#rubber extruded

Explore tagged Tumblr posts

Text

#silicone gasket suppliers#rubber tubing manufacturer#closed cell sponge rubber gaskets#rubber extruded#rubber seal parts manufacturer

0 notes

Text

Choose the Best Rubber Extrusion Manufacturer

Custom Rubber extrusions is the best rubber extrusion manufacturer, focusing on crafting superior quality silicone rubber extrusions. With knowledge honed over the years, we are at the topmost in meticulous engineering, delivering tailor-made solutions for many industries. Our obligation to quality and modernization sets us apart as silicone rubber extrusion manufacturers, offering clients multipurpose and hard-wearing components that meet exact conditions. Our company cartels cutting-edge expertise with a meticulous approach to creating extrusions that outshine performance and durability. As your reliable partner, we take pride in our role as a dependable extrusion manufacturer, constantly exceeding expectations and driving excellence in rubber extrusions.

#rubber-extrusion-manufacturer#silicone-rubber-extrusion-manufacturers#extruded-rubber-manufacturers#rubber-extruder-manufacturers

3 notes

·

View notes

Text

The Rubber Extrusion Manufacturer produces customized rubber extruded products ranging from EPDM seals to silicone gaskets and rubber profiles and additional kinds.

0 notes

Text

Extruded Rubber Profiles Suppliers in Dubai, UAE

In search of trustworthy vendors of extruded rubber profiles in Dubai, UAE? We provide premium rubber gaskets and seals for a range of industries. Get in touch with us now! For more details, visit https://abaw.ae/metal.html

0 notes

Text

Cold Feed Rubber Extruder | Working, Benefits, And Applications

Cold feed rubber extruders are essential machines in the rubber industry, used for shaping and processing rubber compounds without preheating. Unlike hot feed extruders, these machines take in room-temperature rubber and push it through a die to create precise shapes. They offer better efficiency, reduced energy consumption, and improved product consistency.

0 notes

Text

Efficient Cold Feed Rubber Extruder Machine in the USA

Looking for a high-performance Cold Feed Rubber Extruder Machine in the USA? These advanced machines ensure precise and consistent rubber extrusion for various industrial applications, including automotive, construction, and sealing products. Designed for energy efficiency and uniform output, they enhance productivity while reducing material waste. Whether you need a standard or customized extruder, top manufacturers in the USA provide reliable solutions to meet your production needs.

0 notes

Text

UNDERSTANDING THE SYSTEM OF A RUBBER EXTRUDER MACHINE

0 notes

Text

Essential Tool for Successful Silicone Rubber Extrusion

Explore top-quality silicon rubber extrusion manufacturing services. We specialize in custom-designed extrusions for a variety of industries, delivering precision, durability, and reliability. Contact us today for tailored solutions! Read More:- https://krishanicom.wordpress.com/2025/01/06/essential-tool-for-successful-silicone-rubber-extrusion/

#silicone-rubber-extrusion-manufacturer#custom-silicon-gasket-manufacturer#extruded-gasket-supplier#rubber-extrusion-companies

0 notes

Text

0 notes

Text

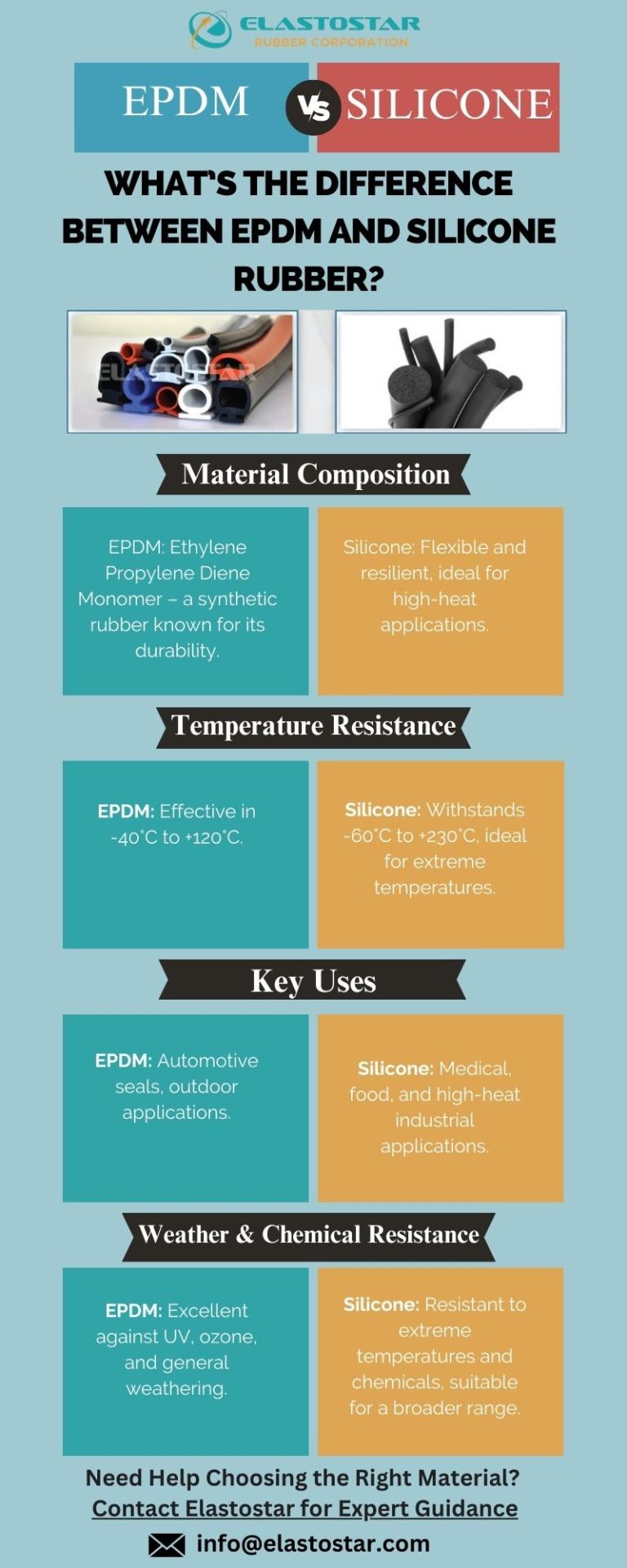

EPDM and Silicone Rubber differ in composition, temperature resistance, and applications. EPDM, a durable synthetic rubber, operates between -40°C to +120°C and is ideal for automotive and outdoor use, offering excellent UV and weather resistance. Silicone, known for its flexibility and resilience, withstands -60°C to +230°C, making it perfect for extreme temperatures, medical, food, and high-heat industrial applications. Silicone also provides superior chemical resistance for broader use. Need Help Choosing the Right Material? Contact Elastostar for Expert Guidance

#silicone rubber tubing#epdm rubber seals#siliconerubber#high-temperature silicone rubber tubing#extruded silicone rubber tubing#food grade silicone rubber cord

0 notes

Text

Extruded Rubber Strips, Manufacturer, Mumbai, India

Contact here to get more details of Extruded Rubber Strips, We are manufacturer, supplier and best service provider of Extruded Rubber Products in Mumbai, India.

#Rubber Products#Moulded Rubber Parts#Extruded Rubber Parts#Sponge Moulded Parts#Metal Bonded Parts#Manufacturers Of Rubber Components#Manufacturers Of Moulded Rubber Parts#Manufacturers Of Extruded Rubber Parts#Rubber Moulded Parts#'O' Rings#Oilseal#U Seal#V Seal#Chevron Packing For Pumps#Hydraulics Seal#Mechanical Seal#Neoprenen Rubber#Nitrile Rubber#Epdm Rubber#Hypalon Rubber#FKM Rubber#Natural Rubber#Polymers#Flourinated Rubber#Silicone Rubber#Polyurethane Rubber#Ethylene Propylene Terpolymers#Synthetic Rubber#Chemical Resistance#O Rings

0 notes

Text

Rubber extruder screw

It adopt two type or three type screw thread feeding, more the benefit to rubber powder addison, adopt grooving on the screw thread to promote material homogenization. Such as butyl rubber, natural rubber, nitrile rubber, styrene-butadiene rubber.

0 notes

Text

Precision Extruded Rubber Seals for Superior Performance

We are a leading extruded gaskets supplier. We have focused our work on delivering superior solutions for the industries that seek high-quality products from us. Our design and manufacturing abilities are highly directed towards creating strong gaskets that can achieve excellent performance levels. Our team is dedicated to ensuring the accuracy and reliability of all the standard as well as custom-profile products.

As one of the rubber extrusion companies that have always been trusted, we provide solutions according to your specific needs. Starting from small to big-volume production, we ensure high-quality extruded rubber parts that can withstand wear, weather, and chemicals. Our competencies include the possibility to work with a variety of rubber materials, as well as the compatibility of these materials with different applications.

Partner with us, and access decades of experience combined with unparalleled customer service with products designed to add value to your processes. From an extruded gasket to our custom rubber profiles, quality combined with innovation sets us miles ahead in the industry. Contact us today to explore your project!

0 notes

Text

Automotive Rubber Extrusions Custom Seals & Manufacturer

Introduction

In this complex field known as automotive production, it is essential to be precise and accurate. As the report shows, Custom Rubber Extrusions stay as vital parts, enhancing the safety, function, and durability of automobiles. Ranging from blocking and fragmenting any external force to deporting the required insulation and shock absorption qualities, they hold stern importance in a myriad of car and truck usages.

Unraveling Rubber Extrusions

Rubber extrusions are co-extruded lengths of rubber produced by compounding a rubber material with a specific cross-sectional profile and forcing it through a die. This extrusion process also makes cross-section shapes and sizes possible for manufacturers to create components with various cross-sectional criteria ideal for automobiles.

Understanding the Range of Uses of Automotive Rubber Extrusions

The realm of automotive rubber extrusions is vast and encompasses a variety of types, each with unique characteristics and applications:

Custom Rubber Extrusions: These are extrusions that are truly custom-made in the sense that they are endowed with precise architectural outlines to create extrusion profiles that will suit the needs of a customer. They can be made from a large number of rubber compounds, which can be natural rubber, synthetic rubber, and silicone; thus the composite boat can have flexibility in the choice of rubber.

Extruded Rubber Tubing: This category includes profiles with a hollow structure, which are used when producing hoses, gaskets, and many other auto parts made from a tube.

Silicone Food Grade Extrusion Tubing: For applications where sanitation, as well as food safety, is important, especially in automotive food service or beverage delivery systems, silicone food grade extrusion tubing is used to meet the greatest level of cleanliness and food safety.

Neoprene Rubber Extrusions: Chemically and oil-fatigue as well as weathering resistant, the neoprene rubber extrusions are useful for engine seals and gaskets where service conditions are severe.

Applications of Automotive Rubber Extrusions: A Multitude of Uses

The versatility of rubber extrusions is evident in their widespread use across various automotive applications:

Seals and Gaskets: Rubber extrusions act as reliable barriers to keep out both water and dust while blocking other harmful substances. The parts rely on rubber extrusions to operate correctly.

Cushioning and Vibration Dampening: By absorbing vibrations and shocks, rubber extrusions improve vehicle rides and lessen interior noise.

Weather-stripping: Sealed gaps around doors and hoods help rubber extrusions block leaks and noise while preventing drafts from entering the car.

Hoses and Tubing: Rubber extrusions help transport fluids and gases throughout vehicles at every stage to keep systems working effectively.

Bumpers and Grilles: The structural strength of bumpers and grilles depends on rubber extrusions that protect and support these vital vehicle components. Our Detailed Examination Reveals the Benefits of Creating Unique Rubber Extrusions

Several key advantages make custom rubber extrusions an attractive choice for automotive manufacturers:

Versatility: Manufacturers can create any desired surface format and color combination with rubber extrusions to match precise design needs.

Durability: Specialized rubber products resist intense conditions because they stand up against mechanical damage and maintain their shape across heat changes and chemical contact.

Cost-Effectiveness: Rubber extrusions made in large quantities help automotive firms achieve affordable production costs.

Customization: The process of creating customized rubber extrusions for exact performance lets them deliver ideal automotive industry performance under tough conditions.

Conclusion

extruded gasket supplier have become essential parts of automotive production today. Their broad adaptability combined with enduring quality and competitive pricing makes rubber extrusions the preferred material selection for multiple applications. Clubbing with expert rubber extrusion manufacturers delivers exceptional performance parts to boost vehicle safety and durability.

Call to Action:

If you want to improve vehicle performance, you should consider as your primary source for custom rubber components trusted for many different motor vehicle applications. Our technical team helps you choose the right materials and creates customized solutions that match exactly what you need. To find out our complete product selection and see how our custom rubber extrusions can improve your vehicle, visit

0 notes

Text

As technology continues to evolve, Qingdao Steady Machinery Co., Ltd., a leading hot feed rubber extruder manufacturer is pushing the boundaries of what these machines can achieve, ensures that the industry remains at the cutting edge of production capabilities.

0 notes

Text

Cold Feed Rubber Extruder: Enhancing Efficiency in Rubber Processing

A Cold Feed Rubber Extruder is a specialized machine used in the rubber industry to shape and form rubber compounds by forcing them through a die. Unlike traditional extruders, cold feed extruders do not require pre-heating of the rubber before feeding it into the machine, which improves energy efficiency and reduces processing time. These extruders are widely used in manufacturing rubber products like profiles, tubes, hoses, and cables.

The key benefits of cold feed rubber extruders include:

Energy Savings: With no need for pre-heating, these machines consume less energy.

Improved Productivity: Faster processing times and consistent output enhance production efficiency.

Better Control: Precise control over temperature, pressure, and die design ensures high-quality rubber products.

If you're in the rubber manufacturing industry, investing in a Cold Feed Rubber Extruder can optimize your operations, reduce costs, and improve product quality. Explore top manufacturers and models to find the right extruder for your needs today.

0 notes