#sewage treatment plant manufacturers in India

Explore tagged Tumblr posts

Text

Advanced Solutions For Water Treatment Plant Manufacturers in India

Water Treatment Plant Manufacturers in India incorporate cutting-edge technology and innovative processes to purify water and meet stringent quality standards. With this project, we have contributed to improving public health and ensuring a sustainable future for communities across India.

#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment

2 notes

·

View notes

Text

Why is pH Control Important in STP & ETP Plants?

In water treatment, it is crucial to ensure the proper functioning of sewage treatment plants (STP) and effluent treatment plants (ETP). One of the fundamental parameters that significantly impacts the performance and efficiency of these systems is the pH level of the water being treated. The pH impacts the chemical and physical properties of water, hence influencing the behaviour of contaminants, development of microbes and the wastewater treatment processes. So why is pH control important in STP & ETP plants? Read on!

Understanding pH Control in STP & ETP Plants

The meaning of pH stands for the potential of hydrogen ions in water. pH of water is a measurement of its acidity or alkalinity defined on the logarithmic scale ranging from 0 to 14. A pH of 7 is considered neutral, while a pH of below 7 implies acidity and values above 7 indicates alkalinity. Fluctuations in pH are normal, but they should stay between 6.3 to 7.6. Variations in pH values of effluents can impact the rate of biological reactions and the survival of various microorganisms. For instance, a pH that is too high or too low can disrupt the metabolic processes of these microorganisms, affecting their ability to break down organic matter. In some cases turning down the pH of the effluent is required for complex effluents to break the long chain compounds. This is why pH control in STP and ETP plants is critical.

Importance of pH Control in STP & ETP Plants

Effective Wastewater Treatment: Maintaining adequate pH levels is crucial for effective biological and chemical processes in wastewater treatment. Improper pH levels can impact the performance of these processes, resulting in poor removal of contaminants and odours and increased operational costs.

Regulatory Compliance: Environmental regulations have stringent standards set for effluent disposal. Failure to comply can lead to heavy penalties and legal proceedings. This is where ETP plant manufacturers in India play a crucial role, helping companies achieve and maintain compliance with regulations and standards.

Odour Control: Odour is a common issue in sewage treatment plants. Wastewater with improper pH levels can trigger the production of odorous gases like hydrogen sulfide. However, controlling the pH level can significantly reduce the production of these gases, creating a better workplace for STP plant operators and improving the quality of surrounding habitats.

Corrosion Prevention: The pH level of wastewater leads to corrosion of pipes, pumps and wastewater treatment plant equipment. This can add to maintenance and replacement costs along with the risk of contamination when corroded substances enter the WTTP system.

Sludge Management: When speaking of STP and ETP plants, sludge generation and treatment are of concern. Proper pH control can affect the properties of sludge, making it convenient to dewater, manage and dispose of. Sludge that is highly acidic or alkaline may need additional treatment processes. Maintaining the correct pH value allows for better sludge management.

Wrapping Up

pH control is essential for STP and ETP plants. It ensures operational consistency, optimizes treatments, protects the aquatic environment and eases sludge management. The inability to control pH can lead to operational shortcomings, ecological impact and WWTP performance. For businesses looking to optimize their ETP and STP plants, Ravi Enviro Industries Private Limited offers a comprehensive range of services. As one of the top effluent and sewage treatment plant manufacturers in India, we provide tailored solutions to ensure efficient pH control, compliance with regulations, and sustainability. To upgrade your existing water treatment facility, call us today.

Check out:- Common Effluent Treatment Plant Advantages

#Why is pH Control Important in STP & ETP Plants#sewage treatment plant manufacturers in India#wastewater treatment plant equipment#ETP plant manufacturers in India#Importance of pH Control in STP & ETP Plants

0 notes

Text

#sewage treatment plant manufacturer#sewage treatment plant manufacturers in india#stp plant manufacturer#sewage treatment plant manufacturer in delhi#best sewage treatment plant manufacturer

0 notes

Text

Want to know about Environmental Advantages Of Sewage Treatment Plant?

Do you want to know What is a Sewage Treatment Plant? in this blog we gives you all information you need to know like sewage treatment plant benefits, sewage treatment plant manufacturers in India, An advantages of sewage treatment plants. To learn more STP plants, visit the blog now!

#environmental advantages of sewage treatment plant#sewage treatment plant benefits#sewage treatment plant manufacturers in India#sewage treatment plant advantages#Advantages of Sewage Treatment Plant#advantages of sewage treatment plants#advantages of STP#Sewage Treatment Plant#STP plants#What is a Sewage Treatment Plant

0 notes

Text

3D Aqua specializes in designing, manufacturing, installing, and maintaining advanced MBR & MBBR STP & ETP plants for industrial, commercial, and residential projects. With our expertise in wastewater treatment solutions, we offer custom designs, consultancy, and comprehensive after-sale services including AMC for plants ranging from 1 KLD to 2 MLD. Based in Noida, Uttar Pradesh, we are committed to delivering sustainable, efficient, and high-performance water treatment systems. Contact us today! #3DAqua #MBRSTP #MBBRETP #WaterTreatment #EffluentTreatment #SewageTreatment #WaterSolutions #WastewaterTreatment #NoidaWaterTreatment #STPDesign #ETPInstallation #WaterConsultancy #AMCServices #IndustrialWaterTreatment #SustainableWaterTreatment #CleanWater #WaterTreatmentIndia #WaterTech #WaterInnovation #EfficientWaterSystems #GreenWaterSolutions

#water treatment#wastewater management#stp plant manufacturer#india stp supplier#sewage treatment#sewage treatment plant supplier#sewage treatment plant#3d aqua

0 notes

Text

Sewage Treatment Plant Manufacturer

Green Aqua Technologies is a leading manufacturer of advanced (STP) sewage treatment plants. With a commitment to sustainable solutions and cutting-edge technology, the company offers a range of innovative wastewater treatment systems designed to meet the diverse needs of residential, commercial, and industrial clients. Green Aqua Technologies specializes in creating customized sewage treatment plants that ensure efficient waste management and water recycling, contributing to environmental conservation and public health. Their state-of-the-art facilities incorporate the latest advancements in biological and chemical treatment processes, ensuring high-quality output and compliance with regulatory standards. Sewage Treatment Plant Manufacturer

#Sewage Treatment Plant Manufacturer#Sewage Treatment Plant Manufacturer in India#Sewage Treatment Plant supplier

0 notes

Text

Rest in peace, Dr. Manmohan Singh, a visionary leader and statesman.

Your wisdom and dedication shaped India's growth and prosperity.

You served with integrity, humility, and a deep sense of duty.

As Prime Minister, your reforms left an indelible mark on the nation.

Your contributions to India’s progress will never be forgotten.

A true architect of modern India, your legacy endures.

May your soul rest in peace, and your work continue to inspire.

#PrimeMinisterOfIndia #prime #primeminister #FormerPrimeMinisterOfIndia #manmohansingla #ManmohanSingh #indian #indiaprimeminister #delhi #DelhiElection #RIP #DelhiNews

#airblowersinchennai#industrial air blower#manufactring company#sludgedewatring#vacuum pumps#airblower#delhi#sewage treatment plant manufacturer#waste water#a1blowers#prime minister#india

1 note

·

View note

Text

Sewage Treatment Plant Manufacturer in Delhi

Are you looking for Best STP Plant Manufacturer in Delhi? Look no further than RJ Jal Raksha Waste Water Treatment Organization, We are a leading manufacturer and supplier of Sewage Treatment Plant Offering Delhi, Ghaziabad, Noida, Greater Noida, Uttar Pradesh, Gujarat, Ahmedabad, Mumbai, Bengaluru and many other cities in India.

For any query, please contact us!

Call Now :- 07017079891

Website :- www.rjjalraksha.com/

#Sewage Treatment Plant Manufacturer in Delhi#STP plant manufacturer#STP plant manufacturer in India#STP plant supplier in India#sewage treatment plant manufacturer in India

1 note

·

View note

Text

Process Flow Diagram of Sewage Treatment Plant

Overview of Sewage Treatment Process Flow

At the start of a sewage treatment process flow, wastewater collection comes from a range of sources. This water comes through widespread pipes and moves on to its first treatment phase. Here, crude substances, such as debris and grit, are eliminated to stop equipment damage. As the water fills the primary treatment tanks, the heavier solids sink to the tanks' bottom surface next. Following completion of this phase, access to secondary treatment takes place for the wastewater. During this phase, organic materials biologically decompose as contaminant concentrations are dropping. The water heads to clarifiers to differentiate the rest of the solids. In the end, it arrives at the third treatment phase that unites advanced filtration with disinfection. Treated clean water enters nearby bodies of water or is used again for uses that do not require drinking water. Every phase of the operation is focused on smooth sewage treatment while remaining by environmental requirements.

Key Components of a Sewage Treatment Plant Flow Diagram

A sewage treatment plant flow chart presents a graphic explanation of the treatment steps. The start is where there is the inflow or inlet, which is the point through which wastewater enters the operation. The model illustrates the primary form of treatment, which eradicates big particles like grit. At this point, the primary treatment begins with settling tanks that cause solids to divide. Following that, secondary treatment takes place, in which biological mechanisms remove organic contaminants. At this phase, the diagram clarifies the difference between solid waste. During tertiary treatment, innovative filters together with disinfectants contribute to better processing of the water. Diagrams include systems for sludge processing along with sludge drying techniques. Arrows alongside labels signal the movement of water across every stage. A properly constructed flow diagram facilitates operator understanding and management of the elaborate sewage treatment process.

Step-by-Step Breakdown of the Sewage Treatment Process

Entry of sewage into the facility launches its sewage treatment plant for industries. During the start-up stage, large solids along with grit are eliminated. Eventually, the wastewater falls into tanks for primary treatment after that. Settling happens beneath because sedimentation originates from this point. The liquids that are remaining proceed into the secondary treatment stage. The biological processes presented, including aerobic decomposition, change organic matter. After that, it is essential to clarify by which the leftover solids differentiate from the water. Following secondary treatment, water first moves on to tertiary treatment. This concluding segment applies filters, along with disinfection, in a direction to remove any superfluous impurities. Eventually, the treated water is either sent down rivers or put to use for irrigation. All steps confirm the safety of wastewater for the environment after cleaning.

Understanding the Flow of Wastewater in Treatment Plants

In a treatment facility, a sequence of stages deals with the wastewater treatment plant. The method initiates once the plant obtains wastewater via the inflow pipes. The screening stage removes large debris as the water's first step. Within primary treatment, it migrates to sedimentation tanks.

Lighter materials head towards the surface, in contrast, thicker materials go down towards the bottom. Following completion of the first treatment phase, the wastewater rapidly flows into secondary treatment. Pollutant reductions happen because microorganisms are busy breaking down organic matter.

The flow carries through to clarifiers, the stage at which the final separation of solids happens. The next phase in treatment starts following the clarification of the water. In the phase where filtration combines with chemical disinfection, the quality of the water becomes better. At last, the water treated is out in rivers or storage for purposes of reuse.

Detailed Guide to Sewage Treatment Process Flow Stages

The several stages of sewage treatment are all important for the cleaning of wastewater. The introductory treatment gets underway with screens that remove substantial items including wood and plastic. Flowing water into primary treatment tanks causes solids to sink to the tank's bottom.

After this stage, secondary treatment will take place for the sewage, letting bacteria manage organic matter treatment. The coming phase consists of separating the liquid from what remains of the solids. Wastewater achieves a superior filtering system via tertiary treatment, which discards little particles and impurities.

Only after disinfection can the water be released or made use of it once more. Every phase is important for assuring that sewage is managed to meet environmental standards. A diagram that illustrates visually shows the transport of sewage through a treatment facility.

The inflow area identifies the leading entry location for wastewater to get to the plant. You can see the route water follows while passing through screens and grit chambers designed for debris separation in the flow diagram. The ensuing part of the diagram points out primary settling tanks, where the separation of solids takes place.

At the end of the day, the wastewater is in secondary treatment tanks receiving treatment from microbes that dissolve organic pollutants. The arrows reveal where the movement of water directs towards clarifiers that provide more separation.

For tertiary-level water treatment, advanced filtration combined with disinfection is a requirement. The diagram contains pathways devoted to sludge treatment as well. Due to the diagram, operators can nimbly manage all phases of the process.

Conclusion

The concluding result of the sewage treatment plant process flow diagram shows the necessary progression stages for wastewater treatment. Every phase, from primary inflow to the ultimate finish of discharge, is hugely important in water purification. At the outset, treatment removes big solid particles, and further on, primary treatment resolves the settling of solid waste. Secondary treatment consists of biological approaches that break apart contaminants. In time, tertiary treatment confirms that the water gets both filtration and disinfection all through the entire process. Operators can keep plant operations efficient and effective thanks to the understanding of how water flows through each phase. Every stage of treatment confirms that wastewater receives proper treatment, to maintain environmental and public health. A structured flow helps sewage treatment plants to uniformly meet environmental regulations over time.

#sewage treatment plant#sewage process#sewage management#sewage plant manufacturer#sewage plant equipments#sewage treatment plant in india#sewage treatment plant for industries#stp plant manufacturer#stp plant#stp plant supplier

0 notes

Text

Top 10 Benefits of Sewage Treatment Plant

Here are the Top 10 Benefits of Sewage Treatment Plant (STP Plant):

1. Protecting Public Health

Sewage treatment plants are fundamental in preventing the spread of waterborne diseases. By treating wastewater before it is released into the environment, STPs remove harmful pathogens and pollutants that could otherwise contaminate drinking water supplies and recreational waters. This helps to significantly reduce the risk of illnesses such as cholera, dysentery, and hepatitis.

2. Safeguarding the Environment

Untreated sewage can be detrimental to the environment, leading to pollution of rivers, lakes, and oceans. STPs play a crucial role in minimizing this impact by breaking down organic matter and removing harmful chemicals. This treatment process helps preserve aquatic ecosystems, maintain water quality, and protect wildlife habitats.

3. Enhancing Water Quality

By removing contaminants, sewage treatment plants improve the quality of water that is eventually released back into natural water bodies. Treated water is generally cleaner and less polluted, which supports healthier aquatic life and reduces the risk of algae blooms that can result from nutrient overloads in untreated sewage.

4. Recovering Valuable Resources

Modern sewage treatment plants are equipped with technologies that allow for the recovery of valuable resources. For instance, biosolids (the solid by-products of the treatment process) can be converted into fertilizers, and methane gas generated during treatment can be harnessed as a renewable energy source. This not only reduces waste but also contributes to sustainability efforts.

5. Supporting Sustainable Urban Development

As cities grow, the demand for efficient waste management systems increases. STPs enable sustainable urban development by providing the infrastructure needed to handle large volumes of wastewater. This ensures that growing populations can be accommodated without compromising environmental standards or public health.

6. Reducing Pollution and Odors

Sewage treatment plants help mitigate pollution and unpleasant odors associated with raw sewage. Through advanced treatment processes, STPs can significantly reduce the concentration of pollutants and eliminate foul smells, leading to a cleaner and more pleasant environment for nearby communities.

7. Promoting Economic Development

A well-managed sewage treatment plant is an asset to any community, fostering economic growth. It creates jobs, supports local businesses, and attracts investment by ensuring that urban areas are equipped with reliable waste management solutions. Additionally, the treated water can sometimes be used for non-potable purposes, such as irrigation, which can reduce costs for local industries and municipalities.

8. Complying with Regulations

Regulations regarding wastewater treatment are stringent in many countries. STPs help municipalities and industries comply with environmental laws and standards, avoiding legal penalties and contributing to overall regulatory adherence. Compliance ensures that communities meet the required environmental quality benchmarks and promotes responsible waste management practices.

9. Mitigating Climate Change

Some sewage treatment plants incorporate technologies that reduce greenhouse gas emissions. For example, capturing methane from the treatment process for energy production helps reduce reliance on fossil fuels. Additionally, advancements in treatment technology continue to improve the energy efficiency of these facilities, further supporting climate change mitigation efforts.

10. Educational and Research Opportunities

Sewage treatment plants serve as valuable sites for research and education. They provide real-world examples of complex environmental processes, offering insights into waste management, water conservation, and sustainable technologies. Educational programs and research initiatives centered around STPs help advance our understanding and drive innovation in environmental protection.

Conclusion

Sewage treatment plants are far more than just facilities for disposing of waste — they are critical components of modern infrastructure that provide extensive benefits for public health, environmental protection, and sustainable development. By ensuring effective wastewater management, STPs help create healthier, cleaner, and more resilient communities, underscoring their indispensable role in our increasingly interconnected world.

Top Sewage Treatment Plant Manufacturer in India

Are you looking for a STP Plant Manufacturer in India?, look no further than TR Aqua Private Limited, We are a leading manufacturer and supplier of STP Plant in India.

For More Details, Please Contact us!

Website :- www.traqua.in

Contact No. :- +91–9971440474

Email :- [email protected]

#Sewage Treatment Plant Manufacturer in India#Sewage Treatment Plant Supplier in India#STP Plant manufacturer in India#STP Plant Supplier in India#tr aqua private limited

1 note

·

View note

Text

Exploring the World of Electromechanical Systems: A Fusion of Electronics and Mechanics

Introduction:

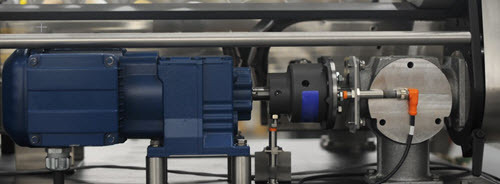

In the realm of facility management, the effective operation and maintenance of electromechanical systems play a vital role in ensuring the smooth functioning of buildings and infrastructure. The fusion of electronics and mechanics has given rise to sophisticated systems that require skilled professionals to handle their operations and maintenance.

Electromechanical systems are a fascinating field that combines the principles of electronics and mechanics. These systems involve the integration of electrical components and mechanical structures to create devices capable of performing a wide range of tasks. From simple household appliances to complex industrial machinery, electromechanical systems are an integral part of our daily lives.

Understanding Electromechanical Systems:

Electromechanical systems are integral to the functioning of modern facilities. These systems combine electrical and mechanical components, utilizing electronic controls to enhance efficiency and automation. Examples include HVAC (Heating, Ventilation, and Air Conditioning) systems, elevators, escalators, fire protection systems, security systems, and energy management systems.

Workforce Requirements:

To ensure the optimal performance of electromechanical systems, facility management teams require a diverse range of professionals with specialized skill sets. Key roles may include:

a. Engineers: Electrical and mechanical engineers are crucial for system design, installation, and troubleshooting. They possess the technical knowledge to handle complex electromechanical systems.

b. Technicians: Skilled technicians play a vital role in maintaining, inspecting, and repairing electromechanical systems. They are responsible for regular maintenance, diagnosing issues, and performing necessary repairs or replacements.

c. Operators: Operators are responsible for monitoring and controlling electromechanical systems, ensuring their proper functioning and responding to alarms or emergencies.

d. Facility Managers: These professionals oversee the operations and maintenance of electromechanical systems, ensuring compliance with regulations, managing budgets, and coordinating the work of the entire facility management team.

Recruitment Strategies:

To build a competent team for operations and maintenance in facility management, consider the following recruitment strategies:

a. Job Portals: Utilize online job portals that cater to the facility management industry to reach potential candidates with the desired skill sets.

b. Industry Networks: Engage with industry-specific networks, associations, and professional forums to connect with qualified professionals in the field of electromechanical systems.

c. Collaboration with Technical Institutes: Partner with technical institutes and vocational schools to tap into fresh talent. Establish internship programs or participate in job fairs to attract entry-level candidates.

d. Skill Assessment: Conduct thorough skill assessments during the recruitment process to evaluate candidates' proficiency in handling electromechanical systems and their related components.

Training and Professional Development:

Given the complexity and evolving nature of electromechanical systems, investing in training and professional development is crucial. Provide regular training sessions to enhance the skills of your workforce, keeping them up-to-date with the latest technologies and maintenance practices. Encourage employees to attend industry conferences, workshops, and certifications to expand their knowledge base.

Safety and Compliance:

Operations and Maintenance in Facility Management must prioritize safety and compliance. Ensure that all staff members are well-versed in safety protocols, including electrical safety, lockout/tagout procedures, and handling hazardous materials. Familiarize your team with relevant regulations and standards, such as building codes, fire safety regulations, and environmental guidelines.

Team Collaboration and Communication:

Effective collaboration and communication within the facility management team are vital for seamless operations and maintenance. Foster a culture of teamwork, encourage knowledge sharing, and promote open lines of communication between different departments and roles. This collaborative approach can lead to efficient problem-solving and improved system performance.

Conclusion:

Electromechanical systems form the backbone of facility management, and staffing considerations for operations and maintenance are crucial to ensure their reliable and efficient functioning. By understanding the workforce requirements, implementing effective recruitment strategies, prioritizing training and professional development.

#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment#Best Electromechanical Systems#Integrated Electronics and Mechanics

2 notes

·

View notes

Text

Electrolytic STP Service for Wastewater Treatment Technology

The Electrolytic STP Service is environmental, user and operator friendly. It is also compact in space.

An electrolytic STP plant is a type of water treatment system that uses electrolysis to remove contaminants from water. This process involves passing an electric current through the water, which causes the contaminants to either precipitate out or be oxidized. This results in clean, safe water that can be reused or safely discharged back into the environment.

Electrolytic West Water Technology is an evolving and emerging field in the treatment of waste water. It is unconventional non biological & chemical free technology. It has the potential to treat effectively the waste water compared to conventional treatment. It has potential to remove even non biological & toxics companiment from the waste streams. The system are compact modular in construction, packaged & noiseless on operation.

SPECIAL FEATURES OF ELECTROLYSIS

- The design uses a unique bipolar technology - It is modular in construction - It can be designed for either batch or continuous operation - It is custom designed & easily expandable - It can be retrofitted in the existing facility - Pollution removal rates in most cases - more than 95%

We provide new installation of Best Electrolytic STP Service with Electrolytic West Water Technology (STP) and STP Maintenance. For more details please Contact us: 9824018522 or email us at [email protected].

#Electrolytic STP Maintenance#Electrolytic STP Plants Maintenance#Maintaining Electrolytic STP Plants#Electrolytic STP Water Treatment Solutions#Electrolytic sewage treatment system#Electrolytic Sewage Treatment Plant in India#Electrolytic Sewage Water Treatment Plant manufacturers#Electrolytic STP Plant manufacturers#treatment of water using Electrolytic techniques#Electrolytic Sewage Treatment#STP Electrolytic Maintenance#STP Electrolytic Plants Maintenance#Maintaining STP Electrolytic Plants#STP Electrolytic Water Treatment Solutions#sewage treatment Electrolytic system#STP Plant Electrolytic manufacturers#STP Electrolytic Sewage Treatment#STP Maintenance#Electrolytic STP Service#Electrolytic West Water Technology

0 notes

Text

#sewage treatment plant manufacturer#stp plant manufacturer#sewage treatment plant manufacturers in india#best sewage treatment plant manufacturer#sewage treatment plant manufacturer in delhi#etp stp plant manufacturers in delhi

0 notes

Text

Looking for Sewage Treatment Plant Manufacturers in India?

Ravi Enviro Pvt.Ltd has got you covered! Our MBBR/FBBR-backed STP plants display less carbon footprint and emission. We serve diverse industries across the globe like petrochemical, pharmaceutical, textiles and agro-product industries. As leading STP plant manufacturers in India, our plants are renowned for high reliability and performance at best prices. Contact us today for more information.

#stp plant manufacturers in india#stp manufacturers in india#domestic stp plant manufacturers in india#sewage treatment plant manufacturers in india#sewage treatment plant suppliers in india

0 notes

Text

Essential Ways A Manufacturer of Sewage Treatment Plant Can Help An Industry!

Plizma Technology functions as a premier manufacturer of superior sewage treatment plants which supplies cutting-edge wastewater management technology. The state-of-the-art systems designed at our company meet environmental standards to deliver reliable treatment of diverse industrial and municipal wastewater with cost-effectiveness.

Know More:- https://shorturl.at/3jXvJ

0 notes

Text

Top 10 Sewage Treatment Plant Manufacturers in Greater Noida

As cities expand and urbanization accelerates, managing wastewater efficiently becomes a critical concern. Greater Noida, one of the fastest-growing cities in India, is at the forefront of urban development, necessitating innovative solutions to handle sewage treatment. Effective sewage treatment not only ensures a sustainable water supply but also plays a crucial role in safeguarding public…

#3D Aqua#India STP supplier#sewage treatment plant#sewage treatment plant supplier#STP plant manufacturer#Wastewater Management#Water Treatment

0 notes