#3d laser cutting

Explore tagged Tumblr posts

Text

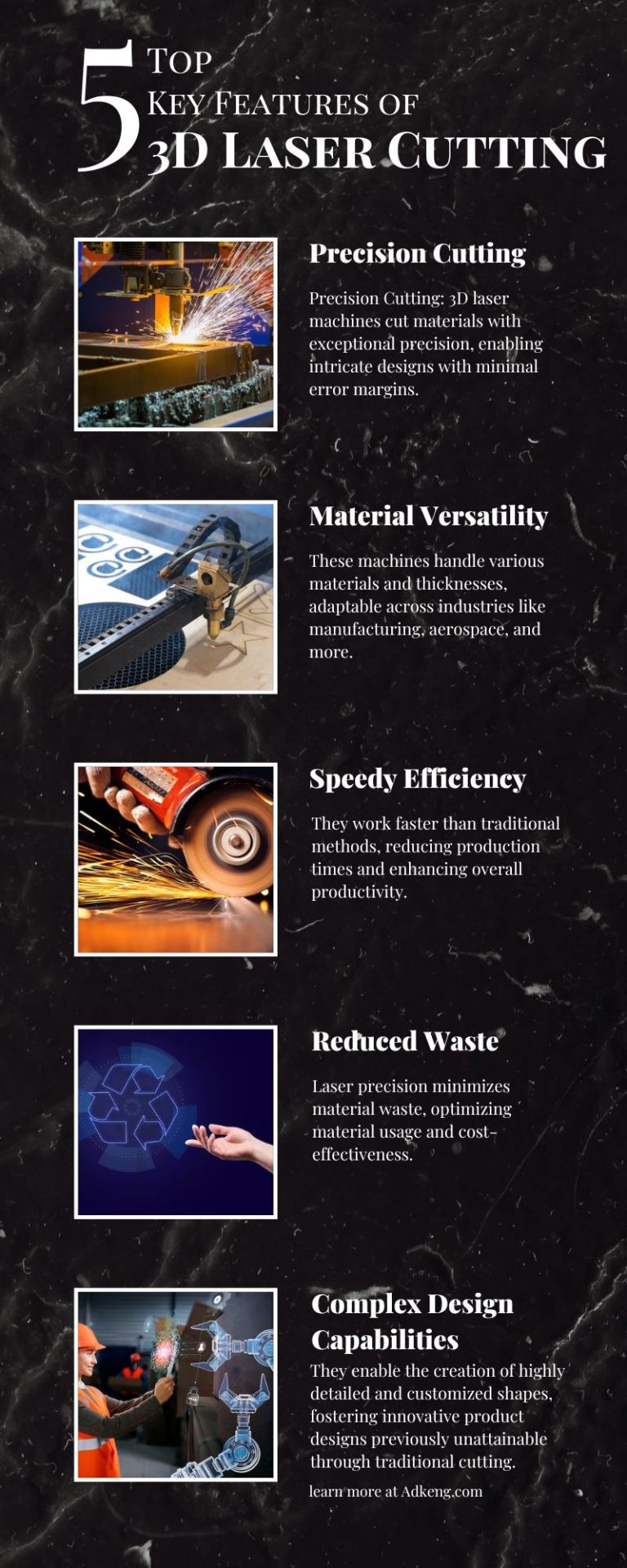

Top 5 points about 3d laser cutting machine

Dive into the transformative world of 3D laser cutting machines and unravel their standout features. These cutting-edge machines redefine precision cutting, offering unparalleled accuracy in shaping diverse materials. From metals to plastics, their versatility spans across industries like manufacturing, aerospace, and beyond, accommodating various material thicknesses with ease. Speed and efficiency are their hallmark, significantly reducing production times while maximizing productivity. Learn More At - ADK Engineering & Solutions

0 notes

Photo

Laser Cutting

Laser cutting is best for extensive requests, tight resistances, and many-sided plans. In case you’re not certain, there are a lot of laser cutting assets accessible, and we’re cheerful to examine whether laser cutting is ideal for your task if you want to converse with a specialist specifically.

#CNC Bending#Laser Cutting#metal fabrication#sheet metal fabrication#3d laser cutting#laser cutting design#laser cutting services#sheet metal fabrication process#sheet metal laser cutting

1 note

·

View note

Text

So I’ve held this close to my chest in case it went horribly wrong, but I love working in a place full of scientists, engineers and general tech enthusiasts because it means when I came across someone’s open source 3D printed and laser cut design for a 4-shaft loom, there were plenty of enthusiasts ready to help make it a reality.

I’ve had great fun over my birthday weekend putting together the bits I’ve gotten so far (only missing the dowling that I’ve ordered and the flexible tpu parts -the heddles)

She also glows in the dark and folds!! you can see the back two arms in the folded position and all the 3D printed parts were made of glowwy filament, which is my favourite thing ever, as an added treat 🌖

There’s still some hiccups to address, such as no assembly instructions, everything (including the screw paths) being mirrored from one side to the next (plus ratchets on BOTH sides??) and I definitely have not quite worked out the how the folding mechanism/lock functions (and I’ve put my reeds on back to front 🤦🏻) but those are all problems for when I’ve got the rods and cut them to size and it starts to feel like a functioning object!!!

#cotton khaleesi#cottonkhaleesi#loom weaving#weaving#4-shaft weaving loom#3d printing#laser cutting#open source

91 notes

·

View notes

Text

the conversation on artist merch and manufacturing is one i'm interested in because i like having my digital pictures as physical objects now and then and i don't know enough about the ethics or economics of it to have a real stance on it, but i do know enough about it to know that a lot of the folks talking about it don't know enough to be talking about it

#the last acrylic charm i got was from an artist in mexico who either owns a laser cutter or visits the manufacturer frequently#and her prices were about the same as everyone else's#so it can probably be done ethically (labor-wise) w/o much change in costs but you can't know if it's ethical unless you know the workers#CoL is one thing but so is the fact that some countries have more manufacturers who cater to that market than others#i've done a quick look into US plastic cutting companies and they often don't have the *printers* necessary for this kind of work#or they cater toward advertising so they're not interested in anything other than printing a logo on 200 keychains#but if we start talking about materials? it never ends#an enamel pin or acrylic charm is more durable than anything your typical indie artist can make at home#the plastic and emissions that go into artist merch is so small compared to what big companies are doing#and you can't blame the consumption of plastic goodies on american tastes without sounding ignorant of like. the world.#but that doesn't justify putting more plastic out there y'know?#there's also the 3rd angle of ���artist merch is better when it's more diy”#which i agree with in the sense that i don't particularly like going to reptile shows and seeing the same 3d printed toys everywhere#but that's not a concrete issue so much as sellers responding to a market where those things sell best#people like colorful goodies. there's not much that can be done about that.#it's a lot more nuanced than a lot of folks want to say but nuance doesn't interest people and it doesn't get notes

2 notes

·

View notes

Text

Ahoy mateys! Just conquered the high seas and completed this epic Flying Dutchman 3D wooden puzzle! This intricate pirate ship was a true test of patience (and rum-drinking skills ) but the final result is a treasure to behold.

#worth the challenge#3d puzzle challenge#wooden craftsmanship#flying dutchman#pirate ship#diy project#model building#adult puzzle#satisfying completion#nautical decor#historical replica#home decor#gift ideas#makers gonna make#weekend project#wooden puzzles#laser cut#mindful building#stress relief#crafts of instagram#show off your skills

3 notes

·

View notes

Text

It was this! Times up on guessing. Giant zipper puller for Bridget's jacket!

#3d printed#3d modeling#3dprinting#bridget cosplay#cosplay props#zippers#trans makers#laser cutter#laser cut foam

10 notes

·

View notes

Text

Explore Our High-Quality Laser Cutting Melbourne Services

The primary benefit of laser cutting is precision. With a traditional saw, cut lines can be made imprecise by the blade's vibration or unbalanced weight. Laser cutters also allow you to cut precisely at any angle, whereas traditional hand and power saws can only make cuts perpendicular to their blade axis. Because of their ability to make precise cuts, laser machines use in manufacturing applications such as metal fabrication, woodworking and stone cutting.

Laser cutting is also safer than traditional cutting methods. The machines use a focused beam of light to slice through the material, which means there is no contact between the material and the laser cutter's blade. In addition to being safer for workers, this method also reduces waste by producing a cleaner cut. Many businesses rely on Laser Cutting Melbourne to manufacture a variety of products.

Laser cutting and engraving are fantastic ways to render intricate designs on the surface of materials. It allows for precision in design and craftsmanship, cutting and engraving materials such as wood, plastic and metal. As technology has developed over time and become more available, designers have been able to harness the potential of laser cutting to produce something truly unique. The process is simple and used to cut or engrave a design into the material, which can be any shape or size. The most common applications include woodworking projects, home decor and small-scale manufacturing.

KEM Signs is a leading laser cutting and engraving service provider. They are known for providing superior-grade material with the latest and sophisticated technology. They have highly qualified professionals who hold expertise in their respective fields, where they can provide you with excellent services. Contact them for any query about laser cutting and engraving near me.

#laser cutting melbourne#safety signage melbourne#illuminated signage melbourne#label makers melbourne#a frame signs melbourne#3d illuminated signs melbourne#cnc cutting services melbourne#construction site signage melbourne#laser cutting and engraving near me#magnetic signs melbourne#reception signage melbourne

2 notes

·

View notes

Text

Liverpool Football Club Wall Art Design Poster

Liverpool Football Club Wall Art Design Poster

Securely framed in one of three colors (black, white, or walnut), these premium posters exhibit varied contents through archive-worthy photo paper and ink. For easy hanging, there’s a backing hardware piece. The framing is made of MDF. Further ensuring durability, the bordering is low maintenance and resistant to swelling and warping.

.: LexJet Premium 200 gsm paper

.: Frames available in black, walnut and white finishes

.: Protective acrylic cover

.: Hanging kit already fixed

.: Matte paper finish

#Liverpool FC merchandise#Wall art#Home decor#Sports memorabilia#Fan gear#Personalized gifts#Custom designs#3D printing#Laser cutting#Woodworking#Metalworking#Digital art

0 notes

Text

3D printing and Laser cutting workshops. Helpful introductions to the software and hardware. My 3D object (in green above) did not get printed in the end due to space limitations however I still believe it to have been worthwhile to become a little more familiar with the ways of which to go about it. As introductions what we were asked to make did not adhere to our brief but showed us alternative materials at which we can use in our project.

0 notes

Text

Find the best laser cutting machine in UAE on TradersFind

Find the best laser cutting machines in UAE on TradersFind. This platform provides access to a vast selection of high-quality 3D laser cutting machines, fiber laser cutting machines, and CNC laser cutting machines from the top manufacturers in UAE. Customers can easily connect with these leading companies and explore the latest laser cutting machines in UAE to enhance their operations. Contact Now!

#laser cutting machines#laser cutting machines in UAE#laser cutting machine suppliers#laser cutting machine manufacturers#best laser cutting machine#laser cutting machine companies#industrial laser cutting machines#3d laser cutting machine#fiber laser cutting machine#cnc laser cutting machine

0 notes

Text

3D Laser Cutting & Ergonomics: Elevating Product Functionality

In the fast-paced world of product design and manufacturing, the quest for enhancing functionality while prioritizing user experience remains an ongoing pursuit. Amidst various innovative methodologies, the convergence of 3D laser cutting and ergonomics has emerged as a game-changer, revolutionizing the way products are conceptualized, designed, and produced.

The Marriage of 3D Laser Cutting and Ergonomics

Unveiling the Power of 3D Laser Cutting

At the heart of this revolution lies 3D laser cutting, a sophisticated technology that enables precision and intricacy in shaping raw materials. Its ability to carve out complex designs with utmost accuracy has transformed traditional manufacturing processes, offering unparalleled possibilities in crafting products with enhanced functionality.

The precision and versatility of 3D laser cutting have transcended industry boundaries, from automotive and aerospace to consumer electronics and healthcare. Intricate components, once deemed impossible to create, now take form effortlessly, thanks to the precision and speed offered by this cutting-edge technology.

Ergonomics: Redefining User-Centric Design

Simultaneously, the integration of ergonomics into product design has redefined the approach towards user interaction. Ergonomics, the science of optimizing design to enhance human well-being and performance, considers user comfort, efficiency, and safety as primary principles.

By employing ergonomic principles during the design phase, products are tailored to fit the human body's mechanics, minimizing user fatigue and maximizing usability. From furniture to gadgets, ergonomics has been pivotal in creating products that seamlessly integrate with the user's needs and movements.

Elevating Product Functionality

Precision Meets Comfort: The Synergy

The amalgamation of 3D laser cutting and ergonomics has unlocked new dimensions in product functionality. Designers and engineers now wield the power to fashion products that not only boast intricate designs but also prioritize user comfort and usability.

Innovations in furniture design showcase this synergy impeccably. Chairs, desks, and even automotive interiors are meticulously crafted using 3D laser cutting techniques, ensuring both structural integrity and ergonomic superiority. The result? Products that not only look aesthetically pleasing but also align with the natural contours of the human body, providing unparalleled comfort and support.

Shaping the Future: Possibilities and Beyond

Looking ahead, the possibilities are boundless. The marriage of 3D laser cutting and ergonomics continues to push the boundaries of product design. From personalized medical devices tailored to individual anatomies to futuristic automotive interiors that prioritize both safety and comfort, the impact of this convergence is reshaping industries and consumer experiences. The fusion of 3D laser cutting and ergonomics stands as a testament to human ingenuity and technological advancement. It heralds a new era where functionality, precision, and user-centric design harmoniously coexist. As this synergy continues to evolve, it promises not just enhanced products but an elevated user experience that transcends conventional boundaries, setting new benchmarks for innovation and excellence.

0 notes

Text

Yeah yeah 3d printing is cool and whatever, you can make little plastic trinkets and a few utilities or whatever, but what we really need for at home making is ways to print circuit boards and fabricate components, and open source communities trading designs for them.

Like, I don't give a fuck about creating a fancy new phone holder or whatever if you are still dependent on (relatively) few companies and foundries for your phone's components and PCBs.

#diy#3d printing#tbh from everything I've seen 3d printing is still mostly a gimmick#you can make some cool toys but home printers just aren't making stuff strong enough and the material is shit plastic#laser cutting looks way better to me#circuit design#also can we make a better toolchain than we have#because fuck the existing vhdl/verilog tools#at least the ones I've used#we need people learning digital and analog logic design#glad we have a good open source thing going for software now let's hit hardware

0 notes

Text

Finally at a stage of actually trialling out this loom (despite all my weaving accoutrements being in storage and reverting to a slapdash cereal box shuttle)! It has a few niggles; namely that the designer clearly doesn’t weave herself, thus didn’t know the practical differences between a 4-shaft and rigid heddle loom, just the cosmetic ones. But unexpected side effect I do love: being able to balance my laptop on top of the whole thing because the shaft controls are on the sides! Wooo!

It works!! Look at that beautiful zigzag pattern.

#cotton khaleesi#cottonkhaleesi#weaving#4-shaft loom#4 shaft loom#the loom that sca built#3D printing#laser cutting

23 notes

·

View notes

Text

Top laser cutting machine companies in UAE on TradersFind

Top laser cutting machine companies in UAE on TradersFind. It is offering a comprehensive selection of cutting-edge solutions for various industries. These companies are recognized for their quality products, technological expertise, and customer satisfaction. With a focus on innovation and precision, laser cutting machine companies provide businesses with top-tier laser cutting machines to enhance their operations. For more information visit:

#laser cutting machines#laser cutting machines in UAE#laser cutting machine suppliers#laser cutting machine manufacturers#best laser cutting machine#laser cutting machine companies#industrial laser cutting machines#3d laser cutting machine#fiber laser cutting machine#cnc laser cutting machine

0 notes

Text

Find the best laser cutting machines in UAE on TradersFind

Discover the finest laser cutting machines in UAE on TradersFind. Explore a curated selection of top-notch machines known for precision, efficiency, and quality output. From industrial to small-scale applications, find reliable laser cutting machines solutions to meet your diverse cutting needs effectively and efficiently. Contact Now!

#laser cutting machines#laser cutting machines in UAE#laser cutting machine suppliers#laser cutting machine manufacturers#laser cutting machine companies#industrial laser cutting machines#3d laser cutting machine#fiber laser cutting machine#cnc laser cutting machine

0 notes

Photo

Duck Keychains!

We're back to keychains!! This is the absolute final push. I am determined to get these out in shops this time!! I designed the 3d printed cages for these in mind with the exact printing specs that I had in mind. A layer height of .25mm in mind. The bottom and top of the cage is 1mm thick. The 4 layers on the top and bottom give enough room to power sand the 3d printed cages down smooth, and the 1.75mm hollow part gives enough room to shimmy the 1.5mm thick piece of engraved wood inside of the cage in the middle of the print! The hardest part about these is creating the pattern in the 3d print. It leverages booleans using a cutting place to create a high(relatively) resolution cut through the 3d base mesh. This is a heavy computational process that likes to freeze blender if you push it past it's limit. Each click on the computer causes blender to freeze for about 20 seconds or more when creating these. After 7 iterations and some frustrations, I have a nice pipeline to make more of these! Hope to really get creative with these things!!

Posted using PostyBirb

#laser#wood#physical#engrave#cut#3d print#dul extrusion#black#brown#pla#wood pla#duck#tree#pine#swirl#texture#cage#multi#media#pattern#text#pun

0 notes