#Gasket Material

Explore tagged Tumblr posts

Text

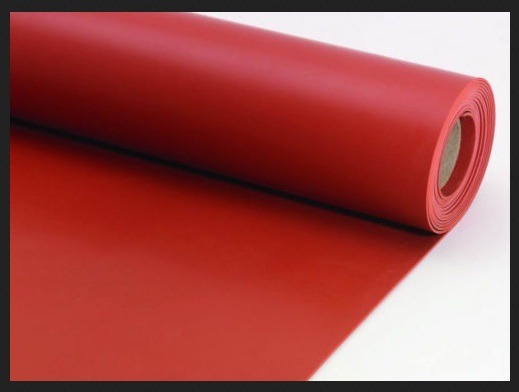

Silicone Sheets- The Versatile Solution for Industrial and Commercial Applications

Silicone sheets have emerged as a highly versatile material in various industries due to their exceptional physical and chemical properties. From industrial sealing to healthcare solutions, silicone sheets offer unparalleled benefits like heat resistance, flexibility, and durability. Their adaptability makes them an essential component in automotive, aerospace, electronics, and food-grade…

#Gasket Material#Gasket Sheet#Silicone Sheets#Silicone Sheets for Industrial and Commercial Applications

2 notes

·

View notes

Text

PTFE tube with PVDF nozzle

Can be customized according to drawings. Please contact me for a quote if required.

3 notes

·

View notes

Text

Top Jointing Sheets Manufacturers – DURASILE Solutions

In the ever-evolving world of industrial manufacturing, reliable sealing solutions are critical to ensuring safety, efficiency, and performance. One name that has emerged as a trusted leader in this space is DURASILE. Renowned for its high-quality products and customer-centric approach, DURASILE has become a preferred choice for industries worldwide. The company has earned its reputation as one of the most reliable Non Asbestos Gasket Sheets Manufacturers, offering advanced solutions for diverse industrial applications.

Setting the Standard as Non Asbestos Gasket Sheets Manufacturers

With increasing environmental awareness and regulations, the demand for non-asbestos products has surged. DURASILE has been at the forefront of this change, providing top-notch sealing solutions as one of the most trusted Non Asbestos Gasket Sheets Manufacturers in the industry. Their non-asbestos gasket sheets are designed to offer superior resistance to heat, pressure, and chemicals, making them ideal for industries like oil & gas, automotive, marine, and chemical processing.

Excellence in Jointing Sheets Manufacturing

DURASILE is also recognized as one of the top Jointing Sheets Manufacturers, producing a wide variety of jointing materials tailored to meet the specific needs of each industry. These jointing sheets are known for their durability, high compressibility, and ability to maintain tight seals even under extreme operating conditions.

Trusted Name Among Gasket Sheets Manufacturers

When it comes to sealing solutions, DURASILE has established itself as a pioneer among Gasket Sheets Manufacturers. Their gasket sheets are used to prevent leaks, ensure safety, and maintain the integrity of various systems in industrial operations. Whether it’s for high-temperature environments or applications requiring chemical resistance, DURASILE’s gasket sheets deliver reliable performance.

Pioneers in Rubberized Cork Sheets Manufacturing

DURASILE also leads the market as one of the most respected Rubberized Cork Sheets Manufacturers. These sheets are a perfect blend of cork and rubber, offering excellent sealing, vibration damping, and noise reduction properties. They are widely used in the automotive and electrical industries for applications requiring flexibility and resilience.

Leading the Market as Millboard Manufacturers

In addition to gasket and jointing sheets, DURASILE is highly regarded as one of the top Millboard Manufacturers. Millboard sheets are essential for thermal insulation and fire protection in industrial settings. DURASILE’s millboards are manufactured using eco-friendly materials and advanced processes to deliver superior insulation and safety.

Conclusion

DURASILE has become synonymous with quality, innovation, and reliability in the sealing solutions industry. As top-tier Non Asbestos Gasket Sheets Manufacturers, Jointing Sheets Manufacturers, Gasket Sheets Manufacturers, Rubberized Cork Sheets Manufacturers, and Millboard Manufacturers, they provide comprehensive solutions that meet the demands of modern industries.

#Jointing Sheet Manufacturers#Gasket Sheets#Non Asbestos Gasket Sheet#Millboard in Uttar Pradesh#Rubberized Cork Sheet#Beater Addition Soft Gasket Material

1 note

·

View note

Text

Expanded PTFE Gasket Material For Flanges

0 notes

Text

Key Benefits of Silicone Foam Sheets by Shenzhen Tenchy Silicone And Rubber Co., Ltd.

Shenzhen Tenchy Silicone and Rubber Co., Ltd. offers high-quality silicone foam sheets, known for their excellent durability and flexibility. These silicone foam sheets provide outstanding thermal insulation, vibration damping, and water resistance, making them ideal for a variety of applications in the automotive, electronics, and construction industries. Their lightweight design, combined with high resistance to extreme temperatures, ensures long-lasting performance. Whether for sealing, gasketing, or cushioning, our silicone foam sheets offer reliable protection and efficiency. Choose Shenzhen Tenchy for premium silicone foam sheets tailored to meet your specific needs. For more information, please feel free to contact us today at +86 18129801081 or visit again here: https://shorturl.at/sBZch

#silicone foam sheet#Silicone foam gasket material#Silicone foam insulation sheet#Silicone sponge sheet#Heat-resistant foam sheet

0 notes

Text

Why Sewer Ejector Pumps Can Fail Sooner.

After conducting a thorough investigation into the premature failure of sewer ejector pumps, several key factors have emerged that explain why these pumps might break down sooner than the manufacturer's warranty period:

Improper Installation.

One of the leading causes of early pump failure is improper installation. If the pump is not installed according to the manufacturer’s specifications—such as incorrect pipe sizing, inadequate venting, or poor alignment—this can cause strain on the motor and moving parts, leading to accelerated wear and tear.

Power Surges and Electrical Issues.

Power surges or fluctuations in the electrical supply can damage sensitive components within the pump, such as the motor or control panel. Even if the surge lasts only a second, it can burn out circuits or compromise the motor's efficiency. Without surge protectors or proper grounding, this can lead to premature failure.

Clogs from Improper Materials. Sewer ejector pumps are designed to handle waste and certain types of debris, but when improper materials—such as feminine hygiene products, wipes labeled as "flushable," or other non-degradable items—are flushed, they can clog or damage the pump. Over time, these clogs can cause the motor to overwork, leading to an early breakdown.

Lack of Regular Maintenance. Routine maintenance is often overlooked. Failing to check and service the pump periodically can result in small issues going unnoticed until they become larger, irreversible problems. Sediment buildup, worn-out seals, or deteriorating gaskets can all contribute to pump failure, especially in areas with hard water where mineral deposits may accumulate.

Overworking the Pump.

Many sewer ejector pumps are not designed to run continuously. If the pump is overworked due to improper sizing, such as being undersized for the household’s waste output or running too frequently, it can result in overheating and breakdown. Ensuring the pump is appropriate for the expected load is essential for longevity.

Environmental Factors.

Harsh environmental conditions such as excessive moisture, flooding, or extreme temperatures can affect the pump’s lifespan. Excessive moisture can cause corrosion of internal components, while extreme cold or heat can affect the motor and seals. Additionally, if the pump is exposed to corrosive chemicals or gases in the sewage, it can degrade faster than expected.

In most cases, premature failure of sewer ejector pumps can be traced to installation errors, misuse, or lack of maintenance. To ensure a pump reaches its full lifespan, it is critical to follow manufacturer guidelines, perform regular maintenance, and avoid flushing materials that can cause clogs. These preventative measures can help avoid costly repairs and ensure the pump functions efficiently for its intended lifespan.

Our local team of plumbing experts at Emergency Plumbing of Highland Park IL is always available to assist you with all your plumbing needs big or small.

Trusted by local communities of North Shore and Northwest suburbs , we are always answer your call and ready to help.

Call us with your plumbing problems. We offer best prices with no hidden fees and quality labor guaranteed !

Phone 224-754-1984

#flushable#Why Sewer Ejector Pumps Can Fail Sooner.#After conducting a thorough investigation into the premature failure of sewer ejector pumps#several key factors have emerged that explain why these pumps might break down sooner than the manufacturer's warranty period:#1. Improper Installation.#One of the leading causes of early pump failure is improper installation. If the pump is not installed according to the manufacturer’s spec#inadequate venting#or poor alignment—this can cause strain on the motor and moving parts#leading to accelerated wear and tear.#2. Power Surges and Electrical Issues.#Power surges or fluctuations in the electrical supply can damage sensitive components within the pump#such as the motor or control panel. Even if the surge lasts only a second#it can burn out circuits or compromise the motor's efficiency. Without surge protectors or proper grounding#this can lead to premature failure.#3. Clogs from Improper Materials.#Sewer ejector pumps are designed to handle waste and certain types of debris#but when improper materials—such as feminine hygiene products#wipes labeled as or other non-degradable items—are flushed#they can clog or damage the pump. Over time#these clogs can cause the motor to overwork#leading to an early breakdown.#4. Lack of Regular Maintenance.#Routine maintenance is often overlooked. Failing to check and service the pump periodically can result in small issues going unnoticed unti#irreversible problems. Sediment buildup#worn-out seals#or deteriorating gaskets can all contribute to pump failure#especially in areas with hard water where mineral deposits may accumulate.#5. Overworking the Pump.#Many sewer ejector pumps are not designed to run continuously. If the pump is overworked due to improper sizing#such as being undersized for the household’s waste output or running too frequently

1 note

·

View note

Text

#As one of the leading Neoprene Rubber Gasket Manufacturers from India#We offer highest quality Neoprene Gaskets made in a wide range of materials and grades in accordance with various international standards.

0 notes

Text

Sealing Solutions Redefined- Exploring Gaskets, Materials, and the Innovation of Silicone Sheets

In the intricate machinery of various industries, the humble gasket stands as a guardian, ensuring tight seals and preventing leaks that could disrupt operations. At the heart of these sealing solutions lie carefully selected materials, each chosen for its unique properties and suitability for specific applications. Among these materials, silicone sheets have emerged as a versatile option,…

View On WordPress

2 notes

·

View notes

Text

Graphite Sheets- The Ultimate Solution for High-Performance Sealing Applications

Graphite sheets are an essential industrial material known for their excellent thermal conductivity, chemical resistance, and flexibility. These sheets are widely used in sealing, insulation, and high-temperature applications across various industries. Their unique properties make them a preferred choice for applications that demand durability and efficiency. Key Features of Graphite…

View On WordPress

0 notes

Text

PCTFE

PCTFE is a high-quality thermoplastic resin with high stability, heat resistance, non-flammability, non-hygroscopicity, air-tightness and inertness. Please contact me for a quote if required. Henan Sixfluorine Chemical Co.,Ltd WhatsApp/Telegram:+(86)15038852660 Mail:[email protected]

1 note

·

View note

Text

Graphite Sheets- The Ultimate Solution for High-Performance Sealing Applications

Graphite sheets are an essential industrial material known for their excellent thermal conductivity, chemical resistance, and flexibility. These sheets are widely used in sealing, insulation, and high-temperature applications across various industries. Their unique properties make them a preferred choice for applications that demand durability and efficiency. Key Features of Graphite…

View On WordPress

0 notes

Text

Graphite Sheets- The Ultimate Solution for High-Performance Sealing Applications

Graphite sheets are an essential industrial material known for their excellent thermal conductivity, chemical resistance, and flexibility. These sheets are widely used in sealing, insulation, and high-temperature applications across various industries. Their unique properties make them a preferred choice for applications that demand durability and efficiency.

Key Features of Graphite Sheets

High-Temperature Resistance: Graphite sheets can withstand extreme temperatures, making them ideal for applications in high-heat environments.

Superior Chemical Resistance: They are resistant to most chemicals, acids, and alkalis, ensuring long-lasting performance in harsh conditions.

Excellent Thermal & Electrical Conductivity: Graphite sheets efficiently transfer heat and electricity, making them valuable in industrial and electronic applications.

Flexibility & Compressibility: Their soft yet strong composition allows them to conform to irregular surfaces, ensuring a tight and effective seal.

Low Friction & Lubrication Properties: Graphite sheets provide self-lubricating properties, reducing wear and tear in dynamic applications.

Applications of Graphite Sheets

Gasket & Sealing Industry: Graphite sheets are widely used in manufacturing gaskets for heat exchangers, pumps, and pipelines.

Electronics & Electrical Industry: Their conductivity makes them ideal for heat dissipation in electronic devices.

Automotive & Aerospace Industry: Used in engine components, brake pads, and exhaust systems due to their high-temperature resistance.

Chemical Processing Plants: Suitable for applications where exposure to aggressive chemicals is common.

Power Generation & Refineries: Graphite sheets play a crucial role in sealing applications in steam turbines, reactors, and fuel cells.

Graphite Sheets from Gasket Materials

If you are looking for premium quality graphite sheets, Gasket Materials offers reliable and high-performance products. Our graphite sheets and graphite foil sheets are designed to withstand extreme conditions, ensuring optimal sealing, insulation, and thermal management solutions for various industries.

Conclusion

Graphite sheets are an indispensable material for industries requiring heat-resistant, chemically stable, and flexible sealing solutions. Their remarkable properties make them the preferred choice for critical industrial applications. Explore the wide range of top-grade graphite sheets at Gasket Materials and find the perfect solution tailored to your business needs.

Original Source: Graphite Sheets

0 notes