#EPDM Gaskets

Explore tagged Tumblr posts

Text

Exploring the Advantages of American Seal and Packing's Comprehensive Gasket Solutions

In the realm of industrial applications, precision, reliability, and quality are non-negotiable. At American Seal and Packing, these core principles are not just upheld; they are elevated to an art form. With an unwavering commitment to excellence, American Seal and Packing proudly offers a full range of Gaskets designed to meet your exact specifications. As a leading name in the industry, they redefine gasket solutions by unveiling a host of benefits that cater to diverse needs and ensure unmatched performance.

A Spectrum of Gasket Materials: American Seal and Packing understands that different applications demand different materials. With an impressive repertoire of gasket materials, including trusted brands such as Durlon, Leader, AS&P, Thermoseal, FMI, and Teadit, they offer a versatile selection that ensures compatibility with varying mediums and environments. From high-pressure applications to corrosive chemicals, their materials are designed to withstand the most demanding conditions.

Cutting-Edge Methods of Cutting: Precision is the cornerstone of effective gasket solutions, and American Seal and Packing’s methods of cutting exemplify this principle. Their range of cutting techniques includes die cutting, knife-edge CNC (dieless flash cutting), laser cutting, and waterjet cutting. This diverse array of cutting options ensures that gaskets are tailored to your unique specifications, allowing for intricate designs, precise dimensions, and seamless integration.

Quality Craftsmanship: Gaskets are not mere components; they are vital elements that ensure the integrity and efficiency of industrial operations. American Seal and Packing’s commitment to quality craftsmanship is reflected in every gasket they produce. Whether it’s a standard size or a custom design, each gasket is crafted with meticulous attention to detail, using materials that meet the highest industry standards.

Tailored Solutions: No two applications are identical, and American Seal and Packing recognizes the importance of offering tailored solutions. Their ability to customize Gaskets to your exact requirements ensures that you receive a product that fits seamlessly within your operational framework. This dedication to customization extends to dimensions, materials, and cutting techniques.

Expertise and Innovation: With years of experience in the industry, American Seal and Packing has evolved alongside technological advancements. Their expertise is coupled with a dedication to innovation, allowing them to provide gasket solutions that align with contemporary needs. As industry requirements evolve, American Seal and Packing remains at the forefront, offering Gaskets that reflect the latest advancements.

Transparent Communication: At the heart of American Seal and Packing’s approach is transparent communication. They work closely with clients to understand their needs, specifications, and challenges. This collaborative approach ensures that the gasket solutions provided not only meet but exceed expectations.

In Conclusion: American Seal and Packing is not just a provider of Gaskets; they are partners in industrial efficiency and reliability. With a commitment to excellence, a diverse array of cutting-edge cutting techniques, and a range of quality materials, they redefine gasket solutions. From standard applications to the most demanding industrial environments, American Seal and Packing’s Gaskets offer advantages that translate into enhanced performance, longevity, and peace of mind. Experience the benefits of precision, customization, and quality with American Seal and Packing’s comprehensive gasket solutions.

0 notes

Text

Top Silicone & EPDM Rubber Extrusion Experts | Gaskets, Tubing & Custom Parts

In the technologically advanced world of nowadays, silicone rubber extrusion manufacturers are the unsung heroes. With an upward push in application throughout a myriad of industries - automotive, production, electronics, and healthcare, the call for remarkable silicone rubber extrusions has amplified considerably.

Premium producers like Star Seals Co, Stock well Elastomerics, and VIP Rubber and Plastic Co play a pivotal role in molding the enterprise requirements. They mixture superior technological methodologies with a commitment to great, delivering flexible, resilient, and premium-grade products that rightfully match the client's precise specifications.

Silicone rubber extrusion manufacturers are continuously innovating, with a pointy cognizance on creating merchandise which can bear severe temperatures, resist water, and stay resilient to physical wear and tear. Compliance with Rohs, REACH, and FDA standards is a testimony to their commitment to championing best and safety.

It's the steadfast adherence to retaining a nice balance of flexibility and stress, durability, and adaptability that sets those enterprise leaders apart. As guidelines turn out to be stricter and requirements greater traumatic, the reliance on adept silicone rubber extrusion manufacturers steepens, promising them a future with colossal increase potentialities. Partnering with silicone rubber extrusion manufacturers ensures that you now not most effectively get superior products, but also a devoted ally invested in efficacy, durability, and your long-term fulfillment.

Sealing Success: The Unsung Heroes - Extruded Gasket Suppliers

In the numerous business panoramas, additives such as gaskets won't seize headlines, but their importance cannot be overstated. This unsung hero paperwork is the bedrock of numerous essential business strategies. By presenting extruded gasket suppliers, we goal to spotlight this pivotal, albeit really uncelebrated industry.

Extruded gaskets are notably famed because of their customization functionality; their potential to mold into different sizes and styles makes them versatile. Because of the complex programs, gasket manufacturers have upped their game to supply super extruded variations that can sustain hostile conditions without compromising on their sealing features.

Dependable suppliers like those are the backbone of industries like car, HVAC, creation, and extra. They cope with pressure situations with no trouble, proving important in getting rid of the hazard of leakages and ensuring choicest device performance. The best of their products, their adherence to specifications, their prompt shipping, and flexible order portions set them aside.

Summing up, dependable gasket suppliers provide the lots-needed warranty in a commercial setup with their top-notch products. Their contributions, even though now not regularly in the highlight, are indeed fundamental for seamless operations. By highlighting them nowadays, we hope to acknowledge their tireless service to the industrial global.

Extruded Rubber Tubing: The Unsung Hero of Indispensable Applications

In the arena of manufacturing, one factor time and again proves instrumental yet not noted - Extruded Rubber Tubing. Strategically designed and diligently produced, this industrial wonder has all the time changed the functionality of numerous sectors.

Rubber Tubing, regarded for its flexibility, durability, and splendid resistance to extreme temperatures, has discovered a myriad of programs. From the scientific field using it for fluid transmission to automotive sectors harnessing it for wiring and gasoline strains, its utilization is large and diversely impactful.

Moreover, its superb resistance to oils, acids, alkalis, and other harsh chemical compounds make it an invaluable asset in chemical processing industries. Throughout its wide-accomplishing applicability, these rubber tubing continues a critical stability between flexibility and pressure, imparting reliable answers where different substances collapse.

Perhaps the most eye-catching factor of these rubber tubing lies in its customizable nature. Its design can be tailor-made to fulfill particular enterprise needs, making it a versatile and adaptable solution in a dynamic world.

These rubber tubing is an unsung hero, silently bolstering lots of our critical packages. As we preserve innovation, one factor is certain - the importance of extruded rubber tubing isn't about to wane.

Mastering the Art of EPDM Profile Extrusion: Shaping the Future

EPDM Profile Extrusion, a key production method, is rapidly gaining traction in industries across the globe. Ethylene Propylene Diene Monomer (EPDM) is a versatile fabric, well-appeared for its first-rate sturdiness, flexibility, and weather resistance, making it a favored choice in applications like automobile weather-stripping and roofing membranes.

The art of Profile Extrusion entails pushing or pulling the heated EPDM fabric via a custom-engineered die. This procedure shapes the cloth, remodeling it into a profile with the favored cross-section. Extrusion is highly green, imparting precise and consistent consequences, ideal for bulk manufacturing, particularly inside the car and creation industries.

Remarkable improvements inside the Profile Extrusion sector have brought about improved efficiency and precision, maximizing product nice and fee-effectiveness. With automation and pc-controlled extrusion, producers can ensure uniform first-rate, stepped forward material conservation, reduced waste, and faster production times.

In global annoying progressive and efficient answers, Profile Extrusion stands out as a promising production technique. As we include this first-rate technology, the industry advances, shaping the future in its particular profile.

Stay tuned to our weblog for more insights and thrilling news about the captivating global of Profile Extrusion. Together, permits explore how this current process is revolutionizing industries internationally.

Extruded Rubber Parts: The Unseen Champions of Manufacturing

Rubber, versatile and durable, silently performs an important function in diverse industries. Specifically, extruded rubber elements are the lifeblood of endless applications. Produced thru an excessive-strain method, extruded rubber components take the form of tubes, rods, and gaskets, adapting to the mold of any design requirement.

These portions comfortably locate themselves in industries from automobile to aerospace, owing their popularity to rubber’s inherent characteristics; resistance towards wear and tear, temperature variations, electricity, and chemical compounds. This makes them perfect for sealing and insulation purposes, climate-stripping, and limitless other business needs.

Extruded rubber parts are also the unsung heroes of expertise; accuracy and precision outline their manufacturing. Their manufacture might also contain customization and stringent specification adherence but fear now not, the end product is really worth it. They healthy flawlessly, decorate product lifecycles and add value to the given product.

We invite you to discover the sector of extruded rubber components, the unseen champions working tirelessly behind the curtain. Their sheer adaptability and resilience echo in our everyday lives, from the vehicles we drive to the planes we fly. Indeed, without extruded rubber elements, our global might be a mile's distinctive location.

Conclusion

The unsung heroes of the technologically evolved world are silicone rubber extrusion producers like VIP Rubber and Plastic Co., Stock well Elastomerics, and Star Seals Co. They produce versatile, robust, and premium-grade solutions that satisfy customer requirements by fusing cutting-edge technology with a dedication to quality.

We at Custom Rubber Extrusions deliver made-to-order rubber extrusion solutions crafted around your needs. Collaborating closely with you and your team, we identify optimal solutions that drive value and measurable ROI. To learn more or schedule a consultation, contact [email protected] or (213)-426-1030.

#Silicone Rubber Extrusion Manufacturers#Extruded Gasket Suppliers#Extruded Rubber Tubing#epdm profile extrusion#extruded rubber parts

0 notes

Text

Hex flange drilling screws (with EPDM gasket)

0 notes

Text

Epdm Dense Rubber Window Locking Gasket Weather Stripping

0 notes

Text

Exploring the Top EPDM Rubber Extrusion in Canada

EPDM rubber extrusionstands out in rubber manufacturing in Canada. This process is essential. EPDM refers to ethylene propylene diene monomer. It is a synthetic rubber. EPDM is renowned for its versatility and durability. Many industries use EPDM. These industries range from automotive parts to roofing systems. In this blog, we will delve into the top EPDM rubber extrusion. We will highlight the top EPDM Rubber Extrusion companies in Canadaand their offerings. We will also emphasize the advantages of EPDM rubber products.

What is EPDM Rubber?

Before we explore EPDM extrusion, let’s first get a grasp on EPDM rubber. What is it? Why is it so popular? EPDM stands for Ethylene Propylene Diene Monomer. It is a type of synthetic rubber. It is known for its high resistance to heat, ozone, and weathering. It can withstand extreme temperatures. These range from -60°F to 150°F (-51°C to 66°C). This makes it an ideal material for both indoor and outdoor applications.

Key Properties of EPDM Rubber

Weather Resistance: EPDM is highly resistant to UV rays and ozone, which makes it suitable for outdoor use.

Temperature Tolerance: It maintains its properties over a wide temperature range.

Chemical Resistance: EPDM can resist many chemicals, acids, and alkalis, though it is not suitable for petroleum-based products.

Electrical Insulation: It also serves as an excellent electrical insulator.

The properties mentioned above establish rubber extrusion as the top choice. Many industries find it appealing. These include automotive construction and manufacturing.

Applications of EPDM Rubber Extrusion

Increasingly, it has become popular. It is used in various industries. Its unique properties are the reason. It is used so widely. Below. Some common applications.

Automotive Industry: These are significant components in the automotive sector. They are used for seals and gaskets in the industry. The material is known for flexibility and durability It protects Vehicles from water. It Preserves the Integrity of vehicle systems.

Construction: EPDM is used in the construction of roofing membranes. Its weather resistance is a key factor. It’s also used in window seals and door frames. It enhances energy efficiency and prevents air leaks.

HVAC Systems: EPDM Profiles are used in HVAC systems. They play a role in insulation and sealing. They help control temperature. They also enhance energy efficiency.

Electrical Applications: EPDM.Used In electrical cable sheathing. Also in connectors. Its properties make it good for this purpose. EPDM is an electric insulator. It keeps the electricity safe and reliable.

Industrial Applications: EPDM is used in industrial machines. It is used in gaskets And seals. EPDM is resistant to chemicals. It lasts In Harsh conditions.

One of the Top EPDM Rubber Extrusion Manufacturers in Canada

Seeking EPDM extrusion? Custom Rubber Extrusions ranks highly among Canada’s top manufacturers. Over 25 Years in the industry Have honed our expertise. .We are skilled at crafting high-quality custom extrusions. Our goal is to deliver Products tailored to our clients’ needs.

Why Choose Custom Rubber Extrusions?

Unmatched Expertise: We boast a team of professionals. They have an in-depth understanding of rubber extrusion processes. This makes us proud. Our problem-solving skills are impeccable. We are adept at taking on complex challenges. The solutions we create are innovative. They are geared to suit your unique requirements.

State-of-the-Art Technology: Utilization Of advanced rubber extruders is something We pride ourselves on. Our aim is to ensure Tight tolerances. We use precision tooling to achieve consistent product quality. Die tooling is done in-house. This helps us to Cater to customer needs swiftly. It doesn’t matter if the specifications are lacking In detail.

Customized Solutions: We acknowledge the unique nature Of every project. For this reason, we offer a co-design process. Our engineers work closely with you. This collaboration ensures that the End product meets your exact specifications. Our Adaptability is visible in material selection. High-performance EPDM is part of our material palette.

Commitment to Quality: Quality Is our forte at Custom Rubber Extrusions.. We implement strict quality control measures. They are in place during the entire production process. Every product produced must meet the highest standards. These standards are for performance. They are also for durability.

For reliable and high-quality rubber extrusion, choose Custom Rubber Extrusions as your trusted partner in Canada. Contact us today to discuss your project needs!

Conclusion

The Canadian manufacturing landscape is abundant . It offers a multitude of high-quality EPDM rubber extrusionproducts. Finding Custom gaskets or specialized profiles is easy. The manufacturers listed above provide tailored services.

Choose your supplier wisely. It can change the destiny of Your project. The key is to consider many factors. Experience is one factor. Take Into account the product range and capabilities. Also, examine the customer service.

Choose your partner wisely. Have the right partner for you. Be it one of the top extruded gasket suppliers. Alternatively, experienced extruded rubber products manufacturersshould have the right partner, which is crucial. This can ensure precision and quality. Your projects can be completed with this care. We are Custom Rubber Extrusions. Today. Reach out today. Call our expert team. Dial at (647) 294-5240. Alternatively, send us an email. Our email address is [email protected].

#extruded-gasket-suppliers#extruded-rubber-products-manufacturers#epdm-rubber-extrusion#top-epdm-rubber-extrusion-in-canada

0 notes

Text

#siliconerubber#silicone rubber tubing#epdm rubber seals#conductive silicone tubing suppliers#high-temperature silicone rubber tubing#gasket rubber#seal and gasket

0 notes

Text

Enhance Your Plumbing System: Discover Grooved EPDM Gaskets

Looking for efficient sealing solutions? Look no further than Groovjoint LLC's range of Grooved EPDM Gaskets. Engineered with precision, our gaskets deliver exceptional performance and durability. Contact us or visit our website for more information and explore our comprehensive gasket options for your projects.

0 notes

Text

EPDM Rubber Gaskets: A Solution for Chemical Resistance and Temperature Flexibility

In the UAE, EPDM rubber gaskets provide a flexible sealing option for a variety of industries. They are perfect for the harsh conditions in this area because of their resistance to chemicals, temperature fluctuations, and environmental factors. For more details, visit https://justpaste.it/gzeua

0 notes

Text

EPDM Gaskets Manufacturers and Dealers in India – Dirak India

EPDM (Ethylene Propylene Diene Monomer) gaskets have become a cornerstone for various industrial and commercial applications due to their exceptional resistance to weathering, ozone, UV radiation, and temperature fluctuations. For businesses in need of reliable and high-quality EPDM gaskets, Dirak India stands out as a leading manufacturer and dealer in the country, offering unmatched expertise and innovative solutions tailored to meet industry standards.

Why Choose EPDM Gaskets?

EPDM gaskets are widely favored for their excellent sealing properties, making them ideal for applications involving air, water, and chemicals. These gaskets are known for their:

Weather Resistance: EPDM gaskets exhibit excellent resistance to aging caused by ozone, UV rays, and extreme weather conditions, ensuring durability even in outdoor applications.

Temperature Tolerance: They can withstand a wide range of temperatures, from -40°C to 120°C, making them suitable for both high-heat and cold environments.

Chemical Resistance: EPDM is resistant to a variety of chemicals, including water-based liquids, making it ideal for sealing applications in chemical plants and automotive industries.

Flexibility and Elasticity: EPDM gaskets retain their flexibility and elasticity over time, offering consistent performance and long service life.

Dirak India: A Trusted Leader in EPDM Gaskets Manufacturing

Dirak India has earned a strong reputation as a prominent manufacturer and dealer of EPDM gaskets in India. Here’s why Dirak India is the preferred choice for businesses:

1. Precision Engineering

At Dirak India, precision is at the heart of every product. The EPDM gaskets produced are designed to meet exact specifications, ensuring a perfect fit for various industrial applications. Whether it’s for electrical enclosures, automotive parts, or HVAC systems, Dirak’s EPDM gaskets guarantee reliable sealing and protection.

2. Advanced Manufacturing Capabilities

Leveraging state-of-the-art manufacturing technologies, Dirak India ensures that all EPDM gaskets adhere to the highest quality standards. The company’s robust production processes ensure consistent quality, enabling them to meet the large-scale demands of industries such as automotive, electronics, construction, and aerospace.

3. Customization for Specific Requirements

Every industry has unique requirements, and Dirak India recognizes the importance of tailored solutions. The company offers custom-designed EPDM gaskets to meet specific needs, including varying thicknesses, shapes, and sizes. This flexibility allows Dirak to serve a broad range of sectors, ensuring the gaskets are perfectly suited to the intended application.

4. Commitment to Quality and Durability

As one of the top EPDM gasket manufacturers in India, Dirak India adheres to strict quality control measures throughout the production process. Every gasket undergoes rigorous testing to ensure it meets both national and international quality standards. This commitment to quality guarantees long-lasting performance in even the most demanding environments.

5. Sustainability and Eco-Friendliness

In line with global sustainability trends, Dirak India ensures that the materials used in its EPDM gaskets are eco-friendly and sustainable. The company focuses on reducing environmental impact by minimizing waste and ensuring that its products contribute to the overall goal of sustainability.

Wide Range of EPDM Gaskets for Various Applications

Dirak India offers an extensive range of EPDM gaskets for diverse applications:

Automotive Industry: EPDM gaskets are used in door seals, window seals, and weatherstripping, providing excellent insulation and protection against external elements.

Construction and HVAC: These gaskets are ideal for sealing doors, windows, and HVAC systems, offering thermal insulation and protection against air leaks.

Electrical and Electronics: EPDM gaskets are commonly used in electrical enclosures to protect sensitive components from dust, moisture, and other environmental factors.

Industrial Machinery: For machinery that requires resistance to chemicals and extreme temperatures, EPDM gaskets provide reliable sealing solutions.

Nationwide Presence and Support

As a leading EPDM gaskets manufacturer and dealer in India, Dirak India has an extensive distribution network that spans across the country. This ensures that businesses from all corners of India have access to top-quality EPDM gaskets. The company’s dedicated customer support team is always ready to assist with product selection, customization, and after-sales service.

Conclusion

When it comes to EPDM gaskets manufacturers and dealers in India, Dirak India is a name you can trust for innovative solutions, superior quality, and unmatched reliability. With a focus on precision engineering, customization, and sustainability, Dirak India has established itself as a leader in the field, catering to a wide range of industries. Whether you need standard gaskets or custom-made solutions, Dirak India has the expertise and capacity to meet your specific requirements with excellence.

For more information on EPDM gaskets or to discuss your specific needs, get in touch with Dirak India today.

0 notes

Text

Custom Silicone gaskets

Custom silicone gaskets provide a snug seal for various applications. Tailored to fit specific needs, these durable gaskets resist heat and pressure, ensuring reliable performance. Ideal for diverse industries, they offer a cost-effective solution for effective sealing.

epdm gasket manufacturers

If you're in search of reliable EPDM gasket manufacturers, look no further. Our company specializes in custom rubber silicone molds, ensuring you get precisely what you need. Trust us for quality craftsmanship and tailored solutions to meet your requirements seamlessly.

0 notes

Text

EPDM Rubber Gasket Suppliers in Hyderabad

If you’re hunting for EPDM Rubber Gasket suppliers in Hyderabad, you’ve landed in the right spot! Poly Projects is among the top EPDM Rubber Gasket manufacturers in Hyderabad known for quality, durability, and customized solutions that fit your exact needs.

What’s so special about EPDM Rubber Gaskets anyway?

Made from Ethylene Propylene Diene Monomer (EPDM) — a fancy name for a rubber that’s tough as nails.

They resist heat, UV rays, and weather like champs.

Perfect for sealing windows, doors, pipes, and machines — basically, wherever you need to keep stuff airtight or watertight.

Why Poly Projects?

We deliver the best EPDM Rubber Gasket products with precision.

Custom sizes and shapes to match your project.

Quick and reliable delivery — no waiting weeks.

Affordable prices without cutting corners on quality.

Not just EPDM Rubber Gaskets!

We also supply:

Polycarbonate Roofing Sheets — let the sunshine in, but keep the rain out.

Galvanized Iron Color Coated Sheets — strength meets style.

UPVC Sheets / Windows — durability that lasts.

Silicon Sealant — perfect for extra tight seals.

Self Drill Screws — strong fastening guaranteed.

Car Parking Sheds, Canopy, Sky Light Duct Covering

Swimming Pool Covering — complete outdoor protection solutions.

Who uses our products?

Builders, architects, contractors, and homeowners all across Hyderabad and Telangana rely on us for quality materials that stand the test of time.

Why trust us?

Top-notch manufacturing with strict quality control.

Environmentally friendly materials.

Expert advice and support whenever you need it.

Thousands of happy clients and growing!

Ready to seal the deal with the best EPDM Rubber Gasket suppliers in Hyderabad? 📞 Call us now at 92909 12888 🌐 Visit polyprojects.in for more info.

#EPDM Rubber Gasket Manufacturers in Hyderabad#EPDM Rubber Gasket Suppliers in Hyderabad#EPDM Rubber Gasket Hyderabad#Best EPDM Rubber Gasket#Top EPDM Rubber Gasket Suppliers#Durable EPDM Rubber Gasket Hyderabad#Custom EPDM Rubber Gaskets#Industrial EPDM Gasket Suppliers Hyderabad#EPDM Gasket for Construction#Weather Resistant EPDM Rubber Gasket#Affordable EPDM Rubber Gasket Hyderabad#EPDM Sealing Gaskets Hyderabad#Polycarbonate Roofing Sheets Hyderabad#Galvanized Iron Color Coated Sheets#UPVC Sheets and Windows Suppliers#Silicon Sealant Suppliers Hyderabad#Self Drill Screws Manufacturer#Car Parking Sheds Hyderabad#Canopy Suppliers Hyderabad#Sky Light Duct Covering Supplier#Swimming Pool Covering Hyderabad

0 notes

Text

The benefits of single-sourcing Rubber products supplier

Single sourcing is defined as procuring a specific category of components from one supplier. It comes with a host of benefits like easy management of vendor records, quick invoice processing, and one-point shipment. On a negative note, some buyers feel that it could make them dependent on one vendor leading to forceful acceptance of their terms and conditions. Moreover, situations like quality issues and running out of stock could put the buyer in a delicate situation. But the above negatives are common when you source from multiple vendors too. Here are some reasons why it is beneficial to single-source your rubber products supplier.

Benefits of single sourcing from Alfa Rubber

Unlimited supply of raw material: South India is renowned for its vast rubber plantations; this ensures constant supply to meet the growing demands of the rubber industry. With no delay in procuring raw materials, the production never stops, making it a reliable single-source rubber products supplier.

Quality and versatility: South Indian Rubber is renowned for its quality and versatility and hence the finished products are bound to be of superior quality. With both natural and synthetic variants available, there is no dearth of supply.

Competitive rates: High production volume and competition among rubber producers result in affordable pricing. Low production cost also gives buyers access to affordable raw materials and the cost is passed onto the buyers by the rubber products suppliers.

Skilled workforce: Traditionally Southeast Asia is known for its competence in plantation, process, and manufacturing. The skilled workforce added with advanced technology promises high-quality rubber products.

For all the above reasons and more, it is advised to bet on single-source rubber product suppliers. Alfa Rubber is a name to recall for your rubber supplies.

Contact us for more details.

ALFA RUBBER & SPRINGS PRIVATE LIMITED

A-13/A, SIPCOT INDUSTRIAL COMPLEX,

GUMMIDIPOONDI. TAMILNADU 601 201, INDIA

PHONE – +91-44-27922057

EMAIL – [email protected]

https://alfarubber.com/products/

#Rubber products supplier#Rubber parts supplier#Dustcap manufacturer#Epdm rubber parts product#Automotive rubber parts#Silicon rubber products#Gaskets and Seals

0 notes

Text

Silicone rubber products - High-strength materials

Silicone rubber products are used in varied applications and industries. Some of them include the food industry, railways, transport industry, medical and pharma, aerospace, automotive, construction, offshore industry, electrical and lighting, power grids, and marine. https://alfarubber.home.blog/2023/10/10/silicone-rubber-products-diversified-industrial-applications/

#Silicon rubber products#O rings manufacturer#Gaskets and Seals#Rubber gasket seal#Rubber Injection Molding#Seal manufacturer#Bush manufacturer#Rubber parts supplier#Dustcap manufacturer#Rubber products supplier#Epdm rubber parts product#Automotive rubber parts#Rubber Grommet manufacturer#Grommet manufacturer

0 notes

Text

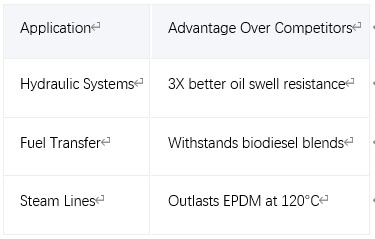

Aohong NBR Sealing Rubber Gaskets: The Cost-Effective Workhorse for Demanding Applications

Let's face it—when that hydraulic system starts leaking after just six months and you're knee-deep in oil-soaked components, you realize not all rubber gaskets are created equal. NBR Sealing Rubber Gaskets from Aohong solve what generic elastomers can't: delivering reliable sealing performance without breaking the bank. Here's why our nitrile rubber solution outperforms the competition where it matters most.

The Science Behind Superior Sealing

That 34% acrylonitrile content in Aohong's formulation isn't just a random number—it's the sweet spot for balancing oil resistance and flexibility. While cheaper NBR compounds cut corners with 28% content (and pay the price in swelling), we've optimized our material to deliver:

70±5 Shore A hardness (ASTM D2240 verified)

<10% oil swell after 1,000 hours in ASTM #3 oil

-40°C to 120°C service range—no brittle fractures in cold climates

85% compression set resistance at 100°C (beats EPDM in hot oil)

Pro Tip: That matte black finish isn't for looks—it's our proprietary carbon black reinforcement that adds 30% more tear strength versus standard NBR.

Real-World Proof: Hydraulic Cylinder Case Study

Take this OEM mining equipment application we solved last quarter:

Problem: Competitor's gaskets swelled 25% after 3 months

Conditions: 1,500 psi hydraulic fluid + 80°C continuous operation

Solution: Aohong's NBR gasket with enhanced oil swell resistance

After 18 months of brutal service: ✓ Zero leaks (pressure tested monthly) ✓ Only 8% thickness variation ✓ Saved $14,000 in downtime costs

Their maintenance supervisor called it "the only gasket that lasts through our service interval."

Installation: Do It Right the First Time

Surface Prep

32-64 RA surface finish (too smooth causes slippage)

Clean with isopropyl alcohol—never WD-40 (leaves silicone residue)

Torque Sequence

30% less torque than FKM gaskets

Criss-cross pattern for even compression

Break-In Period

Allow 24 hours for full compression set

Retorque after first thermal cycle

❌ $8,000 Mistake Using petroleum grease as lubricant—it degrades NBR over time. Silicone-based only.

Where Aohong's NBR Excels

Safety Note: Never use with ketones or esters—they'll dissolve the material in weeks.

The Bottom Line

When your application needs oil resistance without fluoropolymer prices—whether it's a construction equipment hydraulic system or a biodiesel transfer line—Aohong's NBR Sealing Rubber Gasket delivers proven performance where generic rubber fails.

Why gamble with inferior materials? Contact Aohong's engineering team today for application-specific solutions—because in industrial sealing, "good enough" usually fails at the worst possible moment.

3 notes

·

View notes

Text

Exploring the Top EPDM Rubber Extrusion in Canada

EPDM rubber extrusion stands out in rubber manufacturing in Canada. This process is essential. EPDM refers to ethylene propylene diene monomer. It is a synthetic rubber. EPDM is renowned for its versatility and durability. Many industries use EPDM. These industries range from automotive parts to roofing systems. In this blog, we will delve into the top EPDM rubber extrusion. We will highlight the top EPDM Rubber Extrusion companies in Canada and their offerings. We will also emphasize the advantages of EPDM rubber products.

What is EPDM Rubber?

Before we explore EPDM extrusion, let’s first get a grasp on EPDM rubber. What is it? Why is it so popular? EPDM stands for Ethylene Propylene Diene Monomer. It is a type of synthetic rubber. It is known for its high resistance to heat, ozone, and weathering. It can withstand extreme temperatures. These range from -60°F to 150°F (-51°C to 66°C). This makes it an ideal material for both indoor and outdoor applications.

Key Properties of EPDM Rubber

Weather Resistance: EPDM is highly resistant to UV rays and ozone, which makes it suitable for outdoor use.

Temperature Tolerance: It maintains its properties over a wide temperature range.

Chemical Resistance: EPDM can resist many chemicals, acids, and alkalis, though it is not suitable for petroleum-based products.

Electrical Insulation: It also serves as an excellent electrical insulator.

The properties mentioned above establish rubber extrusion as the top choice. Many industries find it appealing. These include automotive construction and manufacturing.

Applications of EPDM Rubber Extrusion

Increasingly, it has become popular. It is used in various industries. Its unique properties are the reason. It is used so widely. Below. Some common applications.

Automotive Industry: These are significant components in the automotive sector. They are used for seals and gaskets in the industry. The material is known for flexibility and durability It protects Vehicles from water. It Preserves the Integrity of vehicle systems.

Construction: EPDM is used in the construction of roofing membranes. Its weather resistance is a key factor. It’s also used in window seals and door frames. It enhances energy efficiency and prevents air leaks.

HVAC Systems: EPDM Profiles are used in HVAC systems. They play a role in insulation and sealing. They help control temperature. They also enhance energy efficiency.

Electrical Applications: EPDM.Used In electrical cable sheathing. Also in connectors. Its properties make it good for this purpose. EPDM is an electric insulator. It keeps the electricity safe and reliable.

Industrial Applications: EPDM is used in industrial machines. It is used in gaskets And seals. EPDM is resistant to chemicals. It lasts In Harsh conditions.

One of the Top EPDM Rubber Extrusion Manufacturers in Canada

Seeking EPDM extrusion? Custom Rubber Extrusions ranks highly among Canada’s top manufacturers. Over 25 Years in the industry Have honed our expertise. .We are skilled at crafting high-quality custom extrusions. Our goal is to deliver Products tailored to our clients’ needs.

Why Choose Custom Rubber Extrusions?

Unmatched Expertise: We boast a team of professionals. They have an in-depth understanding of rubber extrusion processes. This makes us proud. Our problem-solving skills are impeccable. We are adept at taking on complex challenges. The solutions we create are innovative. They are geared to suit your unique requirements.

State-of-the-Art Technology: Utilization Of advanced rubber extruders is something We pride ourselves on. Our aim is to ensure Tight tolerances. We use precision tooling to achieve consistent product quality. Die tooling is done in-house. This helps us to Cater to customer needs swiftly. It doesn’t matter if the specifications are lacking In detail.

Customized Solutions: We acknowledge the unique nature Of every project. For this reason, we offer a co-design process. Our engineers work closely with you. This collaboration ensures that the End product meets your exact specifications. Our Adaptability is visible in material selection. High-performance EPDM is part of our material palette.

Commitment to Quality: Quality Is our forte at Custom Rubber Extrusions.. We implement strict quality control measures. They are in place during the entire production process. Every product produced must meet the highest standards. These standards are for performance. They are also for durability.

For reliable and high-quality rubber extrusion, choose Custom Rubber Extrusions as your trusted partner in Canada. Contact us today to discuss your project needs!

Conclusion

The Canadian manufacturing landscape is abundant . It offers a multitude of high-quality EPDM rubber extrusion products. Finding Custom gaskets or specialized profiles is easy. The manufacturers listed above provide tailored services.

Choose your supplier wisely. It can change the destiny of Your project. The key is to consider many factors. Experience is one factor. Take Into account the product range and capabilities. Also, examine the customer service.

Choose your partner wisely. Have the right partner for you. Be it one of the top extruded gasket suppliers. Alternatively, experienced extruded rubber products manufacturers should have the right partner, which is crucial. This can ensure precision and quality. Your projects can be completed with this care. We are Custom Rubber Extrusions. Today. Reach out today. Call our expert team. Dial at (647) 294-5240. Alternatively, send us an email. Our email address is [email protected].

0 notes

Text

Top 5 Benefits of Using Rubber Gaskets in Industrial Settings

In the demanding world of industrial manufacturing, efficiency and reliability are non-negotiable. From high-pressure pipelines to sanitary processing systems, one seemingly small component plays a critical role in keeping operations running smoothly: the rubber gasket. At California Rubber, we specialize in precision-engineered rubber gaskets designed for performance, durability, and safety across a wide range of applications.

Rubber gaskets offer significant advantages over metal or fiber alternatives in terms of flexibility, resilience, and resistance to extreme conditions. In this blog, we explore the top five benefits of using rubber gaskets in industrial environments.

1. Superior Sealing Capability

The primary function of any gasket is to create a leak-proof seal between two surfaces, and rubber gaskets excel at this. Thanks to their inherent flexibility and compressibility, rubber gaskets can conform to surface irregularities, ensuring a tight seal even in imperfect or worn flange connections.

This superior sealing capability is particularly vital in high-pressure systems or where liquids and gases must be contained with absolute precision. Components like Sanitary Gaskets used in food and beverage manufacturing rely on high-grade rubber to maintain hygiene and prevent leaks under demanding conditions.

Rubber materials such as EPDM, NBR, and silicone are also excellent at maintaining seal integrity across a wide range of temperatures and pressures, making them ideal for dynamic and static applications alike.

2. Chemical and Temperature Resistance

Industrial environments often expose components to aggressive chemicals and extreme temperatures. Rubber gaskets are available in a variety of formulations that offer excellent resistance to these challenges.

EPDM is commonly used for steam and water applications due to its excellent heat and weather resistance.

Nitrile rubber offers superb resistance to oils, fuels, and other hydrocarbons.

Silicone rubber is ideal for high-temperature sealing up to 230°C (446°F).

This adaptability ensures long-term performance without degradation, reducing the frequency of replacements. It’s particularly valuable in environments such as Cannabis Extraction Parts, where chemical exposure is frequent and operational safety is a top concern.

3. Durability and Longevity

Rubber gaskets are known for their excellent wear and fatigue resistance. When properly installed and maintained, they can provide years of reliable service, even in environments with high levels of vibration, pressure fluctuations, or abrasive materials.

This durability not only lowers the total cost of ownership but also contributes to reduced downtime and maintenance cycles. In sectors like brewing, where production schedules are tight and efficiency is key, using high-performance components such as Brewing Gaskets can significantly improve system reliability.

The use of advanced manufacturing techniques like compression molding and injection molding ensures that rubber gaskets meet precise dimensional tolerances for consistent performance.

4. Noise and Vibration Dampening

In addition to sealing, rubber gaskets offer excellent vibration isolation and noise reduction. Their elastic nature absorbs mechanical energy, dampening vibration between metal parts and reducing wear and fatigue on adjacent components.

This feature is particularly useful in dynamic systems such as pumps, compressors, and HVAC systems. Components like aodd pump parts often integrate rubber seals and diaphragms to ensure quieter operation and longer mechanical life.

By minimizing mechanical noise and vibration, rubber gaskets also contribute to safer and more comfortable working environments in industrial facilities.

5. Versatility Across Applications

Rubber gaskets are incredibly versatile, available in a wide variety of shapes, sizes, and materials to suit almost any industrial requirement. Whether you need a standard flange gasket or a custom-molded seal for a unique configuration, rubber provides a flexible solution.

Their usage spans industries including:

Food and beverage processing

Pharmaceuticals and biotechnology

Oil and gas

Automotive and aerospace

Water treatment and chemical processing

Rubber gaskets can also be tailored to meet regulatory and compliance standards such as FDA, NSF, and USP Class VI, depending on the application.

From standard sealing tasks to highly specialized roles, rubber gaskets can be engineered to solve complex challenges efficiently and economically.

Maintenance Tips for Longer Gasket Life

To get the most out of rubber gaskets, consider these simple but effective maintenance tips:

Perform regular visual inspections for signs of wear, cracking, or hardening.

Ensure proper torque is applied during installation to avoid over-compression.

Store spare gaskets in a cool, dry place away from sunlight and ozone sources.

Replace gaskets at the first sign of leakage to prevent downstream damage.

Proactive care will maximize the life span of your gaskets and ensure uninterrupted system performance.

Why Rubber Gaskets Are a Smart Investment

Rubber gaskets are not only a practical solution for sealing and insulation but also a strategic choice for improving operational efficiency. With the right material and design, they reduce maintenance needs, enhance equipment life, and support safe, clean processing environments.

For manufacturers in regulated industries, choosing the correct gasket material is also key to maintaining product quality and compliance. Investing in high-performance rubber gaskets is ultimately an investment in your operation’s reliability and success.

Conclusion

Rubber gaskets offer a powerful combination of sealing performance, chemical resistance, durability, and versatility that make them indispensable in modern industrial settings. At California Rubber, we understand the critical role gaskets play in your operations, and we offer expertly engineered solutions to meet the most demanding requirements.

Whether you're upgrading aodd pump parts, installing FDA-compliant seals in food processing systems, or customizing Brewing Gaskets for specialized production needs, we provide the quality and expertise you can rely on. Reach out today to learn how our custom rubber gasket solutions can optimize your systems and extend the life of your equipment.

2 notes

·

View notes