#Gaskets Sheet

Explore tagged Tumblr posts

Text

#Pipe Fitting#Camlock Coupling#Gaskets#Gaskets Sheet#Valves#Couplings#Hydraulic Hose Fitting#industrial grooved fitting suppliers in uae

0 notes

Text

Silicone Sheets- The Versatile Solution for Industrial and Commercial Applications

Silicone sheets have emerged as a highly versatile material in various industries due to their exceptional physical and chemical properties. From industrial sealing to healthcare solutions, silicone sheets offer unparalleled benefits like heat resistance, flexibility, and durability. Their adaptability makes them an essential component in automotive, aerospace, electronics, and food-grade…

#Gasket Material#Gasket Sheet#Silicone Sheets#Silicone Sheets for Industrial and Commercial Applications

2 notes

·

View notes

Text

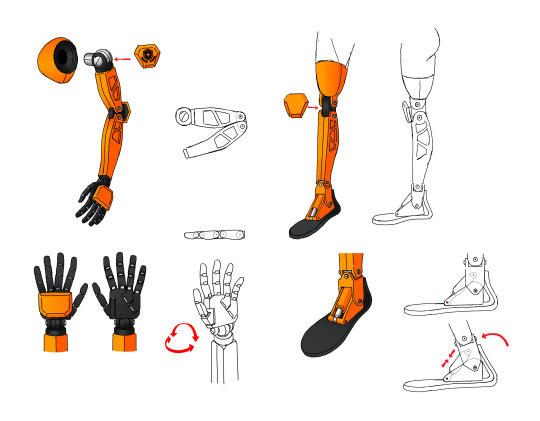

i made some revisions to Gasket's design and figured i should update his ref sheet. so, without further ado, here's version 2!

#furry#furry art#furry oc#sfw furry#cyberpunk#cyberpunk oc#hare#rabbit#ref sheet#reference sheet#character sheet#jam's art#oc#ocs#gasket

11 notes

·

View notes

Text

What to Consider When Choosing Your Gasket Material and Type

A gasket may be a combination of materials, which is employed to stop any fluid entry between two static components. The success of the industrial gasket and materials depends on the sort of fabric utilized in the manufacturing process. counting on the sort of application, a spread of materials are wont to produce gaskets of…

A gasket may be a combination of materials, which is employed to stop any fluid entry between two static components. The success of the industrial gasket and materials depends on the sort of fabric utilized in the manufacturing process. counting on the sort of application, a spread of materials are wont to produce gaskets of the many shapes and sizes. Gaskets also are chosen supported factors like application temperature, pressure, electrical conduciveness, and resistance to extreme environments.

Types of Gasket Materials

While the materials wont to produce gaskets are numerous, on a general basis, they will be segregated into 3 types:

Fibrous materials

Elastometric materials

Metallic materials

Fibrous materials: These materials are made using organic fibers. The gasket sheet is skilled as a binding solution to assist develop the gasket material. they need excellent absorption properties and are flexible enough to be made into various shapes. Some common samples of fibrous gasket materials are:

Asbestos– In fibrous materials, asbestos is perhaps the foremost recognizable and popular material. It is often used for sealing applications during a sort of environment. Asbestos maintains its shape and strength up to 450oF. It doesn’t emit any toxic odor and is safe to handle.

Carbon fibers- As a cloth, carbon fiber has the power to face up harsh chemical environments. It is often used for applications that have high temperatures and pressures. it’s seen as a perfect material because of its low permeability. However, it’s not suitable for oxidization.

Aramid- An artificial fiber, aramid has been used as a substitute for asbestos. it’s a high resistance towards heat and organic solvents. Though it doesn’t have a freezing point, it does tend to degrade when temperatures reach 500oC. However, it doesn’t react well to salts and acids, also as direct contact with UV rays.

Elastometric materials: because the name suggests, these materials are produced using elastomers with various composites. This makes them extremely popular materials for a spread of industries thanks to their high performance and quality. a couple of well-known elastomers are given below:

Silicone- Perhaps the foremost recognized material for gaskets, silicone is well-known for its waterproof properties. It works effectively in extreme temperatures and is immune to UV and ozone elements. Silicone is often easily molded or cut using water jet cutting systems counting on the sort of application.

Rubber- As an organic material, natural rubber has good resistance to heat, and functions wells as a cushioning pad. When utilized in gaskets, it can recover to its original shape from medium temperatures. It is often wont to protect gaskets from alkalis, mild acids, and inorganic salts.

Neoprene- this will be used as an appropriate option for rubber. The advantage that neoprene has is that while it’s almost like rubber in terms of its resistance to acids and alkalis, it also can work against oils, petroleum, and other fuels. However, it’s not recommended to be used against hydrocarbons.

Metallic materials: Usually, the various sorts of metals wont to produce gaskets are a variety of steels, alloys, titanium, copper, and aluminum.

Carbon Steel– this is often one of the favored metallic choices for gaskets. The larger the quantity of carbon within the alloy, the harder and stronger it becomes. Unfortunately, the carbon content has got to be balanced with other metal properties otherwise it can lower the general freezing point.

Aluminum– Aluminum is understood for its lightweight, machinability, and high resistance to corrosion. Aluminum alloys are an honest choice for gaskets thanks to their weldability and strength.

Titanium– Considered to be almost like 304 chrome steel, titanium is understood for its lightweight, strength, and corrosion resistance. It is often used for very high temperatures, and it’s perfect for oxidizing media.

An understanding of the varied sorts of gasket materials used can assist you to decide the proper type to use in your industrial application.

Original Source: Industrial Gaskets

#gaskets#industrial#gasket material#gasket sheet#Asbestos Gaskets#Gasket Material#Rubber Gasket Sheet#Ready Cut Gaskets#Industrial Gaskets

2 notes

·

View notes

Text

Misconceptions About PTFE Sheets

Misconception 1: PTFE Sheets at High Temperatures Are Unsafe The Truth: PTFE sheets are highly resistant to extreme heat, withstanding temperature ranges from -200°C to +260°C. This exceptional thermal stability makes them the choice materials for high temperature environments such as chemical plants, electrical insulation and food processing equipment. Also not prone to degradation or toxic release under high temperatures, unlike many plastics, PTFE conforms to strict standard of safety.

Misconception 2: PTFE Sheets Are Not Environmentally Friendly The Truth: PTFE sheets are chemically non-reactive, meaning they do not react or degrade into harmful substances when used appropriately in chemical environments. Although their production requires some energy consuming processes, the manufacturing has now been made to reduce the environmental footprint. Additionally, the strength and durability of PTFE sheets minimizes the need for frequent replacements, reducing both waste and cost over long periods of time.

Misconception 3: PTFE Sheets Are Only Suitable for High-Tech Industries The Truth: While PTFE sheets excel in high-tech applications like aerospace and electronics, their uses extend to a wide array of diverse industries. PTFE is used from non-stick surfaces on cookwares to gasketing in automotive engines because it is a versatile material used in isolated and commonplace applications.

Misconception 4: PTFE Sheets Are Expensive The Truth: While PTFE sheets might have a higher upfront cost compared to other materials, but it’s a known fact that their superior durability and performance make them a cost-effective choice in the long run. They resist wear and tear, chemical corrosion and extreme temperatures, which means that repairs or replacements are drastically decreased, thus reducing cost.

Misconception 5: PTFE Sheets Are Difficult to Machine or Fabricate The Truth: In truth, PTFE sheets are relatively easy to machine and fabricate using standard tools. Due to their low friction and non-stick properties, they are perfect for custom shapes and application for any industry use cases. With skilled professionals and the right equipment, PTFE sheets can be customized to meet precise industrial requirements.

Ready to experience the unparalleled benefits of PTFE sheets? Spend a few minutes browsing our collection and discover how PTFE Gasket and Sheets can transform your operations. To place enquiry or get expert advice, contact us. Let’s take your business to the next level with PTFE sheets that deliver unmatched performance and reliability.

1 note

·

View note

Text

Key Benefits of Silicone Foam Sheets by Shenzhen Tenchy Silicone And Rubber Co., Ltd.

Shenzhen Tenchy Silicone and Rubber Co., Ltd. offers high-quality silicone foam sheets, known for their excellent durability and flexibility. These silicone foam sheets provide outstanding thermal insulation, vibration damping, and water resistance, making them ideal for a variety of applications in the automotive, electronics, and construction industries. Their lightweight design, combined with high resistance to extreme temperatures, ensures long-lasting performance. Whether for sealing, gasketing, or cushioning, our silicone foam sheets offer reliable protection and efficiency. Choose Shenzhen Tenchy for premium silicone foam sheets tailored to meet your specific needs. For more information, please feel free to contact us today at +86 18129801081 or visit again here: https://shorturl.at/sBZch

#silicone foam sheet#Silicone foam gasket material#Silicone foam insulation sheet#Silicone sponge sheet#Heat-resistant foam sheet

0 notes

Text

PTFE Bridge Bearing Pads, Manufacturer, Mumbai, India

Hindustan Nylons : PTFE Bridge Bearing Pads, PTFE Bridge Bearing Pads manufacturer, CPTFE Bridge Bearing Pads supplier in India. Call us : 9373054560.

#Ptfe Ram Extruded Rods#Ptfe Molded Sheets#PTFE Ram Extruded Pipes#Ptfe Gaskets#Ptfe Wear Strips / Bands#Ptfe Molded Rods#Ptfe Molded Bush#Ptfe Skived Sheets#Ptfe Paste Extruded Tubings#Ptfe Bellows / Expansion Joints#PTFE Valve Components#Ptfe Bridge Bearing Pads#Trexonn Machine Tool Slideway Liners#Chemically Treated Ptfe Parts#PTFE O Rings#Vedge Rings#V Rings#D Rings#PTFE Customised Profiles#PTFE And BR40 Guide Tapes#Filled Grade PTFE Rods#Turcite Products#Turcite Rods#Turcite Bushes#Turcite Sheets#Turcite Machined Components#Boiler Rings#Filled Grade PTFE - All Grades#Satara#Sangli

0 notes

Text

PTFE Stamped and Turned Parts Components Supplier from India

Rubber Gaskets for Sealing and Teflon Components supplier from India, specializing in PTFE Stamped (Sheet) and Turned Parts (Rod)

#Rubber Gaskets for Sealing and Teflon Components supplier from India#PTFE Stamped(Sheet) and Turned Parts( Rod) components supplier from India

0 notes

Text

Sealing Solutions Redefined- Exploring Gaskets, Materials, and the Innovation of Silicone Sheets

In the intricate machinery of various industries, the humble gasket stands as a guardian, ensuring tight seals and preventing leaks that could disrupt operations. At the heart of these sealing solutions lie carefully selected materials, each chosen for its unique properties and suitability for specific applications. Among these materials, silicone sheets have emerged as a versatile option,…

View On WordPress

2 notes

·

View notes

Text

excited to finally unveil what i've been working on—a brand new ref sheet for Gasket! i worked REALLY hard on this for over a month and it took a lot of hours, and i'm really pleased with the result!

#furry#furry art#furry oc#sfw furry#cyberpunk#cyberpunk oc#hare#rabbit#ref sheet#reference sheet#character sheet#jam's art#oc#ocs#gasket

19 notes

·

View notes

Text

Silicone Sheets

Silicone Sheets- The Versatile Solution for Industrial and Commercial Applications

0 notes

Text

Silicon Rubber Gaskets: A Game-Changer for Industrial Applications

Versatility of Silicon Rubber

The versatility of silicon rubber is due to the chemical structure that provides many advantageous characteristics.

Chemical Resistance: The most recognizable features of rubber include enhanced resistance to chemicals, in particular, chemicals that are used in industrial processes. Silicon rubber gaskets can withstand exposure to a wide array of chemicals and solvents, making them ideal for use in harsh industrial environments. It remains astonishing how this resistance includes not only common organic solvents but also acids and bases, thus preserving seal integrity in severe chemical applications such as processing.

Heat Resistance: Heat endurance is another advantageous feature possessed by silicon rubber. It remains flexible and can seal tightly from cryogenic temperatures down to as low as -100°C (-148°F) to temperatures as high as 300°C (572°F). This wide operating range makes silicon rubber gaskets suitable for diverse applications, from refrigeration systems to high-temperature industrial ovens.

Extreme Conditions: In addition, silicon rubber also shows good resistance to weather conditions. It is resistant to UV, ozone, and moisture for extended periods without noticeable fade, crack, or peel. This durability ensures that silicon rubber gaskets maintain their performance and appearance even in outdoor or harsh environmental conditions, contributing to their long service life and reliability in various industrial settings.

Applications of Silicon Rubber Gaskets

The automotive industry extensively utilizes silicon rubber gaskets due to their ability to withstand high temperatures and resist automotive fluids. They are commonly found in engine seals, transmission systems and fuel delivery part. The fact that the material is resistant to oil, fuel or coolants readily explains why it provides robust protection to critical automotive systems.

In industrial processes, silicon rubber gaskets play a crucial role in ensuring the safety and efficiency of operations. These are used mostly in chemical processing plants, where chemical resistance of the material is very much required. In food processing applications, FDA-approved silicon rubber gaskets provide a safe and hygienic sealing solution. The electronics industry also gets to use the properties of silicon rubber through these gaskets in enclosures and connectors to shield sensitive components from the climate.

Specialized applications further demonstrate the versatility of silicon rubber gaskets. They are used in aircraft engines and for pressurizing cabins, as they are suitable for fluctuating high temperatures. Medical devices rely on biocompatible silicon rubber gaskets for sealing in equipment such as dialysis machines and surgical instruments, where cleanliness and chemical inertness are essential.

Takeaway

Silicon rubber gaskets offer a compelling combination of versatility, durability, and performance that makes them an excellent choice for a wide range of industrial applications. It has high chemical, thermal, and environmental endurance which makes it a material that can greatly improve the reliability and performance of industrial products. As industrial business owners seek to optimize their operations and reduce downtime, the adoption of silicon rubber gaskets presents a clear opportunity for improvement. To explore how rubber gasket sheet can benefit your specific industrial applications, we encourage you to reach out to a reputable Gasket Manufacturer and Supplier who can provide expert guidance tailored to your unique needs.

0 notes

Text

Mica Gasket

Mica Gasket

Mica gasket has good mechanical strength and electrical performance at normal conditions, with high temperature resistance and excellent thermal insulation performance and anti-sticking performance. Mica gasket sheet material is composited from double-sided fiber reinforced mica facing and stainless steel metal core. wherein the mica seal layer is composed of expanded mica, high temperature resistance fiber and high grade binder. Recommend use for high temperature exhaust vents, turbochargers sealing applications, as well as to be the insulation pad for electrical appliances, welding machines, lightning arresters and electric heating elements.

Features of Mica Gasket

Heat Resistance: Mica Gaskets are known for their exceptional heat resistance. They can withstand temperatures up to 1000 degrees Celsius, making them ideal for high-temperature applications.

Insulating Properties: Mica, the material from which these gaskets are made, is a naturally occurring mineral with excellent insulating properties. This makes Mica Gaskets perfect for applications requiring electrical or thermal insulation.

Non-Flammable: Mica Gaskets are non-flammable, adding an extra layer of safety in applications involving high heat or fire risk.

Chemical Inertness: Mica Gaskets are chemically inert, meaning they do not react with most chemicals. This makes them suitable for use in various industrial applications.

Mechanical Strength: Despite their flexibility, Mica Gaskets have good mechanical strength and can resist pressure well.

Versatility: Mica Gaskets are flexible and can be cut into various shapes and sizes, making them adaptable to a wide range of sealing and insulation applications.

Applications of Mica Gasket

Designed to meet the diverse needs of the transportation, construction machinery, agricultural machinery, and various industrial equipment industries, Teamful mica gaskets offer unparalleled performance and reliability.

Experience the benefits of our mica gaskets. With excellent electrical insulation properties and resistance to high temperatures, our gaskets ensure a secure and reliable seal, preventing leaks and minimizing downtime. The unique properties of mica make it an ideal choice for applications that require both electrical insulation and heat resistance. Our mica gaskets are suitable for a wide range of applications. From engines and exhaust systems to hydraulic systems and electrical components, our gaskets provide a reliable seal in various equipment and machinery.

Choose our mica gaskets for their superior quality, durability, and performance. Our commitment to OEM standards ensures that you receive the highest quality products that meet your specific requirements.

Contact us now to learn more about our mica gaskets and how they can revolutionize your sealing needs.

0 notes

Text

Exploring the Benefits and Applications of Silicone Rubber Sheets

Silicone rubber sheets are a versatile and high-performance material widely used across various industries due to their unique properties. Renowned for their flexibility, temperature resistance, and durability, these sheets provide reliable solutions in demanding environments. From sealing and insulation to protective applications, silicone rubber sheets have become indispensable in industries…

#Industrial Gaskets#PTFE Sheet#PTFE Sheets#Rubber Gasket Sheet#Silicone Rubber Sheets#Silicone Sheets#Teflon Sheets

0 notes