#3D printing dental technology

Explore tagged Tumblr posts

Text

Dental Implants and Pain Management: A Comprehensive Guide for a Comfortable Experience

In recent years, dental implants have become a popular and reliable solution for patients looking to replace missing teeth. The procedure offers a permanent, durable, and aesthetically pleasing alternative to traditional dentures or bridges. However, one of the top concerns for many patients considering dental implants is pain management. How painful is the procedure? What methods are available…

#3D printing dental technology#best pain relief for dental implants#dental implant pain management#dental implant procedure#dental implants#dental implants recovery tips#dental-care#implant surgery recovery#laser dental implants#minimally invasive dental surgery#modern dental pain relief#oral-health#pain-free dental surgery#post-surgery dental care#sedation dentistry for implants

0 notes

Text

Interactive mouthpiece opens new opportunities for health data, assistive technology, and hands-free interactions

New Post has been published on https://thedigitalinsider.com/interactive-mouthpiece-opens-new-opportunities-for-health-data-assistive-technology-and-hands-free-interactions/

Interactive mouthpiece opens new opportunities for health data, assistive technology, and hands-free interactions

When you think about hands-free devices, you might picture Alexa and other voice-activated in-home assistants, Bluetooth earpieces, or asking Siri to make a phone call in your car. You might not imagine using your mouth to communicate with other devices like a computer or a phone remotely.

Thinking outside the box, MIT Computer Science and Artificial Intelligence Laboratory (CSAIL) and Aarhus University researchers have now engineered “MouthIO,” a dental brace that can be fabricated with sensors and feedback components to capture in-mouth interactions and data. This interactive wearable could eventually assist dentists and other doctors with collecting health data and help motor-impaired individuals interact with a phone, computer, or fitness tracker using their mouths.

Resembling an electronic retainer, MouthIO is a see-through brace that fits the specifications of your upper or lower set of teeth from a scan. The researchers created a plugin for the modeling software Blender to help users tailor the device to fit a dental scan, where you can then 3D print your design in dental resin. This computer-aided design tool allows users to digitally customize a panel (called PCB housing) on the side to integrate electronic components like batteries, sensors (including detectors for temperature and acceleration, as well as tongue-touch sensors), and actuators (like vibration motors and LEDs for feedback). You can also place small electronics outside of the PCB housing on individual teeth.

Play video

MouthIO: Fabricating Customizable Oral User Interfaces with Integrated Sensing and Actuation Video: MIT CSAIL

The active mouth

“The mouth is a really interesting place for an interactive wearable and can open up many opportunities, but has remained largely unexplored due to its complexity,” says senior author Michael Wessely, a former CSAIL postdoc and senior author on a paper about MouthIO who is now an assistant professor at Aarhus University. “This compact, humid environment has elaborate geometries, making it hard to build a wearable interface to place inside. With MouthIO, though, we’ve developed a new kind of device that’s comfortable, safe, and almost invisible to others. Dentists and other doctors are eager about MouthIO for its potential to provide new health insights, tracking things like teeth grinding and potentially bacteria in your saliva.”

The excitement for MouthIO’s potential in health monitoring stems from initial experiments. The team found that their device could track bruxism (the habit of grinding teeth) by embedding an accelerometer within the brace to track jaw movements. When attached to the lower set of teeth, MouthIO detected when users grind and bite, with the data charted to show how often users did each.

Wessely and his colleagues’ customizable brace could one day help users with motor impairments, too. The team connected small touchpads to MouthIO, helping detect when a user’s tongue taps their teeth. These interactions could be sent via Bluetooth to scroll across a webpage, for example, allowing the tongue to act as a “third hand” to open up a new avenue for hands-free interaction.

“MouthIO is a great example how miniature electronics now allow us to integrate sensing into a broad range of everyday interactions,” says study co-author Stefanie Mueller, the TIBCO Career Development Associate Professor in the MIT departments of Electrical Engineering and Computer Science and Mechanical Engineering and leader of the HCI Engineering Group at CSAIL. “I’m especially excited about the potential to help improve accessibility and track potential health issues among users.”

Molding and making MouthIO

To get a 3D model of your teeth, you can first create a physical impression and fill it with plaster. You can then scan your mold with a mobile app like Polycam and upload that to Blender. Using the researchers’ plugin within this program, you can clean up your dental scan to outline a precise brace design. Finally, you 3D print your digital creation in clear dental resin, where the electronic components can then be soldered on. Users can create a standard brace that covers their teeth, or opt for an “open-bite” design within their Blender plugin. The latter fits more like open-finger gloves, exposing the tips of your teeth, which helps users avoid lisping and talk naturally.

This “do it yourself” method costs roughly $15 to produce and takes two hours to be 3D-printed. MouthIO can also be fabricated with a more expensive, professional-level teeth scanner similar to what dentists and orthodontists use, which is faster and less labor-intensive.

Compared to its closed counterpart, which fully covers your teeth, the researchers view the open-bite design as a more comfortable option. The team preferred to use it for beverage monitoring experiments, where they fabricated a brace capable of alerting users when a drink was too hot. This iteration of MouthIO had a temperature sensor and a monitor embedded within the PCB housing that vibrated when a drink exceeded 65 degrees Celsius (or 149 degrees Fahrenheit). This could help individuals with mouth numbness better understand what they’re consuming.

In a user study, participants also preferred the open-bite version of MouthIO. “We found that our device could be suitable for everyday use in the future,” says study lead author and Aarhus University PhD student Yijing Jiang. “Since the tongue can touch the front teeth in our open-bite design, users don’t have a lisp. This made users feel more comfortable wearing the device during extended periods with breaks, similar to how people use retainers.”

The team’s initial findings indicate that MouthIO is a cost-effective, accessible, and customizable interface, and the team is working on a more long-term study to evaluate its viability further. They’re looking to improve its design, including experimenting with more flexible materials, and placing it in other parts of the mouth, like the cheek and the palate. Among these ideas, the researchers have already prototyped two new designs for MouthIO: a single-sided brace for even higher comfort when wearing MouthIO while also being fully invisible to others, and another fully capable of wireless charging and communication.

Jiang, Mueller, and Wessely’s co-authors include PhD student Julia Kleinau, master’s student Till Max Eckroth, and associate professor Eve Hoggan, all of Aarhus University. Their work was supported by a Novo Nordisk Foundation grant and was presented at ACM’s Symposium on User Interface Software and Technology.

#3-D printing#3d#3D model#Accessibility#alexa#app#artificial#Artificial Intelligence#Assistive technology#author#Bacteria#batteries#bluetooth#box#Capture#career#career development#communication#complexity#computer#Computer Science#Computer Science and Artificial Intelligence Laboratory (CSAIL)#Computer science and technology#data#dental#Design#development#devices#do it yourself#Electrical engineering and computer science (EECS)

2 notes

·

View notes

Text

#dental innovation#future dentistry#3D printed teeth#smart toothbrushes#dental technology#oral health care#dental care trends#advanced dentistry

0 notes

Text

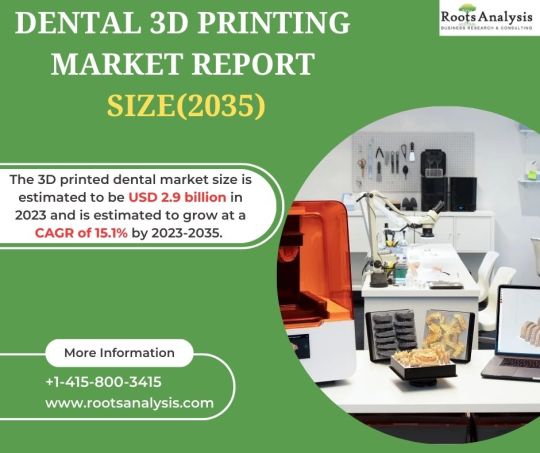

Dental 3d Printing Market | Printing Technology | Size (2035)

The market for 3D-printed dental implants is estimated to reach around $2.9 billion in 2023. It's projected to grow steadily at a rate of 15.1% from 2023 to 2035. The Roots Analysis report offers a comprehensive examination of the current market situation and the size of the dental 3D printing market. Get a comprehensive insights report today!

0 notes

Text

New solvent-free 3D printing material could enable biodegradable implants

Additive manufacturing (AM) has revolutionized many industries and holds the promise to affect many more in the not too distant future. While people are most familiar with the 3D printers that function much like inkjet printers, another type of AM offers advantages using a different approach: building objects with light one layer at a time. One such technology is digital light processing (DLP). Widely used in both industrial and dental applications, DLP works by converting a liquid resin into a solid part using light, essentially pulling solid objects out of a shallow pool of resin one layer at a time. A major challenge to using this 3D printing method, however, is that the resins need to have a low viscosity, almost like water, to function properly at high resolution. Plenty of polymers that would otherwise be useful in DLP printing are solids or too viscous, requiring solvents to dilute them to an appropriate consistency.

Read more.

8 notes

·

View notes

Text

Midway Dental Laboratory Revolutionizes Smiles with Cutting-Edge Veneers and Digital Dentistry

Nowadays, creating the ideal smile has never been easier. Midway Dental Laboratory is a leading way in a digital dental solution. It shapes patients’ smiles through cutting-edge materials, methods, and digital technology.

The Power of Veneers and Digital Dentistry

Veneers are porcelain shells that encase the front teeth and enhance their form, color, and shape. Digital dentistry has changed the veneer’s production and restoration methods. Midway Dental Laboratory manufactures precise, beautiful veneers using cutting-edge technology. This combination of digital equipment and materials ensures every veneer fits naturally.

Digital Dentistry: A Game Changer

Digital dentistry is transforming the way dental specialists treat their patients. Digital tools provide greater precision, quicker turn-around and lower patient morbidity. Midway Dental Laboratory automates digital workflows at every step of veneer production. It ensures each restoration is done accurately and efficiently.

Materials and Techniques

Veneered at Midway Dental Laboratory are made from high-quality materials. These substances provide strength, durability, and naturalness. The latest ones are porcelain and lithium, which offer long-term durability without sacrificing the tooth’s whiteness. The digital dental solutions lab uses advanced methods, ensuring each veneer is tailored to the patient’s specific smile, shaded and textured or seamless continuity.

Digital Imaging and Diagnosis

Digital imaging is one of the most significant benefits of digital dentistry. Midway Dental Laboratory’s professionals scan the patient’s teeth and gums with precise tools. It helps them to create realistic 3D representations. These images make it possible to diagnose and plan accurately. Dental surgeons assess the shape, size, and condition of the teeth so that the veneers fit properly. It also facilitates finding problems that influence the final result and makes patients’ lives easier.

CAD/CAM Technology

Midway Dental Laboratory’s process utilizes Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) technologies. CAD programs enable technicians to make suitable veneer designs that are tailored to the individual anatomy of the patient. CAM software takes these designs and uses automated equipment to sand the veneers to an unprecedented level of precision. This combination of design and manufacturing technology allows the lab to finish functional products.

The Impact of Aesthetic Veneers and Digital Dentistry

The amalgamation of digital dentistry and emax veneers has led to an increase in patient satisfaction. Midway Dental Laboratory’s digital imaging, CAD/CAM and 3D printing methods produce veneers that fit better than traditional restorations. Digital instruments allow more individualistic methods, as the veneers are designed according to the patient’s facial shape.

Meet dental specialists to discover more about digital dentistry at https://midway-dentallab.com/

Original Source: https://bit.ly/49Vvekj

0 notes

Text

Dental Tourism in Hyderabad: Why Avighna’s Attracts Global Patients

Dental tourism has witnessed a remarkable surge over the past decade, with individuals from around the globe seeking high-quality yet affordable dental treatments in countries like India. Hyderabad, renowned as the "City of Pearls," has emerged as a significant hub for dental tourism. Among the top choices for global patients is Avighna Dental Clinic, celebrated as the top dental clinic in Hyderabad. Let’s delve into what makes Avighna a preferred destination for dental tourists and why Hyderabad continues to shine as a beacon for world-class dental care.

Why Hyderabad is a Premier Dental Tourism Destination

Hyderabad seamlessly blends state-of-the-art medical facilities with rich cultural heritage, making it an attractive option for dental tourists. Here are some compelling reasons:

Affordable Treatments Without Compromising QualityDental treatments in Hyderabad cost a fraction of what they do in Western countries. For example, a dental implant in the United States might cost upwards of $3,000, whereas the same procedure in Hyderabad costs between $500 to $1,000, maintaining comparable quality.

Advanced Infrastructure and TechnologyClinics like Avighna are equipped with cutting-edge technology such as 3D imaging, CAD/CAM systems, and digital X-rays, ensuring precision and efficacy in treatments.

Highly Skilled ProfessionalsHyderabad boasts some of the best dental professionals trained in prestigious institutions in India and abroad. These experts are adept at handling complex cases with a focus on patient satisfaction.

Seamless Connectivity and Tourism OpportunitiesHyderabad’s well-connected international airport makes it easy for patients to travel. The city’s tourist attractions—from Charminar to Ramoji Film City—offer an excellent blend of recovery and recreation.

Avighna Dental Clinic: The Top Dental Clinic in Hyderabad

1. A Patient-Centric Approach

Avighna Dental Clinic’s philosophy revolves around prioritizing patient comfort and care. From personalized consultations to post-treatment follow-ups, every aspect of the patient journey is meticulously crafted.

2. Multispecialty Expertise Under One Roof

The clinic offers a wide range of services, including:

Cosmetic Dentistry: Teeth whitening, veneers, and smile makeovers.

Restorative Dentistry: Dental implants, crowns, and bridges.

Orthodontics: Braces and Invisalign for all age groups.

Preventive Care: Routine cleanings, sealants, and oral hygiene education.

3. Global Standards and Accreditations

Avighna adheres to international sterilization protocols and safety standards, ensuring every patient receives the highest level of care.

4. Exceptional Team of Specialists

The clinic is home to a panel of experienced dentists, including implantologists, orthodontists, and cosmetic dentists, who leverage their expertise to deliver outstanding results.

Top Dental Trends Driving Patient Choices

To stay ahead in the competitive field of dental tourism, clinics must align with current trends. Here are some that resonate with Avighna’s offerings:

Digital DentistryDigital tools like intraoral scanners and 3D printing have revolutionized dental care. Avighna integrates these technologies to offer accurate and efficient treatments.

Minimally Invasive ProceduresWith a focus on patient comfort, treatments such as laser dentistry and guided implant surgery are becoming the norm.

Holistic Dental CareToday’s patients seek not just functional solutions but also aesthetic enhancements. Avighna specializes in smile makeovers that combine functionality with beauty.

TeleconsultationsCatering to international patients, Avighna offers virtual consultations to discuss treatment plans before patients arrive in Hyderabad.

Case Study: Sarah’s Smile Transformation

Sarah, a 35-year-old from the UK, visited Avighna Dental Clinic for a smile makeover. Her treatment included teeth whitening, veneers, and a minor gum contouring procedure. The total cost was 70% less than what she’d have paid in her home country. “Avighna not only transformed my smile but also made the entire process stress-free,” she shared. Her story exemplifies the clinic’s commitment to delivering exceptional results.

Exclusive Offers for Dental Tourists

To enhance its appeal to international patients, Avighna Dental Clinic provides:

Complimentary Airport Transfers

Discounted Treatment Packages

Assistance with Accommodation and Sightseeing

Expert Opinions on Dental Tourism in Hyderabad

Dr. Ramesh Gupta, a leading implantologist, says, “Hyderabad’s dental tourism industry thrives because of its ability to deliver world-class treatments at affordable rates. Clinics like Avighna have set benchmarks with their patient-centric approach and use of advanced technology.”

FAQs About Dental Tourism at Avighna

Q1: How can I book an appointment at Avighna Dental Clinic?A: Appointments can be booked through the clinic’s website or via email. Virtual consultations are also available for international patients.

Q2: What documents are needed for dental tourism in India?A: Ensure you carry a valid passport, visa, and medical records for a smooth experience.

Q3: How long will my treatment take?A: Treatment duration varies depending on the procedure. Avighna’s team provides detailed timelines during the consultation phase.

Conclusion

Hyderabad’s status as a global hub for dental tourism is undeniable, and Avighna Dental Clinic stands out as the top dental clinic in Hyderabad. Combining affordability, expertise, and advanced technology, it offers a seamless and enriching experience for patients worldwide. Whether it’s a simple cleaning or a complete smile makeover, Avighna ensures every patient leaves with confidence and satisfaction.

If you’re considering dental tourism, look no further than Hyderabad and Avighna Dental Clinic. Start your journey toward a healthier, brighter smile today!

0 notes

Text

Exploring the Applications of 3D Printing in UAE

The applications of 3D printing in UAE are as diverse as the industries it serves. From healthcare to construction, this technology is revolutionizing the way we create and innovate. C3D, one of the leading 3D printing companies in UAE, plays a vital role in bringing these applications to life.

In construction, 3D printing is being used to create sustainable building materials, paving the way for greener infrastructure. In the automotive industry, it allows for the rapid production of custom parts and components. The healthcare sector is also benefiting immensely, with 3D printing enabling the creation of prosthetics, dental implants, and even surgical guides.

What makes C3D stand out is their ability to cater to such a wide range of industries. Their expertise ensures that clients receive precise, reliable solutions tailored to their unique requirements.As 3D printing in UAE gains momentum, its potential is becoming increasingly clear. Whether it’s reducing production times or minimizing waste, this technology is transforming industries for the better.

0 notes

Text

Dental Devices Market

Dental Devices Market Size, Share, Trends: Dentsply Sirona Inc. Leads

Transforming Dentistry: Digital and CAD/CAM Technology Revolutionizing Dental Care

Market Overview:

The global dental devices market is projected to grow at a CAGR of 6.4% from 2024 to 2031, with North America currently dominating the market. This growth is driven by increasing prevalence of dental diseases, a growing geriatric population, technological advancements in dental devices, and rising demand for cosmetic dentistry.

The market is experiencing steady growth, fueled by the high adoption rates across various dental care segments. Technological advancements, such as digital dentistry and CAD/CAM technology, are enhancing the accuracy and efficiency of dental procedures, leading to improved patient outcomes and increased comfort.

DOWNLOAD FREE SAMPLE

Market Trends:

The adoption of digital dentistry, particularly Computer-Aided Design and Computer-Aided Manufacturing (CAD/CAM) technology, is a major trend in the dental equipment industry. This technology allows for the design and production of high-quality dental restorations, such as crowns, bridges, and implants, with greater accuracy and efficiency. The global dental CAD/CAM market is expected to grow at an 8.9% CAGR between 2024 and 2031, indicating its rapidly increasing adoption. Digital dentistry not only improves the quality of dental restorations but also reduces treatment times and enhances patient comfort, making it popular among both dental professionals and patients.

Market Segmentation:

The Dental Implants category currently dominates the dental devices market. This dominance is primarily due to the increasing prevalence of tooth loss, rising demand for aesthetic dentistry, and technological advancements in implant materials and designs. Dental implants offer a long-term solution for missing teeth, providing both functional and aesthetic benefits.

Recent industrial developments have further strengthened the segment's position. For instance, the introduction of micro dental implants has expanded the patient base by offering options for individuals with insufficient bone density for standard implants. Additionally, advancements in implant surface technology have improved osseointegration, resulting in shorter healing times and better long-term outcomes.

The global dental implants market was valued at over $4.5 billion in 2023 and is projected to grow at a 7.2% CAGR until 2031. This growth is driven by factors such as an aging population, increased dental tourism in emerging economies, and rising awareness of oral health. The use of digital workflows in implant dentistry, such as intraoral scanners and 3D printing for surgical guides, enhances the accuracy and efficiency of implant procedures, further driving market growth.

Market Key Players:

Dentsply Sirona Inc.

Straumann Holding AG

Envista Holdings Corporation

Align Technology, Inc.

3M Company

Henry Schein, Inc.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

2025’s Top Innovations in Dental Care You Need to Know About

At Cosmodont Dentistry, we're committed to staying ahead of the curve when it comes to cutting-edge dental technologies and treatments. As 2025 approaches, the world of dentistry continues to evolve rapidly, driven by breakthroughs in science, technology, and patient care. Whether you're a regular visitor to the dentist or simply looking to learn more about the future of dental care, this blog will introduce you to the top innovations that are set to transform the way we think about oral health.

1. Artificial Intelligence for Personalized Care

Artificial Intelligence (AI) is revolutionizing the dental field by providing more accurate diagnostics, treatment planning, and even patient-specific care. AI algorithms analyze X-rays, scans, and medical histories with a level of precision that can identify potential dental issues earlier than ever before. In 2025, AI will enable personalized care, predicting how a patient’s teeth will respond to treatments and even recommending preventative care tailored to individual needs.

For example, AI-driven software can identify cavities, gum disease, and even early signs of oral cancer much earlier than traditional methods. Dentists can use this technology to create more effective, customized treatment plans, leading to better outcomes and faster recovery times.

2. Teledentistry: Convenient Virtual Care

Teledentistry has exploded in popularity, and by 2025, it will become an even more integral part of the dental care landscape. This virtual service allows patients to have consultations, receive follow-up care, and even access some diagnostic services remotely. Whether it’s a routine check-up or follow-up care after a procedure, teledentistry offers a convenient way to receive dental care without the need to leave home.

For those with busy schedules, teledentistry ensures that access to care is just a video call away. In 2025, teledentistry will likely expand to include remote monitoring of oral health, allowing patients to receive real-time feedback from their dentist and making it easier to stay on top of oral hygiene.

3. 3D Printing for Dental Implants and Restorations

3D printing is making a significant impact in dentistry, particularly in the creation of dental implants, crowns, and bridges. By 2025, the technology will become even more advanced, offering faster, more accurate, and more cost-effective solutions. 3D printing allows for the creation of highly detailed, custom-made dental devices, improving the fit and function of restorations.

Dentists will be able to create crowns, veneers, and bridges in a single visit, with precise measurements and designs tailored to the patient’s unique mouth structure. This will greatly reduce wait times and improve the overall patient experience, with restorations that look and feel more natural.

4. Laser Dentistry: Minimally Invasive Treatment

Laser dentistry is becoming more refined, offering a less invasive, more comfortable alternative to traditional dental procedures. From cavity removal to gum disease treatment, lasers can target problem areas with incredible precision, minimizing discomfort and reducing healing time. By 2025, expect lasers to be used for a wider range of procedures, including teeth whitening, root canals, and even the treatment of oral cancer.

Laser technology offers numerous benefits for both patients and dental professionals, such as reduced bleeding, less risk of infection, and faster recovery times. For patients seeking pain-free options, laser dentistry may be a game-changer in the years to come.

5. Regenerative Medicine for Gum and Bone Health

One of the most exciting innovations in dentistry is the field of regenerative medicine. Advances in stem cell research and tissue engineering are opening up new possibilities for regenerating gum tissue and even bone. This breakthrough is particularly important for patients suffering from severe gum recession or bone loss due to periodontal disease or other factors.

In 2025, regenerative treatments could potentially restore lost tissue, eliminate the need for invasive surgeries, and help maintain the health and structure of the mouth. With the help of biocompatible scaffolds and regenerative growth factors, patients may soon be able to regrow lost bone and gum tissue, resulting in healthier smiles and fewer invasive procedures.

6. Smart Toothbrushes with AI Technology

In the coming years, toothbrushes will get smarter. The rise of AI-powered smart toothbrushes will change the way we think about at-home oral hygiene. These toothbrushes will be equipped with sensors and real-time feedback mechanisms that monitor brushing habits, pressure, and technique. By 2025, these devices will sync with mobile apps to provide personalized feedback, track progress, and even offer reminders to encourage better habits.

Smart toothbrushes will also be able to assess your oral health status, offering suggestions for improvements based on the data they collect. This innovation will not only help prevent cavities and gum disease but also motivate users to adopt healthier brushing practices.

7. Personalized Oral Care Products

Customization is a growing trend in many industries, and oral care is no exception. By 2025, more dental brands will offer personalized oral care products such as toothpaste, mouthwash, and floss. These products will be tailored to an individual’s unique needs based on factors like age, lifestyle, diet, and oral health conditions.

Personalized toothpaste, for example, could be formulated to address specific issues like enamel erosion, tooth sensitivity, or plaque buildup. Through simple at-home tests, patients may be able to receive customized recommendations for oral care products that are optimized for their dental health.

8. Augmented Reality (AR) in Dental Education and Treatment

Augmented Reality (AR) is transforming how dental professionals train and provide treatment. By 2025, AR is expected to become an integral tool in dental education, allowing dental students to learn procedures in a virtual environment before working on real patients. This technology enhances the accuracy and efficiency of treatments, giving dentists the ability to see 3D overlays of a patient's teeth and bone structure during procedures.

For patients, AR may also be used to visualize potential treatments, such as seeing how dental restorations or braces will look after completion. This could help patients make more informed decisions about their care and increase satisfaction with their treatment outcomes.

9. DNA Testing for Oral Health Insights

Personalized dental care will also extend to DNA testing, which is gaining traction as a way to understand an individual's oral health risks. DNA tests can identify genetic predispositions to conditions such as gum disease, tooth decay, or even oral cancer. In 2025, genetic testing may be part of routine dental exams, offering valuable insights into a patient’s unique risks and guiding preventive strategies.

By understanding how a patient’s genetics may affect their oral health, dentists can create proactive treatment plans, target high-risk areas, and provide customized preventive care strategies to mitigate potential issues before they arise.

10. Sustainability in Dental Practices

Sustainability is a key concern across all industries, and dentistry is no exception. In 2025, expect to see more eco-friendly dental products and practices being adopted in dental offices. From biodegradable dental materials to energy-efficient equipment, sustainability will become a major focus for dental practices looking to reduce their environmental impact.

At Cosmodont Dentistry, we’re already looking into ways to implement sustainable practices in our office, from reducing waste to adopting eco-conscious products. By 2025, sustainability will be a crucial aspect of the patient experience and the future of dental care.

Final Thoughts

As 2025 approaches, the future of dentistry looks incredibly promising. From AI and 3D printing to regenerative medicine and sustainable practices, the innovations on the horizon will make dental care more personalized, efficient, and accessible. At Cosmodont Dentistry, we're excited to embrace these advancements and continue offering our patients the most advanced, compassionate care possible.Stay tuned as we continue to explore the latest trends and technologies in dental care. Whether you're seeking a routine checkup or advanced treatments, these innovations will ensure that you receive the best care possible for a healthier, happier smile. Book your appointment today!

0 notes

Text

0 notes

Text

Computer-Aided Design Market Poised for Transformation with Emerging Technologies

As per Intent Market Research, the Computer-Aided Design (CAD) Market was valued at USD 8.4 billion in 2023-e and will surpass USD 21.1 billion by 2030; growing at a CAGR of 14.9% during 2024–2030.

The projected growth of USD 21.1 billion by 2030 is not an isolated trend. CAD's versatility in various sectors—like healthcare for prosthetics, or entertainment for animations—demonstrates its cross-industry relevance. Enhanced accuracy, reduced production timelines, and cost savings are primary motivators for its adoption.

Global Drivers of Market Expansion

Technological Advancements: The integration of artificial intelligence, cloud computing, and the Internet of Things (IoT) in CAD software is a game changer. Cloud-based CAD solutions, for example, enable collaborative design across geographies, enhancing productivity.

Rising Demand in Construction: With urbanization surging worldwide, smart infrastructure projects increasingly rely on CAD for detailed designs, simulations, and workflow optimization.

Adoption in Manufacturing: Industries leveraging Industry 4.0 principles heavily invest in CAD to accelerate prototyping, streamline production processes, and achieve precision engineering.

Expansion in Emerging Markets: Countries like China and India are experiencing industrialization, driving CAD adoption in architecture, automotive, and electronics sectors.

Download Sample Report @ https://intentmarketresearch.com/request-sample/computer-aided-design-cad-market-3032.html

Future-Proof Features: The Transformation of CAD Software

Modern CAD solutions don’t just aid in design—they simulate real-world applications to predict performance. Here’s how the software landscape is transforming:

AI and Machine Learning: Automating mundane tasks like error detection and enhancing design quality.

Generative Design: This feature lets designers input parameters like weight, material, and size to create optimal designs automatically.

Virtual Reality (VR) Integration: VR-enabled CAD platforms allow stakeholders to visualize projects interactively, improving client collaboration.

Challenges Facing the CAD Market

Despite its impressive trajectory, CAD adoption isn't without challenges:

Cost of Implementation: High upfront costs for software and hardware, coupled with ongoing training expenses, can deter smaller businesses.

Complexity: While powerful, CAD systems demand skilled operators, posing an adoption barrier in resource-constrained environments.

Data Security Concerns: As more software moves to the cloud, protecting intellectual property from breaches becomes paramount.

Opportunities for Growth in the CAD Ecosystem

The future of CAD lies in innovation. Here are key areas poised to drive growth:

Integration with 3D Printing: CAD complements 3D printing seamlessly, as designs can be directly translated into physical models.

Custom Manufacturing: Rising trends in bespoke designs (e.g., dental implants, furniture) rely heavily on CAD.

Green Technology Development: CAD plays a critical role in designing eco-friendly solutions, like energy-efficient buildings and electric vehicles.

Access Full Report @ https://intentmarketresearch.com/latest-reports/computer-aided-design-cad-market-3032.html

A Global Perspective on CAD Usage

Dominance of North America and Europe: With a mature infrastructure and well-established industrial base, North America and Europe hold significant CAD market shares. Investments in smart cities and defense bolster CAD adoption.

Asia-Pacific’s Accelerated Growth: Asia-Pacific markets are experiencing exponential CAD uptake, thanks to rapid industrial growth and favorable government initiatives in tech innovation.

FAQs

What is Computer-Aided Design (CAD)? CAD is a software tool used for creating, modifying, and optimizing designs digitally, replacing traditional drafting methods. It enhances precision and workflow efficiency.

Which industries benefit most from CAD? CAD is essential in industries like architecture, aerospace, automotive, construction, healthcare, and manufacturing.

What drives the CAD market growth? Key factors include technological advancements, increased adoption in manufacturing and construction, and rising demand for innovation in emerging markets.

What are the emerging trends in CAD software? Modern trends include AI integration, generative design, cloud-based solutions, and VR-powered visualization.

Why is CAD critical for the future of design? By combining efficiency with innovation, CAD enables industries to conceptualize, simulate, and implement cutting-edge solutions more effectively than ever before.

About Us

Intent Market Research (IMR) is dedicated to delivering distinctive market insights, focusing on the sustainable and inclusive growth of our clients. We provide in-depth market research reports and consulting services, empowering businesses to make informed, data-driven decisions.

Our market intelligence reports are grounded in factual and relevant insights across various industries, including chemicals & materials, healthcare, food & beverage, automotive & transportation, energy & power, packaging, industrial equipment, building & construction, aerospace & defense, and semiconductor & electronics, among others.

We adopt a highly collaborative approach, partnering closely with clients to drive transformative changes that benefit all stakeholders. With a strong commitment to innovation, we aim to help businesses expand, build sustainable advantages, and create meaningful, positive impacts.

Contact Us

US: +1 463-583-2713

0 notes

Text

Exceptional Ceramic Crowns from Top Dental Labs in Kansas

The Growing Demand for Ceramic Crowns in Modern Dentistry Ceramic crowns have revolutionized modern dentistry by providing patients with a durable, natural-looking solution for damaged or decayed teeth. These crowns blend seamlessly with existing teeth, offering both aesthetic appeal and functionality. If you're searching for a reliable Dental Lab Dodge City, KS, you’ll find options that excel in delivering precision and quality. The demand for such services continues to rise as more people prioritize the longevity and appearance of their dental work.

Why Choose Ceramic Crowns for Restorative Needs? Ceramic crowns are crafted to match the exact color and texture of natural teeth, making them an excellent choice for those looking to restore their smiles. Compared to traditional materials like metal or resin, ceramics offer enhanced durability and resist stains better over time. Dentists often rely on a trusted Dental Lab for Ceramic Crowns Salina, KS, to ensure their patients receive crowns with a perfect fit and finish. These labs use cutting-edge technology to fabricate crowns that meet the highest industry standards.

The Role of Dental Labs in Creating Perfect Crowns The success of ceramic crowns heavily depends on the expertise of dental labs. A skilled Dental Lab Salina, KS, can transform a dentist's impression into a masterpiece that enhances both form and function. From the initial design process to the final product, these labs utilize advanced CAD/CAM systems to ensure each crown is tailored to meet individual patient needs. Similarly, a reputed dental lab in Dodge City, KS, focuses on maintaining precision at every stage, ensuring the crowns align seamlessly with the patient’s bite and natural teeth.

Advanced Technology in Kansas Dental Labs Dental labs in Kansas have embraced technological advancements to improve their services. Modern labs use digital impressions, 3D printing, and laser sintering to create ceramic crowns that are not only precise but also efficient to produce. For instance, a dental lab for ceramic crowns in Dodge City, KS, employs these innovations to achieve faster turnaround times without compromising on quality. This commitment to excellence ensures that patients receive long-lasting crowns that look and feel like real teeth.

The Expertise Behind Ceramic Crown Production What sets apart a top-tier dental lab is the expertise of its technicians. These professionals are highly trained in understanding the nuances of dental anatomy and aesthetics. A leading Dental Lab for Ceramic Crowns Dodge City, KS, emphasizes continuous education and training for its staff to stay updated with the latest techniques. This ensures that every crown produced is not just functional but also visually appealing, enhancing the overall patient experience.

Meeting Patient Expectations with Custom Solutions Each patient’s dental needs are unique, and ceramic crowns are no exception. The best dental labs in Kansas specialize in customizing crowns to match the exact requirements of each individual. Whether you’re working with a dental lab in Salina, KS, or its counterpart in Dodge City, the focus is on delivering a personalized solution. This tailored approach guarantees that patients leave with a smile they’re proud to show off.

Building Trust Through Quality and Service The relationship between dentists and dental labs is built on trust, which is earned through consistent quality and timely service. A dependable dental lab in Dodge City, KS, works closely with dental professionals to ensure that every crown meets the expectations of both the dentist and the patient. Similarly, labs in Salina have established themselves as reliable partners by maintaining strict quality control measures and using top-grade materials.

Why Kansas is a Hub for Dental Excellence Kansas has emerged as a hub for dental excellence, thanks to the presence of state-of-the-art labs dedicated to restorative dentistry. Whether you’re seeking a dental lab for ceramic crowns in Salina, KS, or Dodge City, you’ll find facilities equipped with the latest tools and staffed by skilled technicians. These labs are committed to elevating patient care by producing crowns that are both aesthetically pleasing and durable.

Ceramic crowns are a cornerstone of modern restorative dentistry, and their success hinges on the expertise of dental labs. From the precision of advanced technology to the craftsmanship of skilled technicians, every step contributes to creating a flawless crown. Whether you need the services of a dental lab for ceramic crowns in Dodge City, KS, or a dental lab for ceramic crowns in Salina, KS, you can expect exceptional quality and service. These labs not only meet but exceed expectations, ensuring that patients receive the best possible outcomes for their dental restorations.

0 notes

Text

#digital dentistry#3D printing in dentistry#AI in dentistry#dental technology#future of dental care#dental innovation#patient experience in dentistry#dental treatment advancement

0 notes

Text

Are Removable Veneers Worth It?

In the world of cosmetic dentistry, removable veneers have revolutionized smile enhancement, offering an innovative solution for those seeking a confident, beautiful smile without invasive procedures. If you're wondering whether these innovative teeth covers are truly worth the investment, especially for addressing missing teeth or smile imperfections, this comprehensive guide will provide the insights you need.

Understanding Removable Veneers: More Than a Cosmetic Solution

Removable veneers, particularly custom-made snap-on veneers, represent a breakthrough in dental aesthetics. Unlike traditional dental work, these versatile smile solutions offer:

Instant smile transformation

Non-invasive alternative to permanent dental procedures

Affordable cosmetic correction

Flexibility for various dental imperfections

The Game-Changer for Missing Teeth

For individuals struggling with missing teeth, removable veneers provide an exceptional solution that:

Covers unsightly gaps instantly

Restores confidence in your smile

Offers a temporary or long-term aesthetic fix

Eliminates the need for expensive, painful dental implants

Cutting-Edge Technology Behind Premium Removable Veneers

At Removable Veneers USA, we've elevated smile transformation through:

Precision 3D printing technology

Completely custom fitting

High-quality, ultra-thin materials

Expert design by licensed dental professionals

Why Our Veneers Stand Out

Unlike budget alternatives, our removable veneers offer:

Superior craftsmanship

A+ Better Business Bureau Rating

Ability to eat and drink while wearing

Multiple style options to suit your unique smile

Cost-Effective Smile Transformation

Starting at just $499, our removable veneers provide an affordable solution for:

Covering chipped or damaged teeth

Addressing tooth discoloration

Correcting minor misalignments

Replacing missing teeth

Overall smile enhancement

Real-World Cost Comparison

Traditional Dental Procedures:

Dental Implants: $3,000 - $4,500 per tooth

Porcelain Veneers: $925 - $2,500 per tooth

Removable Veneers USA: Starting at $499 for a full set

Practical Benefits of Removable Veneers

Unmatched Convenience

No dental office visits required

Painless application

Comfortable daily wear

Simple maintenance

Versatile Options

Choose between straightened or natural tooth profile

Three premium models available

Suitable for special occasions or everyday use

Addressing Common Customer Concerns

Durability and Quality

Our veneers are engineered to withstand daily wear, including eating and drinking. The key is following our professional care guidelines and choosing a high-quality product.

Natural Appearance

Leveraging advanced 3D printing technology and slim-line materials, our veneers provide an incredibly natural look that seamlessly blends with your existing teeth.

Making the Right Choice for Your Smile

When considering removable veneers for missing teeth or smile improvement, prioritize:

Custom fitting

Premium materials

Proven track record

Positive customer testimonials

Professional design and manufacturing

Why Removable Veneers USA?

We're not just another snap-on veneer provider. Our commitment to quality sets us apart:

Proudly made in the USA

Designed by licensed dental professionals

Superior materials

No painful dental procedures

Affordable smile transformation

Real People, Real Transformations

Our customers consistently report:

Increased confidence

Immediate smile improvement

Comfort and ease of use

Exceptional value for money

Investing in Your Smile: More Than Just Cosmetics

Removable veneers represent more than a cosmetic solution. They're a pathway to:

Enhanced self-confidence

Minimal dental intervention

Affordable smile enhancement

Immediate results

Your Smile, Your Confidence

Removable veneers offer an innovative, practical solution for those seeking to improve their smile without extensive dental work. With Removable Veneers USA, you're not just purchasing teeth covers – you're investing in a confidence-boosting smile transformation.

Take the First Step

Explore our range of custom snap-on veneers and discover the perfect solution for your unique smile. With our A+ BBB rating and unwavering commitment to quality, your dream smile is just a click away.

Whether you’re attending a special event, need a confidence boost, or want a hassle-free alternative to traditional dental work, snap-on veneers offer a practical, elegant solution. Ready to love your smile again? Explore your options today and discover the life-changing benefits of removable veneers for missing teeth at Removable Veneers USA.

Disclaimer: While removable veneers provide an excellent cosmetic solution, they are not a substitute for professional dental care. Consult with a dental professional for comprehensive oral health advice.

0 notes

Text

The Role of Dentists in Cosmetic Dentistry: Innovations and Enhancements

Cosmetic dentistry has evolved significantly over the years, transforming how individuals approach dental care and aesthetics. While traditional dentistry focuses primarily on oral health and the treatment of dental issues, cosmetic dentistry combines the principles of dental health with aesthetic enhancements to improve the appearance of smiles. Dentists, equipped with advanced skills and technology, play a crucial role in this field, helping patients achieve their ideal smiles while ensuring optimal oral health.

Understanding Cosmetic Dentistry

Cosmetic dentistry encompasses a wide range of procedures aimed at enhancing the appearance of teeth, gums, and smiles. These procedures can vary from simple treatments to more complex surgical interventions, catering to diverse patient needs. Some common cosmetic dentistry services include:

Teeth Whitening: Professional teeth whitening procedures effectively remove stains and discoloration, offering brighter smiles.

Veneers: Thin shells made from porcelain or composite resin, veneers cover the front surface of teeth to correct imperfections such as chips, gaps, or misalignment.

Bonding: Dental bonding involves applying a tooth-colored resin to correct minor imperfections and enhance tooth shape and color.

Crowns: Dental crowns restore damaged or decayed teeth while improving their shape, size, and appearance.

Orthodontics: Treatments such as braces or clear aligners help straighten misaligned teeth, contributing to overall facial aesthetics.

Gum Contouring: Sculpting the gum line enhances the smile by addressing issues such as a "gummy smile" or uneven gum distribution.

The Role of Dentists

Dentists specializing in cosmetic procedures undergo additional training to refine their skills in aesthetic techniques and technologies. They combine their knowledge of dental health with an artistic eye to ensure that treatments not only function effectively but also look natural and beautiful. Here are some critical roles of dentists in cosmetic dentistry:

Assessment and Planning: Dentists begin by assessing a patient’s oral health, discussing their aesthetic goals, and developing a tailored treatment plan. This personalized approach ensures optimal results.

Execution of Procedures: Dentist in Boise perform various cosmetic procedures using the latest techniques and technologies to ensure precision and efficacy.

Patient Education: Educating patients about their options and providing aftercare instructions is fundamental. Dentists help patients understand what to expect and how to maintain their results.

Holistic Care: Cosmetic dentists aim to improve not only the aesthetic aspects but also the functionality of teeth, ensuring that treatments enhance overall oral health.

Enhancements in Cosmetic Dentistry

The field of cosmetic dentistry has seen remarkable advancements, driven by technological innovations and a deeper understanding of dental aesthetics. Some key enhancements include:

Digital Imaging and Smile Design: Advanced imaging technologies allow dentists to create digital mock-ups of potential results. Tools like Computer-Aided Design/Computer-Aided Manufacturing (CAD/CAM) enable patients to visualize the end result before treatment begins.

Laser Technology: The use of lasers in procedures such as gum reshaping and teeth whitening has revolutionized cosmetic dentistry. Lasers allow for more precise and less invasive treatments, minimizing discomfort and recovery time.

3D Printing: 3D printing technology has made customized dental solutions more accessible. Dentists can produce tailored crowns, veneers, and aligners quickly and accurately, leading to improved fit and comfort.

Minimal Prep and No-Prep Veneers: Traditional veneers often require significant tooth reduction, but modern options like minimal prep and no-prep veneers preserve more of the natural tooth structure, making it a more conservative approach.

Biocompatible Materials: Advances in dental materials have led to the development of more durable, natural-looking options for restorations. Materials used for crowns, fillings, and veneers are now designed to closely match natural teeth.

Holistic and Customized Treatments: There is a growing trend toward personalized treatment plans that consider not only aesthetic preferences but also overall health and wellness. Cosmetic dentistry Boise Idaho are increasingly integrating holistic approaches, emphasizing the importance of maintaining good oral health alongside cosmetic goals.

Conclusion

Dentists specializing in cosmetic dentistry play an essential role in transforming smiles and enhancing patients' confidence and quality of life. With the integration of advanced technologies, innovative materials, and personalized care, cosmetic dentistry continues to evolve, making treatments more effective, efficient, and comfortable. As interest in aesthetic improvements in dental care grows, seeking advice from a qualified cosmetic dentist can provide patients with the expertise and options they need to achieve their desired smiles. Whether it’s through teeth whitening, veneers, or orthodontic treatments, the enhancements in cosmetic dentistry offer a pathway to radiant and healthy smiles.

0 notes