#ball valve factory

Explore tagged Tumblr posts

Text

The Guide to Small Ball Valves: Types, Applications, Tips.

When it comes to fluid control in compact systems, small ball valves, mini ball valves, and miniature ball valves are indispensable components. These valves are designed for precision, durability, and space efficiency, making them ideal for industries ranging from plumbing and HVAC to chemical processing and manufacturing. In this comprehensive guide, we’ll explore the key features, types, materials, and applications of small ball valves, along with tips for selecting the right valve for your needs.

—

What is a Small Ball Valve

A small ball valve is a quarter-turn valve that uses a hollow, perforated ball to control fluid flow. When the valve handle is turned 90 degrees, the ball rotates to align its bore with the pipeline (open position) or block it completely (closed position). These valves are characterized by their compact size, lightweight design, and ease of operation, making them perfect for tight spaces or applications requiring frequent adjustments.

Key advantages of small ball valves include:

- Leak-proof sealing for reliable performance. - Quick shutoff with minimal torque. - Versatility in handling liquids, gases, and corrosive media. - Low maintenance due to simple construction.

—

Types of Small Ball Valves

Small ball valves are available in various designs to suit specific applications. Below are the most common types:

1. Thread Ball Valve

A thread ball valve features threaded ends (NPT, BSPP, or BSPT) for easy installation in pipelines without welding. These valves are widely used in residential plumbing, compressed air systems, and low-pressure industrial setups.

2. Flange Ball Valve

Flange ball valves have flanged ends for bolted connections, ideal for high-pressure or large-diameter systems. They are common in oil and gas, water treatment, and chemical industries.

3. 2 PC Ball Valve vs. 3 PC Ball Valve

- 2 PC ball valves consist of two main body pieces, offering a balance between cost and serviceability. - 3 PC ball valves feature three separable body sections, enabling easy disassembly for cleaning or repair without removing the valve from the pipeline.

4. Floating Ball Valve

In a floating ball valve, the ball is held in place by compression from the valve seats. This design is cost-effective and suitable for low-to-medium pressure applications.

—

Material Choices for Small Ball Valves

The valve material impacts its durability, corrosion resistance, and compatibility with fluids. Popular options include:

1. Stainless Steel Ball Valve

Stainless steel ball valves (e.g., SS304, SS316) excel in corrosive environments, such as chemical processing, marine applications, or food-grade systems.

2. Carbon Steel Ball Valve

Carbon steel ball valves are robust and economical, ideal for high-temperature and high-pressure systems in oil refineries or power plants.

3. Forged Steel Ball Valve

Forged steel ball valves are manufactured through forging, resulting in superior strength and resistance to extreme conditions. They are commonly used in heavy-duty industrial applications.

—

Applications of Small Ball Valves

- Plumbing and HVAC: Regulating water flow in residential or commercial systems. - Chemical Processing: Handling aggressive fluids with stainless steel or PTFE-lined valves. - Automotive: Fuel and coolant control in compact engine systems. - Pharmaceuticals: Ensuring sterile fluid transfer with sanitary ball valves. - Agriculture: Irrigation and fertilizer distribution.

—

How to Choose the Right Small Ball Valve

1. Pressure and Temperature Ratings: Ensure the valve meets your system’s operational limits. 2. Connection Type: Select threaded, flanged, or welded ends based on installation requirements. 3. Material Compatibility: Match the valve body and seal materials to the fluid type (e.g., PTFE seals for chemicals). 4. Valve Size: Confirm the port size (e.g., ¼” to 2”) matches your pipeline dimensions. 5. Certifications: Look for industry standards like API, ANSI, or ISO for quality assurance.

—

FAQs About Small Ball Valves

Q: What’s the difference between a mini ball valve and a standard ball valve

A: Mini ball valves are smaller in size (typically under 1” diameter) and designed for low-flow or precision applications, whereas standard ball valves cater to larger systems.

Q: Can a stainless steel ball valve handle seawater

A: Yes, SS316 stainless steel valves offer excellent corrosion resistance in marine environments.

Q: When should I choose a 3 PC ball valve over a 2 PC design

A: Opt for a 3 PC ball valve if frequent maintenance or cleaning is required, as it allows easy access to internal components.

—

Conclusion

From thread ball valves in household plumbing to flange ball valves in industrial pipelines, small ball valves play a critical role in modern fluid control systems. By understanding the differences between floating ball valves, stainless steel ball valves, and forged steel ball valves, you can make informed decisions to optimize performance and longevity. Whether you need a miniature ball valve for a lab setup or a heavy-duty carbon steel ball valve for a refinery, prioritize quality materials, proper sizing, and compliance with industry standards.

Need a reliable small ball valve supplier, Contact Chinese NSW valve manufacturer experts today to find the perfect valve for your application.

#ball valve manufacturers in india#ball valve suppliers#ball valve#small ball valve#mini ball valve#china ball valve manufacturer#ball valve manufacturer#ball valve factory#ball valve supplier

0 notes

Text

Flanged type gate valve Class150Lb A216-WCB

#youtube#ball valve#check valve#gate valve#globe valve#china valve factory valve#valve#gatevalve#ballvalve#cantonfair

2 notes

·

View notes

Text

🌟 Ipower's Modern Hot Forging Machines 🌟 With 𝐟𝐮𝐥𝐥𝐲 𝐚𝐮𝐭𝐨𝐦𝐚𝐭𝐢𝐜 𝐩𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧 𝐩𝐫𝐨𝐜𝐞𝐬𝐬, our machines boost efficiency and save energy. Perfect for oil and gas, chemical processing, and water supply systems, our ball valves deliver optimal performance. 💪 We specialize in R&D for efficient non-standard machine tools that handle both small and large-scale processing across various industries, including: 🔷 LPG cylinder valves 🔷 Ball valves 🔷 Steam valves 🔷 Brass nuts 🔷 Rocker arms 🔷 Y-shaped valves 🔷 Safety valves 🔷 Stop valves 🔷 Globe valves 👉 Step into a new era of efficient manufacturing! Learn more: ipowermachinery.com 📞 +86-757-81851980 📞 +86-757-86085083 📞 +86 189 2454 9850 📠 +86-757-86085097 📫 [email protected] 🌐 ipowermachinery.com 🔔 Follow us for updates on hydraulic hot forging technology! #product #valve #brass #machine #forgingmachine #chinesefactory #automaticmachine #hydraulicpress #copper #hotforging #aluminum #industry #bestquality #powerpress

#production line#globe valve#ball valve#lpg cylinder valve#machine#chinese factory#forging machine#hot forging#brass valve#brass ball valves#copper#aluminium#brass product

0 notes

Text

So here’s the deal. I’ve got a small block. Two barrel carb. Runs like a dream (read: recently upgraded to “doesn’t sound like a asthmatic raccoon rolling down a flight of stairs in a metal trash can” when you start it up). So naturally I want to throw off the entire equilibrium and mess with the fuel system.

Swapping fuel pumps is fine. Adding a metal fuel filter where the plastic one (imagine a water balloon filled with gasoline sitting directly next to the exhaust headers. Now imagine something less safe than that) sits right now is a good idea. Not what I’m going for. I want Hilborn fuel injection.

Just the name “Hilborn fuel injection” harkens back to a time when people put little beer kegs full of fuel on the front of their Chevy 210s—imagine slapping a water balloon full of gasoline on the bumper of the car you’re currently axle hopping nose-first into a concrete barrier—and called corvettes without carburetors “fuelies,” which is surprisingly not an Australian slur for gas station attendants.

Ignore all the talk about mechanical fuel delivery. I don’t own a diesel and therefore leave that sort of thing to the special breed of freak that owns an Alfa Romeo. All you need to know is that the unhinged assemblies of gears and ball valves required to do what God designed the carburetor for are really just a big excuse to run those shiny chromed intake trumpets on a car.

You know when BMW guys talk about ITBs? Has nothing to do with irritable bowels. It’s 100% an excuse to put intake trumpets on the side of their engine. It looks cool, just not as cool as eight of those trumpets strapped to the top of your V8 hate machine. And I want that. Except I’m lazy, and according to the niche forums I visit tuning mechanical fuel injection is as pleasant as sticking your hand in a rusty toaster when done right and will ensure you get your steps in on the walk home when done wrong.

Could I simply buy a $1500 carburetor replacement electronic fuel injection setup that requires five bolts and about as many brain cells to install? Sure. I could also live my life as a productive member of society. That would involve living a lifestyle where I pay someone to tune the MFI for me. Both of these things a blow to my personal reputation as “the local skinflint” and my personal devotion to making things harder for myself. So rather than shell out for vintage MFI setups, I turned to the world of EFI. Surely the modern fanatics for Fratzogs and Rat Fink memorabilia would have made enough ruckus for to spark a Hilborn EFI lookalike.

Unfortunately, as far as I can tell they only built them for big blocks. My little hot rod’s factory small block is doomed never to host those shiny little intake trumpets. Sure I could swap in a big block, but when I sat this one next to my dilapidated street machine I began to consider the fact that this is a lot of effort for a lowly hot rod. At the heart of things I’m just as lazy as I am determined to make things harder for myself, and so I decided I need to find something else to put the big block in.

What was the question again? Oh, what am I going to do with the rolling chassis Lola T70 replica behind me?

5 notes

·

View notes

Text

July 8th | Mexico | You actually handed money over for this job...

Daniel from IAS Labs dropped me an email about updating his 1975 Brasilia and its front suspension. He used the word "hacked" in his initial email. I wasn't ready for the pictures that came back.

If ANY experience, for reference, I have 21+ years, resonates with you, head this warning. If you hire someone and you don't vet their work, you could actually hand money over for this kind of work. Please, don't risk your life or the lives around you even thinking of driving around the streets with so many issues. Please.

With that said, Daniel asked for the PRO's expertise on what it would update this Brasilia and bring safety, enjoyment, and quality of ride, back to the forefront of this Classic VW. The Answer. The Stage 2 PRObuilt Beam.

With the vehicle having cosmic wheels and the current 5" narrowed beam, Daniel was having rubbing problem on the inner fenderwells and he also did not like how much it tucked inside the fenders. We opted to do the 2" narrowed version to check as many boxes as possible. Here are the specs on the beam;

Stage 2 PRObuilt Air Ride Ball Joint Beam Complete - 2203

The BEST way to add Air Ride to a Classic Volkswagen Type 1 with ball joint front suspension (1966 through 1977), is by installing a Stage 2 PRObuilt Beam. When the PRO's say complete, they mean complete. You will not need anything in addition to this assembly. The Stage 2 PRObuilt Beam is built on the Ultimate Beam platform. It's made in stock width and up to four inches narrower than OEM to allow for wider wheels, drop spindles, and disc brakes, that add track width. The complete beam comes as you see it, spindle to spindle, with an entire PRObuilt steering system installed and ready to bolt in and go.

What's included? This Stage 2 PRObuilt Beam is spindle to spindle, built in any configuration, from stock to four inch narrowed. It comes powder-coated, satin black, ready to install. The front end comes complete with the following;

New Ultimate Adjustable Beam

Through Rods

New Tie rods

New Air Ride Shocks

New Drum Drop Spindles (CB Performance/EMPI) or OEM Spindles

New Steering Dampener

New Hardware

New Grease Zerks

Premium Tie rod Ends

Premium Ball Joints

PRObuilt Steering Box filled with Corn Head Grease

Reconditioned pitman/drop arm/clamp

PRObuilt Control Arms

New eccentrics

What's recommended?

When it comes to how narrow you need, check out this article here. The PRO's recommend a FOUR Inch narrowed for most applications as it allows for just about any wheel to fit and tuck under the fenders.

If you are going for the dropped look and want to run either Airkewld's GEN 2 Disc Brake kit or your factory drums opt for the DRUM Drop Spindles. If you keep your Factory Disc Brakes (4 lug), opt for the DISC Drop Spindles. If you are keeping the drop moderate, a stock height spindle for the drum or factory disc is available. If you want to run the disc brakes you already have, click here.

Install kit (saves time, ensuring you have everything needed to do the job right) New beam bolts, upper and lower body pads, and inspection plate) .

If you want to make this beam install even more complete, maybe installing a GEN 2 Disc Brake kit might make sense. To have the PRO's install them, you will need to add the labor to do that here, then choose your disc brake kit here.

You will need an Air Management Kit (AMK) to lift and lower the vehicle on demand. If you are only doing front air ride, you can use a 2 valve AMK and use one valve per corner. This will eliminate sway left to right when turning. Trust me. If you are going to do full air ride, then the 4 valve AMK is what you need. (If you decide to use a different manufacture for air management, the PRO's will be UNABLE to tech support any issues you have as we will be unable to replicate the issue in house).

If your steering coupler from your column to your steering box has seen better days, the PRO's suggest the OEM PRObuilt Steering Box Coupler found here.

Kewl Features

American made

7.5 inches of up-and-down movement

Taller shock towers allow for the use of shocks that will work with any ride height adjustment

Industries finest packaging to ensure it will arrive to you unscathed

FAQ

Do I need to do body mods to install this beam? No. The inside dimension is 29 13/16". That gives a clearance of 1/16" on each side.

How do you narrow the beam 4" when I only have 1/2 inch on each side of my stock beam? We utilize the outer ends of the tubes and gusset outwards to give us the needed space. Here is a video that explains it.

Do I need to send in a core? No. The PRO's have a few options for your cores. Check them out here.

Will I need anything in addition to this assembly? No. It's as complete as it comes from the factory.

The front end will be coated apart and assembled to keep the clean look with new hardware. It's set to the medium height setting so that you can adjust it to your liking. It's pre-greased, and alignment will set in a rough application for shipping.

Financing is available during checkout.

What do you think of the old beam build and what do you think of the new beam build?

3 notes

·

View notes

Text

Gate Valve supplier in Oman

Middleeast valve is one of the best Gate valve supplier in Oman . We supply to cities like Ibri, Sur, Muscat, and Mutrah.

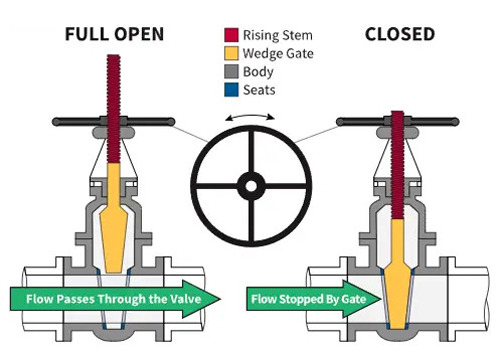

A gate valve is a type of valve used to control the flow of fluids (liquids or gases) by using a gate or wedge-like disc that moves perpendicular to the flow path to either block or allow the passage of the fluid.

The main function of a gate valve is to provide a tight shutoff, effectively stopping the flow of fluid through the pipeline when the valve is fully closed, and allowing unrestricted flow when the valve is fully open. Gate valves are commonly used in applications where the fluid flow needs to be completely shut off, such as in water supply systems, oil and gas pipelines, industrial processes, and more.

Gate valves consist of several main components, including the body, gate (wedge), stem, actuator, and seats. Here's how they work:

Open Position:

In the open position, the gate (wedge) is fully retracted into the valve body, allowing the fluid to flow through the valve with minimal obstruction. The gate moves perpendicular to the direction of the fluid flow. The valve is opened by turning the valve stem (either manually using a handwheel or with an actuator) which is connected to the gate.

Closing Position:

To close the valve, the stem is turned in the opposite direction, causing the gate to move down into the flow path of the fluid. As the gate descends, it gradually restricts the flow until the valve is completely closed. The gate makes contact with the valve seats located at the bottom of the valve body, forming a tight seal that prevents any further flow.

Middleeast valve is the greatest Gate valve supplier in Oman and are known for their ability to provide a tight seal and low pressure drop when fully open. However, they might require more turns to fully open or close compared to other valve types like ball valves. It's important to use gate valves in appropriate applications and avoid using them for flow regulation where frequent adjustments are necessary.

Description:

Available materials: SS304, SS904, SS904L, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Incoloy, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron, super duplex

Size: 1/2″- 64”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operations: Hand Wheel Gate valve, Gear operated Gate valve, Electric actuated Gate valve and Pneumatic Actuated Gate valve

Ends: Flanged(FF,RF,RTJ), Buttweld, Socket weld, Threaded

Standards: API607, DIN, BS, ANSI, AWWA, ASME, API6D

Gate valve types:

Rising Stem Gate Valve

Non Rising Stem Gate Valve

Bellow Seal Gate Valve

Pressure Seal Gate Valve

Cryogenic Gate Valve

Forged Gate Valve

Gate valve advantages :

They have low fluid resistance.

They have superior sealing capability.

They come with a wide application range.

They have dual flow directions.

Gate valve Industries:

Textiles.

Power generation.

Refineries.

Petrochemical plants.

Shipbuilding

Chemical industry.

Paper factories.

Gate valve parts:

Hand wheel.

Stuffing Box.

Bonnet

Gasket

Stem

Flange

Disk

Body seats

Packing

Body

Visit our website: https://www.middleeastvalve.com/product-category/gate-valve/

2 notes

·

View notes

Text

Reliable Exporter of PVC, CPVC & UPVC Ball Valves from India to South Africa – KANA Valves

KANA Valves Pvt. Ltd. is a Reliable Exporter of PVC, CPVC & UPVC Ball Valves from India to South Africa. KANA Valves – Your Export Partner for PVC, CPVC & UPVC Ball Valves, Union Valves, Irrigation & Plumbing Pipes & Fittings in South Africa. Company Overview: KANA Valves Pvt. Ltd. is a leading manufacturer and exporter of high-quality PVC, CPVC, UPVC Ball valves, designed to meet the diverse demands of the plumbing and irrigation sector across South Africa. KANA Valves Pvt. Ltd. has been a manufacturer of PVC, CPVC, UPVC Ball valves, Union Ball Valves, CPVC Pipes and fittings & UPVC Pipes & Fittings for over 15 years in Ahmedabad, Gujarat, India. We offer a wide range of PVC Ball Valves for industries like plumbing, water treatment, agriculture, and more. We ensure that every valve leaving our factory meets the highest quality standards. Each product undergoes rigorous testing to ensure flawless operation, durability, and efficiency in demanding applications. KANA Valves offers competitive pricing without compromising on quality. Our products provide excellent value, making them the preferred choice for customers seeking reliable and affordable valve solutions. As a trusted exporter to South Africa and numerous other international markets, we ensure timely deliveries and reliable support for customers worldwide. Features of KANA Ball Valves: Durable Construction Smooth Flow Control Leak-Proof Design Wide Range of Sizes Easy Installation and Maintenance Technical Details of KANA Ball Valves: Material Options: PVC, CPVC, and UPVC, PP Sizes: Available in a wide range of sizes from ½ inch to 8 inches (DN 15 to DN200) Pressure Ratings: PN10 & PN16 Temperature Range: PVC: 0°C to 60°C CPVC: 0°C to 90°C UPVC: 0°C to 60°C Connection Types: Threaded (BSPT), Socket Weld. Ball Design: Full port. Seal Type: EPDM for leak-proof performance Applications of KANA Ball Valves: Plumbing Systems Water Treatment Plants Agricultural Irrigation Systems Chemical Processing Industrial Flow Control KANA Valves Pvt. Ltd. is a Reliable Exporter of PVC, CPVC & UPVC Ball Valves from India to South Africa including locations Eastern Cape, Port Elizabeth, East London, Mthatha, Queenstown, Grahamstown, Free State, Bloemfontein, Welkom, Phuthaditjhaba, Kroonstad, Gauteng, Johannesburg, Pretoria, Ekurhuleni, Sandton, KwaZulu-Natal, Durban, Pietermaritzburg, Richards Bay, Newcastle, Limpopo, Polokwane, Tzaneen, Makhado, Burgersfort, Mpumalanga, Nelspruit, Witbank, Secunda, Sabie, Northern Cape, Kimberley, Upington, De Aar, Springbok, North West, Mahikeng, Rustenburg, Klerksdorp, Potchefstroom, Western Cape, Cape Town, Stellenbosch, Paternoster, and George. For more information or to place an order, feel free to contact us today! View Product: Click here Read the full article

0 notes

Text

How to Choose Canada's Best Lead-Free Ball Valves?

Selecting the right lead-free ball valves in Canada is vital for industries prioritizing safety and efficiency. With strict regulations and the need for sustainable practices, businesses must invest in quality valves that meet environmental standards. This guide explores how to identify the best lead-free ball valves for your needs, focusing on factors like material, functionality, and compliance.

Why Choose Lead-Free Ball Valves?

Lead-free ball valves are essential for applications where water safety and environmental standards are a priority. They offer several advantages over traditional valves:

Health Benefits: Lead-free materials prevent contamination, ensuring clean and safe water supply.

Environmental Compliance: These valves meet Canadian safety regulations, making them suitable for residential, commercial, and industrial use.

Durability: Lead-free valves are crafted with robust materials, ensuring longevity and reduced maintenance costs.

Features to Consider When Choosing Lead-Free Ball Valves:

When selecting the best lead-free ball valves, evaluate the following factors:

Material Quality: Look for valves made from high-grade brass or stainless steel. These materials resist corrosion and wear, ensuring long-lasting performance.

Size and Compatibility: Ensure the valve’s dimensions match your system specifications for optimal functionality.

Certifications: Opt for valves with certifications like NSF/ANSI 61 to confirm they meet health and safety standards.

Ease of Installation: Choose valves that are easy to install and maintain to save time and resources.

Popular Applications for Lead-Free Ball Valves in Canada:

Lead-free ball valves are used in various industries:

Residential Plumbing: Ideal for potable water systems due to their non-toxic properties.

Commercial Use: Widely implemented in HVAC systems for efficient flow control.

Industrial Settings: Suitable for factories needing durable and compliant components.

Tips for Purchasing the Best Lead-Free Ball Valves:

To find reliable valves, keep the following tips in mind:

Research Reputable Brands: Leading brands in Canada specialize in high-quality, lead-free valves.

Read Customer Reviews: Check feedback to gauge product reliability and customer satisfaction.

Compare Prices: While cost is a factor, prioritize quality to avoid future repairs.

Choosing the best lead-free ball valves in Canada requires careful consideration of material, functionality, and compliance. These valves are critical for ensuring safety, efficiency, and adherence to environmental regulations. Investing in high-quality valves guarantees reliable performance across applications. Whether for residential, commercial, or industrial use, lead-free ball valves are a smart and sustainable choice for businesses.

Explore Further Details!

0 notes

Text

What is A Shut Off Valve: A Guide to Safeguarding Plumbing

A shut off valve is a critical component in piping systems designed to control the flow of liquids or gases. By opening, closing, or partially obstructing pathways, these valves ensure safety, regulate pressure, and prevent leaks. Whether in residential plumbing, industrial processes, or oil and gas pipelines, shut off valves are indispensable for system efficiency and emergency management.

Types of Shut Off Valves

Shut off valves come in various designs, each suited for specific applications. Here are the most common types:

Ball Valve

A ball valve uses a rotating ball with a bore to control flow. It offers quick shut-off, durability, and minimal pressure drop. Ideal for water, gas, and oil systems.

Gate Valve

Gate valves feature a wedge-shaped gate that lifts to allow flow. They’re best for on/off control in low-frequency applications, such as water supply lines.

Globe Valve

Known for precise flow regulation, globe valves use a disc and seat mechanism. Common in HVAC systems and fuel pipelines.

Butterfly Valve

A compact, lightweight valve with a rotating disc. Butterfly valves excel in large-scale water treatment and fire protection systems.

Check Valve

Allows flow in one direction only, preventing backflow. Used in sewage systems and pump discharge lines.

Diaphragm Valve

Utilizes a flexible diaphragm to isolate flow. Ideal for corrosive or slurry fluids in chemical processing.

Needle Valve

Designed for precise flow control with a tapered needle-like plunger. Common in instrumentation and hydraulic systems.

ESDV (Emergency Shutdown Valve)

A specialized valve for rapid closure during emergencies, often automated. Critical in oil refineries and gas pipelines.

Uses of Shut Off Valves

Shut off valves serve diverse roles across industries:

- Residential: Isolate water supply during repairs (e.g., ball valves under sinks). - Industrial: Regulate steam, chemicals, or fuels (globe valves, diaphragm valves). - Oil & Gas: Ensure safety with ESDVs during leaks or pressure surges. - Fire Protection: Butterfly valves enable rapid water flow control in sprinkler systems. - Pharmaceuticals: Needle valves maintain precision in fluid handling.

How Do Shut Off Valves Work

The operating mechanism varies by type but follows a general principle:

1. Actuation: Valves are operated manually (handwheel, lever) or automatically (electric/pneumatic actuators).

2. Flow Control:

– Ball/Butterfly Valves: Rotate 90° to open/close. – Gate/Globe Valves: Linear motion raises/lowers the gate or disc. – Check Valves: Rely on flow pressure to open/close.

3. Sealing: Tight seals (rubber, PTFE) prevent leaks when closed.

Choosing the Right Valve

Selecting a shut off valve depends on factors like:

- Fluid Type: Corrosive fluids demand diaphragm valves; gases suit ball valves. - Pressure/Temperature: High-pressure systems require robust ESDVs or gate valves. - Frequency of Use: Ball valves last longer in high-cycle applications.

Conclusion

From ESDVs in hazardous environments to simple ball valves in homes, shut off valves are the backbone of fluid control systems. Understanding their types, uses, and mechanics ensures optimal performance and safety. Regular maintenance and correct valve selection further enhance system longevity.

#ball valve manufacturers in india#ball valve suppliers#china ball valve#china valve manufacturer#valve manufacturer#valve factory#valve price#shut off valve#gate valve#butterfly valve#esdv

1 note

·

View note

Text

Automatic welding process for gate valve seat, special welding material welding process for wear-resistant and corrosion-resistant sealing of gate valve seat, mechanical arm welding process for gate valve seat,Welcome your visit RTV valve

WhatsApp:+86 15888732537

Email:[email protected]

https://www.rtv-valve.com/

#valve #gatevalve #globevalve #checkvalve #ballvalve #butterflyvalve #plugvalve #y_strainer #Control_valve #hydraulic_valve #electric_valve #pneumatic_valve #canton_fair #coosaivalve #valveimport #valveexport #valvestock #valveshop #valvesupplier #valvesupply #valvefactory #valvemanufacturer #valvedistributor #butterflyvalves #ballvalves #gatevalves #globevalves #knifegatevalves #controlvalves #selfcontrolvalves

#youtube#ball valve#check valve#gate valve#globe valve#china valve factory valve#valve#gatevalve#ballvalve#cantonfair

0 notes

Text

Why is Ball Valve Essential for Automobiles? Check Reasons!

A ball valve is durable, easy to operate, and requires minimal maintenance for precise control over fluid flow and is ideal for critical automobile functions. These valves come with a robust design to handle high-pressure and temperature variations, ensuring optimal performance of some systems including fuel lines, cooling systems, and hydraulics of a car.

Similarly, a check valve, often used alongside ball valves, ensures unidirectional fluid flow to prevent backflow and save sensitive systems from the risks of operational and structural damage.

In challenging and high-pressure applications, they are essential for maintaining system integrity, regulating fluid flow, and guaranteeing safety. Purchasing valves from reputable suppliers ensures long-term value and maximum system performance.

Advantages of Essential Ball and Check Valves from Renowned Manufacturers

Businesses should buy essential valves from renowned manufacturers to ensure reliability and efficiency, precise fluid control, prevent backflow, motion control, fluid power applications, and withstand high-pressure conditions.

These valves are essential to many industries, including water treatment, chemical processing, oil and gas, and pharmaceuticals to improve safety and customer experience with cutting-edge technologies like remote factory acceptance tests and mixed reality training.

Renowned manufacturers adhere to strict quality standards, ensuring durability and consistent performance to maintain global quality. Locally engineered and tested valves meet the specific demands of industries like defence, mining, construction, and power generation.

These experts have expertise in fluid technology, combined with bespoke design and predictive maintenance solutions, to ensure that their valves deliver superior functionality. Additionally, they support industries with services like on-site audits, engineering advice, and technical training.

Find a Trusted Manufacturer of Essential Machinery Parts

Finding a trusted manufacturer of essential machinery parts requires thorough research and consideration.

Evaluate the manufacturer’s experience and reputation in the industry. Check whether they are certified and authorised by authorised bodies which indicates adherence to high-quality standards.

Check if the manufacturer offers customized solutions to meet specific needs and provides services like engineering support, on-site audits, and technical training.

Ensure they have expertise in the required industry and a proven track record of delivering reliable products and after-sales support.

Consider manufacturers that integrate advanced technologies like predictive maintenance or remote testing, as these innovations enhance efficiency and safety.

Finally, select a manufacturer known for precision, durability, and comprehensive support.

Source

0 notes

Photo

Everbilt 3/4 in. Brass FPT x FPT Lever Handle Gas Ball Valve

New in original factory package or box.Box or package may not be in the best condition. Have Question Just Ask?

Listing and template services provided by inkFrog

0 notes

Text

440C Stainless Steel Ball

●Diameter range: 0.3mm~Ø60mm, special specifications can also be customzed

●Available grade: G10-G500

●Surface: polished, finely ground

●440C stainless steel ball(9Cr18Mo), martensitic steel, high precision, hardness up to Rockwell 56-58 degrees, magnetic, good corrosion resistance, rust resistance and wear resistance.

●Application: bearings, stamping/hydraulic parts, valves, aerospace devices, seals, refrigeration equipment, high-precision instruments, etc.

0 notes

Text

Valve components forging

Valve Components Forging, Size From 1/2" To 48",Including Valve Body, Adaptor, Stem, Seat, Ball Etc.

ACE Valve located in Yancheng, Jiangsu Province is a customer-centric manufacturer of professional valve components used in oil and gas, chemical power generation, and mining. water treatment and general industrial systems. our main products are valve bodies. closures, seat rings bonnets, trunnion plates, stems, top flanges, and other accessories. our facilities allow us to manufacture valve assemblies from 1/2-56"it has a group of dedicated and professional staff with ten years of experience in the production line, factory management, and quality control marketing. etc. We are equipped with more than 50 sets of advanced processing equipment including CNC machine tools, and CNC machining centers. lathes, etc., and testing equipment.

E-mail [email protected]

Mobile / Whatsapp / Wechat: +86 - 15722580267

Address No. 1 Shenfeng Rd. Dafeng Economic Zone, Jiangsu, P.R.China.

0 notes

Text

KANA Valves Africa’s Trusted Exporter for PVC, CPVC Pipes, Fittings and Ball Valves

KANA Valves is Africa’s trusted exporter of PVC, CPVC pipes, fittings, and ball valves. Company Overview: KANA Valves Pvt. Ltd. is a leading manufacturer and exporter of high-quality PVC, UPVC, and CPVC pipes & fittings & Ball valves, designed to meet the diverse demands of the plumbing and irrigation sector across Africa. With over 15 years of expertise, we ensure leak-proof, durable, and cost-effective solutions for water distribution, agriculture, and industrial applications. Why Choose KANA Valves? Direct Factory Supply – No middlemen, competitive prices. High-Quality Standards – Designed for high-pressure & tough African conditions. Trusted by Plumbers & Farmers – Ensuring smooth water flow in homes, farms, and industries. Product Description: KANA Valves Pvt. Ltd. provides a wide range of PVC, CPVC, and UPVC ball valves, pipes & fittings, specially designed for African plumbing and irrigation needs. Our valves offer high flow efficiency, chemical resistance, and durability, making them ideal for agriculture, water supply systems, industrial applications, and plumbing projects. Whether you need ball valves, foot valves, non-return valves, hose fittings, or irrigation fittings, we guarantee leak-proof, easy-to-install, and long-lasting solutions. Features: Durable PVC, UPVC, and CPVC Material – Withstands high pressure & temperature. Smooth Water Flow – Precision-engineered design for minimal friction loss. Corrosion & Chemical Resistant – Ideal for all water, irrigation, and plumbing applications. Leak-Proof & Secure Sealing – Prevents water loss & ensures maximum efficiency. Wide Size Availability – Ranging from ½ inch to 2 inches (DN 15 to DN50) in various standards (ANSI, DIN, PN10 & PN16). Benefits of KANA Ball Valves & Fittings in Africa: For Irrigation: Ensures efficient water distribution for agriculture. Reduces water wastage with tight-sealing valves. Durable even in harsh weather conditions. For Plumbing: Long-lasting leak-proof performance. Cost-effective & easy to install. Suitable for domestic, commercial, and industrial water supply. For Industrial Use: Handles high-pressure applications in water treatment plants. Resistant to harsh chemicals & industrial fluids. Technical Details: Material: High-quality PVC, CPVC, Size Range: ½” to 2” (Available in ANSI, DIN, PN10 & PN16) Temperature Resistance: Suitable for hot & cold water applications Pressure Ratings: PN 10 & PN 16, ideal for high-pressure systems Connection Type: Threaded & solvent-weld connections for easy installation KANA Valves is Africa’s trusted exporter of PVC, CPVC pipes, fittings, and ball valves including locations Lagos, Abuja, Kano, Port Harcourt, Ibadan, Cape Town, Johannesburg, Durban, Pretoria, Port Elizabeth, Cairo, Alexandria, Giza, Sharm El-Sheikh, Luxor, Nairobi, Mombasa, Kisumu, Nakuru, Eldoret, Addis Ababa, Dire Dawa, Mekelle, Gondar, Hawassa, Accra, Kumasi, Takoradi, Tamale, Cape Coast, Dar es Salaam, Dodoma, Arusha, Mwanza, Mbeya, Kampala, Entebbe, Jinja, Mbarara, Masaka, Casablanca, Marrakesh, Rabat, Fes, Tangier, Dakar, Thies, Saint-Louis, Ziguinchor, Kaolack, Abidjan, Yamoussoukro, Bouaké, San Pedro, Daloa. Contact us for more details or to place an order. View Product: Click here Read the full article

0 notes

Text

China Valmax Valve Co., Ltd. is a leading manufacturer of industrial valves in China, specializing in ball valves, gate valves, globe valves, check valves, and other valve types used in industries such as oil and gas, chemical engineering, and more. Established in 2004, the company adopted the name Valmax Valve in 2012 as part of its growth strategy. Since then, Valmax has been committed to the research and development of industrial valves, focusing on high-quality production and delivering superior service.

Valmax's products are trusted for their reliable quality, timely delivery, and competitive pricing, ensuring that customers can depend on us for their valve business needs. We are located in Lishui City, known as a famous valve manufacturing hub in China, and we have our own foundry and processing factories.

Our product range includes ball valves, gate valves, globe valves, check valves, slab gate valves, strainers, and valve parts that meet international standards such as API, DIN, and GOST. Our foundry covers an area of 23,000 square meters, where we produce castings in materials like carbon steel, alloy steel, stainless steel, and special steels.

1 note

·

View note