#sheet metal welding

Explore tagged Tumblr posts

Text

Sheet metal fabrication

#design#autos#business#prototype#prototyping#rapid prototyping#prototype machining#sheet metal services tauranga#sheet metal manufacturing#sheet metal fabrication#sheet metal work contractor financing#sheet metal design#metal machining#sheet metal bending#sheet metal stamping#sheet metal welding#sheet metal

2 notes

·

View notes

Video

youtube

How To Weld Sheet Metal The RIGHT WAY - SUPER EASY

0 notes

Text

Sheet Metal Fabrication

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#Sheet Metal Fabrication#Powder Coating & Welding#Complete Turnkey Solutions#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS

2 notes

·

View notes

Text

#sheet metal work ontario#welding work ontario#metal fabrication ontario#metal laser cutting Ontario#tube laser cutting Ontario

0 notes

Text

The manufacture of sheet metal is transforming its whole process creating a new industry involving the use of technologies that go not only to increase the precision and speed of production but also to make it eco-friendly by all means. Lasers, water jets, and AI manufacturing are among the many innovations enabling creative concepts such as these due to their time-efficient and cost-friendly nature. Paired with technology's development, metal fabrication seems to be more practical, personalized, and living in harmony with nature. These improvements, expand not just the efficiency and cost-effectiveness of the industry but also the boundaries of what is possible in the field of metalworking worldwide. For more information about Sheet Metal Fabrication, visit: https://www.metalskills.co.nz/

0 notes

Text

https://sevenarticle.com/top-plastic-fabrication-services-for-complex-projects/

At Petron Thermoplast, we are proud to be a trusted provider of advanced plastic fabrication services, delivering tailored solutions for industries that demand excellence.

#Fabrication Services#Plastic Fabrication Services#metal fabrication services#Custom Fabrication#Custom Metal Fabrication#Custom Fabrication Service#Custom Plastic Fabrication#Custom Welding Fabrication#Custom Pipe Fabrication#Custom Sheet Fabrication#Fabrication Service Company

0 notes

Text

Monocrystalline Furnace Support Machining. The primary function of a monocrystalline furnace support is to hold and stabilize the crucible within the furnace, ensuring the silicon melt is properly positioned for the crystal growth process. It plays a critical role in maintaining the structural integrity and alignment necessary for the successful growth of high-quality single-crystal silicon ingots.

0 notes

Text

Sheet Metal Welding

0 notes

Text

The Value of Quality: Choosing Bespoke Welding Contractors

In the world of metalwork and fabrication, quality is paramount. Whether it's creating custom architectural features or manufacturing precision components for industrial machinery, the craftsmanship of bespoke welding contractors can make all the difference. But with so many options available, how can you ensure that you're choosing the right contractor for your project?

One of the first things to look for when selecting bespoke welding contractors is their commitment to quality and craftsmanship. A reputable contractor will have a track record of delivering high-quality workmanship and attention to detail across a range of projects. Look for certifications, testimonials, and examples of their previous work to gauge the level of quality you can expect.

Additionally, consider the materials and techniques used by the contractor. The best bespoke welding contractors will have expertise in working with a variety of metals, alloys, and fabrication methods. Whether it's MIG welding, TIG welding, or plasma cutting, ensure that the contractor has the skills and equipment necessary to meet your project requirements.

Furthermore, communication is key when working with bespoke welding contractors. A contractor who takes the time to understand your vision, objectives, and design requirements is more likely to deliver results that exceed your expectations. Look for contractors who are responsive, transparent, and proactive in their communication throughout the project lifecycle.

Another factor to consider is the contractor's capacity and capabilities. Whether you're working on a small-scale project or a large-scale production run, ensure that the contractor has the resources and infrastructure to meet your needs. This includes not only their technical expertise but also their ability to manage timelines, budgets, and logistics effectively.

In conclusion, choosing the right bespoke welding contractor is essential to the success of your project. By prioritizing quality, expertise, communication, and capacity, you can ensure that your project is completed to the highest standards of craftsmanship and excellence.

0 notes

Text

What is steel fabrication machines do?

Let's dive in! Steel fabrication machines are essential tools used to shape and assemble steel materials into various structures and products. From cutting and bending to welding and finishing, these machines streamline the fabrication process, making it efficient and precise. Whether you're crafting intricate designs or industrial components, steel fabrication machines are the backbone of the manufacturing industry. Explore the world of steel fabrication and unleash your creativity!

#steel fabrication#steel fabricators near me#custom sheet metal fabrication#welding machine#welding services

0 notes

Text

Choosing the Right Technique for Sheet Metal Welding: MIG vs. TIG Welding

Welding is a crucial process in metal fabrication, and when it comes to sheet metal cutting, two popular techniques stand out — MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding. Each technique has its strengths and weaknesses, making the choice between them essential for achieving optimal results in sheet metal applications. In this blog, we will delve into the key differences between MIG and TIG welding, explore their suitability for sheet metal cutting, discuss the pros and cons of each method, highlight factors influencing the choice between them, and provide real-life examples of successful sheet metal cutting using both techniques.

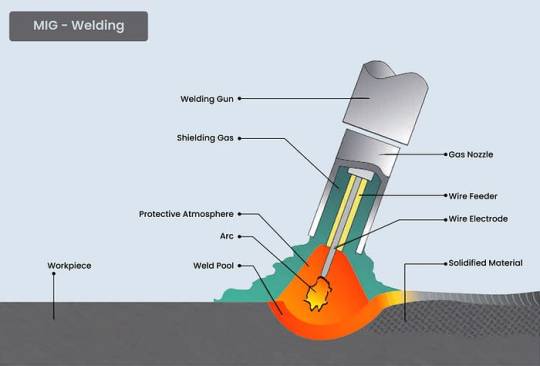

What is MIG welding?

MIG welding involves a continuous wire feed that is fed through a welding gun and melted into the joint. A shielding gas, typically a mixture of argon and carbon dioxide, protects the weld pool from atmospheric contaminants. MIG welding is known for its efficiency and speed, making it a popular choice for various applications

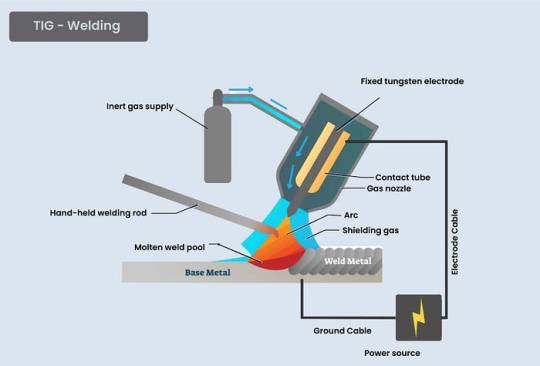

What is TIG welding?

TIG welding is done by using a non-consumable tungsten electrode. The welder manually feeds a filler rod into the weld pool, which is protected by an inert gas, usually argon. TIG welding is recognized for its precision, control, and ability to produce high-quality welds on thin materials.

Which Welding Technique Is More Suitable for Sheet Metal Welding?

The choice between MIG and TIG welding for sheet metal cutting depends on several factors, including the thickness of the metal, the required precision, and the desired finish.

– MIG Welding for Sheet Metal Welding:

MIG welding is well-suited for cutting thin sheet metals due to its high travel speed and efficiency. It is ideal for projects where speed is crucial, such as in mass-production environments. However, MIG welding may not provide the same level of precision as TIG welding, and the heat input can sometimes be a concern for thinner materials.

– TIG Welding for Sheet Metal Welding:

TIG welding is preferred for cutting thinner sheet metals when precision and a clean finish are essential. It offers excellent control over the heat input, reducing the risk of warping or distortion in the metal. TIG welding is commonly used for intricate designs and projects where aesthetics and precision are critical.

What are The Pros and cons of MIG and TIG welding in sheet metal applications?

Pros:

High welding speed, making it suitable for mass production.

Good for thicker sheet metals.

Minimal skill requirement compared to TIG welding.

Cons:

Limited precision, which may not be suitable for intricate designs.

More heat input increases the risk of warping with thin materials.

Pros:

Excellent precision and control, making it ideal for thin sheet metals.

Clean and aesthetically pleasing welds.

Low heat input, reducing the risk of distortion.

Cons:

Slower welding speed compared to MIG welding.

Requires a higher skill level.

What Factors Need to Be Consider When Selecting the Appropriate Welding Method?

Choosing the right welding method for sheet metal cutting involves considering various factors to ensure the desired outcome. Here are some key considerations:

– Material Thickness:

MIG welding is more suitable for thicker sheet metals, while TIG welding excels in precision work on thinner materials.

– Precision Requirements:

If the project demands high precision and intricate detailing, TIG welding is often the preferred choice.

– Speed and Efficiency:

MIG welding is faster and more efficient, making it suitable for projects with tight deadlines and large production volumes.

– Skill Level:

Consider the skill level of the welder, as TIG welding requires more expertise than MIG welding.

– Aesthetics:

If the appearance of the weld is crucial, such as in architectural or decorative applications, TIG welding is often preferred for its cleaner finish.

– Cost Considerations:

Evaluate the cost of equipment, consumables, and labour associated with each welding method to determine the most economical choice for the project.

Read More-https://www.lsw.co.in/choosing-the-right-technique-for-sheet-metal-welding-mig-vs-tig-welding/

#manufacturing#aviation#construction#sheet metal fabrication manufacturers#metalworking#welding services

0 notes

Text

Unveiling The Advantages Of Sheet Metal Welding In Western Sydney

Nestled in the heart of Australia, Western Sydney stands as a hub of innovation and industrial prowess. Within its vibrant landscape, sheet metal welding emerges as a crucial cornerstone of manufacturing and construction industries. The fusion of artistry and precision in this craft unlocks a myriad of benefits, propelling industries forward and contributing significantly to the region's growth and development.

Precision and Customization

Sheet metal welding serves as the backbone of precise fabrication. Western Sydney's industries benefit from its ability to craft intricate designs and shapes with unparalleled accuracy. Whether it's shaping components for aerospace, automotive, or architectural projects, welding allows for the customization of metal sheets to meet specific requirements. This precision ensures that products fit seamlessly within larger structures, enhancing functionality and aesthetic appeal.

Strength and Durability

The welds formed through sheet metal welding create robust bonds, ensuring the strength and durability of fabricated structures. From manufacturing durable machinery components to constructing resilient building frameworks, Western Sydney's industries rely on these welded sheets to withstand environmental stresses and rigorous usage. This durability minimizes maintenance costs and extends the lifespan of various products and infrastructures.

Cost Efficiency and Time Savings

The efficiency of sheet metal welding translates into significant cost savings for industries across Western Sydney. The streamlined process reduces material wastage by allowing for precise cuts and joins, thereby optimizing resource utilization. Moreover, the speed of fabrication and assembly achieved through welding expedites project timelines, enabling businesses to meet deadlines and stay competitive in the market.

Versatility in Applications

One of the standout advantages of sheet metal welding lies in its versatility. Whether it's creating intricate designs for architectural embellishments or fabricating structural components for industrial machinery, welding caters to a diverse range of applications. Western Sydney's industries benefit from this adaptability, harnessing the technique to meet the evolving demands of various sectors, thereby fostering innovation and growth.

Environmental Sustainability

In an era increasingly focused on sustainability, sheet metal welding aligns with eco-friendly practices. The precise nature of welding minimizes material wastage, reducing the environmental impact associated with manufacturing processes. Additionally, the longevity and durability of welded products contribute to a reduction in replacements and repairs, further conserving resources and minimizing carbon footprints.

Skilled Workforce and Economic Growth

Western Sydney's emphasis on skill development and training in welding techniques has created a robust workforce proficient in sheet metal welding. This skilled labor pool drives economic growth by supporting local industries and attracting investments. The presence of highly trained professionals ensures that businesses have access to expertise, fostering a conducive environment for innovation and technological advancements.

In conclusion, sheet metal welding stands as an indispensable asset for industries in Western Sydney. Its precision, strength, cost-efficiency, versatility, sustainability, and contribution to a skilled workforce collectively elevate the region's industrial landscape. As Western Sydney continues to evolve as a powerhouse of innovation and development, sheet metal welding remains a vital force driving progress across multiple sectors.

0 notes

Text

When precision, durability, and quality craftsmanship are essential, custom sheet metal work stands as the ideal solution for various residential and commercial applications. In Ontario, businesses and homeowners alike rely on professional sheet metal fabrication to create tailored solutions that meet their specific needs.

1 note

·

View note

Text

Does your project require professional welding fabrication? Select the finest services if you want accuracy, robustness, and fine craftsmanship. We provide dependable solutions that are suited to your needs, whether they are complex industrial requirements or custom designs. Put your trust in our skilled team to deliver your vision to life with our exceptional welding fabrication services! Visit us now to know more about the Best Welding Fabrication Services.

#metal skills#metal fabrication#welding engineering#steel fabrication#hardware insertion#metal programming#metal cutting#Best welding fabrication Services#new zealand#metal skills in new zealand#metal design#sheet metal fabrication

0 notes

Text

Custom Plastic Fabrication Techniques to Increase Overall Product Value

Custom plastic fabrication is the process of designing, engineering, and manufacturing plastic components or products tailored to meet specific requirements. For advanced custom plastic fabrication services solution, get in touch with Petron Thermoplast now.

Visit Website - https://petronthermoplast.com/custom-plastic-fabrication-techniques-to-increase-overall-product-value/

Contact No. - +91-8218684097

Request for Quotation - [email protected]

#fabrication #plasticfabrication #fabricationtechniques #plasticfabricationtechniques #plastictanks #plasticwelding #plastic #plastics #extrusionwelding #plasticweld

#Fabrication Services#Plastic Fabrication Services#metal fabrication services#Custom Fabrication#Custom Metal Fabrication#Custom Fabrication Service#Custom Plastic Fabrication#Custom Welding Fabrication#Custom Pipe Fabrication#Custom Sheet Fabrication#Fabrication Service Company

0 notes

Text

How to Start a Metal Fabrication Business

🔨 Want to dive into the world of metal fabrication? You're in luck! 🌟 Discover the step-by-step process to kickstart your own metalworking business on a small scale. #metalfabrication #steelfabrication #businessideas #newbusinessideas #business

Metal fabrication encompasses a range of processes that transform raw metal materials into usable components or end products. It involves cutting, bending, welding, and assembling various metals to meet specific requirements. Metal fabrication is a thriving industry in India, contributing significantly to its economic growth. In this industry, from small-scale enterprises to large manufacturing…

View On WordPress

#business ideas#garage welding business#how to start a metal fabrication business#how to start a sheet metal fabrication business#how to start a welding business#make money welding#mobile welding business#small business ideas#stainless steel fabrication business#steel fabrication business#steel fabrication business ideas#welding business#welding business ideas#welding business startup#welding shop business idea

0 notes