#Sewage Treatment Plant Manufacturers in India

Explore tagged Tumblr posts

Text

Advanced Solutions For Water Treatment Plant Manufacturers in India

Water Treatment Plant Manufacturers in India incorporate cutting-edge technology and innovative processes to purify water and meet stringent quality standards. With this project, we have contributed to improving public health and ensuring a sustainable future for communities across India.

#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment

2 notes

·

View notes

Text

Why is pH Control Important in STP & ETP Plants?

In water treatment, it is crucial to ensure the proper functioning of sewage treatment plants (STP) and effluent treatment plants (ETP). One of the fundamental parameters that significantly impacts the performance and efficiency of these systems is the pH level of the water being treated. The pH impacts the chemical and physical properties of water, hence influencing the behaviour of contaminants, development of microbes and the wastewater treatment processes. So why is pH control important in STP & ETP plants? Read on!

Understanding pH Control in STP & ETP Plants

The meaning of pH stands for the potential of hydrogen ions in water. pH of water is a measurement of its acidity or alkalinity defined on the logarithmic scale ranging from 0 to 14. A pH of 7 is considered neutral, while a pH of below 7 implies acidity and values above 7 indicates alkalinity. Fluctuations in pH are normal, but they should stay between 6.3 to 7.6. Variations in pH values of effluents can impact the rate of biological reactions and the survival of various microorganisms. For instance, a pH that is too high or too low can disrupt the metabolic processes of these microorganisms, affecting their ability to break down organic matter. In some cases turning down the pH of the effluent is required for complex effluents to break the long chain compounds. This is why pH control in STP and ETP plants is critical.

Importance of pH Control in STP & ETP Plants

Effective Wastewater Treatment: Maintaining adequate pH levels is crucial for effective biological and chemical processes in wastewater treatment. Improper pH levels can impact the performance of these processes, resulting in poor removal of contaminants and odours and increased operational costs.

Regulatory Compliance: Environmental regulations have stringent standards set for effluent disposal. Failure to comply can lead to heavy penalties and legal proceedings. This is where ETP plant manufacturers in India play a crucial role, helping companies achieve and maintain compliance with regulations and standards.

Odour Control: Odour is a common issue in sewage treatment plants. Wastewater with improper pH levels can trigger the production of odorous gases like hydrogen sulfide. However, controlling the pH level can significantly reduce the production of these gases, creating a better workplace for STP plant operators and improving the quality of surrounding habitats.

Corrosion Prevention: The pH level of wastewater leads to corrosion of pipes, pumps and wastewater treatment plant equipment. This can add to maintenance and replacement costs along with the risk of contamination when corroded substances enter the WTTP system.

Sludge Management: When speaking of STP and ETP plants, sludge generation and treatment are of concern. Proper pH control can affect the properties of sludge, making it convenient to dewater, manage and dispose of. Sludge that is highly acidic or alkaline may need additional treatment processes. Maintaining the correct pH value allows for better sludge management.

Wrapping Up

pH control is essential for STP and ETP plants. It ensures operational consistency, optimizes treatments, protects the aquatic environment and eases sludge management. The inability to control pH can lead to operational shortcomings, ecological impact and WWTP performance. For businesses looking to optimize their ETP and STP plants, Ravi Enviro Industries Private Limited offers a comprehensive range of services. As one of the top effluent and sewage treatment plant manufacturers in India, we provide tailored solutions to ensure efficient pH control, compliance with regulations, and sustainability. To upgrade your existing water treatment facility, call us today.

Check out:- Common Effluent Treatment Plant Advantages

#Why is pH Control Important in STP & ETP Plants#sewage treatment plant manufacturers in India#wastewater treatment plant equipment#ETP plant manufacturers in India#Importance of pH Control in STP & ETP Plants

0 notes

Text

#sewage treatment plant manufacturer#sewage treatment plant manufacturers in india#stp plant manufacturer#sewage treatment plant manufacturer in delhi#best sewage treatment plant manufacturer

0 notes

Text

Want to know about Environmental Advantages Of Sewage Treatment Plant?

Do you want to know What is a Sewage Treatment Plant? in this blog we gives you all information you need to know like sewage treatment plant benefits, sewage treatment plant manufacturers in India, An advantages of sewage treatment plants. To learn more STP plants, visit the blog now!

#environmental advantages of sewage treatment plant#sewage treatment plant benefits#sewage treatment plant manufacturers in India#sewage treatment plant advantages#Advantages of Sewage Treatment Plant#advantages of sewage treatment plants#advantages of STP#Sewage Treatment Plant#STP plants#What is a Sewage Treatment Plant

0 notes

Text

Sewage Treatment Plant Manufacturer in India – ZETA4

As water scarcity and pollution continue to grow in India, effective wastewater management has become a crucial need. Industries, residential societies, and commercial complexes are now required to install sustainable solutions to treat and recycle sewage water. If you are looking for a trusted and innovative Sewage Treatment Plant Manufacturer in India, ZETA4 is your ideal partner.

With years of expertise, cutting-edge technology, and a commitment to environmental stewardship, ZETA4 stands out as one of the leading providers of sewage treatment solutions across the country.

Why Choose ZETA4 as Your Sewage Treatment Partner?

ZETA4 is a trusted name in India for designing, manufacturing, and installing customized sewage treatment plants (STPs) that meet the specific needs of clients from various sectors. Whether it’s a small residential community or a large-scale industrial operation, ZETA4 delivers performance-driven systems that comply with all regulatory standards and help conserve natural resources.

Key Features of ZETA4 STPs:

Advanced treatment technologies (MBBR, SBR, MBR, FAB, and more)

Compact, modular & containerized systems

Energy-efficient design

Eco-friendly operations with low sludge generation

Real-time monitoring with IoT-based automation

Compliant with CPCB, NGT, and local state regulations

Our Sewage Treatment Solutions

ZETA4 offers end-to-end sewage treatment plant solutions that cover everything from planning and design to commissioning and after-sales service.

1. Design & Engineering

Our expert team conducts detailed site inspections and feasibility studies to offer the best possible design based on your space, usage, and budget. Every plant is custom-built to suit your wastewater characteristics and volume.

2. Manufacturing

We use high-grade materials and the latest technology to manufacture durable, efficient, and low-maintenance sewage treatment plants. ZETA4's in-house manufacturing facilities ensure complete quality control.

3. Installation & Commissioning

From excavation and foundation work to pipeline connections and electrical setup, our technicians manage the entire STP installation process. We also provide test runs to ensure that the plant functions flawlessly before handover.

4. Operation & Maintenance (O&M)

Our services do not end at installation. We offer O&M contracts and AMC (Annual Maintenance Contracts) to ensure that your system continues to function efficiently and remains compliant with environmental standards.

Types of Sewage Treatment Technologies We Offer

✅ MBBR (Moving Bed Biofilm Reactor)

Ideal for residential and commercial buildings, MBBR systems are compact, easy to operate, and energy-efficient.

✅ SBR (Sequential Batch Reactor)

Great for high-volume operations, SBR technology provides batch-wise treatment with high removal efficiency for BOD, COD, RO and TSS.

✅ MBR (Membrane Bio-Reactor)

MBR combines membrane filtration with biological treatment, delivering ultra-pure treated water, ideal for water reuse.

✅ FAB (Fluidized Aerobic Bio-Reactor)

Low in operating costs and suitable for hotels, resorts, and apartment complexes.

Industries We Serve

ZETA4 has successfully delivered STP solutions to a wide range of clients across India:

🏙️ Residential Societies & Apartments

🏥 Hospitals & Healthcare Centers

🏢 Hotels & Hospitality

🏭 Food & Beverage Industries

🏫 Schools & Educational Institutions

🛍️ Shopping Malls & Commercial Complexes

🛠️ Manufacturing & Industrial Facilities

No matter your sector or scale, we tailor our solutions to fit your environmental goals and budget.

Why STPs are a Necessity Today

In India, untreated sewage is one of the largest sources of water pollution. Municipal sewage entering rivers, lakes, ESP and groundwater is a serious concern. As regulations tighten and awareness grows, installing an STP is no longer optional—it’s a legal and environmental requirement.

Here’s why every establishment needs a sewage treatment system:

🌍 Protects the environment from harmful contaminants

💧 Enables water recycling and reduces dependency on freshwater

🧾 Fulfills legal compliance with pollution control boards

🏗️ Adds value to properties and supports green building certifications

💸 Lowers water bills through water reuse for flushing, gardening, and cooling

Pan India Presence and Support

Whether your project is located in Delhi NCR, Punjab, Maharashtra, Karnataka, Tamil Nadu, or Gujarat, ZETA4 has the capacity to deliver and support STP installations nationwide.

Our network of project engineers and service technicians ensures:

Timely delivery and setup

Fast response to service requests

Efficient after-sales support

Expert consultancy for environmental audits and clearances

Testimonials

“We installed a 100 KLD STP from ZETA4 in our residential complex in Noida. The system works flawlessly and the treated water is reused for landscaping. Their team is knowledgeable and responsive.”

“ZETA4 helped us upgrade our existing STP with MBBR technology. Our water quality improved and operational costs went down. Highly recommend their services.”

1 note

·

View note

Text

A Guide To Help You Find The Best Sewage Treatment Plant Vendors in India

Plizma Technology is one of the top sewage treatment plant vendors, providing reliable, eco-friendly, and economical wastewater solutions that meet your requirements.

Know More:- https://india.indexing.co.in/3195fd

0 notes

Text

Sewage Water Treatment Plant in India | Ariseo Water Tech

Ariseo Water Tech is a leading manufacturer of sewage water treatment plants in India, offering advanced solutions like MBBR, MBR, SBR, and ASP technologies for efficient wastewater management across industrial and municipal sectors.

https://www.ariseowater.com/sewagetreatment.html

#Sewage Water Treatment Plant in India#Sewage Treatment Plant Manufacturers#Wastewater Treatment Solutions India#Effluent and Sewage Treatment India#Sewage Recycling Solutions India

0 notes

Text

Effective Wastewater Treatment Plant Odour Control: Why Bioscrubbers are the Future

Managing odours from wastewater treatment plants is not just about improving air quality—it's about ensuring community well-being, regulatory compliance, and the smooth functioning of treatment processes. As urban areas expand and industrial activities grow, the demand for advanced odour control solutions has never been higher. One of the most effective technologies today is the bioscrubber—a sustainable, eco-friendly system that neutralizes harmful gases. If you're seeking cutting-edge solutions in this space, leading Bioscrubber Manufacturers in India like Aqoza are setting benchmarks in performance and innovation.

The Challenge of Wastewater Treatment Plant Odour Control

Wastewater treatment processes generate foul-smelling gases such as hydrogen sulfide (H₂S), ammonia (NH₃), and volatile organic compounds (VOCs). These odours, often pungent and hazardous, can negatively impact nearby communities and the environment. Proper wastewater treatment plant odour control is crucial to prevent complaints, health issues, and non-compliance with environmental standards.

Traditional odour control systems—such as chemical scrubbers or activated carbon filters—often come with high operational costs and environmental concerns. This has led to a significant shift towards biological solutions like bioscrubbers, which offer a cleaner and more cost-effective alternative.

Why Bioscrubbers?

A bioscrubber is a biological air treatment device that uses microorganisms to break down and neutralize odorous compounds. Contaminated air is passed through a scrubbing liquid where pollutants dissolve and are then biologically degraded in a separate bioreactor. The result? Clean, odour-free air with minimal environmental impact.

Key benefits of bioscrubbers include:

High efficiency in removing H₂S, NH₃, and VOCs

Low operational costs with minimal chemical use

Environmentally sustainable, leveraging natural microbial processes

Longer system life and lower maintenance compared to chemical alternatives

These advantages make bioscrubbers a preferred choice for industries seeking reliable and sustainable odour control solutions.

Leading the Way: Aqoza – One of the Top Bioscrubber Manufacturers in India

When it comes to reliable and innovative odour control, Aqoza stands out among the top bioscrubber manufacturers in India. With a commitment to sustainability, Aqoza designs and installs customized bioscrubber systems tailored to specific industrial requirements—be it municipal sewage treatment plants, food processing industries, or chemical manufacturing units.

Aqoza's solutions are designed with efficiency, durability, and environmental compliance in mind. The company's bioscrubbers are not only effective in odour neutralization but also built to handle fluctuating gas loads and tough Indian environmental conditions.

Final Thoughts

The importance of effective Wastewater Treatment Plant Odour Control cannot be overstated. With growing environmental awareness and stricter regulations, industries need sustainable, long-term solutions. Bioscrubbers, offered by trusted names like Aqoza, are proving to be the gold standard in odour management.

If your facility is grappling with odour issues, it’s time to explore advanced bioscrubber technology. Visit Aqoza to learn more and take the first step toward cleaner air and a greener future.

#Wastewater Treatment Plant Odour Control#Bioscrubber Manufacturers in India#how to remove smell from sewage treatment plant#odour control in wastewater treatment

0 notes

Text

Media Filtration System in India | ARISEO WATER TECH

ARISEO WATER TECH offers high-quality media filtration systems in India, ensuring removal of impurities and providing clean water for various industrial and municipal applications, with reliable and efficient performance.

https://www.ariseowater.com/mediafilteration.html

#Media Filtration System in India#Sewage Water Treatment Plant in India#Water Pre-Treatment Plant Manufacturers in India

0 notes

Text

Global Enviro is a leading manufacturer and supplier of Sewage Treatment Plant ,SewageTreatment Plant equipments in Pune and India. We also provide maintenance services for Sewage treatment plants.

#Sewage Treatment Plant#Sewage Treatment Plant manufacturer in pune#Sewage Treatment Plant manufacturer in india#Sewage Treatment Plant manufacturer in Maharashtra#Sewage Treatment Plant suppliers in india#Sewage Treatment Plant suppliers in Maharashtra#Sewage Treatment Plant suppliers in pune#Sewage Treatment Plant maintenance services#Sewage Treatment Plant equipment in Pune#Sewage Treatment Plant equipment supplier in Pune

0 notes

Text

Are You Looking For The Best Sewage Treatment Plant Manufacturer In India ?

Water scarcity forces organizations worldwide to implement effective wastewater solutions. Netsol Water uplifts the sewage treatment plant manufacturing sector by introducing innovative technologies that give wastewater new purpose. Our treatment plants enhance operations for industries throughout India and international markets. Our sewage treatment plants help businesses meet environmental standards while conserving water resources. Continuous research allows us to perfect treatment methods that consistently exceed performance targets. Organizations achieve their environmental objectives by choosing our proven wastewater management solutions. In this blog, we’ll discuss Sewage Treatment Plant Manufacturer.

Sewage Treatment Technology and Processes

Modern environmental needs shape the advancement of sewage treatment technologies. A sewage treatment plant stands as the key to transforming contaminated water into environmentally acceptable water. Let us explore the essential components and processes that define our sewage treatment plants:

Primary Treatment Stage

Our screening systems attack large waste materials as water enters the treatment process. Specially engineered grit chambers eliminate sand and related materials instantly. This foundational stage protects equipment and enhances treatment outcomes.

2. Secondary Biological Treatment

Carefully selected bacteria perform the crucial task of organic material decomposition. Our aeration systems maintain perfect bacterial growth conditions around the clock. These tiny organisms convert pollutants into solids that settle quickly from the treated water.

3. Advanced Filtration Systems

Our filtration technology employs multiple layers to catch the finest suspended materials. The combination of engineered sand media and activated carbon creates unmatched filtration power. Water emerges crystal clear and exceeds quality measurements consistently.

4. Disinfection Process

Our UV technology eliminates harmful organisms without adding chemicals to the water. This modern approach guarantees water safety and purity. Every drop meets stringent quality standards before release.

Applications and Benefits Across Industries

Modern sewage treatment plant protect environments and preserve resources for future generations. Each industry receives customized solutions that match specific operational needs.

Let us have a look at how our plants enhance different industrial sectors:

Residential Complexes

Housing communities maximize water efficiency through our innovative treatment solutions. Treated water supports landscaping and maintenance activities year-round. Property owners watch their water expenses decrease while maintenance becomes simpler.

2. Industrial Sector

Our plants transform wastewater management for manufacturing operations worldwide. Companies reintegrate treated water into their processes while meeting environmental guidelines. This creates sustainable water cycles that benefit both industry and environment.

3. Commercial Buildings

Shopping centers and office buildings optimize space through our efficient designs. The systems adjust automatically to changing water demands throughout each day. Building operators maintain consistent service even during high-demand periods.

4. Healthcare Facilities

Medical centers overcome complex wastewater challenges through specialized treatment solutions. Enhanced safety protocols ensure proper handling of sensitive biological materials. Each system maintains strict healthcare regulations while protecting community health.

Quality Standards and Service Excellence

Selecting the right sewage treatment plant manufacturer impacts operations for decades. Excellence flows through every aspect of our organizational approach.

Let us have a look at the elements that distinguish Netsol Water:

a. Advanced Manufacturing Capabilities

Our manufacturing center integrates advanced technologies with precise automated systems. This combination ensures product excellence and punctual project completion. Quality measures guide every production step from start to finish.

b. Comprehensive Quality Standards

International quality protocols direct our manufacturing activities. Testing procedures validate each component before system integration begins. This methodical approach creates systems that perform perfectly year after year.

c. Technical Support Services

Expert teams oversee installation and startup procedures for each project. Comprehensive operator training ensures smooth daily operations. Our support services maximize system performance throughout operational life.

d. Industry Experience

Projects across diverse sectors have built our technical expertise. Team members understand the unique demands of each industry segment. This knowledge enables us to deliver solutions that exceed operational expectations.

e. Design Flexibility

Each system adapts perfectly to specific site conditions and operational requirements. Future expansion becomes simple through our modular design approach. Organizations grow confidently knowing their systems will scale with them.

Conclusion

Netsol Water shapes the future of wastewater treatment as a leading sewage treatment plant manufacturer. We pursue technological advancement to create increasingly sustainable solutions. Organizations seeking to modernize their wastewater management should contact us today. Our engineering teams will create plants that match your exact specifications.

Reach out to our technical experts to learn how our sewage treatment plants and services can transform your operations. We look forward to helping you achieve your environmental and sustainability goals.

To explore customised commercial RO plants, Industrial RO plants, ETP or STP solutions for your needs in your areas and nearby regions, Contact Netsol Water at:

Phone: +91-965-060-8473 Email: [email protected]

#sewage treatment plant#sewage treatment plant manufacturer#sewage treatment plant manufacturer in india#water is life#water treatment plant

0 notes

Text

Exploring the World of Electromechanical Systems: A Fusion of Electronics and Mechanics

Introduction:

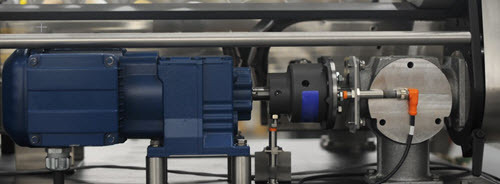

In the realm of facility management, the effective operation and maintenance of electromechanical systems play a vital role in ensuring the smooth functioning of buildings and infrastructure. The fusion of electronics and mechanics has given rise to sophisticated systems that require skilled professionals to handle their operations and maintenance.

Electromechanical systems are a fascinating field that combines the principles of electronics and mechanics. These systems involve the integration of electrical components and mechanical structures to create devices capable of performing a wide range of tasks. From simple household appliances to complex industrial machinery, electromechanical systems are an integral part of our daily lives.

Understanding Electromechanical Systems:

Electromechanical systems are integral to the functioning of modern facilities. These systems combine electrical and mechanical components, utilizing electronic controls to enhance efficiency and automation. Examples include HVAC (Heating, Ventilation, and Air Conditioning) systems, elevators, escalators, fire protection systems, security systems, and energy management systems.

Workforce Requirements:

To ensure the optimal performance of electromechanical systems, facility management teams require a diverse range of professionals with specialized skill sets. Key roles may include:

a. Engineers: Electrical and mechanical engineers are crucial for system design, installation, and troubleshooting. They possess the technical knowledge to handle complex electromechanical systems.

b. Technicians: Skilled technicians play a vital role in maintaining, inspecting, and repairing electromechanical systems. They are responsible for regular maintenance, diagnosing issues, and performing necessary repairs or replacements.

c. Operators: Operators are responsible for monitoring and controlling electromechanical systems, ensuring their proper functioning and responding to alarms or emergencies.

d. Facility Managers: These professionals oversee the operations and maintenance of electromechanical systems, ensuring compliance with regulations, managing budgets, and coordinating the work of the entire facility management team.

Recruitment Strategies:

To build a competent team for operations and maintenance in facility management, consider the following recruitment strategies:

a. Job Portals: Utilize online job portals that cater to the facility management industry to reach potential candidates with the desired skill sets.

b. Industry Networks: Engage with industry-specific networks, associations, and professional forums to connect with qualified professionals in the field of electromechanical systems.

c. Collaboration with Technical Institutes: Partner with technical institutes and vocational schools to tap into fresh talent. Establish internship programs or participate in job fairs to attract entry-level candidates.

d. Skill Assessment: Conduct thorough skill assessments during the recruitment process to evaluate candidates' proficiency in handling electromechanical systems and their related components.

Training and Professional Development:

Given the complexity and evolving nature of electromechanical systems, investing in training and professional development is crucial. Provide regular training sessions to enhance the skills of your workforce, keeping them up-to-date with the latest technologies and maintenance practices. Encourage employees to attend industry conferences, workshops, and certifications to expand their knowledge base.

Safety and Compliance:

Operations and Maintenance in Facility Management must prioritize safety and compliance. Ensure that all staff members are well-versed in safety protocols, including electrical safety, lockout/tagout procedures, and handling hazardous materials. Familiarize your team with relevant regulations and standards, such as building codes, fire safety regulations, and environmental guidelines.

Team Collaboration and Communication:

Effective collaboration and communication within the facility management team are vital for seamless operations and maintenance. Foster a culture of teamwork, encourage knowledge sharing, and promote open lines of communication between different departments and roles. This collaborative approach can lead to efficient problem-solving and improved system performance.

Conclusion:

Electromechanical systems form the backbone of facility management, and staffing considerations for operations and maintenance are crucial to ensure their reliable and efficient functioning. By understanding the workforce requirements, implementing effective recruitment strategies, prioritizing training and professional development.

#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment#Best Electromechanical Systems#Integrated Electronics and Mechanics

2 notes

·

View notes

Text

How Sewage Treatment Plants (STP) Can Protect India’s Rivers and Water Bodies

India's rivers and freshwater bodies are in a major crisis due to a large volume of untreated industrial sewage wastewater. Untreated sewage water comprises toxic chemicals, heavy metals, oils, grease, and other pollutants. A large amount of untreated industrial wastewater is disposed of into the waterbodies, damaging the water quality and causing health and environmental hazards.

Reasons for Rising India’s Rivers and Water Bodies Pollution

Lack of Sewage Treatment Plants: One of the main reasons for water pollution is the lack of STP plants. Many urban and rural areas lack proper STP plants, resulting in dumping sewage water into water bodies.

Outdated STP Plants: Many business facilities use obsolete sewage treatment plants, leading to inefficiency and high-energy consumption systems.

Unregulated Industrial Wastewater Discharge: Many industries contribute to India's rivers and waterbodies pollution by releasing partially or untreated water into freshwater sources.

How Sewage Treatment Plants (STP) Can Protect India’s Rivers and Water Bodies

India is in dire need of more highly efficient STP plants to combat the water pollution and environmental challenges associated with industrial sewage. Ravi Enviro Industries Private Limited, a renowned & trusted STP plant manufacturers in India, is stepping up to the challenge, offering modular-compact & energy-efficient sewage treatment plants. We are committed to helping businesses comply with environmental regulations while safeguarding precious water resources.

Embrace High-performance STP Plants from REIPL

Our compact and modular STP plants are suitable for commercial and industrial applications. They can effectively treat high levels of chemical oxygen demand (CODs) and biochemical oxygen demand (BODs) with minimal energy consumption.

Advanced Technology-Backed Systems

The latest STP plants are powered by advanced technology like MBBR (Moving Bed Biofilm Reactor) for better efficiency. The SBR (Sequential Batch Reactor) improves sludge management, making the industrial sewage treatment process more effective & efficient.

Stringent Compliance with Regulation

Strict compliance with industrial wastewater regulations requires industries to adequately treat wastewater before discharging it in municipal STPs. Zero liquid discharge (ZLD) plants ensure proper water treatment.

REIPL Pioneering Efficient Sewage Treatment Plants

The growing challenges associated with the pollution of rivers and water bodies require advanced STP plants, stringent wastewater disposal regulations, and public awareness. REIPL offers an efficient, eco-friendly, and innovative solution to combat water pollution & promote sustainability. Invest in an STP plant for a clean and greener planet.

Also Check:- Sophisticated Sewage Treatment Plants: Transforming Wastewater Treatment

#stp plant manufacturers in india#Modern Sewage Treatment Plants#domestic stp plant manufacturers in india

0 notes

Text

#sewage treatment plant manufacturer#stp plant manufacturer#sewage treatment plant manufacturers in india#best sewage treatment plant manufacturer#sewage treatment plant manufacturer in delhi#etp stp plant manufacturers in delhi

0 notes

Text

Looking for Sewage Treatment Plant Manufacturers in India?

Ravi Enviro Pvt.Ltd has got you covered! Our MBBR/FBBR-backed STP plants display less carbon footprint and emission. We serve diverse industries across the globe like petrochemical, pharmaceutical, textiles and agro-product industries. As leading STP plant manufacturers in India, our plants are renowned for high reliability and performance at best prices. Contact us today for more information.

#stp plant manufacturers in india#stp manufacturers in india#domestic stp plant manufacturers in india#sewage treatment plant manufacturers in india#sewage treatment plant suppliers in india

0 notes

Text

3D Aqua specializes in designing, manufacturing, installing, and maintaining advanced MBR & MBBR STP & ETP plants for industrial, commercial, and residential projects. With our expertise in wastewater treatment solutions, we offer custom designs, consultancy, and comprehensive after-sale services including AMC for plants ranging from 1 KLD to 2 MLD. Based in Noida, Uttar Pradesh, we are committed to delivering sustainable, efficient, and high-performance water treatment systems. Contact us today! #3DAqua #MBRSTP #MBBRETP #WaterTreatment #EffluentTreatment #SewageTreatment #WaterSolutions #WastewaterTreatment #NoidaWaterTreatment #STPDesign #ETPInstallation #WaterConsultancy #AMCServices #IndustrialWaterTreatment #SustainableWaterTreatment #CleanWater #WaterTreatmentIndia #WaterTech #WaterInnovation #EfficientWaterSystems #GreenWaterSolutions

#water treatment#wastewater management#stp plant manufacturer#india stp supplier#sewage treatment#sewage treatment plant supplier#sewage treatment plant#3d aqua

0 notes