#Cost-Effectiveness in Energy Transmission

Explore tagged Tumblr posts

Text

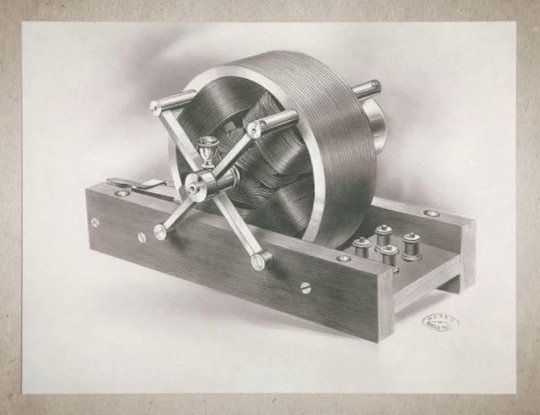

Conceptual Design for a Neutrino Power Transmission System

Overview

Neutrinos could potentially be used to send electricity over long distances without the need for high-voltage direct current (HVDC) lines. Neutrinos have the unique property of being able to pass through matter without interacting with it, which makes them ideal for transmitting energy over long distances without significant energy loss. This property allows neutrinos to be used as a medium for energy transmission, potentially replacing HVDC lines in certain applications.

So the goal is to create a neutrino-based power transmission system capable of sending and receiving a beam of neutrinos that carry a few MW of power across a short distance. This setup will include a neutrino beam generator (transmitter), a travel medium, and a neutrino detector (receiver) that can convert the neutrinos' kinetic energy into electrical power.

1. Neutrino Beam Generator (Transmitter)

Particle Accelerator: At the heart of the neutrino beam generator will be a particle accelerator. This accelerator will increase the energy of protons before colliding them with a target to produce pions and kaons, which then decay into neutrinos. A compact linear accelerator or a small synchrotron could be used for this purpose.

Target Material: The protons accelerated by the particle accelerator will strike a dense material target (like tungsten or graphite) to create a shower of pions and kaons.

Decay Tunnel: After production, these particles will travel through a decay tunnel where they decay into neutrinos. This tunnel needs to be under vacuum or filled with inert gas to minimize interactions before decay.

Focusing Horns: Magnetic horns will be used to focus the charged pions and kaons before they decay, enhancing the neutrino beam's intensity and directionality.

Energy and Beam Intensity: To achieve a few MW of power, the system will need to operate at several gigaelectronvolts (GeV) with a proton beam current of a few tens of milliamperes.

2. Travel Medium

Direct Line of Sight: Neutrinos can travel through the Earth with negligible absorption or scattering, but for initial tests, a direct line of sight through air or vacuum could be used to simplify detection.

Distance: The initial setup could span a distance from a few hundred meters to a few kilometers, allowing for measurable neutrino interactions without requiring excessively large infrastructure.

3. Neutrino Detector (Receiver)

Detector Medium: A large volume of water or liquid scintillator will be used as the detecting medium. Neutrinos interacting with the medium produce a charged particle that can then be detected via Cherenkov radiation or scintillation light.

Photodetectors: Photomultiplier tubes (PMTs) or Silicon Photomultipliers (SiPMs) will be arranged around the detector medium to capture the light signals generated by neutrino interactions.

Energy Conversion: The kinetic energy of particles produced in neutrino interactions will be converted into heat. This heat can then be used in a traditional heat-to-electricity conversion system (like a steam turbine or thermoelectric generators).

Shielding and Background Reduction: To improve the signal-to-noise ratio, the detector will be shielded with lead or water to reduce background radiation. A veto system may also be employed to distinguish neutrino events from other particle interactions.

4. Control and Data Acquisition

Synchronization: Precise timing and synchronization between the accelerator and the detector will be crucial to identify and correlate neutrino events.

Data Acquisition System: A high-speed data acquisition system will collect data from the photodetectors, processing and recording the timing and energy of detected events.

Hypothetical Power Calculation

To estimate the power that could be transmitted:

Neutrino Flux: Let the number of neutrinos per second be ( N_\nu ), and each neutrino carries an average energy ( E_\nu ).

Neutrino Interaction Rate: Only a tiny fraction (( \sigma )) of neutrinos will interact with the detector material. For a detector with ( N_d ) target nuclei, the interaction rate ( R ) is ( R = N_\nu \sigma N_d ).

Power Conversion: If each interaction deposits energy ( E_d ) into the detector, the power ( P ) is ( P = R \times E_d ).

For a beam of ( 10^{15} ) neutrinos per second (a feasible rate for a small accelerator) each with ( E_\nu = 1 ) GeV, and assuming an interaction cross-section ( \sigma \approx 10^{-38} ) cm(^2), a detector with ( N_d = 10^{30} ) (corresponding to about 10 kilotons of water), and ( E_d = E_\nu ) (for simplicity in this hypothetical scenario), the power is:

[ P = 10

^{15} \times 10^{-38} \times 10^{30} \times 1 \text{ GeV} ]

[ P = 10^{7} \times 1 \text{ GeV} ]

Converting GeV to joules (1 GeV ≈ (1.6 \times 10^{-10}) J):

[ P = 10^{7} \times 1.6 \times 10^{-10} \text{ J/s} ]

[ P = 1.6 \text{ MW} ]

Thus, under these very optimistic and idealized conditions, the setup could theoretically transmit about 1.6 MW of power. However, this is an idealized maximum, and actual performance would likely be significantly lower due to various inefficiencies and losses.

Detailed Steps to Implement the Conceptual Design

Step 1: Building the Neutrino Beam Generator

Accelerator Design:

Choose a compact linear accelerator or a small synchrotron capable of accelerating protons to the required energy (several GeV).

Design the beamline with the necessary magnetic optics to focus and direct the proton beam.

Target Station:

Construct a target station with a high-density tungsten or graphite target to maximize pion and kaon production.

Implement a cooling system to manage the heat generated by the high-intensity proton beam.

Decay Tunnel:

Design and construct a decay tunnel, optimizing its length to maximize the decay of pions and kaons into neutrinos.

Include magnetic focusing horns to shape and direct the emerging neutrino beam.

Safety and Controls:

Develop a control system to synchronize the operation of the accelerator and monitor the beam's properties.

Implement safety systems to manage radiation and operational risks.

Step 2: Setting Up the Neutrino Detector

Detector Medium:

Select a large volume of water or liquid scintillator. For a few MW of transmitted power, consider a detector size of around 10 kilotons, similar to large neutrino detectors in current experiments.

Place the detector underground or in a well-shielded facility to reduce cosmic ray backgrounds.

Photodetectors:

Install thousands of photomultiplier tubes (PMTs) or Silicon Photomultipliers (SiPMs) around the detector to capture light from neutrino interactions.

Optimize the arrangement of these sensors to maximize coverage and detection efficiency.

Energy Conversion System:

Design a system to convert the kinetic energy from particle reactions into heat.

Couple this heat to a heat exchanger and use it to drive a turbine or other electricity-generating device.

Data Acquisition and Processing:

Implement a high-speed data acquisition system to record signals from the photodetectors.

Develop software to analyze the timing and energy of events, distinguishing neutrino interactions from background noise.

Step 3: Integration and Testing

Integration:

Carefully align the neutrino beam generator with the detector over the chosen distance.

Test the proton beam operation, target interaction, and neutrino production phases individually before full operation.

Calibration:

Use calibration sources and possibly a low-intensity neutrino source to calibrate the detector.

Adjust the photodetector and data acquisition settings to optimize signal detection and reduce noise.

Full System Test:

Begin with low-intensity beams to ensure the system's stability and operational safety.

Gradually increase the beam intensity, monitoring the detector's response and the power output.

Operational Refinement:

Refine the beam focusing and detector sensitivity based on initial tests.

Implement iterative improvements to increase the system's efficiency and power output.

Challenges and Feasibility

While the theoretical framework suggests that a few MW of power could be transmitted via neutrinos, several significant challenges would need to be addressed to make such a system feasible:

Interaction Rates: The extremely low interaction rate of neutrinos means that even with a high-intensity beam and a large detector, only a tiny fraction of the neutrinos will be detected and contribute to power generation.

Technological Limits: The current state of particle accelerator and neutrino detection technology would make it difficult to achieve the necessary beam intensity and detection efficiency required for MW-level power transmission.

Cost and Infrastructure: The cost of building and operating such a system would be enormous, likely many orders of magnitude greater than existing power transmission systems.

Efficiency: Converting the kinetic energy of particles produced in neutrino interactions to electrical energy with high efficiency is a significant technical challenge.

Scalability: Scaling this setup to practical applications would require even more significant advancements in technology and reductions

in cost.

Detailed Analysis of Efficiency and Cost

Even in an ideal scenario where technological barriers are overcome, the efficiency of converting neutrino interactions into usable power is a critical factor. Here’s a deeper look into the efficiency and cost aspects:

Efficiency Analysis

Neutrino Detection Efficiency: Current neutrino detectors have very low efficiency due to the small cross-section of neutrino interactions. To improve this, advanced materials or innovative detection techniques would be required. For instance, using superfluid helium or advanced photodetectors could potentially increase interaction rates and energy conversion efficiency.

Energy Conversion Efficiency: The process of converting the kinetic energy from particle reactions into usable electrical energy currently has many stages of loss. Thermal systems, like steam turbines, typically have efficiencies of 30-40%. To enhance this, direct energy conversion methods, such as thermoelectric generators or direct kinetic-to-electric conversion, need development but are still far from achieving high efficiency at the scale required.

Overall System Efficiency: Combining the neutrino interaction efficiency and the energy conversion efficiency, the overall system efficiency could be extremely low. For neutrino power transmission to be comparable to current technologies, these efficiencies need to be boosted by several orders of magnitude.

Cost Considerations

Capital Costs: The initial costs include building the particle accelerator, target station, decay tunnel, focusing system, and the neutrino detector. Each of these components is expensive, with costs potentially running into billions of dollars for a setup that could aim to transmit a few MW of power.

Operational Costs: The operational costs include the energy to run the accelerator and the maintenance of the entire system. Given the high-energy particles involved and the precision technology required, these costs would be significantly higher than those for traditional power transmission methods.

Cost-Effectiveness: To determine the cost-effectiveness, compare the total cost per unit of power transmitted with that of HVDC systems. Currently, HVDC transmission costs are about $1-2 million per mile for the infrastructure, plus additional costs for power losses over distance. In contrast, a neutrino-based system would have negligible losses over distance, but the infrastructure costs would dwarf any current system.

Potential Improvements and Research Directions

To move from a theoretical concept to a more practical proposition, several areas of research and development could be pursued:

Advanced Materials: Research into new materials with higher sensitivity to neutrino interactions could improve detection rates. Nanomaterials or quantum dots might offer new pathways to detect and harness the energy from neutrino interactions more efficiently.

Accelerator Technology: Developing more compact and efficient accelerators would reduce the initial and operational costs of generating high-intensity neutrino beams. Using new acceleration techniques, such as plasma wakefield acceleration, could significantly decrease the size and cost of accelerators.

Detector Technology: Improvements in photodetector efficiency and the development of new scintillating materials could enhance the signal-to-noise ratio in neutrino detectors. High-temperature superconductors could also be used to improve the efficiency of magnetic horns and focusing devices.

Energy Conversion Methods: Exploring direct conversion methods, where the kinetic energy of particles from neutrino interactions is directly converted into electricity, could bypass the inefficiencies of thermal conversion systems. Research into piezoelectric materials or other direct conversion technologies could be key.

Conceptual Experiment to Demonstrate Viability

To demonstrate the viability of neutrino power transmission, even at a very small scale, a conceptual experiment could be set up as follows:

Experimental Setup

Small-Scale Accelerator: Use a small-scale proton accelerator to generate a neutrino beam. For experimental purposes, this could be a linear accelerator used in many research labs, capable of accelerating protons to a few hundred MeV.

Miniature Target and Decay Tunnel: Design a compact target and a short decay tunnel to produce and focus neutrinos. This setup will test the beam production and initial focusing systems.

Small Detector: Construct a small-scale neutrino detector, possibly using a few tons of liquid scintillator or water, equipped with sensitive photodetectors. This detector will test the feasibility of detecting focused neutrino beams at short distances.

Measurement and Analysis: Measure the rate of neutrino interactions and the energy deposited in the detector. Compare this to the expected values based on the beam properties and detector design.

Steps to Conduct the Experiment

Calibrate the Accelerator and Beamline: Ensure the proton beam is correctly tuned and the target is accurately positioned to maximize pion and kaon production.

Operate the Decay Tunnel and Focusing System: Run tests to optimize the magnetic focusing horns and maximize the neutrino beam coherence.

Run the Detector: Collect data from the neutrino interactions, focusing on capturing the rare events and distinguishing them from background noise.

Data Analysis: Analyze the collected data to determine the neutrino flux and interaction rate, and compare these to

theoretical predictions to validate the setup.

Optimization: Based on initial results, adjust the beam energy, focusing systems, and detector configurations to improve interaction rates and signal clarity.

Example Calculation for a Proof-of-Concept Experiment

To put the above experimental setup into a more quantitative framework, here's a simplified example calculation:

Assumptions and Parameters

Proton Beam Energy: 500 MeV (which is within the capability of many smaller particle accelerators).

Number of Protons per Second ((N_p)): (1 \times 10^{13}) protons/second (a relatively low intensity to ensure safe operations for a proof-of-concept).

Target Efficiency: Assume 20% of the protons produce pions or kaons that decay into neutrinos.

Neutrino Energy ((E_\nu)): Approximately 30% of the pion or kaon energy, so around 150 MeV per neutrino.

Distance to Detector ((D)): 100 meters (to stay within a compact experimental facility).

Detector Mass: 10 tons of water (equivalent to (10^4) kg, or about (6 \times 10^{31}) protons assuming 2 protons per water molecule).

Neutrino Interaction Cross-Section ((\sigma)): Approximately (10^{-38} , \text{m}^2) (typical for neutrinos at this energy).

Neutrino Detection Efficiency: Assume 50% due to detector design and quantum efficiency of photodetectors.

Neutrino Production

Pions/Kaons Produced: [ N_{\text{pions/kaons}} = N_p \times 0.2 = 2 \times 10^{12} \text{ per second} ]

Neutrinos Produced: [ N_\nu = N_{\text{pions/kaons}} = 2 \times 10^{12} \text{ neutrinos per second} ]

Neutrino Flux at the Detector

Given the neutrinos spread out over a sphere: [ \text{Flux} = \frac{N_\nu}{4 \pi D^2} = \frac{2 \times 10^{12}}{4 \pi (100)^2} , \text{neutrinos/m}^2/\text{s} ] [ \text{Flux} \approx 1.6 \times 10^7 , \text{neutrinos/m}^2/\text{s} ]

Expected Interaction Rate in the Detector

Number of Target Nuclei ((N_t)) in the detector: [ N_t = 6 \times 10^{31} ]

Interactions per Second: [ R = \text{Flux} \times N_t \times \sigma \times \text{Efficiency} ] [ R = 1.6 \times 10^7 \times 6 \times 10^{31} \times 10^{-38} \times 0.5 ] [ R \approx 48 , \text{interactions/second} ]

Energy Deposited

Energy per Interaction: Assuming each neutrino interaction deposits roughly its full energy (150 MeV, or (150 \times 1.6 \times 10^{-13}) J): [ E_d = 150 \times 1.6 \times 10^{-13} , \text{J} = 2.4 \times 10^{-11} , \text{J} ]

Total Power: [ P = R \times E_d ] [ P = 48 \times 2.4 \times 10^{-11} , \text{J/s} ] [ P \approx 1.15 \times 10^{-9} , \text{W} ]

So, the power deposited in the detector from neutrino interactions would be about (1.15 \times 10^{-9}) watts.

Challenges and Improvements for Scaling Up

While the proof-of-concept might demonstrate the fundamental principles, scaling this up to transmit even a single watt of power, let alone megawatts, highlights the significant challenges:

Increased Beam Intensity: To increase the power output, the intensity of the proton beam and the efficiency of pion/kaon production must be dramatically increased. For high power levels, this would require a much higher energy and intensity accelerator, larger and more efficient targets, and more sophisticated focusing systems.

Larger Detector: The detector would need to be massively scaled

up in size. To detect enough neutrinos to convert to a practical amount of power, we're talking about scaling from a 10-ton detector to potentially tens of thousands of tons or more, similar to the scale of detectors used in major neutrino experiments like Super-Kamiokande in Japan.

Improved Detection and Conversion Efficiency: To realistically convert the interactions into usable power, the efficiency of both the detection and the subsequent energy conversion process needs to be near-perfect, which is far beyond current capabilities.

Steps to Scale Up the Experiment

To transition from the initial proof-of-concept to a more substantial demonstration and eventually to a practical application, several steps and advancements are necessary:

Enhanced Accelerator Performance:

Upgrade to Higher Energies: Move from a 500 MeV system to several GeV or even higher, as higher energy neutrinos can penetrate further and have a higher probability of interaction.

Increase Beam Current: Amplify the proton beam current to increase the number of neutrinos generated, aiming for a beam power in the range of hundreds of megawatts to gigawatts.

Optimized Target and Decay Tunnel:

Target Material and Design: Use advanced materials that can withstand the intense bombardment of protons and optimize the geometry for maximum pion and kaon production.

Magnetic Focusing: Refine the magnetic horns and other focusing devices to maximize the collimation and directionality of the produced neutrinos, minimizing spread and loss.

Massive Scale Detector:

Detector Volume: Scale the detector up to the kiloton or even megaton range, using water, liquid scintillator, or other materials that provide a large number of target nuclei.

Advanced Photodetectors: Deploy tens of thousands of high-efficiency photodetectors to capture as much of the light from interactions as possible.

High-Efficiency Energy Conversion:

Direct Conversion Technologies: Research and develop technologies that can convert the kinetic energy from particle reactions directly into electrical energy with minimal loss.

Thermodynamic Cycles: If using heat conversion, optimize the thermodynamic cycle (such as using supercritical CO2 turbines) to maximize the efficiency of converting heat into electricity.

Integration and Synchronization:

Data Acquisition and Processing: Handle the vast amounts of data from the detector with real-time processing to identify and quantify neutrino events.

Synchronization: Ensure precise timing between the neutrino production at the accelerator and the detection events to accurately attribute interactions to the beam.

Realistic Projections and Innovations Required

Considering the stark difference between the power levels in the initial experiment and the target power levels, let's outline the innovations and breakthroughs needed:

Neutrino Production and Beam Focus: To transmit appreciable power via neutrinos, the beam must be incredibly intense and well-focused. Innovations might include using plasma wakefield acceleration for more compact accelerators or novel superconducting materials for more efficient and powerful magnetic focusing.

Cross-Section Enhancement: While we can't change the fundamental cross-section of neutrino interactions, we can increase the effective cross-section by using quantum resonance effects or other advanced physics concepts currently in theoretical stages.

Breakthrough in Detection: Moving beyond conventional photodetection, using quantum coherent technologies or metamaterials could enhance the interaction rate detectable by the system.

Scalable and Safe Operation: As the system scales, ensuring safety and managing the high-energy particles and radiation produced will require advanced shielding and remote handling technologies.

Example of a Scaled Concept

To visualize what a scaled-up neutrino power transmission system might look like, consider the following:

Accelerator: A 10 GeV proton accelerator, with a beam power of 1 GW, producing a focused neutrino beam through a 1 km decay tunnel.

Neutrino Beam: A beam with a diameter of around 10 meters at production, focused down to a few meters at the detector site several kilometers away.

Detector: A 100 kiloton water Cherenkov or liquid scintillator detector, buried deep underground to minimize cosmic ray backgrounds, equipped with around 100,000 high-efficiency photodetectors.

Power Output: Assuming we could improve the overall system efficiency to even 0.1% (a huge leap from current capabilities), the output power could be: [ P_{\text{output}} = 1\text{ GW} \times 0.001 = 1\text{ MW} ]

This setup, while still futuristic, illustrates the scale and type of development needed to make neutrino power transmission a feasible alternative to current technologies.

Conclusion

While the concept of using neutrinos to transmit power is fascinating and could overcome many limitations of current power transmission infrastructure, the path from theory to practical application is long and filled with significant hurdels.

#Neutrino Energy Transmission#Particle Physics#Neutrino Beam#Neutrino Detector#High-Energy Physics#Particle Accelerators#Neutrino Interaction#Energy Conversion#Direct Energy Conversion#High-Voltage Direct Current (HVDC)#Experimental Physics#Quantum Materials#Nanotechnology#Photodetectors#Thermoelectric Generators#Superfluid Helium#Quantum Dots#Plasma Wakefield Acceleration#Magnetic Focusing Horns#Cherenkov Radiation#Scintillation Light#Silicon Photomultipliers (SiPMs)#Photomultiplier Tubes (PMTs)#Particle Beam Technology#Advanced Material Science#Cost-Effectiveness in Energy Transmission#Environmental Impact of Energy Transmission#Scalability of Energy Systems#Neutrino Physics#Super-Kamiokande

0 notes

Text

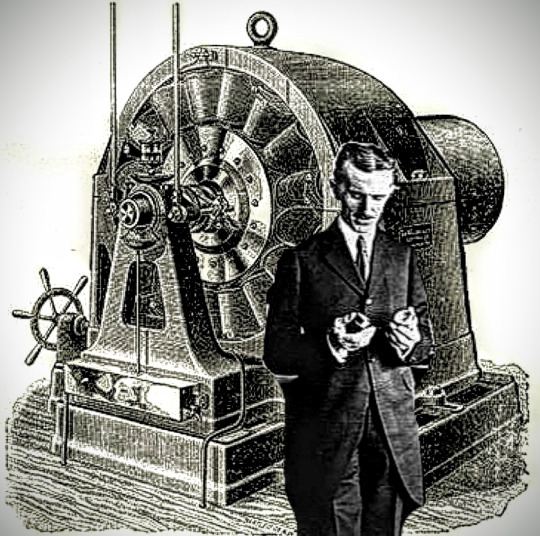

One of the Greatest Inventions of All Time

Nikola Tesla has many revolutionary inventions to his credit, but he is best known for his pioneering work in the development and promotion of alternating current (AC) electrical systems. Tesla's innovations in AC technology revolutionized the generation, transmission, and distribution of electrical power, becoming the foundation for the modern electrical power systems that we use today.

There is a common misconception made that Tesla was the first to invent, or discover, AC, but this is not true. It is well-known that Hippolyte Pixii was the first to discover AC in 1832. Pixii was an instrument maker from Paris who built an early form of an alternating current electrical generator (based on the principle of electromagnetic induction discovered by Michael Faraday), and thus started a new industry in power transmission. Tesla was not the first to discover or invent an AC motor, but he was the first to invent a practical AC induction motor with commercial value that could outperform all other motors. It must be noted that Italian inventor Galileo Ferraris also invented an induction motor similar to Tesla's, but it had no commercial value, and he even admitted himself that it was useless. Tesla's induction motor operates on the principle of electromagnetic induction, properly utilizing a rotating magnetic field that induces a current in a stationary conductor, resulting in rotational motion. The utilization of the rotating magnetic field makes the motor more simple, robust, versatile, efficient, and cost effective in that it has less moving parts reducing the likelihood of mechanical failure (as was common in other motors).

Tesla's induction motor became a fundamental component in the field of electrical engineering and is used today in various applications, being one of the most widely used devices in the world. The motors play a crucial role in transmitting electrical power to homes and businesses. They are commonly used in power generation plants to convert mechanical energy into electrical energy, which is then transmitted through the power grid for distribution to various locations. Induction motors are also widely employed in appliances and machinery within homes and businesses for various applications. These applications include conveyor systems, hoists, cranes, lifts, pumps, fans, ventilation systems, compressors, manufacturing machinery, wind turbines, washing machines, refrigerators, garbage disposals, microwaves, dishwashers, vacuums, air conditioners, robotics, electric vehicles, trains, power tools, printers, etc. Basically, anything that requires a spinning action for power.

The induction motor is widely considered one of the most important inventions in the history of electrical engineering. Its importance lies in its transformative impact on industries, its efficiency and reliability, and its role in the broader electrification of society.

#nikola tesla#science#history#invention#discovery#induction motor#electricity#power#goat#ahead of his time#ahead of our time

152 notes

·

View notes

Text

Also preserved in our archive

by Simon Spichak

Key points you should know:

The only ongoing pediatric trial in the U.S. is testing a drug, called larazotide, aimed at tightening the gaps between cells in the gut to prevent coronavirus spike protein from leaking into circulation.

Because of cost and age discrimination, companies often develop drugs in adults before testing new treatments in kids.

The RECOVER initiative is ramping up to start clinical trials in kids soon, but parents and kids want to see more urgency.

Involving parents and children with Long COVID throughout the clinical trial process is necessary to make trials more effective. After an initial SARS-CoV-2 infection in January 2021, Laura’s then nine-year-old son Matthew* developed symptoms that never went away — fatigue, cognitive dysfunction, rashes, joint pain, and shortness of breath.

His school recognizes he’s at extra risk if he attends in person when there are high levels of COVID-19, flu, or other transmissible diseases. For people with Long COVID, reinfections can make symptoms worse, bring on new diagnoses, and further disable them. So far during the 2024-2025 school year, he’s attended only three and a half days.

“There’s always pretty much just pain,” Matthew, now 12, told The Sick Times.

Matthew is on a baseball team but has to pace himself to avoid crashing. A treatment could make it easier for him to participate. “I wouldn’t have to save up all my energy just to do one thing,” he said.

But as of October 16, there are only two registered drug trials for Long COVID in kids — one in the U.S. and one in Pakistan. Why?

One reason is little acknowledgment of Long COVID in children from policymakers or media outlets, according to Megan Carmilani, founder of the advocacy group Long Covid Families. “There was a lot of rhetoric and denial about the idea that COVID could affect kids so there’s just not a lot of research that has been conducted,” Carmilani said.

The tide started to shift earlier this year in February. The National Institutes of Health’s RECOVER program, which includes studies tracking Long COVID in children, published a review paper in Pediatrics estimating 5.8 million kids in the U.S. were living with Long COVID, more than the 4.9 million children living with asthma.

“Children are in the most high risk environment [for infection],” Carmilani added. Most daycares and schools have not upgraded their air filtration or implemented measures to prevent the spread of airborne infections. “Children cannot consent to infection at all, and they’re legally required to be in some of these environments where families are reporting they’re getting sicker.” Research suggests that kids represent one in every four people with Long COVID.

Carmilani tracked how often children were mentioned during the September meeting kicking off the RECOVER-Treating Long COVID initiative, which will support new clinical trials. “And in two and a half days, I think the total was 53 minutes,” Carmilani said.

The initiative is a direct response from the National Institutes of Health (NIH) to criticism that the research program was moving too slowly to find treatments.

Experts who spoke with The Sick Times brought up many different reasons why developing new drugs for children with Long COVID has moved at such a glacial pace. Many pharmaceutical companies might not see Long COVID as profitable. And running trials in children is complex and expensive, as they can have different symptoms and underlying biological processes behind those symptoms from adults.

“I want more clinical trials focused on cures and effective treatments. We want treatments that are actually getting at the underlying causes and not just sticking a band aid on symptoms,” Katherine, a parent of a 16-year old with Long COVID told The Sick Times.

*Editor’s note: Children with Long COVID and their parents who spoke to The Sick Times for this story are referred to by their first names to protect their privacy.

#mask up#public health#wear a mask#pandemic#covid#wear a respirator#covid 19#still coviding#coronavirus#sars cov 2

15 notes

·

View notes

Text

After a surge in home energy bills that left many New Jersey residents with costs that have doubled, or more, there have been widespread calls for hearings to hold the state utility commission, the governor and supporters of green energy accountable.

State Sen. Mike Testa, R-Salem, echoed those calls and said on Wednesday that much of the blame goes to Democrat Gov. Phil Murphy’s "Energy Master Plan," launched in 2020.

"New Jersey is already one of the most unaffordable states in the United States of America. Now people are being hit with energy bills that are essentially doubled. And look, I get it that it was a hot July, but it wasn't that hot that your energy bills should have doubled," Testa said.

One constituent apparently told Testa they raised their thermostat four degrees on average this summer in the hopes of saving money but that the cost still somehow increased "significantly."

Homeowners in suburban Morris County vented about the news on a local social media group, according to the Morristown Daily Record, with a Parsippany resident questioning a $782 monthly bill.

"Quite frankly, what I think happened is, via the Murphy Energy Master Plan that I've often called the energy disaster plan, it seemed that the BPU (New Jersey Board of Public Utilities) and the Murphy administration are working in tandem chasing this green energy dream.

"It’s what I call the energy disaster plan. It's a green energy nightmare," he said, adding that BPU officials went so far as to wear windmill pins at public functions amid New Jersey’s kerfuffle over offshore turbines.

In a lengthy statement, BPU acknowledged it had received correspondence from New Jerseyans and offered several potential reasons for the rate hikes.

The board cited increases in generation costs and usage, and it asked customers to contact their utility or the board right away if they find an "anomaly and cannot determine an explanation" A one-time $175 bill credit program is also available, a board spokesperson said.

PJM, the energy transmission company that covers much of the Mid-Atlantic, offered data to Fox News Digital on the matter as well.

PJM research showed electricity demand is likely to increase in the region particularly due to "proliferation of high-demand data centers" and "thermal generators retiring at a rapid pace due to government and private sector policies as well as economics."

Meanwhile, at the federal level, Rep. Jeff Van Drew, R-N.J., fumed at the BPU this week in a letter obtained by Fox News Digital, which cited "thousands" of constituents discovering unbearable bill increases.

"Given these alarming reports, I demand that the New Jersey Board of Public Utilities (NJBPU) hold a public hearing in South Jersey to allow residents to voice their concerns directly to the Board," he wrote, adding the board must also determine whether there is a correlation between the rate hikes and the offshore wind turbine operations in his Cape May district.

Van Drew said New Jersey officials must take the situation seriously, and he dismissed claims that the "unseasonably warm summer" was the only variable.

"We need transparency and accountability from the NJBPU to ensure that the needs and concerns of South Jersey residents are being effectively addressed," he said.

Van Drew previously noted how Danish green power company Ørsted withdrew its windmill plans for the Jersey Shore despite Murphy’s full support and taxpayer funding: "They still couldn't make it."

While Murphy’s office did not return a request for comment, the governor previously praised his Energy Master Plan’s goal of 100% clean energy by 2050 in the Garden State.

"The Energy Master Plan comprehensively addresses New Jersey’s energy system, including electricity generation, transportation and buildings, and their associated greenhouse gas emissions and related air pollutants," he said.

In a statement Tuesday, the Murphy administration highlighted a "Residential Energy Assistance Payment (REAP) Initiative" to provide financial relief to thousands of households, of the same $175 figure cited by BPU.

"Making our state more affordable for New Jersey families has been the top priority since day one," Murphy said in the statement.

State Assembly Speaker Craig Coughlin, D-Perth Amboy, added it is "great to see this resource added to the growing list of support available to residents who need a little extra help in our state."

Assemblywoman Nancy Munoz, R-Summit, said price-per-kilowatt hour increases averaged 8.6% in Central Jersey.

"It’s simple economics: When supply drops and demand surges, prices go up," she told Fox News Digital.

"I'm of the belief that Americans are innovative. … The government can't be mandating deadlines at the same time that they're … shutting down natural gas production."

Munoz, who serves on the Budget Committee, said there are likely Democrats who agree the rate hikes are a problem: "That's kind of a silly concept for them to think, like, do they not care that their constituents are the ones that are having to absorb these massive increases in cost?"

Fox News Digital reached out to state Senate President Nick Scutari, D-Clark, for such a perspective.

Citing attempts to make New Jersey vehicle sales 60% electric by 2035, Munoz said there won’t be the proper infrastructure to fulfill the need, regardless of opinions on EVs themselves.

When Testa was asked about other states’ similar green energy endeavors – such as then-New York Gov. Andrew Cuomo shuttering the Indian Point nuke plant on the Hudson River opposite Haverstraw in 2020 – he expressed relief that crackdowns hadn’t gotten that far at home.

A similar nuclear plant in Lower Alloways Creek Township remains operational, he noted, adding that he is proud to have it and its jobs and generation ability in his district.

Testa said the state’s energy portfolio is 50% natural gas, 40% nuclear and 10% other, which flies in the face of Murphy’s aversion to additional natural gas production.

While some energy experts fear crises arising from nuclear power, such as the 1979 Three Mile Island meltdown in Dauphin County, Pa., Testa said technology has advanced since and that there are also small modular nuclear reactors similar to those on submarines that could generate safe, clean energy inland at low cost.

"By the way, we’re positive that those don’t kill whales," he said.

17 notes

·

View notes

Text

Excerpt from this Audubon story:

Too often, the debate over climate solutions centers on perceived trade-offs between habitat conservation and the clean energy transition, preserving community and allowing development, or reducing pollution and maintaining profitability. But responsible clean energy deployment can be balanced with the needs of communities and wildlife, representing a win-win that doesn’t give rise to insurmountable trade-offs. Audubon’s new report, Offshore Wind and Birds: Developing the Offshore Wind that Birds Need, confirms that offshore wind can have immense benefits for birds, people, and the economy. This report advocates for the rapid adoption of offshore wind to combat the climate crisis while protecting birds, supporting coastal communities, and addressing the growing demand from advanced manufacturing and emerging technologies.

The report was published as wildfires rage in California, communities in the Southeastern U.S. continue to deal with severe damage from Hurricanes Helene and Milton, and NASA confirmed that 2024 was the warmest year on record. NASA also found that the world has exceeded the 1.5 degrees Celsius climate threshold—a level of warming that climate scientists warn could lead to irreversible consequences if sustained. Audubon's Survival by Degrees report indicates that over two-thirds of North American bird species could face extinction due to unchecked climate change—a loss that would have dire implications for ecosystems, agriculture, and communities across the country.

The urgency for action on climate change has never been greater. Thankfully, the development of offshore wind can provide a swift and actionable solution to this crisis.

Realizing Offshore Wind’s Potential

The potential capacity of offshore wind energy off the continental U.S. is remarkable. According to the National Renewable Energy Laboratory, the total feasible offshore wind capacity along U.S. coasts is more than three times the total electricity generated nationwide in 2023. By harnessing only 10-13% of this capacity, studies show the U.S. could achieve net-zero greenhouse gas emissions economy-wide while creating as many as 390,000 jobs by 2050, fostering new investment and employment opportunities nationwide.

Offshore wind is also advantageous because it can be generated conveniently close to large population centers. In addition, consistent and strong wind speeds help offshore wind provide a steady stream of clean energy back to the grid. By producing offshore wind along the coast, we can utilize clean energy sources while reducing transmission burdens and increasing our capacity to meet growing energy demand.

Advancing Offshore Wind Development with Bird and Marine Wildlife Conservation

Audubon produced the Birds and Offshore Wind report to examine the best available science regarding the risks to birds. While persistent myths claim widespread and devastating effects of offshore wind turbines on wildlife, the science tells a different story. Our findings clearly indicate that we can responsibly deploy offshore wind in a manner that still protects birds and their habitats. That said, it is important to acknowledge that offshore wind turbines, like all infrastructure, can pose a risk to birds. These risks include turbine collisions, habitat displacement, and avoidance behavior. Fortunately, our research shows developers can effectively manage these risks without significantly increasing project costs.

To tackle the existing risks, Audubon calls for a four-step planning process:

Identify and remove critically important areas for birds from consideration for leasing.

Implement proven strategies to minimize the potential for turbines to impact birds.

Offset unavoidable impacts, when necessary, through investments in conservation.

Monitor bird movements and population trends to ensure solutions are working.

The impact of offshore wind on wildlife is neither disproportionate nor insurmountable. Proven strategies, such as reducing visible lights on turbines and using perching deterrents on turbines, have been effective in addressing bird impacts.

3 notes

·

View notes

Text

Perfect Fit – How Customization Enhances Insulators and Bushings

In the rapidly advancing world of electrical systems, where efficiency and reliability are paramount, the need for customized solutions is growing. Insulators and bushings are critical components in electrical infrastructure, ensuring safety, performance, and longevity. Standard solutions may not always address unique requirements, and that is where customization plays a pivotal role.

In this blog, we delve into the importance of customization in insulators and bushings, exploring how tailored solutions from customized insulator and bushing manufacturers in India drive innovation and efficiency.

The Importance of Insulators and Bushings in Electrical Systems

Insulators and bushings play a crucial role in electrical equipment. They are designed to:

Prevent electrical leakage by separating conductors.

Enhance the safety and efficiency of power systems.

Withstand high voltages and harsh environmental conditions.

As electrical networks grow increasingly complex, there is a pressing need for customized components to meet specific challenges. This is where customized insulators and bushings come into the picture.

Why Opt for Customized Insulators and Bushings?

Customization allows manufacturers to design insulators and bushings tailored to precise requirements. Here are some key benefits:

1. Optimized Performance

Standard insulators and bushings may not fit all operational needs. Customized solutions ensure compatibility with unique designs, operational environments, and performance metrics. This is particularly critical in high-stress applications such as:

High-voltage power transmission.

Industrial power setups.

Specialized equipment like transformers and circuit breakers.

2. Enhanced Reliability

Custom designs consider factors such as voltage capacity, environmental conditions, and material requirements. For instance, epoxy pole housing offers superior durability and resistance, making it a preferred choice for demanding environments.

3. Material Versatility

Customization allows the selection of the most suitable materials. For example:

Epoxy insulator solutions are favored for their high mechanical strength, electrical insulation properties, and resistance to harsh conditions.

Epoxy bushing designs are ideal for providing electrical and mechanical support while withstanding environmental and operational stress.

4. Cost-Effectiveness

While customized solutions may have a higher upfront cost, they provide long-term savings by minimizing downtime, reducing maintenance costs, and enhancing system longevity.

Applications of Customized Insulators and Bushings

Customized insulators and bushings find applications across a wide range of sectors. Let us explore a few key areas:

1. Power Distribution Networks

Power networks rely heavily on reliable insulation and bushing systems. Custom solutions ensure components meet the specific demands of:

Voltage fluctuations.

Harsh weather conditions.

Compact designs in urban environments.

2. Electrical Transformers

Transformers are critical in power systems, and bushings play a vital role in their functionality. Customized epoxy bushing designs are engineered to enhance performance and ensure safe electrical conduction.

3. Circuit Protection Systems

Circuit protection devices like fuse cutouts require specialized housings. Fuse cutout housing can be customized to withstand electrical surges, ensuring the protection of connected equipment.

4. Renewable Energy Systems

The rise of renewable energy has introduced unique challenges for electrical components. Customized insulators and bushings are tailored to handle:

Higher voltage levels in solar and wind power systems.

Corrosive environments such as offshore wind farms.

How Customization Works

Customization is a collaborative process involving manufacturers and clients. Reputable customized insulator and bushing manufacturers in India follow a systematic approach:

1. Requirement Analysis

The first step is understanding the specific needs of the client. Factors like operational environment, voltage levels, and design constraints are carefully assessed.

2. Material Selection

Choosing the right material is crucial. For instance:

Epoxy pole housing is often selected for its excellent thermal stability and electrical insulation properties.

High-performance polymers or ceramics may be used for extreme environments.

3. Design and Prototyping

Manufacturers use advanced CAD software to design custom solutions. Prototypes are created to validate performance before mass production.

4. Testing and Quality Assurance

Customized components undergo rigorous testing to ensure they meet industry standards and client specifications. Testing includes:

Dielectric strength tests.

Mechanical stress tests.

Environmental resistance tests.

5. Production and Delivery

Once approved, the components are manufactured using advanced processes and delivered to the client.

Why Choose Indian Manufacturers for Customized Solutions?

India has emerged as a hub for high-quality electrical components. Here is why partnering with customized insulator and bushing manufacturers in India is a smart choice:

Expertise: Indian manufacturers have extensive experience in designing and producing customized solutions.

Cost-Effectiveness: Competitive pricing without compromising on quality.

Innovation: Use of advanced technologies and materials to meet global standards.

Sustainability: Commitment to eco-friendly manufacturing practices.

Radiant Enterprises: Your Partner for Customized Solutions

At Radiant Enterprises, we specialize in delivering high-quality customized insulators and bushings tailored to the unique needs of our clients. Our expertise extends to:

Epoxy insulator and bushing solutions that ensure top-notch performance and reliability.

Advanced epoxy pole housing designs for a variety of applications.

Durable fuse cutout housing options that protect your systems from electrical faults.

Our team works closely with clients to understand their requirements, ensuring every product meets their expectations. With a focus on quality, innovation, and customer satisfaction, we stand among the leading manufacturers in India.

Conclusion

The need for customized insulators and bushings in today’s electrical systems cannot be overstated. From enhancing performance and reliability to ensuring long-term cost-effectiveness, customization offers unparalleled advantages.

Partnering with a trusted customized insulator and bushing manufacturer in India, like Radiant Enterprises, ensures you receive components designed to meet your specific needs. With our expertise in epoxy insulators, epoxy bushings, fuse cutout housing, and more, we provide solutions that drive efficiency and reliability in your electrical systems.

Contact Radiant Enterprises today to learn how our customized solutions can transform your operations!

#Customised insulators and bushings#Customized insulator and bushing manufacturers in India#Epoxy pole housing#Fuse cutout housing

4 notes

·

View notes

Text

Exploring Photonics and the Role of Photonics Simulation

Photonics is a cutting-edge field of science and engineering focused on the generation, manipulation, and detection of light (photons). From powering high-speed internet connections to enabling precision medical diagnostics, photonics drives innovation across industries. With advancements in photonics simulation, engineers and researchers can now design and optimize complex photonic systems with unparalleled accuracy, paving the way for transformative technologies.

What Is Photonics?

Photonics involves the study and application of photons, the fundamental particles of light. It encompasses the behavior of light across various wavelengths, including visible, infrared, and ultraviolet spectrums. Unlike electronics, which manipulates electrons, photonics harnesses light to transmit, process, and store information.

The applications of photonics span diverse fields, such as telecommunications, healthcare, manufacturing, and even entertainment. Technologies like lasers, optical fibers, and sensors all rely on principles of photonics to function effectively.

Why Is Photonics Important?

Photonics is integral to the modern world for several reasons:

Speed and Efficiency Light travels faster than electrons, making photonics-based systems ideal for high-speed data transmission. Fiber-optic networks, for instance, enable lightning-fast internet and communication.

Miniaturization Photonics enables the development of compact and efficient systems, such as integrated photonic circuits, which are smaller and more energy-efficient than traditional electronic circuits.

Precision Applications From laser surgery in healthcare to high-resolution imaging in astronomy, photonics offers unparalleled precision in diverse applications.

The Role of Photonics Simulation

As photonic systems become more complex, designing and optimizing them manually is increasingly challenging. This is where photonics simulation comes into play.

Photonics simulation involves using advanced computational tools to model the behavior of light in photonic systems. It allows engineers to predict system performance, identify potential issues, and fine-tune designs without the need for costly and time-consuming physical prototypes.

Key Applications of Photonics Simulation

Telecommunications Photonics simulation is crucial for designing optical fibers, waveguides, and integrated photonic circuits that power high-speed data networks. Simulations help optimize signal strength, reduce loss, and enhance overall system efficiency.

Healthcare In the medical field, photonics simulation aids in the development of imaging systems, laser-based surgical tools, and diagnostic devices. For instance, simulation tools are used to design systems for optical coherence tomography (OCT), a non-invasive imaging technique for detailed internal body scans. Medical device consulting provides expert guidance on the design, development, and regulatory compliance of innovative medical technologies.

Semiconductors and Electronics Photonics simulation supports the creation of photonic integrated circuits (PICs) that combine optical and electronic components. These circuits are essential for applications in computing, sensing, and communication.

Aerospace and Defense Photonics simulation enables the design of systems like lidar (Light Detection and Ranging), which is used for navigation and mapping. Simulations ensure these systems are accurate, reliable, and robust for real-world applications. Aerospace consulting offers specialized expertise in designing, analyzing, and optimizing aerospace systems for performance, safety, and innovation.

Energy and Sustainability Photonics plays a vital role in renewable energy technologies, such as solar cells. Simulation tools help optimize light capture and energy conversion efficiency, making renewable energy more viable and cost-effective. Clean energy consulting provides expert guidance on implementing sustainable energy solutions, optimizing efficiency, and reducing environmental impact.

Benefits of Photonics Simulation

Cost-Efficiency: By identifying potential issues early in the design phase, simulation reduces the need for multiple physical prototypes, saving time and resources.

Precision and Accuracy: Advanced algorithms model light behavior with high accuracy, ensuring designs meet specific performance criteria.

Flexibility: Simulations can model a wide range of photonic phenomena, from simple lenses to complex integrated circuits.

Innovation: Engineers can experiment with new materials, configurations, and designs in a virtual environment, fostering innovation without risk.

Challenges in Photonics Simulation

Despite its advantages, photonics simulation comes with its own set of challenges:

Complexity of Light Behavior Modeling light interactions with materials and components at nanoscales requires sophisticated algorithms and powerful computational resources.

Integration with Electronics Photonics systems often need to work seamlessly with electronic components, adding layers of complexity to the simulation process.

Material Limitations Accurately simulating new or unconventional materials can be challenging due to limited data or untested behavior.

The Future of Photonics and Photonics Simulation

Photonics is at the forefront of technological innovation, with emerging trends that promise to reshape industries. Some of these trends include:

Quantum Photonics: Leveraging quantum properties of light for applications in secure communication, advanced sensing, and quantum computing.

Silicon Photonics: Integrating photonics with silicon-based technologies for cost-effective and scalable solutions in telecommunications and computing.

Artificial Intelligence (AI) in Photonics: Using AI algorithms to enhance photonics simulation, enabling faster and more accurate designs.

Biophotonics: Exploring the interaction of light with biological systems to advance healthcare and life sciences.

As photonics continues to evolve, the role of simulation will only grow in importance. Advanced simulation tools will empower engineers to push the boundaries of what is possible, enabling innovations that improve lives and drive progress.

Conclusion

Photonics and photonics simulation are shaping the future of technology, offering solutions that are faster, more efficient, and precise. By harnessing the power of light, photonics is revolutionizing industries, from healthcare to telecommunications and beyond. With the aid of simulation tools, engineers can design and optimize photonic systems to meet the challenges of today and tomorrow. As this exciting field continues to advance, its impact on society will be nothing short of transformative.

2 notes

·

View notes

Text

Future of Power Transformer Market: Innovations and Developments

The global power transformer market was valued at USD 22.83 billion in 2022 and is anticipated to expand at a compound annual growth rate (CAGR) of 7.1% from 2023 to 2030. This growth is primarily driven by the increasing demand for electricity in both emerging and developed countries, coupled with significant investments in infrastructure. As urbanization and industrialization continue to accelerate, the need for reliable and efficient power distribution systems is expected to fuel market growth. Additionally, the rising focus on modernizing the existing energy grid systems and improving energy efficiency will be key factors driving the demand for power transformers over the forecast period.

A major contributing factor to the market's expansion is the growing adoption of smart grid technology. The development of smart grids, which incorporate advanced technologies like smart meters and automated control systems, is creating a significant demand for more sophisticated power transformers. Smart meters, in particular, are integral to the efficient functioning of smart grids as they enable real-time monitoring and management of energy consumption. The widespread push for smart grid development, along with government initiatives to modernize power infrastructure, is expected to have a positive impact on the power transformer market over the next several years.

In addition to smart grids, the power transformer market will be further supported by the rising focus on renewable energy sources and the increasing need to develop transmission networks for remote and off-grid locations. The integration of non-traditional energy sources, such as wind, solar, and hydropower, into the power grid requires efficient power transformers that can manage variable power outputs and ensure reliable electricity distribution.

Gather more insights about the market drivers, restrains and growth of the Power Transformer Market

Phase Insights

The power transformer market can be segmented based on phase type into two categories: single-phase and three-phase transformers. As of 2022, the three-phase transformer segment accounted for the largest share of the market, with a dominant market share of 62.2%. This segment is expected to grow at the fastest rate, with a projected CAGR of 7.2% by 2030.

Three-phase transformers are widely used in various industrial applications due to their high efficiency and ability to handle large power loads. They are commonly used in industries such as manufacturing, mining, petrochemicals, automation, and telecommunications, among others, for both power generation and distribution. These transformers are especially suited for industrial settings because they are more affordable, compact, and lightweight compared to other transformer types, especially when dealing with high power ratings.

In addition to being cost-effective, three-phase transformers offer several operational advantages. They are ideal for low-voltage distribution systems that experience high fluctuations in voltage. Their design allows for superior isolation, common-mode interference suppression, and they can be customized to meet specific end-user requirements. Furthermore, they are particularly effective in environments that require a stable and continuous power supply, making them indispensable for a wide range of applications, including precision machinery and automated systems.

Given their many advantages and the growing number of industries relying on them, three-phase transformers are expected to continue dominating the market and experience robust growth during the forecast period. Their versatile applications and increased adoption across multiple industrial sectors further underline their critical role in the development of power distribution systems worldwide.

Order a free sample PDF of the Power Transformer Market Intelligence Study, published by Grand View Research.

#Power Transformer Market#Power Transformer Market Analysis#Power Transformer Market Report#Power Transformer Industry

2 notes

·

View notes

Text

Unlocking the Potential of Solar Energy: The Role of Solar Management Dashboards

In the era of sustainable energy, solar power has emerged as a pivotal solution for reducing carbon footprints and harnessing renewable resources. As solar energy systems become more prevalent, effective management and optimization are essential to maximizing their benefits. This is where solar management dashboards come into play. These powerful tools offer comprehensive insights and control over solar energy systems, making them indispensable for both residential and commercial solar installations. In this article, we explore the significance of solar management dashboards, the role of solar management dashboard development, and the impact of solar management dashboard development services on the solar industry.

Understanding Solar Management Dashboards

A solar management dashboard is a centralized platform that provides real-time monitoring, analysis, and control of solar energy systems. These dashboards aggregate data from various components of a solar power system, including solar panels, inverters, batteries, and energy meters, to deliver actionable insights and streamline system management.

Key Features of Solar Management Dashboards:

Real-Time Monitoring: Dashboards offer live updates on the performance of solar panels, including energy production, system efficiency, and operational status. This allows users to track performance and detect issues promptly.

Performance Analytics: Advanced analytics tools within the dashboard provide insights into energy production trends, efficiency metrics, and system health. These insights help in optimizing performance and identifying areas for improvement.

Alerts and Notifications: Automated alerts notify users of potential issues such as equipment malfunctions, performance drops, or maintenance needs. This proactive approach helps in addressing problems before they escalate.

Energy Management: Dashboards facilitate the management of energy consumption and storage. Users can monitor energy usage patterns, track battery levels, and make informed decisions about energy distribution and consumption.

Reporting and Visualization: Customizable reports and visualizations help users understand system performance over time. Historical data analysis and graphical representations make it easier to assess the impact of solar energy on overall energy costs and savings.

The Importance of Solar Management Dashboard Development

The development of a solar management dashboard involves creating a user-friendly and feature-rich interface that effectively integrates with solar power systems. This development process is critical for ensuring that dashboards meet the specific needs of users and provide accurate, actionable data.

Key Aspects of Solar Management Dashboard Development:

Integration Capabilities: A well-developed dashboard must seamlessly integrate with various solar components and technologies. This includes compatibility with different types of solar panels, inverters, and energy storage systems.

User Experience (UX) Design: The dashboard should be designed with user experience in mind, offering an intuitive interface that simplifies navigation and data interpretation. A good UX design ensures that users can easily access and understand the information they need.

Data Accuracy and Security: Accurate data collection and transmission are crucial for reliable performance monitoring. Additionally, robust security measures must be implemented to protect sensitive data from unauthorized access or breaches.

Customization and Scalability: The dashboard should be customizable to fit different user requirements and scalable to accommodate future upgrades or expansions of the solar power system.

The Role of Solar Management Dashboard Development Services

Solar management dashboard development services play a crucial role in bringing these dashboards from concept to reality. These services offer specialized expertise in designing, developing, and deploying solar management solutions that cater to the unique needs of each solar energy system.

Key Benefits of Solar Management Dashboard Development Services:

Tailored Solutions: Development services provide customized dashboard solutions that align with the specific requirements of a solar power system, ensuring that the dashboard effectively meets the user's needs.

Expertise and Innovation: Leveraging the expertise of experienced developers and industry professionals, these services bring innovative features and technologies to the dashboard, enhancing its functionality and performance.

End-to-End Support: Development services offer comprehensive support throughout the entire process, from initial consultation and design to implementation and ongoing maintenance. This ensures that the dashboard remains functional and up-to-date.

Optimized Performance: By utilizing advanced development techniques and best practices, these services ensure that the dashboard delivers optimal performance, accuracy, and reliability in monitoring and managing solar energy systems.

Future Trends in Solar Management Dashboards

As technology continues to advance, the future of solar management dashboards holds exciting possibilities:

Enhanced AI and Machine Learning: Future dashboards will increasingly incorporate AI and machine learning algorithms to provide predictive analytics, automated adjustments, and advanced troubleshooting capabilities.

Integration with Smart Grids: The integration of solar management dashboards with smart grid technologies will enable more efficient energy distribution and enhance grid stability.

Advanced Data Visualization: Improved data visualization tools will offer more detailed and interactive representations of solar energy performance, making it easier for users to analyze and act on data.

User-Centric Innovations: Ongoing developments will focus on enhancing user experience, with features such as voice commands, mobile access, and personalized dashboards tailored to individual preferences.

Conclusion

Solar management dashboards are essential tools for optimizing the performance and efficiency of solar energy systems. With the growing importance of solar power in our quest for sustainability, the role of solar management dashboard development and solar management dashboard development services becomes increasingly critical. These dashboards not only provide valuable insights and control over solar power systems but also contribute to the overall success and effectiveness of renewable energy initiatives. As technology continues to evolve, embracing advanced dashboard solutions and development services will help maximize the potential of solar energy and drive us towards a more sustainable future.

2 notes

·

View notes

Text

The Global Impact of High-Quality Current Transformer Bases

In the ever-evolving landscape of energy distribution and management, current transformers play a pivotal role in ensuring accurate measurement and monitoring of electrical currents in power systems. A critical component within these transformers is the current transformer base, which serves as the foundation for the safe and efficient operation of transformers. As global demand for energy continues to surge, the significance of high-quality current transformer bases in modern power infrastructures cannot be overstated.

Current transformer bases are instrumental in energy distribution networks, helping to measure current accurately and protect electrical systems from faults and overloading. This blog will delve into the global impact of high-quality current transformer bases and highlight the importance of reliable manufacturers and exporters in India, the growing role of air-insulated switchgear companies, and the increasing need for advanced power monitoring systems.

The Role of Current Transformer Bases in Power Systems

Current transformers (CTs) are essential in the measurement and control of electrical currents in various applications, from power generation and transmission to industrial automation and energy metering. The current transformer base acts as the structural platform on which the transformer operates, ensuring the stability and insulation of the CT during operation.

High-quality current transformer bases provide enhanced accuracy in current measurement, which is critical for maintaining the efficiency and safety of power systems. These bases also ensure proper insulation and protection of the transformer, preventing short circuits, arcing, and other potential hazards.

For industries where power quality and reliability are paramount, such as manufacturing, utilities, and data centers, the performance of the current transformer base directly impacts the effectiveness of power monitoring and control systems.

India: A Global Hub for Current Transformer Base Manufacturing

India has emerged as a key player in the global energy sector, and its manufacturers are becoming increasingly prominent in the production of critical power components. As a leading current transformer base manufacturer and exporter in India, Radiant Enterprises and other companies have made significant strides in meeting global demand for high-quality products. Indian manufacturers are known for their technical expertise, innovative solutions, and adherence to international standards, making them a trusted source for current transformer bases.

The rise of India as a global manufacturing hub has been driven by several factors:

Cost-Effective Production: Indian manufacturers offer competitive pricing without compromising on quality, making their products attractive to global markets.

Skilled Workforce: India boasts a highly skilled workforce with expertise in the design, production, and testing of electrical components, including current transformer bases.

Adherence to International Standards: Indian manufacturers comply with global quality standards such as ISO, IEC, and other industry certifications, ensuring that their products meet the stringent requirements of international clients.

Growing Export Market: India’s export market for electrical components has seen steady growth, with manufacturers catering to the needs of clients across Europe, North America, Africa, and Asia.

As the global demand for energy continues to rise, the role of Indian manufacturers and exporters in meeting the need for high-quality current transformer bases becomes even more significant.

Impact on Power Monitoring Systems

Power monitoring systems are essential tools in modern electrical infrastructure, providing real-time data on the performance of power distribution networks. These systems help monitor energy usage, detect faults, and optimize the efficiency of electrical systems, thereby ensuring the reliability and safety of power networks.

The accuracy of power monitoring systems depends heavily on the precision of current transformers and, by extension, the quality of the current transformer bases. High-quality current transformer bases ensure that the transformers can operate effectively, delivering accurate data to power monitoring systems.

Some of the key benefits of power monitoring systems include:

Real-Time Data: Power monitoring systems provide instant data on power usage, current levels, and potential faults, allowing for immediate corrective action.

Improved Energy Efficiency: By analyzing data from power monitoring systems, businesses can optimize their energy usage, reduce waste, and lower operational costs.

Enhanced Safety: Power monitoring systems can detect anomalies in current flow, such as overloads or short circuits, and alert operators to potential safety hazards before they escalate.

Preventive Maintenance: With accurate data on system performance, companies can implement preventive maintenance strategies, reducing downtime and preventing costly repairs.

Given the growing emphasis on energy efficiency and sustainability, the demand for high-quality power monitoring systems continues to rise globally. In turn, the importance of reliable current transformer bases in supporting these systems cannot be overstated.

The Role of Air Insulated Switchgear Companies in India

Switchgear is a vital component of power distribution systems, used to control, protect, and isolate electrical equipment. Air-insulated switchgear (AIS) is one of the most widely used types of switchgear in medium- and high-voltage power distribution applications. These systems use air as the primary insulating medium and are designed to protect electrical circuits from faults while ensuring the continuity of power supply.

Air-insulated switchgear companies in India are playing a key role in modernizing electrical infrastructure across the country and globally. India has become a prominent player in manufacturing air-insulated switchgear due to its expertise in power distribution equipment, favorable production costs, and adherence to international quality standards.

Air-insulated switchgear companies in India contribute to the global power industry in several ways:

Innovative Solutions: Indian manufacturers are continually developing advanced air-insulated switchgear solutions to meet the evolving demands of modern power systems. These innovations include more compact designs, improved insulation technologies, and enhanced safety features.

Cost Efficiency: Indian air-insulated switchgear companies offer competitive pricing compared to manufacturers in other parts of the world, making them a cost-effective solution for global clients.

Environmental Considerations: As the world shifts toward greener energy solutions, air-insulated switchgear offers an environmentally friendly alternative to gas-insulated switchgear, which uses greenhouse gases such as SF6 for insulation.

The Global Impact of High-Quality Electrical Components

The global energy landscape is undergoing a profound transformation driven by the increasing demand for electricity, the transition to renewable energy sources, and the need for improved energy efficiency. As a result, the demand for high-quality electrical components, including current transformer bases and air-insulated switchgear, is growing at an unprecedented rate.

High-quality current transformer bases are crucial for ensuring the accuracy and reliability of electrical measurements, which in turn supports the effective operation of power monitoring systems. These systems are essential for optimizing energy usage, improving safety, and ensuring the reliability of electrical infrastructure.

The growing role of current transformer base manufacturers and exporters in India in meeting global demand highlights the country's importance in the global energy sector. Indian manufacturers are supplying high-quality products that meet international standards, helping to improve power distribution networks around the world.

Similarly, air-insulated switchgear companies in India are contributing to the modernization of electrical infrastructure, both domestically and internationally. Their innovations are helping to improve the efficiency and reliability of power systems, while also offering environmentally friendly solutions.

Conclusion: Powering the Future with Quality

As the world moves toward a more connected and energy-efficient future, the importance of high-quality electrical components, such as current transformer bases, air-insulated switchgear, and advanced power monitoring systems, will continue to grow. These components are critical to ensuring the safe, reliable, and efficient operation of power distribution networks, which are essential to the global economy.

Manufacturers and exporters in India, including current transformer base manufacturers, are playing a vital role in meeting global demand for high-quality electrical products. Their commitment to innovation, quality, and sustainability is helping to shape the future of the global energy landscape, ensuring that power systems are equipped to handle the challenges of tomorrow.

With the rise of renewable energy, the expansion of smart grids, and the increasing focus on energy efficiency, the demand for reliable and accurate electrical components will only continue to grow. By investing in high-quality current transformer bases and partnering with reputable air-insulated switchgear companies in India, businesses can ensure that they are prepared for the future of energy.

#Power monitoring system#Current transformer base manufacturer and exporter in India#Air insulated switchgear companies in India

4 notes

·

View notes

Text

Introduction to Glass Privacy Films In today’s modern world, privacy holds significant importance in both residential and commercial environments. Yet, striking a balance between privacy, natural light, and aesthetic allure poses a challenge. This is precisely where the versatility of glass privacy films shines through, providing a pragmatic remedy to bolster privacy without sacrificing style.

Understanding the Need for Privacy

Why Privacy Matters Privacy is essential for creating a comfortable and secure environment, whether at home, in the workplace, or in public settings. It promotes a sense of well-being and helps individuals maintain boundaries.

Traditional Privacy Measures Privacy concerns have traditionally been addressed using curtains, blinds, or frosted glass. While effective to some extent, these methods often come with limitations such as blocking natural light or detracting from the overall design aesthetic.