#Lockout Tagout Devices

Explore tagged Tumblr posts

Text

Explore Clamp on Breaker Lockout Device for Electrical LOTO Procedure

Ensure the highest safety standards in your electrical lockout tagout (LOTO) procedures with our top-tier Clamp-On Breaker Lockout Devices. These breaker lockout devices are meticulously designed to prevent accidental energization and maintain a secure environment for your workforce.

These clamp on breaker lockout devices can be used in various Industrial settings, manufacturing plants and during maintenance operations. Explore a wide range of products on E-Square website.

Contact us today to get more about how our lockout product can enhance your safety protocols.

#Clamp on Breaker Lockout#Lockout Tagout#Circuit Breaker Lockout#Breaker LOTO#Breaker Lockout#Clamp on Breaker Lockout Device#Lockout Tagout Devices#LOTO Devices#E-Square Allianc

0 notes

Text

Explore One Stop Shop for all Types of LOTO Solutions in Australia

Maintaining a safe working environment is paramount in Australia's diverse industries. Lockout Tagout procedures are essential for preventing workplace accidents during maintenance and repair. Finding all the necessary LOTO equipment can be time-consuming. Luckily, there are suppliers in Australia that offer a comprehensive range of LOTO solutions under one roof, simplifying the procurement process and ensuring you have everything you need for effective safety protocols.

These one-stop shops provide a wide range of LOTO devices, from padlocks and tags to lockout boxes and hasps etc. They also stock specialized equipment for various energy sources, including electrical, mechanical, hydraulic, and pneumatic systems. This comprehensive offering ensures you can find the right tools for any LOTO application in Australia.

Wide range of LOTO devices: Padlocks, tags, hasps, valves, lockout boxes, stations, and more.

Solutions for all energy sources: Control all types of energies - electrical, mechanical, hydraulic, and pneumatic.

Expert advice and support: Get guidance on selecting the right LOTO devices and also avail the Lockout Tagout services under one roof.

Compliance with Australian safety standards: Ensuring your LOTO procedures meet regulations.

Don't compromise on safety. Streamline your LOTO procurement process and ensure you have the right tools for the job. Contact a leading LOTO solutions provider in Australia today to explore extensive product range and receive expert advice on implementing effective LOTO procedures.

Explore all types of available LOTO solutions - https://www.safetylock.net

#Lockout Tagout#LOTO Solutions#Lockout Tagout Products#LOTO Devices#Lockout Tagout Services#Lockout Tagout Devices#Lockout Tagout Manufacturer#Lockout Tagout Supplier#LOTO Manufacturer#LOTO Supplier#E-Square Alliance

0 notes

Text

Lockout Tagout Devices Market Set To See Strong Growth by 2030

Lockout Tagout (LOTO) devices are safety devices used to control hazardous energy sources during maintenance or servicing of machinery or equipment. They are designed to prevent the accidental or unexpected release of hazardous energy during these activities, which can cause injury or even death.

For Sample Report Click Here:-https://www.globmarketreports.com/request-sample/258639

There are several types of LOTO devices, including lockout hasps, lockout tags, lockout padlocks, valve lockouts, electrical lockouts, and pneumatic lockouts. Each type of device is designed to be used with a specific type of energy source or piece of equipment.Lockout hasps are used to secure multiple LOTO devices to the same energy source. They typically have multiple lockout points, allowing multiple workers to apply their own lockout device to the hasp.

Lockout tags are used to identify the person who applied the LOTO device and the reason for the lockout. They are usually attached to the LOTO device using a durable tag holder and a cable tie.Lockout padlocks are used to secure LOTO devices, such as hasps or chains, to the energy source. They are designed to withstand harsh environments and prevent tampering.

Valve lockouts are used to prevent the accidental opening or closing of valves. They are typically applied directly to the valve, preventing it from being operated.Electrical lockouts are used to prevent the accidental or unauthorized energization of electrical equipment. They typically consist of a lockout device that is attached to the electrical disconnect switch, preventing it from being turned on.

Pneumatic lockouts are used to prevent the accidental pressurization of pneumatic equipment. They typically consist of a lockout device that is attached to the pneumatic valve, preventing it from being opened.Overall, LOTO devices are an essential part of workplace safety, preventing accidents and protecting workers from harm

0 notes

Text

Welcome to Lukkosafety, your ultimate destination for top-notch lockout and tagout devices designed to ensure workplace safety. In this blog post, we will explore the importance of lockout and tagout procedures in preventing accidents and injuries in industrial settings. Additionally, we will delve into the features and benefits of Lukkosafety's premium-quality devices, recognized as the best in the industry. Whether you are an employer, safety manager, or employee, understanding the significance of lockout and tagout devices is vital for maintaining a secure work environment. Join us as we unveil Lukkosafety's comprehensive range of products designed to enhance workplace safety.

Section 1: The Importance of Lockout and Tagout Procedures (300 words) Lockout and tagout procedures play a critical role in preventing workplace accidents, particularly in industries where machinery and equipment are used. By effectively controlling hazardous energy sources, such as electrical, mechanical, and thermal energy, these procedures ensure the safety of employees during maintenance, repairs, or servicing. Failure to implement proper lockout and tagout protocols can result in severe injuries, fatalities, and costly legal consequences. Employers must prioritize the safety of their workforce by adhering to lockout and tagout regulations set forth by regulatory bodies like OSHA.

#lockout tagout manufacturers in india#lockout tagout safety devices#Lockout Tagout Device for Workplace Safety in India#OSHA Lockout Tagout Standard Equipment

0 notes

Text

[It is January of 2022. I’m entering a wing of the DC Office site that looks older than the others. The carpets are a strange brown, vintage looking, and the lighting casts an almost yellow pallor over the wood paneled walls. I can practically smell the cigarettes. I pass by an empty room labeled “social media office” - boxes piled up by the door. Maybe they’re going to be using it soon. They’ll need it.

I approach a door labeled Necrocommunications, knock lightly twice, then enter.

I am greeted with the sound of a voice drifting softly across the room. A few chairs and tables sit around me, the same vintage style as the hallway before, the same browns and yellows. A high desk is across the room, and a woman is seated at a control panel. She has black curly hair, done up in an old fashioned style, a polka dotted blouse, and though she’s facing away from me, I can see the edges of cats-eye glasses.

The panel she’s working at is huge, and resembles the type of switchboards they used to use in the ‘50s, dozens of physical wire connections crisscrossing the device and attaching via plugs. The woman has a headset, one ear covered in a bulky speaker, with a microphone near her mouth. She speaks casually, with an incredibly heavy New Jersey accent.]

I] Oh, him? He’s circled, babe. Taken as hell. Mhmm. And he still asked you? Ain't that a bite. So now you know he’s out of the question and yarding on. Dodged a bullet, hun.

M] Irene?

I] Oh, god, hold on. My appointment is here. Yeah. I’ll call you later, beautiful. Caio.

[She hung up the call, taking her headset off and turning to me. She looked like she was straight out of my grandfather’s high school photo album, including the color. Her skin was almost grey, it was so pale, but she didn’t seem like she was sick. She looked me over with a smirk and a raised eyebrow, leaning forward on her desk.]

I] Well, hello Miss Meghan Hendricks. What can I do for you, sugar?

M] I’m here to interview you for my audit, Ms Donofrio.

I] All business, aincha?

M] This is my job.

I] ….yeah, you’re right. Sorry. I don’t get cute visitors much.

M] Right.

I] Pull up a chair, hun.

M] I’ll just stand. This won’t be long. I came here because of your Occult Communication Tools poster.

[She sits back with a dramatic sigh.]

I] Yeah, took me forever to convince them to let me do that. We had agents using spirit boards, pendulums, casting runes, tarot cards, ghost boxes, all kinds of shit they brought from home. Bought from Walmart, or worse, a thrift store. I was always telling them, honey, baby, you gotta use our stuff, we maintain it, we disinfect it of ectoplasmic residue, lockout-tagout procedures, the works. It’s so, so unsafe to use anything but our tools. Sure, you gotta do paperwork when you check it out, but it’s better than somethin’ following you home…

M] Right into it, I guess. That’s what Necrocommunications does, right? Talk to the dead?

I] You bet, sugar. The dead, demons, angels sometimes when they ain’t on our plane or in realspace. Other little spiritual twerps and bugaboos.

M] I’ve been asking this a lot in the last few months, but…you can do that? Consistently?

I] Consistent enough to make it worthwhile. S’not perfect. Fails most of the time, depending on who you’re calling.

M] How so?

I] Well, some people don’t wanna be called. Some people are chatterboxes. We got a list of likely contacts who we suggest people contact, but…we do other people sometimes, too. Always worth a shot, I say.

M] How does it work?

[At that, Irene winced slightly and wagged her head from side to side.]

I] We got theories, but more importantly we got procedures. We know different things work for different people. Sometimes it’s cultural. The method that contacts Mr Smith may not work for Mr Chan, y’know?

M] It’s mostly for information gathering, then. Like the Board of Infernal Affairs.

I] Information gathering’s a big part of it. Someone died with a secret? See if they got loose lips now. Also, y’know, helps with hauntings or gettin’ rid of little jerk spirits.

M] You mentioned disinfection….

I] Yeah, yeah, there’s….risks, y’know. Sometimes the person you contact ain’t a fink, you know, and they start a whole new haunting. Sometimes one spirit’ll lie and say they’re another. Then they follow you home, start leeching your energy. Happens less when we cleanse the tools. Which is why there’s procedures for this, and every Office staff member in the building is trained on at least the basics.

M] Is it….is it only for Office personnel? Is it something I could…

[Irene’s face grows into a playful smirk as she hears the hesitation in my voice, leaning her face in her hand.]

I] You got fifty cents?

[She leads me into a back area of the office. Lining the walls in storage containers are row upon row of spirit boards, each box with a paper listing the dates each was used and then cleaned, along with the name of the person who did it. There are other items, too - pendulums, bags of runes, spirit boxes like you see on ghost hunting shows, and other devices and artifacts I don’t recognize. Irene’s attention, however, is on a phone booth at the end of the room. It’s clean but battered, clearly old and used. It has no door, but an open front, and above the phone itself is a depiction of a figure on a boat, with one word beside it: “Charon.”]

I] We confiscated these in the 80’s. It’s easier to use this one than have to sign out spirit board, y’know.

M] Weren’t you just complaining about that?

I] I complain about a lot of things, sugar.

[I approach, standing before the phone in disbelief. Irene senses my hesitation.]

I] Put in the money, then use the keypad to type out the person’s name. It’ll take it from there. Who you gonna call? Grandma? Mom?

M] My brother.

I] Ah. Shit, honey.

M] He died in California. Two summers ago.

[As I reach for the receiver, I see Irene’s face freeze in some sort of concern.]

I] H-honey, that…was he in—

M] Yes.

[I put my hand on the receiver, and I feel her hand on mine. She’s cold. She’s so cold and clammy that I jump slightly and look her in the eyes. Her face is sorrowful and scared, searching me.]

I] Honey…you won’t be able to—

M] You said—

I] If he was in…there’s no one there, sugar. He’s gone.

M] I know he’s gone, but you said I could—

I] No, no, he’s…if he was…he’s gone, gone. There’s nothing left of him. You can pump quarters into that thing all night long and you won’t get anyone.

M] H…how? I was…I was on the phone with him when it—

[As I watch, her eyes go wide, and she covers her mouth.]

I] Th-that’s how you remember, isn’t it? Thought you were just…in the Office but you hadn’t known about…that’s how you remember.

[I let go of the receiver. I can’t feel my fingers. I’m shivering, but not from the cold.]

M] I know how I remember. What I want to know is why everyone else forgot.

#office for the preservation of normalcy#interview#necrocommications#necromancy#microfiction#sci fi#horror#writers on tumblr

153 notes

·

View notes

Text

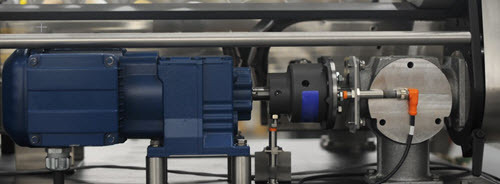

Exploring the World of Electromechanical Systems: A Fusion of Electronics and Mechanics

Introduction:

In the realm of facility management, the effective operation and maintenance of electromechanical systems play a vital role in ensuring the smooth functioning of buildings and infrastructure. The fusion of electronics and mechanics has given rise to sophisticated systems that require skilled professionals to handle their operations and maintenance.

Electromechanical systems are a fascinating field that combines the principles of electronics and mechanics. These systems involve the integration of electrical components and mechanical structures to create devices capable of performing a wide range of tasks. From simple household appliances to complex industrial machinery, electromechanical systems are an integral part of our daily lives.

Understanding Electromechanical Systems:

Electromechanical systems are integral to the functioning of modern facilities. These systems combine electrical and mechanical components, utilizing electronic controls to enhance efficiency and automation. Examples include HVAC (Heating, Ventilation, and Air Conditioning) systems, elevators, escalators, fire protection systems, security systems, and energy management systems.

Workforce Requirements:

To ensure the optimal performance of electromechanical systems, facility management teams require a diverse range of professionals with specialized skill sets. Key roles may include:

a. Engineers: Electrical and mechanical engineers are crucial for system design, installation, and troubleshooting. They possess the technical knowledge to handle complex electromechanical systems.

b. Technicians: Skilled technicians play a vital role in maintaining, inspecting, and repairing electromechanical systems. They are responsible for regular maintenance, diagnosing issues, and performing necessary repairs or replacements.

c. Operators: Operators are responsible for monitoring and controlling electromechanical systems, ensuring their proper functioning and responding to alarms or emergencies.

d. Facility Managers: These professionals oversee the operations and maintenance of electromechanical systems, ensuring compliance with regulations, managing budgets, and coordinating the work of the entire facility management team.

Recruitment Strategies:

To build a competent team for operations and maintenance in facility management, consider the following recruitment strategies:

a. Job Portals: Utilize online job portals that cater to the facility management industry to reach potential candidates with the desired skill sets.

b. Industry Networks: Engage with industry-specific networks, associations, and professional forums to connect with qualified professionals in the field of electromechanical systems.

c. Collaboration with Technical Institutes: Partner with technical institutes and vocational schools to tap into fresh talent. Establish internship programs or participate in job fairs to attract entry-level candidates.

d. Skill Assessment: Conduct thorough skill assessments during the recruitment process to evaluate candidates' proficiency in handling electromechanical systems and their related components.

Training and Professional Development:

Given the complexity and evolving nature of electromechanical systems, investing in training and professional development is crucial. Provide regular training sessions to enhance the skills of your workforce, keeping them up-to-date with the latest technologies and maintenance practices. Encourage employees to attend industry conferences, workshops, and certifications to expand their knowledge base.

Safety and Compliance:

Operations and Maintenance in Facility Management must prioritize safety and compliance. Ensure that all staff members are well-versed in safety protocols, including electrical safety, lockout/tagout procedures, and handling hazardous materials. Familiarize your team with relevant regulations and standards, such as building codes, fire safety regulations, and environmental guidelines.

Team Collaboration and Communication:

Effective collaboration and communication within the facility management team are vital for seamless operations and maintenance. Foster a culture of teamwork, encourage knowledge sharing, and promote open lines of communication between different departments and roles. This collaborative approach can lead to efficient problem-solving and improved system performance.

Conclusion:

Electromechanical systems form the backbone of facility management, and staffing considerations for operations and maintenance are crucial to ensure their reliable and efficient functioning. By understanding the workforce requirements, implementing effective recruitment strategies, prioritizing training and professional development.

#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment#Best Electromechanical Systems#Integrated Electronics and Mechanics

2 notes

·

View notes

Text

Industrial burner repair are vital components in various industries, providing the necessary heat for processes such as power generation, heating, and sterilization. Regular maintenance and timely repairs are essential to ensure their efficiency, safety, and longevity.

Understanding Industrial Burners

Industrial burners are devices that mix fuel and air to produce a controlled flame for heating applications. They are commonly used in boilers, furnaces, kilns, and other industrial equipment. The performance of these burners directly impacts energy consumption, operational costs, and environmental emissions.

Common Issues and Their Causes

Several factors can lead to burner malfunctions:

Fuel Supply Problems: Inconsistent or contaminated fuel can disrupt combustion.

Air Supply Issues: Insufficient or obstructed air intake affects combustion efficiency.

Ignition Failures: Faulty ignition systems can prevent the burner from starting.

Control System Malfunctions: Defective sensors or controllers can lead to improper burner operation.

Maintenance Practices

Regular maintenance is crucial for optimal burner performance:

Daily Inspections: Check for leaks, unusual noises, and ensure proper flame appearance.

Weekly Checks: Inspect air and fuel filters, clean combustion chambers, and verify control settings.

Monthly Maintenance: Examine burner components for wear, calibrate controls, and test safety devices.

Repair Procedures

When issues arise, follow these steps:

Diagnosis: Identify the root cause through inspections and testing.

Component Replacement: Replace faulty parts such as igniters, sensors, or valves.

System Calibration: Adjust settings to manufacturer specifications to restore optimal performance.

Testing: Conduct thorough testing to ensure the burner operates correctly before returning it to service.

Safety Considerations

Always adhere to safety protocols during maintenance and repairs:

Lockout/Tagout: Ensure all power sources are disconnected before servicing.

Personal Protective Equipment (PPE): Wear appropriate gear, including gloves and safety glasses.

Ventilation: Work in well-ventilated areas to prevent the accumulation of hazardous gases.

#weishaupt burner#industrial gas burner#combustion burners manufacturer#duel fuel weishaupt burner#burner spare parts#industrial burner

0 notes

Text

Top Safety Products in UAE: Protecting Your Workforce and Environment

Ensuring workplace safety is a top priority for businesses across the UAE, and having the right safety products is essential for protecting employees and the environment. Leading safety product suppliers in the UAE offer a comprehensive range of personal protective equipment (PPE), including helmets, gloves, safety goggles, and high-visibility clothing. Additionally, fire safety solutions such as extinguishers, smoke detectors, and fire-resistant materials help prevent accidents and ensure compliance with safety regulations. Industrial safety products, including spill containment systems, gas detectors, and first aid kits, further enhance workplace security.

The Importance of Workplace Safety and Compliance

Workplace safety products in UAE is a top priority for businesses across the UAE, where industries such as construction, logistics, and manufacturing require strict adherence to safety regulations. The UAE government enforces stringent workplace safety laws to ensure that employees are protected from potential hazards. Companies that invest in top-quality safety products not only comply with these regulations but also foster a safe working environment that enhances employee productivity and morale. A well-equipped workplace reduces the risk of accidents, minimizes liability issues, and creates a culture of safety that benefits both employers and employees

Personal Protective Equipment (PPE) for Employee Safety

Personal protective equipment (PPE) is one of the most critical safety measures in any workplace, and UAE companies provide a wide range of PPE solutions tailored to various industries. Helmets, gloves, safety goggles, high-visibility clothing, and respiratory masks are essential for workers in high-risk environments such as construction sites and industrial facilities. These products protect employees from potential hazards, including chemical exposure, falling objects, and airborne contaminants. High-quality PPE is designed to provide maximum comfort and durability, ensuring that workers can perform their duties safely and efficiently. Employers in the UAE prioritize investing in certified PPE to meet safety standards and protect their workforce from occupational risks.

Fire Safety Equipment for Workplace and Environmental Protection

Fire safety is a critical concern for businesses in the UAE, given the country’s hot climate and the presence of industries that deal with flammable materials. Top safety product suppliers offer a range of fire safety equipment, including fire extinguishers, smoke detectors, fire alarms, and fire-resistant clothing. Fire suppression systems, such as sprinklers and gas-based fire extinguishing solutions, are widely used in commercial and industrial buildings to prevent fire-related disasters. Ensuring that workplaces are equipped with reliable fire safety products not only protects employees but also prevents environmental damage caused by uncontrolled fires. Regular fire drills and maintenance of safety equipment further enhance fire preparedness and response.

Industrial Safety Solutions for Hazard Control

Industrial safety is essential for maintaining a secure working environment in sectors such as manufacturing, oil and gas, and chemical processing. Businesses in the UAE rely on specialized safety products such as gas detectors, spill containment systems, lockout/tagout devices, and hazardous material storage solutions to prevent workplace accidents. Gas detectors help identify leaks of harmful substances, ensuring that workers are alerted before exposure occurs. Spill containment systems prevent chemical spills from contaminating the workplace and environment, reducing the risk of health hazards and regulatory violations. Lockout/tagout devices enhance worker safety by preventing accidental machine startups during maintenance. These industrial safety solutions contribute to a safer workplace by minimizing hazards and ensuring compliance with safety protocols.

Emergency Response and First Aid Equipment

Accidents can happen at any time, making it essential for businesses to have emergency response and first aid equipment readily available. First aid kits, eyewash stations, defibrillators, and emergency showers are some of the essential safety products that businesses in the UAE invest in to handle medical emergencies effectively. Well-equipped workplaces ensure that minor injuries can be treated on-site, preventing complications and ensuring quick recovery for affected employees. Emergency response training, combined with the availability of first aid equipment, enhances workplace preparedness and promotes a proactive approach to safety. Having designated emergency exits, safety signage, and trained personnel further strengthens a company’s ability to manage unforeseen incidents.

Safety Signage and Awareness Campaigns

Safety signage plays a crucial role in maintaining a secure work environment by providing clear instructions and warnings about potential hazards. In the UAE, businesses use standardized safety signs to communicate essential safety information to employees and visitors. These signs include warnings for hazardous areas, emergency exit directions, fire extinguisher locations, and reminders for PPE usage. Awareness campaigns and safety training programs complement these efforts by educating employees about workplace risks and the importance of following safety protocols. Regular safety workshops and drills ensure that employees remain informed and prepared to handle emergencies effectively. By integrating safety signage and awareness initiatives, businesses create a culture of safety that prioritizes the well-being of everyone in the workplace.

Sustainability and Eco-Friendly Safety Solutions

Sustainability has become a key focus in workplace safety, with companies in the UAE increasingly adopting eco-friendly safety solutions. Sustainable safety products include biodegradable spill containment materials, energy-efficient fire detection systems, and reusable PPE. Businesses are also exploring environmentally friendly alternatives such as water-based fire extinguishers and recyclable safety gear. The shift towards sustainable safety products aligns with the UAE’s vision for environmental responsibility and green business practices. By investing in eco-friendly safety solutions, businesses can reduce their environmental impact while maintaining high safety standards. Sustainable practices not only protect employees but also contribute to corporate social responsibility efforts and long-term cost savings.

Conclusion

Ensuring workplace safety is a shared responsibility that requires investment in high-quality safety products and proactive safety management. The UAE’s top safety product suppliers provide a comprehensive range of solutions, from PPE and fire safety equipment to industrial hazard control and emergency response tools. By prioritizing safety, businesses protect their workforce, enhance productivity, and comply with local regulations. The integration of advanced technology, safety signage, and sustainability initiatives further strengthens workplace safety measures. A well-equipped and safety-conscious workplace fosters a positive work culture, reduces accident risks, and ensures long-term business success.

0 notes

Text

Shop Premium Valve Lockout Devices for Ultimate Safety in Australia

Protect your workforce and machinery with high-quality valve lockout devices available in Australia. These essential safety tools prevent accidental or unauthorized operation during maintenance, ensuring a safe working environment.

Why Choose Our Valve Lockout Devices?

Durability: Constructed from robust materials to endure harsh industrial conditions.

Versatility: Suitable for various valve types, including gate valves, ball valves, and butterfly valves.

Ease of Use: Simple installation and operation for efficient safety management.

Regulatory Compliance: Adheres to Australian safety standards and regulations.

Key Benefits:

Our premium valve lockout devices can fit various valve sizes. These are made from high visible colors for easy identification in the working area. Check out more benefits:

Enhanced Safety: Mitigates the risk of workplace accidents.

Reliable Protection: Secures machinery during maintenance activities.

Long-Lasting: Built to withstand wear and tear in demanding environments.

Wide Selection: Available in different sizes and configurations to meet your specific needs.

Invest in premium valve lockout devices to ensure the safety of your team and compliance with Australian regulations. Shop now and safeguard your workplace with the best safety solutions available in Australia. Check the product range - https://www.safetylock.net/lockout-tagout-devices/valve-lockouts/

#Valve Lockout Devices#Lockout Tagout#Valve LOTO Devices#Valve Lockouts#Gate Valve Lockout#Ball Valve Lockouts#Lockout Tagout Devices#Lockout Tagout Manufacturer#LOTO Supplier#E-Square Alliance

0 notes

Text

Lockout Tagout - Energy Isolation and Notification of Employee

Section (c) states that the process of Lockout Tagout shall be performed only by the authorized employees who are servicing. This is so because, an authorised employee is especially trained for the particular isolation, which any other employee might not be able to perform efficiently.

Lockout Tagout requires technical understanding, which cannot be done by any unskilled professional. Therefore, an authorised employee is assigned by the supervisor.

Notification of Affected Employees.

Lack of information regarding the status of equipment could endanger the employees who re-energize, operate or work around the machines. Whenever LOTO control might directly affect another employee’s work activities, paragraph (c) (9) requires the employer or authorized employee to notify the affected employees prior to applying, and after removing the Lockout Tagout device.

Such notification informs affected employees of the impending interruption of the normal production operation and reinforces the importance of the restrictions imposed.

After removing a LOTO device, notifying employees, alerts them that the equipment is capable of being started-up. Else, employees might mistakenly believe that a system is safe to continue working around the machine, leading to heinous accidents.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#LockotuTagout#OSHA#EnergyIsolation#EnergyIsolationDevices#Safety#OSHAGuidelines#LOTO#OSHAStandard#SafetyTips#LOTOProgram#OSHARegulations#OSHALockoutTagout#AffectedEmployee#LockoutTagoutDevice#LOTODevices#ESquare

0 notes

Text

Lockout Tagout Kits: Ensuring Workplace Safety in UAE

Introduction

Safety in the workplace is paramount, especially in industries that involve machinery, electrical systems, and hazardous equipment. A Lockout Tagout (LOTO) kit is an essential tool for safeguarding workers from accidental energy release during maintenance and servicing. In the UAE, where industrial safety standards are rigorously upheld, LOTO kits are vital in promoting compliance and preventing workplace accidents.

This blog explores the components, benefits, and applications of Lockout Tagout kits, highlighting their importance in the UAE’s industrial landscape.

What is a Lockout Tagout Kit?

A Lockout Tagout kit is a comprehensive set of devices designed to isolate energy sources and prevent the accidental start-up of equipment during maintenance. These kits include various lockout devices, tags, and tools tailored to meet the specific safety needs of different industries.

Key Components of a Lockout Tagout Kit

Padlocks: Durable safety padlocks to secure lockout devices.

Tags: Clearly labeled tags to warn employees of ongoing maintenance.

Valve Lockouts: Secure valves to prevent energy release.

Electrical Lockouts: Isolate circuit breakers and plugs.

Cable Lockouts: Versatile devices for securing multiple energy points.

Hasps: Allow multiple workers to lock out a single energy source.

Carrying Case: Convenient storage for all tools in the kit.

Importance of Lockout Tagout Kits

Industries in the UAE, including oil and gas, construction, and manufacturing, operate under strict safety regulations. LOTO kits play a crucial role in ensuring compliance with these standards while enhancing worker safety.

Accident Prevention: Mitigates risks associated with unexpected energy releases.

Regulatory Compliance: Helps businesses adhere to UAE workplace safety laws.

Enhanced Productivity: Ensures a safer environment, reducing downtime caused by accidents.

Employee Confidence: Promotes a culture of safety, boosting worker morale.

Applications of Lockout Tagout Kit

LOTO kits are indispensable in various sectors:

Electrical Maintenance: Lockout devices secure circuit breakers, switches, and plugs during repair.

Industrial Machinery: Prevent accidental start-up of heavy equipment.

Pipelines and Valves: Valve lockouts isolate hazardous materials in chemical or oil processing plants.

Construction Sites: Ensure safe maintenance of cranes, elevators, and other machinery.

Features of High-Quality Lockout Tagout Kit

Durable Materials: Resistant to harsh environments and extreme temperatures.

Versatility: Includes a wide range of devices for different energy sources.

Compliance Ready: Meets international and UAE-specific safety standards.

Portability: Compact and easy-to-carry cases for on-the-go usage.

Why Choose a Lockout Tagout Kit for Your Workplace?

Investing in a LOTO kit is not just a regulatory requirement but also a proactive measure for workplace safety. Key benefits include:

Cost Efficiency: Prevents financial losses from accidents and legal fines.

Time-Saving: Streamlines the lockout/tagout process during maintenance.

Customizability: Kits can be tailored to fit the specific needs of your industry.

The Role of LOTO Kits in the UAE’s Safety Standards

The UAE’s commitment to workplace safety is evident in its adherence to international standards such as ISO 45001 and the Occupational Safety and Health Administration (OSHA) guidelines. LOTO kits help businesses comply with these regulations, fostering a safer working environment.

In high-risk industries like oil and gas, where energy isolation is critical, the use of lock out tag out UAE is not just recommended but essential.

How to Choose the Right LOTO Kit

Assess Workplace Needs: Identify the types of energy sources and equipment in use.

Ensure Compliance: Select kits that meet UAE and international safety standards.

Check Durability: Opt for kits with robust materials suitable for your environment.

Consider Portability: Choose a kit that is easy to carry and store.

Conclusion

Lockout Tagout kits are indispensable for ensuring workplace safety and regulatory compliance in the UAE. They protect workers, reduce the risk of accidents, and create a culture of safety that is crucial for any business.

By investing in high-quality LOTO kits, UAE industries can not only safeguard their workforce but also enhance productivity and maintain their reputation for excellence in workplace safety.

#lock out kit#loto kit supplier#scaffolding tag#butterfly valve#abb distributors uae#miniature circuit breaker#emergency stop switch#lockout tagout#padlocks dubai#lockout tagout locks#padlock supplier#uae#dubai#abudhabi#safety tag#mcb uae#lockout station

0 notes

Text

Remember, A proper Lockout/Tagout procedure insures that the machinery cannot be tampered with while in maintenance. If you need to shut down and unplug all electronically devices associated with the tagout, you should! An OSHA workplace is a SAFE workplace.

getting a lot of questions about my shirt that says “I WANT TO HAVE SEX WITH INDUSTRIAL MACHINERY” that are already answered by the shirt

24K notes

·

View notes

Text

Core Topic Covered

Introduction to Electrical Safety:

Importance of electrical safety in engineering and industry.

Statistics and case studies on electrical incidents.

Electrical Hazards:

Shock and electrocution risks.

Arc flash and arc blast hazards.

Fire and explosion risks from electrical faults.

Risk Assessment and Hazard Control:

Identifying electrical hazards in the workplace.

Conducting risk assessments and implementing control measures.

Safety Standards and Regulations:

Overview of key standards, such as:

NFPA 70E (Standard for Electrical Safety in the Workplace).

OSHA Electrical Safety Standards.

IEC and ISO standards for global compliance.

Importance of grounding and bonding.

Electrical System Design Safety:

Designing systems to minimize hazards (e.g., safe circuit design, use of protective devices).

Proper selection of cables, circuit breakers, and insulation materials.

Personal Protective Equipment (PPE):

Importance of PPE in electrical work (e.g., arc-rated clothing, gloves, face shields).

Selection and maintenance of PPE.

Safe Work Practices:

Lockout/Tagout (LOTO) procedures.

Working safely on live circuits and de-energizing equipment.

Proper handling of tools and equipment.

Arc Flash Safety:

Understanding arc flash hazards.

Calculating incident energy and determining safe approach distances.

Emergency Preparedness and First Aid:

Responding to electrical accidents, such as shocks and burns.

Administering CPR and using AEDs (Automated External Defibrillators).

Inspection and Maintenance:

Periodic inspection of electrical systems to prevent faults.

Maintenance best practices to ensure safety and system longevity.

safety course in chennai

safety institute in chennai

safety training institute

nebosh course in chennai

nebosh course in madurai

#safety institute in chennai#nebosh course in madurai#eosh course in chennai#safety course in ambattur#safety institute in madurai#education

0 notes

Text

Health and Safety Protocols During Air Conditioner Installations in Canning Vale

Air conditioner installations in Canning Vale require careful adherence to health and safety protocols to ensure the well-being of both installers and occupants. The process involves handling refrigerants, electrical components, and heavy equipment, making safety a top priority. This article outlines the critical safety measures to follow during air conditioner installations in Canning Vale, ensuring a safe and efficient process.

Handling Refrigerants Safely

Refrigerants play a critical role in air conditioning systems, facilitating the cooling process. However, improper handling can lead to health hazards, environmental damage, and legal issues. It is essential to follow these enhanced safety measures:

Use Personal Protective Equipment (PPE): Installers must wear protective gear such as chemically resistant gloves, safety goggles, and respiratory masks designed for handling refrigerants. This minimises the risk of skin burns, eye irritation, or inhalation of toxic fumes during leaks or accidental exposure.

Prevent Leaks: Leaks not only reduce system efficiency but also pose serious environmental risks, particularly to the ozone layer in systems using older refrigerants. Installers should use high-quality sealing techniques, such as O-rings and flare nuts, and test connections with electronic leak detectors or soapy water. Regular maintenance schedules must also be implemented to identify and rectify leaks promptly.

Storage and Disposal: Proper storage and disposal of refrigerants are vital for environmental compliance. Installers should store refrigerants in pressure-rated, certified containers, ensuring they are secured in upright positions to prevent accidental release. Disposal must comply with Australian regulations, which mandate certified recovery and recycling services to handle refrigerants responsibly. Local Canning Vale guidelines may also include penalties for improper disposal, underscoring the importance of adherence.

Training and Certification: Only qualified technicians with updated certifications should handle refrigerants. Familiarity with Material Safety Data Sheets (MSDS) for each type of refrigerant is essential for understanding its unique properties and risks.

Electrical Safety Measures

Electrical systems are integral to air conditioner installations, but they present significant hazards if not handled properly. Here are additional measures to ensure safety during installations in Canning Vale:

De-energising Equipment: Installers should use lockout/tagout (LOTO) procedures to ensure all power sources are safely disconnected before work begins. This prevents accidental energisation, which can lead to serious injuries. Verify de-energisation using a multimeter or voltage tester before proceeding.

Using Insulated Tools: Electricians should exclusively use tools with insulated handles, rated for the system's voltage. This provides a safeguard against accidental contact with live wires. Tools must also be inspected for damage, such as cracks in insulation, before use.

Compliance with Standards: Adhering to the Australian Wiring Rules (AS/NZS 3000) ensures installations meet strict electrical safety requirements. This includes following guidelines for proper earthing, circuit protection, and cable routing. Regular training helps electricians stay updated on code changes and best practices.

Identifying Potential Hazards: Before beginning installation, assess the site for risks such as moisture, exposed wiring, or inadequate grounding. Addressing these issues proactively reduces the likelihood of electrical incidents.

Use of Residual Current Devices (RCDs): Installers should use RCDs to monitor electrical currents and immediately cut power if imbalances are detected, preventing electric shock or equipment damage.

Emergency Protocols: All team members should be trained to handle electrical emergencies, including providing first aid for electric shock and safely shutting down power in case of an incident.

These comprehensive measures not only protect installers and occupants but also ensure the installation process complies with legal standards and industry best practices, making air conditioner installations in Canning Vale both safe and reliable.

Safe Equipment Handling

Handling heavy machinery and working at heights during air conditioner installations involve inherent risks that must be managed effectively. The following expanded measures further enhance safety:

Use Appropriate Lifting Tools: Installers should use lifting equipment such as hoists, dollies, or forklifts to move heavy units. Where manual lifting is unavoidable, adhere to proper lifting techniques, including bending the knees and keeping the load close to the body. Additionally, assess the weight and dimensions of the equipment beforehand to select suitable tools.

Secure Ladders and Scaffolding: Ensure ladders are positioned on stable, non-slip surfaces and are secured at the top to prevent shifting. Scaffolding must be professionally assembled, equipped with guardrails, and inspected regularly for structural integrity. Installers should always maintain three points of contact when climbing ladders.

Work in Teams: Assigning team members specific roles, such as lifting, stabilising, or guiding equipment, reduces the likelihood of injuries. Effective communication is critical, including the use of standardised hand signals or radios when visibility is limited.

Site Assessment and Preparation: Evaluate the work area for hazards such as uneven terrain, overhead obstacles, or confined spaces. Clear the area of debris to ensure unobstructed movement and safe equipment operation.

Protecting Occupants

Protecting occupants during air conditioner installations ensures their safety and comfort while maintaining a professional environment. These enhanced practices contribute to a safer installation process:

Isolate Work Areas: Use physical barriers such as cones, caution tape, or portable fencing to create a clear boundary around the installation site. Install signage indicating restricted access or potential hazards.

Minimise Disruptions: Coordinate with occupants to schedule installations during less active hours, such as weekdays when residents are often away. Notify them in advance of any noise, dust, or temporary power outages that might occur during the process.

Ventilation During Installation: Open windows or use fans to ensure adequate airflow, especially when handling refrigerants or adhesives that may emit fumes. In enclosed spaces, consider using portable air scrubbers or purifiers to maintain air quality.

Clear Communication: Keep occupants informed about the installation timeline, potential risks, and any necessary precautions they should take, such as avoiding specific areas or keeping children and pets away from the work zone.

Emergency Preparedness

Being well-prepared for emergencies ensures quick and effective responses, minimising risks to both installers and occupants. Expanded measures include:

First Aid Kits: Stock kits with a range of supplies, including bandages, antiseptic wipes, burn cream, and cold packs, to address common installation-related injuries. Designate a trained first-aid officer on-site for immediate assistance.

Fire Safety: Installers should carry portable fire extinguishers appropriate for electrical and chemical fires (Class C or CO2 extinguishers). Conduct regular fire safety drills to ensure the team can respond promptly and effectively in emergencies.

Incident Reporting: Use a structured reporting system to document accidents or near-misses. Reports should include a description of the incident, contributing factors, corrective actions taken, and any follow-up measures. This process helps identify patterns and implement preventive strategies.

Evacuation Plans: Establish clear evacuation procedures for both workers and occupants in case of severe incidents. Ensure all team members and residents know exit routes and assembly points, especially in large or complex buildings.

Emergency Contacts: Maintain an up-to-date list of emergency contacts, including local medical services, fire departments, and regulatory bodies in Canning Vale, ensuring rapid assistance when needed.

These enhanced protocols ensure that air conditioner installations in Canning Vale are conducted safely and efficiently, protecting both the workforce and the community.

Conclusion

Implementing stringent health and safety protocols is essential during air conditioner installations in Canning Vale to protect both professionals and residents. Handling refrigerants with care, adhering to electrical safety standards, and maintaining a secure environment are vital steps in ensuring a seamless and hazard-free installation process. By prioritising safety, installers can deliver reliable services while upholding industry best practices.

https://www.gildanairelectrical.com.au/health-and-safety-protocols-during-air-conditioner-installations-in-canning-vale/

0 notes

Text

What Is Electrical Installation?

Electrical installation Newcastle is a complex process that involves the creation of electric circuits and wiring. It can be done in factories, offices, or homes. Electrical installers install new wires, fixtures, and outlets according to blueprints and codes. They also inspect and repair existing wiring.

It is now a legal requirement for landlords to get their fixed electrical installations tested and certified with an EICR report. This is an essential task for ensuring safety in your property.

Qualifications

A person seeking to become an electrician will need a certain set of qualifications. These include technical knowledge and the ability to solve problems. They must be able to read blueprints and understand electrical circuits and codes. Other requirements include physical stamina and attention to detail. Electricians are responsible for installing, maintaining and repairing electrical systems. They are also required to follow local, state and national electrical safety standards.

The Level 3 NVQ Electrotech Apprenticeship qualification is the most common and recognised route to becoming a fully qualified electrician. It requires a level 2 qualification and the completion of the City and Guilds 18th Edition Course, which is a pre-requisite for those who are not already JIB approved electricians.

The City and Guilds 2393-10 Part P Domestic Electrical Qualification is a popular choice for practising electricians, trainee electricians, and other trade professionals, including handypersons, gas engineers, plumbers, landscapers, kitchen fitters, and builders. This qualification is designed to showcase your comprehension of the latest industry regulations on wiring in dwellings and can improve your career prospects.

Experience

Electrical work requires extensive knowledge of the BS 7671 (IET Wiring Regulations) and Part P of the Building Regulations, which govern electrical safety in homes. It is also important to understand the risks involved in working with electricity and have access to appropriate protective gear, such as insulated gloves and safety goggles.

Experienced electricians can perform routine maintenance tasks and help prevent potential issues before they become a problem. This includes conducting planned maintenance, responding to breakdowns, and testing equipment to ensure compliance with health and safety regulations.

Domestic electrical installation begins with planning the layout of outlets, switches, and lighting fixtures. This involves assessing the size of your property, determining how many outlets are needed, and identifying any special requirements like dedicated circuits for high-usage appliances. You should also consider future needs, such as the addition of smart home technology. Taking the time to plan your wiring system can reduce installation costs and ensure compliance with the code.

Safety

Keeping safety measures in mind is critical when working on electrical projects. It’s important to use proper safety equipment, including hard hats, gloves, and eye protection. It’s also a good idea to keep all non-essential devices off of shared circuits to minimise the risk of overloading. Unplugging unnecessary appliances and switches before leaving a workspace can also help to minimise fire risks.

An ECIR report is essential for residential and commercial properties, as it highlights any potential electrical safety issues. It can help you avoid costly repair bills and ensure that your property is in compliance with electrical safety regulations.

Lockout/tagout procedures are designed to prevent workers from accidentally coming into contact with energised equipment while servicing or repairing it. These procedures involve locking or tagging out equipment that’s being serviced or repaired to prevent it from accidentally being re-energised while it’s unattended. They’re essential to preventing accidents, injuries, and downtime. Having an experienced electrician by your side can help you implement these procedures effectively and safely.

Cost

Electrical wiring is a complex and potentially dangerous task that should be left to professional electricians. Although DIYers may be tempted to save money by doing the work themselves, this could cost more in the long run due to mistakes and repairs. A qualified electrician will provide a comprehensive quote itemizing all expenses, which can help homeowners to understand what they are getting for their money.

The price of a residential electrical installation is dependent on a variety of factors, including location and energy efficiency upgrades. For example, installing a smart home system requires specialised equipment and labour. However, the increased convenience and energy savings offered by these upgrades make them worth the upfront investment.

Regional differences also impact costs, as some areas may require additional permits and inspections. In addition, urban regions typically see higher prices, owing to higher demand for electricians and the higher cost of materials. This can lead to significant price variations, and homeowners should always obtain a comprehensive quote before committing to a project.

0 notes

Text

What to Look For in a Dallas CNC Machine Shop

What to Look For in a Dallas CNC Machine Shop

Whether you’re looking for a precision-machined component for your car or a tool for construction, a Dallas CNC machine shop can help. Bates Machine & Mfg. in Farmersville, Texas can produce parts that meet your specifications and provide high quality products at a competitive price.

Precision-machined components

CNC machining is an integral part of the manufacturing process. It allows for greater flexibility and customization, allowing manufacturers

to respond to consumer demand and market changes quickly. This is especially important in the competitive manufacturing sector, where it can be challenging to compete with low prices and fast delivery times. Precision CNC machining is a critical component in many industries, from aerospace to the automotive industry. The technology is essential in fabricating high-quality, dependable components that can withstand harsh environments and rigorous use. It also plays a vital role in the medical industry, where it helps produce precise instruments and devices for surgery and diagnostics. Dedicated machinists enjoy good, dependable wages, and health insurance and vacation time are available to them. Moreover, they can choose their own work hours. This allows them to balance their family life with a career that they love. They can also choose to change careers if they want to.

Quality control inspections

A CNC machining company should follow strict quality control inspections throughout the product lifecycle. This includes the ideation phase, design phase, feasibility study, analysis phase, pilot production, testing, and bulk production phases. This helps to reduce production errors and ensure that the final product meets customer requirements. Inspections are conducted in-process using programmed probes. These help to verify key features and tolerances during the machining process, while also providing real-time feedback. They also allow the QC team to monitor the progress of the work and make necessary adjustments as needed. A good machine shop will address quality issues as soon as they arise. This will involve implementing practical corrective actions, such as adjusting machine settings or retraining employees. It should also invest in regular maintenance and calibration to prevent avoidable errors. In addition, it should rely on reputable suppliers and conduct batch tests to ensure that raw materials are consistent. They should also document the results of each inspection and test to demonstrate that they meet industry standards.

Safety measures

Many machine shop employees need to wear protective eyewear due to the use of small particles or chips that could damage their eyesight. The use of compressed air can also send these particles flying through the air and may cause damage to the eyes. Using safety glasses is an easy way to prevent eye injuries and keep workers safe. A crushing injury can occur when someone becomes caught between two moving parts of a machine or heavy machinery falls on them. These injuries are extremely dangerous and require immediate medical attention. Keeping machines clean, following lockout/tagout protocols, and providing training on how to operate machinery are some of the ways to prevent these types of injuries. Localized special hazard fire suppression systems are one of the most effective tools manufacturers can employ to protect CNC machines and other expensive equipment in their facilities. These systems are designed to monitor, control, and extinguish CNC equipment fires before they spread, ensuring compliance with regulatory requirements and minimizing costly downtime for the facility.

Experience

The right metal fabrication and cnc machine shop will be able to handle your project from start to finish. They will also be able to provide quality work and excellent customer service. In addition, they will have a strong understanding of all aspects of machining processes and CAD/CAM software. They will be able to implement best practices and technologies to improve productivity and enhance product quality. A reputable Dallas CNC machine shop like Bates Machine & Mfg. will follow strict quality control inspections throughout the manufacturing process to ensure that their products meet the client’s specifications. They also make sure that their equipment is up-to-date. In addition, they will maintain a high level of professionalism and confidentiality by signing a non-disclosure agreement with their clients. Another advantage of working with a CNC machine shop is its ability to produce high-quality parts at an affordable price. This means you can save money on labor and production costs, while still achieving the same results as you would with a traditional machining method. Read the full article

0 notes