#ball valve

Explore tagged Tumblr posts

Text

Flanged type gate valve Class150Lb A216-WCB

#youtube#ball valve#check valve#gate valve#globe valve#china valve factory valve#valve#gatevalve#ballvalve#cantonfair

2 notes

·

View notes

Text

The Guide to Small Ball Valves: Types, Applications, Tips.

When it comes to fluid control in compact systems, small ball valves, mini ball valves, and miniature ball valves are indispensable components. These valves are designed for precision, durability, and space efficiency, making them ideal for industries ranging from plumbing and HVAC to chemical processing and manufacturing. In this comprehensive guide, we’ll explore the key features, types, materials, and applications of small ball valves, along with tips for selecting the right valve for your needs.

—

What is a Small Ball Valve

A small ball valve is a quarter-turn valve that uses a hollow, perforated ball to control fluid flow. When the valve handle is turned 90 degrees, the ball rotates to align its bore with the pipeline (open position) or block it completely (closed position). These valves are characterized by their compact size, lightweight design, and ease of operation, making them perfect for tight spaces or applications requiring frequent adjustments.

Key advantages of small ball valves include:

- Leak-proof sealing for reliable performance. - Quick shutoff with minimal torque. - Versatility in handling liquids, gases, and corrosive media. - Low maintenance due to simple construction.

—

Types of Small Ball Valves

Small ball valves are available in various designs to suit specific applications. Below are the most common types:

1. Thread Ball Valve

A thread ball valve features threaded ends (NPT, BSPP, or BSPT) for easy installation in pipelines without welding. These valves are widely used in residential plumbing, compressed air systems, and low-pressure industrial setups.

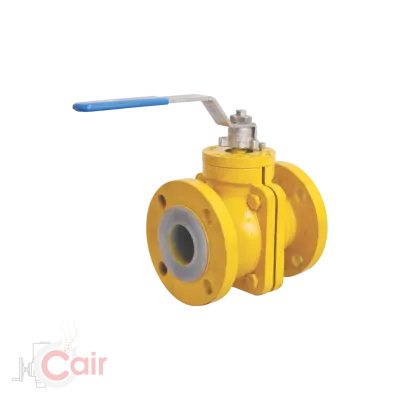

2. Flange Ball Valve

Flange ball valves have flanged ends for bolted connections, ideal for high-pressure or large-diameter systems. They are common in oil and gas, water treatment, and chemical industries.

3. 2 PC Ball Valve vs. 3 PC Ball Valve

- 2 PC ball valves consist of two main body pieces, offering a balance between cost and serviceability. - 3 PC ball valves feature three separable body sections, enabling easy disassembly for cleaning or repair without removing the valve from the pipeline.

4. Floating Ball Valve

In a floating ball valve, the ball is held in place by compression from the valve seats. This design is cost-effective and suitable for low-to-medium pressure applications.

—

Material Choices for Small Ball Valves

The valve material impacts its durability, corrosion resistance, and compatibility with fluids. Popular options include:

1. Stainless Steel Ball Valve

Stainless steel ball valves (e.g., SS304, SS316) excel in corrosive environments, such as chemical processing, marine applications, or food-grade systems.

2. Carbon Steel Ball Valve

Carbon steel ball valves are robust and economical, ideal for high-temperature and high-pressure systems in oil refineries or power plants.

3. Forged Steel Ball Valve

Forged steel ball valves are manufactured through forging, resulting in superior strength and resistance to extreme conditions. They are commonly used in heavy-duty industrial applications.

—

Applications of Small Ball Valves

- Plumbing and HVAC: Regulating water flow in residential or commercial systems. - Chemical Processing: Handling aggressive fluids with stainless steel or PTFE-lined valves. - Automotive: Fuel and coolant control in compact engine systems. - Pharmaceuticals: Ensuring sterile fluid transfer with sanitary ball valves. - Agriculture: Irrigation and fertilizer distribution.

—

How to Choose the Right Small Ball Valve

1. Pressure and Temperature Ratings: Ensure the valve meets your system’s operational limits. 2. Connection Type: Select threaded, flanged, or welded ends based on installation requirements. 3. Material Compatibility: Match the valve body and seal materials to the fluid type (e.g., PTFE seals for chemicals). 4. Valve Size: Confirm the port size (e.g., ¼” to 2”) matches your pipeline dimensions. 5. Certifications: Look for industry standards like API, ANSI, or ISO for quality assurance.

—

FAQs About Small Ball Valves

Q: What’s the difference between a mini ball valve and a standard ball valve

A: Mini ball valves are smaller in size (typically under 1” diameter) and designed for low-flow or precision applications, whereas standard ball valves cater to larger systems.

Q: Can a stainless steel ball valve handle seawater

A: Yes, SS316 stainless steel valves offer excellent corrosion resistance in marine environments.

Q: When should I choose a 3 PC ball valve over a 2 PC design

A: Opt for a 3 PC ball valve if frequent maintenance or cleaning is required, as it allows easy access to internal components.

—

Conclusion

From thread ball valves in household plumbing to flange ball valves in industrial pipelines, small ball valves play a critical role in modern fluid control systems. By understanding the differences between floating ball valves, stainless steel ball valves, and forged steel ball valves, you can make informed decisions to optimize performance and longevity. Whether you need a miniature ball valve for a lab setup or a heavy-duty carbon steel ball valve for a refinery, prioritize quality materials, proper sizing, and compliance with industry standards.

Need a reliable small ball valve supplier, Contact Chinese NSW valve manufacturer experts today to find the perfect valve for your application.

#ball valve manufacturers in india#ball valve suppliers#ball valve#small ball valve#mini ball valve#china ball valve manufacturer#ball valve manufacturer#ball valve factory#ball valve supplier

0 notes

Text

What Is a Ball Valve? A Complete Guide to Its Function and Uses

Ball valves are one of the most commonly used types of valves in industries worldwide. Their design and versatility make them ideal for controlling the flow of various fluids and gases. This comprehensive guide will explore what a ball valve is, how it functions, and its various applications, along with insights into the ball valve manufacturing industry in India.

What is a Ball Valve?

A ball valve is a type of valve that uses a spherical ball to control the flow of media (liquids, gases, or slurries) through a pipe or system. The ball has a hole or port through the center, which aligns with the flow path when the valve is open. When the valve is closed, the ball rotates 90 degrees, blocking the flow path and preventing the passage of the media.

The simplicity of this design allows for quick and efficient operation. Ball valves are known for their durability, reliability, and ability to maintain a tight seal even after long periods of use.

How Does a Ball Valve Work?

A ball valve consists of several key components, including the body, the ball, the stem, and the handle or actuator. The ball is mounted inside the valve body, with the hole or port aligned with the flow path when the valve is open. When the valve handle is turned, the stem rotates the ball, either opening or closing the valve.

The flow direction and the valve's status (open or closed) are determined by the orientation of the ball. In the open position, the flow passes through the hole in the ball, allowing the fluid or gas to move through the valve. In the closed position, the ball rotates 90 degrees, blocking the flow entirely.

One of the key features of ball valves is their ability to create a tight seal. The design ensures minimal leakage, even in high-pressure applications, making them highly reliable in various industries.

Types of Ball Valves

There are different types of ball valves, each suited for specific applications. The most common types include:

Standard Ball Valve: This is the most basic type of ball valve, ideal for simple on/off applications.

V-Port Ball Valve: This valve has a V-shaped ball, which allows for precise flow control, making it suitable for throttling applications.

Multi-Port Ball Valve: These valves have multiple ports, allowing for directional flow control and bypassing multiple channels. They are used when more complex flow control is needed.

Trunnion Ball Valve: A trunnion ball valve has a ball that is supported by bearings, allowing for larger sizes and higher-pressure applications.

Uses of Ball Valves

Ball valves are widely used across different industries due to their efficiency and reliability. Some of the key applications include:

Oil and Gas: Ball valves are essential in oil and gas systems for controlling the flow of crude oil, natural gas, and other fluids. Their ability to withstand high pressures and temperatures makes them ideal for this industry.

Water Treatment: In water treatment plants, ball valves are used to control the flow of water and chemicals. They are often found in filtration systems, distribution lines, and pumping stations.

Chemical Processing: Chemical plants use ball valves to manage the flow of various chemicals, ensuring safe and controlled operations. The tight seal offered by ball valves minimizes leaks and contamination.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, ball valves regulate the flow of fluids used for heating and cooling purposes.

Food and Beverage: In the food and beverage industry, ball valves ensure the smooth flow of ingredients, liquids, and gases, as well as maintain hygienic conditions.

Pharmaceuticals: Ball valves are also critical in the pharmaceutical industry, where cleanliness and precise flow control are required for producing medicines and vaccines.

Why Choose Ball Valves?

There are several reasons why ball valves are favored in various industries:

Durability: Ball valves are highly durable and can withstand harsh operating conditions, such as extreme temperatures and high pressures.

Leak-Proof Performance: Ball valves are designed to provide a tight seal, preventing leaks even in demanding applications.

Ease of Operation: With a simple 90-degree turn, ball valves are easy to operate and provide quick response times.

Versatility: They can be used for a wide range of applications, from small-scale systems to large industrial plants.

Low Maintenance: Due to their robust design and minimal moving parts, ball valves require little maintenance compared to other types of valves.

India has become a significant player in the global valve manufacturing industry, with many reputable ball valve manufacturers producing high-quality valves. A ball valve manufacturer in India is equipped with advanced technology and expertise to meet the growing demand for industrial valves in various sectors.

These manufacturers use state-of-the-art materials and rigorous quality control processes to ensure that their products meet international standards. As a result, India's ball valve manufacturers are well-positioned to cater to both domestic and international markets, offering products that are durable, reliable, and cost-effective.

Conclusion

Ball valves are essential components in many industries, offering excellent control and reliability in fluid and gas handling systems. Their simple design, combined with a tight seal, makes them an ideal choice for various applications. Whether in oil and gas, water treatment, or pharmaceuticals, ball valves continue to play a crucial role in ensuring smooth and safe operations. As the demand for high-quality valves grows, ball valve manufacturers in India are playing a crucial role in supplying the global market with reliable and durable valves to meet diverse industry needs.

0 notes

Text

Guide to choosing the right ball valve for your project

Parth Valves and Hoses LLP, a trusted provider of high-quality hygienic valves, FDA hoses, and dampers, understands the critical role fluid control plays in various industries. Selecting the right valve is essential for ensuring efficient, safe, and reliable operations. This comprehensive guide focuses on ball valves, providing in-depth insights into their functionality, types, applications, and key considerations for choosing the perfect valve for your specific project.

What is a Ball Valve?

A ball valve is a quarter-turn rotational valve that utilizes a hollow, spherical ball to control the flow of liquids or gases. The ball has a bore (a hole through its center) that allows or blocks flow depending on its position. When the bore is aligned with the flow direction, the valve is open, allowing unimpeded flow. A simple 90-degree rotation of the ball, typically using a lever or handle, positions the solid part of the ball to block the flow path, effectively closing the valve and creating a tight seal.

Ball Valves

Advantages of Ball Valves:

Ball valves offer several advantages that make them a popular choice in various industrial applications:

Quick and Easy Operation: The quarter-turn operation enables rapid opening and closing, making them ideal for emergency shut-off situations and processes requiring frequent on/off control.

Excellent Shut-Off Capability: When closed, ball valves provide a reliable and leak-tight seal, preventing leakage and ensuring efficient flow isolation.

Durability and Reliability: With relatively few moving parts, ball valves are known for their robust construction, minimal maintenance requirements, and long service life.

Versatility: Ball valves can handle a wide range of fluids and gases, including corrosive chemicals, making them suitable for diverse industrial applications.

Compact Design: Their compact design makes them suitable for installations with limited space.

Cost-Effectiveness: Compared to some other valve types like gate or globe valves, ball valves often offer a more cost-effective solution for many applications.

Types of Ball Valves:

Different types of ball valves are available to suit various applications:

One-Piece Ball Valves: These are the most economical type, typically used for low-pressure applications.

Two-Piece Ball Valves: Offer greater versatility and can be easily disassembled for cleaning or maintenance.

Three-Piece Ball Valves: Provide easy access to internal components for maintenance and repair, making them suitable for demanding applications.

Multi-Port Ball Valves: These valves have three or more ports, allowing for complex flow control and diversion.

Key Considerations When Choosing a Ball Valve:

Selecting the appropriate ball valve is crucial for optimal performance, safety, and longevity. Consider the following factors:

Material Compatibility: The valve body, ball, and seals must be chemically compatible with the media being handled. Common materials include:

Stainless Steel: Offers excellent corrosion resistance and is suitable for food processing, chemical, and pharmaceutical applications.

Brass: Cost-effective for water and other non-corrosive media.

PVC: Suitable for corrosive applications at lower temperatures and pressures.

Pressure and Temperature Ratings: The ball valve must be rated to handle the maximum operating pressure and temperature of the system.

Port Configuration: Choose the appropriate port configuration (2-way, 3-way, etc.) based on the specific flow control requirements of your system.

Valve Size: Proper sizing is crucial to ensure optimal flow rates and minimize pressure drop.

End Connections: Select end connections (threaded, flanged, welded) compatible with the piping system.

Actuation: Consider the actuation method based on control needs: manual, electric, or pneumatic.

Seat and Seal Materials: The seat and seal materials (e.g., PTFE, Viton) must be compatible with the media and operating temperature.

Parth Valves and Hoses LLP: Expertise in Fluid Control

While Parth Valves and Hoses LLP specializes in hygienic valves, FDA hoses, and dampers, our deep understanding of fluid control principles allows us to provide expert guidance on selecting the right ball valve for various applications. We can assist you in determining the appropriate material, size, and configuration for your specific needs.

Why Choose Parth Valves and Hoses LLP for Your Fluid Control Needs?

Expert Knowledge: Our team possesses extensive knowledge of fluid control systems and components.

Commitment to Quality: Our 12-month product guarantee on our hygienic products reflects our dedication to quality and reliability.

Customer-Centric Approach: We prioritize customer satisfaction and provide excellent support.

Conclusion:

Selecting the correct ball valve is a critical decision that impacts the efficiency and safety of your operations. By carefully considering the factors outlined in this guide and consulting with fluid control experts like those at Parth Valves and Hoses LLP, you can ensure you choose the ideal valve for your project. Contact us today to discuss your specific requirements and discover how we can contribute to your success.

0 notes

Text

Quick Release Coupling, Gemel Italy Ball Valves, Hydraulic Fittings

Distributor of Quick Release Coupling, Micro Hose, Gemel Italy Ball Valve, Hydraulic Fitting, Test Point Couplings, Instrumentation Fittings, Mumbai, India.

#Quick Release Coupling#Quick Release Couplings#Ball Valve#Ball Valves#Gemel Ball Valves#Industrial Ball Valves#Quick Coupling#Quick Couplings#Camlock Coupling#Camlock Couplings#Camlock Quick Coupling#Camlock Quick Couplings#Micro Hose#Micro Hose For High Pressure#Micro Hose For Pressure Fittings#Test Coupling#Test Couplings#Minipress Test Coupling#Minipress Test Couplings#Test Point Test Coupling#Test Point Couplings#Threaded Test Coupling#Threaded Test Couplings#Bulkhead Test Coupling#Bulkhead Test Couplings#Female Swivel Test Coupling#Female Swivel Test Couplings#Plug in Test Coupling#Plug in Test Couplings#Pressure Gauge Adaptors

0 notes

Text

Why is Ball Valve Essential for Automobiles? Check Reasons!

A ball valve is durable, easy to operate, and requires minimal maintenance for precise control over fluid flow and is ideal for critical automobile functions. These valves come with a robust design to handle high-pressure and temperature variations, ensuring optimal performance of some systems including fuel lines, cooling systems, and hydraulics of a car.

Similarly, a check valve, often used alongside ball valves, ensures unidirectional fluid flow to prevent backflow and save sensitive systems from the risks of operational and structural damage.

In challenging and high-pressure applications, they are essential for maintaining system integrity, regulating fluid flow, and guaranteeing safety. Purchasing valves from reputable suppliers ensures long-term value and maximum system performance.

Advantages of Essential Ball and Check Valves from Renowned Manufacturers

Businesses should buy essential valves from renowned manufacturers to ensure reliability and efficiency, precise fluid control, prevent backflow, motion control, fluid power applications, and withstand high-pressure conditions.

These valves are essential to many industries, including water treatment, chemical processing, oil and gas, and pharmaceuticals to improve safety and customer experience with cutting-edge technologies like remote factory acceptance tests and mixed reality training.

Renowned manufacturers adhere to strict quality standards, ensuring durability and consistent performance to maintain global quality. Locally engineered and tested valves meet the specific demands of industries like defence, mining, construction, and power generation.

These experts have expertise in fluid technology, combined with bespoke design and predictive maintenance solutions, to ensure that their valves deliver superior functionality. Additionally, they support industries with services like on-site audits, engineering advice, and technical training.

Find a Trusted Manufacturer of Essential Machinery Parts

Finding a trusted manufacturer of essential machinery parts requires thorough research and consideration.

Evaluate the manufacturer’s experience and reputation in the industry. Check whether they are certified and authorised by authorised bodies which indicates adherence to high-quality standards.

Check if the manufacturer offers customized solutions to meet specific needs and provides services like engineering support, on-site audits, and technical training.

Ensure they have expertise in the required industry and a proven track record of delivering reliable products and after-sales support.

Consider manufacturers that integrate advanced technologies like predictive maintenance or remote testing, as these innovations enhance efficiency and safety.

Finally, select a manufacturer known for precision, durability, and comprehensive support.

Source

0 notes

Text

0 notes

Text

Best Ball Valves Manufacturers in Pune | Parth Valves

Pune, Maharashtra’s industrial hub, is home to top manufacturers in many industries. One of the most trusted names in the industry is Parth Valves and Hoses LLP. Parth Valves, known for their quality and innovation, manufactures and services a comprehensive range of Ball Valves for various industrial needs.

What Are Ball Valves?

Industries that need precise liquid and gas control use ball valves. Quarter-turn valves control material flow via a hollow, perforated, revolving ball. Oil and gas, medicines, water treatment, and manufacturing employ ball valves for their effective sealing.

Ball valves are indispensable for many applications due to their great pressure and temperature tolerance.

Ball Valves

Why Ball Valves Manufacturing Is Popular in Pune

Pune’s industrial ecosystem, facilities, and qualified people make it suitable for ball valve manufacture. The city’s manufacturers value innovation, quality, and durability.

Parth Valves and Hoses LLP, a Pune-based ball valve manufacturer, sets standards with their cutting-edge facilities and customer service. They have years of experience making durable, high-performance ball valves for many sectors.

Ball Valves Trusted Name Parth Valves and Hoses LLP

1. Wide Selection of Ball Valves Parth Valves offers a wide range of ball valves for various industrial applications. There are standard ball valves and sophisticated high-performance models:

Two- and three-piece ball valves are modular and easy to maintain. Flanged Ball Valves: High-pressure friendly. Full-Port and Reduced-Port Ball Valves: Flexible flow control for various applications.

Uncompromising Quality Parth Valves manufactures with quality in mind. Each valve is rigorously tested to meet ISO, ASTM, and ASME standards. Their ball valves work reliably in the harshest situations due to their thorough approach.3. Unique Needs Customization Since every sector has unique needs, Parth Valves excels in tailored solutions. Their professionals work with clients to design and build ball valves to exact specifications for optimal efficiency and lifetime.4. Innovation Focus Innovation also distinguishes Parth Valves. Their valve development team uses cutting-edge technology to improve performance and durability.Applications of Ball Valves Parth Valves ball valves are versatile and appropriate for many applications:Oil and Gas: Pipeline high-pressure fluid and gas management. Pharmaceutical Industry: Hygienic flow regulation in delicate situations. Purification plant water flow regulation. Manufacturing Units: Supporting production line efficiency.

Why Choose Parth Valves and Hoses LLP for Ball Valves?

Ball valve manufacturers should be chosen based on quality, reliability, and customer service. Parth Valves and Hoses LLP excels in these areas:

Their engineers and technicians have decades of experience and provide unmatched expertise. Timely Delivery: They deliver on time to keep projects on track. They offer high-quality valves at competitive prices.

Improvement in Ball Valves Manufacturing

Parth Valves and Hoses LLP provides precision, dependability, and durability in ball valves for industries. Their dedication to quality has made them Pune’s top ball valve producers.

Contact Parth Valves Now

Contact Parth Valves and Hoses LLP for durable ball valves. Industries in Pune and beyond choose them for their experience and customer-first approach.

With Parth Valves, you’re buying a heritage of quality that guarantees your industrial operations run smoothly. Enjoy the greatest ball valves with Parth Valves and Hoses LLP.

Website- https://parthvalve.com/

Email id – [email protected]

Call On- (+91)8600034431

0 notes

Text

youtube

Our machine delivers top-quality results with minimal effort. Perfect for brass and aluminum parts, this machine is your key to efficient, high-volume manufacturing. Welcome inquiry!

📞/WA +86 189 2454 9850 📫 [email protected] 🌐 http://www.ipowermachinery.com

#production line#globe valve#ball valve#lpg cylinder valve#machine#brass valve#brass ball valves#brass product#forging machine#hot forging#Youtube

0 notes

Text

SS Flange End Ball Valve Manufacturer from Ahmedabad - Gold Techno Casting

Gold Techno Casting Company is a leading manufacturer of high-quality ball valves in Ahmedabad, Gujarat. Our range includes SS flange end ball valves, stainless steel ball valves, and SS gate valves, perfect for various industrial applications. Contact us today!

Google Map:--> https://maps.app.goo.gl/LUnHirgkXMPNPJ1V7

SS Flange End Ball Valve Manufacture in Ahmedabad, Ball Valve, SS Flange End Ball Valve, Ball Valve Manufacture in Ahmedabad, SS Ball Valve, Stainless Steel Flanged Valve, SS Gate Valves, Stainless Steel Globe Valve, Kheda, Ahmedabad, Gujarat, India, Gold Techno Casting

#SS Flange End Ball Valve Manufacture in Ahmedabad#Ball Valve#SS Flange End Ball Valve#Ball Valve Manufacture in Ahmedabad#SS Ball Valve#Stainless Steel Flanged Valve#SS Gate Valves#Stainless Steel Globe Valve#Kheda#Ahmedabad#Gujarat#India#Gold Techno Casting

0 notes

Text

Automatic welding process for gate valve seat, special welding material welding process for wear-resistant and corrosion-resistant sealing of gate valve seat, mechanical arm welding process for gate valve seat,Welcome your visit RTV valve

WhatsApp:+86 15888732537

Email:[email protected]

https://www.rtv-valve.com/

#valve #gatevalve #globevalve #checkvalve #ballvalve #butterflyvalve #plugvalve #y_strainer #Control_valve #hydraulic_valve #electric_valve #pneumatic_valve #canton_fair #coosaivalve #valveimport #valveexport #valvestock #valveshop #valvesupplier #valvesupply #valvefactory #valvemanufacturer #valvedistributor #butterflyvalves #ballvalves #gatevalves #globevalves #knifegatevalves #controlvalves #selfcontrolvalves

#youtube#ball valve#check valve#gate valve#globe valve#china valve factory valve#valve#gatevalve#ballvalve#cantonfair

0 notes

Text

Gate Valve Symbols and Pipeline Instrumentation Diagrams: from Design to Manufacturing in China

In industrial pipeline systems, valves are the core components that control fluid flow, and gate valves and check valves are one of the most common types. Whether it is design engineers, procurement personnel or maintenance teams, they need to understand the symbol representation of these valves in pipeline instrumentation diagrams, as well as how to choose high-quality gate valve manufacturers and suppliers. This article will deeply analyze the gate valve symbols, check valve symbols and their meanings in PID diagrams, and explore China’s advantages as an important gate valve manufacturer in the world.

Sample of Valve Symbols in Pipeline Instrumentation Diagrams

Gate Valve Symbols and Check Valve Symbols

1. Gate valve symbol analysis

In the PID diagram, the gate valve symbol is usually composed of the following elements: - Vertical lines: Represents the main structure of the valve body. - Horizontal wedge gate: Symbolizes the opening and closing components of the gate valve, which controls the flow of fluid through lifting and lowering movements. - Handwheel or actuator symbol: Marked on the top of the valve body, indicating manual or automatic operation mode. - Flow direction arrow (optional): Indicates the allowed direction of the fluid.

Example: - Manual gate valve: A horizontal wedge is added in the middle of the vertical line, and the handwheel symbol is marked on the top. - Electric gate valve: Add a motor icon next to the wedge symbol.

2. Check valve symbol analysis

Check valve‘s symbol design emphasizes its unidirectional flow characteristics: - Triangle or arrow: Points to the direction of allowed flow. - Vertical line or spring symbol: Indicates the mechanism of automatic closing of the valve.

Example: - Swing check valve: An arc line is added next to the arrow to indicate the swing of the valve disc. - Lift check valve: vertical line with lift disc symbol.

2. Importance of Piping and Instrumentation Diagram Symbols

PID diagram is the “blueprint” of industrial process design, which clearly expresses pipelines, valves, instruments and control logic through standard symbols. The significance of using symbols correctly is:

1. Improve communication efficiency: The globally common symbol system avoids language and technical misunderstandings. 2. Ensure safety: Clearly mark valve types and functions to prevent operating errors. 3. Optimize maintenance processes: Quickly locate equipment through symbols to reduce downtime.

Common symbol standards: - ISO 10628: Internationally common flowchart symbol standard. - ANSI/ISA 5.1: Detailed symbol specifications developed by the American Instrument Association.

Global Competitiveness of Chinese Gate valve Manufacturers

As an important production base for industrial valves in the world, China’s gate valve factories and manufacturers dominate the market with the following advantages:

1. Technology and manufacturing capabilities

- Material innovation: Adopt corrosion-resistant materials such as high-strength alloy steel and stainless steel to adapt to high temperature and high pressure environments. - Precision machining: CNC machine tools and automated production lines ensure the sealing and durability of valves. - Complete certification: Meet international standards such as API 600 and ISO 9001 to meet the needs of global customers.

2. Cost advantage

- Scaled production: Reduce unit costs through mass production and provide **competitive prices**. - Supply chain integration: Localized raw material procurement and logistics networks further reduce costs.

3. Customized service

- Non-standard design: Support customers to customize valve size, pressure level and connection method. - Fast delivery: Perfect inventory management and efficient production cycle to meet urgent needs.

4. Global supply network

Chinese gate valve suppliers expand international markets through the following ways: - Cross-border e-commerce platforms: such as Alibaba International Station, directly connect with overseas customers. - Localized services: Set up warehousing and after-sales centers in North America, Europe, and the Middle East.

How to choose a high-quality Chinese Gate Valve Supplier

1. Verify qualifications and reputation - Check whether the company holds API, CE and other certifications. - Understand customer feedback through third-party platforms (such as Google Reviews).

2. Request sample testing - Test the sealing, pressure resistance and service life of the valve.

3. Pay attention to after-sales service - Ensure that the supplier provides technical support and fast repair services.

4. Compare prices and delivery dates - Avoid choosing suppliers whose quotations are far below the market level (there may be quality problems).

Application scenarios and selection recommendations for gate valves

1. Typical application areas

- Oil and gas: used for pipeline opening and closing and flow control. - Chemical industry: special gate valves that withstand corrosive media. - Water treatment system: large-diameter gate valves are used in reservoirs and water pipelines.

2. Key selection parameters

- Pressure level: such as Class 150, Class 300. - Connection method: flange, welding or threaded connection. - Operation method: manual, electric or pneumatic.

Conclusion

From the gate valve symbol in the PID diagram to the valve selection in actual application, each step directly affects the safety and efficiency of the industrial system. As the world’s leading gate valve manufacturer, China has become the first choice for international procurement with its technical strength and cost advantages. Whether you are an engineer, a purchaser or a project manager, choosing a reliable China gate valve supplier will be the key to ensuring the success of the project.

#ball valve manufacturers in india#ball valve suppliers#butterfly valve#esdv#ball valve#check valve#gate valve#gate valve manufacturers#globe valve#plug valve

0 notes

Text

Advanced Ball Valves with Actuators for Effortless Control

Upgrade to our state-of-the-art ball valve with actuators, designed for smooth and efficient on/off control. These valves are perfect for applications requiring quick and reliable operation. With a focus on performance and ease of use, our ball valves with actuators offer superior control in various industrial settings. Check out our selection to enhance your operational efficiency.

0 notes

Text

Understanding Ball Valves: Types, Uses, and Advantages

A reliable supplier is crucial when purchasing high-quality ball valves to ensure optimal performance and longevity. Allied Valves India, a leading ball valve supplier in Ahmedabad, offers a wide range of ball valves designed to meet industrial standards.

0 notes

Text

Diaphragm Valve vs. Ball Valve: Which Is Right for Your System?

In the field of fluid control systems, selecting the appropriate valve is critical for optimal performance. Two commonly used valves in industrial applications are the diaphragm valve and the ball valve. In this blog, we’ll delve into the characteristics of both, emphasizing the “diaphragm valve” and “ball valve,” to help you make an informed decision for your specific system needs.

Diaphragm Valve

1. Diaphragm Valve Overview:

Diaphragm valves are known for their versatility and reliable performance. The “diaphragm valve” often resonates with industries requiring precise control over fluid flow. These valves utilize a flexible diaphragm to regulate the flow, making them ideal for applications where contamination prevention is paramount. Pharmaceutical and food industries often favor diaphragm valves due to their sterile design.

Benefits of Diaphragm Valves:

Excellent Containment: Diaphragm valves excel in preventing fluid contamination, ensuring the purity of the transported substances.

Reliable Flow Control: The diaphragm design allows for accurate and consistent flow control, making them suitable for applications requiring precision.

Biocompatibility: In sectors such as biotechnology and pharmaceuticals, the biocompatible materials used in diaphragm valves make them a preferred choice.

Ball Valve

2. Ball Valve Insights:

On the other hand, the “ball valve” is often associated with efficiency and durability. Ball valves are characterized by a spherical disc that controls the flow. They find widespread use in industries requiring a simple yet effective solution for fluid control.

Advantages of Ball Valves:

Quick Operation: The quarter-turn operation of ball valves allows for rapid opening and closing, making them suitable for applications where speed is crucial.

Durability: Ball valves are often praised for their robust construction, providing longevity and reliability in demanding environments.

Low Maintenance: With fewer components, ball valves are easy to maintain, reducing downtime and operational costs.

3. Selecting the Right Valve for Your System:

Consider the application: Evaluate the specific requirements of your system. If precision and contamination control are critical, a diaphragm valve might be the better choice.

Pressure and Temperature Ratings: Both diaphragm and ball valves have different pressure and temperature handling capacities. Ensure the selected valve aligns with your system’s operating conditions.

Maintenance Considerations: Assess the ease of maintenance based on your system’s needs. If simplicity and low maintenance are crucial, a ball valve may be more suitable.

Conclusion:

In the diaphragm valve vs. ball valve debate, the right choice depends on your unique system requirements. By understanding the distinct advantages of each, you can make an informed decision that aligns with the needs of your fluid control system. Whether you prioritize precision, contamination prevention, or efficiency, both diaphragm and ball valves offer reliable solutions for diverse industrial applications.

0 notes

Text

A HD Stucchi Italy Couplings, Flat Face Quick Release Couplings, Mumbai, India

Manufacturer and Supplier of A HD Stucchi Italy Couplings, Flat Face Quick Release Couplings, Inline Valves, Inline Flow Indicator, Mumbai, India.

Quick Release Coupling, Quick Release Couplings, Ball Valve, Ball Valves, Gemel Ball Valves, Industrial Ball Valves, Quick Coupling, Quick Couplings, Camlock Coupling, Camlock Couplings, Camlock Quick Coupling, Camlock Quick Couplings, Micro Hose, Micro Hose For High Pressure, Micro Hose For Pressure Fittings, Test Coupling, Test Couplings, Minipress Test Coupling, Minipress Test Couplings, Test Point Coupling, Test Point Couplings , Threaded Test Coupling, Threaded Test Couplings, Bulkhead Test Coupling, Bulkhead Test Couplings, Female Swivel Test Coupling, Female Swivel Test Couplings, Plug in Test Coupling, Plug in Test Couplings, Pressure Gauge Adaptors, Cartridge Valve, Cartridge Valves, Hydraulic Hoses, Hydraulics Hose, Hoses Crimped Hydraulic, Hydraulic Systems, Pneumatic Systems, Hydraulic Accessories, Hydraulic Couplings, Hydraulic Fitting, Hydraulic Fittings, SS304 Hydraulic Fittings, SS316 Hydraulic Fittings, CS Hydraulic Fittings, DIN 2353 Fittings, Pressure Gauge, Pressure Gauges, Industrial Valves, Coupling Valves, Hydraulic Components, Inline Valve, Inline Valves, Inline Flow Indicator, Inline Flow Indicators, Portable Hydraulic Crimping Machine, Portable Hydraulic Crimping Machines, Portable Hydraulic Instrument, Portable Hydraulic Instruments, Pressure Gauge Anti Shock Valve, Pressure Gauge Anti Shock Valves, Stainless Steel Hydraulic Components, High Pressure Check Valve, High Pressure Ball Valve, High Pressure Flow Control Valve, High Pressure Needle Valve, Non Return Valve, Gemels Italy Ball Valves, Holmbury Uk Couplings, Minipress Italy Couplings, Oleoweb Italy Valves, SS304 Csermeto Fittings, SS316 Csermeto Fittings, Flat Face Coupling, Quick Connect Disconnect Coupling, Screw Coupling 1000 Bar, Dust Cap, Test Point, Test Hose, Test Point Coupling, Test Point Hose, SAE Flange Ball Valve, Rotating Union, Hose Burst Check Valve, Compensated Load Control Valve, Compensated Flow Control Valve, Load Shuttle Ball Valve, End Stroke Valve, Single Acting Pilot Check Valve, Double Acting Pilot Check Valve, Double Cross Line Direct Acting Relief Valve, Single Cross Line Direct Acting Relief Valve, Sequence Valve, Single Counter Balance Valve, Dual Counter Balance Valve, Hand Pumps, Tube Clamp, Instrumentation Fittings, Lubrication Fittings, PP Pipe Clamp, Dowty Seal Copper Washer, Bonded Seal, Nut, Ferrule, asia, asian, india, indian, mumbai, maharashtra, industrial, industries, thane, navi mumbai, pune, nashik, aurangabad, ratnagiri, nagpur, ahmednagar, akola, amravati, chandrapur, dhule, jalgaon, raigad, sangli, satara, belgaum, kolhapur, belgaon.

#Quick Release Coupling#Quick Release Couplings#Ball Valve#Ball Valves#Gemel Ball Valves#Industrial Ball Valves#Quick Coupling#Quick Couplings#Camlock Coupling#Camlock Couplings

1 note

·

View note