#Boiler Components#Flanges#Industrial Flanges#Steel Flanges#Manufacturing#Boiler Manufacturing

0 notes

Text

Steel Imports in India: Key Trends, Data & Top Countries

India, a rapidly developing economy, has witnessed significant growth in infrastructure, construction, and industrial sectors, which has driven the demand for steel. While India is one of the world's largest producers of steel, it still relies on imports to meet its growing domestic demand. Steel imports play a crucial role in complementing domestic production, particularly in specialized steel types where domestic manufacturers face limitations. In this article, we will explore the import of steel in India, analyze data on Indian steel imports, examine the countries that play a key role in this trade, and provide insights into the top 10 steel-importing countries globally.

Import of Steel in India: An Overview

India's steel sector is a cornerstone of its industrial growth, contributing significantly to the nation's GDP. Despite having a strong domestic production base, India has continued to import steel to meet specific needs, such as high-grade and specialized steel used in sectors like automobiles, defense, and infrastructure. The Indian government has undertaken various initiatives to boost domestic steel production, but imports remain essential to filling gaps in domestic supply and ensuring the availability of specific steel grades.

Indian steel imports vary by category and often depend on factors such as demand fluctuations, cost competitiveness, and availability of raw materials. These imports help maintain the supply-demand balance and meet the requirements of various industries, including the construction, manufacturing, and automotive sectors.

Steel Imports by Country

Several countries contribute to India's steel imports, each supplying different types and grades of steel. The top steel exporters to India include countries with advanced steel industries that produce specialized steel variants. Here's a list of steel imports by country:

China

China is one of the largest steel producers and exporters in the world, making it a significant source of steel for India. Despite India’s efforts to curtail its dependency on Chinese imports, Chinese steel, especially finished and semi-finished products, continues to play a critical role in India's steel sector.

Japan

Japan's advanced steel technology and high-quality products make it a reliable exporter to India. Japanese steel is preferred in industries that require precision and high durability, such as automotive and electronics manufacturing.

South Korea

South Korea is another key exporter, known for its high-quality steel. The country's advanced steel production capabilities allow it to cater to India's need for specialized steel in sectors like construction and heavy engineering.

Russia

Russia has emerged as an important steel exporter to India, offering competitive prices and a variety of steel grades. The country’s vast reserves of raw materials enable it to provide high-quality steel at lower costs.

Germany

Germany is renowned for its high-quality engineering and steel products. Although not a major player compared to China or Japan, Germany supplies specialized steel to India, particularly for industries like automotive and machinery manufacturing.

Indian Steel Imports Data: An Analysis

Analyzing steel import data reveals valuable insights into the trends and dynamics of India's steel sector. According to recent reports, India imported approximately 6 million metric tons of steel during the last financial year. The demand for steel imports is primarily driven by sectors such as infrastructure, construction, defence, and automotive industries.

The most significant category of steel imported by India includes finished steel products, semi-finished steel, and flat-rolled products. A substantial share of these imports comes from countries with advanced steel manufacturing industries. A review of Indian steel imports data also highlights a fluctuation in imports based on changes in government policies, global steel prices, and the growing domestic production of steel.

In recent years, the Indian government has introduced measures like imposing anti-dumping duties and other tariffs on imported steel to protect domestic manufacturers from cheap imports. However, the demand for certain types of steel that cannot be produced locally continues to drive imports.

Top 10 Steel Importing Countries

While India is a notable steel importer, it is far from being the largest globally. The following list shows the top 10 steel importing countries, driven by their industrial demand:

United States

The US is the largest steel importer globally. Despite having a significant domestic steel industry, the country relies on imports for various types of steel used in construction, automotive, and manufacturing sectors.

Germany

Germany imports substantial amounts of steel, mainly for its robust manufacturing sector, which includes automotive and heavy machinery industries.

China

Although China is the largest steel producer, it also imports steel, especially raw materials and semi-finished steel products, to meet its domestic and export demands.

South Korea

As a global leader in technology and heavy industries, South Korea imports steel to support its manufacturing sector, which includes shipbuilding and automotive industries.

Italy

Italy is a major importer of steel, with a heavy demand from its industrial and construction sectors. It imports various steel grades to meet the requirements of its manufacturing sector.

Mexico

Mexico imports significant amounts of steel, primarily for use in its booming automotive and construction industries, which contribute to its strong export economy.

Turkey

Turkey imports a large volume of steel for its construction and infrastructure projects, making it one of the largest steel importers in the region.

Vietnam

Vietnam's rapidly growing construction and manufacturing sectors drive its steel imports, positioning it as a key player in the global steel market.

Thailand

Thailand imports steel to support its industrial and construction sectors, contributing to its growing economy.

10. France

France imports steel to meet the needs of its automotive, aerospace, and construction industries, making it a major importer in Europe.

Conclusion

Steel imports are critical to India's industrial growth, complementing domestic production and filling the gaps in demand for specialized steel types. While India aims to strengthen its steel manufacturing capabilities, imports remain essential for meeting the specific needs of high-growth sectors like the construction, defence, and automotive industries. Countries such as China, Japan, and South Korea play a vital role in supplying India with steel, and analyzing steel import data helps shed light on key trends and patterns. On the global stage, countries like the United States, Germany, and China are the largest steel importers, reflecting the dynamic nature of global steel trade. However, if you need steel import data, steel HS code, or global trade data, you can connect with import and export data provider platforms like Seair Exim Solutions.

Frequently Asked Questions (FAQs)

Q1. Why does India import steel despite being a large producer?

India imports steel to meet the demand for high-quality and specialized steel types that are not produced in sufficient quantities domestically, such as those used in the automotive and defense sectors.

Q2. Which countries are the largest steel exporters to India?

The largest steel exporters to India include China, Japan, South Korea, Russia, and Germany.

Q3. How much steel does India import annually?

India imports approximately 6 million metric tons of steel annually, depending on factors such as domestic demand, global steel prices, and government policies.

Q4. What types of steel does India import the most?

India primarily imports finished steel products, semi-finished steel, and flat-rolled products, which are used in various industrial sectors.

Q5. What measures has the Indian government taken to reduce steel imports?

The Indian government has implemented anti-dumping duties, tariffs, and other measures to protect domestic steel manufacturers and reduce their reliance on imports.

Also Read:

The Rising Significance of the Export of Steel from India

Post By:

Seair Exim Solutions Phone No.: 099900 20716 Address: B1/E3 Mohan Cooperative Industrial Estate Near Mohan Estate Metro Station Opposite Metro Pillar No:-336, NH-19, New Delhi, Delhi 110044

#steel#steelimport#steelimportdata#import of steel in India#steel imports by country#Indian steel imports#top 10 steel importing countries#global trade data#international trade#trade data#trade market#global market#steel market#steel industry#import#importers#steel importers

0 notes

Text

"India’s announcement that it aims to reach net zero emissions by 2070 and to meet fifty percent of its electricity requirements from renewable energy sources by 2030 is a hugely significant moment for the global fight against climate change. India is pioneering a new model of economic development that could avoid the carbon-intensive approaches that many countries have pursued in the past – and provide a blueprint for other developing economies.

The scale of transformation in India is stunning. Its economic growth has been among the highest in the world over the past two decades, lifting of millions of people out of poverty. Every year, India adds a city the size of London to its urban population, involving vast construction of new buildings, factories and transportation networks. Coal and oil have so far served as bedrocks of India’s industrial growth and modernisation, giving a rising number of Indian people access to modern energy services. This includes adding new electricity connections for 50 million citizens each year over the past decade.

The rapid growth in fossil energy consumption has also meant India’s annual CO2 emissions have risen to become the third highest in the world. However, India’s CO2 emissions per person put it near the bottom of the world’s emitters, and they are lower still if you consider historical emissions per person. The same is true of energy consumption: the average household in India consumes a tenth as much electricity as the average household in the United States.

India’s sheer size and its huge scope for growth means that its energy demand is set to grow by more than that of any other country in the coming decades. In a pathway to net zero emissions by 2070, we estimate that most of the growth in energy demand this decade would already have to be met with low-carbon energy sources. It therefore makes sense that Prime Minister Narendra Modi has announced more ambitious targets for 2030, including installing 500 gigawatts of renewable energy capacity, reducing the emissions intensity of its economy by 45%, and reducing a billion tonnes of CO2.

These targets are formidable, but the good news is that the clean energy transition in India is already well underway. It has overachieved its commitment made at COP 21- Paris Summit [a.k.a. 2015, at the same conference that produced the Paris Agreement] by already meeting 40% of its power capacity from non-fossil fuels- almost nine years ahead of its commitment, and the share of solar and wind in India’s energy mix have grown phenomenally. Owing to technological developments, steady policy support, and a vibrant private sector, solar power plants are cheaper to build than coal ones. Renewable electricity is growing at a faster rate in India than any other major economy, with new capacity additions on track to double by 2026...

Subsidies for petrol and diesel were removed in the early 2010s, and subsidies for electric vehicles were introduced in 2019. India’s robust energy efficiency programme has been successful in reducing energy use and emissions from buildings, transport and major industries. Government efforts to provide millions of households with fuel gas for cooking and heating are enabling a steady transition away from the use of traditional biomass such as burning wood. India is also laying the groundwork to scale up important emerging technologies such as hydrogen, battery storage, and low-carbon steel, cement and fertilisers..."

-via IEA (International Energy Agency), January 10, 2022

Note: And since that's a little old, here's an update to show that progress is still going strong:

-via Economic Times: EnergyWorld, March 10, 2023

#india#solar power#renewable energy#green energy#sustainability#wind power#population grown#economic growth#developing economies#renewable electricity#carbon emissions#good news#hope#hope posting

861 notes

·

View notes

Text

As President Donald Trump golfed in Florida over the weekend, his hefty new tariffs, which target everywhere from China to the Falkland Islands, started to go into effect, and businesses began to react to them. Jaguar Land Rover, the Anglo-Indian automaker, announced it was pausing shipments to the United States. The American company Howmet Aerospace, which builds parts for airliners made by Boeing and Airbus, also said it may halt sending products that are affected by the new duties.

On Wall Street, where stocks plunged by about ten per cent on Thursday and Friday, analysts and investors prepared for more selling. The widely followed VIX index, a measure of expected volatility, has risen to levels not seen since the early days of COVID. Financial markets often overreact, but this Trump slump is perfectly rational and explicable. Tariffs are taxes on goods, and imposing them reduces over-all buying power in the economy. On Friday, Jerome Powell, the chair of the Federal Reserve, noted that the new tariffs are “significantly larger than expected,” so the “same is likely to be true of the economic effects, which will include higher inflation and slower growth.” It is very unusual for a Fed chairman to say out loud that an Administration’s policies are bad for the economy. Also on Friday, JPMorgan Chase, America’s largest bank, predicted a recession later this year, despite the fact that the Labor Department’s employment report for March showed solid growth. “We now expect real GDP to contract under the weight of the tariffs,” Michael Feroli, the bank’s chief U.S. economist, wrote, in a note to clients.

To some extent, investors are simply anticipating the negative impact that slower growth, or an outright slump, will have on corporate profits. But there is more to it than that. Many people on Wall Street are also suffering from buyer’s remorse. From August to December of last year, the market rose by about twenty per cent. Investors, analysts, and business executives bought into the notion that a Trump Presidency would boost an economy that was already growing faster than the rest of the developed world, with a very low jobless rate. After the election, Jamie Dimon, the C.E.O. of JPMorgan Chase, said bankers were “dancing in the street.” They were also willfully ignoring Trump’s long record of recklessness in his own business dealings and his repeated pledges to upend the global trading system, on which he has now followed through.

In recent years, policy analysts on the left and the right have advocated a retreat from the hyper-globalization that reigned from roughly 1990 to 2016, and which had harmful side effects, including a hollowing out of many industrial regions, and a dependency on fragile global supply chains. Trump’s first term, in which he imposed tariffs on certain goods, including steel, aluminum, and washing machines, and on a much wider range of products from China, marked the end of the free-trade era. The Biden Administration left in place the tariffs that Trump had imposed on China and supplemented them with an ambitious industrial policy designed to boost the industries of the future, including green energy, E.V.s, and semiconductors. Although Trump dismissed these policies as the “Green New Scam,” some conservatives, such as those associated with American Compass, a think tank founded in 2020 by Oren Cass, a former aide to Mitt Romney, supported elements of them. (In an article for the Financial Times last year, Cass referred to “the essential role of public financing, subsidies and procurement in spurring innovation and production at scale.”)

But, even if these developments marked a cross-party revival of what some have termed “neo-mercantilism”—the strategic use of state power to shape trade relationships for national advantage—Trump’s new tariffs constitute a radical departure from previous policies, including his own. Rather than applying to countries that impose specific trade barriers on U.S. goods, they target any nation that runs a trade surplus with the U.S., regardless of how that surplus may have arisen. The arithmetic formula that the Administration used to determine its tariff rates simply takes the bilateral surplus in goods from a given country, divides this figure by the amount of goods imported from that country, and multiplies the resultant fraction by a half. Comically, it also includes some Greek symbols to make it look scientific, but nowhere does it include the level of tariffs that the country imposes on U.S. goods.

In other words, these are not “reciprocal” tariffs. Reciprocity involves an equal give-and-take. According to the World Trade Organization, the European Union imposes tariffs of five per cent on foreign goods, on average; Japan imposes tariffs of four per cent; and Cambodia imposes tariffs of nineteen per cent. Under Trump’s policy, the tariffs on goods from these places are twenty per cent, twenty-four per cent, and forty-nine per cent, respectively. As CNBC’s Steve Liesman noted online, Trump “straight up lied when he said the US is now charging tariffs at half the rate other countries charge.”

Immediately after Trump announced his tariffs, I noted that they represent not neo-mercantilism but a resurgence of the absolutist approach adopted during the sixteenth and seventeenth centuries by European mercantilists who viewed any trade deficit as an evil. In addition to affecting established industrial powers, including China, Japan, and the E.U., the tariffs also hit Asian economic success stories, such as Vietnam and Bangladesh, and impoverished African countries, such as Lesotho and Malawi. The main reason that Lesotho runs a trade surplus with the United States has nothing to do with trade restrictions; it is because of poverty. With a per-capita annual income of less than a thousand dollars a year, Lesothans can’t afford to buy very many iPhones or Caterpillar trucks. And the new tariffs are threatening one of the country’s main sources of income: factories that make textiles for Levi’s and other Western companies.

Trump’s avowed goal is to re-shore American factories and boost manufacturing employment in the long run, but will it work even on its own terms? In making multibillion-dollar capital investment decisions, such as building a new plant in the United States that could operate for decades, companies need to be pretty sure about the future. With Trump, the only certainty is that things could change. Another factor to consider is that many imports are components for domestically produced goods, and slapping tariffs on them raises the costs to American firms that rely on these parts. A Federal Reserve Board study of the tariffs that Trump imposed on China in 2018 found that, when this factor was taken into account, the duties didn’t lead to any increase in manufacturing jobs. In fact, they led to a reduction of 1.4 per cent.

Trump’s new tariffs are so high and wide-ranging that estimating their ultimate impact, assuming they stay in place, would be largely guesswork. We do know for sure that they represent an unprecedented shock to the economy, and they are being accompanied by policies that run directly counter to the goal of promoting American economic dominance. Guided by Elon Musk and his DOGE colleagues, the Trump Administration is busy making cutbacks at the National Science Foundation and National Institutes of Health, which finance basic scientific research on which American businesses rely for their product development. It’s also cancelling grants for clean-energy projects and undermining investments in E.V. manufacturing by, for example, reversing the Biden Administration’s rules on reducing tailpipe pollution. Last week it withdrew funding for a federal program that promotes technical progress and productivity growth at small and medium manufacturing companies across the country. If this is mercantilism, it is mercantilism gone mad.

In recent history, Brexit represents the only comparable act of economic self-harm. But the fallout from the U.K.’s vote, in 2016, to withdraw from the European Union was largely limited to its own inhabitants. This is different. Since the Second World War ended, the U.S. has been the global economic hegemon. While acting in its own interest, sometimes ruthlessly, it has taken the view that promoting international trade and development will ultimately benefit Americans as well as people overseas. The Trump Administration has now formally abandoned this leadership role as a champion of open trade, but it hasn’t stopped there. At least in the short run, it has committed to a policy of inflicting damage not only on itself but on the rest of the world, too, including some of the poorest countries. That’s bad in its own right, but it’s also bad for business. No wonder markets everywhere are tumbling.

23 notes

·

View notes

Note

I was born/raised in America but culturally I’m Trinidadian! Trinidad is a very tiny island in the Caribbean with a huge oil industry 🇹🇹🇹🇹🇹🇹

Our language is english (we only got independence from the British in 1962 rip) but a lot of our television is in Spanish bc we’re so close to Venezuela to the point where you could see it from the island (and my grandparents used to take a small boat there to do shopping XDDD)

Our food is a hodgepodge of lots of different cultures, primarily Indian and African (tho idk specific countries). We also invented the steel pan and have Carnival and Borough Day, two HUGE celebrations

Nicki Minaj is from there and I think Cardi B’s mom?

We have a couple legends and myths:

La Diablesse is a woman who walks at the side of the road at night, her human foot on the pavement and her hoof in the grass, and lures men into the forest (tho only unfaithful men are enchanted by her and follow). Then she disappears and they basically run around lost until they meet their demise

Douens are spirits of children who died before baptism. Their feet are backwards, and if they hear a child’s name, they call it, luring the kid into the forest. Very mischievous and they wear large hats that cover their face, or well a lack therof XDDD

When it comes to myths, we have this thing called “Maljo”. Caused by envy but the way I always knew it was like if you excessively compliment something then you accidentally inflict that thing with Maljo, basically cursing it. My mom had a type of beaded bracelet around her wrist when she was little to sorta ward it off

Lastly, this isn’t common anymore, but my grandparents’ generation has two names. Their public name and the actual name they have which is used at home iirc. It’s like this so it’s harder for ppl with bad intentions to curse you as they only have your public name, not your real one

We have more, all of which are a mix of the different cultures that were brought or came here, but these are the ones I grew up hearing about most and this is already too long so XDDD

I’m always excited to talk abt my culture, so thank the asker for suggesting this and you for indulging! I love your posts !!!🧡🧡🧡

ahh so many facts about Trinidad, thank you!!! <3 The custom of carrying two names as a way to prevent curses is very clever. We sort of have something like that in some (*not all afaik) Indigenous cultures here in Canada, where you have the name you're known by to friends and family, but you can also have a spirit name that follows you from life to life, and this name is typically something that has to come to you as a sort of 'reminder' of your past lives, if that makes sense (i.e. it's not something you can willingly choose or be given). AFAIK tho it doesn't prevent curses LOL but that's another fun fact I was reminded of reading this in exchange for a lot of great ones, tysm again!!!

Also La Diablesse and Douens sound delightfully terrifying ╭( ・ㅂ・)و

30 notes

·

View notes

Note

2, 3, 9!

2. Did you reread anything? What?

I actually did reread a lot this year (for me)

The Priory of the Orange by Samantha Shannon - I reread this as a buddy read with my homie @nataliving who hadn't read it before. It was fun going back after reading A Day of Fallen Night last year. I think overall Priory on a second run meant the pacing issues stuck out to me more, but I was delighted to find that my favorite parts of the book still held up really well.

A Night in the Lonesome October by Roger Zelazny - reread this advent calendar style for the second year in a row. This time got @holdsteady to join me. Super fun, highly recommend this for anyone who wants to read something Halloweeny and fun next October.

Stranger Things Happen and Magic for Beginners by Kelly Link - this was a big Kelly Link year for me. I re-read these two short story collections as well as reading her other two collections for the first time. I'm basically caught up except for The Book of Love. Anyway - there were a few stories in Stranger Things Happen that I really liked, but overall Magic for Beginners hit way better for me

The Blacktongue Thief by Christopher Buehlman - reread this in anticipation of the prequel, The Daughters War, being released. Probably the first book I've ever genuinely been able to call a comfort read. Loved it even more on a re-read.

Whipping Girl by Julia Serano - re-read this when the new edition came out. As vital as ever, able to present things in a very approachable way, it's a foundational and highly recommended intro to transfeminism for a reason, I think everyone should read it at least once.

The Golden Enclaves by Naomi Novik - also reread this with @nataliving. It's my favorite Scholomance book, I wanted to be keeping pace with them while they got to all my favorite parts. Super fun to buddy-read this, I truly love this book.

3. What were your top five books of the year?

okay not counting re-reads

Penance by Eliza Clark - this is a fake true crime book. a book about toxic relationships between girls, a book about true crime fandom, a book about the true crime industry, a book about bias and journalistic ethics and perhaps most importantly a book about TUMBLR a decade ago. Also the most brutal and realistic portrayal of bullying between girls i've ever read. Could NOT put this down.

A Tide of Black Steel by Anthony Ryan - another book in the world of the Covenant of Steel series, which I read and loved last year. Just really good fantasy, I've become such a fan of Anthony Ryan. Love how he writes women and gay people and magic and sword fights! Been patiently working my way through his books, waiting for when I'd get a queer woman out of him and the answer is NOW! Thera, my hyper-competent bisexual viking babe. Love of my life.

The Daughters' War by Christopher Buehlman - as mentioned above I really loved The Blacktongue Thief. My main critique when I first read it was that I wish it had more Galva and then BAM Buehlman announces a prequel from Galva's POV. It's basically a war memoir, Buehlman really gets to show off his horror chops here, which is always a plus for me. Loved it, read it once on audio and then again in print, both versions are great but the narrator was really strong, added a lot.

The Jasmine Throne and The Oleander Sword by Tasha Suri - okay counting these as one entry bc they're part of the same series and I read them pretty close together. EXTREMELY COOL FANTASY SETTING. Indian-inspired, cool mythology, cool magic, lots of intrigue and court politics and some of the best women-vs-misogyny i've ever read in a fantasy book. ALSO a lovers-to-enemies lesbian relationship that made me fully feral. Some of the best pacing I've ever read in 500 - 600 page books, absolutely propulsive, literally no part of these books dragged for me which is WILD.

White Cat, Black Dog by Kelly Link - as mentioned above, it's a big Kelly Link year for me! White Cat, Black Dog might be the strongest collection I read from her this year. There was only one story I didn't really care for. Link is so incredibly talented - her style is so whimsical, but there's always this brilliant, vulnerable emotional honesty to her work. Look, I won't lie, sometimes she's a little hard to follow and I can't say I understand everything I read from her but the way I don't get it STILL feels satisfying somehow. It's a good tension! If you're interested in trying a story from this collection, you can read one of my favorites, The Girl Who Didn't Know Fear for free via Tin House

9. Did you get into any new genres?

Not really! Okay, wait, no, that's a lie. I read some history this year, which I don't usually do. The Devil in the White City by Erik Larson, The Wager by David Grann, The Medici by Paul Strathern. Cool, interesting stuff! Good texture for my reading list!

9 notes

·

View notes

Text

Tata Steel Unveils Ambitious Expansion Plan for India

Steel Giant Aims to Double Domestic Capacity While Focusing on Sustainability Tata Steel’s growth strategy targets 40 MTPA production in India, emphasizing eco-friendly practices and supporting affected UK workers. JAMSHEDPUR – Tata Steel announced plans to double its manufacturing capacity in India to approximately 40 million tonnes per annum (MTPA), signaling a major shift in its global…

#बिजनेस#business#corporate sustainability goals#global steel market#Indian Steel Industry#industrial workforce development#Jamshedpur industrial growth#job transitions in manufacturing#low-emission steel production#Port Talbot modernization#sustainability in steelmaking#Tata Steel Expansion

0 notes

Text

SSMB is India's premier magazine promoting steel in construction, offering insights, trends, and technical advancements. Reach 50,000+ professionals and boost your brand in the fast-growing steel construction sector.

#Steel Structures#Metal Buildings#SSMB Magazine#Indian construction#steel construction#Build with Steel#industry trends#construction magazine#steel industry India

0 notes

Text

TRAINWORKS

The history of the Liège steel industry goes back further than the birth of Belgium in 1830. In 1817, the Englishman John Cockerill founded his first steelworks in Seraing to produce the steel for his looms. In the following decades, the steel industry develops to its peak, until it takes its first hits in the early 1980s. The majority of the steel activity in Liège and Charleroi is then brought together in Cockerill Sambre. Several blast furnaces, coking plants, coal mines, hot and cold rolling mills, factories for processing blast furnace slag,... dominated the Walloon economy for almost 200 years.

Various mergers and acquisitions attempted to revive the declining steel industry. When the Indian steel giant Mittal came on the scene in 2006 and took over Arcelor to form ArcelorMittal, the end was near. Numerous layoffs and austerity measures followed, much to the dismay of workers and unions. In 2013, after years of social unrest and negotiations, the curtain finally fell on the Liège steel industry. Some companies are still being placed "under cocoon", with the prospect of a potential restart, which unfortunately never comes...

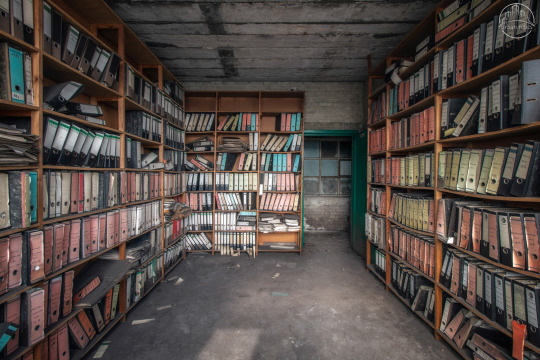

This site contains the administrative buildings, where the main administration of the steel company was located. The main building still contains a number of beautifully dilapidated offices and archives.

Apart from the administrative wing, there is also a large part of the site where there is a workshop where the company's trains were maintained and repaired. This part was mostly emptied.

#urban exploration#urbex#abandoned#urban relics#decay#derelict#abandoned places#ue#photography#urbanexploration#steel industry#industrial#industry#urbexpeople#urbexplaces#urbexworld#urbexphotography#belgium#arcelormittal#liege

98 notes

·

View notes

Text

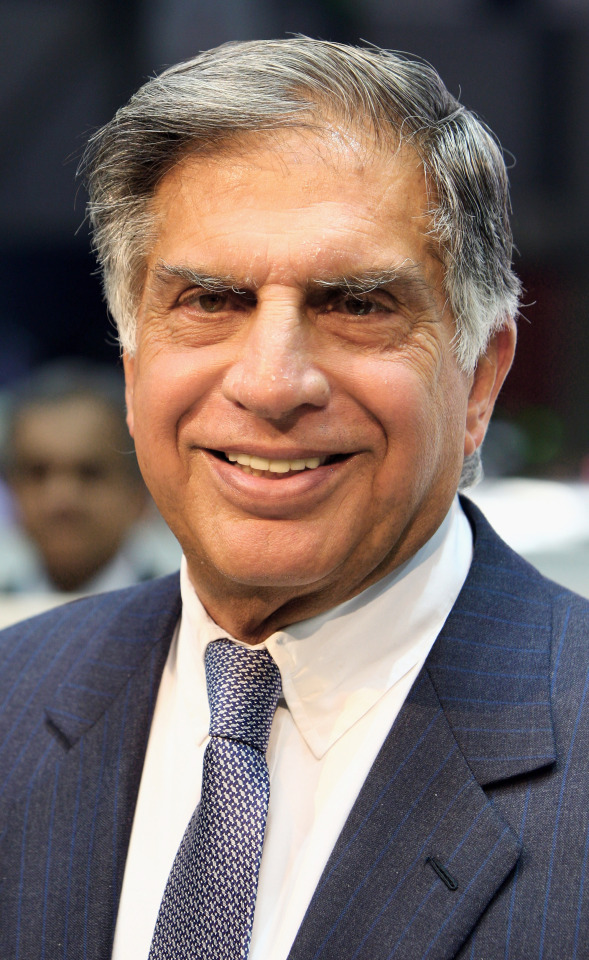

Ratan Tata

Indian business tycoon who turned his family’s Tata Group into a global player, and invested heavily in British industry

Ratan Tata, who has died aged 86, was India’s most celebrated industrialist. He modernised the unwieldy business empire founded by his great grandfather in the 19th century and internationalised it. In the process he spread his interests into western countries, with mixed results.

For the UK, that included the £271m purchase of the Tetley Group in 2000, followed more controversially by the acquisition of the steel company Corus for £6.2bn in 2007. Then, in 2008, Tata, himself a car enthusiast, added the troubled Jaguar Land Rover motor business for a further £1.75bn.

He joined the family firm, Tata Steel, in 1962. Educated in the US, and newly qualified as an architect, the young Tata had, he said, no intention of returning to India. But family ties won out. When his ailing grandmother, Navajbai, who had raised him, asked him to return he did so. He was soon promoted, building his reputation with tough reorganisation, followed by more troubleshooting at the electronics and textile companies.

In 1981, he was made chairman of Tata Industries, and found himself confronting an assortment of separate businesses, with different ownership patterns over which there was little formal control. He made a blueprint for reorganisation, having spent time at the Harvard Business School, but it was rejected after opposition from semi-autonomous bosses.

However, in 1991, the 81-year-old patriarch of the group, JRD Tata, chose him as his successor as the overall chairman. Asked why, he replied: “He has a modern mind.”

Tata soon demonstrated it with a tough programme of reshaping that, against continuing opposition, brought closures, job reductions, and the departure of the heads of the steel, hotel and chemical businesses.

He began to focus more on brands and less on heavy industry, and he benefited from the deregulation of Indian industry championed by Rajiv Gandhi. As part of it, he took the company more heavily into the motor industry. Tata lorries already dominated Indian highways, but now he moved into the car business in line with his own enthusiasms. While always seen as a man of modest habits, he had his own lovingly maintained collection of high-powered and classic cars, and delighted in driving them along Mumbai’s Marine Drive most Sundays.

Tata produced what was called “the first Indian car”, designed by and for Indians, in 1998. Ratan did some of the first drawings himself. The Tata Indica was a success. But when he went further a decade later, and the company conceived the Nano, a tiny saloon described as the world’s most affordable car at a price of about £2,000, the project failed. Such a cheap car was not enticing even to those “on two wheels” whom he hoped to attract.

In 1999 Tata had travelled to Detroit to discuss the sale of the motor business to Ford, only to be asked why his firm had gone into the passenger car business when it clearly knew nothing about it. Later he would turn the tables, buying underperforming Jaguar Land Rover from Ford and reviving it.

With sell-offs and cutbacks, Tata reorganised the group into 98 operating companies from more than 250, reducing the labour force by more than a third. He forged alliances with foreign companies and went into information technology.

He stepped down in 2012, observing the compulsory retirement rule he had himself introduced, but was still regarded as “chairman emeritus” and was brought back unhappily for a few months when his successor was sacked four years later.

His most shocking day came in 2008, when terrorists took over the Tatas’ Taj Mahal hotel on the front at Mumbai with great loss of life. The company has continued to support staff affected and the families of those who died.

Ratan was born in Mumbai, into the large Parsi Tata family, whose wealth came from a scattered collection of businesses including textiles, hotels, engineering, steel and tea. His father, Naval, had been adopted by the son of the founder, Jamsetji Tata. After Naval and his wife, Soonoo, separated when Ratan was seven, the child was brought up with his younger brother, Jimmy, by his grandmother in a grand Tata mansion in central Mumbai.

Aged 17 he was sent to the US to attend Riverdale Country school in New York City, from where he entered Cornell University in Ithaca, New York. He studied engineering before switching to architecture, graduating in 1959. He worked as an architect for a while in Los Angeles before returning to India, and Tata Steel.

In his 20 years at the helm, Tata’s sales grew by 22% annually and its international revenues rose from a quarter to 58% of the total, while Tata Consultancy Services became Asia’s largest software company.

His British investments have been among his less successful. Corus was bought for an over-the-top £6bn just before the global financial crash devastated the industry. Tata claimed it as “the first big step that Indian industry has taken as a global player”. It was later described by a senior Tata executive as “worthless”. The firm is currently negotiating terms of new investment at Port Talbot, which would be accompanied by hundreds of redundancies, while huge plants on Teesside and Scunthorpe have already been closed or sold for a nominal sum.

Jaguar Land Rover was initially a happier story. Tata’s major investment, including in research and development, made the company for a while the largest foreign investor in British industry. But eight years of profits have been followed by losses since 2018.

Surveying the British scene in 2011, Tata told the Times: “Nobody seems to want to exert the effort to make the UK truly competitive. It’s a work ethic issue. In my experience in both Corus and JLR, nobody is willing to go the extra mile.”

He was a major figure in the international business community, close to US politicians as well as the Indian government, advising the former prime ministers Gordon Brown and David Cameron, and sitting on the boards of multinational institutions.

He was also known as a major philanthropist. Many of the Tata companies were owned through trusts he chaired, and huge sums were provided for medical research and university projects both in India and abroad, particularly in the US, where a number of campuses have buildings bearing his name.

A softly spoken man, renowned for his courtesy, he never married, although he described himself as having come close four times. He was known for living modestly, although his recreations included flying his private jet and driving his collection of expensive cars, as well as a speedboat. He was noted for his love of dogs. The Tata headquarters in Mumbai had kennels and made provision for street dogs, and he was a donor to canine charities. In 2014 he was made GBE.

He is survived by Jimmy, by his stepmother, Simone, a half brother, Noel, and two half sisters, Shireen and Deanna.

🔔 Ratan Tata, businessman, born 28 December 1937; died 9 October 2024

Daily inspiration. Discover more photos at Just for Books…?

6 notes

·

View notes

Text

Gulf migration is not just a major phenomenon in Kerala; north Indian states also see massive migration to the Gulf. Uttar Pradesh and Bihar accounted for the biggest share (30% and 15%) of all Indian workers migrating to GCC1 countries in 2016-17 (Khan 2023)—a trend which continues today. Remittances from the Gulf have brought about significant growth in Bihar’s economy (Khan 2023)—as part of a migrant’s family, I have observed a tangible shift in the quality of life, education, houses, and so on, in Siwan. In Bihar, three districts—Siwan, Gopalganj, and Chapra—send the majority of Gulf migrants from the state, mostly for manual labor (Khan 2023). Bihar also sees internal migration of daily wagers to Delhi, Bombay, and other parts of India. Gulf migration from India’s northern regions, like elsewhere in India, began after the oil boom in the 1970s. Before this time, migration was limited to a few places such as Assam, Calcutta, Bokaro, and Barauni—my own grandfather worked in the Bokaro steel factory.

Despite the role of Gulf migration and internal migration in north Indian regions, we see a representational void in popular culture. Bollywood films on migration largely use rural settings, focussing on people who work in the USA, Europe, or Canada. The narratives centre these migrants’ love for the land and use dialogue such as ‘mitti ki khusbu‘ (fragrance of homeland). Few Bollywood films, like Dor and Silvat, portray internal migration and Gulf migration. While Bollywood films frequently centre diasporic experiences such as Gujaratis in the USA and Punjabis in Canada, they fail in portraying Bihari migrants, be they indentured labourers in the diaspora, daily wagers in Bengal, or Gulf migrants. The regional Bhojpuri film industry fares no better in this regard. ‘A good chunk of the budget is spent on songs since Bhojpuri songs have an even larger viewership that goes beyond the Bhojpuri-speaking public’, notes Ahmed (2022), marking a context where there is little purchase for Gulf migration to be used as a reference to narrate human stories of longing, sacrifice, and family.

One reason for this biased representation of migration is that we see ‘migration’ as a monolith. In academic discourse, too, migration is often depicted as a commonplace phenomenon, but I believe it is crucial to make nuanced distinctions in the usage of the terms ‘migration’ and ‘migrant’. The term ‘migration’ is a broad umbrella term that may oversimplify the diverse experiences within this category. My specific concern is about Gulf migrants, as their migration often occurs under challenging circumstances. For individuals from my region, heading to the Gulf is typically a last resort. This kind of migration leads to many difficulties, especially when it distances migrants from their family for much of their lifetime. The term ‘migration’, therefore, inadequately captures the profound differences between, for instance, migrating to the USA for educational purposes and migrating to the Gulf for labour jobs. Bihar has a rich history of migration, dating back to the era of indentured labor known as girmitiya. Following the abolition of slavery in 1883, colonial powers engaged in the recruitment of laborers for their other colonies through agreements (Jha 2019). Girmitiya distinguishes itself from the migration. People who are going to the Arabian Gulf as blue-collar labourers are also called ‘Gulf migrants’—a term that erases how their conditions are very close to slavery. This is why, as a son who rarely saw his father, I prefer to call myself a ‘victim of migration’ rather than just a ‘part of migration’. It is this sense of victimhood and lack of control over one’s life that I saw missing in Bollywood and Bhojpuri cinema.

— Watching 'Malabari Films' in Bihar: Gulf Migration and Transregional Connections

#bhojpuri indentured history#malayalam cinema#bihari labour migration#gulf migrant labour#malayali labour migration#bollywood cinema#bhojpuri cinema#nehal ahmed

23 notes

·

View notes

Text

Carbon Pipe Fittings : Astm A234 WPB Pipe Fittings Manufacturers

Introduction:

ASTM A234 WPB pipe fittings, also known as carbon steel pipe fittings, have largely become standard parts in many industries. The fitting elements will be used to adapt straight pipe or tubing sections, to maintain different size or shape, and to control the rate of flow of liquids.

Always resistant to strength and versatile, ASTM A234 WPB fittings play a critical role in industries dealing with oil, gas, petrochemicals, and power generation.

What are ASTM A234 WPB Pipe Fittings?

They are used to connect pipes in shapes such as elbows, tees, reducers, and caps. The prime factors that make the use of these fittings highly prevalent are their excellent mechanical properties, like high tensile strength and resistance to corrosion. They are very important in ensuring the integrity and efficiency of piping systems across industries.

Manilaxmi Industrial also supplies Carbon ASTM Pipe Fittings around the globe.

Real-Time Advancements in Industries

Ranging from new manufacturing technologies and materials science to improved performance and reliability, these fittings have carved out a niche in use. Applications of the ASTM A234 WPB carbon steel pipe fitting have greatly improved in the industrial sector.For example, refined heat treatment processes leave behind fittings that are easier to manipulate and work under higher pressure and temperature conditions.

Besides, numerous coating and lining innovations provide improved corrosion resistance and give extended life expectancy.

Manilaxmi Industrial the Indian manufacturers, suppliers, and exporters have been among the most active adopters of these developments to ensure that the country is retained as a main supplier of quality pipe fittings in the global market.

Technology and Need in Various Countries

Demands for ASTM A234 WPB carbon steel pipe fittings are ever-increasing in the global scenario. This demand has been hastened further by the requirement of strong, efficient piping systems in the developing countries and renovated or rejuvenated ones in the developed nations.

Such as setting up power plants and oil refineries. In contrast, developed nations always require update works and servicing of already existing facilities. Equipped with state-of-the-art technology in the manufacturing process, these fittings comply with strict standards that make them very important and cardinal for maintaining efficiency and safety during industrial operations.

Conclusion

In conclusion, ASTM A234 WPB pipe fittings are the most essential material in the industrial market, possessing qualities of high durability, adaptability, and tolerance toward extreme situations. With relentless development in the manufacturing technologies, further improvements are made in their performances, making them trustworthy for different applications.

#innovation#management#technology#metalfabrication#metalwork#supplychain#manufacturers#exporters#suppliers

9 notes

·

View notes