#Extruded Rubber Tubing

Explore tagged Tumblr posts

Text

6 Tips for Extending the Lifespan of Rubber Extrusions and Seals

Extruded Rubber Seals are omnipresent in our day-by-day lives, from the tires on our cars to the seals in our machines. They're known for their solidness and adaptability, but like every fabric, elastic can wear out and endure harm over time.

Read More: https://customrubberextrus.wixsite.com/custom-extrusion/post/6-tips-for-extending-the-lifespan-of-rubber-extrusions-and-seals

#Extruded Rubber Seals#Extruded Rubber Parts#Extruded Rubber Tubing#Extruded Rubber Hose#Custom Rubber Extrusion

0 notes

Text

Custom Silicone Rubber Extrusion for Automotive, Food-Grade, and Industrial Applications

Did you ever wonder how many products surrounding you are covered with silicone rubber? Silicone rubber extrusion is an important element in many industries, from the components in your vehicle to the plumbing and hoses that are used to serve up your favorite beverages. In this blog, we’ll dive into the world of silicone rubber extrusion manufacturers, exploring silicone rubber extrusion’s applications in automotive, food-grade, and industrial sectors. Let’s break it down into simple terms!

Understanding Silicone Rubber Extrusion

So, what exactly is silicone rubber extrusion? It is a molding technique in which silicone rubber is formed into a predetermined profile by squeezing it through a die (specially configured opening). Imagine squeezing a tube of toothpaste—whatever shape the opening is, that’s the shape of the toothpaste as it comes out. By using this technique, manufacturers can form long, continuous pieces of silicone in any shape and form.

Automotive Applications

The automotive industry is dependent on automotive rubber extrusion manufacturers to create components that improve vehicle performance and safety. Especially relevant to this situation is silicone rubber which is capable of surviving high temperature, chemical and likewise biochemical attack and retains a foldable silicon elastomer characteristic throughout time. Here are some common uses:

Seals and Gaskets

Hoses and Tubing

Weatherstripping

Vibration Dampening

Electrical Insulation

Thanks to automotive rubber extrusion manufacturers, vehicles are built to last, providing safety and comfort for drivers and passengers alike.

Food-Grade Applications

In the food industry, safety is paramount. That's where silicone food grade extrusion tubing is useful. Silicone is a good candidate as it does not interact with food products and is capable of the high temperatures required for sterilization. Here are some key applications:

Dairy Processing

Beverage Production

Food Packaging

Medical and Pharmaceutical Uses

Manufacturers of silicone food grade extrusion tubing are subject to tight regulations to ensure that it is suitable for use with food. This involves using materials free from harmful chemicals and ensuring easy cleaning.

Industrial Applications

Silicone rubber extrusions have also been widely applied in many industrial fields. Their resistance to wear allows them to be used under extreme conditions such as high temperature or chemical exposure. Some industrial applications include:

Seals and Gaskets

Insulation

Vibration Dampening

Aerospace Components

Civil Engineering Applications

Many industries require custom extruded profiles tailored to their specific needs. This is where skilled silicone rubber extrusion manufacturers come into play, providing solutions that fit unique applications perfectly.

Choosing the Right Manufacturer

When you’re looking for custom rubber profiles, selecting the right silicone rubber extrusion manufacturers is crucial. Here are some tips:

Experience Matters: Seek manufacturers with a proven history of silicone rubber extrusion.

Quality Assurance: Verify if they hold certificates such as ISO 9001 as evidence of their quality control.

Customization Capabilities: Make it possible for silicone rubber extrusion manufacturers to produce the shapes you require for your application.

Material Variety: A quality manufacturer is able to supply a variety of types of silicone compounds, optimized for different applications.

Responsive Customer Service: Select a company that is reputed to be supportive and responsive to customer requirements.

Examples of Custom Extruded Profiles

Custom profiles can take many forms. Here are some common types:

D-Profiles: Alike the letter "D", is a rubber most used for seals, gaskets etc.

L-Profiles: L" shaped, commonly applied at the edge of a corner.

H-Profiles: Shaped like an "H," ideal for joining panels together.

U-Channels: Shape like a "U", to protect “edges†from abrasion or injury.

Tubing Profiles: Hollow shapes designed for transporting fluids or air.

Because of the capabilities of skilled manufacturers, almost all desired shapes can be achieved through silicone rubber extrusion.

Conclusion

Tailorable silicone rubber extrusion provides a wide range of engineering solutions for automotive, food-grade and industrial applications. Through understanding this process and its advantages, companies are in a position to take informed decisions about their production requirements. No matter if you need solid parts for automobiles or safe hoses for food processing, working with experienced silicone rubber extrusion manufacturers assures you of high-quality products engineered to your exact needs. Don't forget to think about experience, quality control, the ability to customize, the range of materials, and customer service when selecting a partner for this critical manufacturing step!

#silicone-rubber-extrusion-manufacturers#automotive-rubber-extrusion-manufacturers#custom-extruded-profiles#custom-rubber-profiles#silicone-food-grade-extrusion-tubing

0 notes

Text

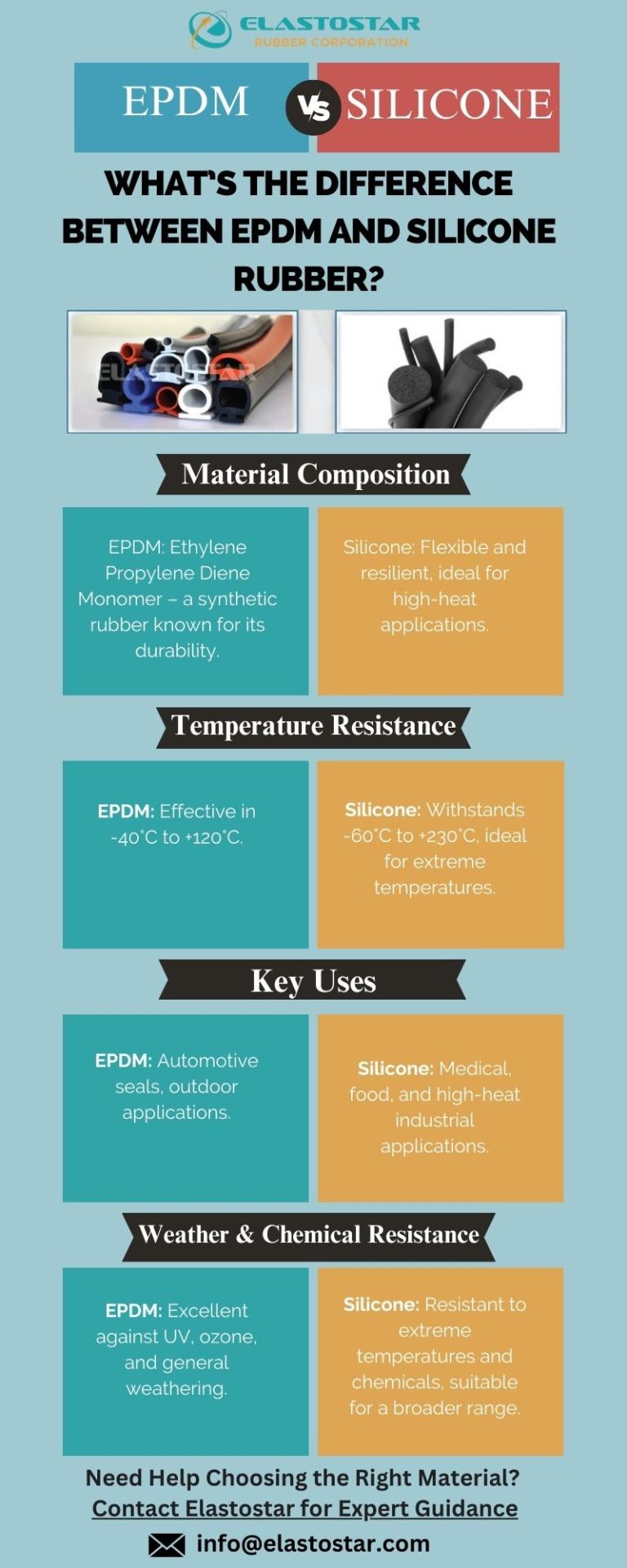

EPDM and Silicone Rubber differ in composition, temperature resistance, and applications. EPDM, a durable synthetic rubber, operates between -40°C to +120°C and is ideal for automotive and outdoor use, offering excellent UV and weather resistance. Silicone, known for its flexibility and resilience, withstands -60°C to +230°C, making it perfect for extreme temperatures, medical, food, and high-heat industrial applications. Silicone also provides superior chemical resistance for broader use. Need Help Choosing the Right Material? Contact Elastostar for Expert Guidance

#silicone rubber tubing#epdm rubber seals#siliconerubber#high-temperature silicone rubber tubing#extruded silicone rubber tubing#food grade silicone rubber cord

0 notes

Text

#silicone gasket suppliers#rubber tubing manufacturer#closed cell sponge rubber gaskets#rubber extruded#rubber seal parts manufacturer

0 notes

Text

Q&A: Research improves understanding of particle interactions for better material design

Toothpaste has a hard job. Not only does it have to perform essential functions like scrubbing that coffee residue from your pearly whites, but it also must stay in the tube, exit smoothly under pressure and balance on a bunch of bristles without running all over the bathroom sink. And every user, everywhere, appreciates it when any excess paste extruded, but not needed on the toothbrush, slides seamlessly back into the tube. This is an example of a thixotropic elastoplastic suspension made from many different particles. Now that's a mouthful. According to Norman Wagner, Unidel Robert L. Pigford Chair in Chemical and Biomolecular Engineering at the University of Delaware, these types of suspensions are found in everything from lotions to 3D-printing inks to building block materials for items, including rubber tires, clays, cements and more.

Read more.

#Materials Science#Science#Particles#Suspensions#Thixotropic#Fluid dynamics#Elastoplaticity#University of Delaware

8 notes

·

View notes

Text

Future of Medical Grade Silicone Rubber Market: Insights from Industry Experts

The global medical grade silicone rubber market size is estimated to reach USD 1.1 billion by 2030, registering to grow at a CAGR of 6.8% from 2025 to 2030 according to a new report by Grand View Research, Inc. The growing medical industry coupled with increasing healthcare expenditure across the world is projected to fuel the global market during the forecast period. The market is projected to register substantial growth due to the rising adoption of silicone rubber for prosthetics and implants, disposables, catheter, surgical instruments, and drug delivery systems.

Properties such as low toxicity, excellent biocompatibility, stain-resistant, extreme temperature applications (from -55°C to 230°C), flexible and durable, resistance to weathering and oxidation, excellent resistance to chemicals, superior dielectric, and insulation characteristics are propelling the product demand in medical applications. In Asia Pacific, the market is anticipated to progress at a CAGR of 7.3% over the forecast period. Increasing expenditure of various governments on public and private health systems are expected to positively impact the regional market growth.

The growth of the market can be attributed to the increasing government’s efforts to improve public access to healthcare services at affordable prices. Increasing government expenditure to improve infrastructure and accessibility in rural and urban areas is expected to drive the demand for medical devices and components, which, in turn, is expected to augment product demand over the forecast period. Moreover, the recent outbreak of COVID-19 in countries such as India, China, Australia, Japan, and Malaysia are creating huge product demand, especially in disposable, catheter application. Thus, the rising positive cases in the region are projected to significantly drive market growth.

High consistency rubber is anticipated to progress at a substantial growth rate over the forecast period. It is widely used in various applications such as balloon catheters, molded medical device parts, and extruded tubing. Properties such as excellent resistance to extreme weather conditions, high viscosity, and consistency are expected to propel demand in these applications.

Gather more insights about the market drivers, restrains and growth of the Medical Grade Silicone Rubber Market

Medical Grade Silicone Rubber Market Report Highlights

• Liquid silicone rubber dominated the market and accounted for a share of 62.1% in 2024 due to its exceptional flexibility, biocompatibility, and rapid curing capabilities.

• Prosthetics & implants led the market with a revenue share of 27.8% in 2024, owing to the growing requirement for biocompatible materials that prioritize patient safety.

• North America medical grade silicone rubber market dominated the global market with a revenue share of 34.1% in 2024.

Medical Grade Silicone Rubber Market Segmentation

Grand View Research has segmented the global medical grade silicone rubber market based on product, application, and region:

Medical Grade Silicone Rubber Product Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

• Liquid Silicone Rubber

• High Consistency Rubber

Medical Grade Silicone Rubber Application Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

• Prosthetics & Implants

• Disposables

• Catheter

• Surgical Instruments

• Drug Delivery Systems

• Others

Medical Grade Silicone Rubber Regional Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o UK

o Germany

o France

o Italy

• Asia Pacific

o Japan

o China

o India

o Australia

• Latin America

o Brazil

o Argentina

• Middle East & Africa

o Saudi Arabia

o UAE

List of Key Players in Medical Grade Silicone Rubber Market

• Dow

• Wacker Chemie AG

• Shin-Etsu Chemical Co., Ltd.

• Momentive Performance Materials

• Elkem ASA

• Avantor, Inc.

• KCC SILICONE CORPORATION

• Zhejiang Xin’an Chemical Group Co., Ltd.

• Simtec Silicone Parts, LLC

• Stockwell Elastomerics

• Trelleborg AB

• Applied Silicone Corporation

• Specialty Silicone Products, Inc.

• Rogers Corporation

Order a free sample PDF of the Medical Grade Silicone Rubber Market Intelligence Study, published by Grand View Research.

#Medical Grade Silicone Rubber Market#Medical Grade Silicone Rubber Market Size#Medical Grade Silicone Rubber Market Share#Medical Grade Silicone Rubber Market Analysis#Medical Grade Silicone Rubber Market Growth

0 notes

Text

Custom Made Extruded Gaskets, Manufacturer, Mumbai, India

Contact here to get more details of Custom Made Extruded Gaskets, We are manufacturer, supplier, dealer and best service provider of Extruded Profiles in Mumbai, India.

Rubber Products, Moulded Rubber Parts, Extruded Rubber Parts, Sponge Moulded Parts, Metal Bonded Parts, Manufacturers Of Rubber Components, Manufacturers Of Moulded Rubber Parts, Manufacturers Of Extruded Rubber Parts, Rubber Moulded Parts, 'O' Rings, Oilseal, U Seal, V Seal, Chevron Packing For Pumps, Hydraulics Seal, Mechanical Seal, Neoprenen Rubber, Nitrile Rubber, Epdm Rubber, Hypalon Rubber, FKM Rubber, Natural Rubber, Polymers, Flourinated Rubber, FKM Rubber, Silicone Rubber, Polyurethane Rubber, Ethylene Propylene Terpolymers, Natural Rubber, Synthetic Rubber, Chemical Resistance, O Rings, U Seals, V Seals, Lip Seals, Wiper Seals, Oil Seals, Diaphragms, Electrical Control Valves, Pneumatic Control Valves, Pressure Regulators, Valve Positioner, Ball & Butterfly Valve, Solenoid Valve With Brass, Stainless Steel Stud, Fabric, Nylon, Canvas, Rayoncord, Wiremess, Gasket, Flange Packing, Pipe Fittings, Filters, Electrical Instrument Panel Board, Electrical Transformer, Packing For Plastic Drums, Packing For Plastic Carbouys, Metal To Rubber Bonded Product, Foundation Pad, Buffers, Coupling Bush With Ms, Coupling Bush With Brass, Coupling Bush With Ss, Bearing Cover, Brake Pad, Extruded Product, Chords, Sleeves, Conveyor System, Dyeing & Oven Packing, Electrical Panel Boards, Conveyor System, Cement & Fertilizers Plant, Switchgear Fittings, Electrical Fittings, Pharmaceutical Rubber Part, Filtration Rubber Part, Triclover Gasket, Envelope Gasket, Body Gasket, Nutche Filter Gasket, Silicone Colour Tubes, Transparent Tubes, Chemical Process Plant, Filtration Plants, Bulk Drugs Manufacturers, Electrical Pushbutton Switches Rubber Parts, Belt Ring, Diffuser Washer, Key Selector U Seal, Lense O Ring, Rubber Boots, Transparent Rubber Boots, Silicone Rubber Boots, Station Cover Gaskets.

0 notes

Text

Shaping the Future: Exploring the World of Plastic Extrusion Profiles

From the intricate trim on your car to the robust window frames in your home, plastic extrusion profiles are ubiquitous in modern life. These versatile components, created through a fascinating manufacturing process, play a crucial role in countless applications across diverse industries. This blog post delves into the world of plastic extrusion profiles, exploring their creation, benefits, applications, and why partnering with a trusted supplier like PARK NON WOVEN can bring your projects to life.

What is Plastic Extrusion?

Plastic extrusion is a manufacturing process where molten plastic is forced through a die of a specific cross-section, creating a continuous profile. This profile can be simple, like a tube or a sheet, or complex, like a custom-designed shape. The extruded plastic is then cooled and cut to the desired length. This process allows for the efficient production of consistent and precise plastic parts.

Types of Plastic Extrusion:

Several variations of plastic extrusion cater to different needs:

Profile Extrusion: Produces shapes with complex cross-sections, like window frames, pipes, and seals.

Sheet Extrusion: Creates flat sheets of plastic, used for packaging, signage, and thermoforming.

Pipe Extrusion: Manufactures pipes and tubing for various applications.

Coating Extrusion: Applies a thin layer of plastic onto a substrate, like wire or cable.

Materials Used in Plastic Extrusion:

A wide range of thermoplastics can be used in plastic extrusion, each offering unique properties:

PVC (Polyvinyl Chloride): Durable, versatile, and cost-effective, used for pipes, window frames, and siding.

ABS (Acrylonitrile Butadiene Styrene): Impact-resistant and easy to process, used for automotive parts, toys, and appliance housings.

Polyethylene (PE): Flexible and lightweight, used for packaging, films, and pipes.

Polypropylene (PP): Strong and heat-resistant, used for automotive parts, containers, and fibers.

Thermoplastic Elastomers (TPEs): Flexible and rubber-like, used for seals, gaskets, and grips.

Benefits of Plastic Extrusion Profiles:

Plastic extrusion offers a variety of advantages:

Design Flexibility: Can create complex shapes and custom profiles.

Cost-Effective: Efficient manufacturing process, especially for large volumes.

Consistent Quality: Produces parts with uniform dimensions and properties.

Lightweight: Plastic profiles are often lighter than metal counterparts.

Corrosion Resistance: Many plastics are resistant to corrosion and weathering.

Versatility: Suitable for a wide range of applications.

Applications Across Industries:

Plastic extrusion profiles find applications in numerous sectors:

Construction: Window and door frames, siding, pipes, and trim.

Automotive: Interior and exterior trim, seals, and gaskets.

Packaging: Containers, bottles, and films.

Consumer Goods: Appliance housings, toys, and furniture components.

Medical: Tubing, catheters, and medical device components.

Electronics: Cable management, enclosures, and connectors.

Choosing the Right Plastic Extrusion Partner:

Selecting a reliable plastic extrusion partner is crucial for project success. Factors to consider include:

Experience and Expertise: A company with a proven track record in plastic extrusion.

Material Selection: Ability to work with a wide range of thermoplastics.

Customization Capabilities: Ability to design and manufacture custom profiles.

Quality Control: Rigorous quality assurance processes.

Production Capacity: Ability to meet your production volume requirements.

PARK NON WOVEN: Expanding Horizons Beyond Non-Wovens

While PARK NON WOVEN is known for its expertise in non-woven materials, we are also expanding our capabilities to serve a broader range of manufacturing needs. We are exploring opportunities in related fields like plastic extrusion profiles, leveraging our commitment to quality, innovation, and customer service. Stay tuned for updates on our expansion into this exciting area!

Why Partner with PARK NON WOVEN?

Commitment to Quality: We adhere to the highest quality standards in all our processes.

Customer Focus: We prioritize customer satisfaction and work closely with our clients.

Technical Expertise: Our team has the knowledge and experience to support your projects.

Innovation: We are constantly exploring new technologies and materials.

Contact PARK NON WOVEN Today!

For inquiries about our current product offerings and future ventures, please contact us.

[email protected] 0124-4816111 Corporate Office: Park Non Woven Pvt. Ltd., Gurugram, HR

#pet acoustic panel#non woven battery gaunlets#compressor felt#breather fabric#fiber glass felt#light weight insulation#pp + pet felt#plastic extrusion profile#high efficiency media#lint free wipes

0 notes

Text

Plastic Extrusion - Best Plastic Extrusion Suppliers

Plastic extrusion has been in use since the early nineteenth century when it was popularized by some different innovators. To begin, Thomas Hancock developed a method for producing usable rubber from processed wastes in 1820. This he referred to as a rubber masticator.

Edwin Chaffee, a colleague of the better renowned Charles Goodyear, then developed the first two-roll rubber mixing machine in 1836. While they were not intended for use with plastic, they were both adaptable and paved the way for further extrusion equipment.

Alexander Parkes invented the first synthetic plastic in 1862. His innovation garnered enough notice that he was allowed to exhibit it at that year's London World Fair. However, due to its high development cost and low quality, this plastic product was never widely utilized.

Celluloid was the first practical man-made plastic. This was created in the United States by John Wesley Hyatt, who co-patented it with his brother Isaiah in 1870.

Following the discovery of Celluloid, a plethora of additional plastic polymers, such as PVC and Bakelite, was developed. As the kinds and uses of plastic expanded, producers sought methods to create them more efficiently and precisely. There are various plastic packaging specialists all over the world.

The range of polymers for which plastic extrusion services are offered is very lengthy. It is composed of low-density polyethylene (LDPE), high-density polyethylene (HDPE), vinyl, polypropylene, polystyrene, butyrate, and PETG, among other materials.

LDPE:

Low-density polyethylene, or LDPE, is a tough and flexible material. Additionally, this plastic is extremely resistant to a wide range of chemicals, including esters, alcohols, bases, and acids.

HDPE:

As is the case with LDPE, HDPE, or high-density polyethylene, is a durable material. Additionally, it is resistant to corrosion and solvents, has a high strength-to-weight ratio, and high tensile strength.

Vinyl:

Vinyl, sometimes referred to as PVC (polyvinyl chloride), is a very common polymer. It is offered in two different types: flexible PVC and stiff PVC. It has the following properties: insulation, resistance to salt, acid, corrosion, base, fat, and alcohol. Unfortunately, vinyl is not particularly thermally stable unless it has a stabilizing ingredient. Siding, pipes, floor coverings, angles, and tubing are just a few of the most popular PVC extrusions.

Polypropylene:

Another very common polymer is polypropylene. It is resistant to heat, acid, base, and chemical solvents. Additionally, it has a low density.

Here at Sreka, you can get the most renowned plastic extrusions suppliers. They are plastic packaging specialists. They are specialized in vinyl polymers for a range of sectors, from commercial furniture and shop fixtures to industrial applications. They've been manufacturing plastic extrusions for a lengthy period of time. Their extruded plastics are utilized in a variety of sectors, from automotive to medical. They have steadily grown and established themselves as a preferred provider of high-quality goods and technical innovation.

0 notes

Text

Transparent Silicone Rubber Tubes Supplier

Vishal Rubber Products is one of the best Extruder Rubber products Manufacturer in Pune, We craft various Silicone Rubber Profiles or beads tailored to fit specific shapes and sizes as needed. These profiles find applications across diverse industrial sectors including Automotive, Pharmaceutical, Chemical, Heavy Industry, Electrical & Electronics, Irrigation, Agriculture, and Food industries. We are the best Transparent Silicone Rubber Tubes Supplier.

Selecting a source who understands your wants and meets your expectations is crucial when it comes to obtaining trustworthy and superior transparent silicone rubber tubes. Because of its versatility, safety, and dependability, silicone rubber tubing is extensively employed in a variety of industries, including the medical, food processing, automotive, and electrical. This article will help you in navigating the choices and understanding the benefits, uses, and characteristics of these tubes if you’re searching for a reliable source of transparent silicone rubber tubes.

1 note

·

View note

Text

Cold Feed Rubber Extruder: Enhancing Efficiency in Rubber Processing

A Cold Feed Rubber Extruder is a specialized machine used in the rubber industry to shape and form rubber compounds by forcing them through a die. Unlike traditional extruders, cold feed extruders do not require pre-heating of the rubber before feeding it into the machine, which improves energy efficiency and reduces processing time. These extruders are widely used in manufacturing rubber products like profiles, tubes, hoses, and cables.

The key benefits of cold feed rubber extruders include:

Energy Savings: With no need for pre-heating, these machines consume less energy.

Improved Productivity: Faster processing times and consistent output enhance production efficiency.

Better Control: Precise control over temperature, pressure, and die design ensures high-quality rubber products.

If you're in the rubber manufacturing industry, investing in a Cold Feed Rubber Extruder can optimize your operations, reduce costs, and improve product quality. Explore top manufacturers and models to find the right extruder for your needs today.

0 notes

Text

Automotive Rubber Extrusions Custom Seals & Manufacturer

Introduction

In this complex field known as automotive production, it is essential to be precise and accurate. As the report shows, Custom Rubber Extrusions stay as vital parts, enhancing the safety, function, and durability of automobiles. Ranging from blocking and fragmenting any external force to deporting the required insulation and shock absorption qualities, they hold stern importance in a myriad of car and truck usages.

Unraveling Rubber Extrusions

Rubber extrusions are co-extruded lengths of rubber produced by compounding a rubber material with a specific cross-sectional profile and forcing it through a die. This extrusion process also makes cross-section shapes and sizes possible for manufacturers to create components with various cross-sectional criteria ideal for automobiles.

Understanding the Range of Uses of Automotive Rubber Extrusions

The realm of automotive rubber extrusions is vast and encompasses a variety of types, each with unique characteristics and applications:

Custom Rubber Extrusions: These are extrusions that are truly custom-made in the sense that they are endowed with precise architectural outlines to create extrusion profiles that will suit the needs of a customer. They can be made from a large number of rubber compounds, which can be natural rubber, synthetic rubber, and silicone; thus the composite boat can have flexibility in the choice of rubber.

Extruded Rubber Tubing: This category includes profiles with a hollow structure, which are used when producing hoses, gaskets, and many other auto parts made from a tube.

Silicone Food Grade Extrusion Tubing: For applications where sanitation, as well as food safety, is important, especially in automotive food service or beverage delivery systems, silicone food grade extrusion tubing is used to meet the greatest level of cleanliness and food safety.

Neoprene Rubber Extrusions: Chemically and oil-fatigue as well as weathering resistant, the neoprene rubber extrusions are useful for engine seals and gaskets where service conditions are severe.

Applications of Automotive Rubber Extrusions: A Multitude of Uses

The versatility of rubber extrusions is evident in their widespread use across various automotive applications:

Seals and Gaskets: Rubber extrusions act as reliable barriers to keep out both water and dust while blocking other harmful substances. The parts rely on rubber extrusions to operate correctly.

Cushioning and Vibration Dampening: By absorbing vibrations and shocks, rubber extrusions improve vehicle rides and lessen interior noise.

Weather-stripping: Sealed gaps around doors and hoods help rubber extrusions block leaks and noise while preventing drafts from entering the car.

Hoses and Tubing: Rubber extrusions help transport fluids and gases throughout vehicles at every stage to keep systems working effectively.

Bumpers and Grilles: The structural strength of bumpers and grilles depends on rubber extrusions that protect and support these vital vehicle components. Our Detailed Examination Reveals the Benefits of Creating Unique Rubber Extrusions

Several key advantages make custom rubber extrusions an attractive choice for automotive manufacturers:

Versatility: Manufacturers can create any desired surface format and color combination with rubber extrusions to match precise design needs.

Durability: Specialized rubber products resist intense conditions because they stand up against mechanical damage and maintain their shape across heat changes and chemical contact.

Cost-Effectiveness: Rubber extrusions made in large quantities help automotive firms achieve affordable production costs.

Customization: The process of creating customized rubber extrusions for exact performance lets them deliver ideal automotive industry performance under tough conditions.

Conclusion

extruded gasket supplier have become essential parts of automotive production today. Their broad adaptability combined with enduring quality and competitive pricing makes rubber extrusions the preferred material selection for multiple applications. Clubbing with expert rubber extrusion manufacturers delivers exceptional performance parts to boost vehicle safety and durability.

Call to Action:

If you want to improve vehicle performance, you should consider as your primary source for custom rubber components trusted for many different motor vehicle applications. Our technical team helps you choose the right materials and creates customized solutions that match exactly what you need. To find out our complete product selection and see how our custom rubber extrusions can improve your vehicle, visit

0 notes

Text

The Future Of Extruded Rubber Tubing In Industry

Amidst these dynamic world of commercial application, the extruded rubber tubing rises as a worthy introduction of an excellent material, which deliver excellent performance in all ways.

Resilience: Extruded rubber tubes have outstanding characteristics, warmness, pressure, chemical and weather and compounds resistance. Such virtues make them a good desire for the harsh climate of many industries ranging from automobile to the chemical industry.

Variety: it likewise offers a range of possibilities of the thickness, the hardness as well as diameter of extruded rubber tubing. You also have the ability to choose between many types of rubber, each with its particularities which perfectly match the expectations of your mission.

Cost-effectiveness: We find extruded rubber tubing as a price-powerful approach in manufacturing and even in the preservation aspect. It is hugely durable which minimizes the need for replacement, and its ease in installation minimizes the exertion expenses.

The careful management of extruded rubber tubing is useful in extending industrial functions, fundamental to performance and routine production. Were it us the situation was reversed, let’s embrace this revolution and unlock what it enables.

Unleashing the Wonders of Extruded Silicone Tubing

These tubing have become an effective solution, shoving challenges in various fields ranging from healthcare to electronics. Extruded silicone tubing is highly appreciated for its recovery, resistance and insulating properties.

Resilience and Durability: Silicone tubing also does not melt under heat, such high temperature that decomposes other tubing materials; it can take pressure, and is also resistant to corrosive materials. Due to such characteristics, it is effective for long-time period application; a price-effective material for industries.

Versatility: From meals and movement elating processing to complicated clinical device, the versatility of silicone tubing is owed several applications. It is versatile to allow variation of wall thickness and diameter which makes it compatible for different sectors.

Non-reactive Nature: Apart from being odorless and tasteless silicone tubing is nontoxic and hypoallergenic which makes it a good thing for use in healthcare products and food processing.

Revolutionize Your Industries with Custom Silicone Extrusions

In a world trending towards generation, conscious industries are selecting adaptable media such as silicone. Custom Silicone extrusions present a cornucopia of phenomenal creates that make them the perfect solution in a number vying business domains.

Unparalleled Versatility: The auto frottage of these extrusions is recognized for versatility. They might be designed to healthy any shape, size or profile relevant to the precise business requirements it successfully serves. Custom silicone has a most helpful tool for any sort of extrusion needed; right from a basic profile too much more involved ones.

Safe & Eco-pleasant: Apart from performance, silicone extrusions are an environment-sensitive solution. They are non-hazardous, friendly on the environment, and the products themselves show great thermal conductivity.

These extrusions are an offering for recreation that offers flexibility, strength, and sustainability all in one package. Change your enterprise completely, or at least improve its performance by introducing the benefits of custom silicone extrusions today.

Unleashing Unmatched Quality: Top-rated Extruded Gasket Suppliers

Within the fashionable global of production, quality, and efficiency are most valued and nothing displays these priorities higher than extruded gasket suppliers.

Customer Satisfaction: They ensure patron expectancies by providing great products. The number one goal of most of them is to develop a piece that would meet the client’s specific requirements.

Availability of Products: Suppliers of the extruded gasket offers a vast range of materials, forms and dimensions to answer the various requirements of industries. For the car industry alone they have you covered as well as the scientific and electronic oriented businesses.

Advanced Processes: In order to stick with the high quality levels, these suppliers utilize the current extrusion techniques, and they offer impressive gaskets. This consciousness in the advance of generation method they are usually within the candy spot of latest tendencies within the zone.

Seal the Deal with Extruded Silicone Gasket: Quality, Flexibility and Durability

As to the sphere of commercial sealing, the Silicone Gasket has made a revolution on the part of recreation. This engineered wonder is only experiencing an ever roasting and escalating demand, and it isn’t difficult to envision why. Here are 3 top reasons:

Customization: One is able to extrude silicone gaskets to conform to the consumers’ needs and therefore makes them ideal for several uses in commerce.

Resilient: It's a well-known fact; silicone is proof against severe situations. This includes high temperatures, UV-radiation, ozone exposure and extra, making these gaskets remarkably long lasting.

The Green Option: As we are turning into greater devoted to lowering our carbon footprint, opting for an extruded silicone gasket is a step in the right route. They are non-poisonous, recyclable and environment friendly.

Unleashing the Power of Silicone U Channel Gaskets: The Unsung Heroes of Sealing Solutions

These gaskets are in practice required in several industries because these possess great and accurate features. These diverse and flexible gears are considered as important players in achieving high degrees of general performance in surroundings characterized by temperature stress, pressure, and nasty chemicals.

Exceptional Durability: Silicone U channel gaskets stand out from their counterparts because of the following reasons with particular emphasis being on the high level of durability. They can endure through extreme weather, protect against dangerous ultraviolet light and hold up under significant physical pressure.

Versatility: This particular sealant provides a comfortable in shape for a range of uses due to this factor of flexibility. In automobile industry, creation, electronics, aviation and so on, these gaskets provide an optimal sealing solution regardless of the layout and scale with the machine.

Chemical Resistance: These gaskets represent high resistance to chemical compositions. Unlike other materials, they do not dissolve or rot by using in acid, oil and solvent, and therefore extend the life span of the product and reduce other charges for alternatives.

Conclusion

Excellent performance, resistance, and affordability make extruded rubber tubing a durable material that may be used in a variety of industries. Because of its recovery, resistance, and insulating qualities, silicone tubing is highly valued and appropriate for long-term uses. Unmatched eco-friendliness, safety, and adaptability are provided by custom silicone extrusions. Quality, client happiness, availability, and cutting-edge procedures are given top priority by leading extruded gasket providers. Because silicone gaskets are customizable, long-lasting, and environmentally friendly, they are perfect for commercial sealing. The remarkable durability, adaptability, and chemical resistance of silicone U channel gaskets make them indispensable in a wide range of sectors.

Custom Rubber Extrusions deals with customized rubber extrusions and will be happy to inform you of the best options that suit your needs in your area. We interact with everyone concerned and analyze return on investment so that you can gain optimum value for your investment. Moreover, we offer services to enhance the feeling of customization including other features aimed at boosting your industry.

To book an appointment or to reach we contact here at [email protected] or (213)-426-1030.

0 notes

Text

Discover the Versatility of Silicone Rubber Tubing Across Industries: From automotive and medical equipment to aeronautics, submarines, and beyond, silicone rubber tubing is a vital component ensuring durability, flexibility, and resistance in diverse applications. Learn more about how Elastostar Rubber Corporation meets industry standards with top-quality silicone solutions.

#RubberTubing#SiliconeRubber#extruded silicone rubber tubing#food grade silicone rubber cord#high-temperature silicone rubber tubing#conductive silicone rubber tubing#silicone rubber tubing

0 notes

Text

Top Advantages of Silicone Rubber Extrusion [Infographic]

Silicone rubber extrusion offers numerous advantages across various industries.

Here are some of the top benefits:

Versatility:

Silicone rubber can be extruded into a wide range of shapes and profiles, making it suitable for many applications, from simple tubing to complex seals and gaskets.

Temperature Resistance:

Silicone rubber maintains its properties over a broad temperature range, typically from -60°C to +200°C (-76°F to +392°F), and can even withstand short-term exposure to higher temperatures. It is therefore suitable for use in extreme settings.

Chemical Resistance:

Silicone rubber is resistant to many chemicals, oils, and solvents, which allows it to be used in harsh chemical environments without degrading.

Flexibility and Elasticity:

Silicone rubber retains its flexibility and elasticity over a wide range of temperatures and conditions, which is essential for applications requiring durable and resilient materials.

Electrical Insulation:

Silicone rubber is an excellent electrical insulator, making it suitable for various electrical and electronic applications.

Biocompatibility:

Silicone rubber is biocompatible and can be used in medical and food-grade applications. It is often used in medical devices, implants, and food processing equipment.

Durability:

Silicone rubber is highly durable, with good resistance to aging, UV radiation, and ozone. This results in long-lasting performance in outdoor and demanding environments.

Ease of Manufacturing:

The extrusion process for silicone rubber is relatively straightforward and cost-effective, allowing for high-volume production with consistent quality.

Customization:

Silicone rubber can be easily colored, modified, and compounded to meet specific application requirements, offering high levels of customization.

Low Toxicity and Odor:

Silicone rubber has low toxicity and odor, making it suitable for applications where these properties are critical, such as in medical devices and consumer products.

To read more information about Silicone Rubber Extrusion, click https://sco.lt/4le372 and call now at +86 18928496321 or email us at [email protected]

0 notes

Text

Medical Tubing: Enabling Life-Saving Technology

Global Demand is Driving Innovation The global medical tubing market is valued at over $12 billion and growing annually as new treatments and technologies save more lives around the world. As demand increases, material scientists and engineers are pushing the boundaries of innovation to develop tubing with ever more sophisticated properties tailored to each medical application. Polyolefin Tubing Remains Popular Choice Polyolefin plastics like polyethylene and polyurethane account for over 60% of the medical tubing market due to their biocompatibility, flexibility and cost effectiveness. Polyolefin tubing is used extensively in basic applications like intravenous and respiratory equipment where tubing must be flexible yet withstand routine handling and transportation. Advances in polymer chemistry allow polyolefin tubing to mimic the soft, resilient properties of natural rubber for enhanced user comfort. Silicone Tubing for Critical Applications Silicone remains the material of choice for medical applications requiring maximum flexibility, oxygen permeability and chemical resistance at elevated temperatures. Silicone tubing is widely used for blood oxygenators in heart-lung machines and for feeding tubes,gastric tubes and catheter components that must withstand repeated sterilization. New crosslinking and curing techniques have expanded the upper use limits of medical grade silicones for implantable devices. Engineering Sterilization Compatible PVC PVC continues to find niche applications due to its low cost and strength despite concerns over plasticizer leachability. Advances in PVC compounding and curing now allow production of medical grade PVC tubing that maintains flexibility through multiple high temperature sterilization cycles. New plasticized and non-plasticized formulations enable uses such as enteral feeding tubes where cost and strength are priorities. Tailoring Tubing for Advanced Procedures As minimally invasive procedures multiply, tubing engineers face new demands for customized properties. Laser cut multiple lumen tubing precisely patterns fluid pathways. Multi-layer co-extruded tubing isolates reactive components. Polymer blends impartself-lubricating properties to reduce friction during device placement. Embedded radioopaque fibers and radiopaque polymer additives improve visualization of tubing position during interventional procedures. Conformal coatings prevent particulation and particle migration to protect delicate blood contacting components. Regulatory Compliance Drives Quality Assurance manufacturers developing advanced formulations for laser cut, multi-lumen and coated tubing face strict regulatory standards. Material selection and processing must minimize particulate matter,extractables and leachables that could impact biocompatibility or thrombosis. Comprehensive testing characterizes material properties like durometer, tensile strength and compression set to ensure tubing maintains integrity under simulated use conditions. Traceability systems track raw material sourcing and finished tubing sterilization history. Quality management registrations to ISO standards reassure medical device OEMs of tubing supplier reliability and product safety. Sustainability Takes on New Meaning in Healthcare As healthcare costs rise globally, attention turns to reducing wasted materials and single-use devices. Engineers design multi-use configurations and reprocessing protocols for tubing sets. Antimicrobial and non-toxic polymer additives maintain hygienic properties through multiple sterilization cycles. "Green chemistry" initiatives aim to utilize renewable resources and minimize environmental impactcompared to petroleum-based plastics. As public awareness of sustainability issues grows,tubing component selection will increasingly considerFull Life Cycle Assessment factors from raw material extraction through final disposal.

0 notes