#sheet metal manufacturer China

Explore tagged Tumblr posts

Video

youtube

Sheet Metal Production Machine In India Factory

sheet metal, sheet metal manufacturer, sheet metal supplier, sheet metal machine, Sheet metal enclosure roll forming machine manufacturer.

#youtube#sheet metal#metal sheet#sheet metal drawing#sheet metal design#sheet metal box supplier#sheet metal manufacturer China

0 notes

Text

Innovate Faster with China Rapid Prototypes - Sanwo Rapid

Sanwo Rapid is your trusted partner for China rapid prototype, accelerating your product development process. Our cutting-edge technologies and expert team ensure precise and efficient prototyping. explore our rapid prototype services and bring your ideas to life with speed and precision.

0 notes

Text

Revolutionizing Motorcycle Manufacturing with CNC Machining

Introduction In the world of motorcycle manufacturing, precision, efficiency, and innovation are key factors that drive the industry forward. Over the years, the advent of CNC machining has brought about a revolution in the manufacturing processes, allowing for the creation of high-quality motorcycles with intricate designs and superior performance. This blog post explores the intersection of CNC machining and motorcycle manufacturing, with a particular focus on China's prototype manufacturing prowess and the growing popularity of online CNC machining services, including sheet metal processing.

The Rise of CNC Motorcycle Manufacturing The integration of CNC machining technology in motorcycle manufacturing has significantly transformed the industry. CNC (Computer Numerical Control) machines offer unparalleled precision, repeatability, and speed in creating complex components, frames, and other motorcycle parts. These machines utilize computer-aided design (CAD) software to precisely control the movements of cutting tools, resulting in highly accurate and consistent production.

China Prototype Manufacturing Dominance China has emerged as a dominant player in the global motorcycle manufacturing industry, leveraging its expertise in prototype production. The country's prototype manufacturing capabilities, coupled with the widespread adoption of CNC machining, have fueled the growth of the motorcycle industry. Chinese manufacturers have harnessed the power of CNC machines to produce motorcycle prototypes quickly and cost-effectively, allowing for rapid design iterations and faster time-to-market.

Online CNC Machining Services In recent years, the rise of online CNC machining services has further revolutionized motorcycle manufacturing. These services provide a convenient platform for motorcycle manufacturers to access high-quality CNC machining capabilities without the need for significant upfront investments in expensive machinery. With just a few clicks, manufacturers can upload their design files and specifications to online platforms and experienced CNC machining service providers take care of the rest.

The advantages of online CNC machining services extend beyond cost savings. They offer a vast range of machining options, including 3-axis, 4-axis, and 5-axis CNC milling, turning, and sheet metal processing services. Motorcycle manufacturers can choose the most suitable machining processes for their specific needs, ensuring the highest precision and quality in the final products.

Sheet Metal Processing Services Sheet metal processing plays a vital role in motorcycle manufacturing, as it involves shaping and forming thin metal sheets to create various components and structures. CNC machines equipped with specialized sheet metal processing capabilities enable precise cutting, bending, and welding, resulting in components that fit together seamlessly. Online CNC machining services often provide comprehensive sheet metal processing services, offering manufacturers a one-stop solution for their motorcycle production needs.

Conclusion CNC machining has become an indispensable tool in the motorcycle manufacturing industry, enabling precise and efficient production processes. China's prototype manufacturing expertise, combined with the rise of online CNC machining services, has further accelerated the pace of innovation and cost-effective production. Motorcycle manufacturers can leverage these advancements to bring their designs to life with exceptional accuracy and quality. As the industry continues to evolve, the integration of CNC machining and sheet metal processing services will play a crucial role in shaping the motorcycles of the future.

By embracing CNC machining and taking advantage of the convenience and versatility offered by online CNC machining services, motorcycle manufacturers can stay at the forefront of the industry, delivering cutting-edge designs and superior performance to motorcycle enthusiasts worldwide.

#cnc motorcycle#china prototype manufacturing#Online CNC Machining Services#Sheet Metal Processing Services

0 notes

Text

Exploring the Art and Science of Sheet metal stamping

In the industrial process known as sheet metal stamping, metal sheets are formed, cut, and shaped into the necessary shapes. The procedure is normally carried out with the aid of a stamping press, which uses mechanical pressure to shape raw materials into finished goods using a sequence of dies and punches. Let’s break the procedure down into its essential steps: Tooling and Design…

View On WordPress

#Metal Stamping China#Metal Stamping Manufacturer#Metal Stamping supplier#Precision Metal Stamping#Sheet metal stamping

0 notes

Text

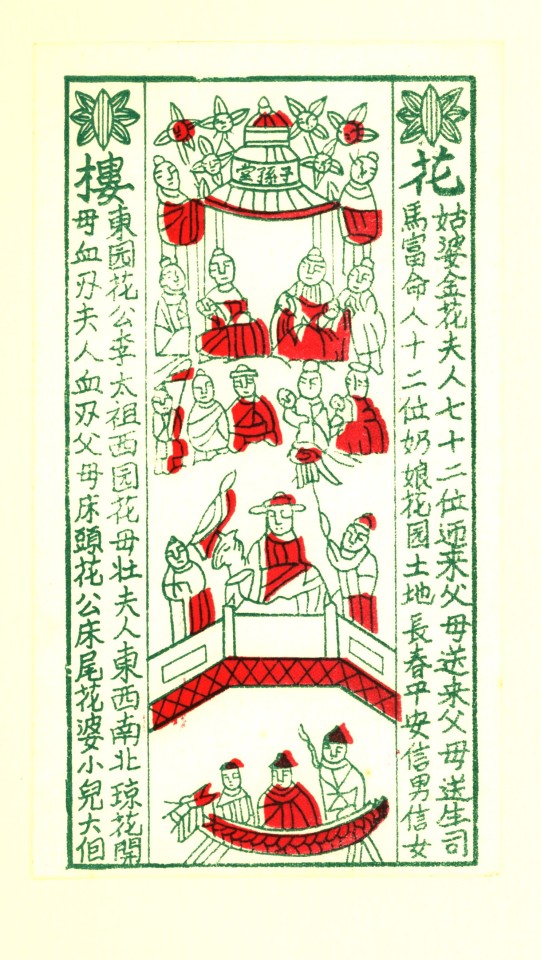

Chinese Ceremonial Papers

Many hundreds of varieties of prayer sheets used to be produced by specialist ma-chang printers all over China. Many of the limited range made today are the cheapest offset-litho jobs on the cheapest machine-made papers, but the designs still imitate the original woodblock prints.

Modern Taiwanese sheets of cash, made from recycled paper, sold very cheaply by weight in Taipei.

Mock money and other ceremonial papers for religious ceremonies will be gathered in "bowls" of crude papers, usually made of a mixture of rice-straw and bamboo fibers.

The simplest form of mock money is made traditionally with thin layers of tinfoil affixed to the center of a small piece of bamboo paper, although in contemporary production the cheapest grades of machine-made paper will be used instead, and in Taiwan and Malaysia metallic inks may be used instead of tinfoil.

Here's a piece of mock money in traditional colors with auspicious designs, and tinfoil brushed over with a dye from the pagoda tree to make it resemble gold.

Contemporary Taiwanese ceremonial paper.

Another variety of gold mock money, with inscriptions and symbols for good fortune building up the design, usually still quite well printed from woodblocks on fairly good quality paper, but sometimes now mass-produced by offset lithography.

Contemporary ceremonial paper printed letterpress on a stout machine-made paper in Hong Kong. The yellow coloring might have been brushed on by hand, but otherwise production of these attractive sheets has been mechanized completely.

At the Feast of Hungry Ghosts many large sheets of paper with pictures of all the clothes one's ancestor could need are burned. Although images of the paraphernalia of modern life like cell phones and computers might be printed on these papers, the clothing is always of traditional style.

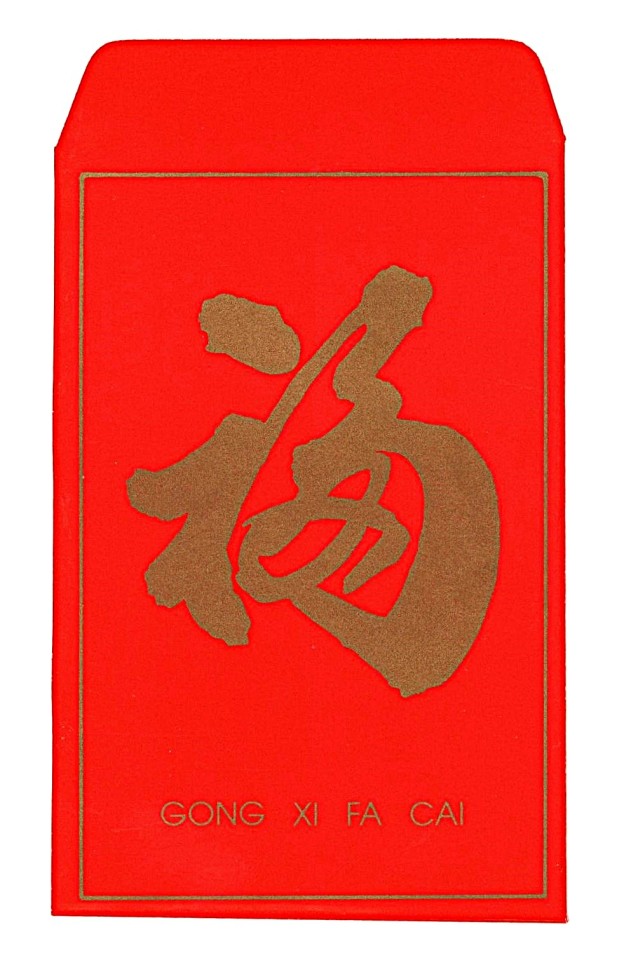

Red paper envelopes with good luck symbols have been used for many years to enclose gifts of money made at New Year. They may be found wherever any ceremonial papers are sold; today usually with elaborate and eye-catching gold-stamping.

Decorative Sunday

The examples shown here are original paper samples included in Roderick Cave's (1935-2019) two-part article on "Ceremonial Papers of the Chinese" published in Matrix 12 (Winter 1992, pp. 51-66) and Matrix 13 (Winter 1993, pp. 161-177), printed at the John and Rosalind Randle’s Whittington Press in Risbury, Herefordshire, England.

In these articles, Cave, a noted print historian, librarian, and educator, discusses the history, manufacturing, printing, distribution, and uses of Chinese ceremonial papers used in rituals, celebrations, and festivals associated with the gods and the ancestors.

Our copies of Matrix are a donation from our friend Jerry Buff.

View more posts on Chinese papers.

View other posts associated with Roderick Cave.

View more Decorative Sunday posts.

#Decorative Sunday#Matrix 12#Matrix 13#Matrix#Whittington Press#Decorative Paper#Chinese ceremonial papers#ceremonial papers#Roderick Cave#Ceremonial Papers of the Chinese#John and Rosalind Randle#decorative arts#Jerry Buff

103 notes

·

View notes

Text

Guaranteed low price Dx51d Dx52d Dx66d galvanized steel coil

Galvanized steel coil is a specially treated steel product whose production process includes a number of fine steps. First, the raw material is all-hard board, which requires a pickling process to remove surface impurities and oxide layers, and then a rolling process to achieve the desired thickness and smoothness. The sheets are then fed into a zinc pan, where they are coated with a uniform and continuous zinc film. This layer of zinc film can not only effectively isolate the direct contact between the air and the substrate, thus greatly enhancing the corrosion resistance of the material; At the same time, because the zinc itself has good plasticity and ductility, the galvanized steel plate also has better processing and forming ability and good coating adhesion.

Hot-dip galvanizing technology is one of the most widely used methods for surface protection of steel products, which takes advantage of the unique electrochemical properties of zinc - when zinc is used as a sacrificial anode, it can be preferentially corroded by oxidation over iron, thereby protecting the internal base metal from damage. This method is especially suitable for those components or equipment that need to be exposed to the outside environment for a long time, such as building structures, Bridges, highway guardrails, etc.

According to the requirements of different application scenarios, the manufacturer can also adjust the specific thickness range of the galvanized layer, which can usually reach a maximum of about 120 grams per square meter. In addition, in cases where the appearance quality of the final product is required to be high, additional polishing treatment can also be selected to obtain a smoother and more delicate surface effect. According to whether such a follow-up processing process is carried out, the common galvanized steel coil on the market can be divided into two categories: zero spot type (that is, no additional treatment is done) and ultra-smooth type.

Our advantage

01. Advanced equipment: We have three production lines, all equipped with the most advanced production equipment in China. These devices not only improve production efficiency, but also ensure the quality and consistency of the product. Our factory covers an area of 30,000 square meters, and spacious production workshops provide ample space for large-scale production.

02. High-quality raw materials: We always adhere to the selection of high-quality raw materials, from the source to ensure the quality of products. We have established long-term and stable cooperation with many well-known suppliers to ensure that the quality of raw materials is reliable and meets international standards.

03. Strict quality inspection: We implement strict quality inspection standards, and strictly monitor and test every production link. Our products comply with ISO and SGS international standards, ensuring that every product can meet 100% of customer requirements.

04. Fast delivery: We use advanced production management processes, from order receipt to production arrangement to product delivery, the entire process is efficient and fast. Our goal is to complete customers' orders in the shortest possible time to ensure that customers receive satisfactory products in a timely manner.

05. Professional Sales services: We have a professional sales team who are fluent in Spanish, Portuguese, French, Arabic and Russian. This enables us to better communicate and cooperate with customers in different countries and regions, and provide customers with more intimate and professional services.

2 notes

·

View notes

Text

Brazil launches China anti-dumping probes after imports soar

Brazil’s industry ministry has launched a number of investigations into the alleged dumping of industrial products by China as Latin America’s largest economy reels from a wave of cheap imported goods.

At the request of industry bodies, the ministry has in the past six months opened at least half a dozen probes on products ranging from metal sheets and pre-painted steel to chemicals and tyres.

The Brazilian measures come at a time when the world is bracing for a flood of exports from China as the world’s second-largest economy struggles with excess capacity amid a property sector slowdown and weak domestic demand.

To stimulate its economy, China is investing in advanced manufacturing, especially in solar energy, electric vehicles and batteries.

Continue reading.

#brazil#brazilian politics#politics#china#economy#foreign policy#image description in alt#mod nise da silveira

4 notes

·

View notes

Text

2 notes

·

View notes

Text

Titanium Metal - Qualities As Well As Uses

Pure titanium is a light-weight, tough, silvery-white, shiny metal. It has unique strength as well as deterioration resistance homes and also a high stamina to weight proportion.

The name Titanium itself is stemmed from the name of God of planet 'Titan" in Greek folklore. The name implies stamina.

Titanium is a chemical element with the sign Ti. It has an atomic number of 22, inhabits team 4, duration 4, and also block d in the periodic table and is classified as a transition steel.

Titanium is the 9th most abundant element in the Planet's crust but is by no means discovered it its pure kind. Its major minerals are anatase, brookite, ilmenite, perovskite, rutile, titanite, too lots of iron ores. Rutile as well as ilmenite are its economically important minerals.

Considerable deposits of ilmenite are found in Western Australia, Canada, China, India, Mozambique, New Zealand, Norway, as well as Ukraine. Substantial amounts of rutile are mined in The United States and Canada and South Africa.

Titanium Tube

One of the most considerable residential properties of Titanium are its strength, its resistance to rust as well as it stamina to weight proportion.

Titanium is 45% lighter than steel but it is just as strong. It is only 60% heavier than aluminium but is 100% more powerful.

Titanium is basically as immune to rust as platinum, and can holding up against acids, salt services, as well as also the extremely destructive chlorine gas.

The humane blend of light weight as well as wonderful stamina in addition to its resistance to rust and also warmth makes it ideal for airplane, spacecrafts projectiles and so on. In sports it is used for making light as well as solid noises, bicycle frameworks, golf clubs etc. Titanium likewise discovers use in making eyewear structures, light-weight laptops, bone and oral implants in medicine.

Titanium vanadium alloys are extensively made use of in aviation in the manufacture of landing gear, hydraulic tubing, fire walls, etc.

Yet probably the really business and also mass intake oriented use of titanium began with the crafting of titanium jewelry as well as today Titanium precious jewelry industry is amongst the fastest growing market sector in fashion jewelry industries.

Titanium is honored with almost all the high qualities important to become an appropriate medium for crafting precious jewelry. It is solid and long lasting, it is immune to rust, and it is hypoallergenic significance that it does not established off allergies with the skin.

A gorgeous, putty-grey shade differentiates titanium from the silver, gold as well as platinum used in jewelry. With different types of gloss it can be given either a matte or a glossy coating.

Titanium Sheet

The setting of Titanium in the periodic table (team 4, period 4, and also block d) identifies it as a change metal. Among the common residential or commercial properties shared by all change steels is that they are able to develop colored substances primarily by anodizing. The process entails producing oxide layers of different density and refractive residential properties on the steel surface. This characteristic is used for crafting titanium precious jewelry in practically every shade of the rainbow.

Titanium is utilized for crafting precious jewelry items like jewelry, pendants, bracelets, rings, wedding bands, money clips and so on.

The metal is frequently viewed as an icon of toughness as well as indestructibility and also this has made titanium wedding bands a preferred option for pairs that desire their marriages to continue to be as strong as well as indestructible.

There is a particular magical top quality concerning titanium as well as it seems specifically appropriate that titanium (before it was so named) was found by a male of God-Reverend William Gregor-in Cornwall, England, back in 1790. It is likewise proper that 5 years later the metal was in fact called titanium, after the Titans, the Greek gods of planet by the German chemist Martin Heinrich Klaproth.

2 notes

·

View notes

Text

The Global Market for Plate Rolling Machines: Trends and Predictions

Have you ever wondered how those massive metal sheets used in buildings, ships, and machinery are shaped? It's not magic—it's the work of powerful plate rolling machines. These machines are the backbone of many industries, transforming flat metal sheets into cylinders, cones, and other shapes.

But what does the future hold for this essential piece of equipment? Let's dive into the global trends and predictions for the plate rolling machine market, with insights from Himalaya Machinery, a leading heavy engineering company in India.

What is a Plate Rolling Machine?

A plate rolling machine is a mechanical device used to roll metal sheets into curved shapes. Whether it's for creating pipes, tanks, or structural components, these machines play a critical role in manufacturing. They come in various sizes and configurations to handle different materials and thicknesses.

Types of Plate Rolling Machines

Understanding the different rolling types is crucial:

2-Roll Plate Rolling Machines

These are simple and best suited for thinner materials.

3-Roll Plate Rolling Machines

The most common type, ideal for a wide range of thicknesses and materials. They use three rollers to shape the metal.

4-Roll Plate Rolling Machines

These machines offer greater precision and control, especially for complex shapes. They are preferred for thicker and harder materials.

Understanding the Rolling Process

The rolling process involves feeding a flat sheet of metal into the machine, where rollers apply pressure to bend it into the desired shape. It's akin to rolling out dough with a rolling pin—the more pressure applied, the thinner and more curved the dough becomes.

Key Players in the Market

Companies like Himalaya Machinery. a leading heavy engineering company in India is at the forefront of this industry. Known for their innovative solutions and robust machines, they cater to various industries, including construction, automotive, and shipbuilding.

Market Trends and Growth Drivers

Increasing Demand in Construction

The booming construction industry, particularly in emerging economies, is driving the demand for plate rolling machines.

Automation and Efficiency

The shift towards automated and more efficient machines is another key trend. Companies are looking for ways to reduce labor costs and increase productivity.

Regional Market Analysis

Asia-Pacific

This region, especially countries like China and India, is experiencing significant growth due to industrialization and infrastructure development.

Europe and North America

These mature markets focus on technological advancements and replacing old machinery with more efficient models.

Innovations and Technological Advancements

The industry is witnessing several innovations, such as:

Advanced Control Systems: For better precision and ease of use.

Energy-Efficient Machines: To reduce operational costs and environmental impact.

Rolling Machine Safety Precautions

Working with heavy machinery always comes with risks. Here are some crucial safety precautions:

Regular Maintenance: Ensures the machine operates smoothly and reduces the risk of accidents.

Proper Training: Operators must be well-trained to handle the machine safely.

Safety Gear: Always wear appropriate protective equipment, like gloves and safety glasses.

Challenges Facing the Industry

High Initial Investment

The cost of purchasing and installing plate rolling machines can be a barrier for small to medium-sized enterprises.

Skilled Labor Shortage

As machines become more advanced, there's a growing need for skilled operators who can handle complex systems.

Future Predictions for the Plate Rolling Machine Market

The future looks promising, with several predictions:

Increased Automation: Expect more fully automated machines that require minimal human intervention.

Sustainability: Eco-friendly machines that consume less energy and produce less waste will be in demand.

Impact of Himalaya Machinery

Himalaya Machinery is making waves in the industry with their state-of-the-art machines. Their commitment to innovation and customer satisfaction has positioned them as a leader in the global market.

Rolling Capacity and its Importance

Rolling capacity refers to the maximum thickness and width a machine can handle. It's a critical factor in selecting the right machine for your needs. A higher rolling capacity means the machine can work with thicker and larger sheets of metal, which is essential for heavy-duty applications.

The Role of Plate Rolling in Manufacturing

The metal rolling process is indispensable in manufacturing, providing the flexibility to create various shapes and components. From automotive parts to industrial machinery, plate rolling is a foundational process that supports countless industries.

Conclusion

The global market for plate rolling machines is on a robust growth trajectory, driven by technological advancements and increasing demand from various sectors. Companies like Himalaya Machinery are leading the charge, offering innovative solutions that meet the evolving needs of the industry. As we look to the future, automation, sustainability, and efficiency will be key drivers shaping the market.

0 notes

Text

Faster your business to market with Kusla rapid manufacturing services

Rapid Prototyping & low volume Manufacturing Service

Machining and Molding For Plastic & Metal Parts

ISO 9001:2015 Certified Factory

Request A Quote

About Us

Kusla, established in 2013, is a rapid prototyping & rapid Manufacturing company based in Suzhou, China.

We have the most advanced machines and the best engineers to provide you with unparalleled rapid prototyping and manufacturing services.

We can offer you plastic and metal prototyping services and low-volume manufacturing utilizing CNC machining, 3D Printing, Sheet Metal Fabrication, Urethane Casting, Injection Molding, and Diamond turning.

0 notes

Text

Unraveling the Art of Rapid Injection Molding | Sanworapid

Discover the dynamic world of Rapid Injection Molding, where speed and precision converge to revolutionize product development. This comprehensive guide delves into the ingenious techniques and cutting-edge technologies that empower businesses to bring their ideas to life faster than ever before. Unravel the secrets behind rapid prototyping, cost-effectiveness, and production efficiency, as we navigate through the intricacies of this transformative manufacturing process.

#rapid injection molding#china rapid prototype#aluminum prototype#sheet metal prototyping#cnc prototyping#rapid manufacturing#prototype machining#vacuum casting

0 notes

Text

China Emerges as a Powerhouse in CNC and Die Casting Industries

Online Platforms Revolutionize CNC Precision Machining, Milling, Turning, and Sheet Metal Fabrication

Date: September 16, 2023

China is making significant strides in the CNC and die casting industries, solidifying its position as a key global player. Leveraging the power of online platforms, CNC precision machining, milling, turning, and custom sheet metal fabrication services have become more accessible to customers worldwide.

Within China die casting, the die casting market has experienced remarkable growth, supported by a robust manufacturing ecosystem, skilled labor, and favorable government policies. Chinese die casting companies have successfully served both domestic and international markets, with industries such as automotive, aerospace, and electronics relying on their top-quality components.

Simultaneously, the online CNC wood milling services market has witnessed a surge in demand, revolutionizing the way individuals and businesses access wood CNC services. Online platforms have simplified the process, offering convenience and efficiency to furniture makers, interior designers, and hobbyists seeking wood cutting, carving, and engraving solutions.

The rise of online CNC precision machining services has transformed the manufacturing landscape. Customers can now effortlessly upload design files and connect with CNC machining service providers through digital platforms. This technology-driven approach ensures accuracy, repeatability, and cost-effectiveness across industries such as automotive, aerospace, medical, and electronics.

In tandem, CNC milling service manufacturers are embracing the online marketplace. Equipped with advanced milling machines, software, and tooling, these companies provide a range of valuable services, including prototyping, production runs, and complex part machining. Online platforms facilitate seamless connections between customers and reliable CNC milling service providers, streamlining the manufacturing process.

Similarly, online platforms have simplified the search for CNC turning services, a crucial aspect of precision manufacturing. CNC turning involves the rotation of a workpiece while a cutting tool shapes it into the desired form. With the aid of online platforms, customers can easily connect with CNC turning service providers, catering to industries such as automotive, aerospace, and energy.

The custom sheet metal fabrication industry, vital to various sectors, has also embraced online platforms. This industry encompasses cutting, bending, welding, and assembly of sheet metal components. Online platforms enable efficient collaboration between customers and sheet metal fabrication shops, allowing customers to request quotes and actively participate in the design process.

The expansion of online services has opened up new growth opportunities in the CNC and die casting industries. Advancements in automation, machine technology, and the rising demand for customized products are driving this upward trend. However, market players must navigate challenges such as intense competition, rising raw material costs, and the need for skilled labor.

As China strengthens its position in the CNC and die casting sectors, the integration of advanced technologies and online platforms will play a crucial role. Manufacturers and service providers that embrace innovation, invest in modern machinery, and adapt to evolving customer requirements are poised to thrive in this competitive landscape.

#china die casting#CNC wood milling services#Online CNC Precision Machining#CNC Milling Service Manufacturer#CNC Turning Services#Custom Sheet Metal Fabrication

0 notes

Text

Neodymium Foil Market: Innovations in Magnetic Materials up to 2033

Market Definition

The Neodymium Foil Market encompasses thin sheets of neodymium, a rare-earth metal known for its high magnetic strength and applications in various advanced technologies. Neodymium foil is used in sectors such as electronics, renewable energy, and advanced manufacturing, where its unique properties, like excellent magnetic capabilities and high thermal stability, are crucial. The market caters to applications in permanent magnets, laser systems, sensors, and other high-tech equipment.

To Know More @ https://www.globalinsightservices.com/reports/neodymium-foil-market

The neodymium foil market is anticipated to expand from $0.45 billion in 2023 to $0.75 billion by 2033, with a CAGR of 5.2%, reflecting robust growth.

Market Outlook

The Neodymium Foil Market is projected to experience growth driven by increasing demand across multiple high-tech industries. The rise in electric vehicles (EVs) and renewable energy projects, such as wind power, has significantly increased the need for neodymium-based permanent magnets. These magnets are essential components in electric motors and wind turbines, where neodymium foil plays a critical role in enhancing magnetic strength and efficiency.

The consumer electronics sector is also contributing to the market’s expansion. Devices such as smartphones, laptops, and headphones rely on neodymium-based components for better sound quality and performance. With the ongoing advancements in electronic gadgets, the demand for neodymium foil is expected to remain strong. Additionally, the growth of the laser technology market, particularly in applications like precision machining and medical devices, is providing further impetus for neodymium foil adoption.

Technological advancements in neodymium foil production, such as improved manufacturing techniques for enhanced material purity and thickness control, are driving market innovation. Manufacturers are focusing on developing higher-quality foils with better magnetic properties and resistance to corrosion, which are vital for ensuring long-term performance in demanding environments.

Despite the positive market outlook, the Neodymium Foil Market faces challenges. The high cost of rare-earth metals, coupled with supply chain vulnerabilities due to geopolitical factors, poses a significant risk to market stability. The dependence on a limited number of countries for rare-earth metal supply, particularly China, raises concerns about resource availability and price volatility. Environmental regulations related to rare-earth metal mining and processing also present challenges to market growth.

However, opportunities are emerging as countries and companies invest in diversifying the supply chain for rare-earth elements and developing recycling technologies. Initiatives to increase domestic production and improve the efficiency of neodymium recycling are gaining momentum, which could help mitigate supply risks. Additionally, advancements in material science are opening new avenues for the application of neodymium foil, particularly in emerging technologies like 5G networks and space exploration.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS31630

0 notes

Text

Screw Suppliers in India: Building a Global Reputation

India has emerged as a significant player in the global screw manufacturing and supply industry, thanks to its skilled workforce, advanced production technologies, and competitive pricing. Indian screw suppliers cater to a wide range of industries, including automotive, construction, electronics, and aerospace, offering products that meet international quality standards. With a focus on precision engineering, durability, and customization, Indian suppliers have earned the trust of clients worldwide. Government initiatives like Make in India and incentives for exports have further fueled the sector’s growth. By adopting sustainable practices and embracing innovation, Indian screw suppliers are solidifying their position in global markets, proving themselves as reliable partners for industrial and commercial needs.

Why Choose Indian Screw Suppliers?

Screw suppliers in India offer a wide range of fasteners that cater to industries like automotive, construction, electronics, and machinery. Known for their cost efficiency, Indian suppliers leverage local raw materials and skilled labor to provide high-quality screws at competitive prices. Additionally, Indian suppliers are adapting to global standards with ISO-certified manufacturing processes, making them a preferred choice for domestic and international clients.

Types of Screws Offered by Indian Suppliers

Machine Screws: Commonly used in industrial applications.

Wood Screws: Ideal for carpentry and woodworking.

Self-Tapping Screws: For sheet metal and plastic.

Hex Screws: Designed for heavy-duty machinery.

Specialty Screws: Custom-designed screws tailored for specific industries.

This diversity ensures Indian suppliers can meet the needs of various sectors, making them versatile and reliable partners.

Regions Leading Screw Supply in India

Ludhiana: Known as a hub for fastener manufacturing, producing high-quality screws and bolts.

Pune and Mumbai: Emerging as centers for automotive fasteners.

Delhi-NCR: Specializes in industrial and construction fasteners.

Chennai and Bengaluru: Key exporters of precision screws for the technology and electronics industries.

These regions not only cater to domestic markets but also serve as significant exporters to countries across Europe, the Americas, and the Middle East.

Technological Advancements in Screw Manufacturing and Supply

CNC Machining: For high precision and uniformity.

Heat Treatment: Ensuring screws meet strength and durability standards.

Surface Coating Techniques: Providing corrosion resistance and enhanced aesthetics.

Automation: Improving efficiency and reducing lead times.

By integrating these technologies, Indian suppliers ensure their products meet international standards, catering to diverse industrial requirements.

Challenges Faced by Screw Suppliers in India

Rising Raw Material Costs: Fluctuations in steel prices directly impact production costs.

Global Competition: Competing with countries like China, which dominate the fastener market.

Skilled Labor Shortage: The need for a workforce trained in advanced manufacturing techniques.

Logistical Barriers: Delays in supply chains affecting delivery schedules.

Addressing these issues through innovation and government support is essential for the industry's sustained growth.

Opportunities for Screw Suppliers in India

The increasing demand for screws in industries like renewable energy, aerospace, and infrastructure development offers significant opportunities. Government initiatives like Make in India and the focus on local sourcing present further growth avenues. Additionally, the rising preference for sustainable and recyclable materials opens doors for eco-friendly screw production.

Export markets also provide tremendous potential. With India gaining recognition for its quality products, suppliers can expand their reach globally, especially in regions seeking cost-effective alternatives to European and Chinese manufacturers.

How to Choose the Best Screw Supplier in India?

Certifications and Standards Compliance: Look for suppliers adhering to ISO and other international standards.

Product Range: Ensure the supplier offers screws suited to your industry’s specific needs.

Customization Options: Check if they can design and produce specialty screws.

Reputation and Experience: Research reviews and track records of suppliers.

Delivery Timelines and Logistics: Ensure they can meet your deadlines efficiently.

A thorough evaluation will help you identify a reliable partner for your screw requirements.

Conclusion

Screw suppliers in India are becoming global leaders due to their ability to provide high-quality, cost-effective solutions across industries. With advancements in technology, increasing demand from domestic and export markets, and support from government policies, the industry is poised for significant growth. However, overcoming challenges like raw material costs and global competition is critical to unlocking the sector’s full potential. By focusing on quality, innovation, and sustainability, screw suppliers in India can secure a stronger foothold in the global market and continue contributing to India's industrial growth.

0 notes

Text

Uses of HVAC Aluminum Foil Tape

DeYou Tape Co.,Ltd. is a leading manufacturer and distributor of pressure sensitive adhesive tape in China. Through the introduction of a series of new aluminum foil tape, we aim to expand our HVAC product portfolio, broaden the scope of application, and enhance product performance. DeYou Tape provides a durable and high-performance tape solution for busy HVAC contractors. For example, our HVAC aluminum foil tape is used for the exhaust pipe of household range hoods and the interior moisture-proof pipe of air conditioners, among other applications.

HVAC aluminum foil tape is a type of aluminum foil tape, it is a versatile and essential tool for sealing, repairing, and insulating various components in heating, ventilation, and air conditioning (HVAC) systems. Its unique properties make it particularly useful for maintaining the integrity and efficiency of these systems.

Uses of HVAC Aluminum Foil Tape

1. Sealing Ductwork: One of the primary uses of HVAC aluminum foil tape is to seal joints and seams in ductwork. It provides a strong and durable bond, preventing air leaks and ensuring proper insulation. This helps to improve the efficiency of the HVAC system by reducing energy loss.

2. Insulation: The tape is also used for insulation purposes in HVAC systems. It can be applied to seal gaps and cracks in ducts, pipes, and other components, preventing heat transfer and maintaining the desired temperature within the system.

3. Repairing Damaged Ducts: HVAC tape is commonly used to repair damaged or torn ducts. It provides a quick and effective solution for sealing holes or gaps, restoring the integrity of the ductwork and preventing air leakage.

4. Sound Dampening: The tape's adhesive properties and ability to adhere to various surfaces make it useful for sound dampening in HVAC systems. It can be applied to seal gaps and joints, reducing noise transmission and improving acoustic performance.

5. Moisture and Vapor Barrier: Aluminum foil tape acts as an excellent moisture and vapor barrier. It is often used to seal and protect insulation materials, preventing moisture from compromising the effectiveness and lifespan of the insulation.

6.Reflecting heat: HVAC aluminum foil tapes has reflective properties, which can be utilized to redirect heat away from sensitive areas. It can be applied to surfaces near heat sources or in areas where heat needs to be controlled, such as around air conditioning units or exhaust vents.

Other HVAC aluminum foil tape uses include repair of metal or steel plate and temporary fixation of outdoor electrical box. In addition, HVAC aluminum foil tapes can be used for furnace installation / replacement, sheet metal fan exhaust system and dryer ventilation or bath fan installation.

Benefits of DeYou Tape:

Improved Energy Efficiency: Reduces energy consumption by preventing air leaks and improving insulation. Reduced Energy Costs: Lower energy bills due to increased efficiency. Enhanced Indoor Comfort: Maintains consistent indoor temperature and humidity levels. Durability: Resists moisture, temperature extremes, and UV radiation. Easy Application: Can be easily applied to various surfaces, including metal, plastic, and fiberglass.

"The contractor has long trusted our AFA series aluminum foil tape for various HVAC applications, especially in achieving a complete system shutdown," said the HVAC tape product manager of DeYou Tape Co., Ltd. Contractors need to minimize air leakage to pass inspection, and want reliable, high-performance tape solutions to provide permanent, airtight bonds. Our tapes may provide a reliable solution for sealing, repairing, and enhancing the performance of heating and cooling installations."

0 notes