#diaphragm valve

Explore tagged Tumblr posts

Text

Tank bottom valves are specialized valves installed at the base of tanks to facilitate the discharge of liquids without leaving any residue. Their design allows for efficient drainage, minimizing product loss and cleaning downtime.

0 notes

Text

Diaphragm Operated Control Valve: How They Work and Their Advantages

Diaphragm operated control valves are an essential component in the control of fluid flow in various industrial applications. These valves are designed to modulate the flow of gases, liquids, or steam by varying the size of the flow passage. What makes diaphragm operated control valves stand out is their ability to provide precise and reliable control, making them ideal for industries where accuracy and safety are paramount.

In this article, we will explore the working principles of diaphragm operated control valves, their advantages, and why Freture Techno Pvt. Ltd. stands out as a leading manufacturer in this domain.

How Diaphragm Operated Control Valves Work

The operation of a diaphragm operated control valve is based on the movement of a diaphragm, which is a flexible membrane that acts as a barrier between the valve body and the actuator. The diaphragm is responsible for translating the force from the actuator into mechanical movement that regulates the flow of media through the valve.

Here's a step-by-step explanation of the working principle:

Actuator Input: The valve actuator receives a signal, typically pneumatic or electrical, which dictates the desired position of the valve.

Pressure Applied to the Diaphragm: The actuator either increases or decreases the pressure on the diaphragm. This change in pressure causes the diaphragm to flex or move accordingly.

Diaphragm Movement: The movement of the diaphragm is transferred to the valve stem, which is connected to the valve plug or disc. Depending on the signal, the valve plug either moves towards or away from the valve seat, thereby regulating the flow of fluid.

Flow Control: As the diaphragm moves, the valve opens or closes partially or fully, allowing for precise modulation of flow, pressure, or temperature.

Diaphragm operated control valves are often used in automated systems, as they respond accurately to control signals, providing fine-tuned control over fluid systems.

Advantages of Diaphragm Operated Control Valves

Diaphragm operated control valves offer numerous advantages that make them highly sought after in various industries, including pharmaceuticals, water treatment, chemical processing, and oil & gas. Here are some of the key benefits:

Precise Flow Control: One of the primary advantages of diaphragm operated control valves is their ability to provide extremely accurate control of flow rates. This precision is essential in processes where even slight variations can lead to operational inefficiencies or safety concerns.

Leak-Free Operation: The diaphragm creates a sealed barrier between the actuator and the media, minimizing the risk of leaks. This is especially critical in industries where handling hazardous or corrosive fluids requires high levels of containment.

Suitable for Corrosive and Viscous Fluids: Diaphragm operated control valves are well-suited for handling abrasive, corrosive, or viscous fluids. The diaphragm material can be chosen based on the nature of the fluid, ensuring compatibility and longevity of the valve.

Low Maintenance: The simple yet robust design of diaphragm valves results in low maintenance requirements. The absence of intricate moving parts reduces wear and tear, thus extending the operational lifespan of the valve.

Isolation of Actuator: Since the diaphragm forms a seal between the actuator and the fluid, the actuator remains unaffected by the media. This ensures the actuator operates in a clean environment, leading to fewer failures and higher reliability.

Versatility in Applications: Diaphragm operated control valves are versatile and can be used across a wide range of applications, from low to high pressures, and in extreme temperatures. They can handle anything from liquids and gases to slurries and steam.

Energy Efficiency: Due to their lightweight design and efficient operation, diaphragm operated control valves consume less energy compared to some other valve types. This can contribute to energy savings, especially in large industrial systems.

Freture Techno Pvt. Ltd.: Leading Manufacturer of Diaphragm Operated Control Valves

Freture Techno Pvt. Ltd., based in Mumbai, India, has established itself as a leading manufacturer of diaphragm operated control valves. With a commitment to innovation and quality, Freture Techno Pvt. Ltd. designs and manufactures high-performance valves that meet the stringent requirements of various industries, including pharmaceuticals, petrochemicals, and water treatment.

Key features that set Freture Techno's diaphragm operated control valves apart include:

Customizability: Freture Techno offers a range of diaphragm materials and valve configurations to suit specific industrial applications, ensuring the best performance under varying conditions.

Durability: The valves are built with high-quality materials, ensuring durability and longevity even in harsh environments.

Compliance with Industry Standards: Freture Techno's valves are manufactured to comply with international standards, ensuring safety, reliability, and performance.

Advanced Manufacturing Processes: With state-of-the-art manufacturing facilities and skilled engineers, Freture Techno ensures that each valve is meticulously designed, tested, and inspected to meet industry benchmarks.

Choosing Freture Techno Pvt. Ltd. as your diaphragm operated control valve supplier means choosing high-quality, reliable, and efficient solutions for your industrial processes.

Conclusion

Diaphragm operated control valves offer precision, safety, and versatility, making them indispensable in industries where the accurate control of fluids is critical. With numerous advantages, including leak-free operation, low maintenance, and adaptability to corrosive fluids, these valves are essential for efficient and safe fluid handling.

Freture Techno Pvt. Ltd. has positioned itself as a trusted manufacturer of diaphragm operated control valves in Mumbai, India. Their commitment to quality and innovation ensures that their valves perform reliably in a range of demanding industrial environments.

For industries looking to optimize fluid control systems, Freture Techno's diaphragm operated control valves present an ideal solution.

0 notes

Text

The DD10-GTFM-E is a high-performance elastomeric diaphragm designed for use in critical industrial applications where reliability, precision, and durability are paramount. Engineered for compatibility with various pump systems, this diaphragm offers an exceptional balance of flexibility and strength, ensuring long-lasting operation in demanding environments. Whether in chemical processing, water treatment, or food manufacturing, this diaphragm delivers reliability and longevity.

0 notes

Text

Diaphragm Valve vs. Ball Valve: Which Is Right for Your System?

In the field of fluid control systems, selecting the appropriate valve is critical for optimal performance. Two commonly used valves in industrial applications are the diaphragm valve and the ball valve. In this blog, we’ll delve into the characteristics of both, emphasizing the “diaphragm valve” and “ball valve,” to help you make an informed decision for your specific system needs.

Diaphragm Valve

1. Diaphragm Valve Overview:

Diaphragm valves are known for their versatility and reliable performance. The “diaphragm valve” often resonates with industries requiring precise control over fluid flow. These valves utilize a flexible diaphragm to regulate the flow, making them ideal for applications where contamination prevention is paramount. Pharmaceutical and food industries often favor diaphragm valves due to their sterile design.

Benefits of Diaphragm Valves:

Excellent Containment: Diaphragm valves excel in preventing fluid contamination, ensuring the purity of the transported substances.

Reliable Flow Control: The diaphragm design allows for accurate and consistent flow control, making them suitable for applications requiring precision.

Biocompatibility: In sectors such as biotechnology and pharmaceuticals, the biocompatible materials used in diaphragm valves make them a preferred choice.

Ball Valve

2. Ball Valve Insights:

On the other hand, the “ball valve” is often associated with efficiency and durability. Ball valves are characterized by a spherical disc that controls the flow. They find widespread use in industries requiring a simple yet effective solution for fluid control.

Advantages of Ball Valves:

Quick Operation: The quarter-turn operation of ball valves allows for rapid opening and closing, making them suitable for applications where speed is crucial.

Durability: Ball valves are often praised for their robust construction, providing longevity and reliability in demanding environments.

Low Maintenance: With fewer components, ball valves are easy to maintain, reducing downtime and operational costs.

3. Selecting the Right Valve for Your System:

Consider the application: Evaluate the specific requirements of your system. If precision and contamination control are critical, a diaphragm valve might be the better choice.

Pressure and Temperature Ratings: Both diaphragm and ball valves have different pressure and temperature handling capacities. Ensure the selected valve aligns with your system’s operating conditions.

Maintenance Considerations: Assess the ease of maintenance based on your system’s needs. If simplicity and low maintenance are crucial, a ball valve may be more suitable.

Conclusion:

In the diaphragm valve vs. ball valve debate, the right choice depends on your unique system requirements. By understanding the distinct advantages of each, you can make an informed decision that aligns with the needs of your fluid control system. Whether you prioritize precision, contamination prevention, or efficiency, both diaphragm and ball valves offer reliable solutions for diverse industrial applications.

0 notes

Text

Most reputed Diaphragm Valve Manufacturer in Ahmedabad

Flowdo Valve is well known as one of the most reputable diaphragm valve manufacturer in Ahmedabad. Diaphragm valves are primarily used to regulate the flow of fluids in applications like chemical processing, water treatment, and pharmaceutical industries. This makes them vital when it comes to system integrity and safety since their design enhances efficient and leak-free flow.

Flowdo Valve has been one of the leading diaphragm valve manufacturers in Ahmedabad that maintains the highest standards of quality in their products and services.

Looking for a best diaphragm valve manufacturer in Ahmedabad? Flowdo Valve - your best choice in this case. Do not let this chance slip and improve your operations with the best diaphragm valve manufacturer in Ahmedabad. Check out our catalogue at our website, or get in touch with us for further details or to make an order.

#diaphragm valve#diaphragm valve manufacturer#diaphragm valve manufacturer in ahmedabad#diaphragm valve supplier

0 notes

Text

0 notes

Text

Practical Guide to Diaphragm Valves in Industrial Settings

Discover the Practical Guide to Diaphragm Valves in Industrial Settings. Learn how these valves simplify fluid control in various industries, from their design to applications. Gain insights on enhancing efficiency and reliability, making informed decisions for your operational needs.

Understanding Diaphragm Valve Mechanism:

At the heart of efficient fluid control lies the diaphragm valve mechanism. This ingenious design employs a flexible diaphragm, often made of elastomers or other resilient materials, to regulate fluid flow. When the valve is closed, the diaphragm seals against the valve body, completely isolating the fluid from the valve's internal components. Upon opening, the diaphragm flexes, allowing fluid to pass through. This simple yet effective mechanism offers advantages like precise throttling, excellent sealing, and minimal dead space—qualities crucial for industries requiring contamination-free processes.

Versatile Applications Across Industries:

Diaphragm valves find their niche in a wide spectrum of industries. From pharmaceuticals and food processing to chemical manufacturing and water treatment, their versatility shines. Their compatibility with corrosive fluids, hygienic design for sanitary processes, and ability to handle viscous media make them indispensable tools. Their adaptability extends to applications in control systems, sampling, draining, and even as shut-off valves. This broad applicability makes diaphragm valves invaluable components in diverse industrial settings.

Benefits of Diaphragm Valves for Fluid Control:

The benefits of diaphragm valves stem from their unique design. Their ability to provide complete isolation between the fluid and the valve's internal components eliminates the risk of contamination or cross-contamination. This property is particularly advantageous in industries with stringent purity requirements. Additionally, the diaphragm's gentle and linear motion during operation minimizes turbulence, reducing the chances of damaging delicate fluids. The absence of crevices where debris can accumulate ensures easy cleaning, contributing to their suitability for hygienic applications.

Choosing the Right Diaphragm Valve for Your Needs:

Selecting the appropriate diaphragm valve hinges on several factors. Fluid characteristics, pressure, temperature, and the intended application all play pivotal roles. Elastomer type and compatibility with the fluid, as well as the valve's material construction, must align with the operational demands. For high-purity industries, choosing valves with minimal dead space and smooth, crevice-free surfaces is essential. Double-diaphragm designs offer increased safety by providing a backup diaphragm in case of failure. By understanding these considerations, industries can make informed decisions to ensure optimal fluid control.

Maintenance and Optimization Strategies for Longevity:

To maximize the lifespan and performance of diaphragm valves, effective maintenance and optimization strategies are crucial. Regular inspection of the diaphragm for wear, cracking, or degradation is essential to prevent leaks and ensure reliable operation. Employing proper cleaning protocols and ensuring the valve is in the right service conditions is imperative. Diaphragm replacement at recommended intervals prevents unexpected failures. By implementing preventive maintenance and monitoring techniques, industries can ensure the longevity and consistent functionality of their diaphragm valves, ultimately contributing to seamless fluid control and operational efficiency.

In conclusion, a comprehensive understanding of diaphragm valve mechanisms, their versatile applications, and the associated benefits can empower industries to make informed choices. By selecting the right diaphragm valves for specific needs and implementing effective maintenance practices, industries can harness these valves' capabilities to achieve efficient fluid control, enhance operational reliability, and facilitate their specific processes across diverse industrial settings. thus, Aira Euromation's diaphragm valves offer precise fluid control with their innovative design. Built for versatility and reliability, they excel across industries, ensuring efficient processes while maintaining purity and minimizing contamination risks.

0 notes

Text

Six Reasons to Choose Blagdon AODD Pumps

An Air-Operated Double-Diaphragm pump (AODD) is a positive displacement (PD) pump with two pumping chambers that use compressed air to move fluids. AODD pumps have been used for the last 60 years now. Over time, these pumps have undergone several changes and upgrades to get better at their job – displacing fluids of various viscosities with accuracy and precision.

#Blagdon AODD pumps#Double Diaphragm pump#Diaphragm pump#AODD pumps#positive displacement#Pump and Valves#IDEX India

0 notes

Text

A Comprehensive Guide to Electric Operated Diaphragm Pumps

This comprehensive guide dives into the world of electric operated diaphragm pumps, offering valuable insights and detailed information for industrial professionals and enthusiasts. We start with an overview of diaphragm pumps, explaining their fundamental design and operational principles. The guide then explores the advantages of diaphragm pump electric driven systems, highlighting their efficiency, reliability, and low maintenance requirements.

Visit: https://www.idexcognito.com/

0 notes

Text

A diaphragm valve is a type of valve that uses a flexible diaphragm to regulate fluid flow. Hygienic diaphragm valves are specifically engineered to meet the sanitary requirements of pharmaceuticals, food, and biotechnology industries.

1 note

·

View note

Text

Diaphragm Direct started 15 years ago to Meet FDA, USP, 3A quality standards for Sanitary Process Components. Diaphragm Direct® replacement diaphragms and seals undergo both performance and challenge testing to assure the highest level of reliability.

0 notes

Text

In the field of industrial fluid control, diaphragm valves play a pivotal role in regulating the flow of liquids and gases. These versatile valves are widely employed in various industries due to their unique design and exceptional functionality. In this comprehensive guide, we will delve into the basics of diaphragm valves, shedding light on their construction, working principles, applications, and the importance of proper maintenance.

0 notes

Text

Efficient Filtration with Y-Type Strainers in India

Flowdovalves is leading valve manufacturing company in India. their y-type strainers play best role of that efficiency and longevity in various industrial valve in India. that y0type strainers remove unwanted debris and impurity from pipelines and make sure that smooth and without stopping flow of fluids. Flowdovalves build for mesh filter in y shaped chamber that without significantly impacting pressure and flowrate. that why they y-type strainer use in water treatment plants and chemical industries or in HVAC system. FlowdoValves providing high quality y type strainer to complete the industrial needs and make sure that reliable and durable also.

FlowdoValves strainer are manufactured with accuracy and using high grade quality material that providing resistance to rust and washed away. If you choosing y-type strainers from FlowdoValves that can benefit from reducing maintenance of cost and improving operational efficiency. if you looking for new y-type strainer installation then Flowdovalves highest quality and long-lasting solution for your all industrial needs.

If you replace your y-type strainer then visit our website for high quality and reliable valves then FlowdoValves is here. explore our wide range of valves for your commercial, residential and industrial needs. If you have quote regarding to valves then visit our website flowdovalves.com and contact with us.

#diaphragm valve#diaphragm valve manufacturer in ahmedabad#diaphragm valve manufacturer#diaphragm valve supplier#ball valve supplier#ball valve manufacturer#ball valve manufacturer in ahmedabad#globe valve manufacturer in ahmedabad#ball valve in ahmedabad#india

0 notes

Text

Global Top 5 Companies Accounted for 83% of total Atomic Layer Deposition (ALD) Diaphragm Valves market

Atomic Layer Deposition (ALD) is a method of applying thin films to various substrates with atomic scale precision. As chip node dimensions are continuously shrinking, traditional deposition techniques have reached their limits. Depositing ultra-thin layer at the nanoscale requires Atomic Layer Deposition (ALD) technology, which allows materials to be deposited one atomic layer at a time. Atomic Layer Deposition (ALD) Diaphragm Valves are used to deliver precise doses of gases during the deposition process.

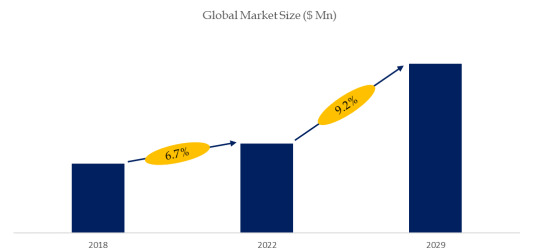

According to the new market research report “Global Atomic Layer Deposition (ALD) Diaphragm Valves Market Report 2023-2029”, published by QYResearch, the global Atomic Layer Deposition (ALD) Diaphragm Valves market size is projected to reach USD 0.12 billion by 2029, at a CAGR of 9.2% during the forecast period.

Figure. Global Atomic Layer Deposition (ALD) Diaphragm Valves Market Size (US$ Million), 2018-2029

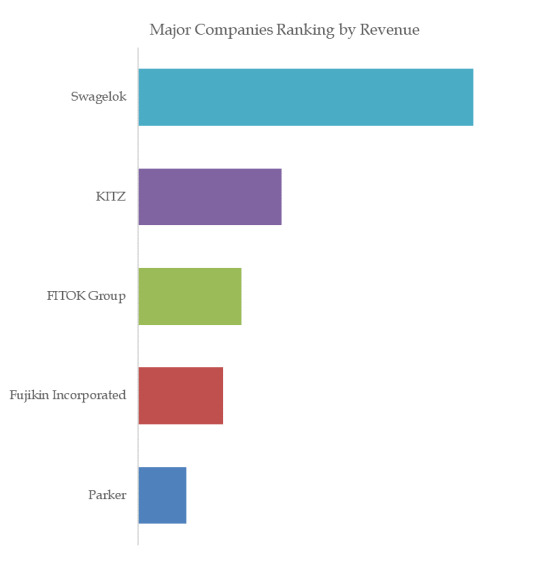

Figure. Global Atomic Layer Deposition (ALD) Diaphragm Valves Top 5 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Atomic Layer Deposition (ALD) Diaphragm Valves include Swagelok, KITZ, FITOK Group, Fujikin Incorporated, Parker, etc. In 2022, the global top four players had a share approximately 83.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

What is a Dosing Pump and How Does it Work?

In industries and other applications, a dosing pump is used as a specialised type of positive displacement pump to inject precise quantities of chemicals or substances into water flow or other mediums like gas and steam with accuracy and consistency for controlled chemical delivery purposes.

#Dosing Pump#Proportional Dosing Pump#Diaphragm metering pump#Hydraulic diaphragm metering pump#Metering pump#Pulsafeeder#idex india#Pump and Valves

0 notes