#PTFE Sheet

Explore tagged Tumblr posts

Text

Sealing Solutions Redefined- Exploring Gaskets, Materials, and the Innovation of Silicone Sheets

In the intricate machinery of various industries, the humble gasket stands as a guardian, ensuring tight seals and preventing leaks that could disrupt operations. At the heart of these sealing solutions lie carefully selected materials, each chosen for its unique properties and suitability for specific applications. Among these materials, silicone sheets have emerged as a versatile option,…

View On WordPress

2 notes

·

View notes

Text

Boost Industrial Safety & Sealing Performance with PTFE Gaskets

When it comes to ensuring leak-proof operations and industrial safety, PTFE gaskets stand out as a reliable and high-performance sealing solution. Known for their chemical resistance, non-stick properties, and high-temperature endurance, PTFE gaskets are ideal for industries such as chemical processing, pharmaceuticals, food & beverage, and oil & gas.

From PTFE envelope gaskets for aggressive chemical environments to glass-filled PTFE for enhanced strength, these gaskets offer versatile sealing solutions. Whether you’re dealing with high-pressure systems or corrosive fluids, a well-fitted PTFE gasket ensures operational integrity.

🛠️ At Amfico Logistics, we supply premium-grade PTFE gasket solutions tailored to various industrial needs—delivering durability, reliability, and performance where it matters most.

#ptfe gasket#ptfe gasket manufacturers#ptfe envelope gasket#ptfe seal#teflon gasket#ptfe sheet#ptfe gasket suppliers#ptfe gasket applications#industrial sealing solutions#ptfe gaskets india#logistics#amficologistics

1 note

·

View note

Text

At Petron Thermoplast, we offer a wide range of premium PTFE sheets tailored to meet the needs of various industries.

0 notes

Text

Why Choose Expanded PTFE Over Standard PTFE Gaskets?

When it comes to industrial sealing solutions, PTFE gaskets are among the most reliable and versatile options available. However, not all PTFE gaskets are created equal. Standard PTFE gaskets provide excellent chemical resistance and durability, but expanded PTFE (ePTFE) gaskets offer enhanced performance in demanding applications. In this article, we will explore the key differences between PTFE gaskets and expanded PTFE gaskets, highlighting why ePTFE is the superior choice for businesses looking for a long-lasting and efficient sealing solution.

0 notes

Text

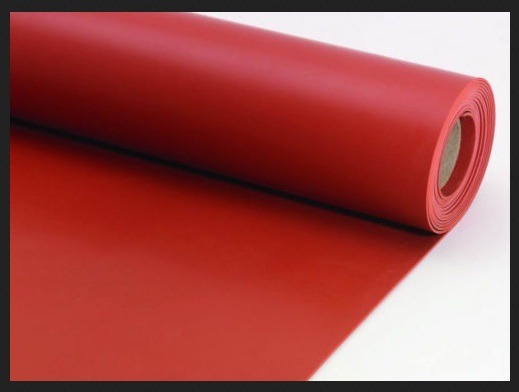

Silicone Rubber Sheets

Exploring the Benefits and Applications of Silicone Rubber Sheets

0 notes

Text

PTFE Stamped and Turned Parts Components Supplier from India

Rubber Gaskets for Sealing and Teflon Components supplier from India, specializing in PTFE Stamped (Sheet) and Turned Parts (Rod)

#Rubber Gaskets for Sealing and Teflon Components supplier from India#PTFE Stamped(Sheet) and Turned Parts( Rod) components supplier from India

0 notes

Text

Exploring the Benefits and Applications of Silicone Rubber Sheets

Silicone rubber sheets are a versatile and high-performance material widely used across various industries due to their unique properties. Renowned for their flexibility, temperature resistance, and durability, these sheets provide reliable solutions in demanding environments. From sealing and insulation to protective applications, silicone rubber sheets have become indispensable in industries…

#Industrial Gaskets#PTFE Sheet#PTFE Sheets#Rubber Gasket Sheet#Silicone Rubber Sheets#Silicone Sheets#Teflon Sheets

0 notes

Text

Buy PTFE Material Products for Industrial Needs

At Petron Thermoplast, we specialize in delivering custom PTFE material products designed to meet the specific demands of our clients. Whether your industry involves extreme temperatures, aggressive chemicals, or the need for low-friction solutions, our PTFE products provide unparalleled performance.

Visit Website - https://petronthermoplast.com/ptfe-sheet/

Contact No. - +91-8218684097

Request for Quotation - [email protected]

#PTFE Sheet#Teflon Sheet#PTFE Plastic Sheets#PTFE Sheet Manufacturer#PTFE Teflon Sheet#PTFE Sheet Supplier#PTFE Parts#PTFE Material

0 notes

Text

Expanded PTFE Gaskets: The Ultimate Solution for High-Performance Sealing

It’s time to upgrade! Expanded PTFE gaskets provide superior sealing, flexibility, and resistance to creep and cold flow. Unlike standard PTFE, ePTFE conforms better to uneven surfaces, ensuring a long-lasting, leak-free seal. Whether in chemical processing, pharmaceuticals, or power plants, ePTFE delivers enhanced performance. Reduce downtime, lower maintenance costs, and improve sealing efficiency with expanded PTFE.

Make the switch today and experience the difference! Contact us to explore high-quality expanded PTFE gaskets for your business.

0 notes

Text

Exploring the Benefits and Applications of Silicone Rubber Sheets

Silicone rubber sheets are a versatile and high-performance material widely used across various industries due to their unique properties. Renowned for their flexibility, temperature resistance, and durability, these sheets provide reliable solutions in demanding environments. From sealing and insulation to protective applications, silicone rubber sheets have become indispensable in industries such as automotive, healthcare, food processing, and electronics. This article delves into the key features, benefits, and diverse applications of silicone rubber sheets, emphasizing their importance in modern industry.

Key Features of Silicone Rubber Sheets

Temperature Resistance: Silicone rubber sheets are exceptionally resistant to extreme temperatures, capable of operating in conditions ranging from -60°C to +230°C (-76°F to 446°F). This makes them suitable for applications involving both high-heat and low-temperature environments.

Chemical Resistance: These sheets offer excellent resistance to chemicals, including acids, alkalis, and solvents. Their non-reactive nature ensures durability in harsh environments, making them ideal for chemical processing and industrial applications.

Flexibility and Elasticity: Silicone rubber sheets are highly flexible and elastic, allowing them to conform to various shapes and surfaces. This adaptability makes them ideal for gaskets, seals, and cushioning applications.

Non-Toxic and Food-Grade Options: Food-grade silicone rubber sheets are FDA-approved, making them safe for use in food processing, kitchen tools, and medical devices. Their non-toxic and hypoallergenic nature ensures compatibility with sensitive applications.

UV and Weather Resistance: Silicone rubber is resistant to UV radiation, ozone, and weathering, making it an excellent choice for outdoor applications where exposure to environmental factors is unavoidable.

Electrical Insulation: Silicone rubber sheets have outstanding electrical insulation properties, making them ideal for use in the electronics and electrical industries to protect sensitive components.

Benefits of Silicone Rubber Sheets

Durability: Silicone sheets are long-lasting, retaining their properties over extended periods even in challenging conditions.

Versatility: Available in various thicknesses, colors, and hardness levels, silicone rubber sheets can be customized to suit specific requirements, from industrial machinery to household applications.

Safety and Compliance: With non-toxic and biocompatible options, silicone rubber sheets meet stringent industry standards for safety, particularly in food, beverage, and medical applications.

Cost-Efficiency: The longevity and low maintenance needs of silicone rubber sheets contribute to cost savings over time, even in high-demand applications.

Applications of Silicone Rubber Sheets

Automotive Industry: Used for gaskets, seals, and vibration dampening, silicone rubber sheets provide reliable performance under the hood and in interior components.

Medical and Healthcare: In the healthcare sector, these sheets are used for medical-grade seals, prosthetics, and equipment pads, offering biocompatibility and flexibility.

Food Processing and Packaging: Silicone rubber sheets are used for non-stick surfaces, gaskets in food-grade machinery, and heat-resistant mats in food preparation.

Electronics and Electrical: Their insulating properties make silicone rubber sheets suitable for protecting electrical components and ensuring safe operation in electronic devices.

Construction and Industrial Use: Silicone rubber sheets are employed in sealing, weatherproofing, and cushioning applications in industrial machinery and construction projects.

Aerospace Applications: Their ability to withstand extreme temperatures and environmental conditions makes them a valuable material in aerospace components and insulation.

PTFE Sheets

Our silicone sheets come in various thicknesses, sizes, and hardness levels to meet your specific requirements. Whether you’re looking for custom-cut sheets or bulk supply, we are your trusted partner for high-performance sealing products.

Expanded PTFE (Polytetrafluoroethylene) sheets are high-performance sealing solutions used in a wide range of industrial applications. These sheets are designed to offer superior chemical resistance, high temperature tolerance, and exceptional durability. Made from 100% virgin PTFE sheets, they provide excellent sealing performance even under extreme conditions.

Conclusion

Silicone rubber sheets are an indispensable material in numerous industries, offering unmatched performance and reliability. Their unique combination of flexibility, chemical resistance, and durability ensures they meet the demands of a wide range of applications, from heavy-duty industrial settings to sensitive medical uses. As industries continue to evolve, silicone rubber sheets remain a cornerstone material for innovative solutions, proving their worth in both traditional and cutting-edge applications. Whether for sealing, insulation, or protection, silicone rubber sheets provide the quality and performance that industries rely on.

Original Source: Silicone Rubber Sheets & Rolls

0 notes

Text

Exploring The Excellence of PTFE Sheets- The Ultimate in Versatile and Durable Sealing Solutions

In the dynamic landscape of industrial applications, the demand for materials that offer superior performance, reliability, and versatility is ever-present. Polytetrafluoroethylene (PTFE) sheets stand out as a remarkable innovation, offering a unique combination of properties that make them indispensable in various sectors. This article delves into the world of PTFE sheets, exploring their…

View On WordPress

1 note

·

View note

Text

Buy PTFE Material Products for Industrial Needs

At Petron Thermoplast, we specialize in delivering custom PTFE material products designed to meet the specific demands of our clients. Whether your industry involves extreme temperatures, aggressive chemicals, or the need for low-friction solutions, our PTFE products provide unparalleled performance.

Visit Website - https://petronthermoplast.com/ptfe-sheet/

Contact No. - +91-8218684097

Request for Quotation - [email protected]

#PTFE Sheet#Teflon Sheet#PTFE Plastic Sheets#PTFE Sheet Manufacturer#PTFE Teflon Sheet#PTFE Sheet Supplier#PTFE Parts#PTFE Material

0 notes

Text

Exploring the Advantages of Expanded PTFE Gaskets in Harsh Environments

Expanded PTFE (ePTFE) gaskets are an advanced sealing solution that offers unparalleled performance in demanding industrial applications. Made from expanded polytetrafluoroethylene (PTFE), these gaskets exhibit superior resistance to high temperatures, aggressive chemicals, and extreme pressures, making them ideal for a variety of sectors, including petrochemical, pharmaceutical, food processing, and power generation.

#gasket manufacturers#ptfe gaskets#rubber gasket#eptfe gaskets#gasket#ptfe envelope gasket#ptfe sheets

0 notes