#structural stability

Explore tagged Tumblr posts

Text

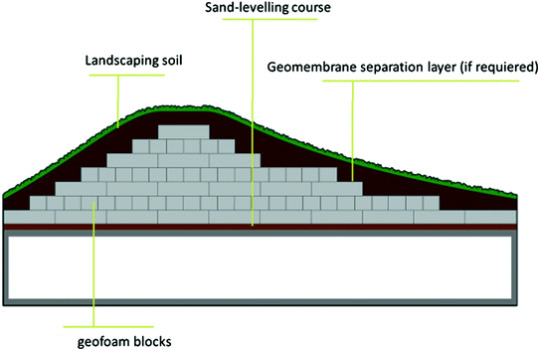

Unraveling the Growth Potential of the Geofoams Market: Global Outlook

The global geofoams market size is expected to reach USD 972.6 million by 2027, expanding at a CAGR of 2.7%, according to a new report by Grand View Research, Inc. Factors such as availability of geofoams at low cost coupled with its superior strength and durability are projected to fuel the market growth. Expansion of the construction industry across the globe coupled with the infrastructural developments in economies such as India, China, Brazil, Mexico, Saudi Arabia, and others is expected to propel the demand for geofoams over the forecast period. In addition, maintenance of the existing infrastructure in developed nations is likely to drive the growth of the market.

Geofoams Market Report Highlights

The expanded polystyrene geofoams segment accounted for USD 508.2 million in 2019 and is projected to expand at a CAGR of 3.1% from 2020 to 2027. The compatibility of the product has resulted in its increasing adoption for applications including roads and highway construction, building and infrastructure, and others

The road and highway construction application segment accounted for 38.07% of the total market and is projected to expand at a CAGR of 3.4% from 2020 to 2027 on account of the rising infrastructural growth across the developing economies including China, India, Brazil, UAE, Saudi Arabia, and others

Asia-Pacific accounted for USD 278.5 million in 2019 and is estimated to expand at a CAGR of 3.2% from 2020 to 2027 owing to the rising demand for road pavement, which is anticipated to further benefit the growth

China accounted for the highest market share in Asia Pacific on account of the rapidly expanding construction industry in the country

Europe market is estimated to expand at a CAGR of 2.8% owing to the rising number of construction and infrastructural activities in economies including Spain, Italy, and others

For More Details or Sample Copy please visit link @: Geofoams Market Report

Geofoams are increasingly used in the construction industry as it helps in suppressing the noise and vibrations. In addition, it is easy to handle and does not require any special equipment for installation. The product is increasingly used in the railway track systems, below the refrigerated storage buildings, storage tanks, and others to avoid ground freezing.

The geofoams undergo chemical changes when it comes in contact with petroleum solvents. It turns into a glue-type substance, thereby losing its strength. This factor is projected to limit the use of geofoams in the construction industry which is projected to restrict the industry growth over the forecast period.

#Geofoam#Expanded polystyrene (EPS)#Geofoam blocks#Construction materials#Road and highway construction#Retaining walls#Geotechnical engineering#Soil stabilization#Environmental protection#Earthquake resistance#Noise and vibration control#Water management#Hydrostatic pressure#Thermal insulation#Structural stability

12 notes

·

View notes

Text

Column Jacketing: Types and Benefits Explained

Column jacketing strengthens columns and improves their load-carrying capacity. Engineers add materials around existing columns to boost their strength, stiffness, and durability. This method helps repair and upgrade structures to meet modern safety standards. Jacketing of columns increases their resistance to seismic forces, making buildings safer during earthquakes. It also improves the…

#building rehabilitation#building renovation#civil engineering#column jacketing#column strengthening#composite jacketing#concrete jacketing#construction repair#FRP jacketing#infrastructure upgrade#load-bearing capacity#reinforced concrete#retrofitting columns#seismic retrofitting#steel jacketing#Structural Engineering#Structural Integrity#structural reinforcement#structural stability#structural strengthening

0 notes

Text

Excavation is a fundamental step in construction, laying the groundwork for a stable and secure structure. This blog delves into the importance of excavation, the techniques involved, and its impact on overall construction quality. Learn how proper excavation practices ensure the longevity and safety of buildings. Visit ShreeTMT to explore more about the role of excavation in construction.

#Excavation#Construction#Building Foundation#ShreeTMT#Construction Techniques#Excavation Practices#Structural Stability#Construction Quality#Building Longevity#Construction Safety

0 notes

Text

Structural Engineers Group & Third-Party Testing, Inspection, Verification & Certification services provider

NDT testing:

Non-Destructive Testing (NDT), provided by Geocontech, encompasses a range of techniques crucial for assessing materials and structures without causing harm. These methods, including Ultrasonic Pulse Velocity testing, Rebound Hammer testing, and Core Cutting testing, allow for thorough inspections to detect flaws, discontinuities, or weaknesses that could compromise structural integrity. By employing NDT services, industries can ensure the reliability and safety of their assets while minimizing downtime and costly repairs. Geocontech offers comprehensive NDT consultancy and inspection services tailored to meet the specific needs of clients across various sectors, maintaining high standards of quality and accuracy in every evaluation.

For businesses seeking Non-Destructive Testing and Inspection Services, Geocontech provides expertise in utilizing advanced techniques like Ultrasonic Pulse Velocity testing, Rebound Hammer testing, and Core Cutting testing. These methods are instrumental in identifying defects and evaluating material properties without causing damage, ensuring the integrity and longevity of critical structures and components. With a commitment to precision and reliability, Geocontech delivers NDT solutions that meet industry standards and regulatory requirements, supporting clients in maintaining operational efficiency and safety across their projects.

structural engineers:

When considering the best companies for structural engineers, Geocontech emerges as a leader in the field of structural stability and testing services. Specializing in Structural Stability Certificate Consultancy, Geocontech provides thorough and reliable structural stability checking services tailored to meet the needs of building owners, developers, and construction firms. Their expertise extends to Building Structural Stability Testing Service, ensuring compliance with rigorous inspection, verification, and certification standards for both new constructions and existing structures.

Geocontech excels in Construction Testing Inspection verification and certification, offering specialized services that guarantee the structural integrity and safety of buildings, factories, and other infrastructure projects. Their commitment to excellence in Building Testing and Factory Testing Inspection further solidifies their reputation as a trusted partner in ensuring structural stability across diverse sectors. By leveraging advanced engineering techniques and adhering to industry best practices, Geocontech delivers comprehensive solutions that prioritize safety, efficiency, and compliance with regulatory requirements.

best concrete repairs and restoration:

When seeking the best concrete repairs and restoration solutions, Geocontech excels in offering comprehensive Structural Rehabilitation Services. Specializing in Structural Repairs and Rehabilitation Services, Geocontech provides tailored solutions to address concrete deterioration, cracks, and structural weaknesses effectively. Their expertise extends to Structural Repairing Service & Rehabilitation, where they utilize advanced techniques and materials to restore the integrity and longevity of concrete structures.

Geocontech's commitment to excellence in Structural Repair Services ensures thorough assessment, precise repair methodologies, and adherence to industry standards. Whether it's repairing structural elements in buildings, bridges, or other infrastructure, Geocontech's skilled team delivers reliable solutions that enhance durability and structural stability. By prioritizing quality craftsmanship and innovative repair techniques, Geocontech stands out as a trusted partner for clients seeking robust concrete repairs and restoration services.

project management consulting:

Project management consulting involves specialized advisory services provided by experts to help organizations effectively plan, execute, and control their projects. Geocontech, a leading name in this field, offers top-tier Project Management Consultants (PMCs) who assist clients in Chennai and beyond with comprehensive PMC Services. These services encompass strategic planning, resource allocation, risk management, and quality control to ensure projects are delivered on time, within budget, and to the highest standards.

Geocontech's PMC Project Management Consultancy includes tailored solutions that cater to the unique needs of each project. Their team of experienced Project Management Consultants brings expertise in overseeing project lifecycles from inception to completion, ensuring efficient coordination among stakeholders and adherence to project goals. By leveraging industry best practices and innovative methodologies, Geocontech enhances project efficiency and minimizes risks, making them a trusted partner for organizations seeking reliable project management consulting services.

Soil Testing & Mix Design Services:

Conducting a Marshall mix design test is essential for determining the optimal asphalt binder content in asphalt mixtures, ensuring durability and performance in road construction. At Geocontech, we specialize in providing comprehensive Soil Test & Concrete Design Mix services, including precise Soil Testing & Mix Design Services and Concrete Mix Design Test Services. The Marshall mix design test begins with careful selection of aggregates and asphalt binders based on project specifications and environmental conditions. Samples are then prepared and compacted using a Marshall compactor to simulate real-world conditions, followed by testing to measure stability, flow, air voids, and density. Through meticulous analysis of these results, our expert team ensures that asphalt mixtures meet stringent quality standards and performance requirements, offering tailored solutions that enhance the longevity and resilience of infrastructure projects.

0 notes

Text

Carefully testing the floor beneath his feet, the kender stepped out into the hall.

"DragonLance Chronicles: Dragons of Autumn Twilight" - Margaret Weis and Tracy Hickman

#book quote#dragonlance chronicles#dragons of autumn twilight#margaret weis#tracy hickman#tasslehoff burrfoot#careful#testing#floor#structural stability#kender#hall of the ancestors

0 notes

Text

Little P.Eng. Engineering for Structural and Piping Design in Hydrogen Pilot Plant for Green Energy

In the race to counteract climate change, green energy solutions are imperative. Hydrogen, known as the universe's most abundant element, offers a promising pathway. Pilot plants are experimental setups designed to understand and optimize large-scale industrial processes. Little P.Eng. Engineering has emerged as a pivotal player in realizing this potential by specializing in the structural and piping design for hydrogen pilot plants.

Hydrogen's Role in Green Energy

Hydrogen is not just another energy source; it's a powerful, clean fuel that, when consumed, emits only water as a byproduct. Green hydrogen, especially, is produced using renewable energy sources, ensuring a low-carbon footprint. As governments and industries realize its potential, pilot plants that can produce, store, and utilize hydrogen efficiently are in demand.

Little P.Eng. Engineering’s Expertise

Little P.Eng. Engineering's team specializes in addressing the unique challenges posed by hydrogen in pilot plants. Their structural and piping designs consider factors such as hydrogen's low density, its propensity to embrittle metals, and the safety requirements necessary when working with the element.

Structural Design Considerations

Hydrogen Embrittlement: Hydrogen can make metals brittle, especially under high-pressure conditions. The structural components must be designed with materials resistant to this phenomenon.

Safety Measures: Hydrogen is flammable. Incorporating explosion-proof structures, safe zones, and preventive measures against accidental leaks is paramount.

Modularity: As pilot plants are often experimental setups, flexibility and modularity in design allow for changes based on the evolving understanding of the process.

Piping Design Considerations

Material Selection: Given hydrogen's small molecule size, it can easily leak through many materials. Piping must be constructed with materials that prevent leakage and are resistant to embrittlement.

Pressure Challenges: Hydrogen storage and transport require high-pressure conditions. The piping system must handle these pressures, ensuring safety and efficiency.

Temperature Factors: Liquid hydrogen storage needs extremely low temperatures. This necessitates designs that can handle thermal stresses and expansion-contraction challenges.

Safety Valves and Monitoring Systems: Real-time monitoring of the hydrogen flow, pressure, and potential leaks are essential. Incorporating advanced monitoring systems and safety valves ensures timely detection and mitigation of any risks.

Applications in Green Energy

Hydrogen pilot plants are not just limited to producing hydrogen. They also focus on:

Storage: Efficiently storing hydrogen is a challenge. Pilot plants explore solutions like high-pressure gas storage or cryogenic liquid storage.

Power Generation: Pilot plants test fuel cells and other means to convert hydrogen back into electricity.

Integration with Other Renewable Sources: Connecting hydrogen production with wind, solar, and hydroelectric power sources ensures a continuous energy supply, even when these sources aren't generating power.

Green Mobility: Hydrogen fuel cell vehicles (FCVs) are on the rise. Pilot plants play a pivotal role in researching and optimizing hydrogen production, storage, and refueling stations for these vehicles.

Advancing the Future

Little P.Eng. Engineering's commitment to green energy is evident in its consistent research and innovation in structural and piping designs. By regularly updating their designs based on feedback from pilot plants, they ensure safety, efficiency, and scalability for large-scale hydrogen production.

The company also collaborates with universities, research institutions, and industries to stay at the forefront of technology. Such partnerships help in the exchange of ideas and the rapid adoption of best practices.

Challenges and Opportunities Ahead

While the potential of hydrogen as a green energy source is immense, there are challenges:

Economic Feasibility: Bringing down the costs associated with hydrogen production, storage, and usage is essential for its mainstream adoption.

Scalability: While pilot plants offer invaluable insights, scaling these solutions to meet global energy demands requires further research and innovations.

Public Awareness and Acceptance: For hydrogen to be widely adopted, both as an energy storage medium and a fuel, public understanding and acceptance of its benefits and safety are crucial.

Little P.Eng. Engineering, with its expertise and dedication, is poised to address these challenges, turning them into opportunities for a greener future.

Conclusion

As we grapple with the urgency of transitioning to green energy solutions, hydrogen emerges as a beacon of hope. With its abundant availability and potential for clean energy generation, it can revolutionize the energy landscape. Companies like Little P.Eng. Engineering, through their specialized structural and piping designs, play a pivotal role in this transition. As the world moves towards a sustainable future, the role of such innovators becomes even more significant.

Tags:

Meena Rezkallah

Little P.Eng. Engineering

Structural design

Energy efficiency

Engineering expertise

Hydrogen pilot plant

Green energy

Piping design

Sustainable energy sources

Hydrogen storage

Hydrogen transportation

Structural stability

Pressure-relief systems

Safety mechanisms

Hydrogen production

Electrolysis

Advanced simulations

Material embrittlement

Leak prevention

Optimal hydrogen flow

Seismic resilience

Weather-resistant structures

Modular designs

Renewable energy

Zero carbon emissions

Advanced safety

North American energy transition

Environmental consciousness

Hydrogen infrastructure

Hydrogen diffusivity

Hydrogen Production Plant Design

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Meena Rezkallah#Little P.Eng. Engineering#Structural design#Energy efficiency#Engineering expertise#Hydrogen pilot plant#Green energy#Piping design#Sustainable energy sources#Hydrogen storage#Hydrogen transportation#Structural stability#Pressure-relief systems#Safety mechanisms#Hydrogen production#Electrolysis#Advanced simulations#Material embrittlement#Leak prevention#Optimal hydrogen flow#Seismic resilience#Weather-resistant structures#Modular designs#Renewable energy#Zero carbon emissions#Advanced safety#North American energy transition#Environmental consciousness#Hydrogen infrastructure#Hydrogen diffusivity

0 notes

Text

one of my favourite ot3 dynamics is like these two people who are entangled by fate and revenge and honour and the guy who got caught up in it because of unceasing, unflinching devotion to one of them

#ot3#hanwenzhou#also zhanchengxian but not in the way you would expect#definitely whatever jo yeong lee gon and jeong tae-eul have got going on#and one day ill tell you all about how this is also about kundavai poonkuzhali and vanathi#i like to this the kebab ki haddi dynamic#the haddi provides stability and maintains the structural integrity of the kebab

420 notes

·

View notes

Text

The moon will sing a song for me

I loved you like the sun

Doomed lovers,,, star crossed lovers,,, maybe in another world they will have the chance meet again as Capitano/Thrain won’t be reborn in this one

#she was the sun and he was the moon#Mavuika prepared to go out in a final fiery blast but instead it was the cold that froze and stabilized her world#leaving her to blaze a new path for the future as the sacrificial structure he left behind allows her to move on when he can’t#mavuika#capitano#mavuitano#genshin impact#genshin 5.3#genshin 5.3 spoilers#genshin spoilers#my stuff#genshin#my post#genshin impact screenshots#I didn’t have her sig weapon so a 3 star one was the best one I had aesthetically 😢

140 notes

·

View notes

Text

I have a controversial yet brave opinion about Gilmore girls

Gigi is one of the most tragic characters in the whole show

Her mother ups and leaves her when she’s a toddler, she’s left to be raised mostly by rotating nannies because her father works half the time. Then suddenly she’s 3-4 years old and her mom decides “oh right I have a daughter! I wanna be a mommy again :)” and whisks her away to a foreign country to spend a few months with her.

She comes back to a new house and her dad having suddenly been married to a woman she’s only met when she babysat her 1 time. Then like 2 months after that they divorce and she moves away again.

And worst of all. Her father? Christopher Hayden.

Like damn girl I’d be screaming too

#Gilmore girls#like yeah she was a hellspawn for a while but what can you expect from a toddler with absolutely no structure or stability or proper parenti#correction. she did meet lorelai after the babysitting but like#still#justice for Gigi

15 notes

·

View notes

Text

Pros of knitting a round yoke colorwork sweater from the top down:

Can try it on as you go and make sure it fits

No seams to sew

Small number of stitches to cast on initially

Cons:

Fucking none, it's a perfect sweater format

Pros of knitting a round yoke colorwork sweater from the bottom up:

Can use a sleeve as a swatch to double check your gauge and color harmonies, assuming there is colorwork on the sleeve cuffs

The yoke is often the most exciting part and leaving it for last is satisfying

Cons:

Had to use like 5 different needles to get the sleeve stitches off of waste yarn and join them to the body, playing a game of absolute musical chairs with interchangeable needle tips

Can't easily try it on as you go so you've just gotta hope you didn't screw up too bad and that it'll fit when you're done

Danger of running out of one or more colors of yarn at the yoke, which is arguably the most important part of the design

Gotta sew up the little underarm holes when you're done

I know I already pointed out that you can't try it on as you go but I will bring it up again as I believe it is the most salient point here

What if you bind off too tight and can't get the collar over your head? What then???

In conclusion why do my friends keep letting me knit sweaters from the bottom up

#the bottom up sweater hater has logged on#don't even get me started on seamed sweaters#you are making the fabric!! it can be any shape why would you choose to sew seams!!#“livali it adds structure and stability” i am not listening to you i am over here knitting a sweater i don't have to put together twice#or i would be if i didn't keep falling in love with bottom up patterns#HEAVY SIGH#knitting#me posts#getting disproportionately irritated by niche fiber arts hobby concerns

64 notes

·

View notes

Text

If i had a robot that looks like a human with visibal robot fearures you don't wanna know how long i'd stare at the joints just to draw them

#I don't think yall understand how unnormal I am about those types of thibgs#Like what do you mean you don't wanna to anolize the robot person fasinated by the joints and structure?#like i realy want a realistic v1 moddle just to stare at and see how it intereacts with light#like im so fasinated by them joints the wires the mesh the metal plating the connection point and the stability of robots#robots are so cool i need a billion of them

7 notes

·

View notes

Text

"If the structure of your world ever evaporates, I will still be here."

I think The Q might contain one of the greatest declarations of friendship/love ever.

#books#the q#beth brower#this seems clunkier out of context but trust me in context it's very moving#they're discussing how quincy's entire world is wrapped up in work#so even if she likes the people there if the business somehow disappeared she probably wouldn't see them again#because they all have other family/friends to go to and she doesn't really have any#leading to this promise#and let me tell you it's just about enough to make me believe in found family#because this works as a romantic or platonic declaration#it's a promise#a commitment to provide safety and stability when there's nowhere else to go#and i love it#this book is so odd because i liked it quite a bit last year#then rereading i was at first like 'why did i like this at all?'#there's no scene-setting or character description it's just kind of stuff there#but then the relationship starts to develop and i am SO invested#under normal rules it shouldn't take 100 pages for the story to get good but in this case it's worth it#it's such an odd structure#each chapter is almost like its own little short story#or a character sketch#almost like the character have stopped to discuss their own character worksheet#but in context it somehow works#and it drives home how much traditional publishing and writing rules stifle creativity#because your average editor would look at this and try to smooth it over#make it all into one flowing narrative#and it would lose so much of what makes it unique and compelling#following the rules of 'good writing' robs you of all the stories that don't follow those rules#there is so much scope outside of the one 'best practice' that is currently in fashion#and those stories need to get told too!

21 notes

·

View notes

Text

Fantasy Worldbuilding Questions (Stability, Conflict, and Power Structures)

Stability, Conflict, and Power Structures Worldbuilding Questions:

What is the biggest cause for competition and conflict in this world?

What is required to happen in order for harmony/peace to reign?

Who stirs up the moment conflict, is the most divisive figure, and why?

Who or which group flourishes or prospers during times of conflict, and who during times of peace?

Where are hotbeds of conflict that are perpetually flaring up, and why?

Where do primary conflicts in the world originate, in what situation, disagreement or misunderstanding?

When was the most stable period in this world’s history, and why was it stable? time

When was the time of heaviest conflict in the world, and why?

Why will reaching stability be difficult between fighting factions?

Why do conflicts arise in this world, what economic, political, religious or other factors contribute?

❯ ❯ ❯ Read other writing masterposts in this series: Worldbuilding Questions for Deeper Settings

#writeblr#writing tips#fiction writing#writing advice#novel writing#writing#worldbuilding#power structures#fwq#writing research#writing resources#conflict#stability#now novel

54 notes

·

View notes

Text

took that mbti test for the first time since high school because i wanted to see if it was as much bullshit as i remembered it being and sure enough i didn't even get the same result (intp then vs. istj now). it's just astrology for redditors

#anyway. humans are complex and ever-changing animals and any attempts to fit them into boxes will always always always fail#ESPECIALLY regarding personality traits and emotional stability which are both things that can change under the right circumstances#anything from trauma to a well-structured fitness plan will do it. sometimes things just change on a whim. that's the way it is

15 notes

·

View notes

Text

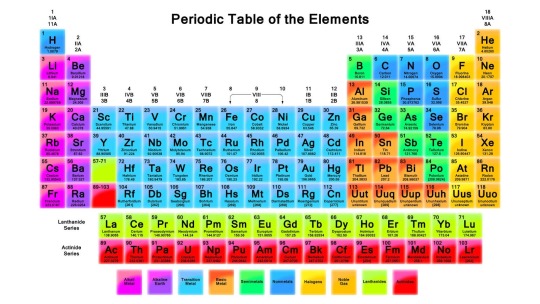

Thinking about Her again...

#ITS JUST ORGANIZERD SO PERFEVTLT#AND IT CAME TO MENDELEEV IN A GOD DAMN DREAM#fucking message from the gods type shit#like you can just glance at the table and instantly get a ton of knowledge about any element#number of subatomic particles; how filled its valence shell is; how to put it in a lewis structure; how it decays if it's radioactive#its electron configuration; its molar mass; how it tries to achieve stability etc etc etc#I LOVE HER (the periodic table of elements)#zelle.txt#chem posting

9 notes

·

View notes

Text

Leading the Future with Structural and Piping Design for Hydrogen Pilot Plants in the Green Energy

As the world gradually transitions towards sustainable energy sources, hydrogen stands out as a beacon of hope in the quest for green energy. The intricacies involved in harnessing hydrogen's power necessitate advanced pilot plants equipped with state-of-the-art designs. Enter Little P.Eng. Engineering, the torchbearer of structural and piping design for hydrogen pilot plants, pushing the boundaries of innovation and safety in North America.

The Growing Importance of Hydrogen in Green Energy

With zero carbon emissions when burned, hydrogen promises a cleaner future, especially when produced through green methods like electrolysis of water using renewable energy. The challenge lies in efficiently storing and transporting hydrogen, which requires meticulously designed infrastructure. This is where pilot plants come into play, acting as the testing grounds for groundbreaking technologies and methodologies.

Understanding the Role of Structural and Piping Design

In any hydrogen pilot plant, the importance of structural and piping design cannot be overstated:

Structural Design: Ensures the physical stability and safety of the plant. With hydrogen's volatile nature, the infrastructure must be robust enough to withstand pressures, prevent leaks, and guarantee longevity.

Piping Design: Deals with the intricate network of tubes and pipes that transport hydrogen and other fluids within the plant. An optimized piping system reduces losses, increases efficiency, and ensures the safe transportation of hydrogen.

Little P.Eng. Engineering's Expertise in Action

1. Customization: Every pilot plant has unique needs. Little P.Eng. Engineering’s team initiates a thorough groundwork phase, understanding the plant's specific requirements, and then tailoring designs to fit those needs perfectly.

2. Advanced Simulations: Before any design is finalized, it undergoes rigorous simulations to test its viability, strength, and efficiency. This ensures that any potential issues are addressed long before implementation.

3. Safety Above All: Given hydrogen's highly flammable nature, safety is paramount. Designs incorporate advanced safety mechanisms, pressure-relief systems, and fail-safes, ensuring the utmost protection for both the workers and the environment.

4. Seamless Integration: Little P.Eng. Engineering’s designs aren’t just about functionality – they're about integration. The designs ensure that all components of the pilot plant work in harmony, enhancing the overall operational efficiency.

A Look at Piping in Detail

Hydrogen, with its low viscosity and high diffusivity, poses unique challenges:

Material Selection: Hydrogen can lead to material embrittlement. Little P.Eng. chooses materials that resist this phenomenon, ensuring the pipes remain durable even under intense hydrogen flow.

Leak Prevention: With advanced sealing technologies and meticulous design, the piping systems are virtually leak-proof, preventing hydrogen wastage and potential hazards.

Optimal Flow: The piping designs ensure that hydrogen flows at optimal rates, reducing energy consumption and maximizing efficiency.

The Structural Marvels of Little P.Eng. Engineering

When it comes to structural design, it's a balance of strength, flexibility, and longevity:

Earthquake Resilience: Many areas in North America are prone to seismic activities. Designs from Little P.Eng. factor in these challenges, ensuring that structures can withstand tremors without sustaining damage.

Weather Resistance: Whether it's the freezing Canadian winters or the blistering heat of the southern USA, the structures are built to weather it all, quite literally.

Modularity: As the hydrogen industry evolves, pilot plants might need upgrades. Little P.Eng.'s modular designs ensure that expansions and modifications can be made without major overhauls.

Conclusion

The green energy revolution is upon us, and hydrogen is at its forefront. As pilot plants become the crucibles of innovation in this sector, having the right structural and piping design is crucial. Little P.Eng. Engineering, with its blend of expertise, innovation, and commitment to sustainability, is not just a participant but a leader in this transition towards a cleaner future. Their designs for hydrogen pilot plants stand as testaments to what is possible when engineering prowess meets environmental consciousness.

Tags:

Little P.Eng. Engineering

Structural design

Energy efficiency

Engineering expertise

Hydrogen pilot plant

Green energy

Piping design

Sustainable energy sources

Hydrogen storage

Hydrogen transportation

Structural stability

Pressure-relief systems

Safety mechanisms

Hydrogen production

Electrolysis

Advanced simulations

Material embrittlement

Leak prevention

Optimal hydrogen flow

Seismic resilience

Weather-resistant structures

Modular designs

Renewable energy

Zero carbon emissions

Advanced safety

North American energy transition

Environmental consciousness

Hydrogen infrastructure

Hydrogen diffusivity

Cleaner future

Hydrogen Production Plant Design

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#Structural design#Energy efficiency#Engineering expertise#Hydrogen pilot plant#Green energy#Piping design#Sustainable energy sources#Hydrogen storage#Hydrogen transportation#Structural stability#Pressure-relief systems#Safety mechanisms#Hydrogen production#Electrolysis#Advanced simulations#Material embrittlement#Leak prevention#Optimal hydrogen flow#Seismic resilience#Weather-resistant structures#Modular designs#Renewable energy#Zero carbon emissions#Advanced safety#North American energy transition#Environmental consciousness#Hydrogen infrastructure#Hydrogen diffusivity#Cleaner future

0 notes