#Gaskets

Explore tagged Tumblr posts

Text

What to Consider When Choosing Your Gasket Material and Type

A gasket may be a combination of materials, which is employed to stop any fluid entry between two static components. The success of the industrial gasket and materials depends on the sort of fabric utilized in the manufacturing process. counting on the sort of application, a spread of materials are wont to produce gaskets of…

A gasket may be a combination of materials, which is employed to stop any fluid entry between two static components. The success of the industrial gasket and materials depends on the sort of fabric utilized in the manufacturing process. counting on the sort of application, a spread of materials are wont to produce gaskets of the many shapes and sizes. Gaskets also are chosen supported factors like application temperature, pressure, electrical conduciveness, and resistance to extreme environments.

Types of Gasket Materials

While the materials wont to produce gaskets are numerous, on a general basis, they will be segregated into 3 types:

Fibrous materials

Elastometric materials

Metallic materials

Fibrous materials: These materials are made using organic fibers. The gasket sheet is skilled as a binding solution to assist develop the gasket material. they need excellent absorption properties and are flexible enough to be made into various shapes. Some common samples of fibrous gasket materials are:

Asbestos– In fibrous materials, asbestos is perhaps the foremost recognizable and popular material. It is often used for sealing applications during a sort of environment. Asbestos maintains its shape and strength up to 450oF. It doesn’t emit any toxic odor and is safe to handle.

Carbon fibers- As a cloth, carbon fiber has the power to face up harsh chemical environments. It is often used for applications that have high temperatures and pressures. it’s seen as a perfect material because of its low permeability. However, it’s not suitable for oxidization.

Aramid- An artificial fiber, aramid has been used as a substitute for asbestos. it’s a high resistance towards heat and organic solvents. Though it doesn’t have a freezing point, it does tend to degrade when temperatures reach 500oC. However, it doesn’t react well to salts and acids, also as direct contact with UV rays.

Elastometric materials: because the name suggests, these materials are produced using elastomers with various composites. This makes them extremely popular materials for a spread of industries thanks to their high performance and quality. a couple of well-known elastomers are given below:

Silicone- Perhaps the foremost recognized material for gaskets, silicone is well-known for its waterproof properties. It works effectively in extreme temperatures and is immune to UV and ozone elements. Silicone is often easily molded or cut using water jet cutting systems counting on the sort of application.

Rubber- As an organic material, natural rubber has good resistance to heat, and functions wells as a cushioning pad. When utilized in gaskets, it can recover to its original shape from medium temperatures. It is often wont to protect gaskets from alkalis, mild acids, and inorganic salts.

Neoprene- this will be used as an appropriate option for rubber. The advantage that neoprene has is that while it’s almost like rubber in terms of its resistance to acids and alkalis, it also can work against oils, petroleum, and other fuels. However, it’s not recommended to be used against hydrocarbons.

Metallic materials: Usually, the various sorts of metals wont to produce gaskets are a variety of steels, alloys, titanium, copper, and aluminum.

Carbon Steel– this is often one of the favored metallic choices for gaskets. The larger the quantity of carbon within the alloy, the harder and stronger it becomes. Unfortunately, the carbon content has got to be balanced with other metal properties otherwise it can lower the general freezing point.

Aluminum– Aluminum is understood for its lightweight, machinability, and high resistance to corrosion. Aluminum alloys are an honest choice for gaskets thanks to their weldability and strength.

Titanium– Considered to be almost like 304 chrome steel, titanium is understood for its lightweight, strength, and corrosion resistance. It is often used for very high temperatures, and it’s perfect for oxidizing media.

An understanding of the varied sorts of gasket materials used can assist you to decide the proper type to use in your industrial application.

Original Source: Industrial Gaskets

#gaskets#industrial#gasket material#gasket sheet#Asbestos Gaskets#Gasket Material#Rubber Gasket Sheet#Ready Cut Gaskets#Industrial Gaskets

2 notes

·

View notes

Text

Title: The Unsung Hero of Sealing Solutions: Exploring the World of Gaskets

Introduction

In the intricate world of engineering and machinery, there exists a crucial component that often goes unnoticed, yet plays a vital role in ensuring the smooth operation of various systems: the gasket. These unassuming pieces of material are the unsung heroes of sealing solutions, preventing leaks, minimizing energy loss, and maintaining the integrity of countless applications. In this blog, we will dive into the fascinating world of gaskets, exploring their types, applications, and significance in various industries.

What Is a Gasket?

A gasket is a mechanical seal that fills the gap between two or more mating surfaces to prevent the leakage of gases or liquids under compression. Gaskets are typically made from a wide range of materials, such as rubber, metal, cork, silicone, and composite materials. The choice of gasket material depends on the specific application, including the temperature, pressure, and chemical compatibility requirements.

Types of Gaskets

Rubber Gaskets: These gaskets are made from various elastomers like neoprene, EPDM, and nitrile rubber. They are known for their flexibility and resistance to moisture and temperature variations. Rubber gaskets find applications in plumbing, automotive, and HVAC systems.

Metal Gaskets: Composed of materials like stainless steel, copper, or aluminum, metal gaskets excel in high-temperature and high-pressure environments. They are commonly used in the oil and gas industry and for sealing flange connections.

Spiral Wound Gaskets: These gaskets are formed by winding a metal strip and a filler material into a spiral. They are ideal for applications where high pressures and temperatures are involved, making them a favorite choice for the chemical and petrochemical industries.

Graphite Gaskets: Known for their excellent heat and chemical resistance, graphite gaskets are often used in high-temperature and high-pressure applications, such as steam systems and refineries.

Non-Asbestos Gaskets: In response to health concerns associated with asbestos, non-asbestos gaskets have become popular. They use materials like aramid fibers and synthetic rubber to provide a safe and effective sealing solution.

Applications of Gaskets

Automotive Industry: Gaskets are used in engines, transmissions, and exhaust systems to prevent leaks and maintain the efficiency of these crucial components.

Plumbing: Gaskets ensure watertight seals in plumbing fixtures and pipelines, preventing water leaks and minimizing water wastage.

Aerospace: Gaskets are employed in aircraft engines and hydraulic systems to withstand extreme temperatures and pressures, ensuring safe and reliable operation.

Oil and Gas: The industry relies heavily on gaskets to seal flange connections, valves, and pipelines, preventing the escape of hazardous materials.

Chemical Industry: Gaskets play a crucial role in chemical processing, where they must withstand aggressive chemicals and high temperatures.

Significance of Gaskets

Gaskets are the unsung heroes of various industries, silently performing their duties to maintain the integrity and safety of systems and equipment. Their significance can be summarized as follows:

Leak Prevention: Gaskets are designed to create a barrier between mating surfaces, preventing the escape of fluids or gases, which is critical for safety, efficiency, and environmental protection.

Energy Efficiency: Properly sealed systems help conserve energy by preventing leaks and reducing heat loss, ultimately leading to cost savings and reduced environmental impact.

Safety: In industries like oil and gas and chemical processing, gaskets are crucial for containing hazardous materials and preventing accidents.

Conclusion

Gaskets may not be the most glamorous components in the world of engineering, but their role in sealing solutions is indispensable. From the engines of our cars to the pipelines of the oil and gas industry, gaskets quietly ensure that everything runs smoothly and safely. As technology advances, gasket materials and designs will continue to evolve, contributing to more efficient and sustainable systems across various industries. So, the next time you see a gasket, remember the unsung hero that it is, working tirelessly to keep our world sealed and secure.

#home & lifestyle#kitchen appliances#cookware#kitchen#gaskets#kitchenware#cooker#daily blog#daily update#home cooking#home lifestyle

2 notes

·

View notes

Photo

📰 TAEVision Engineering 's Posts - Thu, May 25, 2023 TAEVision 3D Mechanical Design • Parts AutoParts EngineParts Aftermarket Glaser SealingProducts Dana Holding Corp. Porsche Exhaust System CarPlates LicensePlates Bosch ICON wiperblades • Automotive Audi A4 Jeep Wrangler Rubicon SUV 01 - Data 145 Parts EngineParts Aftermarket Glaser SealingProducts gaskets seals Dana Holding Corp. ▸ TAEVision Engineering's Post on Tumblr 02 - Data 466 Design Applications Parts AutoParts Aftermarket Porsche Exhaust System Titanium Slip-On ▸ TAEVision Engineering's Post on Tumblr 03 - Data 211 Parts AutoParts Aftermarket CarPlates LicensePlates showroom Automotive - Audi A4 ▸ TAEVision Engineering's Post on Tumblr 04 - Data 112 Parts AutoParts Aftermarket Bosch ICON wiperblades WindshieldWipers (Rain Ambient 1) ▸ TAEVision Engineering's Post on Tumblr 05 - Data 432 3D Design Applications Automotive AUTUMN DREAMS 🍃🍂🍁 Jeep Wrangler Rubicon SUV 2010 OffRoad ▸ TAEVision Engineering's Post on Tumblr

📰 I just updated my Pressfolio: TAEVision Mechanics's Online Portfolio - Global Data - May 25, 2023 ▸ TAEVision Mechanics's Online Portfolio (last update)

Global Data - May 25, 2023

#TAEVision#engineering#3d#mechanicaldesign#parts#autoparts#engineparts#aftermarket#GLASER#sealing products#SealingProducts#gaskets#seals#DANA Holding Corp#Porsche#exhaust system#ExhaustSystem#Titanium Slip-On#car plates#CarPlates#license plates#LicensePlates#automotive#Audi A4#BOSCH ICON#wiperblades#AUTUMN DREAMS#Jeep Wrangler#Jeep Wrangler Rubicon#SUV offroad

2 notes

·

View notes

Text

What Material is Used for Sealing Washers? | Key Materials

When it comes to creating a secure, leak-proof seal in machinery, vehicles, and plumbing systems, sealing washers play a critical role. Sealing washers are components used to prevent the leakage of fluids or gases between two joined surfaces. The material used in manufacturing these washers is key to ensuring their performance and durability.

Whether you’re a DIY enthusiast or an industrial engineer, understanding the types of materials used for sealing washers can help you make the best choices for your projects. In this article, I’ll dive deep into the various materials that go into sealing washers and explain which one might be right for your specific needs.

What are Sealing Washers and Their Purpose?

Sealing washers are circular components designed to create a tight, leak-proof seal between fasteners (such as bolts or screws) and the surface they’re securing. Their purpose is simple: prevent the passage of air, water, oil, or any other liquids that could potentially cause damage, corrosion, or other problems.

A sealing washer typically combines a metal core (often a washer material like stainless steel) with a sealing layer (made of rubber, silicone, or another flexible material). The sealing washer material compresses when tightened, conforming to the surface of the parts being sealed and forming a barrier that stops leaks.

Materials Used for Sealing Washers

Sealing washers come in various materials, and each one has specific characteristics that make it suitable for particular applications. Below are the most common materials used for sealing washers:

Rubber

Rubber sealing washers are one of the most common types, due to their flexibility, durability, and resistance to water, oil, and many chemicals. Rubber provides an excellent seal and is highly effective at filling gaps between the surfaces.

Advantages:

Excellent flexibility for a tight seal

Resistant to corrosion, wear, and extreme temperatures

Ideal for general-purpose applications

Easy to compress and adapt to surface contours

Common Applications:

Plumbing

Automotive industry

Electrical systems

Silicone

Silicone sealing washers are made from a synthetic rubber-like material, known for its high-temperature resistance and long-lasting elasticity. Silicone is great for applications that require sealing in environments exposed to both high and low temperatures.

Advantages:

High resistance to temperature extremes (from -60°C to 250°C)

Good for use in outdoor applications and high-stress environments

Resistant to water, oxidation, and UV light

Common Applications:

Aerospace

High-temperature automotive systems

Electronics and electrical equipment

Neoprene

Neoprene is another rubber material often used for sealing washers. It offers great resistance to oils, chemicals, and weathering. Neoprene is ideal for sealing applications where resistance to harsh chemicals or fluctuating temperatures is necessary.

Advantages:

Good chemical resistance

Excellent weather resistance

Long-lasting under moderate temperature changes

Common Applications:

HVAC systems

Marine applications

Automotive seals

EPDM (Ethylene Propylene Diene Monomer)

EPDM is a type of synthetic rubber that offers exceptional resistance to UV radiation, ozone, and weathering. It’s widely used in sealing washers that are exposed to outdoor elements or harsh conditions.

Advantages:

Exceptional resistance to ozone and UV light

Great elasticity, even in extreme temperatures

Resists aging, oxidation, and chemical degradation

Common Applications:

Roofing systems

Automotive weatherstripping

Water treatment systems

Cork

Cork sealing washers are made from natural cork material, offering a softer seal that is perfect for applications where a compressible material is needed. Cork washers are often used when the seal must be pliable and create a tight fit, especially in low-pressure applications.

Advantages:

High compressibility for a tight seal

Naturally resistant to weathering and oils

Soft and flexible for better sealing under pressure

Common Applications:

Engine gaskets

Hydraulic systems

Fluid and gas line sealing

Metal and Rubber Combinations

Metal and rubber combination washers combine the strength of a metal core with the sealing ability of a rubber layer. These washers are particularly useful in applications requiring high-pressure sealing, such as automotive and industrial systems.

Advantages:

High resistance to mechanical stress

The metal core provides added strength, while the rubber layer ensures a tight seal

Suitable for high-pressure and high-temperature environments

Common Applications:

Hydraulic and pneumatic systems

Automotive engines

Industrial machinery

Conclusion

Choosing the right material for sealing washers depends on the specific requirements of your application, including factors like temperature, chemical exposure, pressure, and environmental conditions. Whether you need rubber, silicone, neoprene, or EPDM, each material has distinct advantages that can help you create a durable, leak-proof seal.

By considering the key characteristics of each material, you can make an informed decision that ensures your sealing washers will provide reliable performance for years to come. Don’t overlook the importance of quality in your sealing washer choice—after all, the success of your project depends on a secure, efficient, and leak-free seal.

0 notes

Text

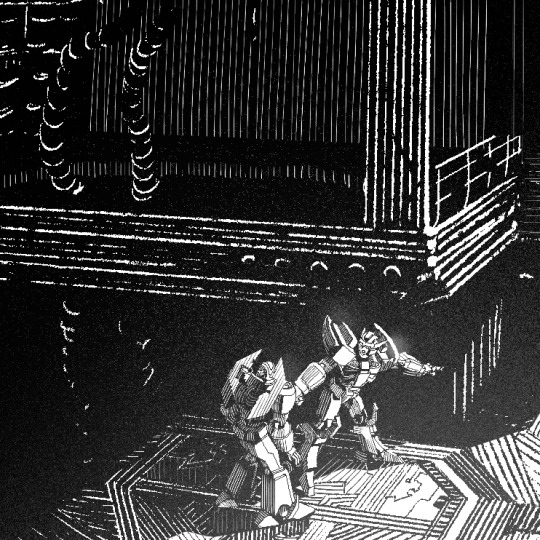

oops, still feral over pre-war Dead End Dratchet

(drift: you're rusting at every joint gasket: but isn't that doctor chummy with the cops? we're literal thieves??)

started with the headcanon that drift hung around the clinic like a feral wet cat for a while, then halfway through shading these, I started thinking, what if deadlock was an especially reliable assassin because he knew what kind of damage would make sure that even the best of the best couldn't bring you back

#couple million years later#ratchet is performing autopsies and very determinedly not thinking about teaching that one kid which energon lines are most volatile#you ever get this image in your head of a guy lurking around the guy who saved his life and then think#guess i need to design a clinic#but because your dumb brain needs context you think i guess i need to design the surroundings so you start a daytime wide shot too#and then an even dumber part of your brain is like let's do it all in that fake etching style that you haven't totally worked out yet#and then you also get sad about gasket so you stick him in too#they're done at least we achieved something aaaaaaa????#transformers idw#maccadam#tf drift#dratchet#tf ratchet#ratchet#gasket#drift#mtmte#my art

4K notes

·

View notes

Link

Hey gearheads and machine enthusiasts!

Today, we're diving into the not-so-glamorous but super important world of hydraulic cylinder seals. These unsung heroes are the guardians against leaks, friction, and contamination, keeping your hydraulic systems running smoothly.

What's the Deal with Seals?

Imagine a powerful hydraulic cylinder – the muscle behind everything from construction equipment to factory robots. But without proper seals, it's like a leaky faucet. Fluid escapes, pressure drops, and performance goes pfft.

Seals are like tiny ninjas, strategically placed to:

Block Leaks: They create a tight barrier between high and low-pressure zones, keeping the juice flowing where it needs to.

Block Out Dirt: They act as bouncers for nasty contaminants that can damage your precious hydraulic system.

Minimize Friction: A smooth seal means less energy wasted on rubbing and more on getting the job done.

Seal Squad: Different Seals for Different Deals

Just like there's a superhero for every situation, there's a hydraulic seal for every application. Here's a sneak peek at some of the key players:

Piston Seals: These bad boys seal the deal between the piston and the cylinder bore, keeping the pressure where it belongs.

Rod Seals: They guard the exit point where the piston rod emerges, preventing leaks and keeping grime out.

Buffer Seals: Think of them as shock absorbers, dampening pressure spikes and keeping things smooth during operation.

Choosing the Right Seal: It's All About Compatibility

Not all seals are created equal. To pick the perfect one, consider factors like:

Pressure and Temperature: Some seals can handle the heat (and pressure) better than others.

Fluid Type: Match the seal material to the type of fluid your system uses for optimal performance.

Keeping Your Seals Happy: Maintenance Matters!

Just like any hard-working component, hydraulic seals need some TLC to last. Here are some tips:

Regular Inspections: Keep an eye out for wear and tear, and replace seals before they fail.

Cleanliness is Key: Contamination can shorten a seal's lifespan, so keep your system clean.

The Right Fluid: Using the recommended hydraulic fluid will ensure your seals stay happy and healthy.

So, next time you see a hydraulic cylinder in action, remember the silent heroes – the hydraulic seals – keeping everything running smoothly.

#hydraulicpower #engineering #machines #maintenance #seals

#hydraulic cylinder seals#hydraulics#fluidpower#manufacturing#engineering#hydrauliccylinders#seals#gaskets#leakproof#highperformance#constructionequipment#industrialautomation#agriculture

0 notes

Text

Armstrong Heat Exchanger Gaskets

We supplies gasket spares for over 20 different models of Armstrong's Gasketed Plate Heat Exchanger (PHE) products, with a variety of configurations, connections and material options.

Features of Armstrong Heat Exchanger Gaskets

High temperature resistance, NBR gasket 120°C (250°F), EPDM gasket 160°C (320F).

Materials: Nitrile, EPDM, Viton, PTFE.

Helps seal surfaces and prevent leaks.

Wide application range.

0 notes

Text

🚛 Looking for high-quality gaskets ( https://gispares.in/product/gasket-coolant-pipe/ ) for your Volvo trucks' coolant pipes? Look no further! 🛠️ At gispares.in, we're your trusted wholesaler for top-notch Volvo truck gasket coolant pipes. We've got the parts you need to keep your fleet running smoothly, and we're here to deliver the best solutions for your business. ✅ Premium Quality: Our gaskets are built to withstand the toughest conditions and ensure a leak-free, efficient cooling system. ✅ Competitive Prices: Get the best value for your money without compromising on quality. We offer competitive pricing that suits your budget. ✅ Bulk Orders: Whether you need a single gasket or a bulk order, we've got you covered. No order is too big or too small for us. ✅ Fast Shipping: We understand the importance of timely delivery. Count on us for swift shipping to get your trucks back on the road ASAP. Ready to order or inquire? Visit our website gispares.in to explore our wide range of Volvo truck gasket coolant pipes or contact us for personalized assistance. Let's keep your Volvo trucks cool and efficient!

#gaskets#india#european truck spare parts#global impex#volvo trucks#europeantruckspareparts#distributor#volvo truck spare parts#european truck spare parts supplier#gispares

0 notes

Text

Spiral Wound Gasket | Spiral Gasket Manufacturers

Find Top-notch and high-performance Spiral Wound Gaskets from leading manufacturers. Benefit from their excellent sealing capabilities and durability.

0 notes

Text

#mechanicalseals#engineering#mechanicalseal#hydraulics#seals#pumps#oilseals#hydraulicseals#gaskets#hnbr#ffkm#glandpacking#uksupplier#vmq#totallyseals#viton#rubber#fkm#silicone#nbr#orings#nitrile#mechanicalworkshop#mechanical#nicos#sellosmecanicos#ukmanufacturing#stainlesssteel#mechanicalroom#sealingproducts

0 notes

Text

Spiral Wound Gasket Materials- A Comprehensive Guide to Superior Sealing Solutions

Spiral wound gaskets are renowned for their outstanding sealing capabilities, especially in applications that involve extreme temperatures, high pressure, and aggressive chemicals. The secret behind their exceptional performance lies in the unique combination of materials used in their construction. Designed for use in critical industrial sectors like oil and gas, petrochemical, power generation, and pharmaceuticals, spiral wound gasket provide a versatile solution for preventing leaks and ensuring system integrity. In this article, we will explore the various materials used in spiral wound gaskets and their significance in different industrial applications.

The Structure of Spiral Wound Gaskets

Spiral wound gasket consist of a combination of metallic and non-metallic materials. The gasket is formed by winding alternating layers of a metallic strip and a soft filler material in a spiral manner. This design allows the gasket to be both flexible and robust, making it ideal for handling the most demanding sealing applications.

Metallic Materials Used in Spiral Wound Gaskets

The metallic component of a spiral wound gasket provides structural integrity and strength, allowing it to withstand high pressures and temperatures. Common metals used include:

Stainless Steel:

The most widely used metal for spiral wound gaskets, stainless steel (grades such as 304, 316, and 321) offers excellent corrosion resistance and mechanical strength. This material is suitable for most applications involving exposure to chemicals, steam, and corrosive environments.

Monel:

Monel, a nickel-copper alloy, is known for its superior resistance to acids, alkalis, and seawater. Gaskets made from Monel are ideal for use in marine environments and chemical processing industries where harsh chemicals are present.

Inconel:

Inconel is a high-strength nickel-chromium alloy that excels in high-temperature and high-pressure environments. This material is used in applications where extreme heat, such as in power generation plants and refineries, can degrade other metals.

Titanium:

For applications requiring resistance to both high temperatures and aggressive chemicals, titanium is an excellent choice. Its lightweight yet durable properties make it ideal for use in aerospace and chemical processing industries.

Filler Materials in Spiral Wound Gaskets

While the metal provides strength and durability, the filler material ensures effective sealing. The choice of filler material depends on the application’s specific requirements, such as temperature, chemical exposure, and operating pressure. Common filler materials include:

Flexible Graphite:

Flexible graphite is known for its excellent thermal conductivity and chemical resistance. It can handle temperatures up to 450°C (850°F) and is used in applications involving high temperatures, such as in steam systems, boilers, and heat exchangers. It also resists oxidation and can withstand exposure to a wide range of chemicals.

PTFE (Polytetrafluoroethylene):

PTFE is one of the most chemically resistant materials available. It provides exceptional resistance to corrosive chemicals and solvents, making it suitable for gaskets used in chemical processing and pharmaceutical industries. PTFE can operate in temperatures ranging from -200°C to +260°C (-328°F to 500°F), making it highly versatile for both high and low-temperature applications.

Mica:

Mica is a naturally occurring mineral known for its high heat resistance. It can withstand temperatures up to 1000°C (1832°F) and is primarily used in applications involving extreme heat, such as power generation and high-temperature industrial furnaces.

Additional Components: Inner and Outer Rings

Spiral wound gaskets also incorporate inner and outer rings made from materials like carbon steel or stainless steel. These rings provide stability, help center the gasket within the flange, and prevent over-compression during installation. The rings also protect the sealing element from the corrosive environment and enhance the gasket’s longevity.

Inner Ring: The inner ring prevents the filler material from being exposed to the inner media and maintains gasket integrity under high pressure.

Outer Ring: The outer ring is used for accurate centering in the flange and to protect the spiral wound element from excessive tightening forces.

Advantages of Spiral Wound Gasket Materials

High Durability:

The combination of metallic and non-metallic materials ensures that spiral wound gasket materials can withstand extreme operating conditions without deteriorating or losing sealing performance.

Versatility:

By selecting different combinations of metals and fillers, spiral wound gasket can be customized to meet the specific needs of any industrial application, from cryogenic temperatures to high-temperature steam systems.

Resilience:

Spiral wound gasket maintain flexibility, allowing them to adapt to flange imperfections and provide a secure seal even when there are changes in pressure and temperature.

Excellent Chemical and Thermal Resistance:

The use of high-quality filler materials like PTFE and flexible graphite ensures resistance to a wide range of chemicals, high temperatures, and pressure fluctuations, making spiral wound gasket suitable for diverse applications.

Common Applications of Spiral Wound Gaskets

Oil and Gas:

Spiral wound gaskets are widely used in pipelines, refineries, and offshore platforms where high pressure, extreme temperatures, and corrosive chemicals are common.

Power Generation:

Power plants utilize spiral wound gasket in boilers, heat exchangers, and steam turbines, where they are exposed to high-temperature steam and varying pressure conditions.

Chemical Processing:

The chemical industry benefits from the chemical resistance of spiral wound gasket, using them in reactors, pumps, and pipelines carrying aggressive chemicals.

Petrochemical:

Refineries and petrochemical plants rely on these gaskets to seal joints in process equipment that handles corrosive chemicals and extreme heat.

Conclusion

Spiral wound gaskets, with their combination of durable metals and flexible filler materials, provide an unmatched sealing solution for the most challenging industrial environments. The versatility of material options ensures that spiral wound gasket can be tailored to meet the specific demands of any application, whether in the oil and gas sector, chemical processing, or power generation. The right selection of metallic and filler materials guarantees long-lasting performance, cost-efficiency, and safety, making spiral wound gasket a preferred choice for industries worldwide.

Original Source: Spiral Wound Gasket Materials

0 notes

Text

Exploring the Advantages of American Seal and Packing's Comprehensive Gasket Solutions

In the realm of industrial applications, precision, reliability, and quality are non-negotiable. At American Seal and Packing, these core principles are not just upheld; they are elevated to an art form. With an unwavering commitment to excellence, American Seal and Packing proudly offers a full range of Gaskets designed to meet your exact specifications. As a leading name in the industry, they redefine gasket solutions by unveiling a host of benefits that cater to diverse needs and ensure unmatched performance.

A Spectrum of Gasket Materials: American Seal and Packing understands that different applications demand different materials. With an impressive repertoire of gasket materials, including trusted brands such as Durlon, Leader, AS&P, Thermoseal, FMI, and Teadit, they offer a versatile selection that ensures compatibility with varying mediums and environments. From high-pressure applications to corrosive chemicals, their materials are designed to withstand the most demanding conditions.

Cutting-Edge Methods of Cutting: Precision is the cornerstone of effective gasket solutions, and American Seal and Packing’s methods of cutting exemplify this principle. Their range of cutting techniques includes die cutting, knife-edge CNC (dieless flash cutting), laser cutting, and waterjet cutting. This diverse array of cutting options ensures that gaskets are tailored to your unique specifications, allowing for intricate designs, precise dimensions, and seamless integration.

Quality Craftsmanship: Gaskets are not mere components; they are vital elements that ensure the integrity and efficiency of industrial operations. American Seal and Packing’s commitment to quality craftsmanship is reflected in every gasket they produce. Whether it’s a standard size or a custom design, each gasket is crafted with meticulous attention to detail, using materials that meet the highest industry standards.

Tailored Solutions: No two applications are identical, and American Seal and Packing recognizes the importance of offering tailored solutions. Their ability to customize Gaskets to your exact requirements ensures that you receive a product that fits seamlessly within your operational framework. This dedication to customization extends to dimensions, materials, and cutting techniques.

Expertise and Innovation: With years of experience in the industry, American Seal and Packing has evolved alongside technological advancements. Their expertise is coupled with a dedication to innovation, allowing them to provide gasket solutions that align with contemporary needs. As industry requirements evolve, American Seal and Packing remains at the forefront, offering Gaskets that reflect the latest advancements.

Transparent Communication: At the heart of American Seal and Packing’s approach is transparent communication. They work closely with clients to understand their needs, specifications, and challenges. This collaborative approach ensures that the gasket solutions provided not only meet but exceed expectations.

In Conclusion: American Seal and Packing is not just a provider of Gaskets; they are partners in industrial efficiency and reliability. With a commitment to excellence, a diverse array of cutting-edge cutting techniques, and a range of quality materials, they redefine gasket solutions. From standard applications to the most demanding industrial environments, American Seal and Packing’s Gaskets offer advantages that translate into enhanced performance, longevity, and peace of mind. Experience the benefits of precision, customization, and quality with American Seal and Packing’s comprehensive gasket solutions.

0 notes

Text

📰 TAEVision Engineering 's Posts - Mon, Jul 17, 2023 TAEVision 3D Mechanical Design • Automotive BMW Coupe M3 Imola Red • Parts AutoParts EngineParts Aftermarket Elring SealingProducts SealingCompounds HONDA Lighting Systems • Automotive Tools Repair RemovalInjectors Automotive HONDA Civic Injectors HONDA 1️⃣ Data 547 3D Design Applications Automotive BMW "The Ultimate Driving Machine" BMW Bayerische Motoren Werke BMW Coupe M3 Imola Red ▸ TAEVision Engineering's Post on Tumblr 2️⃣ Data 173 Parts EngineParts Aftermarket Elring cylinderhead gaskets sealing SealingProducts SealingCompounds ▸ TAEVision Engineering's Post on Tumblr 3️⃣ Data 072 Parts AutoParts Aftermarket HONDA Lighting Systems ▸ TAEVision Engineering's Post on Tumblr 4️⃣ Data 217 Tools GarageTools Repair RepairTools RemovalTools RemovalInjectors Automotive HONDA Civic injectors HONDA ▸ TAEVision Engineering's Post on Tumblr

📰 I just updated my Pressfolio: TAEVision Mechanics's Online Portfolio - Global Data - Jul 17, 2023 ▸ TAEVision Mechanics's Online Portfolio (last update)

Global Data - Jul 17, 2023

#TAEVision#engineering#3d#mechanicaldesign#automotive#BMW#BMW Bayerische Motoren Werke#BMW Ultimate Driving Machine#BMW Coupe M3#Imola Red#parts#autoparts#engineparts#aftermarket#Elring#CylinderHead gaskets#gaskets#sealing#sealing products#sealing compounds#HONDA#lighting#LightingSystems#lighting systems#tools#repair#RemovalInjectors#HONDA Tools#injectors HONDA#HONDA Civic

1 note

·

View note

Text

Here. A bunch of rough doodles of these two idiots bc I wanna draw but don’t have energy for anything fancy hehe

#maccadam#transformers#prowl#jazz#jazzprowl#drift#gasket#I’m actually going through fics you recommended to me rn#eheheheh#which is#thank you for your recommendations#also Im so damn impressed by their word counts#jazzprowl writers are wild

1K notes

·

View notes

Text

Safer sealing solutions for the Oil & Gas industry To find out the range of our gaskets. Drop us an email at [email protected] | Visit us at petracarbon.com

1 note

·

View note

Text

JE Pro Seal Cylinder Head Gaskets

The cylinder head gasket is a commonly overlooked area. When upping cylinder pressures with boost and timing the head gasket is required to still perform and maintain that crucial seal. JE’s Pro Seal line up is undoubtedly one of the best on the market. Readmore

0 notes