#ball valve supplier

Explore tagged Tumblr posts

Text

What Is a Ball Valve? A Complete Guide to Its Function and Uses

Ball valves are one of the most commonly used types of valves in industries worldwide. Their design and versatility make them ideal for controlling the flow of various fluids and gases. This comprehensive guide will explore what a ball valve is, how it functions, and its various applications, along with insights into the ball valve manufacturing industry in India.

What is a Ball Valve?

A ball valve is a type of valve that uses a spherical ball to control the flow of media (liquids, gases, or slurries) through a pipe or system. The ball has a hole or port through the center, which aligns with the flow path when the valve is open. When the valve is closed, the ball rotates 90 degrees, blocking the flow path and preventing the passage of the media.

The simplicity of this design allows for quick and efficient operation. Ball valves are known for their durability, reliability, and ability to maintain a tight seal even after long periods of use.

How Does a Ball Valve Work?

A ball valve consists of several key components, including the body, the ball, the stem, and the handle or actuator. The ball is mounted inside the valve body, with the hole or port aligned with the flow path when the valve is open. When the valve handle is turned, the stem rotates the ball, either opening or closing the valve.

The flow direction and the valve's status (open or closed) are determined by the orientation of the ball. In the open position, the flow passes through the hole in the ball, allowing the fluid or gas to move through the valve. In the closed position, the ball rotates 90 degrees, blocking the flow entirely.

One of the key features of ball valves is their ability to create a tight seal. The design ensures minimal leakage, even in high-pressure applications, making them highly reliable in various industries.

Types of Ball Valves

There are different types of ball valves, each suited for specific applications. The most common types include:

Standard Ball Valve: This is the most basic type of ball valve, ideal for simple on/off applications.

V-Port Ball Valve: This valve has a V-shaped ball, which allows for precise flow control, making it suitable for throttling applications.

Multi-Port Ball Valve: These valves have multiple ports, allowing for directional flow control and bypassing multiple channels. They are used when more complex flow control is needed.

Trunnion Ball Valve: A trunnion ball valve has a ball that is supported by bearings, allowing for larger sizes and higher-pressure applications.

Uses of Ball Valves

Ball valves are widely used across different industries due to their efficiency and reliability. Some of the key applications include:

Oil and Gas: Ball valves are essential in oil and gas systems for controlling the flow of crude oil, natural gas, and other fluids. Their ability to withstand high pressures and temperatures makes them ideal for this industry.

Water Treatment: In water treatment plants, ball valves are used to control the flow of water and chemicals. They are often found in filtration systems, distribution lines, and pumping stations.

Chemical Processing: Chemical plants use ball valves to manage the flow of various chemicals, ensuring safe and controlled operations. The tight seal offered by ball valves minimizes leaks and contamination.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, ball valves regulate the flow of fluids used for heating and cooling purposes.

Food and Beverage: In the food and beverage industry, ball valves ensure the smooth flow of ingredients, liquids, and gases, as well as maintain hygienic conditions.

Pharmaceuticals: Ball valves are also critical in the pharmaceutical industry, where cleanliness and precise flow control are required for producing medicines and vaccines.

Why Choose Ball Valves?

There are several reasons why ball valves are favored in various industries:

Durability: Ball valves are highly durable and can withstand harsh operating conditions, such as extreme temperatures and high pressures.

Leak-Proof Performance: Ball valves are designed to provide a tight seal, preventing leaks even in demanding applications.

Ease of Operation: With a simple 90-degree turn, ball valves are easy to operate and provide quick response times.

Versatility: They can be used for a wide range of applications, from small-scale systems to large industrial plants.

Low Maintenance: Due to their robust design and minimal moving parts, ball valves require little maintenance compared to other types of valves.

India has become a significant player in the global valve manufacturing industry, with many reputable ball valve manufacturers producing high-quality valves. A ball valve manufacturer in India is equipped with advanced technology and expertise to meet the growing demand for industrial valves in various sectors.

These manufacturers use state-of-the-art materials and rigorous quality control processes to ensure that their products meet international standards. As a result, India's ball valve manufacturers are well-positioned to cater to both domestic and international markets, offering products that are durable, reliable, and cost-effective.

Conclusion

Ball valves are essential components in many industries, offering excellent control and reliability in fluid and gas handling systems. Their simple design, combined with a tight seal, makes them an ideal choice for various applications. Whether in oil and gas, water treatment, or pharmaceuticals, ball valves continue to play a crucial role in ensuring smooth and safe operations. As the demand for high-quality valves grows, ball valve manufacturers in India are playing a crucial role in supplying the global market with reliable and durable valves to meet diverse industry needs.

0 notes

Text

Efficient Filtration with Y-Type Strainers in India

Flowdovalves is leading valve manufacturing company in India. their y-type strainers play best role of that efficiency and longevity in various industrial valve in India. that y0type strainers remove unwanted debris and impurity from pipelines and make sure that smooth and without stopping flow of fluids. Flowdovalves build for mesh filter in y shaped chamber that without significantly impacting pressure and flowrate. that why they y-type strainer use in water treatment plants and chemical industries or in HVAC system. FlowdoValves providing high quality y type strainer to complete the industrial needs and make sure that reliable and durable also.

FlowdoValves strainer are manufactured with accuracy and using high grade quality material that providing resistance to rust and washed away. If you choosing y-type strainers from FlowdoValves that can benefit from reducing maintenance of cost and improving operational efficiency. if you looking for new y-type strainer installation then Flowdovalves highest quality and long-lasting solution for your all industrial needs.

If you replace your y-type strainer then visit our website for high quality and reliable valves then FlowdoValves is here. explore our wide range of valves for your commercial, residential and industrial needs. If you have quote regarding to valves then visit our website flowdovalves.com and contact with us.

#diaphragm valve#diaphragm valve manufacturer in ahmedabad#diaphragm valve manufacturer#diaphragm valve supplier#ball valve supplier#ball valve manufacturer#ball valve manufacturer in ahmedabad#globe valve manufacturer in ahmedabad#ball valve in ahmedabad#india

0 notes

Text

Enhancing Industrial Automation with Ball Valves

Ball valves play a pivotal role in enhancing industrial automation by providing unparalleled efficiency, precision, and reliability. These versatile valves offer swift and smooth flow control, minimizing downtime and optimizing production processes. Their robust construction ensures dependable performance even under harsh conditions, safeguarding critical systems. With precise control over fluid flow, they facilitate accurate positioning and regulate flow rates precisely, leading to improved overall system efficiency. Ball valves are a go-to choice for industries seeking to streamline operations and achieve peak automation performance.

Understanding Ball Valve Basics :

A ball valve is a mechanical device used to control the flow of fluids in a pipeline. Its fundamental design consists of a spherical ball with a hole in the center, which allows or restricts the passage of fluids. When the ball's bore aligns with the pipeline, flow occurs, and when it rotates 90 degrees, the bore blocks the flow. Ball valves are operated by a lever or actuator, offering quick and reliable on/off control. The simple yet efficient design makes them ideal for a wide range of applications in various industries.

Advantages of Ball Valves:

Ball valves boast numerous advantages, making them a popular choice in industrial settings. They provide excellent flow control capabilities, allowing for precise regulation of fluid movement. Their quick and quarter-turn operation ensures speedy response, reducing downtime and optimizing system efficiency. The tight seal around the ball minimizes leakage, enhancing reliability. Additionally, ball valves are resistant to contamination and perform well in high-pressure and high-temperature conditions. Their low maintenance requirements and long service life further contribute to their cost-effectiveness and widespread use across industries.

Types of Ball Valves: Floating, Trunnion, and Multi-Port

There are three main types of ball valves, each designed for specific applications. Floating ball valves are held in place by the flow pressure, suitable for low to medium-pressure systems. Trunnion ball valves have additional anchoring support, making them ideal for high-pressure applications. Multi-port ball valves, also known as diverter or L-port valves, have multiple ports on the ball, enabling complex flow direction control. Depending on the operational requirements and fluid characteristics, selecting the appropriate type of ball valve is essential for achieving optimal performance and reliability.

Selecting the Right Ball Valve for Your Application:

Choosing the right ball valve for a particular application involves considering various factors. Firstly, the valve's material should be compatible with the fluid to prevent corrosion or contamination. Secondly, the required pressure and temperature ratings should match the valve's capabilities. Different ball valve types offer unique features, so understanding the system's demands helps in making an informed decision. Furthermore, factors like size, end connections, and actuation methods should be carefully evaluated to ensure seamless integration and efficient performance in the intended system.

Maintenance and Troubleshooting Tips for Ball Valves :

Proper maintenance ensures the longevity and optimal functioning of ball valves. Regular inspection for leaks, corrosion, or debris buildup is crucial. Lubrication of moving parts and stem seals helps to reduce friction and maintain a tight seal. In case of valve performance issues, troubleshooting techniques like identifying worn-out seats, stems, or seals can aid in resolving problems. Routine testing and calibration of actuation systems contribute to reliable operation. Following manufacturer guidelines and adhering to best practices in maintenance can significantly extend the lifespan of ball valves and minimize downtime in critical industrial processes.

Conclusion :

In conclusion, the Aira Euromation ball valve proves to be a reliable and efficient solution for fluid flow control in industrial applications. Its well-engineered design, which includes a precision-machined spherical ball and robust construction, ensures smooth and precise operation. The valve's quarter-turn actuation and tight sealing capabilities enhance system efficiency and minimize leakage risks, contributing to increased productivity. With a wide range of options available, including floating, trunnion, and multi-port variants, our ball valve offers versatility to suit diverse operational requirements. Its durability, low maintenance demands, and compatibility with various fluids make it a cost-effective and trusted choice for critical processes.

0 notes

Text

The Role of Certifications in Selecting a Reliable Ball Valve Manufacturer

When it comes to industrial applications, ball valves are widely used for their reliable and efficient control of fluid and gas flow. They provide a quick shut-off mechanism and are highly durable, making them ideal for various industries. However, with numerous ball valve manufacturers in the market, it can be challenging to identify a reliable and trustworthy supplier. This is where certifications play a crucial role in helping customers make informed decisions.

Understanding Ball Valve Certifications

Certifications are official recognitions that indicate a manufacturer's compliance with industry standards and regulations. These certifications are obtained through a rigorous evaluation process conducted by authorized certification bodies. Two of the most significant certifications for ball valve manufacturers are the API (American Petroleum Institute) certification and the ISO (International Organization for Standardization) certification.

API Certification

API certification, specifically API 6D, is widely recognized in the oil and gas industry. It sets the standard for design, manufacturing, testing, and inspection of pipeline and pipeline-related valves, including ball valves. Manufacturers with API 6D certification demonstrate their commitment to producing valves that meet stringent industry requirements. This certification ensures that the valves are reliable, durable, and capable of withstanding high pressures and harsh operating conditions.

ISO Certification

ISO certification is a globally recognized standard for quality management systems. ISO 9001 certification, in particular, indicates that a manufacturer follows robust quality management practices throughout their operations. It ensures that the manufacturer has well-defined processes, continuous improvement measures, and effective quality control systems in place. ISO 9001 certification is not specific to ball valves but demonstrates a manufacturer's commitment to overall quality and customer satisfaction.

Ensuring Product Quality and Performance

Certifications provide assurance regarding the quality and performance of ball valves. Reliable manufacturers prioritize using high-quality materials and follow stringent manufacturing processes to deliver valves that meet or exceed industry standards.

Material Standards

Certified manufacturers carefully select materials for ball valve construction to ensure corrosion resistance, mechanical strength, and longevity. Certifications validate that the manufacturer uses materials that comply with industry standards, such as ASTM (American Society for Testing and Materials) or EN (European Norm) specifications.

Testing and Inspection Procedures

Certifications require manufacturers to conduct rigorous testing and inspection procedures to verify the performance and integrity of their ball valves. These tests may include pressure testing, leakage testing, material analysis, and dimensional inspections. By obtaining certifications, manufacturers demonstrate their commitment to delivering reliable and high-performing products.

Compliance with Industry Standards and Regulations

Compliance with industry standards and regulations is crucial to ensure the safety of personnel and the environment. Certifications act as evidence that a manufacturer follows established safety guidelines and adheres to environmental regulations.

Safety Standards

Certified manufacturers design and produce ball valves that meet recognized safety standards, such as API 6D, ASME (American Society of Mechanical Engineers), or ANSI (American National Standards Institute) standards. These standards ensure that the valves can withstand high pressures, temperature variations, and other demanding operating conditions without compromising safety.

Environmental Regulations

In industries where environmental protection is paramount, certifications such as ISO 14001 demonstrate a manufacturer's commitment to sustainable practices. These certifications validate that the manufacturer implements processes to minimize waste, reduce energy consumption, and limit their environmental impact.

Reliable Manufacturing Processes

Certifications not only guarantee product quality but also reflect a manufacturer's commitment to reliable manufacturing processes.

Quality Management Systems

Certifications like ISO 9001 confirm that a manufacturer follows strict quality management systems. These systems encompass all aspects of manufacturing, including design, procurement, production, and customer service. By adhering to these systems, manufacturers can consistently deliver high-quality products and provide excellent customer support.

Traceability and Documentation

Certified manufacturers maintain comprehensive documentation and traceability records throughout the manufacturing process. This ensures that every valve can be traced back to its raw materials, facilitating quality control, product recalls, and after-sales support. Certifications guarantee that the manufacturer maintains robust documentation practices.

Reputation and Trustworthiness

Certifications also contribute to a manufacturer's reputation and trustworthiness in the industry. They provide third-party validation of a manufacturer's commitment to quality, compliance, and customer satisfaction.

Customer Reviews and Testimonials

Certifications often go hand in hand with positive customer reviews and testimonials. By choosing a certified manufacturer, customers can rely on the experiences and feedback of other industry professionals who have used their products. This social proof enhances the manufacturer's credibility and builds trust.

Industry Recognition

Certifications can also lead to industry recognition and awards, further establishing a manufacturer's reputation. Manufacturers with certifications are often acknowledged as leaders in their field and are preferred by customers seeking reliable and high-quality ball valves.

Evaluating Certifications during the Selection Process

When selecting a ball valve manufacturer, it is essential to evaluate the certifications they hold. Look for certifications that align with your industry requirements, such as API 6D or ISO 9001. Consider the reputation of the certification bodies and the specific standards covered by the certifications. A manufacturer with multiple certifications indicates a comprehensive commitment to quality and compliance.

Remember that certifications should not be the sole criteria for selecting a manufacturer. It is equally important to assess their product range, technical expertise, customer support, and overall reliability.

Conclusion

Certifications play a vital role in the selection of a reliable ball valve manufacturer. They provide assurance regarding product quality, compliance with industry standards, reliable manufacturing processes, and a manufacturer's reputation. By choosing a certified manufacturer, you can mitigate risks, ensure the longevity of your operations, and have confidence in the performance of the ball valves you select.

0 notes

Text

UPVC ball valves are an excellent choice for industries and households looking for affordable, durable, and high-performance fluid control solutions. If you need a reliable UPVC ball valve at the best price, Petron Thermoplast offers a wide range of options tailored to your needs.

Visit Website - https://petronthermoplast.com/upvc-valves/

Contact No. - +91-8218684097

Request for Quotation - [email protected]

#upvcballvalve #upvcballvalvemanufacturer #upvcballvalvesupplier #upvcplasticballvalve

#UPVC Ball Valve#UPVC Valves#UPVC Plastic Ball Valve#UPVC Ball Valve Manufacturer#UPVC Ball Valve Supplier

0 notes

Text

Trunnion ball valve suppliers & manufacturers in Dubai, UAE | Instruments Fittings

Dubai, the thriving business hub of the UAE, is home to a wide variety of industries requiring awesome components to maintain their operations. Among the critical components for diverse commercial applications are trunnion ball valves. These valves are designed for durability, performance, and reliability, making them vital in industries that include oil and gas, petrochemicals, water treatment, and production. This blog explores the leading trunnion ball valve providers, sellers, and manufacturers in Dubai-UAE, losing mild on why these valves are a favored preference for crucial operations.

What Are Trunnion Ball Valves?

Trunnion ball valves are specialized forms of ball valves that characterize a pivot or trunnion to aid the ball inside the valve. Unlike preferred ball valves, in which the ball is free to move, trunnion ball valves have a mechanical anchoring device that enhances their operational performance. This design is specifically useful for managing high-stress systems as it guarantees higher sealing, reduced put-on, and longer provider lifestyles.

The versatility and robust design of trunnion ball valves lead them to be perfect for traumatic programs in industries wherein reliability is non-negotiable. Whether it’s coping with the drift of oil and fuel or coping with corrosive chemicals inside the petrochemical area, trunnion ball valves providers in Dubai offer products that supply top-notch performance.

Leading Trunnion Ball Valve Manufacturers in Dubai-UAE

Dubai’s commercial landscape is exceedingly competitive, and corporations rely upon quality products to preserve their aspect. Trusted trunnion ball valve producers inside the region make certain their valves meet the very best standards of durability and overall performance. Here are a few key motives why deciding on local manufacturers advantages businesses:

Customised Solutions: Manufacturers in Dubai apprehend the precise demands of the location’s industries and provide tailored trunnion ball valves to meet precise desires.

High-Quality Standards: With a dedication to excellence, Dubai-primarily based trunnion ball valve manufacturers ensure their products adhere to global satisfactory standards.

Faster Turnaround: Choosing neighborhood manufacturers reduces delivery instances, making sure that organizations face minimal downtime.

Technical Support: Manufacturers in Dubai offer sturdy technical assistance, providing steerage on valve choice and renovation.

At Instrument Fittings, our aim is to offer pinnacle-notch additives, together with trunnion ball valves, that set new benchmarks for quality and sustainability within the fittings and fasteners industry.

Reliable Trunnion Ball Valve Suppliers in Dubai-UAE

For industries working in excessive stress and high-temperature environments, the reliability of their additives is important. This is where the position of trunnion ball valve suppliers in Dubai turns fundamental. Suppliers act as the bridge between manufacturers and cease-users, making sure seamless get-right of entry to first-rate products.

Key attributes of top trunnion ball valve providers include:

Wide Range of Products: Suppliers in Dubai offer an intensive stock, catering to numerous business packages.

Expertise and Knowledge: They are ready with in-depth know-how approximately trunnion ball valves, assisting clients pick the right valve for his or her wishes.

After-Sales Support: Leading suppliers provide splendid after-income offerings, ensuring the valves characteristically over time.

Competitive Pricing: Dubai’s trunnion ball valve sellers make sure that remarkable valves are to be had at competitive charges, making them available to agencies of all sizes.

Why Choose Trunnion Ball Valves?

Trunnion ball valves are the favored desire for industries requiring sturdy and dependable drift control answers. Here’s why:

Enhanced Sealing: The trunnion design guarantees better sealing even under high strain, making these valves ideal for essential programs.

Durability: Made from corrosion-resistant materials, trunnion ball valves are constructed to face up to harsh environments.

Ease of Operation: These valves provide easy operation, lowering put-on and tear over time.

Low Maintenance: With fewer moving parts and enhanced sealing, trunnion ball valves require minimal preservation, ensuring cost and financial savings.

The trunnion ball valve manufacturers and providers in Dubai always meet the stringent needs of various industries, presenting products that ensure safety, efficiency, and reliability.

Instrument Fitting New Standards

Instrument Fittings is dedicated to revolutionising the fittings and furnishings area with the aid of providing products that combine high-quality with sustainability. As a relied-on provider of trunnion ball valves, we ensure our products meet global standards, catering to the various wishes of our customers.

Our understanding lies in delivering fittings that assure seamless connections, making sure your operations run smoothly. By setting new benchmarks within the industry, we intend to create lasting relationships with our customers while specializing in a sustainable future.

Choosing the Right Trunnion Ball Valve Dealer

Selecting the proper trunnion ball valve dealers is vital for making sure the achievement of your industrial operations. Here are some elements to bear in mind whilst choosing a supplier in Dubai:

Product Range: Ensure the supplier gives a huge range of trunnion ball valves to satisfy your unique desires.

Reputation: Opt for sellers with a strong popularity for delivering tremendous products and first-rate customer service.

Certifications: Check if the provider’s products are licensed to fulfill international standards.

Experience: Look for dealers with years of experience in offering trunnion ball valves to diverse industries.

The Future of Trunnion Ball Valves in Dubai-UAE

As industries in Dubai continue to expand, the call for dependable components like trunnion ball valves is about to grow. Manufacturers and suppliers in the place are constantly innovating to meet this call for, specializing in sustainable and efficient solutions.

Trunnion ball valve producers, providers, and sellers in Dubai are well-placed to cater to the evolving needs of industries, supplying products that make certain operational efficiency and safety.

Conclusion

Trunnion ball valves are a cornerstone of business operations, imparting reliable glide-managed solutions for a variety of packages. Dubai’s trunnion ball valve manufacturers, providers, and dealers have mounted themselves as dependent on companions for industries throughout the UAE, making sure of great performance in every product.

Whether you’re in oil and gas, petrochemicals, or water treatment, deciding on the proper provider or manufacturer is important for seamless operations. With Instrument Fittings, you may rest assured that you’re getting the quality-in-elegance additives designed to decorate your approaches even as focusing on sustainability and innovation.

trunnion ball valve manufacturers

#Trunnion ball valve suppliers#Trunnion ball valves dealers#Trunnion ball valves manufacturers#Instruments Fittings#trunnion ball valves

0 notes

Text

#automated ball valve#pneumatic actuated ball valve#automated ball valve manufacturers and suppliers in saint clair#automated ball valve suppliers in saint clair#missouri#usa

0 notes

Text

The Future of Valve Automation: How Technology Will Revolutionize Industrial Processes

In the industrial world, technological advancements are ongoing. The efficiency, accuracy, and safety of system functioning will all alter. Valve automation is an essential aspect of industrial systems. The future of valve technology is exciting and full of promises, from ball valves and gate valves to the latest automation solutions.

Modern industry valves and risk management solutions are our specialty at AG Tech Industries, where we leverage cutting-edge technologies. Let's examine the ways that industrial processes are being transformed by developments in valve automation.

The Role of Valves in Modern Industry

Controlling liquids, gases, and slurries in a variety of applications, valves are a vital aspect of industrial systems. These elements serve as the foundation for efficient operations in sectors including manufacturing, water treatment, and oil and gas, whether they are ball valves for precise flow control or gate valves for fluid isolation.

These days, automation is elevating outdated valves to a new level, making them more advanced and efficient industrial instruments.

The Evolution of Valve Automation through Technology

1. Responsive Valves: Industry valves' capacity to transmit data in real time is another feature of IoT technology that contributes to the precise control and sensitivity of valves. Temperature, pressure, and flow may all be tracked with sensors built into smart valves, enabling operators to make well-informed decisions that help prevent system failures.

2. Automated to Provide Safety

Automated gate and ball valves are designed to react quickly to system changes, which minimizes leaks and guarantees safety during crucial operations. By enabling operators to operate valves remotely, remote monitoring capabilities improve safety in dangerous situations.

3. AI-Powered Predictive Maintenance

The implementation of maintenance techniques is evolving due to artificial intelligence. By incorporating AI to analyze data from automated valves, potential issues can be identified before they become serious, limiting downtime and lowering maintenance expenses.

4. Sustainability and Energy Efficiency

Automated industry valves minimize waste, energy use, and fluid flow. This lowers operating expenses and encourages industrial activities to be more sustainable.

The Evolution of Gate and Ball Valves

Ball Valves: Actuators are being added to ball valves, which are known for their accuracy and robustness, to enable automated operation. They are therefore perfect for applications that need precise and fast flow control.

Gate Valves: Originally employed for isolation, gate valves are increasingly being automated to increase system adaptability and dependability.

These valves can function in high-pressure settings and are more resistant to adverse conditions thanks to developments in materials and technology.

Why Choose AG Tech Industries for Your Valves?

At AG Tech Industries, we combine human ingenuity with technology to provide the most innovative valves, ball valves, gate valves, and similar products. Your industrial systems can function under extreme conditions because of their commitment to quality and performance.

Discover how our automation solutions may transform your business by looking through AG Tech Industries' extensive selection of industry valves.

The Future Is Here

Valve automation has a more promising future because of technical advancements that will lead to exceptional efficiency and dependability. Investing in automated ball valves, gate valves, and other industry valves is your first step toward improved performance with lower risk, whether you're replacing your current system or thinking about a new industrial installation.

Stay ahead of the curve with AG Tech Industries, where quality and innovation coexist.

1 note

·

View note

Text

Shop Premium Valve Lockout Devices for Ultimate Safety in Australia

Protect your workforce and machinery with high-quality valve lockout devices available in Australia. These essential safety tools prevent accidental or unauthorized operation during maintenance, ensuring a safe working environment.

Why Choose Our Valve Lockout Devices?

Durability: Constructed from robust materials to endure harsh industrial conditions.

Versatility: Suitable for various valve types, including gate valves, ball valves, and butterfly valves.

Ease of Use: Simple installation and operation for efficient safety management.

Regulatory Compliance: Adheres to Australian safety standards and regulations.

Key Benefits:

Our premium valve lockout devices can fit various valve sizes. These are made from high visible colors for easy identification in the working area. Check out more benefits:

Enhanced Safety: Mitigates the risk of workplace accidents.

Reliable Protection: Secures machinery during maintenance activities.

Long-Lasting: Built to withstand wear and tear in demanding environments.

Wide Selection: Available in different sizes and configurations to meet your specific needs.

Invest in premium valve lockout devices to ensure the safety of your team and compliance with Australian regulations. Shop now and safeguard your workplace with the best safety solutions available in Australia. Check the product range - https://www.safetylock.net/lockout-tagout-devices/valve-lockouts/

#Valve Lockout Devices#Lockout Tagout#Valve LOTO Devices#Valve Lockouts#Gate Valve Lockout#Ball Valve Lockouts#Lockout Tagout Devices#Lockout Tagout Manufacturer#LOTO Supplier#E-Square Alliance

0 notes

Text

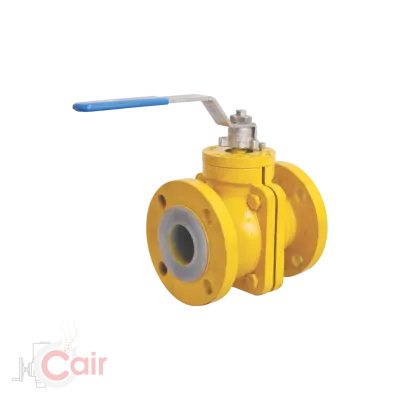

A Ball Valve is a quick-operation, on/off valve that uses a pivoting ball to control the flow of liquid or gas. It has a bore through which media passes, and its position determines whether the valve is open or closed. At Cair Euro we are the premium Ball Valve Manufacturer in India.

#ball valve#plug valve#cair euro#valve exporter#valve manufacturer#ball valve manufacturer#ball valve supplier#valve supplier

0 notes

Text

Understanding Ball Valves: Types, Uses, and Advantages

A reliable supplier is crucial when purchasing high-quality ball valves to ensure optimal performance and longevity. Allied Valves India, a leading ball valve supplier in Ahmedabad, offers a wide range of ball valves designed to meet industrial standards.

0 notes

Text

Find the best globe valve manufacturer in Ahmedabad

Globe valves can be used in different sectors such as oil and gas, pharmaceuticals, water treatment, and power industries amongst others. This makes them very useful in managing the flow rates of different fluids and also being able to work under very harsh temperatures. Ahmedabad is the city very popular for industrial growth in the state. This has put the city in a strategic position advantageous for large scale production due to its infrastructure and availability of human resource. Flowdo Valve is recognized as one of the leading globe valve manufacturer in Ahmedabad.

Choosing the right globe valve manufacturer is important, especially if you want an industrial process to run as smoothly as possible. The following are some tips that can help you in choosing the right globe valve manufacturer in Ahmedabad.

Make sure that the materials used by the manufacturer are of the finest quality to last longer and serve the purpose well.

Ensure conformity to industry norms and accreditations.

Evaluate the technological development of their production lines.

Search for a manufacturer who has the capacity to design valves that would suit a certain need.

A good customer service team must be willing and able to address queries from customers within the shortest time possible.

Select manufacturers who have the best after-sales maintenance service.

Ask for material certifications to guarantee high quality of the applied materials.

Check compliance to standards internationally such as ISO and API.

Ask for product samples so that you can evaluate the quality of the workmanship, and the ability of the product in use.

Flowdo Valve has an impeccable record in valve manufacturing. The company runs highly efficient plants using advanced equipment and technology. Such a sophisticated structure makes it possible for Flowdo Valve to manufacture different types of high-standard valves. It’s not simply the choice of the material that is used, but every aspect of its creation is monitored to ensure perfection. Flowdo Valve is a top globe valve provider that provides a vast array of products for various applications in industries. Their globe valves featuring excellent throttling and steady service life are applied in oil and gaseous, pharmaceutical, and water industries. Every single valve is aimed at delivering high quality and durability which has made Flowdo Valve to be highly demanded in the market.

Flowdo Valve keeps on maintaining the tradition of being the premier globe valve manufacturer of Ahmedabad by committed passion and unprecedented innovation fully satisfying its customers.

It is easy to communicate with Flowdo Valve and all their operations are customer-oriented.

Visit Flowdo Valve website for more detail about the company and their wide range of products at https://www.flowdovalves.com/globe-valve-manufacturer-in-ahmedabad/

The site also contains a contact form where you need to provide detailed information about your needs or concerns.

#globe valve manufacturer in ahmedabad#ball valve manufacturer in ahmedabad#diaphragm valve#diaphragm valve manufacturer#diaphragm valve supplier#diaphragm valve manufacturer in ahmedabad#ball valve in ahmedabad#ball valve manufacturer#ball valve supplier

0 notes

Text

0 notes

Text

EVERYTHING YOU NEED TO KNOW ABOUT VALVE TYPES: A COMPREHENSIVE GUIDE

Valves play a pivotal role in controlling the flow of liquids, gases, and slurries within various industrial systems, including oil and gas, petrochemicals, water treatment, and power generation. Understanding the different types of valves and their respective applications is vital for selecting the most appropriate solution for specific operational requirements. This content delves into the various valve types, their functionalities, and how European Valve Manufacturers, Valve Suppliers, and Valve Stockists contribute to ensuring the supply of reliable, high-performance valves across industries.

Ball Valves

Ball valves are quarter-turn valves that use a spherical ball with a hole through the center to control the flow of materials. When the ball’s hole aligns with the pipe, the fluid flows freely, while turning the valve 90 degrees moves the ball, shutting off the flow. Ball Valves Suppliers typically offer these valves in various configurations, including full-port, reduced-port, and V-port designs, making them ideal for on/off and throttling applications. Due to their tight shut-off capability and resistance to corrosion, ball valves are widely used in applications with high-pressure or high-temperature fluids, such as natural gas transmission and chemical processes. They are favored for their durability, low-maintenance design, and ease of operation.

Gate Valves

Gate valves are primarily used for isolating or shutting off fluid flow in a pipeline. The valve operates by raising or lowering a wedge-shaped gate to allow or block flow. Typically, Gate Valves Suppliers recommend these valves for applications where the valve is either fully open or fully closed, and throttling control is unnecessary. They are well-suited for high-flow, low-pressure applications, such as in water distribution networks and HVAC systems. Their primary advantage lies in their ability to offer minimal flow resistance when fully open, though they are not ideal for applications requiring precise flow regulation. Moreover, gate valves can experience wear over time due to their design, especially when used for throttling or in systems that require frequent operation.

Globe Valves

Globe valves are designed for flow regulation, providing excellent throttling capabilities due to their precise internal components. The valve’s body is shaped like a globe, and it utilizes a plug or disc to control the flow of fluids. Globe Valves Suppliers typically recommend these valves for applications where flow control is critical, such as in steam, gas, and water distribution systems. Their key advantage is their ability to handle both high pressures and temperatures while maintaining accurate flow regulation. Globe valves are often preferred in scenarios where system adjustments need to be frequent and precise, such as in heating, ventilation, and air conditioning (HVAC) systems, power plants, and industrial cooling systems.

Control Valves

Control valves are an integral part of automated process systems, providing precise control over parameters such as pressure, temperature, and flow rate. These valves work in conjunction with control systems, where they adjust their position to maintain a desired setpoint within a closed-loop system. Control Valves Suppliers often offer valves with actuators and positioners to ensure optimal performance, even in complex systems. These valves are used extensively in industries such as chemical processing, oil refineries, and power generation, where real-time control of fluid dynamics is essential to maintain system stability and efficiency. The accuracy and responsiveness of control valves make them indispensable for applications that require continuous modulation.

Water Valves

Water valves are engineered specifically for applications within potable water systems, wastewater treatment, and industrial water handling. These valves are designed to withstand corrosion and wear from harsh water environments. As a Water Valve Supplier, selecting valves based on factors such as pressure, temperature, and the type of water (e.g., clean or dirty water) is essential for ensuring optimal performance. Ball, gate, and globe valves are commonly used in water systems, but more specialized valves like check valves and pressure-reducing valves are often employed to ensure proper water flow and pressure management. Water valves are fundamental in preventing contamination, controlling pressure fluctuations, and maintaining consistent water flow in municipal and industrial systems.

Conclusion

Selecting the right valve for a specific application requires a deep understanding of its operating principles, material compatibility, and functional performance. European Valve Manufacturers, along with Valve Suppliers and Valve Stockists, offer a vast array of high-quality valve solutions tailored to meet the rigorous demands of diverse industries. we are specialized for stock valves, whether you’re dealing with high-pressure fluid systems, water treatment, or intricate process controls, working with reputable valve suppliers ensures access to the latest valve technologies and reliable products. Understanding the distinct functions and advantages of valve types such as ball valves, gate valves, globe valves, control valves, and water valves allows you to make informed decisions, ensuring long-term efficiency and safety in industrial operations.

0 notes

Text

UPVC Ball Valve – Best Quality & Affordable Prices

UPVC ball valves are an excellent choice for industries and households looking for affordable, durable, and high-performance fluid control solutions. If you need a reliable UPVC ball valve at the best price, Petron Thermoplast offers a wide range of options tailored to your needs.

Visit Website - https://petronthermoplast.com/upvc-valves/

Contact No. - +91-8218684097

Request for Quotation - [email protected]

#upvcballvalve #upvcballvalvemanufacturer #upvcballvalvesupplier #upvcplasticballvalve

#UPVC Ball Valve#UPVC Valves#UPVC Plastic Ball Valve#UPVC Ball Valve Manufacturer#UPVC Ball Valve Supplier

0 notes

Text

Trunnion-mounted Mounted Ball manufacturer in Dubai | Instruments Fittings

Dubai, referred to as a hub for business excellence, is home to many global-class manufacturers, suppliers, and sellers of advanced commercial fittings and furniture. Among those, Trunnion Mounted Ball Valves maintain an important vicinity because of their performance, reliability, and alertness versatility throughout numerous industries. If you're looking for the pleasant Trunnion ball valve manufacturers, suppliers, and dealers in Dubai, you’re within the proper region.

What Are Trunnion Mounted Ball Valves?

Trunnion ball valves manufacturers are a specialized kind of ball valve where the ball is supported with the aid of bearings or trunnions at both ends. This layout guarantees the valve can take care of excessive pressures and go with the flow quotes effectively, even minimizing wear and tear on the valve components.

These valves are perfect for industries along with oil and gas, petrochemicals, strength generation, and water treatment, imparting unmatched durability, unique flow control, and value-efficiency.

Key Features of Trunnion Mounted Ball Valves

High Pressure Tolerance: Designed to deal with extreme pressures without compromising performance.

Reduced Operating Torque: The trunnion aid reduces the torque required to perform the valve, making them green and user-friendly.

Enhanced Safety: The design ensures no leakage, even underneath excessive-strain applications.

Long Lifespan: Built for durability, trunnion-mounted ball valves provide long provider life with minimum protection.

Wide Range of Applications: Suitable for various industries, such as oil and fuel, chemical processing, and power generation.

Why Dubai is a Hub for Trunnion Ball Valves

Dubai’s strategic location as an international exchange middle makes it a hub for Trunnion ball valves suppliers, providers, and dealers. The vicinity's commercial attention guarantees the availability of incredible valves that meet global requirements.

Leading producers in Dubai prioritize innovation, quality, and sustainability. Companies like Instrument Fittings have carved a gap for themselves with the aid of consistently handing over dependable solutions to diverse industries.

A Trusted Name in Trunnion Mounted Ball Valves

At Instrument Fittings, we take pride in being one of the top Trunnion ball valve producers in Dubai. Our dedication to the best and sustainability drives us to supply products that no longer most effectively meet but exceed purchaser expectations.

Why Choose Instrument Fittings?

Superior Quality: Our valves are crafted using excessive-grade materials and undergo stringent high-quality exams.

Innovative Designs: We usually innovate to make sure our products are green, long-lasting, and dependable.

Sustainability: we are dedicated to green production practices, placing benchmarks within the fittings and fasteners zone.

Customer-Centric Approach: We prioritize our clients, making sure tailor-made answers for diverse business needs.

Our popularity as one of the most trusted Trunnion ball valve providers and dealers is constructed on a basis of excellence, innovation, and sustainability.

Applications of Trunnion Mounted Ball Valves

Oil and Gas: Used drastically in upstream, midstream, and downstream operations for secure and green go with the flow control.

Petrochemical Plants: Essential for handling corrosive and high-temperature fluids.

Water Treatment: Ensures green waste management in desalination and wastewater control structures.

Power Generation: utilized in both traditional and renewable energy structures for his or her reliability.

Chemical Processing: Ideal for applications requiring precision and sturdiness.

Advantages of Choosing Trunnion Ball Valves from Dubai

Global Standards: Products meet API, ASME, and ISO requirements, ensuring reliability and performance.

Competitive Pricing: Dubai gives splendid industrial valves at aggressive prices.

Easy Accessibility: The city’s brilliant connectivity ensures quick delivery across the globe.

Customization: Manufacturers provide tailored answers to satisfy particular commercial requirements.

When you partner with main Trunnion ball valve dealers in Dubai, you’re assured of receiving products that beautify your operations' efficiency and protection.

Finding the Right Trunnion Ball Valve Suppliers

Selecting the proper Trunnion ball valve suppliers is critical for making sure pleasantness and reliability. Consider the subsequent factors:

Reputation: Look for suppliers with a strong track record of delivering superb products.

Certifications: Ensure the dealer adheres to worldwide standards.

Customer Support: A reliable provider gives splendid pre- and submit-sale support.

Customization Options: Check if the supplier can offer solutions tailored to your desires.

Instrument Fittings ticks a lot of these containers, making us a trusted companion for industries worldwide.

Why Sustainability Matters

We consider this in constructing a sustainable destiny. As one of the main Trunnion ball valves dealers, we undertake eco-friendly production practices to reduce our carbon footprint.

By selecting our products, you’re not just making sure superior overall performance but also contributing to a greener planet.

Conclusion

Dubai stands tall as a global chief in business excellence, and its Trunnion ball valve producers, providers, and dealers have earned recognition for reliability and first-class reliability. Instrument Fittings is proud to be part of this legacy, supplying unequalled products and services to industries internationally.

Whether you’re searching out remarkable fittings for the oil and fuel region or particular answers for chemical processing, our Trunnion ball valves deliver overall performance and durability you can count on.

We are right here to make sure seamless connections and sustainable solutions for your industrial wishes. Connect with us today to explore our range of trunnion set up ball valves and revel in the difference in high-quality and provider!

0 notes