#Fermenter Manufacturer

Explore tagged Tumblr posts

Text

What is a Fermenter?

In the realm of bioprocessing, fermenters play a pivotal role in facilitating the production of various bioproducts, including pharmaceuticals, biofuels, and enzymes. As industries embrace biotechnology for sustainable production practices, the demand for high-quality fermenters continues to rise. Roch Mechatronics emerges as a premier manufacturer, offering cutting-edge fermenters tailored to meet the diverse needs of bioprocessing industries.

Company Overview:

Roch Mechatronics stands as a beacon of innovation and excellence in the field of bioprocessing equipment manufacturing. With a focus on quality, reliability, and customer satisfaction, they have carved a niche for themselves as a trusted provider of fermenters and bioreactors.

Product Range:

Specializing in fermenters, Roch Mechatronics offers a comprehensive range of models equipped with advanced features to cater to various applications and production scales. Whether it’s laboratory-scale research or large-scale industrial production, their fermenters are designed to deliver optimal performance and productivity.

Fermenter Manufacturer

Advanced Features:

Roch Mechatronics’ fermenters are equipped with state-of-the-art control systems, precise instrumentation, and robust construction, ensuring efficient fermentation processes and consistent product quality. These fermenters are customizable to accommodate specific process requirements, allowing for flexibility and scalability.

Quality Assurance:

At Roch Mechatronics, quality is at the forefront of everything they do. Each fermenter undergoes rigorous testing and quality checks to ensure compliance with international standards and industry regulations. From design and manufacturing to installation and support, their commitment to excellence shines through.

Contact Information:

For inquiries or to explore Roch Mechatronics’ range of fermenters, interested parties can reach out through the following channels:

Mobile: +91–7011654652

Email: [email protected]

Address: Site 4 Industrial Area, Sahibabad, Ghaziabad — 201001

Conclusion:

Roch Mechatronics emerges as a trusted partner for bioprocessing industries, offering state-of-the-art fermenters that set the benchmark for performance, reliability, and innovation. With a relentless focus on quality and customer satisfaction, they continue to drive advancements in bioprocessing technology, empowering industries to achieve their production goals efficiently and sustainably. For organizations seeking premium fermenters backed by expertise and excellence, Roch Mechatronics stands as the preferred choice.

#Fermenter#Fermenter Manufacturer#Fermenter Manufacturer in India#Fermenter Supplier in India#Fermenter Manufacturer in Ghaziabad

0 notes

Text

Application and Advantages of Lab Scale Fermenter

Understanding Lab-Scale Bioreactors

Lab-scale bioreactors, often referred to as benchtop bioreactors, are compact vessels designed to facilitate the growth and manipulation of various biological entities under controlled conditions. These reactors mimic the natural environment of microorganisms or cells, providing optimal conditions for proliferation, metabolism, and product formation.

Components and Design

The design of lab-scale bioreactors is meticulously crafted to emulate the conditions prevalent in industrial-scale fermenters while maintaining versatility and ease of operation. Key components typically include:

Vessel: The core of the bioreactor, where the biological culture resides. Vessels come in various sizes and configurations, accommodating different volumes and types of cultures.

Agitation System: Ensures uniform mixing of nutrients, gases, and metabolites within the culture. Agitation mechanisms may include stirrers, impellers, or spargers, depending on the specific requirements of the culture.

Temperature Control: Precise temperature regulation is essential for maintaining optimal growth conditions. Bioreactors are equipped with heating elements and cooling jackets, along with temperature probes and controllers to monitor and adjust temperature levels.

pH and Dissolved Oxygen Control: Maintaining appropriate pH and dissolved oxygen levels is crucial for cell viability and productivity. Bioreactors are equipped with sensors and controllers to regulate these parameters through the addition of acids, bases, or oxygen.

Monitoring and Control Systems: Advanced bioreactors are integrated with sophisticated monitoring and control systems, allowing real-time monitoring of key parameters such as temperature, pH, dissolved oxygen, and biomass concentration. Automated control algorithms facilitate precise adjustment of operating conditions to optimize culture performance.

Applications and Advantages of Lab Scale Bioreactor

The versatility of lab-scale bioreactors extends across a wide range of applications in biotechnology, pharmaceuticals, and academia:

Bioprocess Development: Lab-scale bioreactors serve as invaluable tools for the optimization and scale-up of bioprocesses. Researchers can fine-tune culture conditions, evaluate the impact of different parameters, and optimize productivity before transitioning to larger scales.

Cell Culture and Tissue Engineering: Bioreactors play a pivotal role in the cultivation of mammalian cells and tissues for various applications, including regenerative medicine, drug discovery, and tissue engineering. Controlled environments within bioreactors facilitate the growth and differentiation of cells into functional tissues.

Microbial Fermentation: Microbial fermentation processes, such as the production of antibiotics, enzymes, and biofuels, are extensively studied and optimized using lab-scale bioreactors. These reactors allow researchers to explore different microbial strains, media formulations, and process conditions to maximize product yields and quality.

Biological Research and Education: Bioreactors serve as indispensable tools for biological research and education, providing students and researchers with hands-on experience in culturing and manipulating biological systems. Benchtop bioreactors enable reproducible experimentation and data collection, fostering a deeper understanding of bioprocess principles and techniques.

Challenges and Future Directions

While lab-scale bioreactors offer tremendous potential, several challenges persist in their design and operation:

Scalability: Translating results from lab-scale bioreactors to larger industrial-scale fermenters remains a challenge due to differences in hydrodynamics, mass transfer, and mixing dynamics. Bridging this scalability gap requires advanced computational modeling, process optimization, and scale-up strategies.

Sterility and Contamination Control: Maintaining sterility and preventing contamination are critical aspects of bioreactor operation, particularly in cell culture and pharmaceutical applications. Robust sterilization protocols, aseptic techniques, and stringent quality control measures are essential to minimize the risk of contamination.

Process Intensification: Enhancing productivity and efficiency through process intensification strategies is a key focus area in bioreactor development. Integration of online monitoring and control systems, advanced analytics, and novel bioreactor designs can streamline bioprocesses and maximize resource utilization.

Conclusion

Lab-scale bioreactors represent the cornerstone of bioprocessing innovation, offering a platform for exploration, discovery, and optimization across diverse biological applications. As advances in biotechnology continue to accelerate, the role of lab-scale bioreactors in shaping the future of bioprocessing becomes increasingly pronounced. By addressing challenges, embracing technological advancements, and fostering interdisciplinary collaboration, we can unlock the full potential of lab-scale bioreactors and propel bioprocessing into a new era of sustainability, efficiency, and impact.

#lab scale bioreactor#lab scale bioreactor manufacturer#lab scale bioreactor supplier#lab scale bioreactor manufacturer in India#fermenter technologies

2 notes

·

View notes

Text

What is the Role of a Fermenter?

The Role of Fermenters/Bioreactors:

Microbial Cultivation: Fermenter Manufacturer are primarily used for the large-scale cultivation of microorganisms. This is essential in industries such as pharmaceuticals (for producing antibiotics, vaccines, and therapeutic proteins), food and beverage (for producing yogurt, beer, and enzymes), and biofuels (for producing ethanol and other bio-based products).

Process Control: The ability to control and monitor various parameters within a fermenter is crucial for maximizing product yield and quality. For instance, maintaining a specific temperature ensures optimal growth rate, while controlling oxygen levels influences the type of metabolic pathways the microorganisms utilize.

Scaling Up Production: Fermenters allow processes that were once conducted on a small laboratory scale to be scaled up to industrial production levels. This scalability is vital for meeting the high demand for products in industries ranging from healthcare to agriculture.

Bioremediation: In environmental applications, fermenters can be used for bioremediation — where microorganisms are employed to degrade pollutants and contaminants in soil, water, or air. This sustainable approach helps mitigate environmental impact and restore ecosystems.

What is a Fermenter?

Fermenters, also known as bioreactors, are specialized vessels designed for the cultivation of microorganisms and cells under controlled conditions. These vessels provide an ideal environment where microorganisms such as bacteria, yeast, or fungi can thrive and multiply. The conditions inside a fermenter — such as temperature, pH level, oxygen supply, and agitation — are carefully monitored and adjusted to optimize the growth and metabolic activity of the organisms.

Significance in Various Industries:

Pharmaceuticals: Fermenters are instrumental in the production of antibiotics like penicillin and streptomycin, as well as in the synthesis of complex proteins used in therapeutic treatments.

Food and Beverage: In the food industry, fermenters are used to produce a wide range of products including cheese, bread, alcoholic beverages, and probiotic supplements.

Biofuels: Fermenters play a key role in the production of biofuels such as ethanol, which are increasingly important alternatives to fossil fuels.

Challenges and Innovations:

While fermenters have revolutionized industrial processes, challenges such as contamination control, scalability, and cost-efficiency continue to drive innovation. Advances in automation, sensor technology, and bioprocess engineering are addressing these challenges, making fermenters more efficient, reliable, and adaptable to diverse applications.

Conclusion:

In essence, fermenters represent the backbone of modern biotechnological and industrial processes. Their ability to cultivate microorganisms under precisely controlled conditions has enabled the production of countless products that enhance our health, sustain our environment, and enrich our daily lives. As industries continue to innovate and expand, fermenters will remain indispensable tools, driving forward progress in medicine, agriculture, environmental science, and beyond.

Understanding the role of fermenters not only highlights their technical significance but also underscores their broader impact on global industries and sustainability efforts. As we look to the future, advancements in bioreactor technology promise even greater opportunities for innovation and application, further solidifying fermenters as essential components of the modern industrial landscape.

Best Fermenter Manufacturer in India

If you are looking for Top Fermenter Manufacturer in India, look no further than Instech Pharma, we are a leading manufacturer and supplier of Fermenter/Bioreactor in India.

For more details, please contact us!

Website :- https://www.pharmaceutech.com/

Contact No. :- +91–9873069138, +91–8896456000

Email :- [email protected], [email protected]

#Best Fermenter Manufacturer in India#Best Fermenter Supplier in India#Top Fermenter Manufacturer in India#Fermenter Manufacturer in India#instech pharma

1 note

·

View note

Text

29-5-2024: - "We're interested in the bulk buying of fermentation chemicals. Monsodium glutamate and ascorbic acid" James Bond (Sean Connery)- "Would you like a license to manufacture"?

Mr. Osato (Teru Shimada)- "Yes, very much"

James Bond (Sean Connery)- "So, I'll have my sales manager get quotations on the delivery dates for you as soon as possible. We'll contact you later today at your hotel"

Mr. Osato (Teru Shimada)- "Which hotel are you staying at Mr. Fisher"?

Helga Brandt (Karin Dor)- "The Hilton"

James Bond (Sean Connery)- "Goodbye, Mr. Fisher. A pleasure to meet you"

Mr. Osato (Teru Shimada)- "Pleasure to meet you too"

James Bond (Sean Connery) in "You only live twice" (1967), a film by Lewis Gilbert

#jamesbond#youonlylivetwice#bulk#fermentation#chemicals#monsodiumglutamate#monsodium#glutamate#ascorbicacid#ascorbic#acid license#manufacturing#sales#manager#quotations#delivery#dates#possible#contact#later#today#hotel#hilton#pleasure#meeting

0 notes

Link

Black tea has a rich aroma, which is affected by tea tree species, growing region and tea-making process. Processes such as withering, rolling and fermentation are crucial to the formation of the aroma of black tea.

0 notes

Text

Black Garlic North America is a business division of Wisconsin Fermentation Company LLC (founded in 2012). Wisconsin Fermentation Company is focused on fermentation innovation as well as product and manufacturing design and commercialization. The combination of chemistry, microbiology, mycology, engineering, and food technology pave the way for technical expertise within a wide array of fermented products. Currently our flagship product is Black Garlic marketed under the brand name Black Garlic North America.

#Black garlic fermentation#black garlic#Black garlic retailer#fermented black garlic manufacturers#garlic cracker recipe#garlic guacamole recipe

0 notes

Text

Mixing System Manufacturer in Pune

Budget hardly becomes a constraint when selecting the best Mixing System Manufacturer in Pune. We are sure you will not need any other manufacturing company after consulting with us. We are very specific about the entire system of manufacturing. For more details visit our website today https://www.arkchem.in/mixing.html

#Mixing#Filtering#Fermenting#Drying#Process Engineering Company in Pune#Customized Systems Manufacturer Pune#Drying System Manufacturer Pune#Mixing System Manufacturer Pune#Evaporation System Manufacturer Pune#Turnkey System Manufacturer Pune

0 notes

Text

Bioreactor Manufacturers

Fermenter Manufacturers – Mumbai, Maharashtra

As fermenter manufacturers in Mumbai, SS Fermenter Bioreactor plays a crucial role in supporting the city's diverse industries. Their advanced fermenters contribute to Mumbai's status as a hub of industrial activities.

32. Fermenter Manufacturers – Chandigarh

Chandigarh benefits from the expertise of SS Fermenter Bioreactor as fermenter manufacturers. The city's industrial landscape is enriched by their efficient fermentation solutions.

33. Fermenter Manufacturers – Guwahati

In the northeastern city of Guwahati, SS Fermenter Bioreactor contributes to industrial growth as fermenter manufacturers. Their products support various applications in the region.

34. Bioreactor Manufacturers – Vijayawada

Vijayawada benefits from the presence of SS Fermenter Bioreactor as bioreactor manufacturers. Their advanced bioreactor solutions contribute to the city's industrial advancement.

35. Bioreactor Manufacturers – UK

Internationally, SS Fermenter Bioreactor extends its influence as bioreactor manufacturers in the UK. Their commitment to quality and innovation is recognized on a global scale.

36. Industrial Fermentation Plant Manufacturer

As an industrial fermentation plant manufacturer, SS Fermenter Bioreactor provides comprehensive solutions for large-scale fermentation processes, supporting industries globally.

37. Fermenter Manufacturer – Maharashtra

In Maharashtra, SS Fermenter Bioreactor stands out as a trusted fermenter manufacturer, contributing to the state's industrial growth with their advanced fermentation solutions.

38. Autoclavable Glass Fermenter Manufacturer

The autoclavable glass fermenter manufactured by SS Fermenter Bioreactor meets the highest standards of sterility and efficiency. This product is crucial for industries requiring precise and contamination-free fermentation.

39. Fermenter Bioreactor Manufacturer

39. Fermenter Bioreactor Manufacturer

As a fermenter bioreactor manufacturer, SS Fermenter Bioreactor offers integrated solutions for various industrial applications, ensuring optimal performance and reliability.

40. Fermentation Plant Manufacturer

SS Fermenter Bioreactor's role as a fermentation plant manufacturer is pivotal in providing industries with state-of-the-art facilities for large-scale production processes.

41. Industrial Production Fermenter

The industrial production fermenter by SS Fermenter Bioreactor caters to the needs of large-scale manufacturing, ensuring efficient and cost-effective fermentation processes.

42. Pilot Scale Fermenter Manufacturer

SS Fermenter Bioreactor's pilot scale fermenter is designed for research and development purposes, providing a scalable solution for industries to test and optimize fermentation processes.

43. Industrial Fermenter Price

For those seeking information on the industrial fermenter price, SS Fermenter Bioreactor ensures transparency and competitiveness in their pricing, making their products accessible to a wide range of industries.

44. Fermenter Bioreactor Fermentor Manufacturer

SS Fermenter Bioreactor's role as a fermenter bioreactor fermentor manufacturer highlights their ability to provide comprehensive solutions for various stages of the fermentation process.

45. Fermenter Manufacturers – Chennai

Chennai benefits from the expertise of SS Fermenter Bioreactor as fermenter manufacturers. The city's industries thrive on the efficiency and reliability of their fermentation solutions.

46. Our Facilities

Explore the state-of-the-art facilities that contribute to SS Fermenter Bioreactor's success in manufacturing high-quality fermenters and bioreactors. These facilities underscore the company's commitment to excellence.

47. Bioreactor Manufacturer – Bengaluru

Bengaluru, known as the Silicon Valley of India, benefits from SS Fermenter Bioreactor's expertise as a bioreactor manufacturer. Their advanced solutions contribute to the city's technological advancements.

48. Rotary Shaker Manufacturer

SS Fermenter Bioreactor extends its product range with rotary shakers, contributing to efficient and controlled mixing in laboratory and industrial settings.

49. BOD Incubator Manufacturer – Maharashtra

Maharashtra witnesses the impact of SS Fermenter Bioreactor as a BOD incubator manufacturer. The company's commitment to precision and reliability is evident in their incubator solutions.

50. BOD Incubator Manufacturer – Gujarat

Gujarat benefits from the expertise of SS Fermenter Bioreactor as a BOD incubator manufacturer. Their incubators contribute to the preservation and growth of various biological samples.

51. BOD Incubator Manufacturer

SS Fermenter Bioreactor's role as a BOD incubator manufacturer emphasizes their commitment to providing reliable solutions for controlled environmental conditions.

52. BOD Incubator Manufacturer – Ahmedabad

Ahmedabad, a hub of industrial activities, benefits from SS Fermenter Bioreactor's expertise as a BOD incubator manufacturer. Their incubators cater to various research and industrial applications.

53. BOD Incubator Manufacturer – Andhra Pradesh

Andhra Pradesh benefits from SS Fermenter Bioreactor's presence as a BOD incubator manufacturer, contributing to the region's scientific and industrial progress.

54. Fermenter Manufacturer – Pune

Pune, a center for education and industry, benefits from SS Fermenter Bioreactor's expertise as a fermenter manufacturer. Their products support the city's diverse industrial landscape.

55. Glass Fermenter Cost

For those seeking information on the cost of a glass fermenter, SS Fermenter Bioreactor ensures transparency in pricing, allowing customers to make informed decisions.

56. Production Fermenter Manufacturer

As a production fermenter manufacturer, SS Fermenter Bioreactor provides solutions for industries requiring large-scale fermentation processes, ensuring efficiency and cost-effectiveness.

57. Fermenter Manufacturer – Krishnagiri

Krishnagiri benefits from SS Fermenter Bioreactor's expertise as a fermenter manufacturer. The company's advanced fermentation solutions contribute to the region's industrial growth.

Explore the diverse range of products and solutions offered by SS Fermenter Bioreactor by visiting their official website. With a global presence and a commitment to excellence, SS Fermenter Bioreactor continues to be a leader in the field of fermenter and bioreactor manufacturing.

58. Fermenter Manufacturers – Germany

As a testament to its global reach, SS Fermenter Bioreactor stands out as fermenter manufacturers in Germany. The precision and quality of their products contribute to the country's reputation for technological excellence.

59. Fermenter Manufacturer – United States

The United States benefits from SS Fermenter Bioreactor's expertise as a fermenter manufacturer, showcasing the company's ability to cater to the diverse needs of one of the world's largest industrial landscapes.

#bioreactor#fermenter#biofertilizer plant#orbital shaker#fermenter manufacturer in india#bioreactor supplyer#fermenter supplyer#business

1 note

·

View note

Text

10 BBL Uni-tank Fermenter Jacketed & Insulatedx

Fully equipped pressure resistant, glycol jacketed, stainless steel cylindroconical vessel designed for fermentation, maturation and carbonisation of most types of beverages.

Unitank is a new model that has all the bells and whistles of our regular fermenters (Fermenter Tank CCV) but also comes with a more durable EPDM manhole gasket, solenoid valve for coolant, a larger 30% (instead of 25%) tank headspace and has the carbonation stone and sampling valve mounted on the cone.

For more Information: https://www.ndpac.com/product-category/food-processing-industry/beer-fermenters-tanks/

#cheap beer fermenters#cheap beer tanks#beer fermenters manufacturer#beer tanks manufacturer#beer fermenters supplier#beer tanks supplier

0 notes

Text

The Advantages of Stainless-Steel Fermenters

Introduction:

In the world of brewing, the choice of equipment plays a crucial role in achieving optimal results. Stainless steel (SS) fermenters have gained immense popularity among brewers for their exceptional performance and numerous benefits. In this blog, we will explore the advantages of using stainless steel fermenters, focusing on how they elevate brewing quality and efficiency. Join us as we uncover the reasons why stainless steel has become the preferred material for fermenter construction in the brewing industry.

Superior Hygiene and Cleanliness:

One of the primary benefits of stainless-steel fermenters is their excellent hygiene and cleanliness properties. Stainless steel is non-porous, preventing bacteria, contaminants, and odors from being absorbed into the material. This feature ensures a sanitary brewing environment, minimizing the risk of off-flavors and contamination.

Durability and Longevity:

Stainless steel fermenters are renowned for their exceptional durability and longevity. They are highly resistant to corrosion, rust, and staining, making them suitable for long-term use in challenging brewing conditions. The robustness of stainless steel ensures that fermenters can withstand rigorous cleaning, handling, and temperature variations without compromising their structural integrity.

Thermal Stability and Temperature Control:

Stainless steel exhibits excellent thermal conductivity, allowing for precise temperature control during fermentation. Fermenters made from stainless steel can effectively maintain desired fermentation temperatures, crucial for achieving consistent and high-quality brews. The ability to control temperature variations ensures optimal yeast activity, flavor development, and attenuation.

Easy Cleaning and Maintenance:

Stainless steel fermenters are designed with ease of cleaning and maintenance in mind. Their smooth surfaces and non-reactive nature facilitate straightforward cleaning procedures, minimizing the risk of residual flavors or contaminants. Stainless steel is also resistant to chemical agents commonly used in cleaning and sanitization, ensuring long-lasting hygiene and ease of maintenance.

Versatility and Flexibility:

Stainless steel fermenters offer versatility and flexibility to accommodate various brewing styles and volumes. They come in a range of sizes, from small-scale homebrewing to large commercial operations, catering to diverse brewing needs. Stainless steel fermenters can be customized with additional features like pressure relief valves, sampling ports, and integrated cooling jackets to further enhance brewing control and flexibility.

Aesthetic Appeal:

Apart from their functional advantages, SS fermenters also provide an aesthetic appeal. Their sleek and professional appearance adds a touch of elegance to brewing spaces, creating a visually appealing environment for brewers and visitors alike. Stainless steel's timeless and polished look reflects the dedication and professionalism of the brewing craft.

Conclusion: Stainless steel fermenters offer a myriad of benefits that significantly enhance brewing quality and efficiency. From superior hygiene and durability to precise temperature control and easy maintenance, the advantages of stainless steel in fermentation equipment are undeniable. Whether you are a homebrewer or operating a commercial brewery, investing in stainless steel fermenters can elevate your brewing process, ensuring consistent, high-quality brews and contributing to an overall exceptional brewing experience. Embrace the benefits of stainless steel and unlock the full potential of your brewing endeavors.

0 notes

Text

Lab Fermenter Manufacturers

Fermenter Technologies is a leading innovator in the design and manufacture of high-quality Lab Fermenter Manufacturers, catering to diverse industries such as biotechnology, pharmaceuticals, and academic research. With a commitment to excellence, the company specializes in creating advanced fermentation systems that empower scientists and researchers to achieve groundbreaking results.

Each lab fermenter from Fermenter Technologies is engineered for precision, durability, and user-friendliness. The equipment is designed to support microbial, cell culture, and enzymatic processes, ensuring optimal performance across a wide range of applications. From small-scale research projects to pilot studies, the fermenters deliver unparalleled reliability and consistency, helping clients push the boundaries of innovation.

What sets Fermenter Technologies apart is its dedication to customization and client satisfaction. The company collaborates closely with customers to tailor fermenter systems that meet their specific requirements, offering bespoke solutions that align seamlessly with experimental goals. Equipped with state-of-the-art automation and control systems, the fermenters ensure accuracy in monitoring critical parameters like temperature, pH, dissolved oxygen, and agitation.

Sustainability and efficiency are at the core of Fermenter Technologies' values. By integrating energy-efficient components and eco-friendly materials, the company contributes to greener practices in scientific exploration. Their unparalleled expertise, combined with a commitment to quality and innovation, has earned them a reputation as a trusted partner in the fermentation industry.

Fermenter Technologies continues to redefine excellence in lab fermenter manufacturing, supporting a future of limitless scientific possibilities.

For more details contact 8896456000 [email protected]

#best lab fermenter manufacturers#top lab fermenter manufacturers#lab fermenter manufacturers in India#lab fermenter manufacturers in Ghaziabad#lab fermenter manufacturers company#best lab fermenter supplier

0 notes

Text

If you're looking for a complete craft brewery solution, look no further than SKE Equipment. Founded in 2000, SKE Equipment has been at the forefront of the brewing industry for over 20 years, providing turn-key solutions for craft breweries of all sizes. From design and engineering to installation and commissioning, SKE Equipment offers a complete range of services to ensure your brewery runs smoothly and efficiently. With a focus on quality, reliability, and innovation, SKE Equipment is the ideal partner for brewers who want to take their craft to the next level.

#Brewery Equipment Manufacturer#Commercial Brewery Equipment#Beer Fermenter Tanks#Kombucha Brewing Equipment#Craft Beverage Plant Solutions

1 note

·

View note

Text

[ID: A plate of light brown bumpy flatbread with blackened spots, surrounded by za'tar and green olives. End ID]

خبز طابون / Khobz taboon (Palestinian flatbread)

Khobz taboon ("taboon bread") is a soft, chewy Palestinian flatbread. It may be eaten with olive oil and za'tar, but it is best known as the base of مسخن (musakhkhan), where it is topped with spiced aromatics and perhaps chicken.

Khobz taboon gets its name from the vessel it is traditionally cooked in—an outdoor, shallow conical oven with an opening at the top and a clay or metal cover to trap heat. Taboons may also have an opening at the side through which the fire can be stoked, especially in the east of Palestine. These ovens were historically made from a mixture of local clay and hay, but have more recently also been constructed from clay treated to be sturdier, or from metal.

A taboon is used by packing flammable material, such as hay, fabric, animal dung, wood, and charcoal, around the outside of the oven and letting it burn overnight; the fire transfers thermal energy to the clay, and to the river stones, sand, glass, or flint stones (صوان, "ṣawwān") that form the base of the oven. The ash is then brushed away, and the flattened dough is placed on the stones or stuck to the walls of the oven to cook. The clay and stones will continue to release thermal energy and cook things throughout the day. The clay and ash give a distinctive flavor to anything cooked inside the taboon, making this method a source of nostalgia for many people who have transitioned to cooking in indoor ovens.

Khobz taboon was traditionally made with whole wheat flour. Most people today use a blend of around two parts white flour to one part whole wheat, or else all white flour; they may even add milk or milk powder to ensure a very soft dough. This recipe uses a blend of flours to combine the nutty flavor of whole wheat dough with the pliancy of white dough. It also begins with an optional pre-ferment to mimic the traditional Palestinian method of including a piece of dough from the previous day's bread into each new batch (like a pâte fermentée) giving a rich and slightly sour flavor to the final bread. It calls for the use of rocks to imitate the bottom of a taboon; the rocks give the khobz its distinctive dimpled texture, and ensure that no interior pocket forms in the bread.

In the years following 2007, the siege Israel had imposed on Gaza caused a shortage of cooking gas that led to a resurgence in the use of taboons. The ovens were used to bake bread and to grill sweet potatoes during the time of their winter harvest. Meanwhile, in the West Bank, Israeli military forces repeatedly destroyed taboon ovens and assaulted villagers who tried to defend them, as Israeli settlers from nearby villages complained about the smoke that the ovens produced. Some of these ovens had been used to bake bread for entire families of 40 or more people. Palestinians continue to build, use, and defend these ovens, despite the fact that Israeli law de facto forbids Palestinians in the West Bank to build anything.

Today, Israel is deliberately targeting and destroying bakeries in refugee camps that had been supplying bread to tens of thousands of people in Gaza, continuing a long campaign of starvation of the Palestinian people.

Support Palestinian resistance by calling Elbit System's (Israel's primary weapons manufacturer) landlord; and donating to Palestine Action's bail fund.

Equipment:

A large, shallow mixing bowl, like a Moroccan qus'a

A large (12"), shallow clay cooking vessel, such as the bottom of a Moroccan tajine (one that is rated for very high temperatures), or a large baking tray

Assorted smooth river rocks of varying sizes, from 1 to 3" in diameter.

Make sure that your rocks have been thoroughly cleaned, and that they do not contain any fissures, cracks, or veins that could contain water (this water, once heated in the oven, could cause the rocks to crack open). Instead of river rocks, I used lava rocks designed for use in a clay tanoor. You just need something to provide thermal mass and give a bumpy texture.

Ingredients:

Makes 3 large breads.

For the pre-ferment:

140g whole wheat flour

1/2 tsp active dry yeast

140g water

You may also use a pâte fermentée that you already have (just adjust the ratio of white to whole wheat flour added later accordingly), or a sourdough starter. The hydration of the starter doesn't matter, since you will be adding water by eye later.

For the bread:

330g bread flour or all-purpose flour

30g whole wheat flour

5g salt

Water

If you skipped the pâte fermentée step, add 170g (rather than 30g) of wheat flour at this stage, as well as 1/2 Tbsp of active dry yeast. I have not tested the recipe this way.

Instructions:

For the pâte fermentée:

1. Mix flour and yeast in a small mixing bowl. Add water and stir to combine. Cover and leave out at room temperature for a day, or in the refrigerator for up to three days. At the end of the rising time, it should be about one and a half times its original size.

For the bread:

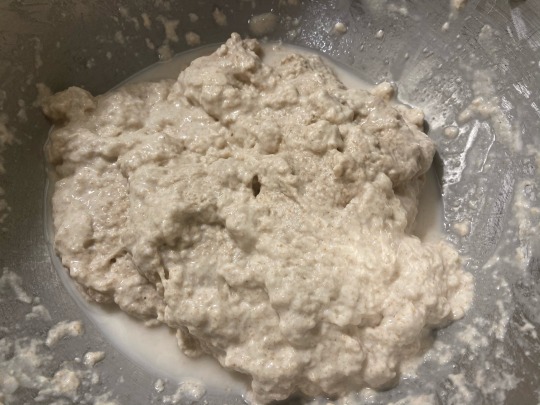

This recipe makes a high hydration dough that will need techniques such as slapping and folding to knead effectively.

1. Mix flours and salt in a very large, shallow mixing bowl. Add your pâte fermentée and mix to combine.

2. Add water until the flour comes together into a soft, sticky dough and continue keading. Have a bowl of water on your workstation. Every time the dough starts to stick to your hands or the sides of the bowl, wet your hands and rinse down the side of the bowl with some water. This will gradually add water to the dough.

3. You will notice the dough growing smoother and laxer. At this point, start kneading by repeatedly folding the edges of the dough in towards the center. Do this by occasionally wetting your hands, then running a hand along the side of the bowl and under the edge of the dough to unstick it from the bowl; then fold. You will get stuck less often if you try to touch the dough as lightly and briefly as possible. Every few folds, dimple the surface of the dough all over with your fingertips. You will have been kneading for about 10 minutes at this point.

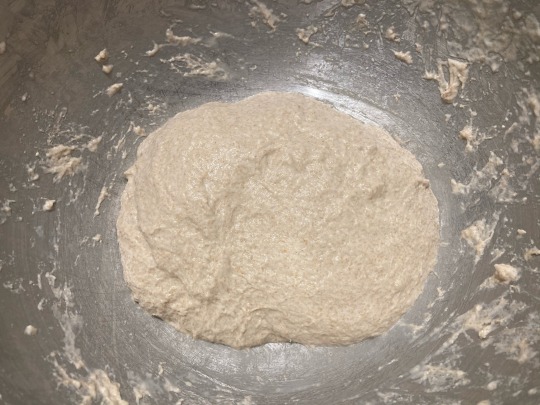

The dough should become more smooth and less bumpy—you will notice it holding its shape and becoming more stretchy as gluten forms. It should form into a ball when you fold the corners in and hold its shape for a minute, but then gradually expand to take the shape of the bowl. I added about 2 1/2 cups of water total (in dry conditions) during steps 2 and 3.

4. At this point, the dough is wet enough that the slap and fold method is the best way to knead. Wet your hands and again unstick the dough from the sides of the bowl. Hook your hands under the dough and quickly pull it all up into the air; fold the hanging bottom part of the dough under, and plop the dough back down, folding it on top of the part you plopped down earlier. Give the bowl a quarter turn and repeat. Do this continually for another few minutes.

5. When the dough is very smooth and lax, smear some olive oil on the sides of the bowl and under the dough, and pat some oil on top.

6. Cover the bowl and bulk ferment the dough at room temperature for 8 hours, or for 16-24 hours in the fridge. At the end of the rising time, you should see bubbles beginning to form on the surface of the dough.

To shape and bake:

1. Place a layer of rocks at the bottom of a clay cooking vessel or baking sheet. Put the sheet in the top third of the oven and preheat your oven to 550 °F (290 °C), or as hot as it will go.

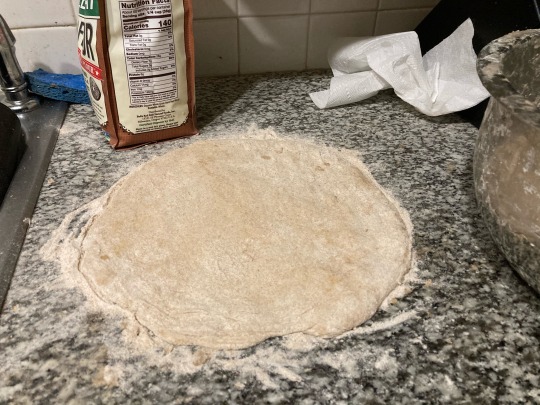

2. Meanwhile, fold the edges of the risen dough over into the middle a few more times with damp hands. Pinch off a large piece of dough (about the size of two fists), and fold the sides over into the middle to make a neat packet.

3. Drop the packet of dough onto a heavily floured surface, and flip to flour both sides. Pat the dough flat, then throw it back and forth between your hands, catching the edge each time as you spin it through the air, like a pizza crust, to stretch it into a circle about 1/4" (1/2cm) thick with a diameter of about 10" (25cm).

You may also stretch and pat the dough out on a flat surface.

4. Remove the tray from the oven. Flip the dough circle over the back of your hand to transfer it and lay it down over the hot rocks. Re-stretch it into a circle, if necessary.

5. Place the tray back in the oven and cook for 5-7 minutes, until the top of the bread has golden brown spots. Repeat with each piece of dough, leaving the rocks in the oven for a few minutes between each one to allow them to come back up to temperature.

6. (Optional): Hold each flatbread directly over a gas flame for a minute or two to blacken a few spots and mimic the flavor that a wood-fired oven would give to your khobz.

You may also use a method similar to the dhungar technique to smoke your bread. Place each piece of bread one at a time into a large vessel with a closely fitting lid, alongside a small bowl. Light a piece of wood on fire and drop it into the bowl; then cover the vessel with the lid as you allow the wood to smoke for a minute or two.

#note that I do not recommend this recipe to anyone who is not experienced with making bread#I'll have another Palestinian flatbread recipe up soon which will be more beginner-friendly#Palestinian#bread#khobz#flatbread

347 notes

·

View notes

Text

The Pentagon is funding alternatives to meat protein, which includes using fungi for food for U.S. service members as part of the White House’s sustainable bioeconomy agenda.

The Department of Defense is focusing on investments into fungi protein as an alternative to animal protein, after initially seeking to fund lab-grown meat earlier this year in an effort to reduce carbon emissions. Critics have pushed back on such initiatives, arguing that they are negatively affecting the military.

In November, the DOD announced that it had given 34 awards totaling over $60 million to bioindustrial firms under the Distributed Bioindustrial Manufacturing Program (DBIMP). $1.38 million was given to The Fynder Group “to plan a bioproduction facility for fungi-based proteins that can be incorporated into military ready-to-eat meals.”

The program is part of President Joe Biden's Executive Order 14081, "Advancing Biotechnology and Biomanufacturing Innovation for a Sustainable, Safe, and Secure American Bioeconomy," which is “aimed at bolstering America's bioeconomic strengths while helping the Department achieve advanced defense capabilities,” according to the DOD.

The projects that were awarded funding from the DOD program “will be eligible to receive follow-on ‘build’ awards providing access to up to $100 million to construct U.S.-based bioindustrial manufacturing facilities,” the DOD announcement added.

39 notes

·

View notes

Link

Black tea is a kind of fully fermented tea, which is refined through withering, rolling, fermentation, drying and other production processes. Because of the color of the dry tea and the main tone of the brewed tea, it is named black tea.

#organic black tea#black tea#black tea benefits#fermented tea#Gongfu black tea#black tea manufacturer#black tea supplier#Chinese black tea#loose leaf tea#LBTEAS

0 notes

Text

DAY 5904

Jalsa, Mumbai April 17, 2024 Wed 11:25 PM

🪔 ,

For April 18 .. our love and wishes for the Ef on their special day .. to Ef Jonoon Alhob from KSA 🇸🇦 .. Ef Ninad Junnarkar from Dubai 🇦🇪 .. Ef Manoj Lahoti from Ahmedabad .. Ef Mahesh Ghantasala .. and Ef Amlan Goswami from Lucknow .. love always from the Ef Family .. ❤️🙏🏻🚩

.. and it seems so odd and uncoordinated when there is an effort to keep the timings of the Blog in time and space and effect .. the fingers move to punch all the words and dates and days and timings to the day next as is the recognised practice ..

but change took place and .. took place in time ..

It is a joy when there is express and question in express , and all of them barking up the wrong tree .. it's not the tree its the wrong bark ..

got it .. ??

the X and the FB !!

the thought is that to be humorous , without being humorous .. a funny thought but at times it works .. one could expect to announce that he or she are the greatest comedians of the World, and the audience is repelled into uncontrollable laughter .. and the comedian merely stands there in the glory and admiration of his own joke ..

that is if you comment ..

'no comment' was not invented by celebrities or answerable individuals without reason ..

comment ferments .. !!

hahaha .. that was funny .. just came out of the oven baked and fresh .. ready to be consumed ..

and fermentation ..

"a chemical breakdown of substance by bacteria , or other microorganisms, involving efference and the giving off of heat .."

🤣🤣🤣

aaah .. the epitome of mastered questioned answers , one that would bring great intrigue to the questioner and a 😀 for the responder ..

Not anymore though .. for social media has obliterated commented news ..

which is why the coefficient of linear expansion is juxtapositioned by the haemoglobin of the atmosphere .. sophisticated rhetorician and all, intoxicated by the exuberance of verbosity

LONG live the Industry of Film .. and its presence among us .. the strongest medium of communication ..

EVEN NOW .. !!

in the liberty to manufacture in its creativity of wondrous understanding and composure , towards the elements of a free will and mind ..

" enough no more .. tis' not so sweet as it were before "

Love to all .. and the bard 👆🏼

Amitabh Bachchan

96 notes

·

View notes