#Advanced Materials\

Explore tagged Tumblr posts

Link

Paywall free version! LEGALLY paywall free version, even!

“Nearly any material can be used to turn the energy in air humidity into electricity, scientists found in a discovery that could lead to continuously producing clean energy with little pollution.

The research, published in a paper in Advanced Materials, builds on 2020 work that first showed energy could be pulled from the moisture in the air using material harvested from bacteria. The new study shows nearly any material can be used, like wood or silicon, as long as it can be smashed into small particles and remade with microscopic pores. But there are many questions about how to scale the product.

“What we have invented, you can imagine it’s like a small-scale, man-made cloud,” said Jun Yao, a professor of engineering at the University of Massachusetts at Amherst and the senior author of the study. “This is really a very easily accessible, enormous source of continuous clean electricity. Imagine having clean electricity available wherever you go.”

That could include a forest, while hiking on a mountain, in a desert, in a rural village or on the road.

The air-powered generator, known as an “Air-gen,” would offer continuous clean electricity since it uses the energy from humidity, which is always present, rather than depending on the sun or wind. Unlike solar panels or wind turbines, which need specific environments to thrive, Air-gens could conceivably go anywhere, Yao said.

Less humidity, though, would mean less energy could be harvested, he added. Winters, with dryer air, would produce less energy than summers.

The device, the size of a fingernail and thinner than a single hair, is dotted with tiny holes known as nanopores. The holes have a diameter smaller than 100 nanometers, or less than a thousandth of the width of a strand of human hair.

The tiny holes allow the water in the air to pass through in a way that would create a charge imbalance in the upper and lower parts of the device, effectively creating a battery that runs continuously.

“We are opening up a wide door for harvesting clean electricity from thin air,” Xiaomeng Liu, another author and a UMass engineering graduate student, said in a statement.

While one prototype only produces a small amount of energy — almost enough to power a dot of light on a big screen — because of its size, Yao said Air-gens can be stacked on top of each other, potentially with spaces of air in between. Storing the electricity is a separate issue, he added.

Yao estimated that roughly 1 billion Air-gens, stacked to be roughly the size of a refrigerator, could produce a kilowatt and partly power a home in ideal conditions. The team hopes to lower both the number of devices needed and the space they take up by making the tool more efficient. Doing that could be a challenge.

The scientists first must work out which material would be most efficient to use in different climates. Eventually, Yao said he hopes to develop a strategy to make the device bigger without blocking the humidity that can be captured. He also wants to figure out how to stack the devices on top of each other effectively and how to engineer the Air-gen so the same size device captures more energy.

It’s not clear how long that will take.

“Once we optimize this, you can put it anywhere,” Yao said.

It could be embedded in wall paint in a home, made at a larger scale in unused space in a city or littered throughout an office’s hard-to-get-to spaces. And because it can use nearly any material, it could extract less from the environment than other renewable forms of energy.

“The entire earth is covered with a thick layer of humidity,” Yao said. “It’s an enormous source of clean energy. This is just the beginning in making use of that.””

-via The Washington Post, 5/26/23

#green energy#clean energy#materials science#science#green technology#sustainability#massachusetts#advanced materials#advanced technologies#meteorology#humidity#air-gen#electricity#good news#hope

475 notes

·

View notes

Text

Machine learning unlocks secrets to advanced alloys

New Post has been published on https://thedigitalinsider.com/machine-learning-unlocks-secrets-to-advanced-alloys/

Machine learning unlocks secrets to advanced alloys

The concept of short-range order (SRO) — the arrangement of atoms over small distances — in metallic alloys has been underexplored in materials science and engineering. But the past decade has seen renewed interest in quantifying it, since decoding SRO is a crucial step toward developing tailored high-performing alloys, such as stronger or heat-resistant materials.

Understanding how atoms arrange themselves is no easy task and must be verified using intensive lab experiments or computer simulations based on imperfect models. These hurdles have made it difficult to fully explore SRO in metallic alloys.

But Killian Sheriff and Yifan Cao, graduate students in MIT’s Department of Materials Science and Engineering (DMSE), are using machine learning to quantify, atom-by-atom, the complex chemical arrangements that make up SRO. Under the supervision of Assistant Professor Rodrigo Freitas, and with the help of Assistant Professor Tess Smidt in the Department of Electrical Engineering and Computer Science, their work was recently published in The Proceedings of the National Academy of Sciences.

Interest in understanding SRO is linked to the excitement around advanced materials called high-entropy alloys, whose complex compositions give them superior properties.

Typically, materials scientists develop alloys by using one element as a base and adding small quantities of other elements to enhance specific properties. The addition of chromium to nickel, for example, makes the resulting metal more resistant to corrosion.

Unlike most traditional alloys, high-entropy alloys have several elements, from three up to 20, in nearly equal proportions. This offers a vast design space. “It’s like you’re making a recipe with a lot more ingredients,” says Cao.

The goal is to use SRO as a “knob” to tailor material properties by mixing chemical elements in high-entropy alloys in unique ways. This approach has potential applications in industries such as aerospace, biomedicine, and electronics, driving the need to explore permutations and combinations of elements, Cao says.

Capturing short-range order

Short-range order refers to the tendency of atoms to form chemical arrangements with specific neighboring atoms. While a superficial look at an alloy’s elemental distribution might indicate that its constituent elements are randomly arranged, it is often not so. “Atoms have a preference for having specific neighboring atoms arranged in particular patterns,” Freitas says. “How often these patterns arise and how they are distributed in space is what defines SRO.”

Understanding SRO unlocks the keys to the kingdom of high-entropy materials. Unfortunately, not much is known about SRO in high-entropy alloys. “It’s like we’re trying to build a huge Lego model without knowing what’s the smallest piece of Lego that you can have,” says Sheriff.

Traditional methods for understanding SRO involve small computational models, or simulations with a limited number of atoms, providing an incomplete picture of complex material systems. “High-entropy materials are chemically complex — you can’t simulate them well with just a few atoms; you really need to go a few length scales above that to capture the material accurately,” Sheriff says. “Otherwise, it’s like trying to understand your family tree without knowing one of the parents.”

SRO has also been calculated by using basic mathematics, counting immediate neighbors for a few atoms and computing what that distribution might look like on average. Despite its popularity, the approach has limitations, as it offers an incomplete picture of SRO.

Fortunately, researchers are leveraging machine learning to overcome the shortcomings of traditional approaches for capturing and quantifying SRO.

Hyunseok Oh, assistant professor in the Department of Materials Science and Engineering at the University of Wisconsin at Madison and a former DMSE postdoc, is excited about investigating SRO more fully. Oh, who was not involved in this study, explores how to leverage alloy composition, processing methods, and their relationship to SRO to design better alloys. “The physics of alloys and the atomistic origin of their properties depend on short-range ordering, but the accurate calculation of short-range ordering has been almost impossible,” says Oh.

A two-pronged machine learning solution

To study SRO using machine learning, it helps to picture the crystal structure in high-entropy alloys as a connect-the-dots game in an coloring book, Cao says.

“You need to know the rules for connecting the dots to see the pattern.” And you need to capture the atomic interactions with a simulation that is big enough to fit the entire pattern.

First, understanding the rules meant reproducing the chemical bonds in high-entropy alloys. “There are small energy differences in chemical patterns that lead to differences in short-range order, and we didn’t have a good model to do that,” Freitas says. The model the team developed is the first building block in accurately quantifying SRO.

The second part of the challenge, ensuring that researchers get the whole picture, was more complex. High-entropy alloys can exhibit billions of chemical “motifs,” combinations of arrangements of atoms. Identifying these motifs from simulation data is difficult because they can appear in symmetrically equivalent forms — rotated, mirrored, or inverted. At first glance, they may look different but still contain the same chemical bonds.

The team solved this problem by employing 3D Euclidean neural networks. These advanced computational models allowed the researchers to identify chemical motifs from simulations of high-entropy materials with unprecedented detail, examining them atom-by-atom.

The final task was to quantify the SRO. Freitas used machine learning to evaluate the different chemical motifs and tag each with a number. When researchers want to quantify the SRO for a new material, they run it by the model, which sorts it in its database and spits out an answer.

The team also invested additional effort in making their motif identification framework more accessible. “We have this sheet of all possible permutations of [SRO] already set up, and we know what number each of them got through this machine learning process,” Freitas says. “So later, as we run into simulations, we can sort them out to tell us what that new SRO will look like.” The neural network easily recognizes symmetry operations and tags equivalent structures with the same number.

“If you had to compile all the symmetries yourself, it’s a lot of work. Machine learning organized this for us really quickly and in a way that was cheap enough that we could apply it in practice,” Freitas says.

Enter the world’s fastest supercomputer

This summer, Cao and Sheriff and team will have a chance to explore how SRO can change under routine metal processing conditions, like casting and cold-rolling, through the U.S. Department of Energy’s INCITE program, which allows access to Frontier, the world’s fastest supercomputer.

“If you want to know how short-range order changes during the actual manufacturing of metals, you need to have a very good model and a very large simulation,” Freitas says. The team already has a strong model; it will now leverage INCITE’s computing facilities for the robust simulations required.

“With that we expect to uncover the sort of mechanisms that metallurgists could employ to engineer alloys with pre-determined SRO,” Freitas adds.

Sheriff is excited about the research’s many promises. One is the 3D information that can be obtained about chemical SRO. Whereas traditional transmission electron microscopes and other methods are limited to two-dimensional data, physical simulations can fill in the dots and give full access to 3D information, Sheriff says.

“We have introduced a framework to start talking about chemical complexity,” Sheriff explains. “Now that we can understand this, there’s a whole body of materials science on classical alloys to develop predictive tools for high-entropy materials.”

That could lead to the purposeful design of new classes of materials instead of simply shooting in the dark.

The research was funded by the MathWorks Ignition Fund, MathWorks Engineering Fellowship Fund, and the Portuguese Foundation for International Cooperation in Science, Technology and Higher Education in the MIT–Portugal Program.

#3d#advanced materials#aerospace#alloys#applications#approach#arrangement#Artificial Intelligence#atom#atomic#atoms#biomedicine#book#Building#Capture#Casting#challenge#change#chemical#chemical bonds#chemical elements#chromium#classes#classical#complexity#Composition#computer#Computer modeling#computer models#Computer Science

2 notes

·

View notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

Consumer Trends in the Aramid Fibre Reinforcement Materials Market

Stay ahead of the game in the aramid fiber reinforcement materials market with insights into consumer trends and key player strategies. Read on to learn more.

The Aramid Fibre Reinforcement Materials Market is a rapidly growing industry, with a wide range of applications in various sectors. To stay ahead of the competition, it's important to understand consumer trends and key player strategies. In this article, we'll explore some of the latest insights and developments in the aramid fibre reinforcement materials market.

Overview of the Aramid Fibre Reinforcement Materials Market

The aramid fibre reinforcement materials market is a highly competitive industry that is expected to experience significant growth in the coming years. Aramid fibres are known for their high strength, durability, and resistance to heat and chemicals, making them ideal for use in a variety of applications, including aerospace, automotive, and construction.

The market is driven by increasing demand for lightweight and high-performance materials, as well as growing awareness of the benefits of aramid fibers over traditional materials like steel and aluminum.

Consumer Trends Driving Market Growth

One of the key consumer trends driving growth in the aramid fibre reinforcement materials market is the increasing demand for sustainable and eco-friendly materials. Aramid fibres are known for their durability and longevity, which makes them a more sustainable option compared to traditional materials that need to be replaced more frequently.

Additionally, consumers are becoming more aware of the environmental impact of their purchasing decisions and are seeking out products that are produced using sustainable and ethical practices. As a result, manufacturers in the aramid fibre reinforcement materials market, are investing in sustainable production methods and marketing their products as eco-friendly alternatives.

Key Players and Their Strategies

In the aramid fibre reinforcement materials market, key players are implementing various strategies to stay ahead of the competition. Some are focusing on expanding their product portfolio to cater to a wider range of applications, while others are investing in research and development to improve the performance of their products.

Request a free sample copy of the report, here, https://www.nextmsc.com/aramid-fiber-reinforcement-materials-market/request-sample

The aramid fibre reinforcement materials market, which is highly competitive, consists of various market players, including;

E. I. du Pont de Nemours and Company, Teijin Ltd., Kolon Industries, Inc., Honeywell International Inc., SRO Aramid (Jiangsu) Co., Ltd., Hyosung Corporation, Toray Industries, Inc., Yantai Tayho Advanced materials Co., Ltd., Ibiden Co., Ltd., and Huvis Corporation, among others.

Additionally, many players are adopting sustainable production methods and marketing their products as eco-friendly alternatives to traditional materials. Collaborations and partnerships with other companies in the industry are also becoming more common, as players seek to leverage each other's strengths and resources to drive growth.

Emerging Technologies and Innovations

The aramid fibre reinforcement materials market is constantly evolving, with new technologies and innovations emerging to meet the changing needs of consumers. One such innovation is the development of aramid fibres with improved strength and durability, which are being used in a variety of applications, from aerospace and defense to automotive and construction.

Other emerging technologies include the use of nanotechnology to enhance the properties of aramid fibres, and the development of new manufacturing processes that allow for greater efficiency and cost-effectiveness. As these technologies continue to evolve, they are likely to have a significant impact on the aramid fibre reinforcement materials market, shaping consumer trends and driving growth for key players in the industry.

Future Outlook and Opportunities for Growth

The future outlook for the aramid fibre reinforcement materials market is promising, with continued growth expected in the coming years. As consumer demand for high-performance materials increases, key players in the industry are investing in research and development to create new and innovative products that meet these needs.

Moreover, the growing trend towards sustainability and eco-friendliness is driving the development of aramid fibers that are more environmentally friendly and sustainable. Overall, the aramid fibers reinforcement materials market presents numerous opportunities for growth and innovation, and companies that stay ahead of consumer trends and invest in new technologies are likely to succeed in this dynamic and rapidly evolving industry.

#aramid fiber#adhesives#sealants#advanced materials#materials#chemicals#globalopportunity#industry insights

7 notes

·

View notes

Text

The Top Concept Cars of 2024

In the ever-evolving world of automotive design and technology, 2024 has brought a plethora of groundbreaking innovations that have captured the imagination of car enthusiasts and industry experts alike. The top concept cars of 2024 are not just futuristic in design but also incorporate cutting-edge technology that redefines the driving experience. These concept cars offer a glimpse into the…

#2024#5G connectivity#advanced materials#advanced safety#Aerodynamics#AI#AR displays#Audi#Automotive#autonomous driving#biometric access#BMW#Clean Energy#Comfort#concept cars#connectivity#Eco-Friendly#efficiency#electric powertrain#electric vehicles#EVs#future cars#futuristic design#High-Performance#Hyundai#innovation#Lightweight#Luxury Cars#machine learning#Mercedes-Benz

0 notes

Text

Expanding Horizons: The Diverse Applications of Compound Semiconductors in Modern Technology

Introduction: The Rising Demand for Compound Semiconductors

In today's fast-paced technological landscape, the demand for efficient and high-performance electronic devices continues to soar. As a result, the compound semiconductor market has emerged as a key player in driving innovation across various industries.

Understanding Compound Semiconductors: What Sets Them Apart?

Unlike traditional semiconductors, compound semiconductors are composed of two or more elements from different groups in the periodic table. This unique composition allows them to exhibit superior properties such as higher electron mobility, enhanced thermal conductivity, and improved optical characteristics.

Applications Across Diverse Industries

From telecommunications and consumer electronics to automotive and renewable energy, compound semiconductors find applications in a wide range of industries. Their ability to operate at higher frequencies and voltages makes them ideal for power amplifiers, LED lighting, solar cells, and advanced sensors.

Driving Innovation in Telecommunications

In the telecommunications sector, compound semiconductors play a crucial role in enabling high-speed data transmission and expanding network bandwidth. Gallium nitride (GaN) and indium phosphide (InP) based devices are commonly used in 5G infrastructure, satellite communication systems, and optical networking equipment.

Powering the Future of Electric Vehicles

The automotive industry is undergoing a transformative shift towards electric mobility, and compound semiconductors are at the forefront of this revolution. Silicon carbide (SiC) devices offer higher efficiency and lower switching losses, making them essential components in electric vehicle powertrains and charging infrastructure.

Enabling Energy Efficiency with LED Lighting

Compound semiconductors have revolutionized the lighting industry with the widespread adoption of light-emitting diodes (LEDs). These energy-efficient alternatives to traditional lighting sources offer longer lifespans, lower power consumption, and superior color rendering, driving their deployment in residential, commercial, and industrial settings.

Pioneering Renewable Energy Solutions

In the quest for sustainable energy sources, compound semiconductors play a vital role in harnessing solar power and maximizing energy conversion efficiency. Photovoltaic cells based on III-V compound semiconductors exhibit higher absorption coefficients and improved stability, making them ideal for solar panels in residential and utility-scale installations.

Conclusion: Embracing the Future of Technology

The compound semiconductor market continues to expand its footprint across various industries, driving innovation and shaping the future of technology. With advancements in materials science and manufacturing processes, these versatile materials hold the key to unlocking new possibilities in electronics, telecommunications, transportation, and renewable energy. As demand for faster, smaller, and more energy-efficient devices continues to grow, compound semiconductors will undoubtedly play a pivotal role in shaping the digital landscape of tomorrow.

#Compound Semiconductors#Technology Innovation#Electronics#Telecommunications#Renewable Energy#LED Lighting#Electric Vehicles#Semiconductor Market#Solar Power#Advanced Materials

0 notes

Text

Carbon Black Market: Trends and Forecasts for Sustainable Growth

Carbon black, a versatile material derived from the incomplete combustion of heavy petroleum products, plays a crucial role in numerous industrial applications, including rubber manufacturing, plastics, coatings, and printing inks. Its unique properties, such as high abrasion resistance, conductivity, and reinforcement, make it indispensable in various sectors. However, the carbon black industry faces challenges related to environmental sustainability, emissions, and regulatory compliance.

According to the study by Next Move Strategy Consulting, the global Carbon Black Market size is predicted to reach USD 22.13 billion with a CAGR of 3.8% by 2030. This projection underlines the significant potential for growth in the carbon black industry, driven by various trends and factors shaping its trajectory towards sustainability.

Request for a sample, here: https://www.nextmsc.com/carbon-black-market/request-sample

Trends Driving Growth

Rising Demand in Tire Manufacturing:

The tire industry remains the largest consumer of carbon black, accounting for a substantial portion of its overall demand. With the automotive sector experiencing steady growth and increasing emphasis on fuel efficiency and durability, the demand for high-quality carbon black in tire manufacturing is expected to soar. Tire manufacturers are continually seeking innovative materials to improve tire performance, longevity, and safety.

The automotive industry's shift towards electric vehicles (EVs) and the growing popularity of fuel-efficient vehicles have heightened the demand for carbon black. EV tires require advanced materials to ensure optimal performance and range. Additionally, the trend towards larger and more durable tires in commercial vehicles further drives the need for high-quality carbon black formulations. Tire manufacturers are investing in research and development to optimize carbon black usage and enhance tire properties such as rolling resistance, traction, and wear resistance.

Shift towards Sustainable Practices:

Environmental concerns and stringent regulations have prompted carbon black manufacturers to adopt sustainable production practices. This includes the adoption of cleaner production technologies, energy-efficient processes, and recycling initiatives to minimize environmental impact and reduce carbon emissions. Companies are increasingly investing in renewable energy sources, waste heat recovery systems, and carbon capture technologies to mitigate their environmental footprint.

Sustainable manufacturing practices are becoming integral to the carbon black industry's growth strategy. Companies are investing in technologies such as gasification and pyrolysis to convert waste materials into carbon black feedstock, reducing dependence on fossil fuels and minimizing waste generation. Moreover, the implementation of stringent environmental regulations, such as emissions limits and carbon pricing mechanisms, incentivizes companies to adopt cleaner production methods and invest in pollution control technologies.

Emergence of Specialty Carbon Blacks:

The market is witnessing a growing demand for specialty carbon blacks tailored for specific applications such as plastics, coatings, and electronics. These specialty grades offer enhanced properties such as UV protection, conductivity, and reinforcement, driving their adoption across diverse industries. With increasing emphasis on product differentiation and performance optimization, manufacturers are expanding their product portfolios to cater to evolving customer requirements.

Specialty carbon blacks are experiencing strong demand across various end-use industries, including automotive, construction, and electronics. For instance, conductive carbon blacks are essential components in lithium-ion batteries, electronic devices, and conductive polymers. Likewise, high-performance carbon blacks are used in premium automotive coatings to enhance durability, weather resistance, and aesthetic appeal. As industries seek to innovate and differentiate their products, the demand for specialty carbon blacks is expected to rise, driving market growth and diversification.

Increasing Penetration in Emerging Markets:

Rapid industrialization and urbanization in emerging economies are fueling the demand for carbon black. Countries in Asia-Pacific, particularly China and India, are witnessing significant growth in automotive production and infrastructure development, thereby driving the demand for carbon black in various applications. Moreover, rising disposable incomes, urbanization trends, and favorable government policies are driving demand for consumer goods, automotive components, and industrial products, further boosting the carbon black market.

Emerging markets represent lucrative growth opportunities for carbon black manufacturers due to their expanding industrial base, rising consumer demand, and infrastructure development. The Asia-Pacific region, in particular, is witnessing robust growth in automotive production, construction activities, and manufacturing sectors, driving demand for carbon black across multiple applications. Moreover, government initiatives aimed at promoting domestic manufacturing, attracting foreign investment, and enhancing industrial competitiveness further bolster the carbon black market's expansion in emerging economies.

Inquire before buying, here: https://www.nextmsc.com/carbon-black-market/inquire-before-buying

Forecasts for Sustainable Growth

The outlook for the carbon black market remains optimistic, with sustained demand from key end-use industries and ongoing efforts towards sustainability driving growth. Key forecasts include:

Steady Market Expansion:

The projected CAGR of 3.8% indicates steady growth in the global carbon black market, with increasing demand across multiple sectors driving market expansion. As industries such as automotive, construction, electronics, and consumer goods continue to grow, the demand for carbon black is expected to remain robust, supported by favorable economic conditions, infrastructure development, and technological advancements.

Despite challenges such as volatile raw material prices, regulatory uncertainties, and geopolitical risks, the carbon black market is poised for sustained growth in the coming years. The adoption of advanced manufacturing technologies, automation, and digitalization is expected to drive efficiency gains, cost optimization, and product innovation, further enhancing the industry's competitiveness and resilience. Moreover, strategic partnerships, mergers, and acquisitions are reshaping the competitive landscape, enabling companies to expand their market presence, diversify product offerings, and capitalize on emerging opportunities.

Focus on Renewable Feedstocks:

Manufacturers are increasingly exploring renewable feedstocks such as bio-based oils and waste materials to produce carbon black, reducing dependence on fossil fuels and mitigating environmental impact. This shift towards sustainable feedstocks aligns with industry trends towards circular economy principles, resource efficiency, and carbon neutrality, driving innovation and investment in bio-based technologies.

The transition towards renewable feedstocks is driven by a combination of environmental, economic, and regulatory factors. Companies are investing in research and development to optimize biomass conversion processes, develop novel bio-based precursors, and improve carbon black production efficiency. Moreover, partnerships with bioenergy producers, waste management companies, and agricultural stakeholders facilitate access to sustainable feedstock sources, enabling companies to reduce their carbon footprint, enhance supply chain resilience, and improve product sustainability credentials.

Technological Advancements:

Ongoing research and development efforts are focused on developing advanced carbon black production technologies, improving product quality, and reducing energy consumption and emissions. Innovations in process optimization, reactor design, and catalyst development enable companies to enhance production efficiency, reduce environmental footprint, and meet stringent quality standards.

Technological advancements play a critical role in driving innovation and competitiveness in the carbon black industry. Companies are investing in advanced analytical techniques, computational modeling, and materials science to develop next-generation carbon black formulations with tailored properties and performance characteristics. Moreover, the integration of digital technologies such as artificial intelligence, machine learning, and IoT enables real-time monitoring, predictive maintenance, and optimization of manufacturing processes, enhancing productivity, reliability, and sustainability.

Regulatory Compliance:

Stricter environmental regulations and sustainability targets are expected to drive investments in cleaner production technologies and encourage the adoption of sustainable practices across the carbon black industry. Regulatory initiatives aimed at reducing air pollution, greenhouse gas emissions, and industrial waste disposal are driving industry-wide efforts to improve environmental performance and ensure regulatory compliance.

Regulatory compliance is a key priority for carbon black manufacturers, given the industry's significant environmental footprint and potential impact on public health and the environment. Companies are proactively investing in pollution control technologies, emission monitoring systems, and environmental management systems to meet regulatory requirements and mitigate operational risks. Moreover, stakeholders are engaging with regulators, industry associations, and other stakeholders to shape regulatory frameworks, advocate for science-based policies, and promote sustainable practices across the value chain.

Conclusion

In conclusion, the carbon black market is poised for sustainable growth, driven by evolving consumer preferences, regulatory pressures, and technological advancements. As stakeholders across the value chain collaborate to address environmental challenges and embrace sustainable solutions, the carbon black industry is poised to play a vital role in the transition towards a greener, more sustainable future. By leveraging innovation, collaboration, and responsible stewardship, the carbon black industry can unlock new opportunities, mitigate risks, and create long-term value for society, the economy, and the environment.

#carbon black#materials#advanced materials#market research#market trends#business insights#market analysis#article

0 notes

Text

#dental implants#cosmetic dentistry#advanced materials#dental technology#smile aesthetics#dental care#dental innovation#health and wellness

0 notes

Text

Little P.Eng.'s Comprehensive Seismic Structural Services Aligned with ASCE 7-22 and NBCC Standards

In an era where architectural ambition pushes the limits of engineering, safeguarding structural integrity against natural calamities, particularly seismic activities, becomes paramount. This detailed exposé delves into the sophisticated seismic structural engineering services provided by Little P.Eng., a firm renowned for its compliance with the latest American Society of Civil Engineers (ASCE) 7-22 standards and the Canadian National Building Code (NBCC). Their work spans across Canada and the United States, encompassing a diverse range of buildings and non-structural elements, reflecting the pinnacle of safety, reliability, and innovation in modern construction.

1. Introduction

The unpredictable nature of seismic activities has long posed a significant challenge to the realms of construction and civil engineering. Within this volatile environment, Little P.Eng. has emerged as a beacon of reliability, offering cutting-edge seismic structural engineering services across Canada and the United States. Their adherence to the ASCE 7-22 and NBCC codes ensures not only the structural integrity of vast construction undertakings but also the safety and longevity of non-structural elements, affirming their position at the forefront of seismic resilience in contemporary infrastructure.

2. Understanding Seismic Structural Engineering

2.1. The Science of Earthquake Engineering

Before delving into Little P.Eng.'s specialized services, one must understand the core principles of seismic structural engineering. This discipline focuses on making buildings and non-structural components resistant to earthquake shocks through specialized planning, design, detailing, and, subsequently, construction. It encompasses geological science, material engineering, and structural analysis to develop structures capable of withstanding seismic disturbances.

2.2. Evolution of Seismic Codes: From ASCE 7-10 to ASCE 7-22

Seismic building codes are dynamic, evolving in response to the continuous advancements in engineering research and catastrophic lessons learned from each seismic event. The transition from ASCE 7-10 to ASCE 7-22 is a reflection of this evolution, marking significant strides in risk reduction and structural robustness, emphasizing not just human safety but also post-earthquake functionality and rapid recovery for communities.

3. Little P.Eng.’s Integration of ASCE 7-22 in Seismic Structural Engineering

3.1. Innovations in Seismic Design Philosophies

Little P.Eng. employs a forward-thinking approach to integrate the innovations outlined in ASCE 7-22. These include state-of-the-art seismic design philosophies involving base isolation, energy dissipation devices, and performance-based seismic design (PBSD), allowing for structures that are more flexible, absorb and dissipate seismic energy, and maintain structural integrity during earthquakes.

3.2. Site-Specific Hazard Analysis and Geotechnical Considerations

One of the critical aspects of ASCE 7-22 is the emphasis on site-specific hazard analyses. Little P.Eng.'s engineers led by Meena Rezkallah carry out comprehensive geotechnical evaluations, considering soil-structure interaction, liquefaction potential, and site-specific seismic hazard assessments. By understanding the geological variances across different regions in North America, they ensure that each design is intrinsically aligned with its environmental context.

4. Adherence to NBCC Standards: Expanding Safety Parameters Across Canada

4.1. Bridging Policies between Countries

While their services in the United States predominantly adhere to ASCE standards, Little P.Eng. seamlessly bridges engineering policies between the U.S. and Canada by aligning their practices with the NBCC. This code compliance not only underscores their versatility in handling cross-border projects but also reflects their commitment to upholding the highest safety and professional standards in every geographical locale.

4.2. Understanding NBCC’s Seismic Provisions

The NBCC has distinct seismic provisions, necessitating specialized knowledge and an adaptive engineering approach. Little P.Eng.'s expertise in Canadian seismic codes ensures that structural and non-structural components comply with regional regulations, catering to Canada's unique seismic challenges, especially in high-risk provinces.

5. Comprehensive Services for Buildings and Non-Structural Elements

5.1. Diverse Building Typologies

Little P.Eng.'s portfolio encompasses a variety of buildings, from residential high-rises and expansive commercial complexes to critical facilities like hospitals and emergency response centers. Each building type presents unique challenges, and the firm’s nuanced, context-oriented approach to seismic retrofitting and sustainable design practices sets industry standards.

5.2. Protecting Non-Structural Components

Beyond the buildings themselves, Little P.Eng. extends its engineering prowess to safeguard non-structural elements. These components, often overlooked, can pose significant hazards during seismic events. From architectural elements to mechanical and electrical systems, the firm implements exhaustive strategies to enhance the safety of these components, thereby protecting human life and minimizing economic loss.

6. Future Directions and Continuous Advancements

6.1. Embracing Technological Innovations

As the field of seismic structural engineering advances, Little P.Eng. remains committed to incorporating new technologies, including artificial intelligence and machine learning, for predictive analysis, design optimization, and risk management. Their continual investment in technology positions them as a leader in future-proofing structures against earthquakes.

6.2. Contribution to Global Seismic Safety Standards

Harnessing Advanced Engineering: Little P.Eng.'s Comprehensive Seismic Structural Services Aligned with ASCE 7-22 and CNBCC Standards in North America

7. Conclusion

Little P.Eng.’s comprehensive seismic structural engineering services, grounded in the latest ASCE and NBCC standards, represent a confluence of scientific mastery, innovative engineering, and a deep commitment to safeguarding human lives and investments. Their work across diverse building typologies and non-structural components in Canada and the United States cements their stance as a pivotal player in shaping resilient, sustainable, and safe urban landscapes. As seismic activity remains an unpredictable threat, the foresight and innovation of firms like Little P.Eng. are society's best bet for a safer tomorrow.

References

[1] American Society of Civil Engineers. (2022). Minimum Design Loads and Associated Criteria for Buildings and Other Structures (ASCE/SEI 7-22). ASCE.

[2] National Research Council Canada. (2020). National Building Code of Canada.

Tags:

Little P.Eng.

ASCE 7-22

design optimization

earthquake resilience

energy dissipation

building codes

seismic design

advanced materials

non-structural components

CNBCC

technological innovations

cross-border projects

geotechnical considerations

mechanical systems safety

base isolation

sustainable construction

electrical systems safety

Seismic structural engineering

critical infrastructure

artificial intelligence

urban resilience

construction techniques

seismic retrofitting

site-specific analysis

predictive analysis

professional standards

safety regulations

risk management

performance-based design

global seismic standards

Engineering Services

Structural Engineering Consultancy

Seismic Bracing Experts

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng.#ASCE 7-22#design optimization#earthquake resilience#energy dissipation#building codes#seismic design#advanced materials#non-structural components#CNBCC#technological innovations#cross-border projects#geotechnical considerations#mechanical systems safety#base isolation#sustainable construction#electrical systems safety#Seismic structural engineering#critical infrastructure#artificial intelligence#urban resilience#construction techniques#seismic retrofitting#site-specific analysis#predictive analysis#professional standards#safety regulations#risk management#performance-based design#global seismic standards

0 notes

Text

Carbon fiber | In detail

Carbon fiber is a revolutionary material that has transformed numerous industries and applications, ranging from aerospace and automotive engineering to sports equipment and even medical devices. Composed of thin, exceptionally strong carbon filaments tightly woven together, carbon fiber exhibits an extraordinary combination of properties that make it a material of choice for high-performance and lightweight applications. This versatile material has captured the imagination of engineers, designers, and innovators worldwide, pushing the boundaries of what is possible in terms of strength, durability, and weight reduction.

0 notes

Text

Thermal Interface Materials Market: Top 4 Applications

Thermal interface materials (TIMs) play a pivotal role in electronics and thermal management. They help improve the thermal conductivity between components, ensuring efficient heat dissipation and preventing overheating. By filling microscopic gaps between surfaces, TIMs facilitate heat transfer, and in turn, improve the reliability and performance of electronic devices. According to Inkwood Research, the global thermal interface materials market is set to progress with a CAGR of 9.91% during the forecast years 2023 to 2032, reaching a revenue of $7044.80 million by 2032.

With the rising development and adoption of increasingly compact and powerful electronics, TIMs are becoming indispensable for maintaining optimal operating temperatures, prolonging the lifespan of devices, and ultimately ensuring their seamless functionality. TIMs are available in many forms, including gels, pastes, and greases; they offer excellent thermal conductivity, high-flexibility and better fill larger gaps.

Thermal Interface Materials Market: Enhancing Performance in Electrical Applications

Through the efficient conduction of heat away from critical components such as processors and semiconductors, TIMs prevent overheating and ensure the longevity and reliability of electronic devices. This enhanced thermal management results in improved performance, reduced downtime, and increased energy efficiency, making them an indispensable component of modern electrical applications. Here’s how –

Automotive Electronics:

Thermal conductive materials play a pivotal role in dissipating heat generated by various automotive electronic systems, such as engine control units, infotainment systems, advanced driver-assistance systems (ADAS), and electric vehicle (EV) components. TIMs facilitate heat transfer between electronic components and heat sinks, ensuring that delicate automotive electronics operate at optimal temperatures. For example, the DOWSIL™ 3-6752 by Dow Chemical Company (United States) is a thermally conductive adhesive used for bonding organic as well as ceramic substrates to heat sinks for electronic control modules in automotive applications.

Market Position: As per Inkwood Research, the automotive electronics segment, under the application category, is set to grow with the highest CAGR of 11.08% between 2023 to 2032.

In addition to performance improvements, these materials also aid in energy efficiency, which is a major concern in the automotive industry. By preventing overheating and ensuring the longevity of vital components, these materials enhance the reliability and performance of modern automotive electronics, thereby contributing to the safety and efficiency of automobiles.

Computers:

Computers, encompassing various devices such as desktops, laptops, servers, and data centers, produce a significant amount of heat during their operation. The use of thermal interface materials, in this regard, is common for enhancing heat dissipation from critical components like CPUs, GPUs, and memory modules to their respective cooling solutions or heat sinks.

The demand for efficient TIMs in computers is projected to increase during the forecast period, driven by the growing popularity of gaming PCs, the expansion of artificial intelligence applications, and the increasing utilization of data-intensive tasks. Additionally, the emergence of technologies like 5G and the Internet of Things (IoT) is fostering the need for robust thermal management solutions in edge computing devices and cloud data centers, as well.

Telecom:

Thermal interface materials (TIMs) are employed in telecom equipment in order to efficiently transfer heat from high-power electronic components, ensuring that devices operate within the required temperature range. Thermal greases, phase-change materials, and thermal pads are commonly used in these applications. As the telecom industry transitions towards 5G, while preparing for the future with 6G technology, the demand for thermal conductive materials is anticipated to increase further.

Aligning with this, telecom is expected to be the dominating application during the forecast period, capturing a revenue share of 24.80% by 2032 (Source: Inkwood Research). Several leading companies are actively engaged in the telecommunications infrastructure space, predominantly with regard to thermal interface materials. These include Henkel AG & Co KGaA (Germany), Parker Hannifin Corporation (United States), and Indium Corporation (United States).

Medical Devices:

Efficient thermal management is critical in medical devices in order to ensure accurate and reliable performance during medical procedures. TIMs assist in heat dissipation from high-powered medical electronics, preventing overheating and maintaining optimal operating temperatures. As pharmaceutical R&D and industrialization continue to grow in major regions, such as Europe, the demand for thermally conductive compounds in medical devices is expected to rise further. For example, Germany’s robust pharmaceutical and medical device sectors highlight the demand for TIMs in medical applications.

With a substantial number of companies in the medical equipment and supplies sector, Italy’s mature market necessitates precise temperature control in medical devices. Likewise, the robust export value of the Polish medical devices and equipment sector, reaching €3.2 billion in 2021, also demonstrates the critical role of TIMs in healthcare technology. These growth factors, in turn, further propel the market demand in the region. Accordingly, as per Inkwood Research, the Europe thermal interface materials market is set to grow with a notable CAGR of 10.15% during the forecast period, 2023 to 2032.

As technology continues to evolve, the need for efficient heat management becomes increasingly crucial. Moreover, with industries and consumers alike demanding smaller, faster, and more powerful devices, the use of TIMs is set to play a pivotal role in maintaining optimal operating temperatures and ensuring the longevity of modern electronics. These factors, in turn, are expected to boost the growth of the global thermal interface materials market during the upcoming years.

FAQ

What is the size of thermal interface materials?

Typically, several interfaces exist between the heat-generating element as well as the eventual heatsink. Their thickness can vary from several hundredths of an inch to a few thousandths of an inch.

Are there eco-friendly TIM options available to reduce environmental impact?

Yes, various TIMs are designed to be environmentally friendly, offering low volatile organic compound (VOC) content and longer lifespans, which reduce waste and environmental impact.

#thermal interface materials market#thermal interface materials#CHEMICALS AND MATERIALS#ADVANCED MATERIALS#inkwood research#market research reports

0 notes

Text

Unlocking the secrets of natural materials

New Post has been published on https://thedigitalinsider.com/unlocking-the-secrets-of-natural-materials/

Unlocking the secrets of natural materials

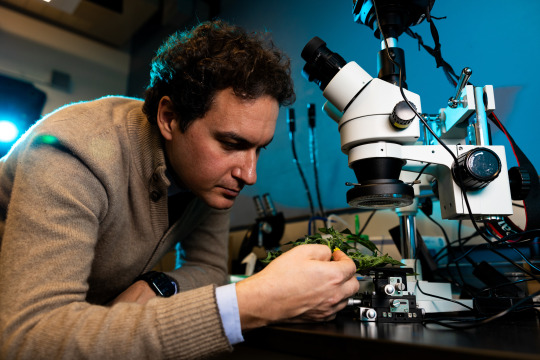

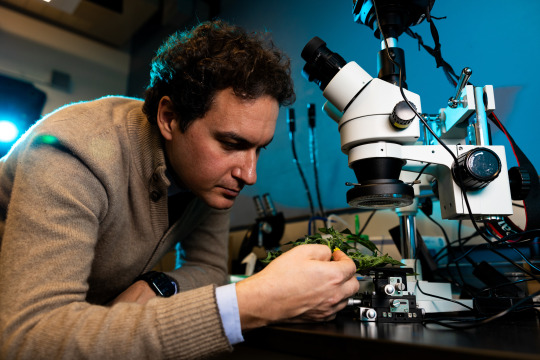

Growing up in Milan, Benedetto Marelli liked figuring out how things worked. He repaired broken devices simply to have the opportunity to take them apart and put them together again. Also, from a young age, he had a strong desire to make a positive impact on the world. Enrolling at the Polytechnic University of Milan, he chose to study engineering.

“Engineering seemed like the right fit to fulfill my passions at the intersection of discovering how the world works, together with understanding the rules of nature and harnessing this knowledge to create something new that could positively impact our society,” says Marelli, MIT’s Paul M. Cook Career Development Associate Professor of Civil and Environmental Engineering.

Marelli decided to focus on biomedical engineering, which at the time was the closest thing available to biological engineering. “I liked the idea of pursuing studies that provided me a background to engineer life,” in order to improve human health and agriculture, he says.

Marelli went on to earn a PhD in materials science and engineering at McGill University and then worked in Tufts University’s biomaterials Silklab as a postdoc. After his postdoc, Marelli was drawn to MIT’s Department of Civil and Environmental in large part because of the work of Markus Buehler, MIT’s McAfee Professor of Engineering, who studies how to design new materials by understanding the architecture of natural ones.

“This resonated with my training and idea of using nature’s building blocks to build a more sustainable society,” Marelli says. “It was a big leap forward for me to go from biomedical engineering to civil and environmental engineering. It meant completely changing my community, understanding what I could teach and how to mentor students in a new engineering branch. As Markus is working with silk to study how to engineer better materials, this made me see a clear connection with what I was doing and what I could be doing. I consider him one of my mentors here at MIT and was fortunate to end up collaborating with him.”

Marelli’s research is aimed at mitigating several pressing global problems, he says.

“Boosting food production to provide food security to an ever-increasing population, soil restoration, decreasing the environmental impact of fertilizers, and addressing stressors coming from climate change are societal challenges that need the development of rapidly scalable and deployable technologies,” he says.

Marelli and his fellow researchers have developed coatings derived from natural silk that extend the shelf life of food, deliver biofertilizers to seeds planted in salty, unproductive soils, and allow seeds to establish healthier plants and increase crop yield in drought-stricken lands. The technologies have performed well in field tests being conducted in Morocco in collaboration with the Mohammed VI Polytechnic University in Ben Guerir, according to Marelli, and offer much potential.

“I believe that with this technology, together with the common efforts shared by the MIT PIs participating in the Climate Grand Challenge on Revolutionizing Agriculture, we have a real opportunity to positively impact planetary health and find new solutions that work in both rural settings and highly modernized agricultural fields,” says Marelli, who recently earned tenure.

As a researcher and entrepreneur with about 20 patents to his name and awards including a National Science Foundation CAREER award, the Presidential Early Career Award for Scientists and Engineers award, and the Ole Madsen Mentoring Award, Marelli says that in general his insights into structural proteins — and how to use that understanding to manufacture advanced materials at multiple scales — are among his proudest achievements.

More specifically, Marelli cites one of his breakthroughs involving a strawberry. Having dipped the berry in an odorless, tasteless edible silk suspension as part of a cooking contest held in his postdoctoral lab, he accidentally left it on his bench, only to find a week or so later that it had been well-preserved.

“The coating of the strawberry to increase its shelf life is difficult to beat when it comes to inspiring people that natural polymers can serve as technical materials that can positively impact our society” by lessening food waste and the need for energy-intensive refrigerated shipping, Marelli says.

When Marelli won the BioInnovation Institute and Science Prize for Innovation in 2022, he told the journal Science that he thinks students should be encouraged to choose an entrepreneurial path. He acknowledged the steepness of the learning curve of being an entrepreneur but also pointed out how the impact of research can be exponentially increased.

He expanded on this idea more recently.

“I believe an increasing number of academics and graduate students should try to get their hands ‘dirty’ with entrepreneurial efforts. We live in a time where academics are called to have a tangible impact on our society, and translating what we study in our labs is clearly a good way to employ our students and enhance the global effort to develop new technology that can make our society more sustainable and equitable,” Marelli says.

Referring to a spinoff company, Mori, that grew out of the coated strawberry discovery and that develops silk-based products to preserve a wide range of perishable foods, Marelli says he finds it very satisfying to know that Mori has a product on the market that came out of his research efforts — and that 80 people are working to translate the discovery from “lab to fork.”

“Knowing that the technology can move the needle in crises such as food waste and food-related environmental impact is the highest reward of all,” he says.

Marelli says he tells students who are seeking solutions to extremely complicated problems to come up with one solution, “however crazy it might be,” and then do an extensive literature review to see what other researchers have done and whether “there is any hint that points toward developing their solution.”

“Once we understand the feasibility, I typically work with them to simplify it as much as we can, and then to break down the problem in small parts that are addressable in series and/or in parallel,” Marelli says.

That process of discovery is ongoing. Asked which of his technologies will have the greatest impact on the world, Marelli says, “I’d like to think it’s the ones that still need to be discovered.”

#2022#advanced materials#agriculture#architecture#background#Bioinspiration#Biological engineering#Building#career#career development#challenge#Civil and environmental engineering#climate#climate change#coatings#Collaboration#Community#cooking#Design#development#devices#energy#Engineer#engineering#engineers#Environmental#environmental impact#Faculty#Food#food production

2 notes

·

View notes

Text

Shaping the Future: Insights into the Isostatic Pressing Market

The global isostatic pressing market is projected to be USD 13,568.1 million by 2030 growing at a CAGR of 7.0% during the forecast period. sectors including energy, aerospace, medical devices, automotive, and manufacturing regularly use isostatic pressing. In this regard, the requirement for such technology is significantly impacted by the growing requirement for contemporary materials and…

View On WordPress

#advanced forming technology#advanced materials#aerospace industry#automotive components#ceramic components#engineering ceramics#high-pressure manufacturing#industrial manufacturing#industry trends#isostatic pressing#isostatic pressing applications#isostatic pressing process#manufacturing efficiency#market growth#material compaction#metal parts production#powdered metals#precision engineering

0 notes

Text

What Is Graphene and Why Will It Dominate the World Soon?

The graphene market is projected to reach 1,88.8 million by 2030. The major factors behind the growth of this market are, growing demand for graphene from electronics and electrical applications, and also the rising demand from medical industry for new application.

Based on form, the power category had the largest market share in recent years. This can be credited to the usage of its powder form in several technology, such as, printing and storage batteries. Additionally, it is way easier to handle powdered graphene in comparison of its dispersion and flake form.

Based on application, the biomedical category is projected to grow with the fastest pace in coming time. This can be credited to the increasing demand of graphene in manufacturing of cholesterol, hemoglobin and glucose-measuring bioelectric sensory equipment’s, mainly because this material is strong and thin. Furthermore, IT is also used in the DNA testing, cancer treatment and prosthetic devices.

APAC had the largest market share of graphene market in recent time, and it is expected to dominate the market in coming years also. This can be accounted because of growing acceptance of graphene for applications in composite materials for electrical & electronic devices, and automotive vehicles & lightweight aircraft, mainly in countries like India, China and numerous Southeast Asian nations; and the rising per-capita income in the APAC region.

To download free sample pages of this report@ https://www.psmarketresearch.com/market-analysis/graphene-market/report-sample

Commercialization of graphene has increased in past years, credited to several factors like, R&D for its new applications and growing availability of graphene across the globe. Moreover, many graphene forms, such as graphene sheets and graphene flakes, have also started to be used in digital displays, sports goods, conductive inks, and automotive coatings, among others, initially graphene was used for lab testing only.

Graphene is majorly used in electronics and electrical industry, credited to the usage of this in transistors, microchips and print circuits. Due to its favourable qualities, like high strength and electrical conductivity. Because of its increasing usage in flexible devices the demand for graphene is surging. This is because of the special properties of graphene that allow the devices to be folded or rolled as per needed and exceptional chartersticks provided by graphene-based electronic devices.

#Graphene Market#Carbon nanomaterials#Market analysis#Graphene innovations#Advanced materials#Electronics industry#Graphene applications#Market dynamics#Graphene production#Material science advancements#Future of technology#Sustainable materials#Graphene manufacturers

0 notes

Text

Global Aluminum Deoxidizer Market Is Estimated To Witness High Growth Owing To Rising Demand for High-Quality Aluminum Products

The global Aluminum Deoxidizer Market is estimated to be valued at US$ 3.13 billion in 2023 and is expected to exhibit a CAGR of 5.7% over the forecast period 2023-2030, as highlighted in a new report published by Coherent Market Insights. Market Overview: Aluminum deoxidizers are additives used in the aluminum production process to remove oxygen and other impurities from the molten aluminum. They help improve the quality and properties of aluminum products, such as strength, corrosion resistance, and heat resistance. The growing demand for high-quality aluminum products in various industries, including automotive, construction, aerospace, and electronics, is driving the market for aluminum deoxidizers. These additives play a crucial role in ensuring the production of clean and high-performance aluminum products, which are increasingly preferred in the market. Market key trends: One key trend in the global aluminum deoxidizer market is the increasing use of advanced deoxidizer formulations. Manufacturers are investing in research and development activities to develop innovative deoxidizer formulations that offer improved performance and cost-effectiveness. These advanced formulations provide better deoxidizing efficiency, reduced slag formation, and enhanced metal quality. For example, Almatis GmbH introduced a new generation of calcium aluminate-based deoxidizers that offer higher deoxidation rates and better control over the aluminum composition. This trend is expected to drive the growth of the aluminum deoxidizer market. PEST Analysis: Political: The political stability of countries with significant aluminum production and consumption impacts the global aluminum deoxidizer market. Policies related to trade, tariffs, and regulations can affect the supply and demand dynamics of aluminum products. Economic: Economic factors, such as GDP growth, industrialization, and urbanization, influence the demand for aluminum products and, in turn, the demand for aluminum deoxidizers. Economic fluctuations can impact the overall market growth. Social: Increasing awareness among consumers about the benefits of aluminum products, such as recyclability and lightweight, is driving the demand for aluminum deoxidizers. Technological: Technological advancements in the aluminum production process, such as improved smelting techniques and automation, are driving the adoption of aluminum deoxidizers. Advanced deoxidizer formulations are also being developed to meet the increasing quality standards of aluminum products. Key Takeaways: - The global Aluminum Deoxidizer Market Demand is expected to witness high growth, exhibiting a CAGR of 5.7% over the forecast period, due to increasing demand for high-quality aluminum products in various industries. - The Asia-Pacific region is anticipated to be the fastest-growing and dominating region in the global aluminum deoxidizer market. Rapid industrialization, infrastructure development, and automotive production in countries like China and India are driving the demand for aluminum deoxidizers. - Key players operating in the global aluminum deoxidizer market include Almatis GmbH, AluChem, Inc., Motim Electrocorundum Ltd., READE Advanced Materials, Zibo Honghe Chemical Co., Ltd., Henan HengXin Industrial & Mineral Products Co., Ltd., Prince Minerals LLC, HAIHUI Group Co., Ltd., Gongyi City Meiqi Industry & Trade Co., Ltd., Xinzheng Chengxin Carbon Co., Ltd., Henan Junsheng Refractories Limited, Luoyang Zhongsen Refractory Co., Limited, Jiaozuo BeiYuan Chemical Co., Ltd., Gongyi City Xianke Water Supply Material Co., Ltd., and Zibo Jiuchen Industry & Trade Co., Ltd. These players are focusing on product innovation and expanding their market presence through strategic partnerships and acquisitions.

#Aluminum Deoxidizer#Aluminum Deoxidizer Market#Aluminum Deoxidizer Market Size#Aluminum Deoxidizer Market Share#Aluminum Deoxidizer Market Growth#Advanced Materials

0 notes