#china rapid prototype

Explore tagged Tumblr posts

Text

Unlocking Innovation : Aluminum Prototype And Sheet Metal Prototyping

In the dynamic world of manufacturing and design, prototyping stands as a crucial step in the development process. Among the various materials and techniques used, aluminum prototypes and sheet metal prototyping have gained significant attention for their versatility, durability, and cost-effectiveness. This blog explores the advantages, applications, and innovations in aluminum and sheet metal prototyping.

0 notes

Text

Know About the Post-Processing in Rapid Prototyping

Rapid Prototyping China is a ray of efficiency and inventiveness in the field of product development and innovation. By offering quick iterations and concrete concept representations, it transforms conventional methodologies. However, inside this miracle of contemporary engineering, there is a critical—often disregarded but unquestionably necessary—step called post-processing. It's the period of transformation that unlocks the actual potential of a rough prototype and turns it into a polished masterpiece.

Enhancement of Visual Appeal

Even in the world of prototypes, first impressions count. Post-processing makes it possible to improve the visual appeal of a prototype by removing flaws and rounding off edges. Simple models may be transformed into visually beautiful representations by using techniques like painting, polishing, or sanding, which can improve the model's aesthetic appeal and professionalism.

The perception of a product is greatly influenced by its aesthetics, which also affects consumer acceptability and engagement. Consequently, spending money on post-processing guarantees that prototypes not only work effectively but also grab attention due to their striking appearance.

Improvement of Material

Chinese Rapid Prototyping Services relies heavily on material selection, which affects characteristics like strength, flexibility, and durability. Nevertheless, the intrinsic qualities of raw materials could not meet the required standards. A solution is provided by post-processing, which enhances material qualities to satisfy demands. One can achieve desired characteristics like heat resistance, conductivity, or waterproofing by applying coatings, surface treatments, or chemical procedures. Post-processing broadens the possibilities by improving material qualities, making prototypes more resilient to real-world use and more environment-adaptable.

Individualization and Tailoring

Each product is different from the others and meets the demands of different users. Post-processing makes it easier to customize and personalize prototypes to suit these unique tastes. Prototypes may be given individuality and flare by post-processing, which includes adding textures, engravings, and detailed detailing. It also makes it possible to incorporate branding components, which promote brand loyalty and awareness.

Iterative Enhancement

Iteration is the lifeblood of Rapid Prototype; each cycle improves and refines the idea. Post-processing provides insightful input for iteration cycles, acting as a stimulus for iterative progress. Designers can identify areas for improvement and identify strengths and shortcomings by evaluating post-processed prototypes. Prototypes are refined through iterative development, which encourages ongoing learning and innovation.

#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Chinese Rapid Prototyping Services

2 notes

·

View notes

Text

CNC Car Parts: Revolutionizing Automotive Manufacturing with Precision and Efficiency

Introduction In the ever-evolving world of automotive manufacturing, the demand for high-quality, precise, and efficient production processes has become paramount. The advent of advanced technologies, such as online machining, SLA rapid prototyping, aluminum casting in China, CNC prototypes, and small metal parts fabrication, has brought about a paradigm shift in the production of car parts. This article explores the significance of CNC (Computer Numerical Control) in the automotive industry and how it has revolutionized the manufacturing of car parts.

Online Machining: Streamlining Production Processes Online machining, also known as CNC machining, has emerged as a game-changer in car part manufacturing. With online machining, manufacturers can create intricate and complex car parts with exceptional precision and speed. By utilizing computer-aided design (CAD) software, engineers can develop 3D models that are then translated into machine instructions for CNC machines.

The CNC machines, equipped with high-speed rotating tools, cut, drill, and shape raw materials, such as aluminum, steel, and alloys, into precise car parts. The automated nature of online machining not only enhances accuracy but also reduces the risk of human errors, resulting in improved quality control.

SLA Rapid Prototyping: Accelerating Innovation SLA (Stereolithography) rapid prototyping is another technology that has significantly impacted the automotive industry. It enables the creation of quick and cost-effective prototypes for car parts. Using SLA, manufacturers can transform digital designs into physical models by using a specialized machine that cures liquid resin layer by layer, producing a solid object.

The application of SLA rapid prototyping allows automotive designers and engineers to iterate and test their designs more efficiently. This iterative approach helps identify and rectify flaws or design issues at an early stage, saving both time and resources. By accelerating the prototyping process, SLA technology fosters innovation and drives the development of cutting-edge car parts.

Aluminum Casting China: Cost-Effective and Versatile Aluminum casting in China has gained prominence as a cost-effective and versatile method for producing car parts. Aluminum, with its lightweight properties and excellent thermal conductivity, is an ideal material for automotive applications. China, with its well-established manufacturing infrastructure, offers competitive advantages in terms of cost, quality, and production capacity.

By utilizing aluminum casting techniques, manufacturers can create complex shapes and structures that would be challenging to achieve with traditional methods. The process involves pouring molten aluminum into pre-designed molds, allowing for the production of intricate car parts with high dimensional accuracy. Furthermore, aluminum casting provides excellent surface finishes and is highly resistant to corrosion, making it suitable for various automotive components.

CNC Prototypes: Transforming Design Concepts into Reality CNC prototypes play a pivotal role in the development of car parts. Before moving into full-scale production, manufacturers often create prototypes to validate the design, functionality, and performance of the intended car parts. CNC machines excel in producing accurate prototypes that closely resemble the final product.

By using CNC prototypes, automotive engineers can evaluate the form, fit, and function of car parts, ensuring they meet the desired specifications. Any necessary modifications or improvements can be identified and implemented at this stage, minimizing the risk of costly errors during mass production.

Small Metal Parts Fabrication: Precision at Scale The production of small metal parts is a critical aspect of automotive manufacturing. These components, although small in size, play a vital role in the overall performance and functionality of a vehicle. CNC machining enables the precise fabrication of small metal parts, ensuring that they meet the stringent requirements of the automotive industry.

Whether it's engine components, brackets, connectors, or fasteners, CNC machining can accurately produce small metal parts with high repeatability. The ability to manufacture these parts at scale while maintaining consistent quality is a significant advantage of CNC technology.

Conclusion The use of CNC technology has had a significant impact on the overall cost of manufacturing CNC car parts. The integration of online machining, SLA rapid prototyping, aluminum casting in China, CNC prototypes, and small metal parts fabrication has revolutionized the manufacturing of car parts. These advanced technologies offer enhanced precision, efficiency, and cost-effectiveness in the production process. As the automotive industry continues to evolve, the utilization of CNC in car part manufacturing will be instrumental in meeting the demands for innovation, quality, and performance in vehicles worldwide.

#online machining#SLA rapid prototyping#aluminum casting china#CNC prototypes#CNC car parts#small metal parts fabrication

0 notes

Text

Unprecedented U.S. Hypersonic Weapons Test From Guam Has Occurred

Joseph TrevithickPUBLISHED Mar 19, 2024 7:02 PM EDT

The Air Force has conducted an unprecedented test launch of a live AGM-183A ARRW hypersonic missile in the Western Pacific, sending signals to China and elsewhere in the region amid uncertainty about this particular program's future.

Lockheed Martin

The U.S. Air Force has confirmed that it conducted its final planned end-to-end test launch of a live AGM-183A Air-Launched Rapid Response Weapon hypersonic missile, or ARRW, earlier this week. A B-52H bomber flying from the highly strategic U.S. Pacific island territory of Guam fired the missile. The War Zone was the first to predict this test was coming after the Air Force curiously released pictures of a live AGM-183A at a show-and-tell training event at Guam's Andersen Air Force Base in late February.

This is the first time an ARRW missile, or any other known American hypersonic weapon, has been test launched in this region. As such, the test sends signals across the Pacific, especially toward China. At the same time, this comes as ARRW's future continues to be murky with signs pointing to a potential follow-on program, which may already be in progress.

A live AGM-183A ARRW hypersonic missile seen under the wing of a B-52H bomber at Andersen Air Force Base on Guam on February 27, 2024. USAF

“A B-52H Stratofortress conducted a test of the All-Up-Round AGM-183A Air-launched Rapid Response Weapon," an Air Force spokesperson told The War Zone in a statement. "This test launched a full prototype operational hypersonic missile and focused on the ARRW’s end-to-end performance The test took place at the Reagan Test Site with the B-52 taking off from Andersen Air Force Base, Guam on March 17, 2024 local time."

The Reagan Test Site consists of various facilities spread across multiple islands at Kwajalein Atoll in the Republic of the Marshall Islands. The site is one of the U.S. military's premier missile test ranges and is regularly used to support the testing of very long-range munitions, including hypersonic weapons like ARRW.

Andersen Air Force Base on Guam is a key U.S. military hub in the Western Pacific and the Air Force's main base for staging long-range bomber operations in the region. It would play a central role in any future major conflict in the region, including one against China. U.S. hypersonic weapons, which are expected to be very expensive and acquired in relatively limited numbers, would be particularly valuable in a high-end fight for conducting conventional strikes against very high-value and heavily defended targets. These could include major air defense and other command and control nodes.

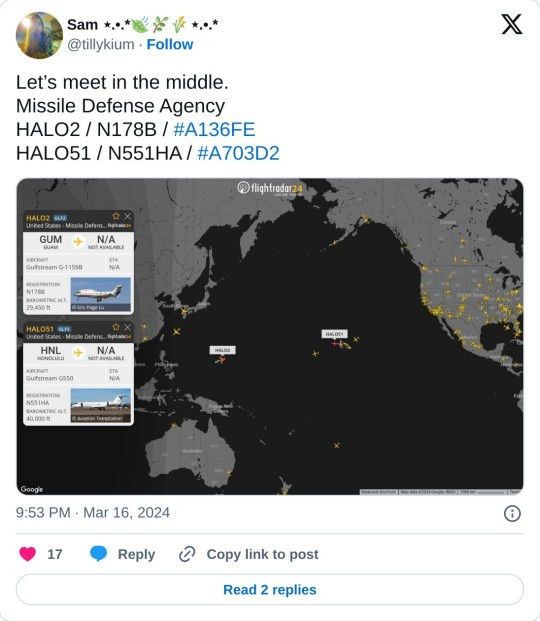

There had already been evidence that the ARRW test had occurred on or about March 17 based on the appearance and then cancellation of various warning notices. Online flight tracking data also showed signs the test was finally about to happen, including specially modified High Altitude Observatory (HALO) Gulfstream business jets operating in relevant areas. The HALO aircraft have supported past ARRW flight tests.

ARRW Update: New round scheduled tonight between 00:09 and 04:30 UTC.

So I guess launch did not happened last night despite 49th T&E Squadron's B-52H spotted by @FMilcoms.

The Air Force has only provided limited information so far about the test's outcome and has not explicitly said whether or not it was successful.

"The Air Force gained valuable insights into the capabilities of this new, cutting-edge technology. While we won’t discuss specific test objectives, this test acquired valuable, unique data and was intended to further a range of hypersonic programs," the Air Force spokesperson said in their statement to The War Zone. "We also validated and improved our test and evaluation capabilities for continued development of advanced hypersonic systems.”

The Air Force has used roughly similar language in statements about the previous three end-to-end tests of live ARRW missiles, which occurred in March, August, and October 2023. The March 2023 test ended in failure. Information about the August and October 2023 launches remains scant. The service also conducted another end-to-end ARRW test in December 2022, but this appears to have not involved a live all-up-round missile.

An AGM-183A missile seen during an earlier test launch in 2021 that did not involve a full end-to-end demonstration of the weapon. USAF

Whatever the exact outcome of the March 17 test was, ARRW's future is uncertain, as The War Zone has previously reported in depth.

"Currently, right now, we do not have the ARRW in the [Fiscal Year] 25 budget," Air Force Lt. Gen. Dale White, the Military Deputy at the Office of the Assistant Secretary of the Air Force for Acquisition, Technology, and Logistics, told members of the House Armed Services Committee at a hearing last week. "However, we are continuing to analyze the test data that we have from that capability."

"With ARRW ... we are undergoing the final test of the all-up-round [AUR] with a planned test program completion by the end of [the] second quarter [of] Fiscal Year 2024," White added. "Future ARRW decisions are pending final analysis of all flight test data."

Following years of at best mixed test results, the Air Force announced in March 2023 that it planned to end the ARRW program and shift resources to work on a different type of hypersonic weapon, the Hypersonic Attack Cruise Missile (HACM). You can read more about the differences between ARRW, which has an unpowered hypersonic boost-glide vehicle payload, and air-breathing hypersonic cruise missiles like HACM here.

A rendering of a notional air-breathing hypersonic cruise missile from Raytheon, the prime contractor for the Air Force's HACM program. Raytheon

The Air Force has subsequently appeared on multiple occasions to be backtracking on its ARRW decision, despite the program still being officially set to come to an end this year. There are now signs that the service could be looking at a follow-on air-launched hypersonic boost-glide vehicle program, if it isn't already in the works.

Whatever the case, the Air Force has now completed its final planned end-to-end test of an ARRW missile, which it has said will inform its future hypersonic weapon plans.

Contact the author: [email protected]

9 notes

·

View notes

Text

PTS-Rapid Prototyping & On-demand Production Services https://www.ptsindu.com/

PTS Industrial Ltd was founded in 2002, located in Dong Guan and Shenzhen, China. PTS starts from precision plastic injection molds making, and step into plastic injection molding services, cnc machining services, After 20 years of development, now we have 4 subsidiaries. Since 2002, PTS has been proudly providing high-quality CNC machining parts, injection molding services, and plastic injection molds to a diverse range of industries, Serving well-known companies such as HUA WEI, BMW, EPSON, etc.

plastic injection molding services, cnc machining services, cnc milling services, cnc turning services, plastic injection molds maker

9 notes

·

View notes

Text

Vacuum Forming Is a Game Changer in Manufacturing

Innovation in the manufacturing sector is what propels cost-effectiveness, adaptability, and efficiency. Vacuum forming is one such cutting-edge method that has completely changed the way goods are created and manufactured. Due to its many benefits, vacuum forming technique has become more and more common in a variety of sectors.

Production at a Low Cost

The affordability of vacuum forming is one of its main benefits. Vacuum forming uses less expensive machinery and tools than conventional production techniques like die casting or injection molding. Because of this, vacuum forming is a desirable alternative for small- to medium-sized production runs, allowing companies to save costs without sacrificing quality.

Quick Prototyping

Rapid prototyping is made possible by Vacuum Forming China, which enables engineers and designers to test and iterate product concepts fast. It is possible to build several prototypes at a reasonable cost because to the short lead times and inexpensive tooling costs. This quickens the process of developing new products, allowing companies to launch new concepts more quickly and adapt quickly to the needs of their customers.

Flexibility in the Choice of Materials

A large variety of thermoplastic materials may be used with vacuum forming, giving producers the freedom to select the material that is best suited for their particular purpose. Because of their versatility, goods with different levels of flexibility, transparency, and durability may be made. Vacuum forming is a flexible solution for a multiplicity of sectors, accommodating a wide range of material needs from durable automotive components to thin-gauge packaging.

Smooth Customization of the Design

Vacuum forming makes it simple to easily customize complex designs. It is possible to accomplish intricate textures, undercuts, and forms without the requirement for costly tool adjustments. Vacuum forming is a great option for creating aesthetically pleasing and useful items in a variety of sectors, including consumer electronics, car interiors, and signs, because of its adaptability in design customization.

Lightweight Goods

Because vacuum-formed materials by vacuum forming manufacturer are lightweight by nature, they are appropriate for uses where weight is a crucial consideration. This benefit is especially pertinent to the aerospace and automobile sectors, where weight reduction may improve overall performance and fuel economy. Additionally, vacuum-formed items' lightweight design makes handling, shipping, and installation simpler.

Next: Investment Casting Offers Both Versatility and Precision

#Vacuum Forming#Vacuum Forming Process#vacuum forming manufacturer China#vacuum forming manufacturer#Vacuum Forming Companies#Custom Vacuum Forming

2 notes

·

View notes

Text

7 Facts You Must Know Regarding Startups In 2023

You are saying that you have a burning inkling that you think could transform the world in any way? Oh, you are desiring about earning millions or even billions of dollars by launching a business around this boiling idea? Then you could probably be the father of a Startup.

Industry professional, Ashish Aggarwal, CEO of Acube Ventures insinuates that Startups are prominent business prototype that steers invention and economic promotion across the world. An exotic set of products and services are established by startups each year. They are the articulation of imaginative and ambitious entrepreneurs who have remarkable ideas.

India has evolved to be the third-largest startup ecological community in the world after the US and China. The first Unicorn was seen in India in 2011, and almost after a decade in 2022, India crossed the mark of 100 Unicorns. The bragging of 100 Unicorns is not an ordinary affair, and that is why the startup ecosystem is flinging in joy and bulging with dignity.

"Startups in India have grown remarkably over the last six years.

The number of newly recognised startups around the world has heightened to over 14,000 in 2021-22 from only 733 in 2016-17, a survey said.

When someone says the word “startup”, we usually instantly think of diverse triumph stories and exponential business expansion. However, in actuality, not all startups are prosperous. We usually only hear about the winners, and that is one-sided information that doesn’t tell the entire story. Everyone wants to listen to favourable achievement anecdotes, but you need to know all of the details if you want your startup to prosper.

Mr Ashish Aggarwal, an Industry Expert and Consultant has laid out 7 most crucial details about startups, including statistics, facts, and trends that will help you give a decent awareness of the universal startup landscape:

1. Dispersion of startups worldwide as per industry - 7.2% of the startups in the world function in the Fintech industry which is followed by the healthcare sector with 6.9%, Artificial intelligence with 4.9%, Gaming industry with 4.7%, Adtech commerce with 3.2%, and Edtech sector with 2.9%. Even though there isn’t entirely accurate data about enterprise dispersion, it’s clear that contemporary startups gravitate more towards the online network, cyberspace, the internet and digital technologies. With this information, we can also discern which industry is adequate for startups at the moment.

2. The valuation of E-Commerce revenues globally is approximately $3.5 trillion - E-Commerce is one out of the most prominent industries for young startups with rapid growth expected in the future. The next enterprise in line is “FinTech” i.e. Financial technology. Another huge focus of new startups is cybersecurity. These companies realize how crucial online security will be in the future. FoodTech combines food and technology and is another famous enterprise for startups. With over $16 billion of investments in 2018, EdTech is coming to be another outstanding startup industry that provides educational technology remedies to people worldwide.

3. Over 68% of startup businesses started as home businesses - The idea has to commence somewhere and form posture. Even though maximum startups don��t have the integral allocation at the onslaught to insulate office expenses, they can launch their operations from home.

4. The ‘sharing economy market' is expected to cross a total revenue of $335 billion by 2025 - In just a matter of a few years, sharing economy startups namely, Airbnb and Uber have grown exponentially and solidified a global existence. At the moment, Airbnb is valued at $24 billion, and Uber is worth $50 billion. In 2014, the total revenue of market sales was $17 billion, which means that in just eight years, the projected earnings of this market grew more than 20 times.

5. AI is presently the most profitable innovation technology -Over 63℅ of entrepreneurs agree that AI, not just presently but for at least the next 10 years is the most prominent technology. The tracts of this technology with the highest potential are autonomous transportation and huge data. Even though these two sectors are already making strides, it’s anticipated that they will flourish substantially in the close future.

6. ByteDance is valued at over $350 billion - The most profitable unicorn company in the world, ByteDance (China) is a tech company that owns Tiktok. There are presently 1000+ Unicorn companies around the world. However, the maximum of them is tracked down in China or the United States.

7. 95% of entrepreneurs that establish startups have at least a bachelor’s degree - Many people claim that education isn’t significant. They talk about Mark Zuckerberg and Elon Musk as instances. However, the majority of the people who birthed the world’s most triumphant startups have a higher education.

Ashish Aggarwal aspires to watch numerous Indian Startup Parents succeed in their entrepreneurial endeavours, which is why he shares his invaluable insights about startups. According to him, The startup industry will persist to be the driving component for global innovation and business development for many years. Nonetheless, companies must learn how to adapt to trends while being endurable and productive so that more startups can withstand the dynamic business environment.

#ashish aggarwal#ashish aggarwal indo innovation#ashish aggarwal acube venture#ashish aggarwal space mnatra

2 notes

·

View notes

Text

Medical Component Manufacturing Market Key Players, Revenue And Growth Rate

The global medical component manufacturing market size is expected to reach USD 15.93 billion by 2030, according to a new report by Grand View Research, Inc. It is expected to expand at a CAGR of 4.4% from 2021 to 2030. The rising demand for 3D printed parts in the medical industry is projected to contribute to market growth.

Penetration is the adoption of medical component manufacturing in various applications in the market. The penetration of medical component manufacturing is likely to be the highest in the 3D printing segment. The benefits of 3D printing such as improved productivity, cost-effectiveness, personalization, and customization of medical products, applications in complex operations, and rapid medical prototyping are projected to benefit the growth of the 3D printing market.

The plastic injection molding process segment accounted for the largest revenue share of over 65.0% in 2020. The segment is projected to grow due to the development of efficient products using better-engineered resins. Moreover, the process can help component manufacturers produce cost-effective products in various sizes and shapes. Some of the low-cost products include disposable gloves, syringes, plastic instruments, and different one-time products for healthcare facilities.

The rising geriatric population is projected to remain an indirect contributor to market growth. There has been a change in the pattern of the aging population across the globe in the recent past owing to the decreasing levels of fertility and rising life expectancy. This has led to a longer lifespan of people, wherein the share of old people or geriatric population is growing at a rapid pace. As per the United Nations, there are over 727 million people globally who are aged 65 or above as of 2020.

Gather more insights about the market drivers, restrains and growth of the Medical Component Manufacturing Market

Medical Component Manufacturing Market Report Highlights

• The 3D printing process segment is anticipated to register the fastest CAGR of 20.8% from 2021 to 2030. Suitability to produce complex and customized products, along with cost efficiency in low volume production, is projected to drive the segment over the forecast period

• The plastic injection molding process segment held the largest revenue share of over 65.0% in 2020. Advantages such as durability, strength, ease of handling, and improved sterilization make the process comply with stringent regulations set by different government bodies

• North America accounted for the largest revenue share of over 40.0% in 2020. The Increasing geriatric population, along with a rise in lifestyle diseases, is projected to benefit the growth of the medical device industry in the region, thus benefiting the demand for various medical components

• Leading companies in the industry are focused on the development of advanced processes such as 3D printing and are likely to increase their R&D expenditure over the coming years. The merger & acquisition activities are anticipated to rise over the coming years as companies are focused on improving their market share

Medical Component Manufacturing Market Segmentation

Grand View Research has segmented the global medical component manufacturing market on the basis of process and region:

Medical Component Manufacturing Process Outlook (Revenue, USD Billion, 2017 - 2030)

• Forging

• Metal Injection Molding

• 3D Printing

• Ceramic Injection Molding

• Investment Casting

• Plastic Injection Molding

Medical Component Manufacturing Regional Outlook (Revenue, USD Billion, 2017 - 2030)

• North America

o U.S.

• Europe

o Germany

o France

o U.K.

o Spain

• Asia Pacific

o China

o India

o Japan

Order a free sample PDF of the Medical Component Manufacturing Market Intelligence Study, published by Grand View Research.

#Medical Component Manufacturing Market#Medical Component Manufacturing Market Size#Medical Component Manufacturing Market Share#Medical Component Manufacturing Market Analysis#Medical Component Manufacturing Market Growth

0 notes

Text

Computer-Aided Design Market Poised for Transformation with Emerging Technologies

As per Intent Market Research, the Computer-Aided Design (CAD) Market was valued at USD 8.4 billion in 2023-e and will surpass USD 21.1 billion by 2030; growing at a CAGR of 14.9% during 2024–2030.

The projected growth of USD 21.1 billion by 2030 is not an isolated trend. CAD's versatility in various sectors—like healthcare for prosthetics, or entertainment for animations—demonstrates its cross-industry relevance. Enhanced accuracy, reduced production timelines, and cost savings are primary motivators for its adoption.

Global Drivers of Market Expansion

Technological Advancements: The integration of artificial intelligence, cloud computing, and the Internet of Things (IoT) in CAD software is a game changer. Cloud-based CAD solutions, for example, enable collaborative design across geographies, enhancing productivity.

Rising Demand in Construction: With urbanization surging worldwide, smart infrastructure projects increasingly rely on CAD for detailed designs, simulations, and workflow optimization.

Adoption in Manufacturing: Industries leveraging Industry 4.0 principles heavily invest in CAD to accelerate prototyping, streamline production processes, and achieve precision engineering.

Expansion in Emerging Markets: Countries like China and India are experiencing industrialization, driving CAD adoption in architecture, automotive, and electronics sectors.

Download Sample Report @ https://intentmarketresearch.com/request-sample/computer-aided-design-cad-market-3032.html

Future-Proof Features: The Transformation of CAD Software

Modern CAD solutions don’t just aid in design—they simulate real-world applications to predict performance. Here’s how the software landscape is transforming:

AI and Machine Learning: Automating mundane tasks like error detection and enhancing design quality.

Generative Design: This feature lets designers input parameters like weight, material, and size to create optimal designs automatically.

Virtual Reality (VR) Integration: VR-enabled CAD platforms allow stakeholders to visualize projects interactively, improving client collaboration.

Challenges Facing the CAD Market

Despite its impressive trajectory, CAD adoption isn't without challenges:

Cost of Implementation: High upfront costs for software and hardware, coupled with ongoing training expenses, can deter smaller businesses.

Complexity: While powerful, CAD systems demand skilled operators, posing an adoption barrier in resource-constrained environments.

Data Security Concerns: As more software moves to the cloud, protecting intellectual property from breaches becomes paramount.

Opportunities for Growth in the CAD Ecosystem

The future of CAD lies in innovation. Here are key areas poised to drive growth:

Integration with 3D Printing: CAD complements 3D printing seamlessly, as designs can be directly translated into physical models.

Custom Manufacturing: Rising trends in bespoke designs (e.g., dental implants, furniture) rely heavily on CAD.

Green Technology Development: CAD plays a critical role in designing eco-friendly solutions, like energy-efficient buildings and electric vehicles.

Access Full Report @ https://intentmarketresearch.com/latest-reports/computer-aided-design-cad-market-3032.html

A Global Perspective on CAD Usage

Dominance of North America and Europe: With a mature infrastructure and well-established industrial base, North America and Europe hold significant CAD market shares. Investments in smart cities and defense bolster CAD adoption.

Asia-Pacific’s Accelerated Growth: Asia-Pacific markets are experiencing exponential CAD uptake, thanks to rapid industrial growth and favorable government initiatives in tech innovation.

FAQs

What is Computer-Aided Design (CAD)? CAD is a software tool used for creating, modifying, and optimizing designs digitally, replacing traditional drafting methods. It enhances precision and workflow efficiency.

Which industries benefit most from CAD? CAD is essential in industries like architecture, aerospace, automotive, construction, healthcare, and manufacturing.

What drives the CAD market growth? Key factors include technological advancements, increased adoption in manufacturing and construction, and rising demand for innovation in emerging markets.

What are the emerging trends in CAD software? Modern trends include AI integration, generative design, cloud-based solutions, and VR-powered visualization.

Why is CAD critical for the future of design? By combining efficiency with innovation, CAD enables industries to conceptualize, simulate, and implement cutting-edge solutions more effectively than ever before.

About Us

Intent Market Research (IMR) is dedicated to delivering distinctive market insights, focusing on the sustainable and inclusive growth of our clients. We provide in-depth market research reports and consulting services, empowering businesses to make informed, data-driven decisions.

Our market intelligence reports are grounded in factual and relevant insights across various industries, including chemicals & materials, healthcare, food & beverage, automotive & transportation, energy & power, packaging, industrial equipment, building & construction, aerospace & defense, and semiconductor & electronics, among others.

We adopt a highly collaborative approach, partnering closely with clients to drive transformative changes that benefit all stakeholders. With a strong commitment to innovation, we aim to help businesses expand, build sustainable advantages, and create meaningful, positive impacts.

Contact Us

US: +1 463-583-2713

0 notes

Text

Innovations in China’s Rapid Prototype and Rapid Manufacturing Industries

China has established itself as a global leader in the fields of rapid prototyping and rapid manufacturing, revolutionizing industries with its cutting-edge technologies and efficient processes. These advancements are reshaping product development cycles, reducing time-to-market, and enabling innovative designs across various sectors.

0 notes

Text

Manufacturability Design in Rapid Prototyping

Quickly producing physical models or prototypes with additive manufacturing technologies like 3D printing, CNC machining, or other sophisticated fabrication techniques is known as Rapid Prototyping China. With this method, designers may test their ideas, evaluate functionality, and spot problems in their designs early on, which cuts down on development expenses and time-to-market.

Manufacturability-focused design (DFM)

DFM is a collection of best practices and standards for improving a product's design so that it can be manufactured more easily. DFM concepts are as important at the rapid prototyping stage, even though they are typically linked with mass production. Engineers may minimize problems and streamline the prototype process by taking manufacturing restrictions into account early in the design phase.

Essential DFM Takeaways for Quick Prototyping

Material Choice

Select materials that work well with the quick prototyping method you've chosen.

Depending on the planned use, take into account the material's strength, flexibility, and heat resistance.

Complexity of Geometry

Simplify designs to save money and time during manufacture.

Reduce overhangs and complex features, which might be difficult to create using some fast prototyping techniques.

Accuracy and Tolerance

Recognize the dimensional accuracy constraints of the fast Rapid Prototype technique that you have selected.

To guarantee the required precision in the finished prototype, design with the proper tolerances.

Assisting Frameworks

To avoid deformations during fabrication, especially in 3D printing, take into account the essential support structures in the design.

Reduce post-processing work and material waste by optimizing support structures.

Assembly Considerations

Create components that are simple to test and dismantle for adjustments.

When it's feasible, reduce the amount of components to expedite the prototype process.

Time Efficiency Gains from Using DFM in Rapid Prototyping

Designers may expedite the whole prototype phase by avoiding several revisions and delays by addressing manufacturability problems early on.

Lowering of Expenses

During the fast prototype stage, optimal design decisions result in cost savings through effective material consumption and less waste.

Better Cycles of Iterations

Faster design iterations are made possible by the prompt discovery and resolution of manufacturability difficulties, which enable more extensive testing and refinement.

Improved Prototyping Caliber

By keeping DFM principles in mind, you may minimize unforeseen difficulties during testing and validation by ensuring that the final Rapid prototyping manufacturer closely resembles the planned design.

#Rapid prototyping manufacturer#Rapid Prototype#Rapid Prototyping Services#Metal Rapid Prototyping Services#Rapid prototyping Supplier#Rapid Prototyping China#Chinese Rapid Prototyping Services

2 notes

·

View notes

Text

2025 to 2030 Market Report: Key Dynamics in the Generator Sets Industry

The global generator sets market size is estimated to reach USD 57.9 billion by 2030, expanding at a CAGR of 9.3% from 2025 to 2030, according to a new report by Grand View Research, Inc. Growing demand for reliable and continuous power supply from several end-use industries including manufacturing and construction, power generation, oil and gas, chemical, marine, healthcare, telecom, and chemical are likely to strengthen market growth over the forecast period.

Infrastructure development, rapid industrialization, and continuous population growth are among the key factors resulting in an all time high power demand. The growing penetration of electronic load across several medium scale facilities such as data centers has led to increased usage of gensets in order to provide uninterrupted electricity supply during chronic power outages and prevent disruption of daily business activities.

Natural gas-powered enginegen sets are expected to witness higher growth compared to diesel gensets owing to fluctuating diesel prices and stringent regulations regarding usage of cleaner fuels. In addition, higher fuel efficiency powered engines gensets are expected to reduce the power generation cost and thereby increase the product penetration rate across various industries.

Genset manufacturers adhere to several codes and compliances regarding the design, installation, and safety of the systems. For instance, the genset should be manufactured in facilities certified to ISO 9001 or ISO 9002 and designed in facilities certified to ISO 9001. The prototype test program authenticates the performance reliability of the genset design. Certifications to leading organizations such as International Building Code, Underwriters Laboratories, CSA group, and US Environmental Protection Agency (EPA), increase the marketability of the product.

Generator Sets Market Report Highlights

Diesel generatoroccupied largest market revenue share in 2024 owing to the reliable performance, low capital cost of the generator, and longer lifespan of the engine.

The gas generator segment is projected to grow at the highest CAGR owing to the stringent regulations regarding emission control and usage of cleaner fuels.

Low power generators occupied for largest revenue market share in power rating segment owing to their increasing application in residential and commercial sector.

The medium power generator sets are expected to grow at a CAGR of 10.2% over the forecast period owing to its application across several industries including telecom sector, commercial complexes, small scale industries, and petrol stations.

The commercial segment occupies the largest revenue share in application segment and is projected to grow at a significant CAGR owing to wide application base including government centers, data centers, educational institutions and other such facilities.

In Asia Pacific, the market is expected to grow at the fastest CAGR owing to increasing power demand from developing economies such as China and India.

Generator Sets Market Segmentation

Grand View Research has segmented the global generator sets market based on type, fuel type, application, and region:

Generator Sets Type Outlook (Revenue, USD Million, 2018 - 2030)

Low Power Gensets

Medium Power Gensets

High Power Gensets

Generator Sets Fuel Type Outlook (Revenue, USD Million, 2018 - 2030)

Diesel

Gas

Generator Sets Application Outlook (Revenue, USD Million, 2018 - 2030)

Industrial

Commercial

Residential

Generator Sets Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

Russia

UK

France

Asia Pacific

China

India

Japan

South Korea

Latin America

Brazil

Argentina

Middle East and Africa

UAE

Saudi Arabia

Order a free sample PDF of the Generator Sets Market Intelligence Study, published by Grand View Research.

0 notes

Text

PLA Chinese Air Force Y-20 aircraft transports air defense missile unit for the first time

Fernando Valduga By Fernando Valduga 19/01/2023 - 17:30 in Military

0

Views

Share on Facebook

Share on Twitter

An air-to-air missile unit of the China People's Liberation Army (PLAAF) air force recently participated in a systematic confrontation exercise, in which it first tested its rapid deployment capability by flying aboard a large Xian Y-20 transport aircraft.

This method will significantly increase the flexibility of China's air defense, analysts said on January 18, according to the Global Times.

Parked in the border region of southwest China, a land-based missile battalion affiliated with the air force of the PLA Southern Theater Command participated in the Red Sword exercise and won the maximum prize, the Golden Shield, China Central Television (CCTV) reported on January 16. The exercise marked the first time this battalion tested its rapid deployment capability by flying with Y-20 transport aircraft, CCTV said.

The rapid and long-range deployment of heavy land-to-air missiles has great tactical and even strategic significance, as it allows the PLA to improve regional air defense in a flexible way. This is possible thanks to the commissioning of the Y-20 transport plane by the PLA Air Force in large numbers, since an air defense missile unit usually consists of many elements that require a fleet of strategic cargo planes

In April 2022, many large Y-20 transport aircraft flew from China to Serbia for several consecutive days to deliver FK-3 air defense missile systems that Serbia had acquired from China. Observers called the mission at the time the largest operation outside the Y-20.

The Y-20 Kunpeng was developed by Xian Aircraft Industrial Corporation. The aircraft is nicknamed "Chubby Girl" in the Chinese aviation industry because its fuselage is much wider than the aircraft previously developed in China.

Tags: Military AviationPLAAF - China Air ForceXian Y-20

Sharing

tweet

Pin

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has works published in specialized aviation magazines in Brazil and abroad. He uses Canon equipment during his photographic work in the world of aviation.

Related news

HELICOPTERS

Austria signs contract for 18 more AW169M helicopters

19/01/2023 - 19:02

EMBRAER

Embraer offers the A-29 Super Toucan to India

19/01/2023 - 15:54

VANT - UAV

Kuwait buys drones manufactured in Turkey in a $370 million agreement

19/01/2023 - 14:00

WAR ZONES

Ukrainian leader has his eye on the Tornado jets that will be deactivated in Germany

19/01/2023 - 12:00

The KF-21 Boramae fighter prototype, developed in South Korea, performs the first supersonic test flight on Tuesday afternoon. (Photo: Administration of the Defense Acquisition Program)

MILITARY

VIDEO: South Korean KF-21 fighter flies at supersonic speed

19/01/2023 - 11:00

BRAZIL

Explained the mission of the USAF WC-135R aircraft near the Brazilian coast

19/01/2023 - 08:01

homeMain PageEditorialsINFORMATIONeventsCooperateSpecialitiesadvertiseabout

Cavok Brazil - Digital Tchê Web Creation

Commercial

Executive

Helicopters

HISTORY

Military

Brazilian Air Force

Space

Specialities

Cavok Brazil - Digital Tchê Web Creation

4 notes

·

View notes

Text

Exploring the 3D Bioprinting Market: A Revolutionary Leap in Healthcare and Biotechnology

The 3D bioprinting market represents a cutting-edge frontier in healthcare and biotechnology, offering innovative solutions for creating complex biological structures. This transformative technology combines 3D printing with biomaterials and cells, enabling the fabrication of tissues and organs for research, therapeutic, and transplantation purposes. The growth of this market signifies a shift towards personalized medicine and regenerative therapies.

Download PDF Brochure

What is 3D Bioprinting?

3D bioprinting is the process of creating three-dimensional biological structures using specialized printers, biomaterials (biocompatible polymers or hydrogels), and living cells. The technique enables precise layer-by-layer deposition of materials to replicate the natural architecture of tissues and organs. This technology is used across various domains, including drug discovery, cancer research, tissue engineering, and organ transplantation.

Market Drivers

Increasing Demand for Organ Transplants

Organ shortages have prompted research into 3D bioprinted organs as a viable solution. Bioprinting offers the potential to eliminate organ rejection risks by using patient-specific cells.

Advancements in Regenerative Medicine

The ability to create tissue scaffolds and skin grafts is driving the adoption of bioprinting in regenerative medicine, catering to burn victims and patients requiring reconstructive surgery.

Drug Development and Testing

Pharmaceutical companies leverage bioprinted tissues to test drugs in realistic human tissue models, reducing the reliance on animal testing and accelerating drug discovery.

Technological Innovations

Continuous innovations, such as multi-material bioprinting and advancements in bio-inks, are enhancing the capabilities and applications of 3D bioprinting systems.

Request Sample Pages

Key Market Segments

By Technology

Inkjet Bioprinting: Offers high precision and cost efficiency for creating complex tissues.

Extrusion Bioprinting: Preferred for fabricating larger tissue structures due to its ability to use a wide range of bio-inks.

Laser-Assisted Bioprinting: Ideal for intricate tissue engineering applications requiring high resolution.

By Application

Research Applications: Includes drug testing and disease modeling.

Therapeutic Applications: Focused on organ repair and transplantation.

Cosmetic and Personalized Medicine: Bioprinting for skin grafts and customized prosthetics.

By Material

Hydrogels: Most commonly used due to their biocompatibility and tissue-mimicking properties.

Living Cells: Critical for creating functional tissues and organs.

Synthetic and Natural Biomaterials: Used for structural support and scaffolding.

Regional Insights

North America

North America dominates the market due to robust R&D funding, academic partnerships, and the presence of leading biotech firms. The U.S., in particular, is a hub for innovation in 3D bioprinting technologies.

Europe

European countries like Germany and the U.K. are witnessing significant investments in bioprinting research, particularly for medical applications.

Asia-Pacific

Rapid technological adoption in countries like Japan, China, and South Korea is driving growth in the Asia-Pacific region. Governments and private sectors are collaborating to develop cost-effective bioprinting solutions.

Rest of the World

Emerging economies in Latin America and the Middle East are increasingly investing in bioprinting, spurred by growing healthcare demands.

Challenges and Opportunities

Challenges

High Initial Costs: Bioprinting equipment and bio-ink formulations are expensive.

Regulatory Hurdles: Ensuring safety and efficacy standards for bioprinted tissues is complex.

Scalability: Transitioning from prototypes to large-scale manufacturing remains a challenge.

Opportunities

Personalized Medicine: Tailoring treatments using patient-specific bioprinted tissues.

Bioprinted Organs: Meeting the critical demand for organ transplants.

Cosmetic Applications: Skin bioprinting for wound healing and anti-aging treatments.

Competitive Landscape

Prominent players in the 3D bioprinting market include:

Organovo Holdings, Inc.: A pioneer in developing bioprinted tissues for medical research.

Cellink (BICO Group): Specializes in bio-ink development and bioprinting systems.

Allevi: Focuses on affordable and user-friendly bioprinters.

Aspect Biosystems: Known for its microfluidic 3D bioprinting platform.

Startups and established companies alike are investing in research and collaborations to enhance their technological capabilities and market presence.

Future Outlook

The future of the 3D bioprinting market is bright, with applications extending beyond healthcare into industries such as cosmetics, food production, and space exploration. Innovations in bio-inks, improved scalability, and regulatory approvals are expected to drive widespread adoption.

By 2030, the market is anticipated to witness exponential growth, fueled by advancements in artificial intelligence, machine learning, and automation in bioprinting processes. As the technology matures, it holds the promise of revolutionizing how we approach medicine, making healthcare more efficient, personalized, and accessible.

Conclusion

The 3D bioprinting market is a testament to the power of innovation in solving some of humanity’s most pressing healthcare challenges. With continuous advancements, collaborations, and investments, this market is set to redefine the landscape of medical science and beyond. Whether it's creating life-saving organs, testing new drugs, or pioneering personalized treatments, 3D bioprinting holds the key to a healthier future.

0 notes