#welding and metal fabrication

Explore tagged Tumblr posts

Text

Top 20 Welding Tools and Accessories for All Welding Projects

Welding is an all-industry skill. It is used in projects of construction, manufacturing, automotive repair, and metal fabrication. Whether an experienced welder or just a beginner, the right tools and accessories do make a difference in welding services such as efficiency and safety. If you are also a welder, you might be well aware of the importance of the correct tools. And if you are a…

#on-site welding services#welding and fabrication companies#welding and fabrication services#welding and metal fabrication#welding services#Welding Tools

0 notes

Text

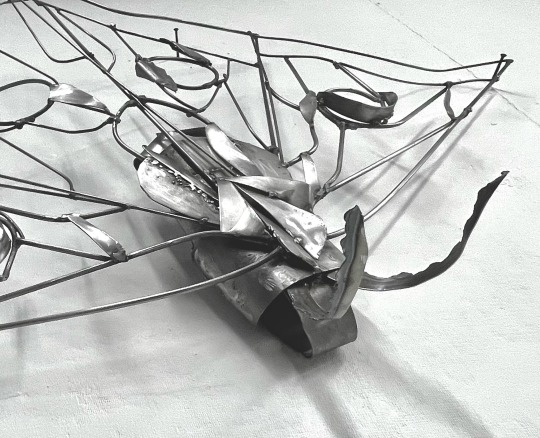

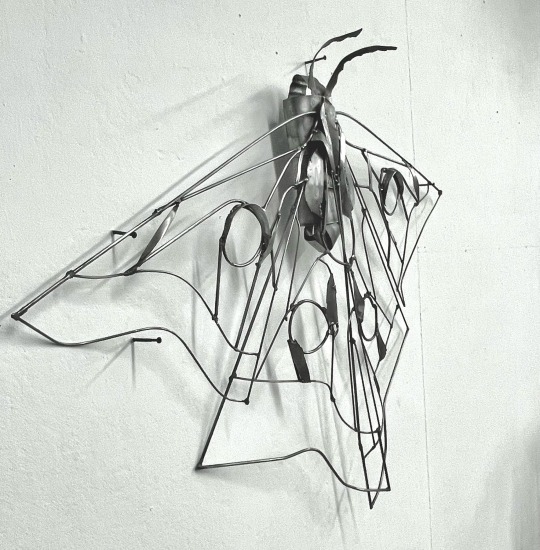

Metal moth COMPLETE!

#metalworking#welding#metal#art#artists on tumblr#artists of tumblr#sculpture#metal fabrication#moth#moon moth#my art#this was for a class and I’m actually pleasantly surprised with how it turned out#yippe

377 notes

·

View notes

Text

im making my own fold out table for camping. i just re-used a stool seat for the table part, its lookin good!

13 notes

·

View notes

Text

IF BLOOD AND BONES ARE WHAT YOU WANT, I SUGGEST THAT YOU LOOK BEHIND YOU

🗡️ 🗡️ 🗡️

🩸 🩸 🩸

👠 👠 👠

13: An old OC of yours: This is an old dnd character i made in middle school called Crimson! I think they were a neutral or lawful evil warlock? but i can't really remember much. i just know that they were a fancy little bitch

#deliver me from being perfect and complete [queue]#you dont ask questions about project mayhem [boards]#lyrics: blood and bones by the blake robinson synthetic orchestra#fabric#textiles#floral#ice#hearts#drinks#berries#flowers#water#dagger#fashion#dnd#welding#metal#jewelry#blacksmithing#metalworking#fruit#juice#skirt#fidget toys#dress#red#white#black#silver#gray

16 notes

·

View notes

Text

Finished this guy this year..

DRAGON!

#scrap metal#metal art#artwork#art#metal#welding#steel fabrication#Craftsmanship#Dragon#Fantasy#Sculpture

2 notes

·

View notes

Text

aughhhh. aughhhhhjhhhh

#everhoneignore this post classic rant post i don't have real problems everyone can move along#truly have had such a bad couple of days here and i am not even close to finishing the assignments i need to finish in welding being in#clsss makes me want to quit and die i don't know why i'm so slow i don't know why everyone else can intuit this stuff and improve and#understand how to do it and im always always falling behind if i could try harder wouldn't i be able to do that ive got no drive to push#myself at all i guess i like the english and i can do the physics i thought i at least liked drafting and metals fabrication but i feel so#stupid everything i do makes me feel so stupid and my teacher talks to me like i'm always doing everything wrong when i do some classroom#ettiquette breaches that everyone else does too and i can't get myself to go to sleep on time can't get myself to go in early i have hours#and hours and hours and i blink and it's gone and i've done nothing i should've welded today and gone in early to draft but i didn't because#im stupid and im slow and i can't do anything right i have always been able to square away a little bit of pride on being precise on doing#things well because people are always telling me that i am but i am below average here i just can't do things right and i feel like everyone#hates me and thinks i'm obnoxious and i don't know how to interface with my class or my teacher or how to improve or how to be less anxious#and i feel even stupider for that because i am so stuck up not being able to deal with even a little bit of failure or issue or hardship#and everyone around me is sick all my classmates and people in my dorm are sick im sure it's covid they haven't said it's covid but none of#them would test and i've been wearing a mask again but im certainly been exposed to it already and no one else is wearing a mask anyway so#what difference does it even make and i can hear them coughing in my dorm and in the classroom and when i go to get food and i miss seeing#my friends from philly and everuthing will be terrible forever and ever#alex talks

2 notes

·

View notes

Text

#metal work#restoration#awesome#classic#fabrication#itswhatido#welding#bodywork#painting#mechanical#upholstery

14 notes

·

View notes

Text

Sheet metal fabrication

#design#autos#business#prototype#prototyping#rapid prototyping#prototype machining#sheet metal services tauranga#sheet metal manufacturing#sheet metal fabrication#sheet metal work contractor financing#sheet metal design#metal machining#sheet metal bending#sheet metal stamping#sheet metal welding#sheet metal

2 notes

·

View notes

Text

Keep your tools safe and organized with our stainless steel tool chests. Explore our range of durable and spacious storage options.

#homedecor#pinturaeletrost#industrialdesign#officefurniture#customfurniture#fabrication#industrialfurniture#welding#metal#table#industrial#steelfurnituredesign#stainlesssteel

2 notes

·

View notes

Text

Sheet Metal Fabrication

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#Sheet Metal Fabrication#Powder Coating & Welding#Complete Turnkey Solutions#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS

2 notes

·

View notes

Text

Nick Willoughby, “ELEVATE”

Metal Sculpture (2023)

#artists on tumblr#artwork#handcrafted#sculpture#metalwork#welding#metal fabrication#design#abstracart#abstract#new artist#welder#maryland#metal design#eastern shore#landscape aesthetic#original art

2 notes

·

View notes

Text

Finished and ready to rock

#knights forge#rock band#custom design and fabrication#metal fabrication#medieval#woodworking#welding#gothic#dark grunge#spooky#skull art#Spotify

2 notes

·

View notes

Text

Forged Fittings Vs Wrought Fittings

What is Wrought Fittings?

A Wrought Fittings product is a form of steel made from forged, rolled, ring-rolled, extruded or welded components, while forging refers to one of these forms.

What are uses of Wrought Fittings?

For the construction of buildings, the wrought iron plate girder evolved as a basic device. There were many decorative uses for wrought iron in historical times, including fences, gates, railings, balconies, porches, canopies, roof crestings, lamps, grilles, hardware, nails, cramps, and structural members in tension (I, H, etc.).

What is Forged Fittings?

Forged Fittings is a material produced by alloying iron and carbon under extreme pressure. The surface porosity of forged steel is lower, its grain structure is finer, it has a greater tensile and fatigue strength, and its ductility is significantly higher than steel that has been processed by other means.

What are uses of Forged Fittings?

It is common for forged fitting components to be used in automotive and truck applications, for manufacturing valves, fittings, hand tools and hardware, as well as in manufacturing industrial, heavy construction and mining equipment. The components are made of steel, and these components include the powertrain, axle beams, shafts, wheel spindles and kingpins.

What are the types of forged Fittings?

In order to keep things simple, we divide steel forging into three categories based on the temperature at which it is forged.

Hot forged steel

As the temperature reaches 950°C, the forging process is carried out between 950°C and 1250°C, which is over the temperature of recrystallization. Steel that has been hot forged has good formability and requires a low level of force to shape, which is why it is so popular.

Hardened steel forging

As a general rule, the forging temperature is between 750°C and 950°C. There are limitations in the ductility of this material as well as higher forming forces required than forging at a hot temperature. Besides its great advantages, it can also be considered a middle ground between hot and cold forging, which makes it more versatile than either one alone.

Cold forged steel

This process is carried out under ‘room conditions,’ that is, under temperatures as high as 150 degrees Celsius. The forging process is characterized by the low formability of the material, which demands high forces during the forming process. As a result, it is of great advantage for the conservation of material and for the smoothness of the surface that is achieved with this method.

Here are some comparisons between wrought steel products and forged steel products:

It is important to keep in mind that the major difference between wrought steel and forged steel is their strength. There is no doubt that forged steel is much more durable than wrought steel, since forged steel becomes a casting that is then forged, which adds to its durability even further.

Tap here to read more about:

2 notes

·

View notes

Text

0 notes

Text

At HJ Burton, we provide top-tier welding services, specializing in MIG, TIG, and spot welding to meet a wide range of project needs. Whether you’re working with steel, aluminum, stainless steel, or other metals, our experienced welders ensure precision, strength, and durability in every joint.

#metal fabrication ontario#powder coating service ontario#welding works ontario#CNC tube laser cutting Ontario#Custom Laser Tube Cutting Ontario

0 notes