#Ptfe Molded Bush

Explore tagged Tumblr posts

Text

PTFE Bridge Bearing Pads, Manufacturer, Mumbai, India

Hindustan Nylons : PTFE Bridge Bearing Pads, PTFE Bridge Bearing Pads manufacturer, CPTFE Bridge Bearing Pads supplier in India. Call us : 9373054560.

#Ptfe Ram Extruded Rods#Ptfe Molded Sheets#PTFE Ram Extruded Pipes#Ptfe Gaskets#Ptfe Wear Strips / Bands#Ptfe Molded Rods#Ptfe Molded Bush#Ptfe Skived Sheets#Ptfe Paste Extruded Tubings#Ptfe Bellows / Expansion Joints#PTFE Valve Components#Ptfe Bridge Bearing Pads#Trexonn Machine Tool Slideway Liners#Chemically Treated Ptfe Parts#PTFE O Rings#Vedge Rings#V Rings#D Rings#PTFE Customised Profiles#PTFE And BR40 Guide Tapes#Filled Grade PTFE Rods#Turcite Products#Turcite Rods#Turcite Bushes#Turcite Sheets#Turcite Machined Components#Boiler Rings#Filled Grade PTFE - All Grades#Satara#Sangli

0 notes

Text

PFA, commonly known as meltable PTFE, is the crown of fluoroplastics in terms of various properties and is used similarly to FEP. Widely used in the semiconductor industry, as well as medical, chemical anti-corrosion, automotive and other fields Characteristics of PFA:

The continuous working temperature of 260 degrees Celsius, except for PTFE, PFA has the highest working temperature among all fluoroplastics. It has good welding and molding potential, is insulated from electricity, heat, chemicals, and solvents, has good impermeability, and can provide high-purity grades.

The main uses of PFA are:

1. Suitable for producing corrosion-resistant parts, wear-resistant parts, seals, insulation parts, and medical device components.

2. Insulation layer for high-temperature wires and cables, anti-corrosion equipment, sealing materials, pump valve bushings, and chemical containers.

0 notes

Text

Best Carbon Filled PTFE: Revolutionizing CFT Products with Goa Polymer

Polytetrafluoroethylene, commonly known as PTFE, has been a game-changer in industries that demand materials with high chemical resistance, low friction, and excellent thermal properties. But as industries evolved, so did the need for PTFE's capabilities. This brought about Carbon Filled PTFE—a modified form of PTFE that enhances its mechanical and electrical properties, making it more versatile and efficient for a wide range of applications. Goa Polymer, a leader in the industry, offers high-quality Carbon Filled PTFE and CFT products that are trusted by various sectors globally.

In this article, we will delve deep into the world of Carbon Filled PTFE (CFT) and how Goa Polymer has made a mark with its superior product offerings, serving industries ranging from chemical processing to electronics. Let’s explore the advantages of CFT products and why you should consider Goa Polymer for your carbon-filled PTFE needs.

Understanding Carbon Filled PTFE (CFT)

Before discussing the advantages and applications of Carbon Filled PTFE, it is crucial to understand what this material is and how it differs from standard PTFE.

PTFE is a synthetic fluoropolymer of tetrafluoroethylene that is highly durable and provides resistance to chemicals, corrosion, and high temperatures. Carbon Filled PTFE is created by blending PTFE with carbon fibers or powder. This mixture enhances certain properties, particularly in terms of:

Increased Wear Resistance: Carbon reinforcement improves the wear characteristics, making the material more durable for demanding applications.

Improved Thermal Conductivity: Carbon-filled PTFE can conduct heat more effectively, allowing for improved thermal management in machinery.

Enhanced Electrical Conductivity: The addition of carbon particles enhances electrical conductivity, making it ideal for specific electronic applications.

Improved Mechanical Strength: The carbon blend significantly increases the mechanical strength of PTFE, allowing it to handle higher pressure and stress conditions.

Goa Polymer has been at the forefront of developing Best Carbon Filled PTFE, creating products that combine these enhanced characteristics to deliver optimum performance.

Why Choose Carbon Filled PTFE?

Carbon-filled PTFE is not just an enhancement over regular PTFE. It offers unique features that make it indispensable for numerous applications:

Lower Friction: Carbon reduces the friction coefficient, making it ideal for applications where low friction is essential, such as bearings and bushings.

High Resistance to Chemicals: Just like pure PTFE, carbon-filled PTFE offers excellent resistance to corrosive chemicals, ensuring long-lasting performance in chemically harsh environments.

Better Dimensional Stability: The added carbon improves the dimensional stability of PTFE, ensuring it holds its shape even under high pressure and temperatures.

Given its numerous advantages, it’s no surprise that CFT products have become widely used across a variety of industries, and Goa Polymer stands out as a premier provider of these products.

Goa Polymer: The Leader in Carbon Filled PTFE

Goa Polymer has established itself as a reliable name in the PTFE industry, known for its unwavering commitment to quality and innovation. Their expertise in producing the best carbon-filled PTFE ensures that clients receive the highest grade materials suited for a wide array of applications.

Here’s why Goa Polymer is the preferred choice for CFT products:

1. Unmatched Quality Assurance

At Goa Polymer, quality is the priority. The company employs strict quality control measures at every step of the production process to ensure that its carbon-filled PTFE products meet the highest standards. Whether you need PTFE sheets, rods, gaskets, or custom-molded parts, Goa Polymer ensures that all products adhere to industry regulations and customer specifications.

2. Cutting-Edge Manufacturing Facilities

With state-of-the-art manufacturing facilities, Goa Polymer stays ahead of the curve by utilizing the latest technological advancements in the field. Their manufacturing units are equipped to handle the large-scale production of CFT products, ensuring quick delivery without compromising on quality.

3. Custom Solutions

Not all applications are the same, and sometimes off-the-shelf solutions just won’t cut it. Goa Polymer provides custom carbon-filled PTFE solutions tailored to the specific needs of your project. From precise measurements to the incorporation of additional materials for specialized functions, their expert team ensures you get the perfect product for your requirements.

4. Sustainability and Environmental Responsibility

With increasing emphasis on sustainability, Goa Polymer is dedicated to producing eco-friendly CFT products. Their production processes are designed to minimize waste and energy consumption, making them a responsible choice for businesses that prioritize environmental conservation.

Applications of Carbon Filled PTFE

Carbon-filled PTFE finds applications in a wide variety of industries due to its enhanced properties. Below are some of the key sectors that benefit from CFT products offered by Goa Polymer:

1. Automotive Industry

In the automotive industry, reducing friction and improving wear resistance is crucial to prolonging the life of mechanical components. Carbon-filled PTFE is widely used in making bearings, seals, and gaskets for high-performance vehicles. Its high thermal conductivity also allows for better heat dissipation in engines and braking systems.

2. Chemical Processing Industry

The chemical processing industry requires materials that can withstand exposure to harsh chemicals. Carbon-filled PTFE is resistant to a wide range of corrosive substances, making it ideal for seals, gaskets, and linings used in chemical plants. Goa Polymer’s CFT products are designed to withstand the most demanding chemical environments.

3. Electronics and Electrical Industry

Carbon-filled PTFE's excellent electrical conductivity makes it useful in the production of electronic components. From circuit boards to connectors, CFT products from Goa Polymer help improve the efficiency and durability of electronic systems.

4. Oil and Gas Industry

The oil and gas sector relies heavily on materials that can handle extreme pressure and corrosive conditions. Carbon-filled PTFE offers exceptional resistance to wear, making it a prime material for seals and gaskets in oil and gas exploration and production equipment.

5. Aerospace Industry

In aerospace, reducing weight without compromising on strength is essential. Carbon-filled PTFE offers a lightweight yet highly durable solution for various aerospace components, including seals, insulators, and bushings.

6. Medical Equipment

Carbon-filled PTFE's biocompatibility and resistance to sterilization methods make it an excellent material for use in medical devices. It is used in surgical instruments, tubing, and implantable devices, thanks to its non-reactive and non-toxic nature.

Why Goa Polymer’s Carbon Filled PTFE is the Best

With countless companies offering carbon-filled PTFE, you may wonder why Goa Polymer stands out as a leader in the industry. The answer lies in their commitment to innovation, superior product quality, and customer satisfaction.

1. Industry Expertise

Goa Polymer has been a pioneer in the development of CFT products for years. Their deep understanding of PTFE materials allows them to offer the best carbon-filled PTFE solutions tailored to various industrial needs.

2. Customizable Solutions

Not all industries require the same specifications. Recognizing this, Goa Polymer offers customizable carbon-filled PTFE products that meet the exact requirements of their clients. Whether it's adjusting the carbon content or designing a unique shape, Goa Polymer's team works closely with customers to ensure they get the perfect fit for their application.

3. Competitive Pricing

Despite offering premium-quality CFT products, Goa Polymer ensures that their products remain competitively priced. Businesses across sectors can benefit from top-tier materials without straining their budgets.

4. Global Reach

Goa Polymer serves clients worldwide, ensuring that no matter where you are, you have access to the best carbon-filled PTFE products. Their vast distribution network allows them to meet the needs of international businesses quickly and efficiently.

Conclusion

Carbon Filled PTFE is a superior material that brings enhanced performance to industries that demand durability, chemical resistance, and thermal management. Goa Polymer, with its expertise and dedication to quality, provides some of the best carbon-filled PTFE and CFT products available on the market.

Whether you're in the automotive, electronics, oil and gas, or aerospace industry, choosing Goa Polymer for your carbon-filled PTFE needs ensures you're getting top-quality products designed to meet the challenges of modern industrial applications. For any business looking for reliable, high-performance materials, Goa Polymer is the ultimate choice.

0 notes

Text

Arvicorubber Shaping the Future - Arvico Profile Video

Arvico Rubber, established in 1966, has over 55+ years of expertise in manufacturing high-quality rubber products, offering customized solutions across various industries. Our commitment to precision and stringent quality control ensures that each product meets the highest standards, providing reliable performance in demanding applications. From rubber Diaphragms that deliver effective sealing in pumps and valves to Expansion Joints that absorb vibrations and accommodate thermal expansion in piping systems, our products are designed to enhance operational efficiency. We also specialize in components like Stators for screw pumps, Bearing Bushes that minimize friction, and durable rubber Gaskets that prevent leaks. Our extensive range includes custom O-rings, Extruded profiles, Molded parts, and PTFE Components known for chemical and temperature resistance. Additionally, we offer durable Hoses for fluid transfer and Rubber Sheets for anti-skid solutions and vibration protection. By integrating advanced technology and sustainable practices, Arvico delivers innovative rubber solutions that cater to diverse industrial needs while minimizing environmental impact.

For more information, visit our website: https://www.arvicorubber.com/

0 notes

Text

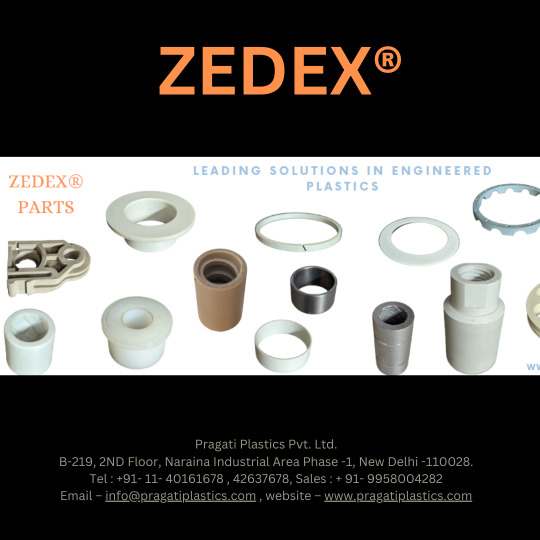

ZEDEX® composite polymer materials are robust and ultimate in performance for bushing, sliding, thrust and extreme pressure sealing applications, when all other polymers have failed or give less than expected life. ZEDEX® grades are supplied as rods, sheets, hollows, machined parts, granular for injection molding and filaments for 3-D printing. ZEDEX® materials replace and outperform phos-bronze, brass, St. steel, PTFE/ filled PTFE, POM, Nylon, PEEK and others. Outstanding features of ZEDEX® are:

Extremely low wear and creep.

Very low coefficient of friction starting 0.07.

High Compressive Strength from 70 MPa upward.

Cryogenic grades down to -200 deg. C.

High edge strength.

Perfectly machinable down to tight tolerances.

Thoroughly tested both in labs and application conditions.

Hundreds of proven applications worldwide in equipment.

For More Info :

Pragati Plastics Pvt. Ltd.

B-219 , 2ND Floor , Naraina Industrial Area Phase -1 ,New Delhi -110028.

Tel : +91- 11- 40161678 , 42637678, Sales : + 91- 9958004282

Email – [email protected] , website – www.pragatiplastics.com

0 notes

Text

SHREE SHAKTI INDUSTRIES

rubber plastic Molded Components manufacture and suppler in Ahmedabad. material like Silicone Rubber, Acrylic, natural rubber, Viton rubber, Bakelite, Cast Polyurethane, Delrin, Epdm, Fluoro Rubber, Fluor silicone Rubber, HDPE, is polypropylene, nylon, Isoprene Rubber, LDPE, nitrile rubber, nbr, neoprene, nylon, Polyamide, polycarbonate, polyethylene, polypropylene, polyvinyl chloride, ptfe, pu, Teflon etc.

parts like rod, house, strip, Sleeves, Bushes, anti vibration pad, anti skid and anti slip pad, wheel, rollers, Profiles, mattings, rubber cord, valve, belts, washer, Wheel Caster, diaphragm, gasket, tubes, v ringe, o rings, sheets, V Seal, T Seal, U Seal, Hydraulic Oil Seals, Mechanical Seals, bellow, sucker, Chevron Set etc. SHREE SHAKTI INDUSTRIES A-302, K.B. ROYAL HOMES, OPP. SWATI-5 RESIDENCYNR, HEMANGI FLAT, CHANDKHEDA ahmedabad, Gujarat 382424

shree-shakti.com

2 notes

·

View notes

Text

How to work with the NYLON filament for 3D Printing?

When it comes to 3D printing, NYLON can be dubbed as a common material. You might have heard this being used for the creation of ropes or textile use. However, it can also be used for the production of perfect 3D prints. Not just that, this filament can quickly be dubbed as one among the highly versatile & dependable materials that help in creating top-notch prints. In this particular article, we are going to outline the best ways to work with NYLON filament.

But before we do that, let us know more about nylon.

What is NYLON?

NYLON, in essence, is a term assigned to the synthetic co-polymer that is comprised of polyamides with various configurations. This filament is actually a thermoplastic that can be melted and processed into different shapes. This particular property of NYLON works beautifully when it comes to 3D printing for commercial or personal needs.

Taking a look at the history of NYLON, the earliest application record comes from the creation of toothbrushes made of NYLON-bristles and use in women’s stockings. This filament offers strength, hardness, as well as friction.

Benefits of NYLON

NYLON filament is popular for serving as a lightweight & strong material. It acts as an example of strength. For years, it has been used heavily for the manufacture of tents, parachutes, ropes, tires, as well as similar military supplies.

Present-day applications of this filament include reinforcement supplies for the car tires, clothing, as well as mechanical equipment that is injection molded. Apart from being strong, NYLON filament is highly resistant to chemical degradation & abrasions. It is highly elastic & easy-to-go when it comes to washing off the stains. It further flaunts a low variant of friction co-efficient which makes it the perfect material designed for bushings & gears.

How can you work with the NYLON filament?

There are several challenges as well as requirements when it comes to 3D printing with the use of NYLON filament.

The very first challenge is from the fact that you have to print at high temperatures such as 260 degrees Celsius to somewhere around 280 degrees Celsius. Now, this could be a problem given the fact that several printers might not be equipped to handle such high temperatures. Most of the printers available today come with the hot ends created from the use of plastics like PTFE or PEEK. These plastics tend to degrade when the temperature gets anything more than 240 degrees Celsius, thus emitting fumes that can be noxious. This is why printing with NYLON requires the use of hot ends that are completely metal in nature.

Another issue with NYLON is the fact that it can be vulnerable to warping during the drying process, similar to the ABS filament. This is why it is recommended that you have a heated bed made from glass that goes to a temperature of 75 degrees Celsius. You can also obtain proper adhesion with your heated bed by coating a thin PVA-glue layer. You can also work with the adhesion sheets as per requirement.

The use of a cooling fan during the printing process should entirely be avoided. You should also steer clear of printing the 3D prints in a room that is too cold. If possible, take things a step ahead with the use of heated chambers or enclosures that help maintain temperatures within 45 degrees Celsius.

NYLON can easily be printed with the use of a high variant of speed settings. It is recommended that you follow the setting ranging between 30mm/s-60mm/s. Another critical factor to keep in mind when you are working with NYLON filament is the fact that it is extremely hygroscopic. This suggests that the filament can readily take in moisture present in the air. This is why it is recommended that you keep the filament in an air-tight container to avoid the seepage of moisture.

Conclusion

To get the best prints with NYLON filament, you need to work out its drawbacks and make the best out of the situation. If you happen to get things right, you will surely get a print that is perfect to the core. Another factor that might make or break the printing process is the fact that it should always come from a reputed seller. The quality of the NYLON filament you buy can also manipulate the printing process. So, always trust a reliable seller to purchase your filament.

0 notes

Text

PTFE Bellows Expansion Joints, PTFE Bellows Expansion Joints Manufacturer

Hindustan Nylons : PTFE Bellows Expansion Joints, PTFE Bellows Expansion Joints manufacturer, PTFE Bellows Expansion Joints supplier in India. Call us : 9373054560.

Ptfe Ram Extruded Rods, Ptfe Molded Sheets, PTFE Ram Extruded Pipes, Ptfe Gaskets, Ptfe Wear Strips / Bands, Ptfe Molded Rods, Ptfe Molded Bush, Ptfe Skived Sheets, Ptfe Paste Extruded Tubings, Ptfe Bellows / Expansion Joints, PTFE Valve Components, Ptfe Bridge Bearing Pads, Trexonn Machine Tool Slideway Liners, Chemically Treated Ptfe Parts, PTFE O Rings, Vedge Rings, V Rings, D Rings, PTFE Customised Profiles, PTFE And BR40 Guide Tapes, Filled Grade PTFE Rods, Turcite Products, Turcite Rods, Turcite Bushes, Turcite Sheets, Turcite Machined Components, Boiler Rings, Filled Grade PTFE - All Grades, Satara, Sangli, Kolhapur, Mumbai, India.

0 notes

Text

Properties and applications of UHMWPE Rod

1. Product characteristics of UHMWPE Rod

Excellent abrasion resistance, good resistance to low temperature impact, self-lubricity, non-toxic, water and chemical resistance, heat resistance is better than general PE, disadvantages are heat resistance (thermal deformation temperature) low, poor processing and molding, surface hardness, rigidity, creep resistance as general engineering plastics, expansion coefficient larger. UHMWPE has poor fluidity and extremely high viscosity in the molten state. It is a rubber-like high-viscosity elastomer. At the early stage, it can only be molded by pressing and sintering methods.

Higher mechanical properties than ordinary high density polyethylene. Excellent impact resistance, stress cracking resistance, high temperature creep resistance, low friction coefficient, self-lubrication resistance, excellent chemical corrosion resistance, fatigue resistance, noise damping resistance, nuclear radiation resistance, etc.

The operating temperature is 100 ~ 110℃.Good cold resistance, can be used at -269℃.The product has a density of 0.935g/cm3 and a molecular weight of 2 million. Its tensile strength at break is 40MPa, elongation at break is 350%, elastic modulus at bending is 600MPa, and the cantilever beam is constantly impinged by the gap. Abrasion (MPC method)20mm.

2. Application field of uhmwpe rod

Uhmpe bar can replace carbon steel, stainless steel, bronze and other materials for textile, paper making, food machinery, transportation, medical treatment, coal mine, chemical industry and other sectors. Such as textile industry on the shuttle, shuttle rod, gear, coupling, sweeping rod, buffer block, eccentric block, rod sleeve, swing consequences and other impact wear resistant parts. Paper industry to do box cover plate, wiper plate, compression parts, joints, transmission machinery seal shaft, deflector wheel, scraper, filter, etc. The lining of hoppers, silos and chutes for powdery materials in the transport industry.

Uhmwpe rod can be used for all kinds of mechanical parts, including food machinery gear, worm wheel, worm, bearing. Chemical pumps, valves, baffles, filters. Medically, it can also be used for heart valves, short surgical parts, artificial joints and birth control implants. Sports to do skating floor, ground track, ski, motor sledge parts.

Application scope and polyamide, ptfe similar, wear resistance than carbon steel, do gear, bearing, bearing bush, star wheel, valve, pump, guide rail, sealing packing, equipment lining, sliding plate, artificial joints, fiber for bulletproof jacket, rope, etc.

Ultrahigh molecular weight polyethylene (uhmwpe) rod has many excellent properties, but few people know its existence, which is mainly due to the lack of previous research on the melt characteristics of uhmwpe, and the processing method is basically still in the backward press-sintering process. In recent years, with the continuous development of uhmwpe processing technology, its products have been successfully applied in many fields.

Color: primary color (white), black, other colors can be customized

0 notes

Text

Global Engineering Plastics Market is expected to grow at a CAGR of 6.8% during the forecast period 2018-2023

According to the new market research report by IndustryARC titled “Engineering Plastics Market By Type (ABS, PA, PC, POM, PMMA, PEEK, PET, PBT, Cast Nylon); By End-User (Aerospace, Building & Construction, Food, Mechanical, Medical, Others); By Application (CD/DVD, Medical Implants, Advanced Batteries, Shoes, Others); By Geography – Forecast Period (2018–2023),” the market will be driven by the replacement of metal parts by engineering plastics in various industries.

Asia Pacific Dominates the Engineering Plastics Market

Asia Pacific has the largest share in the Engineering Plastics Market due to the growing demand for engineering plastics by the end-user industries such as electrical & electronics, and automotive & transportation. The increase in the production of automotive parts in the region will bolster the market over the forecast period. China is the largest market for engineering plastics. The country’s engineering plastics market is primarily driven by the rapid growth of the automotive and transportation industry and the easy availability of feedstock.

Selected Regulatory Analysis Done in theEngineering Plastics Market Report

The automotive and transportation sector will dominate the Engineering Plastics Market over the forecast period. Engineering plastics are used in the automotive industry for applications in the wheel well, connectors and housing, under the hood components, headlamps, and fog lamps. The automotive sector growth rate is high in Asia-Pacific, particularly in China, India, Japan, and South Korea. The automotive and transportation market in these countries will drive the demand for engineering plastic products over the forecast period.

To access/purchase the Engineering Plastics Market report, click the link below: https://industryarc.com/Report/15507/engineering-plastics-market.html

Selected Driving Factors Mentioned in the Engineering Plastics Market Report

• Growth of the end-user industries such as electrical, electronics, packaging, automotive, construction, and consumer appliances will drive the demand for engineering plastic products.

• The easy availability of raw materials and low cost of production will boost the demand for engineering plastics.

• The benefits of engineering plastics such as flame resistance, durability, chemical resistance, and wear resistance compared to commodity plastics will provide ample opportunities for the engineering plastics market.

• Major investments by governments and companies in developing new technologies will propel the growth of the engineering plastics market.

Key Players of the Engineering Plastics Market

BASF SE, Covestro, and Celanese Corporation are the key players of the engineering plastics market. — BASF produces engineering plastics for extrusion, injection molding, and blow molding. The engineering plastics produced by BASF are developed for applications in the automotive & engineering, and electrical & electronic sectors. — Covestro offers products which have a desirable balance of properties such as impact strength and heat resistance to other materials. — Celanese provides high-performance engineering resins that offer resistance to friction and wear, and deliver good mechanical properties such as stiffness and strength.

The Engineering Plastics Market Is Segmented as Indicated Below:

The growing demand for electronic and electrical appliances will propel the growth of the engineering plastics market.

A. Engineering Plastics Market –By Type 1. ABS 2. Acetal 3. Acrylic 4. Bakelite 5. High Performance Materials 6. Nylon 7. PETP 8. Polycarbonate 9. Polyethylenes (PE) 10. Polypropylene (PP) 11. Polyurethane 12. PTFE 13. PVC 14. PEK 15. PEEK

B. Engineering Plastics Market – By Application 1. Abrasion Resistant Liners 2. Acid Trays 3. Anti-Corrosive Liners 4. Braking Tray Liners 5. Bearings 6. Bench Top 7. Boat Chopping Board 8. Boat Windscreen 9. Bolts & Nuts 10. Bottle Line Wear Plate 11. Buffer Pads 12. Bushes 13. Chain Guide 14. Chevron Packing’s 15. Conveyor Mechanisms 16. Cooling Towers 17. Cutting Boards 18. Display 19. Electrical Insulator 20. Exhaust Ducts 21. Feedscrolls 22. Food Production 23. Fume Ducting 24. Gaskets 25. Gears 26. Guards 27. Guide Strips 28. Guide Wheels 29. Heat Seal Surfaces 30. High Precision Parts 31. Hoppers 32. Insulators 33. Kicker Arms 34. Lantern Rings 35. Level Indicators 36. Lighting 37. Machine Guards 38. Metal Detector Chutes 39. Nuts and Bolts 40. Piston Rings 41. Piston Seals and Cups 42. Plating Tanks and Hoods 43. Pressure Plates 44. Pump Components 45. Rollers 46. Safety Glass and Guards 47. Scraper Blades 48. Seals 49. Security Windows 50. Self-Lubricating Parts 51. Sightglass 52. Skylights 53. Slide Bearings 54. Slideways 55. Terminal Boards 56. Thermal Insulators 57. Thrust Washers 58. Valve Bodies 59. Valve Components 60. Washer 61. Wear Pads 62. Wear Plates 63. Others

C. Engineering Plastics Market – By End User 1. Aerospace 2. Automotive 3. Building 4. Food 5. Packaging 6. Mechanical 7. Medical 8. Oil & gas 9. Semiconductor 10. Construction 11. Others

D. Engineering Plastics Market – By Geography (33+ countries) E. Engineering Plastics Market Entropy F. Company Profiles 1. BASF SE 2. Covestro 3. Solvay S.A. 4. Celanese Corporation 5. DuPont 6. LG Chem 7. Evonik Industry AG 8. Lanxess AG 9. Company 9 10. Company 10

More than 10 companies are profiled in this report

G. Appendix: Abbreviations, Sources, Research Methodology, Bibliography, Compilation of Experts, Disclaimer.

What can you expect from the report?

The Engineering Plastics Market Report is prepared with the main agenda to cover the following 20 points:

1. Market Size by Product Categories 2. Market Trends 3. Manufacturer Landscape 4. Distributor Landscape 5. Pricing Analysis 6. Top 10 End User Analysis 7. Product Benchmarking 8. Product Developments 9. Mergers & Acquisition Analysis 10. Patent Analysis 11. Demand Analysis (By Revenue & Volume) 12. Country-level Analysis (15+) 13. Competitor Analysis 14. Market Shares Analysis 15. Value Chain Analysis 16. Supply Chain Analysis 17. Strategic Analysis 18. Current & Future Market Landscape Analysis 19. Opportunity Analysis 20. Revenue and Volume Analysis

Any other major customizations can be discussed with our team. We can also provide you with a separate quote based on your requirements. You can drop an e-mail to [email protected] to learn more about our consulting services.

Media Contact

Mr. Venkat Reddy Sales Manager Email 1: [email protected] Or Email 2: [email protected] Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC

IndustryARC is a Research and Consulting Firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food & Beverages, Information Technology, and Life Sciences & Healthcare.

#engineering plastic products#Engineering Plastics market#engineering plastic material#engineering plastics applications

0 notes

Text

Global Engineering Plastics Market is Expected to Grow at a CAGR of 6.8% During the Forecast Period 2018-2023.

According to the new market research report by IndustryARC titled “Engineering Plastics Market By Type (ABS, PA, PC, POM, PMMA, PEEK, PET, PBT, Cast Nylon); By End User (Aerospace, Building & Construction, Food, Mechanical, Medical, Others); By Application (CD/DVD, Medical Implants, Advanced Batteries, Shoes, Others); By Geography – Forecast Period (2018–2023),” the market will be driven by the replacement of metal parts by engineering plastics in various industries. Asia Pacific Dominates the Engineering Plastics Market Asia Pacific has the largest share in the Engineering Plastics market due to the growing demand for engineering plastics by the end user industries such as electrical & electronics, and automotive & transportation. The increase in the production of automotive parts in the region will bolster the market over the forecast period. China is the largest market for engineering plastics. The country’s engineering plastics market is primarily driven by the rapid growth of the automotive and transportation industry, and the easy availability of feedstock. Selected Regulatory Analysis Done in the Engineering Plastics Market Report The automotive and transportation sector will dominate the Engineering Plastics Market over the forecast period. Engineering plastics are used in the automotive industry for applications in wheel well, connectors and housing, under the hood components, head lamps, and fog lamps. The automotive sector growth rate is high in Asia-Pacific, particularly in China, India, Japan, and South Korea. The automotive and transportation market in these countries will drive the demand for engineering plastic products over the forecast period. Talk to one of our sales representatives about the Engineering Plastics Market report in the link below: https://industryarc.com/support.php?id=15507 Selected Driving Factors Mentioned in the Engineering Plastics Market Report Growth of the end user industries such as electrical, electronics, packaging, automotive, construction, and consumer appliances will drive the demand for engineering plastic products. The easy availability of raw materials and low cost of production will boost the demand for engineering plastics. The benefits of engineering plastics such as flame resistance, durability, chemical resistance, and wear resistance compared to commodity plastics will provide ample opportunities for the engineering plastics market. Major investments by governments and companies in developing new technologies will propel the growth of the engineering plastics market. To access/purchase the Engineering Plastics Market report, click the link below: https://industryarc.com/Report/15507/engineering-plastics-market.html Key Players of the Engineering Plastics Market BASF SE, Covestro, and Celanese Corporation are the key players of the engineering plastics market. BASF produces engineering plastics for extrusion, injection molding, and blow molding. The engineering plastics produced by BASF are developed for applications in the automotive & engineering, and electrical & electronic sectors. Covestro offers products which have a desirable balance of properties such as impact strength and heat resistance to other materials. Celanese provides high performance engineering resins that offer resistance to friction and wear, and deliver good mechanical properties such as stiffness and strength. The Engineering Plastics Market Is Segmented as Indicated Below: The growing demand for electronic and electrical appliances will propel the growth of the engineering plastics market. Engineering Plastics Market Analysis –By Type ABS Acetal Acrylic Bakelite High Performance Materials Nylon PETP Polycarbonate Polyethylenes (PE) Polypropylene (PP) Polyurethane PTFE PVC PEK PEEK Engineering Plastics Market Growth – By Application Abrasion Resistant Liners Acid Trays Anti-Corrosive Liners Braking Tray Liners Bearings Bench Top Boat Chopping Board Boat Windscreen Bolts & Nuts Bottle Line Wear Plate Buffer Pads Bushes Chain Guide Chevron Packing’s Conveyor Mechanisms Cooling Towers Cutting Boards Display Electrical Insulator Exhaust Ducts Feedscrolls Food Production Fume Ducting Gaskets Gears Guards Guide Strips Guide Wheels Heat Seal Surfaces High Precision Parts Hoppers Insulators Kicker Arms Lantern Rings Level Indicators Lighting Machine Guards Metal Detector Chutes Nuts and Bolts Piston Rings Piston Seals and Cups Plating Tanks and Hoods Pressure Plates Pump Components Rollers Safety Glass and Guards Scraper Blades Seals Security Windows Self-Lubricating Parts Sightglass Skylights Slide Bearings Slideways Terminal Boards Thermal Insulators Thrust Washers Valve Bodies Valve Components Washer Wear Pads Wear Plates Others Engineering Plastics Market Share – By End User Aerospace Automotive Building Food Packaging Mechanical Medical Oil & gas Semiconductor Construction Others Engineering Plastics Market Forecast – By Geography (33+ countries) Engineering Plastics Market Entropy Company Profiles BASF SE Covestro Solvay S.A. Celanese Corporation DuPont LG Chem Evonik Industry AG Lanxess AG Company 9 Company 10 More than 10 companies are profiled in this report Appendix: Abbreviations, Sources, Research Methodology, Bibliography, Compilation of Experts, Disclaimer. Related Reports: Biodegradable Plastic Market Carbon Fiber Reinforced Plastic Market What can you expect from the Engineering Plastics Market Report? The Engineering Plastics Market Report is prepared with the main agenda to cover the following 20 points: Engineering Plastics Market Size by Product Categories Engineering Plastics Market Trends Engineering Plastics Manufacturer Landscape Distributor Landscape Pricing Analysis Top 10 End User Analysis Product Benchmarking Product Developments Mergers & Acquisition Analysis Patent Analysis Demand Analysis (By Revenue & Volume) Country level Analysis (15+) Competitor Analysis Engineering Plastics Market Growth Analysis Engineering Plastics Market Forecast Analysis Engineering Plastics Market Shares Analysis Engineering Plastics Market Value Chain Analysis Engineering Plastics Market Supply Chain Analysis Engineering Plastics Market Strategic Analysis Current & Future Market Landscape Analysis Engineering Plastics Market Opportunity Analysis Engineering Plastics Market Revenue and Volume Analysis FAQs: Does IndustryARC publish country, geography, or application–based reports in Engineering Plastics? Yes, we do have separate reports and database as mentioned below: Engineering Plastics Market Analysis (2018–2023) North America Engineering Plastics Market Forecast (2018–2023) South America Engineering Plastics Market Growth (2018–2023) 4. Europe Engineering Plastics Market Share (2018–2023) Asia Pacific Engineering Plastics Market Share (2018–2023) Middle East & Africa Engineering Plastics Market Growth (2018–2023) Aerospace Engineering Plastics Market Analysis (2018–2023) Automotive Engineering Plastics Market Growth (2018–2023) Does IndustryARC provide customized reports and charge additionally for limited customization? Yes, we can customize the report by extracting data from our database of reports and annual subscription databases. We can provide the following free customizations: Increase the level of data in application or end user industry. Increase the number of countries in geography or product chapter. Find out market shares for other smaller companies or companies that are of interest to you Company profiles can be requested based on your interest. Patent analysis, pricing, product analysis, product benchmarking, and value and supply chain analysis can be requested for a country or end use segment. Any other major customizations can be discussed with our team. We can also provide you with a separate quote based on your requirements. You can drop an e-mail to [email protected] to learn more about our consulting services. Media Contact Mr. Venkat Reddy Sales Manager Email : [email protected] Contact Sales: +1-614-588-8538 (Ext-101)

0 notes

Text

PTFE-LINED PLASTIC LINEAR BUSHINGS MANUFACTURERS IN INDIA

Today’s manufacturing industry extensively uses linear plain bushings. With the advancement in material sciences and technologies, the capabilities of linear plain bearings have been improved, especially those made of plastic have been. Plastic linear bushings are designed to operate without maintenance, do not require external lubricants like grease or oil, are of low cost than metal bearings, low contamination risk, etc. These are also designed to suit wet and dirty environments, lab applications, sensitive foods, etc.

Igus is one of the plastic linear bushings manufacturers in India. Their range of DryLin Plastic Linear are light weight, corrosion- resistant, better performing in high acceleration experiencing applications, and are capable of withstand higher shock and static loads. These Igus products are manufactured using dry-tech plastic composites.

The dry-tech plastic composites are composed of particles of solid lubricants, a base polymer, and reinforcing fibers. This plastic material is homogenously blended, and injection molded to make bearings. These exhibit self-lubricating and constant coefficients of frictionthroughout their lifetime. In their initial working stages, tiny deposits of solid lubricant are moved into the shaft’s microfinish. This layer acts to eliminate the need for external lubrication, increases the machine’s lifetime, and lowers friction.

Another thing that makes Igus’ DryLin linear plastic bearings unique is their geometry. The grooves at the insides of the bearing’s inner diameter are designed to fulfil two functions. Firstly, they diminish thermal expansion and leads to a more tightly toleranced running clearance. Secondly, they perform the role of “dirt channels” in hostile environments by letting debris to easilypass through the system.

Another design feature is that their liner has a lengthwise slit. This enables a tool-free, easy and “slip fit” installation. On the outer diameter, DryLin liners have featuresthat maintain axial security and enable anti-rotation. The adaptor or housing is an aluminum sleeve. This gives the bearing an installation dimension similar to that of a standard recirculating ball bearing.

The concept of PTFE-Lined Bearings

Another option for linear bearing applications is Igus’ Polytetrafluoroethylene (PTFE)-lined metal bearings. Here, a typical bearing hasa thin, permanently bonded (to an aluminum housing), and self-lubricating layer implanted with PTFE. This liner cannot be replaced.

E7 material from Igus

Igus now uses E7, its latest self-lubricating liner material for its liner instead of PTFE. This material has been designed for low friction, lower wear and optimized service life than PTFE. This material also has an inherent superior corrosion resistance property.

Plastic linear bushings manufacturers in India- Igus

Igus is a manufacturer of moving components for industrial applications. These include drag chains, echains, robotic components, guides, bearings, and more using high quality, superior performing, and durable plastics. Each of these products are made available in a huge range by Igus. Each item has specific set of features.

You can order an item that suits your need from their catalogue. If none of those suit the purpose you are looking for, you can make a custom- made order. The best thing is that, you can order any quantity of items from Igus, without worrying about the maximum or minimum limits.

0 notes

Text

ZEDEX® composite polymer materials are robust and ultimate in performance for bushing, sliding, thrust and extreme pressure sealing applications, when all other polymers have failed or give less than expected life. ZEDEX® grades are supplied as rods, sheets, hollows, machined parts, granular for injection molding and filaments for 3-D printing. ZEDEX® materials replace and outperform phos-bronze, brass, St. steel, PTFE/ filled PTFE, POM, Nylon, PEEK and others. Outstanding features of ZEDEX® are:

Extremely low wear and creep.

Very low coefficient of friction starting 0.07.

High Compressive Strength from 70 MPa upward.

Cryogenic grades down to -200 deg. C.

High edge strength.

Perfectly machinable down to tight tolerances.

Thoroughly tested both in labs and application conditions.

Hundreds of proven applications worldwide in equipment.

For More Info :

Pragati Plastics Pvt. Ltd.

B-219 , 2ND Floor , Naraina Industrial Area Phase -1 ,New Delhi -110028.

Tel : +91- 11- 40161678 , 42637678, Sales : + 91- 9958004282

Email – [email protected] , website – www.pragatiplastics.com

0 notes

Text

Crevice Tool Nozzle For Hoover Vacuum Cleaners 32mm Accessories (black)

Product Description This lightweight, yet rock-solid box-side access step employs a rugged die-cast aluminum alloy linkage assembly that is crafted in the USA. Black anodized and PTFE powder-coated for maximum corrosion protection. Precision, stainless-steel hinge points and press-fit bushings ensure trouble-free action and reliable, maintenance-free operation for decades. Die-cast-aluminum alloy linkage components and precision-machined pivot points give BedStep2 rock-solid stability. The ridged, non-slip step is molded of strong glass-reinforced resin, for safe footing even in mud, snow or ice. Mounts just behind the cab, forward of the rear wheel, providing a faster, easier and safer route to access toolboxes, equipment and cargo in the bed. Easily installed, this frame-mounted, retractable truck step can be mounted on either side of the truck box, and it flips down or retracts with just the nudge of your foot.

Price: Too low to display

Non-slip, retractable step can be mounted on either side of the truck box, just behind the cab and forward of the rear wheel to provide easy access to the truck bed, tool box or 5th wheel hitch

Step quickly flips down or retracts with just the nudge of your foot and is engineered to support loads up to 300 pounds

High-strength aluminum alloy components and precision stainless-steel pivot pins for rock-solid stability

Maintenance-free, self-lubricating bushings for all-weather performance

Made in the USA and backed by a 3-year limited warranty

Product Description Features: 100% brand new and high quality. It can be used with a vacuum cleaner , professional suction to remove difficult dust. For corner, slit, bookshelves, corner sofa, window slits, foot of the bed, windows, slide, etc. Easy to operate, easy to use. ABS plastic, real materials, trustworthy Specification: Item type: Flat suction Color: Black Material: plastic Function: Wet and dry Nozzle shape: flat nozzle Vacuum cleaner style: Horizontal Fit for: Vacuum Cleaners 32mm Package includes: 1 x flat suction

Price: $2.19

Fit for: Vacuum Cleaners 32mm

It can be used with a vacuum cleaner , professional suction to remove difficult dust.

For corner, slit, bookshelves, corner sofa, window slits, foot of the bed, windows, slide, etc.

Material: ABS plastic, real materials, trustworthy

Package includes: 1 x flat suction

The post Crevice Tool Nozzle For Hoover Vacuum Cleaners 32mm Accessories (black) appeared first on Top Seller Website.

from Top Seller Website https://topsellers.website/crevice-tool-nozzle-for-hoover-vacuum-cleaners-32mm-accessories-black/

0 notes

Text

PTFE Wear Strips Bands, Manufacturer, Supplier, Mumbai, India

Hindustan Nylons : PTFE Wear Strips / Bands, PTFE Wear Strips Bands manufacturer, PTFE Wear Strips Bands supplier in India. Call us : 9373054560.

ptfe ram extruded rods, ptfe molded sheets, ptfe ram extruded pipe, ptfe gaskets, ptfe wear strips / bands, ptfe molded rods, ptfe molded bush, ptfe skived sheets, ptfe paste extruded tubings, ptfe bellows / expansion joints, ptfe valve component, ptfe bridge bearing pads, trexonn machine tool slideway liners, chemically treated ptfe parts, satara, sangli, kolhapur, mumbai, india.

0 notes