#two-piece ball valves

Text

Top-Quality Ball Valves Manufacturers in Ahmedabad: A Comprehensive Guide

Ball Valve Manufacturers in Ahmedabad – Discover the best ball valve manufacturers in Ahmedabad, Gujarat.

Gold Techno Casting offers a comprehensive range of high-quality ball valves for various industrial applications.

Google Map:--> https://maps.app.goo.gl/JWfxEKP31rKn8mxj8

Ball Valve Manufacturers in Ahmedabad, Ball Valve in Ahmedabad, Ball Valve Manufacturer in Ahmedabad, Ball Valves Manufacturers in Ahmedabad, Manufacturer of Ball Valve, Manufacturer of Ball Valve Ahmedabad, Ball Valve Manufacturers Compnay in Ahmedabad, Ball Valve Manufacturers Services in Ahmedabad, Two-Piece Ball Valves Manufacturers in Ahmedabad, Three-Piece Ball Valves Manufacturers in Ahmedabad, Trunnion Mounted Ball Valves Manufacturers in Ahmedabad, Non-Rising Stem Ball Valves Manufacturers in Ahmedabad, IC Ball Valves Manufacturers in Ahmedabad, IC Ball Valves Manufacturers from Ahmedabad, Jacketed Ball Valves Manufacturers in Ahmedabad, Cast Iron Ball Valve Manufacturers in Ahmedabad, Manufactures, Exporter, Dealers, Supplier in Ahmedabad Gujarat, Ahmedabad, Gujarat, Ahmedabad Gujarat India, www.goldtechnocasting.com/ball-valve-manufacturers-in-ahmedabad.php, Gold Techno Casting, Gold Techno Casting Ahmedabad Gujarat India

#Ball Valve Manufacturers in Ahmedabad#Ball Valve in Ahmedabad#Ball Valve Manufacturer in Ahmedabad#Ball Valves Manufacturers in Ahmedabad#Manufacturer of Ball Valve#Manufacturer of Ball Valve Ahmedabad#Ball Valve Manufacturers Compnay in Ahmedabad#Ball Valve Manufacturers Services in Ahmedabad#Two-Piece Ball Valves Manufacturers in Ahmedabad#Three-Piece Ball Valves Manufacturers in Ahmedabad#Trunnion Mounted Ball Valves Manufacturers in Ahmedabad#Non-Rising Stem Ball Valves Manufacturers in Ahmedabad#IC Ball Valves Manufacturers in Ahmedabad#IC Ball Valves Manufacturers from Ahmedabad#Jacketed Ball Valves Manufacturers in Ahmedabad#Cast Iron Ball Valve Manufacturers in Ahmedabad#Manufactures#Exporter#Dealers#Supplier in Ahmedabad Gujarat#Ahmedabad#Gujarat#Ahmedabad Gujarat India#www.goldtechnocasting.com/ball-valve-manufacturers-in-ahmedabad.php#Gold Techno Casting#Gold Techno Casting Ahmedabad Gujarat India

0 notes

Text

Two Piece Ball Valve manufacturer in India | Instrument fittings

Instrument fittings is the top Two Piece Ball Valve manufacturer in India. Specializing in the manufacturing of 2 piece ball valves, our company in India offers high-quality valves designed for efficient flow control and shut off in industrial and commercial applications. Our valves are constructed using durable materials and precision engineering to ensure reliable performance and long-term durability. With a focus on meeting industry standards and customer requirements, our 2 piece ball valves are suitable for a wide range of industries, making them a versatile and cost-effective solution for your valve needs.

0 notes

Text

0 notes

Text

Learn About On Titanium Ball Valve Types And Features

Ladhani Metal Corporation is one of the leading Titanium Ball Valve Manufacturers in India. Our company provides these Titanium Ball Valves with high demand due to its features like lightweight, high strength, sturdy design, easy to install, high performance and longer service life.

According to the Titanium Ball Valve Manufacturer that is to be used for radioactive material will have different requirements than one that is to be used for storing or handling gasoline.This titanium ball valve is a type of valve that controls the flow of fluids or gases by using a ball with a hole in the centre. It is mostly constructed of titanium, which is a strong, lightweight, and corrosion-resistant metal.

Types Of Titanium Ball Valve

Titanium One Piece Ball Valve

Titanium Two Piece Ball Valve

Titanium Three Piece Ball Valve

Titanium Top Entry Ball Valve

Titanium Orbit Ball Valve Manufacturer

Titanium Jacketed Ball Valve

Titanium Unibody Ball Valve

Features On Titanium Ball Valve

Titanium ball valves have a number of distinguishing characteristics that make them suited for a wide range of applications. Here are some significant characteristics of titanium ball valves:

Titanium Construction: Titanium ball valves are largely made of titanium, a metal that is strong, lightweight, and corrosion-resistant. Titanium is extremely durable and resistant to corrosion, chemicals, and severe conditions.

Full Bore Design: This design reduces flow constraints, pressure drop, and turbulence, enabling for efficient fluid or gas flow.Titanium ball valves are normally full bore, which means the internal diameter of the valve is the same as the pipe's Diameter.

Two-Way Flow Control: Titanium ball valves provide reversible flow control, which allows fluid or gas to travel through the valve in both directions. This feature allows for greater flexibility in system setups and easy control of flow direction.

Various End Connections: The type of end connection used is determined by the application and installation requirements.Titanium ball valves are offered with a variety of end connectors to accommodate a variety of pipe systems.Threaded, flanged, socket weld, and butt weld connectors are all common forms of end connections.

Wide Temperature and Pressure Range: Titanium ball valves are resistant to a broad variety of temperatures and pressures. They can be used in both low-temperature cryogenic applications and high-temperature procedures, making them adaptable to a wide range of industrial conditions.

In conclusion,Titanium ball valves are a highly dependable and adaptable solution for applications needing corrosion resistance, high strength, and effective flow control. Their distinctive qualities, such as superior corrosion resistance, a high strength-to-weight ratio, and temperature/pressure resistance, make them suitable for a wide range of sectors, including chemical processing, oil and gas, petrochemical, power generation, water treatment, and aerospace.

#Titanium Ball Valve#Titanium Ball Valve Manufacturers#Titanium One Piece Ball Valve#Titanium Two Piece Ball Valve#Titanium Three Piece Ball Valve#Titanium Top Entry Ball Valve#Titanium Orbit Ball Valve#Titanium Jacketed Ball Valve#Titanium Unibody Ball Valve

0 notes

Text

Agile Valves: Streamlining Flow Control with Two-Way Valves

Two-way valves play a crucial role in fluid control systems, enabling efficient and precise flow regulation. When it comes to high-quality valves, Agile Valves is a trusted brand, providing innovative solutions for various applications.

Agile Valves understands the importance of reliable flow control, and their two-way valves are designed to deliver exceptional functionality and performance.

Here are several reasons why Agile Valves' two-way valves are the preferred choice for industries worldwide:

Superior Quality: Agile Valves is committed to delivering products of the highest quality. Their two-way valves are meticulously manufactured using premium materials, ensuring durability and long-lasting performance. Stringent quality control measures are implemented throughout the production process to meet or exceed industry standards.

Versatile Design: Agile Valves' two-way valves feature a versatile design that allows for seamless integration into different systems. These valves can handle various fluids, including gases, liquids, and steam. They offer reliable shut-off and control capabilities, ensuring precise regulation of flow in both directions.

Efficient Flow Control: Precise flow control is critical in many industries, and Agile Valves' two-way valves excel in this aspect. With their advanced design and engineering, these valves provide smooth operation, low pressure drops, and excellent flow characteristics. This allows for optimal control over fluid movement, enhancing system efficiency and performance.

Robust Construction: Agile Valves two-way valves are built to withstand demanding conditions. They feature robust construction, including sturdy bodies, reinforced components, and reliable sealing mechanisms. These design elements ensure durability and reliable performance even in harsh operating environments.

Customized Solutions: Agile Valves recognizes that each industry and application has unique requirements. They offer customized solutions tailored to specific needs. Their team of experts works closely with clients to understand their specific challenges and design two-way valves that meet their precise specifications and performance expectations.

Expertise and Support: Agile Valves combines industry expertise with a customer-centric approach. Their team of professionals possesses extensive knowledge and experience in fluid control systems, providing valuable guidance and support to customers. They collaborate closely with clients to ensure the selection of the most suitable two-way valve solutions for their applications.

Agile Valves two-way valves provide reliable and efficient flow control solutions. Their commitment to quality, versatility, and customer satisfaction has made Agile Valves a trusted partner in the industry.

For dependable and high-performance two-way valves, trust Agile Valves to deliver exceptional products that meet your specific requirements. Experience the reliability and precision of Agile Valves' two-way valves and streamline your flow control processes with confidence.

0 notes

Text

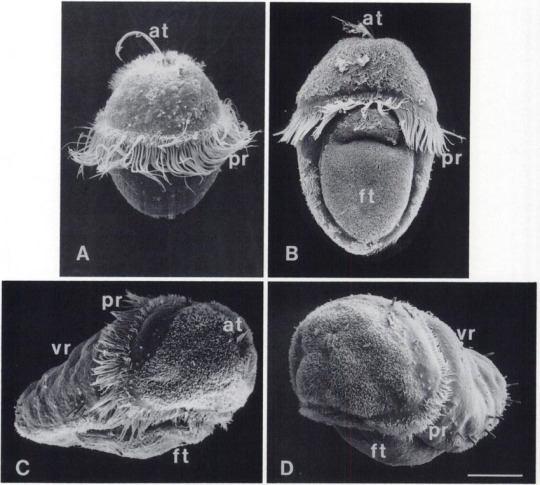

Wet Beast Wednesday: chitons

For last week's Wet Beast Wednesday I talked about a weird invertebrate whose name starts with "c" so this week I'm gonna branch out from that and talk about a weird invertebrate whose name starts with a "c". Chitons are marine mollusks of the class Polyplacophora that bear a resemblance to limpets, but have a segmented shell that allows for more flexibility. They are named after a form of clothing worm by the ancient Greeks.

(image id: a chiton. It is an oval animal with a flat shell composed if 8 overlapping green and white plates. Surrounding the shell is brown, soft tissue)

Chitons are similar in appearance and ecology to limpets, though they are not closely related. The shell of a chiton is made of 8 plates called valves. Valves are the name of any mollusk shell that is divided into multiple pieces. Most mollusk shells are made of one continuous piece and the only ones that have valves are the chitons, bivalves, and a few weird snails. The valves of a chiton overlap slightly, allowing for flexibility while still giving protection. Chitons can curl up into balls and flex backwards to move over concave surfaces that limpets wouldn't be able to. The valves are imbedded in and held together by a thick, muscular ring called the girdle that encircles the body. In most species, only the sides of the valves are covered by the girdle, leaving the rest exposed to the water. A few species cover more or all of the valves with the girdle. When a chiton dies and the girdle decays, the valves will separate. Individual valves sometimes wash up on beaches and are called butterfly shells due to their v-shaped appearance. The shell is used for defense. Chitons can curl up in a ball when not attached to a rock. If one is attached to a rock, it can suction on, presenting predators with no good way to attack its soft underbelly. Some species have spikes, bristles, or other ornaments on their valves and girdles that can provide additional protection.

(image: a chiton curled up into a ball. Its plates are pale pink and its girdle is white and brown)

Underneath the shell, the chiton's body is soft. It consists largely of a muscular foot that is used for movement. To either side of the foot is the mantle cavity, which consists of channels filled with gills that water is pulled through. There is no distinct head, but a mouth is present on the front end. Inside the mouth is the radula, a tongue-like appendage that is covered in teeth. The teeth are special because they are coated in magnetite, a very hard magnetic mineral that has iron as one of its main ingredients. While the metal is used to reinforce the teeth and keep them from wearing out (in fact, the chiton Chaetopleura apiculata has the hardest teeth of any known animal), it may also be used for magnetoreception. This is when an animal can sense magnetic fields. It is possible that the magnetic teeth of chitons can sense the Earth's magnetic field and help with navigation and migration. Most chitons are herbivores or omnivores that feed on algae, bryozonans, diatoms, and other tiny rock-dwellers by scraping at rocks with their radulae. Some are carnivores that target barnacles and can even eat small crustaceans and fish. They often hunt by holding the front ends of their girdles up in the water. Should an animal mistake it for shelter, the chiton will clamp down on them. Food is forced through the esophagus by a current of mucus moved by cilia.

(image: the underside of a chiton. it is oval and orange all over. Two groves filled with brown gill filaments go down each side of the body, encircling a central foot. The mouth is visible as a small hole on one end)

When it comes to senses, chitons have a few options. Like their gastropod cousins, chitons have a chemosensory organ called the subradular organ used for smell and their feet and girdles are full of sensory nerves. They also have special organs called aesthetes. These consist of light-sensing cells that are just below the surface of the shell. The aesthetes are not true eyes, only being able to distinguish light from dark, though they can tell the difference between a shadow and the effects of clouds moving over the sun. Some species use collections of aesthetes to form simple eyes called shell eyes. Unlike the aesthetes, the shell eyes can form images, though Chitons do not have nerve structures needed to form a high resolution image. Shell eyes are distinct from those of any other animal in their structure. Most animals have eye lenses made of protein-based structures, but chiton lenses are crystalline, made of aragonite, the same material that makes up the shell of most mollusks. Each shell eye is compound. The shell eyes are almost certainly used for predator detection. Fossil chitons have been found dating back to the Cambrian period. but shell eyes have only been found in fossils from less than 10 million years old. This likely makes chitons the most recent animal group to have evolved true eyes. Chiton eyes have also been found to work both in water and air, which is tricky due to the way light travels differently through both mediums.

(image: a close-up of a chiton's shell showing the eyes. The shell is yellow and lumpy with the eyes visible as darker, almost black lumps)

The majority of chitons live in intertidal or sub-tidal areas, making them a shallow water group. A few species have been found living in much deeper water, up to 2,000 meters down. Chitons have been known to have homing behavior as they will consistently return to a safe spot after feeding. How they do this is unknown. Sensing the magnetic field of the Planet may play a role, though it is also possible that they lay down chemical trails to find their way home. Chitons are broadcast spawners, with both males and females releasing gametes into the water. Larvae can swim for a while before moving to the substrate.

(image: microscope images of a chiton larva at 4 different developmental stages. It begins as a round blob ringed with hair-like cilia. As the animal develops the cilia recede and the animal elongates, with a distinct foot becoming visible. source)

I will close by bringing up an animal I only learned about recently but has rapidly become one of my favorite weird beasts. This is Cryptochiton stelleri. Its common name is the gumboot chiton, but some people call it the wandering meatloaf, which is objectively the best name ever. It is the largest chiton, growing up to 36 cm (14 in) and 2 kg (4.4 lbs). Its girdle completely covers its shell, which does make it look more like a meatloaf. They can live up to 40 years and are the first known animals to have the mineral santabarbarite in their bodies. They live throughout the north pacific and have been used as a food source by many different cultures. There may be a lot of bad stuff in the world, but if things get too bad, just remember that we live on the same planet as an animal called the wandering meatloaf that can live for 40 years and has a tongue covered in magnetic teeth.

(image: a wandering meatloaf. It is an ovoid animal with red-orange tissue covering the body. Its shell is not visible, but the ridges where each plate overlaps can be seen through the girdle)

#wet beast wednesday#chiton#wandering meatloaf#gumboot chiton#mollusk#molluscs#marine biology#biology#zoology#ecology#animal facts#marine animals

460 notes

·

View notes

Note

Im here to beg for some synth-en megaratch because i dont havr any meaning in life besides stalking your blog <3

hgrhhh you are leaving me an open stage, i don’t know where to start… okay. The synth-en not only increasing both bloodlust and arousal, but mixing them together, which means that when Ratchet gets to Megatron he is, number one, filled with unbridled fury, number two, extremely horny after all the vehicons he knocked down on his way, and number three… Megatron can tell.

But you know, not a lot of people have the balls to just dominate Megatron himself like he’s just some piece of metal found on the street. So obviously, while Megatron is stronger than Ratchet, he lets him pin him down anyways, curious to see what the medic, seemingly unaware of the charge basically dancing across his plating, will do now. Spoiler: he doesn’t kill him. He fucks him. What a surprise.

mhmmm Megatron is so big that his valve doesn’t need to be prepared, all Ratchet has to do is shove his spike in and start pounding into him with more strength than he really should have in him, at any point. Megatron gasping in surprise, inner nodes assaulted carelessly, with no concern for whether he might try and point his fusion cannon at Ratchet’s head, or beat the shit out of him if Ratchet does something wrong, no, the autobot didn’t care about any consequences at the moment and Megatron enjoyed it tremendously. Maybe Ratchet degrades Megatron a little. Or a lot. Calls him all the things he’d normally call him, a monster, a maniac, an evil bastard, but this time he whispers it through grit denta as he nears his overload, each squeeze and punch and scratch delivered to Megatron’s plating that leaves a visible mark making him so much hornier.

hghhhh Ratchet’s transfluid being filtered out synthetic energon which means that everytime he overloads into Megatron, he gets him a little bit more high off the synth-en as well. By the time they’re found, Megatron is twitching and moaning through his Nth overload in the past half hour and Ratchet is still digging into him without breaking a beat in his pace, except to cum, but he recovers quickly and keeps going. I think Ratchet’s the one to tell Optimus to get the fuck out of here, this is between him and Megatron now.

#my ideal tfp megaratch dynamic is ’’guy with a degradation kink x guy who just hates him#and also ratchet telling optimus ’’fine. i’ll fuck him. since you’re so fucking complicated#this is kind of long but i have to deliver. you shall remain here to stalk my blog forever#valveplug#dubcon#not even bc of megs getting pinned down i just think the synth-en is messing with ratchet’s head a lil#megaratch#text

104 notes

·

View notes

Text

↳four

chapter four of "meddle about" series

brian o'conner x reader

iv. the shitty, yet perfect car

"What about parts and service?" Mia asked as she held a folder full of papers in her hands. Y/n and Letty stood by a car, fixing it up.

"Hold off on that." Dom answered.

"But, Dom, I don't know what to do with--" Mia cut herself off as a nasty, old wrecked, car was backed into the garage.

"All right, what the hell is this?" Dom asked Brian, coming closer. Everyone else came closer as well, wanting to know what the hell that thing was. "What do you got there?"

"This is your car." Brian said, proudly.

"My car?" Dom pointed to himself as Jesse hit on the side of it with his fist. "I said a ten-second car, not a ten-minute car."

"You could push this across the finish line, or tow it." Y/n said making Letty laugh.

"You couldn't even tow that across the finish line." Dom said.

"No faith." Brian shook his head a little with a smile, as the group laughed.

"Oh, I have faith in you, but this isn't a junkyard." Dom said, gesturing to the car. "This is a garage."

"Hey, pop the hood." Brian told Jesse

"Pop the hood?"

"Pop the hood." Brian grinned at Dom. The team moved the car into the garage where Jesse opened the hood, making it fall completely off.

"Two J.Z. engine. No shit." Jesse said.

"Goddamn, look at that thing." Y/n leaned closer to inspect it.

"And what did I tell you?" Brian smiled, crossing his arms.

"I retract my previous statement." Dom said, a little impressed.

"You know what?" Jesse said holding onto the crowbar he used to open the hood. "This will decimate all after you put about fifteen grand in it or more, if we have to overnight parts from Japan."

"We'll put it on my tab at Harry's." Dom said.

"Yes!"

"I gotta get you racing again so I can make some money off your ass." Dom said to Brian. "There's a show down in the desert called Race Wars and that's where you'll do it." Dom started to walk away but stopped and turned to Brian. I'll tell you what. When you're not workin' at Harry's, you're workin' here. If you can't find the right tool in this garage, Mr. Arizona, you don't belong near a car."

Y/n walked closer to Brian with a smirk, she got close enough to feel his breath on her face, "Guess your his bitch now." She chuckled at her comment before going working on her car.

The next day after a morning at the garage, the Toretto family decided to make the team a family dinner.

"Mia! Y/n! Come on, the chicken's dry already." Dom called out to them as Monty and himself grilled the chicken.

"Oh, shut it, we're coming!" Y/n called back to him, as she, Mia, Jesse, and Brian walked out the door bringing the things to set the table. Once the table was set and the food was placed onto it, they sat down, ready to eat.

"Wait. Hold up." Dom said, as Jesse grabbed a piece of chicken. "Because you were the first out of everyone here to reach in to get the chicken, you say grace."

Everyone bowed their heads, and locked their hands.

"Dear heavenly, uh--" Jesse blanked for a moment, making Y/n want to burst out laughing.

"Spirit." Leon finished for him.

"Spirit. Thank you." Jesse continued. "Uh, thank you for providing us with a direct port nitrous, uh, injection," Y/n let out a quiet snort making Brian nudge her side in amusement. "Four-core intercoolers and ball-bearing turbos, and, um, titanium valve springs. Thank you."

"Amen!" Leon said, as the rest of them clapped.

"He was prayin' to the car gods, man." Letty said, amused.

"If he's not the best--" Dom said with a smile, as he passed the plate of chicken around.

"Look who it is." Leon said. Y/n turned her head to see Vince walking towards them. "Old Coyotes 'R' Us. I thought you we're hungry, pumpkin."

Y/n's face dropped from joy to annoyance. Brian saw this and placed a comforting hand on her thigh. She looked at him and then down at his hand. He quickly pulled it away and before he could apologize, she put it back, placing hers on top of it.

"You know, I gotta eat." Vince said.

"He's always hungry." Letty said, blankly.

"All right, sit down." Dom waved him over. As Vince passed, he rubbed Dom's head inaudibly saying thank you. Vince greeted Mia before patting his brother's shoulder. His eyes fell onto Y/n as he sat down but she converted hers to Brian, who smiled at her making her smile back.

After dinner, the team went to the living room to watch a movie. Y/n decided to wash the dishes, opting to do it then rather than later.

"You need a hand with anything else?" Brian asked, bringing in the rest of the plates.

"No, I'm good." Y/n said, focusing on the dishes. "You can go join the boys watchin' the movie."

"No, you see, the cook doesn't clean where I come from." Brian said, slipped beside her. He took a towel and started drying the already clean plates and cutlery.

"Yeah?" Y/n questioned, glancing at him. "I'd love to go there." She then remembered something from a few days ago. "Hey, you remember you were gonna ask me something the day of the race?" She asked after a beat of silence. She stopped and turned, leaning her back against the sink. "What was it?"

Brian sighed and sat the plate he was drying down, "I was gonna ask you out. Which reminds me, do you wanna go out with me?"

Y/n tapped her lips in thought, "Hmmm, I don't know. I don't really date my cousin's friends."

"Oh, well, I guess I'll have to kick his ass then."

Y/n tried to hid her smile as she nodded her head, "Oh, yeah, I'd love to see that one. I would even pay to see it."

"Okay, but seriously. Am I gonna have to get on my knees and beg you or?"

Y/n smile grew even more, her heart bursting with adoration. "I don't know. You on your knees sounds like a good sight to see."

Y/n's head turned at the sound of the microwave opening. Vince let out a wheeze as he popped in a bag of popcorn.

"Wash my car when you get done." he said, laughing.

"Excuse me?" Y/n glared at him.

"No, Y/n, I'm talking to the punk. And wear your favorite dress, 'cause when you're done, I'm puttin' you on the street where you belong, cutie." Y/n bit her tongue so hard she could taste blood. Vince laughed before looking back at the microwave. He pushed some buttons and hit the side. "Is this thing broken? What's wrong with this thing?"

She couldn't stay quiet anymore. "V?" She walked closer, grabbing his attention. "V, what was that Cuban restaurant you wanted to take me to? The one with the picadillo and the--"

"Little red candles and the wooden table?" Vince grinned.

"Yeah," Y/n said, coming a bit closer. "the plantain too. I see it all over the place, what's it called?"

"Cha Cha Cha." Vince said, still grinning. Y/n grinned back and she turned to Brian, walking closer to him. "Well, you can take me there. Does Friday night at 10 sound good to you?"

"Yeah, it's perfect." Brian said.

"Good." Y/n said, looking down at his lips before going back up to his eyes. The two of them looked at Vince, who was backing out of the kitchen. He hit the door as he walked, angry.

"Make your own goddamn popcorn!" they heard Vince shout. Y/n placed a hand over her mouth to keep in her giggles. Brian smiled, not believing he's got a date with the most beautiful girl he's ever seen.

98 notes

·

View notes

Text

Get My Heart Under Contract

Written because I couldn't shake this post by @stonelionhearts. Thanks to @velvethopewrites for the little push i needed to write it!

ao3 1400 words, rated T (for now anyhow) 4926 word, Rated E

This is all Gabriel’s fault.

Cas’s business is doing just fine. He’s staying busy. He has a steady stream of customers. Home improvement never goes out of fashion. But his brother has insisted he join a--God, Cas can hardly even think it without rolling his eyes--networking group. Which is why Cas is dressed in a goddamn dress shirt, tie, and slacks on a Tuesday morning instead of finishing up the jetted tub install on his latest job.

Which reminds him. He needs to pick up a part. Glancing at the time, he sees he has a few minutes to kill before the meeting starts. He’s across town from his usual hardware store, but these chains are all the same so he can pop into the one over here and kill two birds with one stone.

He strides purposely into the store, confident he’ll know the layout, to grab the piece and be on his way again. Instead, he finds himself wandering from aisle to aisle, frustration building as he does. By the time he finds the plumbing section, he’s muttering to himself about inefficient store planners and glaring at the long rows of products as if they've personally offended him. Honestly, if he had the time he’d start re-organizing the entire layout in a way that actually makes sense. Sighing, he tries again to find what he’s looking for, a small headache beginning behind his eyes. Definitely Gabriel’s fault.

A friendly voice comes from his left. “Can I help you?”

Cas tugs at his own collar in an attempt not to snap at this salesperson who has no idea he’s just taken his life into his own hands. He turns to crisply dismiss the poor fellow and finds himself face to face with what can only be described as an incredibly beautiful man. He’s looking at Cas expectantly, green eyes wide. There’s a smattering of freckles on his face, and he wets his lips as he waits for Cas to answer. Which Cas should definitely do, but this is such an unexpected turn of events that Cas finds they’re standing and staring at each other for much longer than is socially appropriate.

The man--and now Cas sees he’s got a name tag pinned to his work apron--Dean nods at the display and tries again. “Looks like you’re working on a plumbing project. Those can be tricky. Do you know what piece you need?”

Of course Cas knows what he needs. He’s got all the dimensions memorized. He could do this job in his sleep. “Uh,” he begins, and has to clear his throat. He holds out his hands. “About this big?”

Dean studies the display, his tongue poking out at his concentrates. It’s all Cas can do not to reach out a hand to steady himself. He’s watching Dean’s face instead of finding the part he needs, and maybe he should feel bad about all this blatant staring, but he feels something akin to starstruck by this man.

“It’s probably this one.” Dean reaches for the exact part Cas was looking for, and Cas watches the muscles of his shoulder flex beneath his tight black t-shirt. “But just to be on the safe side, you might want to take this size as well.” He turns to face Cas, a part in each hand. “We make returns as easy as possible,” he says with a smile.

Cas definitely only needs the larger size. He takes both parts, happy to have something to do with his hands at least. “Thank you. That’s very helpful.”

“Anything else?”

If Cas leaves right now, he’ll only be about five minutes late for the networking meeting. He takes a step to his left, moving into Dean’s personal space, and pivots to the display behind them. “Can you tell me about these?”

They’re nothing complicated. Ball valve shut offs. Cas has an entire drawer of them in his tool box. Still, Dean answers his question respectfully, explaining various uses and pointing out the differences. “And these?” Cas realizes he's pointed to a display of brass nipple fittings and why do all these pieces sound so dirty? Cas works on not blushing as he lets Dean’s words wash over him, watching the way Dean’s face lights up as he talks, his strong hands picking things up to show Cas the minute differences. There’s nothing condescending in his speech, just the pure joy of sharing his knowledge with someone who wants to learn.

And does Cas ever want to learn. He wants to learn if Dean’s lips are as soft as they look. He wants to learn if those gold flecks in his green eyes look different under candlelight. He wants to learn how the calloused touch of those work-worn hands would feel on Cas’s shoulder and chest and hip…

“You know a lot about building things, it seems,” Cas manages. “Where did you learn it all?”

Dean glances away. “My dad was all about uh, DIY, I guess you could say. Left me with some skills.” There’s a story there, Cas is sure. He wants to learn that, too. Dean, however, seems eager to change the subject. “What about you? Are you working your way through your honey-do list?”

Cas watches as Dean’s mouth twists, like he regrets the words as soon as they leave his mouth. It warms something inside him and he’s quick to respond. “Nothing like that. I live alone.”

Dean smiles at him. “You know, you’re going to need a piece of drywall to patch the hole after that installation.”

He’s not wrong. And Cas has many pieces available already. He feels his head tilt, eyes squinting in confusion. “Where would I find that?”

“Happy to show you!” Dean leads the way, and dear God now Cas can see that he’s got bowed legs, his hips swaying as he walks in a way that has Cas wanting to learn many, many more things.

Dean continues to guide him through the process, at some point grabbing a flat bed cart and loading it up with everything Cas might need. He opens up a register so that he can handle the payment himself. “Thank you, Mr. Novak,” he says, handing him the receipt. And then he offers to help Cas out to his car.

“Oh, that won’t be necessary,” Cas says quickly, because this has gotten out of hand. “I can do it.”

“Nonsense,” Dean says. “No point in you getting dirty when you’re all dressed up nice for work.” He reaches a hand out and Cas freezes, breath caught in his throat, but all Dean does is flip his tie which has somehow turned backwards. While Cas will his pulse to slow, Dean grips the cart. “Now, where are you parked?”

Any other protests die on his lips. There’s nothing to be done and Cas leads him across the parking lot, doing a walk of shame to his very own contractor van parked at the end of a row.

Dean pulls up short with the cart, eyes blinking rapidly. “Novak,” he says. “That’s you?”

“I’m so sorry,” Cas says in a rush, knowing that he’s ruined this. “I didn’t mean to mislead you, it’s just that…”

Dean raises an eyebrow. “Just that what?”

Cas can’t look at him. He stares miserably at his stupid dress shoes. “I was enjoying your company so much.”

There’s a long pause. “Hmm.” Chancing a look, Cas sees Dean is smiling at him. It’s a bit smug, but it looks good on him nonetheless. Dean pulls out his phone and takes a picture of the side of the van. “So, I could call you if I want to continue this conversation?”

Relief has Cas smiling back. “I wish you would.”

Together they unload the cart. “So, what’s with the monkey suit?” Dean asks.

“My brother convinced me to go to a business networking meeting.” Cas checks his watch. “Which I am now embarrassingly late for.”

Dean leans a hip against the side of the van. “That so? Guess you’ll never meet anybody new then.”

“Guess not.” They’re staring at each other again.

Finally, Dean breaks eye contact. “I gotta get back.” He reaches out a hand. “It was a pleasure helping you today, Mr. Novak.”

Cas clasps his hand longer than necessary. It’s warm and strong and Dean uses his thumb to rub a small, secret circle on Cas’s skin. “Call me,” Cas says and it only sounds a little desperate.

“Oh, I will,” Dean assures him with a wink. “You look like the answer to all my pipe-laying needs.”

164 notes

·

View notes

Note

hey!! Your blog is really cool and has a ton of great info. I love the way you talk about things :)

Just wondering, I’ve been having a really hard time trying to control my brain. Been bad recently. Just a lot of accidental telepathy and silly brain things that I don’t quite have a grip on.

I like all the power, don’t get me wrong, but it’s just a lot to deal with day to day. Do you have any tips on how I could put a handle on it? Even just a little

Thanks^^

Hello!

Lee Morgan said it well (I'm sure it was his book), albeit in reference to witchcraft, that practicing is like a fire that burns away your fat. Like, we're all slabs of bacon and we can throw ourselves on the skillet to cook. Using your skills is exposing yourself to the raw flame of the Other.

And we can render out very nicely and produce something lovely.

But, also, when your "protective layer" is burned away, then problems start. Then the fire starts licking your brain directly.

And that's not good.

So really you've got to take breaks. People don't want to, because it's lots of fun to practice and they get enamored with how their brain pops and sizzles when held directly over the firepit.

But you have to take breaks. And I don't mean fifteen minutes a day of not-practice. I mean, days off. Weeks off. A season off - or two, if you've really gone overboard.

Imagine that your craft is a fireplace, and every time you intentionally practice you are laying another stick of wood on the fire. And that fire is getting bigger and bigger. And if you keep going, your house is going to be too hot to stay in.

The house is your self. You cannot leave.

But even when you stop putting wood on the fire, well - you've still got a raging fire! It's going to have to burn itself out and calm itself down. And that process is not a few minutes of deep breathing. That process is waiting. Days, weeks, seasons. You have to let it cool down.

So you have to look yourself in the eye and say, "is my house getting too hot? Can I really afford to keep putting wood on this fire?"

And besides, you're never going to be able to sweep out your fireplace and clean your chimney while the fire is still going, but that's a metaphor for another time.

During one long period of my life I had been going through Too Much Input, and all these things were happening to me and around me that was a lot to deal with, on a day to day basis. My boyfriend is quite wise in the ways of wizardry, so I asked him how he handles it. How do you handle all these things you can perceive and know?

And he shrugged and said, "ignore it."

I was gobsmacked! Ignore it? Just pretend it isn't happening and get on with my day?

Well he was right, wasn't he. That's a crispy looking psychic stick, sun-dried and well aged. I'm just meant to ignore it? I'm not supposed to snap it up like a rowdy dog and drop it directly onto the bonfire of my mind?

I'm meant to just walk the trail without grabbing every single piece of kindling I can stuff in my mouth?!

How else will I burn my house down??

So another thing is, you can't let yourself chase after it all like a Golden Retriever after tennis balls.

There will always be another message, another snippit, another tidbit, another spirit.

You've got to learn to let them go past you, like you're in a Ghibli movie on a sun-lit hill on a cloudy day, watching cars far below you on the freeway.

It's a freeway. There will always be more cars. Let them go. Let them go before your house burns down.

"What about such-and-such psychic technique for turning off power?"

Oh, sure. There are plenty. Imagine a valve closing. An amulet to limit sensing. Shielding techniques.

The danged heck of it is, such-and-such techniques are tinder. More psychism to stop psychism is just fire on fire.

They're good tricks to know. They're the equivalent of an iron shield to dissipate heat, or building a flue to control the air, or wearing fire-resistant clothing.

But they don't put the fire out, do they.

One day, when your fire is not making your house too hot, perhaps you'd really benefit from knowing such-and-such techniques to more expertly control your hearth.

Let it cool down. Sweep the ashes out. Check your chimney. Do not be afraid of never being able to light the fire again.

Lighting it is easy. Putting it out is the hard part.

Strive to find balance. Some people like a huge bonfire once a month. Other people have tiny little fires to warm their feet that they keep going constantly. Others never let the coals get cold, and only stoke them for mealtimes.

Figure out what you need to make your house a home. Figure out how often to feed the fire to make meals for yourself and your friends, to keep the house warm, to make it a lovely place.

Learn how to let it die down. Do not chase after all shiny things. Learn as many such-and-such techniques as you like, as long as you understand they're fire too.

73 notes

·

View notes

Text

Floating Ball Valve: A Comprehensive Guide to Optimal Fluid Control

Floating Ball Valves are essential components in fluid control systems, offering reliable shut-off and excellent sealing capabilities. In this comprehensive guide, we will explore the features, benefits, and applications of floating ball valves, providing valuable insights to help you make informed decisions for your fluid control needs.

Section 1: Understanding Floating Ball Valves

Floating ball valves are designed with a Floating Ball that is not fixed to the valve stem. This unique design allows the Ball to float and move with the fluid pressure, ensuring optimal sealing and minimizing the risk of leakage. These valves are commonly used in various industries for their versatility and reliable performance.

Section 2: Advantages of Floating Ball Valves

Excellent Sealing: Floating ball valves provide exceptional sealing performance due to the pressure exerted on the ball by the fluid, ensuring tight shut-off and preventing leakage.

Wide Range of Applications: Floating Ball Valves are suitable for a wide range of applications, including oil and gas, petrochemicals, chemical processing, water treatment, and many more. Their versatility makes them a popular choice in various industries.

Easy Operation and Maintenance: Floating Ball Valves are designed for ease of operation and maintenance. The simple structure and fewer components contribute to quick and efficient maintenance, reducing downtime and overall costs.

Section 3: Types of Floating Ball Valves

Two-Piece Design: This type of floating ball valve consists of two main parts—the body and the Ball. It offers ease of maintenance and is commonly used in low-pressure applications.

Three-Piece Design: Three-piece floating ball valves feature a detachable body, allowing easy access to the internals for maintenance. They are suitable for high-pressure and high-temperature applications.

Section 4: Selecting the Right Floating Ball Valve

Consider the following factors when choosing a Floating Ball Valve:

Material Compatibility: Ensure that the valve materials are compatible with the fluid being handled, considering factors such as corrosion resistance and temperature limitations.

Pressure and Temperature Rating: Select a valve with the appropriate pressure and temperature ratings to ensure optimal performance and safety.

End Connection Type: Choose the correct end connections (flanged, threaded, or welded) based on your piping system requirements.

Section 5: Maintenance and Safety Tips

Proper maintenance and safety practices are crucial for the optimal performance and longevity of floating ball valves. Regular inspection, lubrication, and adherence to safety guidelines are essential to ensuring reliable and safe operation.

Floating Ball Valves are reliable and versatile components for fluid control applications. Their excellent sealing capabilities, a wide range of applications, and ease of operation make them a popular choice in various industries. By understanding the advantages, types, and selection criteria for floating ball valves, you can make informed decisions and optimize your fluid control systems for efficient and reliable performance.

2 notes

·

View notes

Text

Ball Valve - Ball Valve Manufacturer from Ahmedabad

Manufacturer of Ball Valve - Ball Valve, Ball Valve, Valve and Gate Valves offered by Gold Techno Casting, Ahmedabad, Gujarat.

Google Map:--> https://maps.app.goo.gl/F1SNixhuGB5EoE3SA

Ball Valve Manufacturers in Ahmedabad, Ball Valve Manufacturer in Ahmedabad, Ball Valve Manufacturers Compnay in Ahmedabad, Ball Valve Manufacturers Services in Ahmedabad, Ball Valve Manufacturers Ahmedabad, Ball Valve, Ball Valve Manufacturer from Ahmedabad, Cast Iron Ball Valve, Two Piece Ball Valve, SS Bar Stock Ball Valve, WCB Ball Valve, 3 Way Ball Valve, Ball Valve, Ball Gate Valves, Ahmedabad, Gujarat, Gold Techno Casting, Top Ball Valve Manufacturers in Ahmedabad, Valve Manufacturers in Ahmedabad, Ball Valve Manufacturers in Ahmedabad, Ball Valve Dealers in Ahmedabad, Popular Ball Valve Manufacturers in Ahmedabad, Top Ball Valve Manufacturers in Ahmedabad, Ball Valves in Ahmedabad, Gujarat, Custom Ball Valve Manufacturers in Ahmedabad, Ball Valves Suppliers in Ahmedabad, Ball Valves Exporters in Ahmedabad, Ball Valve Mfg in Ahmedabad, 2 Piece SS Ball Valve Manufacturer from Ahmedabad, Ball Valves Ahmedabad, Top Pvc Ball Valve Manufacturers in Ahmedabad, Ball Valve Manufacturers in Ahmedabad, IC Ball Valves Manufacturers from Ahmedabad, Cast Iron Ball Valve Manufacturers in Ahmedabad, Two Piece Ball Valve Manufacturers in Ahmedabad, Ball Valve, IC Ball Valves, Cast Iron Ball Valve, Two Piece Ball Valve, SS Bar Stock Ball Valve, WCB Ball Valve, www.goldtechnocasting.com/ball-valve-manufacturers-in-ahmedabad.php, Gold Techno Casting

#Ball Valve Manufacturers in Ahmedabad#Ball Valve Manufacturer in Ahmedabad#Ball Valve Manufacturers Compnay in Ahmedabad#Ball Valve Manufacturers Services in Ahmedabad#Ball Valve Manufacturers Ahmedabad#Ball Valve#Ball Valve Manufacturer from Ahmedabad#Cast Iron Ball Valve#Two Piece Ball Valve#SS Bar Stock Ball Valve#WCB Ball Valve#3 Way Ball Valve#Ball Gate Valves#Ahmedabad#Gujarat#Gold Techno Casting#Top Ball Valve Manufacturers in Ahmedabad#Valve Manufacturers in Ahmedabad#Ball Valve Dealers in Ahmedabad#Popular Ball Valve Manufacturers in Ahmedabad#Ball Valves in Ahmedabad#Custom Ball Valve Manufacturers in Ahmedabad#Ball Valves Suppliers in Ahmedabad#Ball Valves Exporters in Ahmedabad#Ball Valve Mfg in Ahmedabad#2 Piece SS Ball Valve Manufacturer from Ahmedabad#Ball Valves Ahmedabad#Top Pvc Ball Valve Manufacturers in Ahmedabad#IC Ball Valves Manufacturers from Ahmedabad#Cast Iron Ball Valve Manufacturers in Ahmedabad

0 notes

Text

SS Ball Valve Manufacturer in India: A Comprehensive Guide

Stainless Steel (SS) ball valves are indispensable in a wide array of industries, from oil and gas to water treatment and chemical processing. In India, the manufacturing of SS Ball Valves manufacturers in Ahmedabad, Vadodara, Mumbai, Delhi, Chennai, Bangalore, Ghaziabad, Rajasthan, Gujarat has seen significant growth due to the increasing demand for high-quality and durable valve solutions. This article explores the world of SS ball valve manufacturing in India, providing insights into the products, processes, and leading manufacturers in the industry.

What is an SS Ball Valve?

An SS ball valve is a quarter-turn valve that uses a hollow, perforated, and pivoting ball to control the flow of liquids or gases. When the valve handle is turned, the ball's position changes, either allowing or blocking the flow through the valve. The "SS" in SS ball valve standsfor Stainless Steel, the material used in constructing the valve body, which provides excellent resistance to rust and corrosion.

Key Components of an SS Ball Valve

Valve Body: The outer casing that houses the internal components.

Ball: The pivoting component with a hole in the center that controls flow.

Stem: Connects the ball to the handle, allowing for the turning action.

Seats: The seals that ensure a tight closure when the valve is in the off position.

Handle: The external lever that rotates the ball.

Why Stainless Steel?

Stainless steel is preferred in ball valves for several reasons. Its excellent resistance to corrosion makes it ideal for environments where the valve may be exposed to moisture or chemicals. Additionally, stainless steel is known for its durability, ensuring that the valve can withstand high pressures and temperatures without warping or deforming over time.

and there manufacturers By pedlock SS Ball Valves in Ahmedabad, Vadodara, Mumbai, Delhi, Chennai, Bangalore, Ghaziabad, Rajasthan, Gujarat.

Benefits of Using Stainless Steel in Ball Valves

Corrosion Resistance: Ideal for harsh environments.

Strength and Durability: Suitable for high-pressure and high-temperature applications.

Hygienic Properties: Often used in food, beverage, and pharmaceutical industries.

Types of SS Ball Valves

SS ball valves come in various designs, each suited for specific applications. Understanding these types can help in choosing the right valve for your needs.

Two-Piece Ball Valves:

These valves consist of two separate pieces that are bolted together. They are easier to clean and maintain, making them a popular choice in industries where hygiene is critical.

Three-Piece Ball Valves:

Three-piece valves are designed for applications requiring frequent cleaning or repair. The valve body can be disassembled without removing the entire valve from the pipeline, reducing downtime.

Applications of SS Ball Valves

SS ball valves are incredibly versatile, making them suitable for various applications:

Industrial Applications

In industries like oil and gas, chemical processing, and power generation, SS ball valves are essential for controlling the flow of hazardous or corrosive substances. Their durability and resistance to corrosion make them a reliable choice in these demanding environments.

Commercial Applications

In commercial settings, SS ball valves are commonly used in HVAC systems, water treatment facilities, and fire protection systems. Their ability to withstand high pressure and temperatures ensures smooth operation in critical systems.

Residential Applications

Even in residential plumbing, SS ball valves play a crucial role. They're often used in water supply systems due to their reliability and long lifespan.

Key Materials Used in SS Ball Valves

Stainless steel is the material of choice for these valves due to its excellent properties:

304 Stainless Steel: This is the most commonly used material, offering a good balance of corrosion resistance and cost.

316 Stainless Steel: This type contains molybdenum, which enhances corrosion resistance, especially against chlorides. It's ideal for marine and chemical applications.

316L Stainless Steel: Similar to 316, but with a lower carbon content, this material offers even better corrosion resistance and is often used in highly corrosive environments.

Manufacturing Process of SS Ball Valves

The production of SS ball valves is a complex process that requires precision and expertise:

Design and Engineering

It all starts with a design that meets specific requirements. Engineers use CAD software to create detailed designs, considering factors like pressure ratings, flow rates, and operating temperatures.

Material Selection

Choosing the right type of stainless steel is critical. The selection depends on the valve's intended use, with factors like corrosion resistance, strength, and temperature tolerance being taken into account.

Forging and Machining

The selected stainless steel is forged into the basic shape of the valve. This is followed by precision machining, where the valve components are shaped to exact specifications.

Assembly and Testing

Once all components are machined, the valve is assembled. Rigorous testing follows, including pressure testing, to ensure the valve operates correctly under expected conditions.

Quality Standards and Certifications

SS ball valves must adhere to stringent quality standards to ensure safety and reliability:

ISO Standards: Most manufacturers adhere to ISO 9001 for quality management and ISO 14001 for environmental management.

Indian Standards (IS): Valves must also comply with Indian Standards (IS), which are specific to the local market.

Other Global Standards (API, ANSI, etc.): For international markets, valves often meet standards set by organizations like the American Petroleum Institute (API) and the American National Standards Institute (ANSI).

Technological Innovations in SS Ball Valve Manufacturing

The manufacturing of SS ball valves is evolving, with technology playing a key role:

Environmental Sustainability in Manufacturing

Sustainability is becoming a priority, with manufacturers adopting eco-friendly practices such as using recycled materials and reducing energy consumption in production.

Factors to Consider When Choosing an SS Ball Valve Manufacturer

When selecting an SS ball valve manufacturer, several factors should be considered:

Quality and Durability: The valves should meet industry standards and be built to last.

Pricing and Cost-Effectiveness: Competitive pricing is important, but it should not come at the expense of quality.

After-Sales Service and Support: Good manufacturers offer robust after-sales support, including maintenance and repair services.

Challenges Faced by SS Ball Valve Manufacturers in India

Despite the industry's growth, manufacturers face several challenges:

Raw Material Costs and Availability

The cost and availability of high-quality stainless steel can be a significant challenge, affecting production costs and timelines.

Competition from Global Manufacturers

Indian manufacturers face stiff competition from global players, particularly from countries like China, which can offer lower prices.

Regulatory and Environmental Challenges

Compliance with strict regulations, both domestic and international, can be challenging. Additionally, environmental concerns are pushing manufacturers to adopt greener practices, which can increase costs.

Future Trends in the SS Ball Valve Industry

The SS ball valve industry is poised for growth, driven by several trends:

Growing Demand in the Oil and Gas Sector

The expanding oil and gas industry in India and globally is driving demand for high-quality SS ball valves, particularly in offshore and deep-sea applications.

Conclusion

Choosing the right SS Ball Valves manufacturers in Ahmedabad, Vadodara, Mumbai, Delhi, Chennai, Bangalore, Ghaziabad, Rajasthan, Gujarat is vital for ensuring the smooth operation of your industrial processes. By focusing on quality, material integrity, customization options, and customer support, you can find a manufacturer that meets your specific needs and helps you achieve operational excellence.

#SS Ball valve manufacturer in Mumbai#SS Ball valve manufacturer in Delhi#SS Ball valve manufacturer in chennai#SS Ball valve manufacturer in Bangalore#SS Ball valve manufacturer in Rajasthan#SS Ball valve manufacturers in ghaziabad#SS Ball valve manufacturer in Gujarat#SS Ball valve manufacturer in Vadodara#SS Ball valve manufacturer in ahmedabad

0 notes

Text

Pipe Nipple by Platinex piping

About the product

In piping and piping construction, a nipple is a fitting consisting of a short piece of pipe, usually with external threads at both ends, for connecting two other fittings. In piping and piping construction, a nipple is a fitting consisting of a short piece of pipe, usually with external threads at both ends, for connecting two other fittings.

To loosen a closed nipple, you will need to grab the threaded end with a pipe wrench, but doing this will damage the threads, requiring the nipple to be replaced, or using a pipe wrench called a nipple wrench (or inner tube wrench). The inner tube must be tightened using a special tool. Remove the pipe and release it without damaging the threads. If the ends are two different sizes, it is called a reducer or unequal nipple.

They may have a hexagonal section in the middle for gripping with a wrench (sometimes called a “hex nipple”), or they may simply be made from a short piece of pipe (a “barrel nipple” or “barrel nipple”). A “tight nipple” has no unthreaded areas. When screwed between two female threaded connections, very little of the nipple is exposed.

Grades in Pipe Nipple

Stainless Steel Pipe Nipple

Carbon Steel Pipe Nipple

Low Temperature Carbon Steel Pipe Nipple

Alloy Steel Pipe Nipple

Duplex Steel Pipe Nipple

Nickel Alloy Pipe Nipple

The material of the plumbing pipe nipple is also related to the material of the nipple, such as plastic material, stainless steel material, copper material, or iron coated pipe material. Stainless steel pipe fittings are generally of the highest quality, as they are rust resistant and durable.

However, the problem is that the price is a little high. Copper and iron plated pipe nipples are normal.

Specifications

The specifications of sanitary pipe nipples are usually determined based on various interface sizes. There are two types of pipe nipples: 1/2 and 3/4. Plumbing pipe nipples have different interface sizes, so when purchasing a plumbing pipe nipple, please be sure that it is compatible with your water pipe, etc., to avoid problems with returns or exchanges due to non-conformance with specifications.

Open type

In an open water pipe connection, both ends of the water pipe connection are separated into a male end and a female end. Generally, the male end with a pin shape on one end is called the male head, and the male end with a hole shape on the other end is called the female head.

When connected and used, when the jacket of the female head of the water pipe fitting is pushed to the opposite side, the male head will come out due to the rolling of the steel ball inside the water pipe fitting. This way, there are no valves in the male and female parts to allow fluid to escape

Types of plumbing pipe nipples

Closed type

There is a thimble and a spring inside the closed water pipe joint.. When not in use, the ends of the water pipe fitting can be pressed against the pipe by the action of the thimble and spring, impeding the flow of liquid. After connecting the water pipe, the thimble returns to its original position under the action of a spring, allowing the fluid to circulate.

Use of the product

In piping and piping construction, a nipple is a fitting consisting of a short piece of pipe, usually with external threads at both ends, for connecting two other fittings. Aluminum pipe nipples are widely used in hydraulic and pneumatic systems, piping applications, and the oil and gas industry. They are known for their versatility and their ability to connect two pipes, fittings, or devices of different sizes and materials. Pipe nipples are pipe fittings used in a variety of industrial tasks, such as:

Waste incineration industry

Oil & Gas industry

Chemical processing industry

Petrochemical industry

Pharmaceutical industry

Semiconductor industry

Food & beverage industry

Paper & Pulp industry

Shipbuilding industry

Machine building industry

Architecture industry

Manufacturing Standards

Left and right steel nipples are available in standard and extra-strength sizes from 1 to 8 inches to 4 inches NPS (8 to 50 DN), and lengths of 4 inches (102 mm) and 6 inches (152 mm). Nipples are available in stock from 1 to 8 inches NPS (6 to 200 DN) in diameter and nearly 12 NPS (300 DN) in length. Nipples are available in stock from 1 to 8 inches NPS (6 to 200 DN) in diameter and nearly 12 NPS (300 DN) in length.

Pipe nipples are manufactured in accordance with specific standards to ensure their quality and compatibility with various applications. Round nipples, ranging from 1/8″ to 4″, and hexagon nipples, from 1/8″ to 2″, adhere to the BS3799 standard. Swaged nipples, within the 1/8″ to 2″ size range, comply with SH/T3419 and MSS SP 95-2006. These products encompass a wide range of materials, including brass, stainless steel, carbon steel, aluminum, and alloys like monel, nickel, inconel, and hastelloy. Stainless steel pipe nipples come in various grades, such as 202, 304, 304L, 316, and more, while copper nickel pipe nipples include CuNi10Fe1Mn and CuNi30Mn1Fe grades. These manufacturing standards ensure consistent quality and dimensional accuracy across different types and sizes of pipe nipples, meeting the diverse needs of industries like construction, plumbing, and manufacturing.

Pipe nipples are manufactured in accordance with specific standards to ensure their quality and compatibility with various applications. Round nipples, ranging from 1/8″ to 4″, and hexagon nipples, from 1/8″ to 2″, adhere to the BS3799 standard. Swaged nipples, within the 1/8″ to 2″ size range, comply with SH/T3419 and MSS SP 95-2006. These products encompass a wide range of materials, including brass, stainless steel, carbon steel, aluminum, and alloys like monel, nickel, inconel, and hastelloy. Stainless steel pipe nipples come in various grades, such as 202, 304, 304L, 316, and more, while copper nickel pipe nipples include CuNi10Fe1Mn and CuNi30Mn1Fe grades. These manufacturing standards ensure consistent quality and dimensional accuracy across different types and sizes of pipe nipples, meeting the diverse needs of industries like construction, plumbing, and manufacturing. Left and right steel nipples are available in standard and extra-strength sizes from 1 to 8 inches to 4 inches NPS (8 to 50 DN), and lengths of 4 inches (102 mm) and 6 inches (152 mm). Nipples are available in stock from 1 to 8 inches NPS (6 to 200 DN) in diameter and nearly 12 NPS (300 DN) in length.

Why platinex for the product

Choose Platinex Piping Solutions LLP for your pipe nipple needs because we’re experts in manufacturing and exporting piping solutions. Whether you have a small job or a big project, we can make pipe nipples to fit your needs exactly. Our products meet international standards, so you can trust their quality. We offer a wide range of materials, including stainless steel, carbon steel, aluminum, brass, copper, and more. From hexagons to swage nipples, we’ve got what you need. Plus, our pipe nipples come in various sizes and can be polished to your liking. Trust Platinex for reliable and customized pipe nipples.

Contact Platinex Piping Solutions LLP for your pipe nipple needs because we offer unparalleled expertise and versatility in manufacturing.

0 notes

Text

Best Quality Titanium Ball Valve Manufacturer in India

Ladhani Metal Corporation is a well-known Titanium Ball Valve Manufacturer in India. Our Titanium Ball Valve is in great demand due to its advantages such as lightweight, high strength, solid construction, ease of installation, excellent performance, and extended service life.

As a supplier, stockiest, and manufacturer, we provide these Titanium Ball Valves in custom-built thicknesses and sizes according to exact requirements of our well-regarded patrons.Titanium Ball Valves come in a variety of diameters and finishes.Titanium Ball Valve is a high-quality product with an ever-increasing demand in the industry.

Types of Titanium Ball Valve Manufacturer & Stockists in India

Titanium One Piece Ball Valve

Titanium Two Piece Ball Valve

Titanium Three Piece Ball Valve

Titanium Top Entry Ball Valve

Titanium Orbit Ball Valve Manufacturer

Titanium Jacketed Ball Valve

Titanium Unibody Ball Valve

Also, We Export Titanium Ball Valves in Various Country Titanium Ball Valve Supplier in Brazil ,Titanium Ball Valve Supplier in Qatar and Titanium Ball Valve Supplier in Singapore

For More Details:

Mail us: [email protected]

Source:Titanium Ball Valve Manufacturer in India

#Titanium Ball Valve Manufacturer#Titanium One Piece Ball Valve#Titanium Two Piece Ball Valve#Titanium Three Piece Ball Valve#Titanium Top Entry Ball Valve#Titanium Orbit Ball Valve Manufacturer#Titanium Jacketed Ball Valve#Titanium Unibody Ball Valve

0 notes

Text

High quality ball valve manufacturer in Ahmedabad

Flowdo Valve is one of the premier ball valve manufacturers in Ahmedabad, recognized for its excellent quality and advanced products. Ball valves are widely used in oil and gas industry, chemical industry, water treatment industry and other industries because of their dependability and effectiveness in regulating the flow of the fluid.

Flowdo Valve is an eminent ball valve manufacturing company based in Ahmedabad, India that specializes in offering a wide assortment of ball valves for various applications. Our product lineup includes:

Ball Valve 3PC F/E: A three times body located full encapsulation valve which is highly reliable in terms of its construction and can also be easily maintained.

Ball Valve 2PC F/E: A two-piece full-encapsulation form valve made suitable for different applications in which it is necessary to ensure the tightness of the sealing.

Ball Valve 1PC F/E: This valve is half-circle full-encapsulation valves that consist of one body that makes it cheap and small in size.

Ball Valve 2PC F/E (High Pressure): Suitable for high pressure for instance in an organization so as to boost the performance and durability of a product.

Ball Valve 3PC & 1PC (S/E & S/W): These valves are available in screwed end (S/E) version and socket weld (S/W) and the buyer is free to choose according to the requirements.

PTFE Lined Ball Valve 2PC F/E: Including PTFE lining to give greater chemical endurance it is suitable for corrosive environment.

3 & 4 Way Ball Valve F/E: Valves that have multiple ports to permit regulation of directional flow to improve functionality.

Jacketed Type Ball Valve: It has a jacket for thermal management, perfect for operations that need to maintain or alter the temperature.

Flowdo Valve is an ISO 9001:2015 certified company as a sign or guarantee of the highest quality and reliability. It increases confidence that the quality management systems are being improved continuously and responsive to customer needs. Also, our products are API, ANSI, and DIN-coded qualities that are accepted internationally due to high set standards in the production of valves.

Flowdo Valve is one of the leading ball valve manufacturers based in Ahmedabad that offers reliable valves for various industries. Their products are durable and very accurate making them key in different industries and sectors.

Flow Regulation: Used in pipelines where the flow of the liquid or the gaseous commodity need to be regulated accurately and effectively.

Isolation Services: Employees get full isolation solutions to avoid accidents and control the fluid leakage.

Mixing and Diverting: Used in applications where it is necessary to combine various liqu ids or to change the route of the current.

Discover all our ball valve products and additional information about our manufacturing processes on

#ball valve manufacturer in Ahmedabad#ball valve manufacturer#valve manufacturer in Ahmedabad#valve manufacturer#ball valve

0 notes