#sheet metal design

Explore tagged Tumblr posts

Text

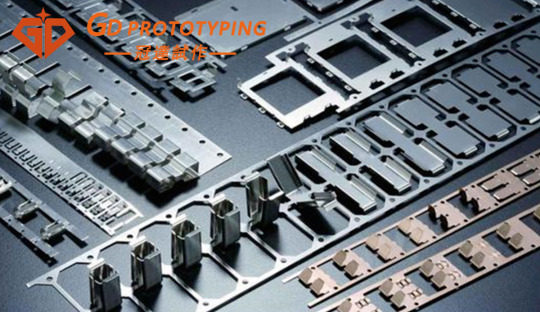

Sheet metal fabrication

#design#autos#business#prototype#prototyping#rapid prototyping#prototype machining#sheet metal services tauranga#sheet metal manufacturing#sheet metal fabrication#sheet metal work contractor financing#sheet metal design#metal machining#sheet metal bending#sheet metal stamping#sheet metal welding#sheet metal

2 notes

·

View notes

Text

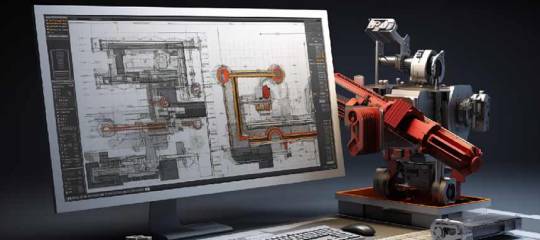

Mastering Precision Sheet Metal Fabrication: Where Art Meets Science

Precision sheet metal fabrication is the artful synergy of craftsmanship and scientific knowledge. Whether it's in the automotive industry, electronics manufacturing, or medical equipment production, precision sheet metal plays a pivotal role. In this blog post, we delve deep into the world of precision sheet metal and explore how this art and science intertwine.

Defining Precision Sheet Metal

Precision sheet metal fabrication is a highly specialized manufacturing process that encompasses various methods of cutting, bending, stamping, and welding metal sheets. The goal of these processes is to produce parts and components to exact specifications and dimensions without compromising the quality of the metal material. These parts are typically used in applications that demand high levels of precision, requiring meticulous control and inspection at every step.

Applications of Precision Sheet Metal

Precision sheet metal finds wide-ranging applications across various industries, including but not limited to:

Electronics Manufacturing: Precise enclosures, panels, and connectors are essential to ensuring the safety and stability of internal components in electronic products.

Medical Equipment: Medical devices often require highly precise components to ensure accurate measurements and operations.

Aerospace Industry: Aerospace demands lightweight, high-strength components, and precision sheet metal is key to achieving this goal.

Automotive Manufacturing: Various components in automobiles, including bodywork, chassis, and engine parts, rely on precision sheet metal fabrication.

The Craftsmanship of Precision Sheet Metal

The manufacturing process of precision sheet metal is an art that marries precision with expertise. It involves critical steps such as:

Design and Planning: Careful design and planning are necessary before commencing fabrication, ensuring accuracy and consistency.

Material Selection: Choosing the right metal material is crucial for the performance of the final product.

Cutting and Stamping: Employing cutting and stamping machinery to shape the metal sheets into the desired form.

Bending and Shaping: Utilizing bending and shaping operations to curve metal sheets into the required shapes.

Welding and Assembly: Welding individual components together to assemble the final product.

Quality Control

The essence of precision sheet metal lies in quality control. Rigorous quality control procedures and inspection methods ensure that every component meets specifications. This includes the use of high-precision measuring tools, visual inspections, and material testing.

Conclusion

Precision sheet metal fabrication is a domain where craftsmanship and scientific knowledge beautifully converge. Its wide-ranging applications, from electronics to aerospace, make it indispensable in our modern world. Through continual refinement of processes and quality control methods, precision sheet metal fabrication will continue to play a pivotal role in supporting our modern way of life and technological advancements. It's a testament to how art and science work hand in hand to create excellence in manufacturing.

#aviation#sheet metal fabrication#sheet metal manufacturing#sheet metal stamping#sheet metal design#sheet metal market#robots#robotics

8 notes

·

View notes

Text

american typewriter

2 notes

·

View notes

Text

Sheet Metal Welding

0 notes

Text

Sheet Metal Chair Designs for Auditorium Room

Creating a comfortable and aesthetically pleasing auditorium chair involves more than selecting the right materials. At Shalin Designs, we specialize in transforming client concepts into precise, manufacturable sheet metal designs, ensuring that every component is perfectly crafted. Our expertise extends from the initial design stages to the final creation of the Modeling, Drawings with Bill of Materials (BOM), and nesting dwg, making the production process seamless and efficient. In this blog, we'll explore our comprehensive approach to designing sheet metal parts for auditorium room chairs, highlighting key processes and considerations.

Designing auditorium chairs involves a blend of creativity, engineering, and precision. Shalin Designs is dedicated to providing top Sheet Metal Design Services that meet our client's exact specifications, ensuring the end product is both functional and visually appealing.

Understanding Client Requirements

The first step in our process is understanding the client's vision and requirements. This involves detailed discussions to grasp their aesthetic preferences, functional needs, and any specific constraints they might have. Our goal is to align our designs with their expectations while ensuring manufacturability.

Key Aspects We Consider:

Comfort and Ergonomics: Ensuring the chair provides adequate support and comfort for prolonged use.

Durability: Selecting materials and designs that can withstand regular use in an auditorium setting.

Aesthetics: Aligning with the overall design theme of the auditorium.

Creating Custom Sheet Metal Parts

Once we have a clear understanding of the client's requirements, we move on to the design phase. Using advanced CAD for Sheet Metal Design, we create detailed 3D models of the auditorium chair components. These models are meticulously crafted to ensure they can be efficiently manufactured using sheet metal.

Steps in the Design Process:

Initial Sketches and Concepts: Rough sketches to visualize the design and get client feedback.

3D Modeling: Creating detailed 3D models of each component, focusing on precision and fit.

Material Selection: Choosing the appropriate sheet metal materials that balance strength, weight, and cost.

BOM and Drawings Creation

A crucial part of the design process is creating the Bill of Materials (BOM) and detailed drawings. The BOM lists all the components, materials, and quantities required for manufacturing, ensuring no detail is overlooked.

Importance of BOM and Drawings:

Accuracy: Ensures that every part is accounted for and manufactured correctly.

Cost Management: Helps in estimating and controlling production costs.

Efficiency: Streamlines the manufacturing process by providing clear instructions.

Sheet Metal Nesting for CNC Machine

Nesting is the process of arranging the cut patterns on the sheet metal to minimize waste and maximize efficiency. This is particularly important in large-scale production where material costs can be significant.

Our Nesting Process:

Optimization Software: Using specialized software to arrange parts in a way that reduces waste.

Precision Cutting: Ensuring that the CNC machine cuts the parts accurately according to the nested layout.

Quality Control: Inspecting the cut parts to ensure they meet the design specifications.

Client Deliverables

Our clients receive comprehensive deliverables that facilitate the manufacturing process. This includes detailed drawings in DWG format, which can be directly used by CNC machines for cutting the sheet metal parts.

Deliverables:

DWG Files: Precise drawings for CNC cutting.

BOM: Detailed list of materials and components.

Assembly Instructions: Step-by-step guide for assembling the chair components.

Advantages of Our Approach

Choosing Shalin Designs for your auditorium chair project comes with numerous benefits:

Precision: Our detailed designs ensure that every component fits perfectly, reducing assembly time and errors.

Efficiency: Optimized nesting reduces material waste, saving costs.

Customization: Tailored designs that meet specific client requirements.

Support: Continuous support throughout the design and manufacturing process.

For a deeper understanding of the intricacies involved in sheet metal design and drawing, you can explore our detailed guide on all you need to know about sheet metal design and drawing services. This resource provides valuable insights into our design methodology, the latest industry standards, and tips for optimizing your sheet metal projects to achieve the best results.

Conclusion

Designing sheet metal parts for auditorium chairs requires a blend of creativity, technical expertise, and attention to detail. At Shalin Designs, we pride ourselves on delivering top-quality designs that meet our clients' exact specifications, ensuring their vision is brought to life with precision and efficiency. Our comprehensive approach, from initial design to final deliverables, ensures a smooth and cost-effective manufacturing process.

If you're looking for expert Custom Sheet Metal Fabrication Services for your auditorium chairs, look no further than Shalin Designs. Contact us today to discuss your project and see how our Industrial Sheet Metal Design services can help transform your ideas into reality. Our expertise in Outsourcing Sheet Metal Design Services ensures that your designs are handled with the utmost professionalism and precision.

#Auditorium Chair Designs#CAD design services#Chair Design Services#Sheet Metal Chair Design#Sheet Metal Design#Shalin Designs

0 notes

Text

"Precision Engineered Sheet Metal Pulleys: Comprehensive Catalogue for Industrial Applications"

0 notes

Text

What is the sheet metal?

Sheet metal is a flat, thin piece of metal that can be easily cut, bent, and shaped into various forms. It is produced through industrial processes that roll or extrude metal into thin, flat pieces. Sheet metal can be made from various metals, including steel, aluminum, brass, copper, tin, nickel, and titanium. Each type has its own properties and is selected based on the specific requirements of the application.

The thickness of sheet metal is commonly specified in gauges, with a lower gauge number indicating thicker metal. For example, 10-gauge sheet metal is thicker than 20-gauge sheet metal. In some cases, thickness is also measured in millimeters or inches.

Sheet metal is used in a wide range of applications, including automotive bodies and parts, airplane fuselages and wings, refrigerators, washing machines, and architectural elements such as (roofing, siding, ducts).

#science#materials science#engineering#materials#materials science and engineering#sheet metal fabrication#sheet metal manufacturing#sheet metal design#sheet metal

0 notes

Text

The Versatility of Sheet Steel Work in Modern Construction

Sheet steel work has become a cornerstone in modern construction, owing to its versatility, strength, and durability. The adaptability of sheet steel makes it an ideal choice for various applications, from building frameworks to intricate architectural details. Let’s delve into the multifaceted world of sheet steel work and understand its pivotal role in contemporary construction.

What is Sheet Steel Work?

Sheet steel work involves the manipulation of steel sheets into different shapes and sizes for use in construction and manufacturing. These steel sheets are typically fabricated through processes like cutting, bending, and welding, allowing for precise and customised applications. The inherent strength of steel, combined with its flexibility, makes it a preferred material for both structural and aesthetic purposes.

Applications in Construction

Structural Components: One of the primary uses of sheet steel is in the construction of structural components. Steel sheets are used to create beams, columns, and girders that form the skeleton of buildings and bridges. The high tensile strength of steel ensures that these structures are robust and can withstand substantial loads.

Cladding and Roofing: Sheet steel is extensively used for cladding and roofing due to its weather-resistant properties. Steel sheets can be coated with various finishes to enhance their resistance to corrosion and provide an attractive appearance. This makes them suitable for both industrial and residential buildings.

Architectural Details: The malleability of sheet steel allows architects to design intricate details that add aesthetic value to buildings. From decorative facades to customised fittings, sheet steel can be shaped into virtually any form, offering endless design possibilities.

HVAC Systems: Sheet steel work is also crucial in the fabrication of HVAC (Heating, Ventilation, and Air Conditioning) systems. Ductwork made from steel sheets ensures efficient airflow and longevity, making it a reliable choice for both commercial and residential applications.

Advantages of Using Sheet Steel

Durability: Steel is one of the most durable materials available, offering a long lifespan with minimal maintenance. This durability translates into cost savings over the long term, as structures require fewer repairs and replacements.

Sustainability: Steel is 100% recyclable, making it an environmentally friendly choice. Using recycled steel in construction reduces the demand for virgin materials and lowers the overall environmental impact of building projects.

Strength-to-Weight Ratio: Steel has a high strength-to-weight ratio, meaning it can support large loads without being excessively heavy. This is particularly beneficial in high-rise buildings and bridges, where weight is a critical consideration.

Conclusion

Sheet steel work is an indispensable component of modern construction, providing the necessary strength, flexibility, and aesthetic appeal required in today's architectural projects. Whether for structural support, decorative elements, or functional components, sheet steel continues to prove its worth in various applications. As construction techniques and technologies evolve, the role of sheet steel is set to become even more significant, paving the way for innovative and sustainable building solutions.

0 notes

Text

Master the art of sheet metal design! This guide explores 10 expert tips for optimizing and improving your sheet metal drafting and modeling techniques, ensuring precision and efficiency in your designs. Learn effective strategies for documentation, grain direction, material selection, and more.

#Sheet Metal Design#Sheet Metal Modeling#Sheet Metal Drafting#3D CAD Modeling#Material Selection#Grain Direction

0 notes

Video

youtube

Sheet Metal Production Machine In India Factory

sheet metal, sheet metal manufacturer, sheet metal supplier, sheet metal machine, Sheet metal enclosure roll forming machine manufacturer.

#youtube#sheet metal#metal sheet#sheet metal drawing#sheet metal design#sheet metal box supplier#sheet metal manufacturer China

0 notes

Text

What is Sheet Metal Fabrication? Processing Principle and Method

Sheet metal fabrication refers to the processing of sheet metal (usually under 6mm) by shearing, bending, forming, stamping, welding, stretching and other processes.

A broad definition is that the thickness is unchanged in the processing of parts.

1.Processing Principle of Sheet Metal Working

The processing principle of sheet metal working is mainly based on the plastic deformation properties of metal materials. Through the action of external forces, such as stretching, compressing, bending, etc., the shape and size of the sheet metal is changed to achieve the desired shape and structural requirements. This process requires precise calculation and control of the magnitude, direction and point of action of the force to ensure that the sheet metal does not suffer from rupture, folds and other defects during deformation.

2.Processing Method of Sheet Metal Working

Do you know what are the common processing methods for sheet metal fabrication? The following several commonly used processing methods are introduced:

① Single stamping

Metal parts of musical instrument with curved distribution or in the state of pinholes, grids, etc. can be sheet-metal processed by a single stamping, which makes it possible to separate the metal structure and shape the metal product in a short period of time.

② Continuous feeding

This sheet metal processing method can be divided into two types: unidirectional and multidirectional. Of these, the multi-directional blanking method is usually suitable for processing large metal layers or forming large metal holes, while the unidirectional blanking method is suitable for processing multiple metal parts in a stacked state. Different processing results can be achieved by setting different machine angles and functions in the continuous blanking processing mode.

③ Punching material processing

This drop-feed processing method, also known as punch processing, is mainly used to polish and finish the post-processing of sheet metal working parts, which plays a role in precise positioning and fine grinding during sheet metal processing. Usually the processing mill used in this process has small round type, small arc type, etc.

④ Array formation

With the help of CNC machines, this method is often used to meet the needs of mass production sheet metal working. Large sheet metal products can be processed quickly by combining several existing moulds. In this process, the styles and types of sheet metal working products are basically the same, which facilitates the design of templates in the form of arrays.

⑤ Single or multiple continuous processing

On the basis of CNC machine tools, the metal parts to be processed are stretch-formed in a single operation according to the requirements for the selection of the moulds, thus obtaining metal parts that match the existing moulds. However, if the metal part after the above treatment does not meet the desired requirements, it should be machined several times in succession to form the final shape.

Sheet metal fabrication is used in a wide range of applications including but not limited to aerospace, automotive manufacturing, construction, petrochemical, aviation, electronics, electrical appliances and other fields. In addition, sheet metal processes play an important role in vehicle maintenance and repair which are widely used for body damage analysis, measurement, shaping, tensile straightening, stress relief welding, accessory assembly and adjustment.

#sheet metal bending#design#sheet metal design#sheet metal manufacturing#sheet metal fabrication#sheet metal#prototype machining#prototyping#prototype#rapid prototyping

1 note

·

View note

Text

0 notes

Text

#3d art#3d printing#rapidprototyping#sheet metal design#sheet metal parts#manufacturing#prototype#silicon#3dmodel#scans#3d scanning services

0 notes

Text

Sheet Metal Bending Surface Treatment

0 notes

Text

Sheet Metal Drawing Services and Sheet Metal Shop Drawings Service

Shalin Design, a premier metal design services company, specializes in sheet metal design and drawing services for contractors, fabricators, and engineers.

#Sheet Metal Design and drawing Services#sheet metal design#sheet metal design services#sheet drawing services#Shalin Designs

0 notes

Text

Sheet Metal Fabrication

Santech Sheet Metal exceeds standards with quality sheet metal fabrication solutions. We produce custom-made metal components with immaculate quality and quick turnaround times using cutting-edge equipment and a competent crew. Trust us with your sheet metal needs and you will see the highest level of craftsmanship and dependability in every project.

#display racks#display racks manufacturers#retail display racks#supermarket display racks#santech sheet metal#sheet metal fabrication#sheet metal manufacturing#sheet metal design

0 notes