#Valve Lockouts

Explore tagged Tumblr posts

Text

Shop Premium Valve Lockout Devices for Ultimate Safety in Australia

Protect your workforce and machinery with high-quality valve lockout devices available in Australia. These essential safety tools prevent accidental or unauthorized operation during maintenance, ensuring a safe working environment.

Why Choose Our Valve Lockout Devices?

Durability: Constructed from robust materials to endure harsh industrial conditions.

Versatility: Suitable for various valve types, including gate valves, ball valves, and butterfly valves.

Ease of Use: Simple installation and operation for efficient safety management.

Regulatory Compliance: Adheres to Australian safety standards and regulations.

Key Benefits:

Our premium valve lockout devices can fit various valve sizes. These are made from high visible colors for easy identification in the working area. Check out more benefits:

Enhanced Safety: Mitigates the risk of workplace accidents.

Reliable Protection: Secures machinery during maintenance activities.

Long-Lasting: Built to withstand wear and tear in demanding environments.

Wide Selection: Available in different sizes and configurations to meet your specific needs.

Invest in premium valve lockout devices to ensure the safety of your team and compliance with Australian regulations. Shop now and safeguard your workplace with the best safety solutions available in Australia. Check the product range - https://www.safetylock.net/lockout-tagout-devices/valve-lockouts/

#Valve Lockout Devices#Lockout Tagout#Valve LOTO Devices#Valve Lockouts#Gate Valve Lockout#Ball Valve Lockouts#Lockout Tagout Devices#Lockout Tagout Manufacturer#LOTO Supplier#E-Square Alliance

0 notes

Text

https://www.ingenyriamart.com/valve-lockouts

0 notes

Text

https://www.ingenyriamart.com/valve-lockouts

0 notes

Text

Lockout Tagout Kits: Ensuring Workplace Safety in UAE

Introduction

Safety in the workplace is paramount, especially in industries that involve machinery, electrical systems, and hazardous equipment. A Lockout Tagout (LOTO) kit is an essential tool for safeguarding workers from accidental energy release during maintenance and servicing. In the UAE, where industrial safety standards are rigorously upheld, LOTO kits are vital in promoting compliance and preventing workplace accidents.

This blog explores the components, benefits, and applications of Lockout Tagout kits, highlighting their importance in the UAE’s industrial landscape.

What is a Lockout Tagout Kit?

A Lockout Tagout kit is a comprehensive set of devices designed to isolate energy sources and prevent the accidental start-up of equipment during maintenance. These kits include various lockout devices, tags, and tools tailored to meet the specific safety needs of different industries.

Key Components of a Lockout Tagout Kit

Padlocks: Durable safety padlocks to secure lockout devices.

Tags: Clearly labeled tags to warn employees of ongoing maintenance.

Valve Lockouts: Secure valves to prevent energy release.

Electrical Lockouts: Isolate circuit breakers and plugs.

Cable Lockouts: Versatile devices for securing multiple energy points.

Hasps: Allow multiple workers to lock out a single energy source.

Carrying Case: Convenient storage for all tools in the kit.

Importance of Lockout Tagout Kits

Industries in the UAE, including oil and gas, construction, and manufacturing, operate under strict safety regulations. LOTO kits play a crucial role in ensuring compliance with these standards while enhancing worker safety.

Accident Prevention: Mitigates risks associated with unexpected energy releases.

Regulatory Compliance: Helps businesses adhere to UAE workplace safety laws.

Enhanced Productivity: Ensures a safer environment, reducing downtime caused by accidents.

Employee Confidence: Promotes a culture of safety, boosting worker morale.

Applications of Lockout Tagout Kit

LOTO kits are indispensable in various sectors:

Electrical Maintenance: Lockout devices secure circuit breakers, switches, and plugs during repair.

Industrial Machinery: Prevent accidental start-up of heavy equipment.

Pipelines and Valves: Valve lockouts isolate hazardous materials in chemical or oil processing plants.

Construction Sites: Ensure safe maintenance of cranes, elevators, and other machinery.

Features of High-Quality Lockout Tagout Kit

Durable Materials: Resistant to harsh environments and extreme temperatures.

Versatility: Includes a wide range of devices for different energy sources.

Compliance Ready: Meets international and UAE-specific safety standards.

Portability: Compact and easy-to-carry cases for on-the-go usage.

Why Choose a Lockout Tagout Kit for Your Workplace?

Investing in a LOTO kit is not just a regulatory requirement but also a proactive measure for workplace safety. Key benefits include:

Cost Efficiency: Prevents financial losses from accidents and legal fines.

Time-Saving: Streamlines the lockout/tagout process during maintenance.

Customizability: Kits can be tailored to fit the specific needs of your industry.

The Role of LOTO Kits in the UAE’s Safety Standards

The UAE’s commitment to workplace safety is evident in its adherence to international standards such as ISO 45001 and the Occupational Safety and Health Administration (OSHA) guidelines. LOTO kits help businesses comply with these regulations, fostering a safer working environment.

In high-risk industries like oil and gas, where energy isolation is critical, the use of lock out tag out UAE is not just recommended but essential.

How to Choose the Right LOTO Kit

Assess Workplace Needs: Identify the types of energy sources and equipment in use.

Ensure Compliance: Select kits that meet UAE and international safety standards.

Check Durability: Opt for kits with robust materials suitable for your environment.

Consider Portability: Choose a kit that is easy to carry and store.

Conclusion

Lockout Tagout kits are indispensable for ensuring workplace safety and regulatory compliance in the UAE. They protect workers, reduce the risk of accidents, and create a culture of safety that is crucial for any business.

By investing in high-quality LOTO kits, UAE industries can not only safeguard their workforce but also enhance productivity and maintain their reputation for excellence in workplace safety.

#lock out kit#loto kit supplier#scaffolding tag#butterfly valve#abb distributors uae#miniature circuit breaker#emergency stop switch#lockout tagout#padlocks dubai#lockout tagout locks#padlock supplier#uae#dubai#abudhabi#safety tag#mcb uae#lockout station

0 notes

Text

F-14 TOMCAT ISSUES AND ACCIDENTS

The following is a compilation of issues with the F-14 Tomcat that have been encountered by pilots throughout its lifespan due to both mechanical and other reasons. Some are based on individual accidents and some cover epidemics in which many aircraft were lost to the issue *cough* compressor stalls *cough* basically it’s a bunch of ways you can hurt your fav characters in your fics so if you write something pls let me know cause I want to read it!!!

The issues range from minor hydraulic leaks to an explosion where pilots survive but the aircraft is literally in a million pieces.

LAST UPDATED 10/25/2023

Added some links to relavant FFFOTDs

Side note, the F-14 was a frickin massive tank of a fighter jet. She has taken damage to major components and still been able to land safely, so every situation is pretty unique.

Water Damage- Any type of water intrusion would cause issues with the electrical systems. It was a very common thing, so much so that they would have to duct tape anywhere water might be able to enter as a precaution when they knew it would rain.

Hydraulic Fluid Leaks - The F-14 did leak hydraulic fuel fairly often. There was a joke going around that if there isn't a bucket leaking hydraulic fluid underneath the plane then you are out of hydraulic fluid.

The Staple - On F-14 As and Bs, they would limit the jet to 4Gs maximum for three months and then they would install a metal staple to the bottom of the aircraft just forward of the tail hook. The point of the staple was to prevent severe bulkhead cracks and fuselage delamination by reducing the torquing moments caused by material fatigue. The staple is described as being a 1 foot-long and 1 inch wide solid steel part that looks exactly like a staple. As a part of their pre-flight checks, pilots would have to hang on it to ensure it wouldn’t fall out.

Airbags - Now and then, the airbags would rip and they would have to fix them.

Hydraulic Failures - Hydraulic failures happened somewhat often, but not often enough to be a prevalent issue. Generally speaking, it was common knowledge that if an F-14 wasn't leaking hydraulic fluid then it was out of hydraulic fluid. They would place buckets underneath to catch the liquid when the aircraft was not flying.

An incident from 1988 resulted from a complete hydraulic failure of both the main and the backup systems. They ruled the accident to be caused by the combination of failure of a relief valve and material failure. The Commander of the Pacific Fleet at the time believed that it could have possibly been the result of entrapped air that had been introduced into the hydraulic system through minor system maintenance.

AICS Programmers - They would have to start the airplane and then run the intake ramps aka would have to cycle the intake ramps otherwise they wouldn't be able to get off the ground.

Flap-Slat Lockout - If the flaps on either side of the jet didn't program at the same rate, it would cut it out and lock them up. They were then unable to move them as the lockout was a precaution to prevent asymmetry. This forced pilots to land without flaps, requiring an extra 22 knots during landing. It was difficult to land when they were locked out, and in many situations the end result would be pulling up next to the carrier and ejecting. Flap-Slat Lockout was a consistent issue throughout the Tomcat's life.

Unreliable Fire Warning Light - Sometimes the fire warning light would just barely start to flicker on and steadily become more prominent. Overall "just a bad system." You never actually know if there's a fire or not.

Wings Won’t Come Out - This happened at NAS Oceana. The airplane landed at a speed of 230 mph, so very close to the F-14’s stall speed. When the wings are stuck back, you can't hit the brakes during landing because there is no anti-skid and you would overheat them, if you pulled the stick back you would rotate, and with the wings back you have no spoilers so there is nothing to slow you down. In this particular incident, the pilot was able to take the long landing, but if this issue was encountered at sea it would require an ejection or divert to an airfield nearby if possible. No big explosions or fires though, it’d be a fairly calm procedure and the plane could fly into range of the ship for easy retrieval after ejection.

Low Fuel (Barricade Landing) - Bad weather at night combined with air traffic personnel being too occupied with diverting tons of airplanes, launching tankers, etc. can cause an aircraft to get low on fuel. There was a situation covered in the F-14 Tomcast episode called "F-14 Barricade" where they were unable to refuel using a tanker and were forced to do a barricade landing for their safety. They were almost forced to pull up alongside the carrier and eject. After the landing, one of the crew calculated based on the amount of fuel left that they only had about 90 seconds of flying left. This is literally the only night F-14 barricade landing ever I am pretty sure (in real life Maverick's doesn't count lol). I like it because the pilot and RIO had to tell the aircrew straight up "You have to take us now" because the pilot could no longer see the tape on the fuel gage. The crew tells their story really well and it’s really funny to listen to, especially considering the fact that they had to keep sending them around because they fucked up setting up the barrier.

Hitting the Canopy (During Ejection) - Goose's story is based on a real story in which a RIO hit the canopy during ejection and broke his spine. The reason the pilot does not also hit the canopy is because the ejection sends the RIO out first. The canopy is ejected after a couple of seconds after the handle is pulled, then the RIO is ejected after a second or two, and then the pilot another second later. The ejection seats also launch them in different trajectories so the pilot and the RIO do not collide in the air, meaning they may or may not end up in the same area. The solution would be to wait for the canopy to clear before ejecting but sometimes your don’t have that luxury.

Front Landing Gear Failure During Takeoff- While launching off of the catapult of the aircraft carrier, the nose gear attached to the shuttle broke. The landing gear and shuttle proceeded to the end of the runway without the jet, hitting the end of the ship at 305 knots and damaging the front of the carrier. The jet went off the ship with far less speed than necessary (at barely 60-70 knots) and began falling into the water as it was not enough to get the Tomcat in the air. They ejected to barely 50 feet high and were in serious danger of getting run over by the aircraft carrier. In the accident covered on the Fighter Pilot Podcast FPP004 - Ejection Seats, the RIO tells the story of his survival and the tragic loss of the pilot.

Radome (Nose Cone) Detachment - An F-14 Tomcat lost its radome during a flight due to the failure of the latching mechanism. The radome crashed into the canopy, shattering te glass of the windscreen. The pilot could only see out of a 3 inch hole in the windscreen due to the cracked windshield. He couldn't hear anything due to the noise of the wind in the cockpit, so he was unsure of the state of his RIO but assumed he was unconscious because he hadn't ejected them. The pilot flew over the carrier three times before successfully landing the plane, despite having glass in both eyes and a broken collarbone. It turns out that the RIO had been completely unharmed but with comms down he was unable to tell the pilot such. Upon landing the plane, the pilot was medevaced for eye surgery and then returned to the US.

Midair Collision - F-14A BUNo 159832 was a midair collision between two F-14 Tomcat. In this particular situation, one of the airplanes was able to divert to a nearby airport due to losing part of the right wing whereas the other crew was forced to eject. Obviously you could probably picture a situation where both jets went down.

Landng with Damage - Tomcats are a very sturdy aircraft, often described as being a tank both due to how much fuel they were able to carry and the sheer size of the aircraft. There has been an incident where an F-14 landed without one of its vertical stabilizers. In the Radome Deatchment section, the pilot was able to land the plane. The following video shows an aircraft, although not an F-14, landing aboard an aircraft carrier with significant damage on its right right side.

youtube

Single Engine Cat Shot- There was an incident where an aircraft had engine issues the moment it left the carrier. Immediately after the launch, they lost the left engine, and the first thing the pilot did was go through engine failure procedures, wingman at their side. They set up for an engine start using normal air before they attempted a cross-bleed air start using bleed air from the right engine to rotate the starter in the left engine, but neither worked. The pilot addressed the fuel distribution situation by feeding the right engine with fuel from the left to even them out and then they began dumping fuel to get to the "max trap" weight. Upon successfully landing, the Commanding Officer initially believed that the pilot had allowed the left engine throttle to roll back to idle during the acceleration of the catapult stroke, however, after maintenance personnel spun up the engine to troubleshoot, the engine spun well past its normal rpm immediately without the mechanical load it usually carried by the tower shaft meaning that something was very, very wrong. An image of the aircraft after launch can be seen below. Note the singular engine lit up.

F110 Afterburner Failure - The new engines installed were great, but they initially had a problem with the afterburner. In one recorded accident, the pilot lit the afterburner, damaging the afterburner can's lining and leading to an explosion. The Navy prohibited use of the afterburner below 10,000 ft on the F-14+/B/D until the problem could get solved but it took nearly a year to remedy.

"Thump Bang" - The easiest way to incorporate any sort of accident is to call it what the Naval Aviators call a "thump bang". A "thump bang" refers to a series of events that occur when an aircraft experiences some sort of issue they described as a "thump" and then an explosion. It's kind of hard to describe what is like in the cockpit during this sort of accident as it could have happened quickly or could have been a delayed explosion, and it could have been caused by any number of reasons. If they don't know what actually happened, they'll call it a "thump bang" and can only hypothesize what occurred. The likely scenario would have been an issue with the TF30 engines.

TF30 - The "Turd in the punch bowl, " the TF30s had two specific issues that were kind of intertwined.

Throwing Fan Blades - One of the largest issues with the TF30s was that they were with the fan blades. When the fan blades become eroded or damaged over time, they no longer compress the airflow efficiently, potentially leading to an engine stall (see Compressor Stall below). Additionally, the TF30 was known for "throwing" fan blades. This is when the fan blade becomes detached and is shot out to the side into the interior of the aircraft. Not good. Pretty bad actually. They didn't initially know they were throwing fan blades until after a couple of accidents. when they started to be more common they would retrieve the aircraft from the water (if in large enough pieces and then investigate the cause.

Compressor Stall - The actual biggest issue with the F-14 Tomcat and its TF30 engines is the compressor stalling. They literally happened all the time from a variety of different causes. Generally speaking, the compressor stalls were the result of disruption to the airflow into the compressor of the engine. The compressor has fan blades that require the airflow to be undisturbed for maximum efficiency. It was theorized to be the result of foreign object debris (FOD) ingestion into the engines. They check religiously for loose objects on the airplanes as a result, oftentimes having a crew member dive into the intake ducts to check for loose bolts. Additionally, compressor stalls could be caused by operating the aircraft outside of its limits, improper handling, etc.

The F-14 had a gated afterburner, meaning it had 5 “gates” inside of the afterburner and each one lit up a flame rack. There was no variable thrust, so it had to be either on or off. Each of the five racks was labeled as a zone. Zone 3 is what they were allowed to take off with. Coming in or out of afterburner with any angle or attack would cause the compressor to immediately stall. This was mostly due to poor design of the intake.

In general, approximately 30% of F-14A losses were attributed to high-altitude compressor stalls. When one engine stalls, more often than not it will induce the other engine to stall as well. There is a procedure to counteract the compressor stall, the specific protocol was to ease the amount of Gs, slow down, the T.I.T. would go crazy and you shut it down. Or in fighter pilot slang, “ease, slow cook it, shut it down.”

One incident in particular that was assumed to be caused by engine failure resulted in an explosion that looked so bad it was a miracle the pilot and RIO survived (see image below). The pilot escaped with minor burns to his hands, face, and neck and was able to fly within a couple of weeks. The RIO sustained more serious burns on his hands but was flying again after several weeks.

youtube

youtube

Not Touching Them For Two Days - True story; they flew best when they were used a lot.

#I’ll be your wingman anytime#fanfic writing wingman that is#it’s my birthday and all I want is for people to tag me when my posts help you because I want to read them!!!!!#I’m obsessed#I like angst#and airplanes#angst and airplanes#I like research#and f-14 tomcats#top gun#tom kazansky#top gun: maverick#iceman#top gun maverick#top gun iceman#pete mitchell#icemav#my boys#ron kerner#tgm#research#Youtube#mine#I like planes#tom iceman kazansky#just a little thing I wrote#EDIT 10/6: Expanded Hydraulic Failure section and added the single engine cat shot section#reference#f 14 tomcat has ✨issues✨#information

206 notes

·

View notes

Text

What is Lockout Tagout Video in Hindi

Lockout Tagout is a critical safety practice that protects workers from hazardous energy during the maintenance of machinery and equipment. This Hindi-language video explains the concept of LOTO, its importance, and how it can prevent workplace accidents. The video emphasizes the role of proper training and adherence to safety protocols in minimizing risks and safeguarding workers' lives.

Viewers can learn about common lockout devices like padlocks, hasps, and valve lockouts, along with tips on compliance with workplace safety regulations. With a focus on simplicity and real-world application, this video serves as an essential resource for Hindi-speaking audiences, empowering them to foster a culture of safety in their workplaces.

#What is Lockout Tagout in Hindi#what is LOTO#Lockout Tagout Video#LOTO Safety Video#What is LOTO Video in Hindi#E-Square Alliance

0 notes

Text

VNI4140K Load Handling Capabilities

The VNI4140K is an integrated power driver designed to manage high-power loads in various industrial and automotive applications. Its load-handling capabilities make it a highly efficient and reliable solution for driving multiple outputs simultaneously. Below is an overview of its key features and load-handling abilities:

1. High Current Capability

The VNI4140K is capable of handling output currents of up to 0.7A per channel. This makes it suitable for driving inductive and resistive loads such as motors, relays, and lamps. With four independent channels, it can control multiple loads at once, offering versatility in a wide range of applications.

2. Integrated Protection Features

To ensure safe operation under challenging conditions, the VNI4140K is equipped with several protection mechanisms:

Overcurrent Protection: Limits the current in case of short circuits or overloading to protect both the IC and the load.

Overtemperature Shutdown: Protects the device from damage by automatically shutting down when a critical temperature threshold is exceeded.

Undervoltage Lockout (UVLO): Ensures that the system operates only when the input voltage is within safe limits, protecting against low-voltage conditions.

3. Wide Operating Voltage Range

The VNI4140K supports a wide supply voltage range from 8V to 36V, allowing it to handle loads in both low-voltage and higher-voltage systems. This flexibility makes it ideal for automotive systems that require 12V or 24V power supplies, as well as industrial applications with varied power requirements.

4. Robust Load Switching

The VNI4140K utilizes high-side MOSFET switches to control the connected loads. These switches are capable of fast and efficient switching with minimal heat generation, making the device well-suited for applications where heat management is crucial.

5. PWM and Diagnostics

For precise load control, the VNI4140K supports Pulse Width Modulation (PWM), which allows for fine-tuning the power delivered to the load. It also features diagnostic feedback that provides information about the load status (e.g., open load, short to ground) for better control and system diagnostics.

Applications

The VNI4140K can handle a wide variety of loads in different environments, including:

Automotive lighting systems (e.g., headlights, indicators)

DC motors for industrial and automotive applications

Solenoids and valves in fluid control systems

Resistive loads such as heaters and lamps

Conclusion

The VNI4140K's load-handling capabilities make it an excellent choice for high-power applications requiring multiple, independent output channels. Its ability to handle up to 0.7A per channel, combined with advanced protection and diagnostic features, ensures reliable and efficient performance across a wide range of industrial and automotive systems.

0 notes

Text

ADJUSTABLE VALVE LOCKOUT LARGE |RYXO SAFETY #14875

COLOURRedWEIGHT343gmMATERIALStandard A3 Steel platePADLOCK NUMBERS6BALL VALVES SUITABLEFor DN50-DN200 ball valveAPPLICATIONSuitable for 31.8mm to 76.2mm pipes

#adjustablevalvelockout#adjustablevalvelockoutlarge#adjustablevalvelockoutsupplierinabudhabi#clearway#clearwayabudhabi#clearwaysafety#clearwaysafetystore#clearwayuae#lockouttagoutuae#lockouttagoutwholesaleuae#lockuttagoutsupplieruae#ppesafetystore#ryxo#ryxoabudhabi#ryxobrand#ryxosafety#ryxouae#safetyshopabudhabi#safetyshopuae#valvelockout#valvelockoutsupplierinuae#valvelockoutwholesalesupplierinuae

0 notes

Text

Maintaining a Safe and Uninterrupted Production Floor

A critical aspect of maintaining a steady product outflow is minimizing work stoppages. In the packaging industry, automated line machinery is complex, elevating the number of interactions between operators and equipment. The process increases the potential for accidents. Plus, frequent stops that require manual loading slow the line and expose workers to safety risks as they take steps to correct the issue.

Frequent stop issues are particularly prevalent in pneumatic control sections of the assembly line, which involve the use of compressed air or gas in controlling mechanical component movements. Such systems are common in manufacturing and automation settings, including packaging.

Traditional methods of ensuring operator safety include safety circuits with a redundant dump valve and a pressure release system to see that one failure does not cause other and potentially catastrophic failures. The safety elements have lockout/tagout (LO/TO) applications that perform functions such as shutting off the air supply and releasing compressed air from the system. These applications safely and efficiently stop equipment operation. The control structures provide assurance that prevents the sudden reintroduction of air into the pneumatic system, which can damage components and cause unexpected movements that injure workers.

With zoned safety technologies in place, it shuts down air and power near a specific human operator or piece of equipment that poses safety and equipment risks. This configuration fulfills safety mandates while allowing production within the system to continue.

In achieving this, technicians place a variety of standard valve functions, as well as independent safety circuits, within each pneumatic valve manifold or discrete system within the whole. Technicians can program safety functions and commands, such as “return home,” “stop motion,” “unclamp,” “remain clamped,” and “exhaust air” into each zone of the manifold without affecting other zones.

Another issue in packaging plants is the loss of power, which results in equipment downtime and potential data loss. The system design must include robust and secure data backup systems hosted remotely and carefully calibrated monitoring and assessing of electrical load. It allows backup electricity sources such as generators to come online and keep the facility running.

Systems may need to prioritize individual loads to ensure continuous power for critical operations when a power failure occurs. Production machinery, lighting, compressed air systems, and HVAC are among the elements that often carry critical loads.

Electronic control systems, computers, and servers are susceptible to power surges, voltage sags, and other electrical disruptions. When damage occurs to the control systems, the production line enters a state of chaos, with complex, interlocking components often operating unpredictably and running into each other, products coming out defective, and operators caught in the crossfire, needing to resolve critical issues immediately.

Implementing uninterruptible power supplies (UPS) keeps programmable logic controllers, communication devices, and primary equipment functioning to minimally acceptable levels throughout unexpected outages. UPS systems deliver immediate backup power, providing options for either continuing processes on the production floor as usual or safely and methodically shutting down production elements until someone resolves the situation. A well-constructed and designed UPS provides a reliable and continuous production floor operations environment that keeps workers, products, and equipment safe.

0 notes

Text

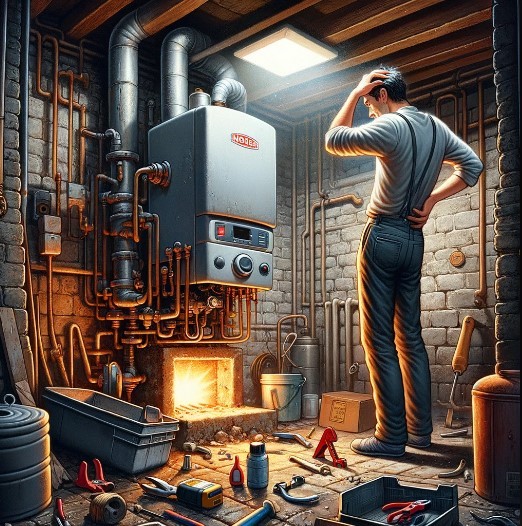

Troubleshooting Guide: Boiler Not Firing Up – 9 Reasons Your Heating and Hot Water Boiler Won’t Start

In homes across Fulham SW6, encountering a boiler that won't fire up can be a source of frustration, particularly during the colder months. Understanding the potential causes behind this issue is essential for swift resolution and the restoration of warmth and hot water. Here, we'll explore nine common reasons why your boiler may not be starting and why seeking assistance from Fulham plumbing and heating professionals is crucial in such situations.

Lack of Power Supply

One of the most straightforward explanations for a boiler failing to start is a lack of power. Check that the boiler's power switch is turned on and that there are no issues with the electrical supply to the unit.

Faulty Thermostat

A faulty thermostat can prevent your boiler from receiving the signal to start heating. Ensure that the thermostat is set to the correct temperature and that its batteries, if applicable, are working correctly.

Low Water Pressure

Low water pressure within the boiler system can hinder its ability to start up. Check the pressure gauge on the boiler and, if necessary, repressurize the system according to the manufacturer's instructions.

Frozen Condensate Pipe

During cold spells, condensate pipes can freeze, causing a blockage that prevents the boiler from firing up. Thawing the pipe with warm water or a hot water bottle may resolve the issue.

Airlock in the System

Airlocks within the boiler or central heating system can disrupt water flow and prevent the boiler from starting. Bleeding the radiators and/or the boiler itself can help alleviate airlock-related issues.

Faulty Pilot Light or Ignition System

If your boiler relies on a pilot light or electronic ignition system, a fault in either component can prevent the boiler from firing up. Professional inspection and repair may be necessary to resolve this issue.

Blocked or Faulty Pump

A blocked or faulty pump can impede the circulation of water within the boiler system, resulting in startup failures. A qualified plumber Fulham SW6 can assess the condition of the pump and address any blockages or malfunctions.

Gas Supply Issues

A disruption in the gas supply to the boiler can prevent it from igniting. Ensure that the gas valve supplying the boiler is open and that there are no issues with the gas meter or supply line.

Overheating or Safety Lockout

Boilers are equipped with safety mechanisms that may trigger a lockout if the system detects overheating or other potentially hazardous conditions. Resetting the boiler and addressing any underlying issues is essential to restoring normal operation.

Seeking Professional Assistance

While some boiler issues can be resolved through DIY troubleshooting, others require the expertise of a qualified professional. In Fulham, plumbing and heating specialists are available to diagnose and rectify boiler problems promptly and efficiently. In emergencies, such as a boiler breakdown during the winter months, contacting an emergency plumber Fulham is advisable to ensure timely assistance.

Conclusion

A boiler that won't fire up can disrupt daily life and leave you without essential heating and hot water. By familiarising yourself with the potential causes of this issue and seeking assistance from Fulham plumbing and heating professionals when needed, you can ensure that your boiler is quickly restored to optimal working condition. Don't let a malfunctioning boiler leave you out in the cold – contact a reliable plumber Fulham SW6 for expert assistance today.

0 notes

Text

Safety First: 6 Best Practices for Establishing a Secure Manufacturing Unit

We've all heard it before: safety first. But let's be honest, there are times when those safety measures at work seem like a hassle, right? Therefore, it's tempting to skip them and save some time and effort.

But here's the thing – a little extra time spent on safety is always worth it. After all, nobody wants to get hurt at work, right?

So, whether you're a supervisor responsible for your team's safety or own a manufacturing unit, we have some straightforward tips to help establish a secure workplace.

Let's dive in and explore these six best practices!

Proactive Hazard Identification

When talking about keeping a manufacturing unit safe, it's like being a detective looking for anything that could go wrong. This is called Proactive Hazard Identification. Simply put, you must keep your eyes wide open for any risks in how you make things.

For example, if you're generating hydrogen, you must check if there’s anything around that might make the process unsafe.

Hazardous Material Handling

Handling chemicals and materials in a manufacturing unit can be a daunting task. But with the right approach, you can make it safe and seamless. To begin with, the right equipment must be installed.

It is your manufacturing unit's superhero, safeguarding your employees and the environment from potential risks. One of the most effective equipment that has gained popularity is CRN-certified Clark Cooper’s ER Series valves. They regulate the flow of chemicals and ensure that everything moves where it should, without any unwanted leaks or spills.

Well, installing the right equipment is just part of the equation. Employees must also be trained in how to use this equipment effectively and safely. That’s what the next practice is all about!

Comprehensive Employee Training

Well-informed, trained employees ensure a safe, happy workplace by using machines, handling materials properly, and preventing accidents.

But how do you make sure that employees are trained well? For this, you must create a good safety training program. It will help to have the right safety rules and clear training so everyone can work safely.

Also, it is essential to understand that learning about safety is not a one-time thing. Instead, employees should keep learning new things and practicing safety rules to be super safe at work. This way, you can also teach new friends joining the factory, making the workplace like a big happy and secure family!

Machine and Equipment Safety

In a place where lots of big machines work, it is really important to keep everyone safe. For this, make sure machines have proper guards and safety locks. They’re there to protect the machines and the people using them. If something goes wrong, these safeguards help prevent accidents.

Also, think about routine maintenance and inspection of this machinery. When you check all parts of the machines, ensure they are working well. You can fix any issues before they become big problems!

Lastly, let’s talk about something called lockout/tagout procedures. This might sound complicated, but it’s like putting a “Do Not Use” sign on a machine if it’s not working correctly or is being fixed. This would ensure no one uses it by accident, preventing mishaps.

Emergency Preparedness

Developing and practicing effective emergency response plans is like having a map and knowing exactly where to go when there’s trouble. This means everyone should know where the exits are, where to find fire extinguishers, and where to meet outside. You can conduct regular drills to practice these plans to make sure everyone knows the drill.

Moreover, equipping the facility with essential first-aid resources is vital. It means having band-aids, antiseptic wipes, and other helpful stuff ready in case someone gets a cut or a scrape. This way, minor injuries can be handled quickly, and everyone can get back to work safely.

Emphasizing Protective Equipment

Safety is like a shield when you make things in a factory. One of the super important parts of this shield is wearing the right gear, called protective equipment. These include safety gear like helmets, gloves, and glasses.

But the gear only works if everyone wears it every time. So, you must make rules to ensure everyone puts on their safety gear and regularly check if everyone is following these rules.

Plus, you must ensure that every gear is in perfect condition, ready to protect every worker. This way, your workers can work happily and safely, knowing they have their superhero shields on!

Bottomline

No one wants to see anyone get hurt, and by following these practices, you’re ensuring a safer environment for everyone. It might take a little extra effort, but it’s worth it! And here’s the cool part – when you work together for safety, it creates a positive vibe, making your manufacturing unit a safe place and a happy one.

0 notes

Text

Ensure Workplace Safety with Mechanical / Valve Lockout Tagout Kits

Checkout a wide range of mechanical / valve LOTO kits with the essential devices to implement lockout procedures safely. These lockout tagout kits are essential for the mechanical department, which can be used to prevent accidents and ensure compliance with safety regulations.

These valve lockout tagout kits include lots of products like lockout safety padlocks, LOTO tags, valve LOTO devices, lockout hasps, cable lockouts and many others which are essential to isolate hazardous energies.

#valve lockout kit#mechanical lockout kit#valve lockout tagout kits#valve LOTO kits#lockout tagout kit#LOTO kits#lockout kits for mechanical department#lockout tagout manufacturer#E-Square Alliance

0 notes

Text

The 6-T Pull Type Hydraulic Press & Assembly is a heavy-duty industrial press that is ideal for a variety of applications, including metalworking, woodworking, and plastic fabrication. The press features a powerful hydraulic system that provides up to 6 tons of pulling force, making it capable of handling even the most demanding jobs. The press is also equipped with a variety of safety features, including a pressure relief valve and a lockout switch, to ensure operator safety.

0 notes

Text

Safety Measures and Best Practices for Working with Pneumatic Valves

Pneumatic valves are widely used in industries such as manufacturing, oil and gas, automotive, and more. They control the flow of compressed air, allowing automation and precise control of machinery and processes. However, it is essential to prioritize safety when working with these valves to prevent accidents, injuries, and equipment damage.

Understanding Pneumatic Valves

What are Pneumatic Valves?

Pneumatic valves are devices that regulate the flow of compressed air in a pneumatic system. They act as on/off switches, allowing or blocking the air supply to control the movement or operation of pneumatic actuators, cylinders, or other devices. Pneumatic valves come in various types, each serving different purposes and applications.

Types of Pneumatic Valves

5/3 Way Valves: These valves have five ports and three positions. They control the direction and flow of air to a double-acting actuator.

2/2 Way Valves: These valves have two ports—one for the air supply and the other for the output. They control the flow by opening or closing the passage between the two ports.

3/2 Way Valves: These valves have three ports—one for the air supply, one for the output, and one exhaust port. They can divert the airflow or control the direction of the actuator's movement.

5/2 Way Valves: These valves have five ports and two positions. They allow the control of two different actuators or the reversal of motion of a single actuator.

Safety Precautions

To ensure safe working conditions and prevent accidents, it is important to follow these safety precautions when dealing with pneumatic valves:

Proper Training and Familiarization

Before operating pneumatic valves, individuals should receive comprehensive training on their usage, potential hazards, and emergency procedures. Understanding the valve's functions and associated risks is crucial for safe operation.

Personal Protective Equipment (PPE)

Always wear appropriate personal protective equipment, including safety glasses, gloves, and hearing protection when working with pneumatic valves. PPE helps safeguard against potential injuries from debris, fluid leaks, or loud noises.

Lockout/Tagout Procedures

Implement lockout/tagout procedures to isolate the pneumatic system and prevent accidental energization. This procedure involves disconnecting power sources, locking switches, and labeling them to communicate that maintenance or repairs are in progress.

Pressure Relief

Before conducting any maintenance or repairs, release the pressure from the pneumatic system. This precautionary step minimizes the risk of sudden movements or unexpected releases of energy.

System Inspection and Maintenance

Regularly inspect pneumatic valves and associated components for signs of wear, leaks, or damage. Perform routine maintenance tasks, such as cleaning, lubrication, and calibration, as recommended by the manufacturer.

Best Practices for Working with Pneumatic Valves

To ensure optimal performance and longevity of pneumatic valves, it is essential to follow these best practices:

Follow Manufacturer's Guidelines

Always refer to the manufacturer's guidelines, user manuals, and documentation for specific instructions related to the installation, operation, and maintenance of pneumatic valves. Adhering to these guidelines helps prevent misuse or damage to the valves.

Proper Installation

Ensure correct installation of pneumatic valves by following the recommended procedures. This includes verifying proper alignment, securely fastening connections, and avoiding over-tightening or under-tightening of fittings.

Regular Lubrication

Apply appropriate lubricants to pneumatic valves as recommended by the manufacturer. Lubrication prevents friction and wear, ensuring smooth operation and extending the valve's lifespan.

Preventive Maintenance

Implement a preventive maintenance program to detect potential issues before they cause failures or malfunctions. Regularly inspect valves, clean filters, replace worn-out seals, and address any abnormalities promptly.

Valve Position Monitoring

Utilize position monitoring devices or feedback systems to verify the position of pneumatic valves accurately. This allows for effective control and ensures that the valves are functioning as intended.

Troubleshooting Common Issues

Pneumatic valves may encounter certain issues during their lifespan. Here are some common problems and troubleshooting steps:

Leaks and Seal Failures

Leaks can occur due to worn-out seals, damaged O-rings, or loose connections. To address this, inspect the valve for visible leaks, tighten connections, and replace faulty seals or O-rings.

Valve Sticking

Sometimes, pneumatic valves may stick or fail to move freely. This can be caused by dirt, debris, or inadequate lubrication. Clean the valve, remove any obstructions, and apply suitable lubricants to ensure smooth operation.

Pressure Drop

If the pneumatic system experiences a significant pressure drop, it may indicate a valve-related issue. Check for leaks, inspect pressure regulators, and ensure proper adjustment of valves to maintain desired pressure levels.

Conclusion

Working with pneumatic valves requires careful attention to safety measures and adherence to best practices. By following proper training, wearing appropriate protective equipment, implementing lockout/tagout procedures, and conducting regular inspections and maintenance, you can ensure a safe working environment and maximize the efficiency of pneumatic valve systems.

0 notes

Text

Ensuring Worker Safety with Valve Lockout: A Lukko Safety Guide

Welcome to Lukko Safety, India's top provider of lockout and tagout equipment. We specialise in high-quality lockout and tagout items designed to keep workers safe while working with machinery and equipment. This post will go through valve lockout, which is one of the most prevalent lockout processes utilised in industry.

What exactly is a valve lockout?

A valve lockout is a method that prevents energy from flowing via a valve or a pipeline. It is a critical step in guaranteeing the safety of personnel who must maintain or repair fluid or gas-using equipment. A mechanism is used to immobilise the valve handle during valve lockout, preventing the valve from being switched on or off.

What is the significance of valve lockout?

Valve lockout is necessary to prevent mishaps caused by sudden starts of machinery or equipment. When a valve is not shut out, the energy in the system might force it to open or close abruptly, potentially causing harm or death. Valve lockout guarantees that the valve stays locked until the person has finished their task and is ready to switch on the machine safely.

How Does a Valve Lockout Work?

Valve lockout is accomplished in a few easy steps:

Step 1: Locate the valve that has to be shut off.

Step 2: Disconnect the valve-using equipment.

Attach the valve lockout device to the valve handle in step three.

Step 4: Secure the lockout device with a lock and a tag that indicates who locked out the valve and when it was locked out.

Step 5: Check that the valve cannot be opened or closed.

We provide a variety of valve lockout devices at Lukko Safety, including ball valve lockout, gate valve lockout, and butterfly valve lockout. Our lockout devices are high-quality, long-lasting materials that can resist rigorous working circumstances. They are also simple to use, with detailed instructions included with each product.

Finally, valve lockout is a critical safety procedure that should be followed whenever working with fluids or gases. We at Lukko Safety are dedicated to offering high-quality lockout and tagout devices that keep workers safe. Contact us today to learn more about our valve lockout solutions and how we can help you enhance workplace safety.

1 note

·

View note

Text

OSHA Lockout Tagout 1910.147(c): Protective Materials and Hardware

To perform service or maintenance safely and effectively under Lockout Tagout, employees must be provided with protective equipment, hardware and appliances for isolating, securing, or blocking of machines & equipment from their energy sources. Under paragraph (c)(5) of the OSHA Standard, it is the employers’ responsibility to provide necessary devices. Protective material and hardware that may be needed include locks, tags, cable ties, chains, breakers and valve lockouts, wedges, blocks, blinds, pins, fasteners and other hardware.

When launching a lockout tagout program, a survey of the workplace is needed, not only to identify the machines, equipment and processes that are covered by the program, but also to become familiar with the configuration of the equipment. When ordering the necessary hardware, the employer must also ensure that the hardware meets specific requirements for design & construction.

Under paragraph (c)(5)(ii) it states that the Lockout & Tagout devices should be singularly identified. Which means- the best suitable device should be placed on the isolating point and should not be used for any other purpose apart from Lockout Tagout on machines & equipment.

Section A-D of paragraph (c)(5)(ii) specifies certain requirements of lockout Tagout devices, i.e. The device must be durable, Standardized, Substantial and Identifiable.

In paragraph 1910.147(c)(5)(iii), OSHA requires that the major message printed on the tag “warn against hazardous condition of the equipment is re-energized. Five examples of acceptable warnings are provided, including Do Not Start. Do Not Open. Do Not Close. Do Not Energize. Do Not Operate. In all cases, employees must know and understand the meaning of the Tag.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#OSHA#OSHALockoutTagout#ProtectiveMaterial#LockoutTagout#OSHAViolations#OSHAGuidelines#LOTO#LockoutTagoutProgram#OSHAStandard#ESquare#ESquareAlliance

0 notes