#steel iron industry

Explore tagged Tumblr posts

Text

Buy superior quality TMT Bar Fe500D from Vedanta MetalBazaar

Buy high-quality TMT Bar Fe500D from the top manufacturers in India. Vedanta MetalBazaar provides a wide range of TMT Bars at a very affordable cost.

#TMT Bars#tmt saria#TMT manufacturer in India#steel iron industry#TMT bars supplier#tmt bars exporter#Vedanta Metalbazaar

1 note

·

View note

Text

slag hauler

530 notes

·

View notes

Text

My Adventures with Superman Season 2 Easter Eggs

Welcome to another week of My Adventures with Superman and what a great episode this one was! I CALLED IT THAT WE'LL BE SEEING A CERTAIN CHARACTER SHOW UP SINCE EPISODE 1 SEASON 1!!! OK lets get to the easter eggs!

My Easter eggs lists for season 1 is here if you haven't seen it!

My season 2 episode 1 Easter eggs and references in My Adventures with Superman post is here.

My season 2 episode 2 Easter eggs and references in My Adventures with Superman post is here.

My Easter eggs and references in My Adventures with Superman comic issue 1 post is here.

My season 2 episode 4 Easter eggs and references in My Adventures with Superman post is here

My season 2 episode 5 Easter eggs and references in My Adventures with Superman post is here

My season 2 episode 6 Easter eggs and references in My Adventures with Superman post is here

My season 2 episode 7 Easter eggs and references in My Adventures with Superman post is here

My Easter eggs and references for My Adventures with Superman comic issue 2 post is here

My season 2 episode 8 Easter eggs and references in My Adventures with Superman post is here

My season 2 episode 9 Easter eggs and references in My Adventures with Superman post is here

My season 2 episode 10 Easter eggs and references in My Adventures with Superman post is here

My Easter eggs and references for My Adventures with Superman comic issue 3 post is here

Spoilers if you haven't seen it yet.

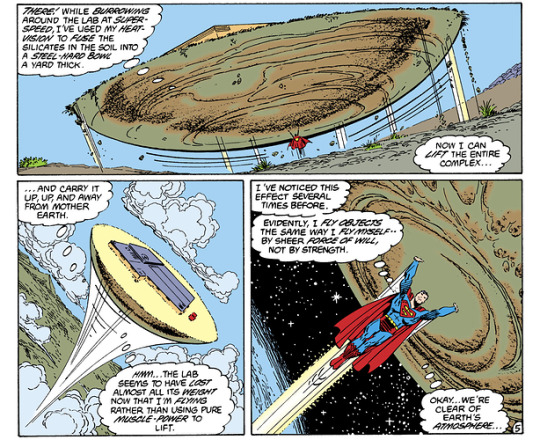

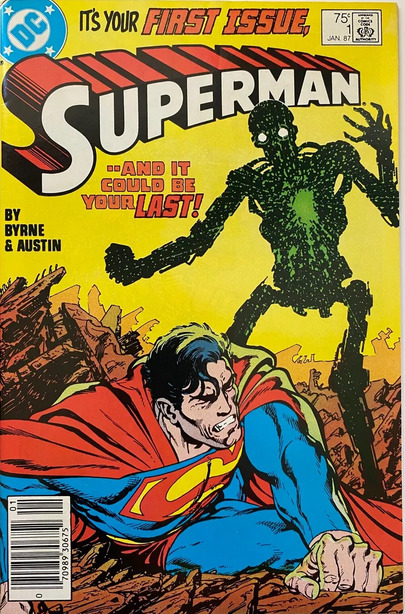

At the start of the episode we see Clark discover a new power of his to protect a person (we'll talk about him soon) during a fire. What we are seeing here is Clark using his Bio Electric Aura. Superman's Bio Electric Aura was first introduced in Superman #1 (1987) where Superman is investigating an abandoned laboratory where stats on Superman are plastered over the computer monitors and he finds the body of the scientist who's neck was snapped by something powerful. So in order to to keep the things inside safe and way from bad people (we'll talk more about this later), Superman does this (W&P: John Byrne, I: Terry Austin, C: Tom Zuiko, L: John Costanza:

He takes it up to space so the vacuum can keep it preserved. But Superman is able to lift such a large piece of land thanks to his Bio Electric Aura. What it does is help protect the Bio Electric Aura user from damage and enhance their strength, speed, and durability. The user extends their aura to whatever object they are interacting with, in Superman's case, this giant piece of land, and be able to lift it up without IRL physics affecting them. Check out All-Star Superman to see how far Clark can use his bio electric aura!

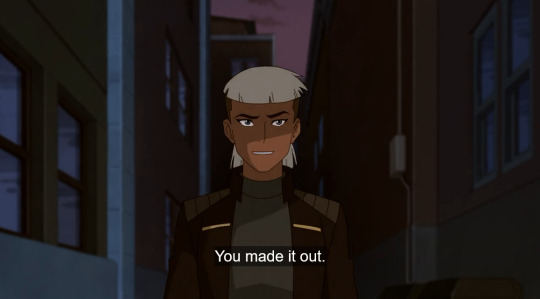

Clark was able to save the man's life from the fire started by Livewire (I talked more about her here). But before the reveal, we have a fun name drop in the scene! The man Clark saved was Silas Stone, the father of Victor Stone aka Cyborg of the Teen Titans/Titan (yeah I know Cyborg was with the Justice League sometimes but he fits with the Teen Titans/Titans more)!

Silas Stone made his first appearance in DC Comics Presents #26 (1980) [W: Marv Wolfman, P: George Perez, I: Dick Giordano, C: Adrienne Roy, L: Ben Oda] as a STAR Labs scientist. After his son's accident, Silas had Victor rebuilt with new cybernetic parts in order to keep him alive, a move that strained his relationship with his son. Here in the pages Raven was showing the Teen Titans that Silas was in trouble trying contact this protoplasmic cell.

Speaking of Victor, we get a reference to him after Livewire threatened his life and Victor was forced to delete the files he had on AmerTek (we'll talk more about that later).

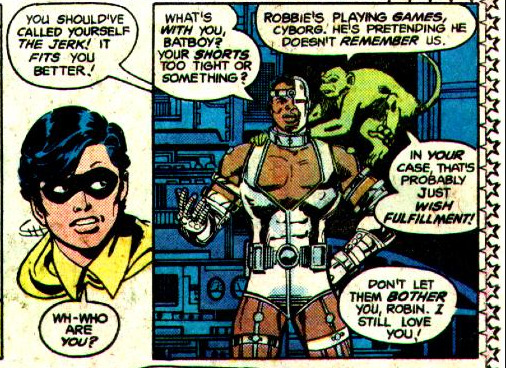

Victor Stone makes his first appearance also in DC Comics Presents #26 (1980) [ W: Marv Wolfman, P: George Perez, I: Dick Giordano, C: Adrienne Roy, L: Ben Oda]. Robin and the rest of the Titans gather at Titan's Tower but for some reason Robin can't recognize the team.

The title for this episode is a nod to Hiromu Arakawa's manga/anime Fullmetal Alchemist, IMO the gold standard when it comes to action manga/anime. Fantastic read and watch highly recommend either watching the anime, Fullmetal Alchemist Brotherhood and the first Fullmetal Alchemist just to see how the two are different, but also read the manga because its just that good! A very appropriate title for what we will be discussing next!

Finally the one character I hope would show up in MAwS, John Henry Irons! In MAwS like his comic book counterpart worked for AmerTek, but in MAwS Irons hoped he could use AmerTek be beneficial for his neighborhood, Bakerline (which I talked more about here.)

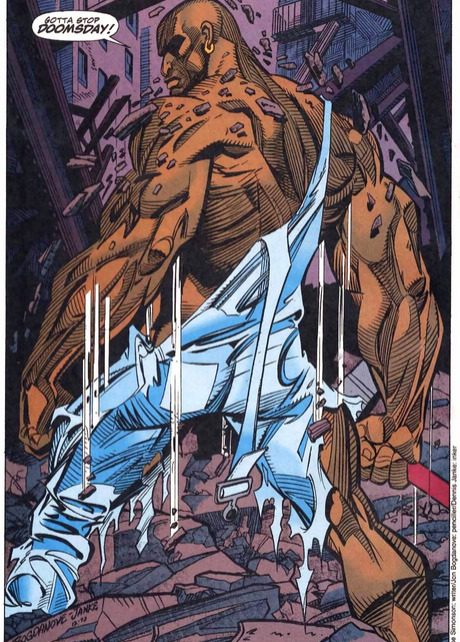

John Henry Irons makes his first appearance in Adventures of Superman #500 (1993) [First Sighting: Man of Steel segment - W: Louise Simonson, P: Jon Bogdanove, I: Dennis Janke, C: Glenn Whitmore, L: Bill Oakley] during the start of the Reign of the Supermen storyline where we see John be buried under rubble after saving one of foreman coworkers and with the help of Superman was able to save both of them. However Doomday attacked the city and John was ready to pay Superman back by helping him fight Doomsday as well but the building John was in collapsed burying him.

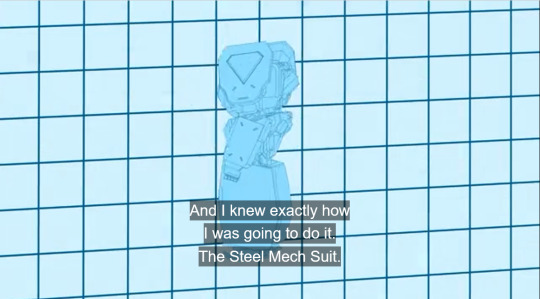

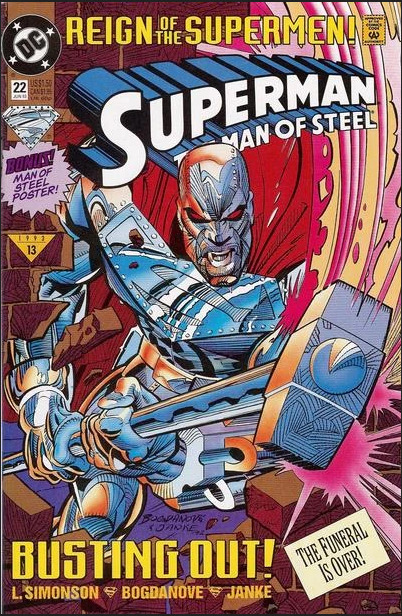

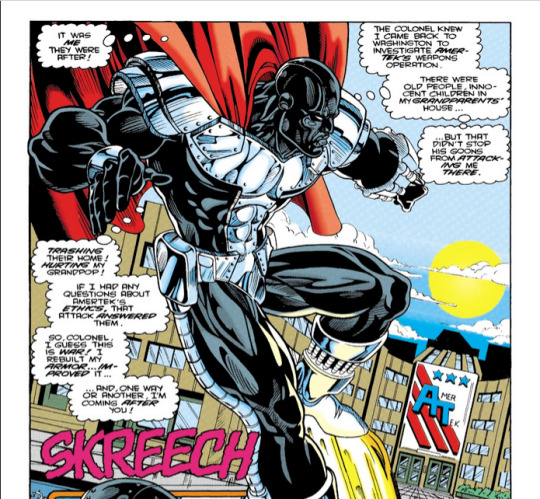

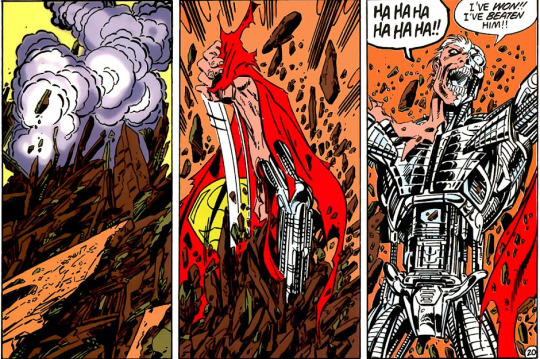

Like his comicbook counterpart, John don's a suit to help out Superman later in the episode. In the comics John wears the Steel armor in Superman: The Man of Steel #22 (1993) [Cover art by Jon Bogdanove and Dennis Janke]. After Superman's death at the hands of Doomsday, John builds the Steel suit in order figure out why the weapons he created but ultimately destroyed were in the hands of the gangs of Metropolis. He later learns that Amertek Industries, his former employer was still in business distributing the weapons.

As Clark is running late for a date with Lois as Waid's cafe (I talked about this reference here and you hear a bit of the MAwS leitmotif in the cell jingle.

At the AmerTek demo, Lois is in the crowd to see what they have for their showcase and we see Thomas Weston demonstrate the Metallo, two DC characters from the comics.

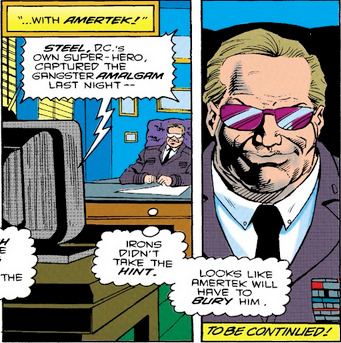

Thomas Weston and AmerTerk makes their first appearance in Steel #2 (1994) [W: Louise Simonson, Jon Bogdanove, P: Chris Batista, I: Rich Faber, Andrew Pepoy, C: Gina Going, L: Pat Brosseau]. In the comics Thomas Weston is a Colonel and CEO of Amertek Industries where it is a weapons manufacturing company for the government but upon seeing the weapons be used in the streets of Metropolis, John Henry Irons quits his job as their engineer and destroys all the schematics he had on the weapons, but Amertek Industries was still able to steal John's armor designs for soldiers. If you want to check out John's adventures as Steel give Death of Superman, Reign of the Supermen, Steel, and the current series Steelworks, a read. They're all pretty awesome! Also if you like John Henry Iron's premise give Milestone Comics' Hardware a shot too, same with the current Hardware series too!

Metallo's name was first used in World's Finest #6 (1942) [W: Jerry Seigel, P&I: John Sikela) where Metalo, here aka George Grant, was a scientists who wore a metal suit to rob a train.

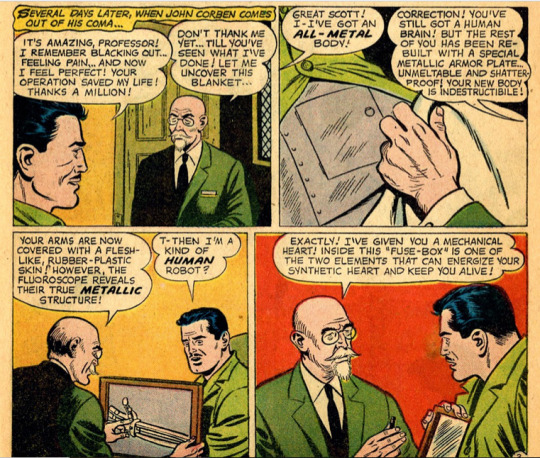

The next Metallo was John Corben who first appeared in Action Comics #252 (1959) [W: Robert Bernstein, P&I: Al Plastino], the same comic with Supergirl's first appearance. Here, John Corben's car swerved off a cliff and Professor Vale was able to replace his limbs and heart with metal while his heart is powered by uranium until John Corben learned that Kryptonite would be a better substitute because his uranium heart can only last for a day, while Kryptonite would not need to be replaced at all.

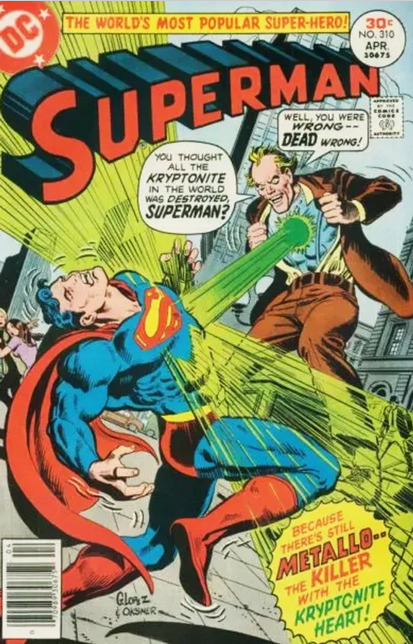

The next Metallo is Roger Corben who first appeared in Superman #310 (1977) [Cover art by Jose Luis Garcia-Lopez and Bob Oksner]. Here, Roger Corben was part of SKULL who engineered Roger's death in order to create a second Metallo just like his deceased brother, John Corben. SKULL manipulated Roger to blame Superman for his misfortune and to seek revenge for his brother.

The more modern Metallo returns this time as John Corben again post-Crisis on Infinite Earths, in Superman #1 (1987) [Cover art by John Byrne, W&P: John Byrne, I: Terry Austin, C: Tom Zuiko, L: John Costanza]. Here, Metallo was built by scientist Emmet Vale, who transferred John Corben's brain to the robot body after Corben's car accident, and using technology stolen from Clark's rocket ship that brought him to Earth. He found bits of Kryptonite and coined it that which is used to power Corben's new body.

At the presentation Vicki Vale tries to get the story from Lois and I talked a bit about her here and she later name drops Palmer Tech. While not in the comics Palmer Tech is a reference to Palmer Technologies from the CW Arrow-verse where it is specialized in nanotechnology founded by Ray Palmer (played by Brandon Routh who was formerly Superman in Superman Returns and Superman again in the CW Arrow-verse) which segues to...

Ray Palmer aka the Atom who first appeared in Showcase #34 (1961) [Cover art by Gil Kane, Murphy Anderson, and Ira Schnapp]. Ray Palmer is a professor from Ivy Town. He stumbles upon a White Dwarf Star fragment which when shot with ultraviolet light can cause anything touching the light to shrink, however after a few minutes later that shrunk object would explode. When Ray used the fragment on himself though, he was able to shrink fine and returned to his normal height. It's hypothesized that his Metagene is what made it safe for him to shrink and grow and as a result he built a device to control the size shrinking and growing on his belt and thus the Atom was born.

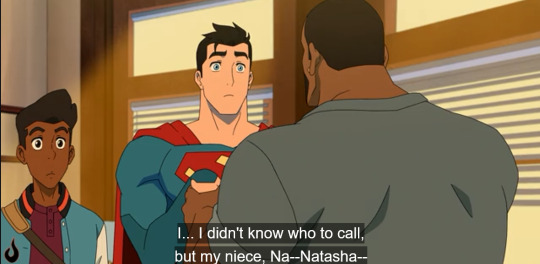

Later in the episode Clark and Jimmy meet up with Flip and John comes in to greet the former two and name drops his niece, Natasha.

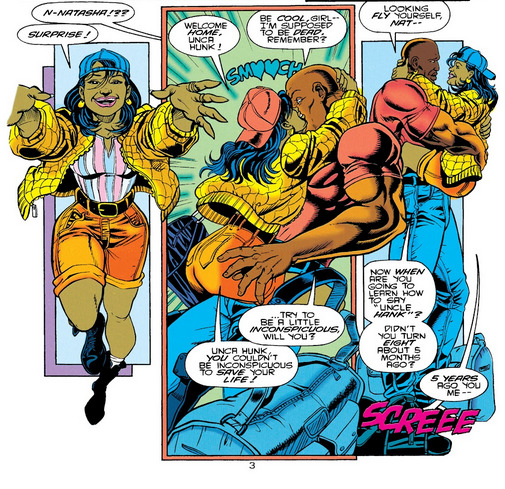

Natasha Irons makes her first appearance in Steel #1 (1994) [W: Louise Simonson, Jon Bogdanove, P: Chris Batista, I: Rich Faber, C: Gina Going, L: Pat Brosseau] where she greets John who arrived back in Washington DC. Years later in Action Comics #806 (2003) [W: Joe Kelly, P&I: Karl Kerschel , C: Guy Major, L: Comicraft] where after facing the news of her uncle John retiring the Steel mantle, Natasha discovers the hammer and unlocks a recording he made where he discussed the new suit he built. Natasha dons the cool as hell new armor and takes up the Steel name. Fingers crossed Natasha gets to show up and suit up as well, maybe even team up with Kara in the future if that happens?!

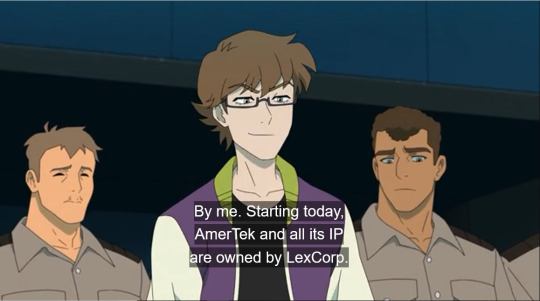

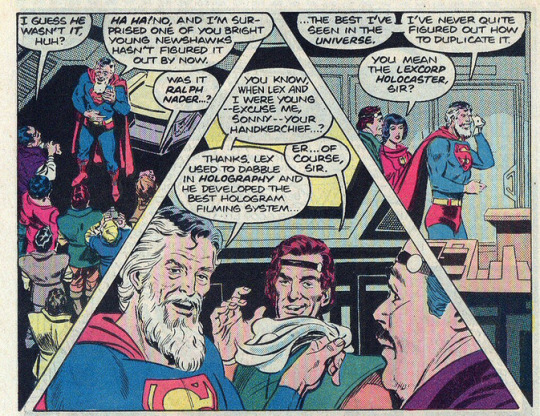

At the end of the episode Lex unfortunately buys out AmerTek and renames it to LexCorp. LexCorp was first mentioned in Superman #416 (1986) [W: Elliot S. Maggin, P: Curt Swan, I: Al Williamson, C: Gene D'Angelo, L: Duncan Andrews] where Superman encounters a hologam message from Future Superman telling him to not pursue Lex who will save a child that will cure him of his obsessive hatred for Superman which then leads to Lex using his brains to benefit humankind like the holocaster that is mentioned in the panels. The later iteration of Lex where he is a shady businessman when John Byrne took over the Man of Steel and Superman titles helped establish LexCorp to what we know today in pop culture (fantastic runs btw definitely recommend reading them).

And with that episode 3 is done! Come back next week for episode 4's references and Easter eggs!

My Easter eggs lists for season 1 is here if you haven't seen it!

My season 2 episode 1 Easter eggs and references in My Adventures with Superman post is here

My season 2 episode 2 Easter eggs and references in My Adventures with Superman post is here

My Easter eggs and references in My Adventures with Superman comic issue 1 post is here

My season 2 episode 4 Easter eggs ad references in My Adventures with Superman post is here

My season 2 episode 5 Easter eggs and references in My Adventures with Superman post is here

My season 2 episode 6 Easter eggs and references in My Adventures with Superman post is here

My season 2 episode 7 Easter eggs and references in My Adventures with Superman post is here

My Easter eggs and references for My Adventures with Superman comic issue 2 post is here

My season 2 episode 8 Easter eggs and references in My Adventures with Superman post is here

My season 2 episode 9 Easter eggs and references in My Adventures with Superman post is here

My season 2 episode 10 Easter eggs and references in My Adventures with Superman post is here

My Easter eggs and references for My Adventures with Superman comic issue 3 post is here

#my adventures with superman#My adventures with superman season 2#MAwS season 2#MAwS#Clark Kent#Superman#Lois Lane#Jimmy Olsen#Bio Electric Aura#Silas Stone#Victor Stone#Cyborg#Fullmetal Alchemist#John Henry Irons#Steel#Thomas Weston#Metallo#John Corben#Roger Corben#Ray Palmer#Atom#The Atom#Palmer Tech#Palmer Technologies#AmerTek#Amertek Industries#Natasha Irons#LexCorp#DC#DC Comics

101 notes

·

View notes

Text

youtube

How Tamahagane (Japanese steel) was made, video by Life were I'm from.

As Japan did not have many iron ore deposits, it had for a long time to rely on more available satetsu 砂鉄 (ironsand, carried for ex. by rivers). Ironsand was then processed in special furnaces called tatara to make prized tamahagane 玉鋼 (traditional Japanese steel, used among other things to forge swords).

If you've seen Princess Mononoke, you know exactly how tatara forge could look like thank to Lady Eboshi's Iron Town:

... and now I have the Tatara women work song stuck into my head <3

youtube

#japan#video#Life were I'm from#arts and crafts#japanese history#tamahagane#steel#satetsu#iron#ironsand#forge#tatara#furnace#industry#princess mononoke#mononoke hime#Tatara women's work song#music#Youtube

297 notes

·

View notes

Text

Steel mill

“Metallurgist working by the blast furnaces in Třinec Iron and Steel Works.” - via Wikimedia Commons

#wikipedia#wikipedia pictures#wikimedia commons#industry#metallurgy#metallurgist#blast furnace#lavacore#steel mill#manufacturing#industrial manufacturing#fire#steel works#třinec iron#steel

36 notes

·

View notes

Text

#fallen london#some of these are not like the others lmao had to stretch for pages cups and wines#and one of them is an es!#it's iron for me personally i live in pgh and steel industry dangerous and scary XD#the real horror is the real industries etc#and real antique shops feel haunted ok bye

51 notes

·

View notes

Text

Excerpt from this story from Grist:

Demand for steel is on the rise globally, driven by population growth and the expanding economies in developing nations. The material will also be important to the green energy transition, forming the backbone of infrastructure like wind turbines, solar panels, and hydroelectric dams. Every part of the steel supply chain is heavily polluting, and the places in the U.S. where the steel industry is concentrated are disproportionately low-income and nonwhite, highlighting yet another instance in which the promises of development and climate solutions come at a steeper cost for some communities. What’s more, the country’s steel production is dominated by just two companies: U.S. Steel and Cleveland Cliffs.

For both companies, much of their production begins with taconite, a low-grade iron ore mined in the northeast Minnesota’s Mesabi Iron Range, which is processed into pellets that get shipped to the steel mills of Gary, Indiana. The extraction of the ore from taconite rock releases a slew of toxic pollutants into the air, including mercury, lead, and dioxins. In this region, the most concerning of these emissions is mercury.

Studies have connected mercury to a litany of negative health effects. It’s a neurotoxin that can interfere with brain development in unborn children and an endocrine disruptor that can weaken the immune system. Scientists have yet to determine a quantity of mercury that is safe for human consumption. One recent study found that there is “no evidence” for a threshold “below which neuro-developmental effects do not occur.” And while the taconite industry releases less than a ton of mercury into the atmosphere every year, the metal is toxic in extremely small quantities: A fraction of a teaspoon can contaminate a 20-acre lake.

The nation’s six taconite plants, all in this region of Minnesota, are owned by U.S. Steel and Cleveland Cliffs. In May 2023, the Environmental Protection Agency proposed a regulation that would require the companies to cut their mercury emissions by around 30 percent. In order to meet that standard, the companies would have to install equipment that would inject carbon atoms into their industrial chimneys so that the carbon would attach itself to the mercury atoms, making the pollution particles bigger and allowing them to get trapped in a filter before they would be released into the atmosphere. The agency estimates that its regulation would cost the industry $106 million in capital costs and $68 million per year thereafter.

Last month, when the standards were finalized, both companies sued. They argue that the regulation would pose “irreparable harm” to the industry, because of the steep costs of implementation. They also argue that the EPA’s proposed method for reducing mercury pollution would actually be worse for public health, causing a 13 percent increase in the amount of the toxic metal deposited in the local environment.

Jim Pew, a lawyer at Earthjustice who has litigated multiple lawsuits against the EPA for its failure to curb pollution from the taconite industry, pointed out that the costs of implementing the required equipment would be a tiny fraction of the companies’ annual sales, which totaled $40 billion in 2023. Pew noted that U.S. Steel recently initiated a $500 million stock buyback program, the mark of a healthy income revenue stream. As for the companies’ claim that the technology would increase mercury pollution, Pew called it “meritless.” The companies are “relying on a premise they know to be false” — that taconite plants would add the carbon technology without also improving their filtration system.

“I find this reprehensible and shameful,” Pew said. “While it’s claiming that it can’t spend money to clean up historic pollution, U.S. Steel is just handing out money to its shareholders.”

2 notes

·

View notes

Text

اليوم العالمي للسرطان 🎗️🌎

4 - فبراير

اليوم العالمي للسرطان الذي يقام كل 4 فبراير هو مبادرة عالمية موحدة يقودها الاتحاد الدولي لمكافحة السرطان (UICC). من خلال رفع الوعي العالمي وتحسين التعليم وتحفيز العمل الشخصي والجماعي والحكومي .

🔺ما هو السرطان؟

السرطان هو مرض يصيب الخلايا في الجسم، مما يؤدي إلى نموها بشكل غير طبيعي وانتشارها إلى أجزاء أخرى من الجسم.

🔺ما هي أعراض السرطان؟

تختلف أعراض السرطان حسب نوعه، ولكن بعض الأعراض الشائعة تشمل:

تغيرات في الجلد

كتل أو تورم في أي مكان في الجسم

نزيف غير طبيعي

ألم أو إزعاج مستمر

تغيرات في عادات الأمعاء أو المثانة

فقدان الوزن غير المبرر

التعب الشديد

ماذا يمكننا أن نفعل معًا لمحاربة السرطان؟

نشر الوعي حول مرض السرطان وطرق الوقاية منه،

🌹🎗️دعم مرضى السرطان وعائلاتهم

🔴 اليوم العالمي للسرطان

"اللهم اجعل الكيماوي برداً وسلاماً على مرضى السرطان"

اللهم اشفي جميع مرضي السرطان

اللهم اشفيهم شفاء لا يغادر سقمآ🤲🎗️

#Algerian Qatari Steel#Slag steel#slag#AQS#IRON#DRI#British uk cares#billets#Rebar#Wirerode#Filmachine#manufacturing#Import#CCM#Export#Industrie#Future#Quality is matter of honor#اليوم العالمي للسرطان#معًا ضد السرطان#worldcancerday#CloseTheCareGap

4 notes

·

View notes

Text

#tmt manufacturer in india#tmt bars#tmt bars exporter#tmt bars supplier#tmt saria#steel iron industry#vedanta metalbazaar

0 notes

Text

What is the difference between steel alloy and cast iron?

To begin with, steel alloy and cast iron are both types of metal alloys that are widely used in various industries. Although they share some similarities, there are significant differences that set them apart. Steel alloy is made by combining iron with other elements such as carbon, manganese, and chromium. Steel typically contains less carbon than cast iron, making it more ductile and malleable. Its tensile strength is higher, and it's more resistant to corrosion, making it ideal for use in building structures, machinery, and automobiles.

Cast iron, on the other hand, is formed by melting iron and adding carbon, silicon, and other elements. Cast iron contains a higher percentage of carbon, making it harder and more brittle. It is generally used in applications where high compressive strength is required, such as in the production of engine blocks, cookware, and pipes. Cast iron is also more prone to cracking under pressure or impact than steel alloy.

In conclusion, the differences between steel alloy and cast iron are based on their composition and properties. Both materials have distinct advantages and disadvantages, and their suitability depends on the specific application. By the way, after talking about it, only one company name comes to my mind that is Datre Corporation Ltd, is a leading manufacturer of high-quality steel casting products that meet the highest industry standards in Eastern India. So you can confidently utilise their products for your industrial needs.

Company name: Datre Corporation

Address: Falta Industrial Growth Center (F.I.G.C), Sector — III South 24 Parganas, Pin — 743 504, West Bengal, India

Phone No: 7605087010, 7605087007, 7605087008

Landline No: +91 7605087008

#stainless steel#cast iron#steel alloy#carbon#steel casting manufacturer#manufacturing industry#manufacturing company#aluminium manufacturer#manufacturer

3 notes

·

View notes

Text

Maintaining Steel Pipes - An insight

MS pipes, also known as Mild Steel Pipes, are increasingly becoming popular in numerous industry domains. The mild steel pipes contain a lower concentration of carbon. Due to the low carbon content, pipes made of mild steel don’t harden.

When the context is about pipe-lining and tubing purposes, you cannot look past mild steel pipes. The mild steel pipes are suitable for firefighting, plumbing, and other industrial applications.

Selecting High-Quality Steel Pipes

Selecting top-quality steel pipes involves many factors. You should approach these considerations to recognize the strengths and weaknesses of the pipe materials. Steel is strong, rigid, and has a lower coefficient of thermal expansion.

Pipes made from structural steel are suitable for in-steam condensate systems. You can also purchase galvanized MS pipes. The galvanized steel pipes are corrosion-resistant and last longer. A galvanized steel pipe has all the benefits of a steel pipe with improved corrosion resistance.

Prevent Contact with Metals to Eliminate Scratches

The last thing you want in a finished steel pipe is scratches. The most frequent cosmetic damages while manufacturing steel pipes are due to the scraping against the die edges. To address this issue, most manufacturers leverage the use of special dies with a larger radius.

The stainless metal sheets are large and thin. If they are not appropriately supported during the casting process, there will be scratches present in the MS square pipe. Manufacturers prevent friction scratching due to other metals by polishing the surface. Polishing and oiling the surface eliminates surface disinfectants.

Dents can affect the structural stability of the mild steel pipes adversely. Manufacturers install systems that can absorb shocks and bumps. By absorbing shocks and bumps, the manufacturers can reduce dents and scratches. The steel pipes should be applied at a sufficient distance from each other to prevent the formation of blemishes.

Conducting a Thorough Inspection is Must

While purchasing mild steel pipes, conducting a thorough inspection is a must. The assessment should analyze certain factors like damage, corrosion, or rusting of the pipes. While purchasing a high-quality MS square pipe, you should look for the presence of scratches and dents.

Pipes made from mild steel are flexible and can get deformed. You should look for signs of surface deformities while buying steel pipes.

Be on the Lookout for the Signs of Rust and Corrosion

Buying non-galvanized steel pipes can derail your project. Corrosion is one of the primary reasons behind the degradation of steel pipes.

While conducting a thorough inspection, you should look for signs of rust. Note that corrosion starts from the inner and outer surface coating. It is necessary for the iron & steel industries to inspect corrosion before procuring them.

Proper Coating and Polishing can Enhance the Stability of Pipes

Coating and polishing can keep the rust away from the surface of the pipes. Here are some of the benefits associated with coating and polishing.

They possess high flexibility when coated with the proper layers

They wouldn’t develop cracks when twisted or bended

The iron & steel industries adopt various measures to make the steel pipes long-lasting. If you are looking for good-quality steel pipes, consult with Suman Industries. They have proven experience in manufacturing high-quality pipes of mild steel.

2 notes

·

View notes

Text

forged in fire

59 notes

·

View notes

Text

Scunthorpe manufacturing history

The iron ore fields of north Lincolnshire attracted iron smelting to Frodingham and Appleby, two villages within what became Scunthorpe. Both companies added steel making, but Frodingham’s pig iron production from the north Lincolnshire ore greatly exceeded its steel making capacity. This attracted Harry Steel, managing director of the Sheffield firm, Steel, Peech and Tozer, who, in the aftermath…

0 notes

Text

0 notes

Text

Ferrochrome Market Size, Share, Demand, Future Growth, Challenges and Competitive Analysis

"Global Ferrochrome Market – Industry Trends and Forecast to 2029

Global Ferrochrome Market, By Type (High Carbon, Medium Carbon, Low Carbon, and Ferro Silico Chrome), Application (Stainless Steel, Cast Iron, Powder Metallurgy, and Others) - Industry Trends and Forecast to 2029.

Access Full 350 Pages PDF Report @

**Segments**

- **Type**: - High Carbon Ferrochrome - Medium Carbon Ferrochrome - Low Carbon Ferrochrome

- **Application**: - Stainless Steel - Engineering Steel - Alloy Steel - Others

- **End-Use Industry**: - Aerospace - Automotive - Construction - Others

The ferrochrome market can be segmented based on type, application, and end-use industry. In terms of type, the market is divided into high carbon ferrochrome, medium carbon ferrochrome, and low carbon ferrochrome. High carbon ferrochrome is primarily used in stainless steel production, while medium and low carbon ferrochrome find applications in engineering steel and alloy steel manufacturing. Regarding applications, ferrochrome is extensively utilized in stainless steel, engineering steel, alloy steel, and other sectors. Moreover, in terms of end-use industries, aerospace, automotive, construction, and other sectors are major consumers of ferrochrome.

**Market Players**

- Glencore - Eurasian Resources Group - Samancor Chrome - Hernic Ferrochrome - IFM (International Ferro Metals)

The ferrochrome market features key players such as Glencore, Eurasian Resources Group, Samancor Chrome, Hernic Ferrochrome, and IFM (International Ferro Metals). These companies are actively involved in the production, distribution, and marketing of ferrochrome products globally. Glencore, a renowned name in the mining and metals industry, has a significant presence in the ferrochrome market. Similarly, Eurasian Resources Group and Samancor Chrome are major players with a strong foothold in the market. Hernic Ferrochrome and IFM (International Ferro Metals) also play crucial roles in shaping the competitive landscape of the ferrochrome industry.

https://www.databridgemarketresearch.com/reports/global-ferrochrome-marketThe ferrochrome market is witnessing significant growth driven by the increasing demand for stainless steel, engineering steel, and alloy steel across various industries. Stainless steel, a key application of ferrochrome, is widely used in sectors such as construction, automotive, and aerospace due to its corrosion resistance and durability. The aerospace industry, in particular, relies on high-quality stainless steel components for aircraft manufacturing, driving the demand for high carbon ferrochrome. Similarly, the automotive sector utilizes ferrochrome in the production of components such as engine parts and exhaust systems, contributing to the market's growth.

Moreover, the construction industry plays a crucial role in the demand for ferrochrome, as stainless steel is extensively used in infrastructure projects, architectural structures, and building materials. The superior strength and aesthetic appeal of stainless steel make it a preferred choice in construction applications, thereby propelling the consumption of ferrochrome in this sector. Additionally, the engineering steel segment benefits from the properties of medium and low carbon ferrochrome, which enhance the mechanical properties and machinability of steel products used in various industrial applications.

In terms of market players, companies such as Glencore, Eurasian Resources Group, Samancor Chrome, Hernic Ferrochrome, and IFM (International Ferro Metals) are key players driving the growth and innovation in the ferrochrome industry. These companies have a strong global presence and invest in research and development to improve product quality and cater to evolving consumer needs. Glencore, known for its expertise in mining and metals, leverages its extensive resources and technological capabilities to maintain a competitive edge in the ferrochrome market.

Furthermore, technological advancements and strategic alliances among market players are expected to shape the future landscape of the ferrochrome market. Collaboration between manufacturers, end-users, and research institutions can lead to the development of advanced ferrochrome products tailored to specific industry requirements. The growing focus on sustainable practices and environmental regulations also drives innovation in ferrochrome production processes, aiming**Global Ferrochrome Market Analysis**

- **Market Trends**: - The ferrochrome market is experiencing growth due to the rising demand for stainless steel across various industries, including automotive, construction, and aerospace. Stainless steel's corrosion resistance and durability make it a preferred material, driving the need for ferrochrome as a key alloying element. - The construction industry is a significant driver of ferrochrome consumption, as stainless steel is widely utilized in infrastructure projects and architectural applications. The strength and aesthetic appeal of stainless steel contribute to its popularity in the construction sector, thereby boosting the demand for ferrochrome. - Technological advancements and strategic collaborations among market players are shaping the future of the ferrochrome market. Companies are investing in research and development to enhance product quality and meet evolving consumer requirements. Additionally, a focus on sustainable practices and environmental regulations is driving innovation in ferrochrome production processes.

- **Market Forecast**: - The global ferrochrome market is projected to witness steady growth in the coming years, driven by an increasing preference for stainless steel in various applications. The aerospace industry's demand for high-quality stainless steel components and the automotive sector's reliance on ferrochrome for engine parts and exhaust systems will further propel market growth. - The construction industry's continued investments in infrastructure development and architectural projects will fuel the consumption of ferrochrome for stainless steel applications. Moreover, the engineering steel segment is expected to benefit from the properties of medium and low carbon fer

Highlights of TOC:

Chapter 1: Market overview

Chapter 2: Global Ferrochrome Market

Chapter 3: Regional analysis of the Global Ferrochrome Market industry

Chapter 4: Ferrochrome Market segmentation based on types and applications

Chapter 5: Revenue analysis based on types and applications

Chapter 6: Market share

Chapter 7: Competitive Landscape

Chapter 8: Drivers, Restraints, Challenges, and Opportunities

Chapter 9: Gross Margin and Price Analysis

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Browse Trending Reports:

Bio Based Succinic Acid Market Baselayer Compression Shirts Market Trauma Devices Market Dairy Flavours Market Immunogenetics Market l Carnitine Market Iv Infusion Bottle Seals And Caps Market Self Storage And Moving Services Market Acute Bronchitis Market Thrombophilia Market Tetracyclines Market Agricultural Biologicals Market Two Part Adhesive Market Labeling Equipment Market Fruit And Herbal Tea Market Air Filter For Automotive Market Organic Feed Market Soy Milk Infant Formula Market Pallet Stretch Wrapping Machine Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

#Global Ferrochrome Market – Industry Trends and Forecast to 2029#Global Ferrochrome Market#By Type (High Carbon#Medium Carbon#Low Carbon#and Ferro Silico Chrome)#Application (Stainless Steel#Cast Iron#Powder Metallurgy#and Others) - Industry Trends and Forecast to 2029.#Access Full 350 Pages PDF Report @#https://www.databridgemarketresearch.com/reports/global-ferrochrome-market#**Segments**#- **Type**:#- High Carbon Ferrochrome#- Medium Carbon Ferrochrome#- Low Carbon Ferrochrome#- **Application**:#- Stainless Steel#- Engineering Steel#- Alloy Steel#- Others#- **End-Use Industry**:#- Aerospace#- Automotive#- Construction#The ferrochrome market can be segmented based on type#application#and end-use industry. In terms of type#the market is divided into high carbon ferrochrome

0 notes

Text

Australia, the land of iron ore exports, faces a green reckoning. (Washington Post)

Excerpt from this story from the Washington Post:

For more than a century, Australia has fed the world’s hunger for iron ore. Vast swaths of the rusty red Outback have been dug up and delivered overseas to make the steel that helped transform other nations: first the United States, then Japan and most recently China,which buys more than 80 percent of Australia’s iron ore.

Now that trade is at risk as China’s slumping economy dries up its demand for construction materials.

But there is a bigger threat. Governments around the globe are beginning to crack down on the steel industry, which is responsible for roughly 10 percent of global CO2 emissions.

Australia — the world’s biggest iron ore exporter, accounting for almost 60 percent of the global market — has the most to lose. That’s because its ore happens to be poorly suited for making the “green” steel the globe increasingly demands.

Australian iron miners are trying to adapt and maintain their place in the global market. For decades, they have been pulling raw iron ore out of the ground and exporting it to be made into steel. That was the dirty, basic commodity way.

But as Beijing begins to look elsewhere for better ore, Australian miners are looking to move up the value — and the environmental — chain by using renewable energy to turn their ore into “green” iron for export.

Companies and state governments are pressing ahead with efforts to use green hydrogen — which is made using solar or wind power and produces almost no carbon emissions, unlike coal — to enable them to churn out more valuable and environmentally friendly “green iron” for export. Steelmaking nations such as Japan, South Korea, Germany and China will turn that iron into green steel for electric vehicles, appliances, bridges and skyscrapers.

Companies in other parts of the world — from Sweden and Canada to Brazil and parts of Africa — are attempting to make the same shift.

The state has all the ingredients for green iron, according to analysts and officials. Though it mines far less than Western Australia, South Australia is rich in magnetite, a type of iron ore that, when processed, is pure enough for making green iron and steel. It also has abundant wind and sun, one of the country’s two remaining steelworks and, importantly, political resolve.

Steelmaking is normally a dirty business. Iron oxide ore is fed into coal-fired blast furnaces, which remove the oxygen and produce iron that can be strengthened into steel. For each ton of steel, the process creates about two tons of CO2.

More than 70 percent of the world’s steel is still made using the centuries-old technique. But efforts are underway to clean up the industry, driven in part by tougher regulation. The European Union will impose levies on steel and other carbon-intense imports starting in 2026, and the United States is considering similar steps.

“We don’t get to net zero by 2050 globally without decarbonizing steel,” Malinauskas said. “Markets are realizing this. Regulators are realizing this.”

One way to clean up the industry is by replacing blast furnaces with a process called direct reduction, which uses natural gas or hydrogen to lower emissions.

Only a handful of countries have both the iron ore and green hydrogen ability required, Nicholas said.

1 note

·

View note