#spokeshaved rasp

Explore tagged Tumblr posts

Text

I Want To Shout About It — JOE BONAMASSA #jbonamassa #bluesguitar #BluesRoots

I Want To Shout About It — JOE BONAMASSA #jbonamassa

The blues rock legend JOE BONAMASSA is back with a brand-new single from his eagerly awaited new studio album, due later this year on his J&R Adventures label. Joe performs a mesmerising cover of “I Want To Shout About It,” which was originally recorded by “Speakeasy” Ronnie Earl and the Broadcasters, a Queen’s New York blues-elder statesman that’s never before properly celebrated until this…

View On WordPress

#Asbury Jukes#Charles Jones#Dannielle DeAndrea#Darrell Nulisch#Flushing railcar#I Want To Shout About It#J&R Adventures#Josh Smith#neil mach#Paulie Cerra#raw ramp#rawramp#Reese Wynans#Ronnie Earl and the Broadcasters#Southside Johnny#spokeshaved rasp

0 notes

Photo

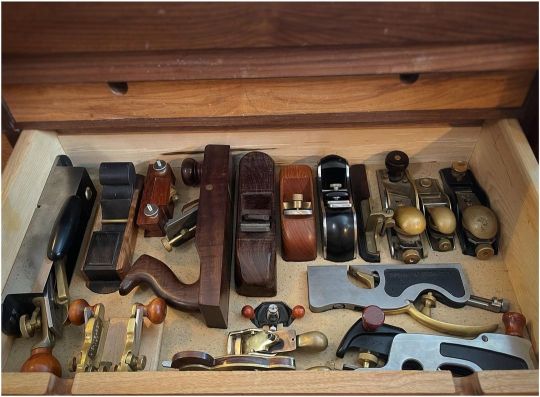

There’s something very satisfying about having your most used hand tools at arms reach. Safely stored, ready to work. This week I’ve been fitting out the drawers in my workbench, French fitting planes and building sliding trays that will hold chisels, spokeshaves and rasps. This is something that’s been on my “to-do” list for quite some time now so it feels great to finally make time to do it. I’m waiting for my wood to arrive before I can begin work on my exterior wooden doors so this is a quick little project while I wait. Follow along with this week’s episodes… details on the Unplugged Woodshop website. #theunpluggedwoodshop #anunpluggedlife #woodworking #workbench #handtools #handplanes #handtoolsonly #unpluggedwoodworking #woodworkingproject #madebyhand #handcrafted #frenchfit #toronto #leslieville #unplugged (at The Unplugged Woodshop) https://www.instagram.com/p/CoGuZUEODZY/?igshid=NGJjMDIxMWI=

#theunpluggedwoodshop#anunpluggedlife#woodworking#workbench#handtools#handplanes#handtoolsonly#unpluggedwoodworking#woodworkingproject#madebyhand#handcrafted#frenchfit#toronto#leslieville#unplugged

8 notes

·

View notes

Text

Side axe continued. Roughed out handle has been rasped, planed and then spokeshaved to shape, being careful to keep the grown in curve just below where the axe head will sit so that in use the angle will keep one's hand out from the work, but the axe head flush to it. Cut and shape the haft to fit the axe socket, with slot for wedge, cut oak wedge, hammer home, then steel wedge across that. I now have a century and a half old side axe to use.

4 notes

·

View notes

Text

Filing, Planing, And Sanding Supplies Used In Woodworking

After wood pieces have been cut to a demanding silhouette, they want more job to present a attractive, finished appearance. No matter how nice your saw blade is and just how fine the quality, you need some kind of submitting, planing and sanding supplies. Here's what starting carpenters Should Think about investing in:

Wood Planes

Wood planes are cutting tools in place of abrasive, and sanding devices. All sorts of planes make work with of a blade to shave wood fibres, letting them become simpler and choose shape. Depth and blade measurement will be the essential factors in how much material may be eliminated at a moment; point. Visit our website for effective information about Tools cue now.

You will hear a few plane are known which sound quite international, if not amusing. planes and port planes shave timber, however they have software. You hear terms such as blocks jointer and spokeshaves. You'll notice them referred to by numbers. They types of hand planes which beginning carpenters should investigate. These are hand planes' Array you may need:

Jack plane: All these tools take away a lot of stuff in an extended given pass. It's really a "jack of all trades" tool mainly because you will find both curved border and directly edge types obtainable - for either smoothing or jointing, respectively.

Block Planes: These planes are somewhat smaller and stout. They truly are perfect for operate.

Joining Planes: Like jack planes, except they truly are designed to easy borders and also join items together. Typically, jointers have frames.

Rabbet Planes: Employed for cutting angle grooves along plank grain. These joints have been known as rabbets, which range from membranes termed dadoes.

Scraper Planes: Designed to scratch off fine fibers timber surfaces for super-smooth finishes. These planes are called cupboard scrapers.

Spokeshaves: solid planes created for curved surfaces. They were for wagon wheel spokes, however they found their handy method to all carpenters.

Orbital-Sander

If you're going to get a electrical wood-finishing tool, it needs to really be an orbital sander. All these machines that are fast-action take all of the stress out of hand sanding and then do it a lot faster. Sanders vary from in-line tools like belt sanders. They use glue pads revolving at a round or orbital pattern.

Regular ultrasonic sanders take a circular abrasive sandpaper disk and twist it in a circle. They have a tendency to render Even though they take away material quick. A orbital sander is the very best purchase. They do not float. They oscillate at a random style leaving the timber surface clean and mark-free.

Hand Files

Often, there is absolutely no greater tool than the usual palm file to shape and smooth timber. Data files are inexpensive and persist for a very long time should you get ones made out of steel. Hand files will be replaced in the place of trying to sharpen them, After uninteresting. Here are your hands file choices:

Rasps are all rough-edged tools with coarse tooth. They may be used to eliminate large quantities timber to shaping allow files that were finer to shoot over.

Half round files possess a flat coating on a single side along with a curved deal with on the other. This enables these be functioned on straight and curved surfaces.

Mill files are horizontal onto both the faces. They normally have rough teeth one side and fine around the opposite. Mill files additionally have potential advantages for restricted spaces.

Rotary cutters are somewhat similar to hand files, except they truly are intended as electrical drill pieces. Now you let the abrasive actions take out substance and set them. Documents are offered in grits that are cutting and different layouts.

Employed files are also utilised to sharpen your other woodworking blades and bits. Metal files have teeth that are exceptionally handsome and are composed of stainless steel. Just like absolutely any tool, you get what you buy, and it's worth investing in high-grade hand files.

Meeting equipments For carpentry

Cutting and smoothing wood is only part of your total carpentry procedure. They need assembling once your parts are precisely sized and eloquent for endings. Woodwork meeting that is successful is dependent upon just two things. You need accuracy straps that'll match. In addition, you need the tools to build and fasten them.

1 note

·

View note

Text

Restored Hand Tools

They don’t make hand tools like they used to, and these ones have already held up for more than a lifetime.

The set included a small shoulder plane, a No. 5 plane, a compass plane, a rasp and two different-sized spokeshaves.

Everything was de-rusted, paint stripped, blades cleaned, wood refinished and re-assembled. The compass plane needed a lot more metalworking than I’m comfortable with, so I sent to Eric at Hand Tool Rescue who restored it in this fantastic video.

1 note

·

View note

Photo

Yesterday Freddie and his Mum joined me in the workshop, here is the oak stool he made! I particularly liked the curved back of the seat, this was shaped by Freddie using a spokeshave and a Auriou rasp. Nice to see such enthusiasm from a young aspiring woodworker 😃 (at David Stephenson Bespoke Furniture Hampshire) https://www.instagram.com/p/B8uDOUfAyjI/?igshid=9iysvqqpjj31

0 notes

Photo

For #handtoolthursday, from front to back: UW Two-Handed Corse Rasp, @leevalleytools flat bottom spoke shave, @hntgordon round bottom spokeshave, @bearkatwood chair scraper. These were the tools I used to shape the chair back stiles for the #jsmakesmorrischair project, which is quickly coming to a close. #jstarrmakes #theUnpluggedWoodshop #theUWToronto #woodworking #handtools #Toronto #Ontario #Canada #RiversideTO #leslieville #madebyhand #handcrafted #wood #woodworkingschool #nopowernoproblem (at The Unplugged Woodshop)

#jsmakesmorrischair#jstarrmakes#riversideto#leslieville#handcrafted#madebyhand#ontario#theunpluggedwoodshop#toronto#canada#theuwtoronto#handtools#woodworkingschool#nopowernoproblem#handtoolthursday#wood#woodworking

1 note

·

View note

Text

Travisher

I’ve briefly mentioned the idea of using a travisher on bowls, in this post for example. The travisher in that post was one I had made years before using a blade that I purchased from Country workshops. I used it for the occasional chair seat and for other tasks. It’s the one at the top of the photo below:

The travisher below it in the photo is one that I purchased from James Mursell’s website. I found that it had some great features. Two deeply recessed set-screws hold the blade firmly in position. The shavings exit the top rather than the back, allowing for thumbs to be placed on the solid wood behind the blade, great for control and comfort. The tighter radius (about a 4 1/2″ radius) made it more versatile than my other travisher.

Still, there were some aspects of the design that made it difficult to use for bowls — which is no surprise, since it wasn’t designed for that use. I experimented and made some important modifications to the body that made it more ideal for bowl shaving. I’ll show you what I did below. Pretty simple, really. By the way, I have absolutely no connection with James Mursell.

Notice the red line I drew on the travisher in the photo above. Trim the sole back to the red line, leaving about 1/2″ of sole in front of the blade. The set screws are recessed deeply enough that they’re not affected at all. In the photo below, that has been done.

Above and below are two different views of the handles after I shaved recesses to either side of the blade. This allowed my ring and pinky fingertips to fit under the handles which also helps with control.

The last step is to round the sole in front of the blade down to a line about 1/8″ or so above the existing toe (see the pencil line in the photo below).

You want a gentle arc from the existing wood right in front of the blade down to the pencil line.

I used a finely set spokeshave, but a rasp or block plane would work as well.

Here’s how I hold it in general. My thumbs are pressing on the wood behind the blade.

You certainly don’t need a travisher for carving bowls, and it’s really off limits for some bowl designs and sizes, but for general medium to large bowls it can be useful for fairing the hollow. The compact size makes it pretty nimble and versatile. I’ve used it occasionally as an intermediate step, but I suppose one could choose to leave the surface directly from the travisher.

Here’s one final shot with a ruler for reference.

from David Fisher, Carving Explorations http://bit.ly/2M4JQ6h

0 notes

Photo

0 notes

Photo

Without further ado, I present The Unplugged Woodshop TWO-HANDED RASPS. Now available for pre-order!!! "For years I’ve been watching boat builders and luthiers, furniture, chair and cabinet makers use traditional style rasps for shaping their work. I’ve also noticed that we tend to hold the rasp handle with one hand, and awkwardly grip the tip of the rasp with the other. With a very real danger of injury and discomfort, I’ve seen makers wrap the ends of their rasps with tape, be forced to wear gloves while they work, and even purchase auxiliary, clip-on handles in an attempt to make these tools more user friendly. I finally decided there had to be a better way. Reaching out to Noel Liogier, a master rasp maker in Lyon, France with four generations of experience, I asked if he could make us a set of two-handed rasps ranging from a coarse #9, a medium #6, to a fine #13. I designed these rasps to be used like a spokeshave and have dimensioned them accordingly. With a working area approximately 4” long and 1” wide, these rasps have both a flat and a half round surface. Another critical factor we considered is the direction of the cut. Standard rasps have the teeth running along the length, while ours have the teeth running horizontally, across the width of the tool, again having a feel similar to a draw knife or spokeshave. With an overall length of 12 3/4”, these two handed rasps feel absolutely amazing in hand and in use. Boat builders and luthiers, saw makers and furniture makers will love using these tools. With comfortable, locally sourced walnut handles and fine brass ferrules, they’re available individually or as a set of three. The Unplugged Woodshop Two-Handed Rasps are now available for pre-order, and once again, they’ll change the way you work wood." #theunpluggedwoodshop #twohandedrasp #newtools #preorder #internationalshipping #toolmaker #toolmaking #woodworkingtools #shapingwood #handtoolsonly #handtools #instrumentmaker #designermaker #furnituremaker #boatbuilding #guitarmaker #torontomakers #madebyhand #nopowernoproblem #liogier #handstitched #walnut #toronto #leslieville #anunpluggedlife #2handedrasp (at The Unplugged Woodshop)

#liogier#shapingwood#13#preorder#instrumentmaker#handstitched#furnituremaker#leslieville#9#guitarmaker#internationalshipping#nopowernoproblem#torontomakers#madebyhand#woodworkingtools#boatbuilding#designermaker#toolmaking#toronto#twohandedrasp#6#anunpluggedlife#theunpluggedwoodshop#newtools#toolmaker#handtoolsonly#walnut#2handedrasp#handtools

9 notes

·

View notes

Photo

My mobile bow making set up 😊 Otherwise know as the mess in the back of my vehicle. I often need to get a potential bow quickly roughed out immediately after harvesting so it will dry properly without cracking. I use the drawknife for big pieces, then the spokeshave for around knots. I'll clamp this stave to a board for a week and then finish the rest of the bow with rasps and cabinet scrapers. Look how pretty this piece of vine maple is. Took me hours to find it, but there's no knots and this sapling told me it really wants to be a bow! #bowyer #longbow #deadlystick #primitivearchery #traditionalarchery #archery

7 notes

·

View notes

Text

Craft an impressive cutting board in eight easy steps

Start now so you're ready the next time you see another human being. (Courtney Starr/)

The warmth and natural qualities of a handmade charcuterie board make it the perfect way to welcome a guest. This is a simple project that can be completed with a basic set of tools—without electricity, even. You’ll find plenty of uses for this piece as you chop veggies on it, serve food to friends and family, and display it in your kitchen.

Warning: DIY projects can be dangerous, even for the most experienced makers. Before proceeding with this or any other project on our site, ensure you have all necessary safety gear and know how to use it properly. At minimum, that may include safety glasses, a face mask, and/or ear protection. If you’re using power tools, you must know how to use them safely and correctly. If you do not, or are otherwise uncomfortable with anything described here, don’t attempt this project.

Stats

<b>Time:</b> 4 hours

<b>Material cost:</b> $10 (wood only)

<b>Difficulty:</b> easy

Materials

One piece of hardwood (mine was an 8-by-16-inch piece of live edge cherry)

Paper (for a template)

<a href="https://ift.tt/2A5VGeb" target=_blank>Osmo TopOil</a>

Tools

<a href="https://ift.tt/2WX0XOt" target=_blank>Hand plane</a> (or a <a href="https://ift.tt/3bTUsA9" target=_blank>thickness planer</a>)

<a href="https://ift.tt/2TRPRsV" target=_blank>Coping saw</a> (or a <a href="https://ift.tt/2uAj6WE" target=_blank>bandsaw</a>)

<a href="https://www.googleadservices.com/pagead/aclk?sa=L&ai=C_KVJVUKTXuXCNJP6j-8P1tKrgA_4uKWwXJnvs_v2Cq_oiNyQDAgDEAEguVRgyfaliqSkxBGgAZjP1MoCyAEBqQKhyCQLAwuoPsgD2CCqBD5P0P6t_eFFkd5jUoz2HHoQOX9QgRsQ9galhACxZnqOK02fqV4zyUJFr6_7E9-U9C5AEUN5DmbmE8ht2hVg0MAEiq7hx8QCgAWQTqAGWYAH0LCrtQGQBwGoB6a-G6gH8NkbqAfy2RuoB_PRG6gH7tIbqAfK3BuoB8LaG9gHAbAIAdIIBRACIIQBmglhaHR0cHM6Ly93d3cubGVldmFsbGV5LmNvbS9lbi11cy9zaG9wL3Rvb2xzL2hhbmQtdG9vbHMvZHJpbGxzLzMyMzAwLXR3by1hbmQtdGhyZWUtamF3LWNodWNrLWJyYWNlc7EJca3tqLcYz1y5CXGt7ai3GM9c-AkBmAsB&ved=2ahUKEwi2jMH3p-PoAhUPUa0KHRhVBacQ0Qx6BAgOEAE&dblrd=1&val=GgiKeByPLS3EgyABKAAw2rWKy8Llv-LoATirkr_rBUCJ_Mz0BQ&sig=AOD64_3mvyHEb8ppLC_P0Wyf_ingpz2YVQ&adurl=https://www.leevalley.com/en-us/shop/tools/hand-tools/drills/32300-two-and-three-jaw-chuck-braces" target=_blank>Bit brace</a> (or a <a href="https://ift.tt/2NYaTSQ" target=_blank>drill press</a>)

<a href="https://ift.tt/2GjTAY6" target=_blank>Drawknife</a> (or a <a href="https://ift.tt/3c1nVby" target=_blank>spokeshave</a>)

<a href="https://amzn.to/3cSs2I6" target=_blank>Rat tail rasp</a>

<a href="https://ift.tt/2ZuRgZ8" target=_blank>Hand sanding block</a>

<a href="https://amzn.to/3bP1lCQ" target=_blank>Compass</a>

Scissors

Build it

1. Trace a shape onto a piece of wood. I’ve always been attracted to serving boards that embrace the natural qualities of wood. Live edge boards do this well, as each slab features the natural exterior of the tree it came from. I’d recently picked up a piece of live edge cherry that seemed perfect for this project, I let the natural edge of the piece define the shape of the board. Additionally, because I enjoy inviting the wood to make design decisions, I shaped the handle on my charcuterie board to follow the cathedral grain pattern in the wood. I recommend using a hard wood for your project, as it will resist the wear and tear of chopping.

You can freehand a unique shape that you won't find in a store, but feel free to use a compass if you want any precise curves. (Courtney Starr/)

2. Create a template. Cutting a template out of paper can help you get a feel for whether or not you like the shape you’ve drawn. You can hold it in your hand, see if the size feels good, and easily manipulate the shape by slicing off slivers of paper to get the design just right. Additionally, you’ll have the benefit of being able to reproduce the project in the future if you’d like. If you need help making nice curves, consider using a French curve, or even tracing the shape of an existing item in your house that you find attractive.

3. Prepare the wood. You’ll want a nice, flat board, so it doesn’t wobble around on your countertop. I started by removing the bark from my piece with a drawknife, then proceeded to use a hand plane to make both sides of the board perfectly flat.

<b>Note:</b> You can use a power jointer and planer for this step if you have access to them.

<b>Tip:</b> To flatten a board with a hand plane, place the wood on a flat surface and press on each corner to find the high spots on the wood. Then flip the board over and plane them down, checking your work often.

Remove any bark. It doesn't taste very good. (Courtney Starr/)

4. Transfer the template to your board. When your wood is flat and ready to go, trace the final shape onto it.

5. Bore a hole in the handle. If you’re going to make a handmade charcuterie board, you might as well display it. I like when I can hang kitchen accessories, so I recommend boring a hole in the handle of your board around a ¾-inch in diameter. Be sure to leave at least a ½-inch of wood between the hole and the outside edge of the handle.

6. Cut out your board. A simple coping saw will do the job, as its thin blade makes it especially good at cutting along the tight curves of the handle. Don’t fret too much about cutting a perfectly smooth line, as you can correct any mistakes at the next step.

<b>Note:</b> If you have a bandsaw, you can use that for this step.

Use a saw with a thin blade, like a coping saw, to unique designs. (Courtney Starr/)

7. Shape the wood. I prefer to use a drawknife to get the final shape on a charcuterie board. With this basic tool, you can quickly go from heavy stock removal to finessing the smallest details, without missing a beat. I also love the faceted look that drawknives give to the wood since each of the small surfaces left by the blade catch the light in a different way. I figure if I’m making something by hand, you might as well be able to tell! To shape tight corners like the one on the handle, use a round rasp, also called a rat tail rasp.

<b>Tip:</b> If you’re not confident with a rasp or drawknife, try them out on a scrap piece of wood. They’re fairly simple to use with a bit of practice.

You’ll want to round the hole in the handle of your board so it’s easier to hang. (Courtney Starr/)

8. Sand the wood. There’s no need to employ a power sander on such a small project, so sanding by hand will do the trick. I recommend sanding up to 220 grit in order to get a nice, smooth surface that will be easy to clean.

9. Finish the board. Applying finish to a charcuterie board is important, as it will encounter harsh treatment from chopping, serving moist foods, and getting washed after use. I chose Osmo’s TopOil to finish my board because it’s food safe and gives the wood a beautiful look and feel.

<b>Note:</b> It’s imperative to choose a finish that is food safe. Make sure to read the production description carefully to determine whether or not your finish of choice is rated for direct contact with food.

Apply a finish that is food safe and easy to refinish after extended use. (Courtney Starr/)

0 notes

Text

Craft an impressive cutting board in eight easy steps

Start now so you're ready the next time you see another human being. (Courtney Starr/)

The warmth and natural qualities of a handmade charcuterie board make it the perfect way to welcome a guest. This is a simple project that can be completed with a basic set of tools—without electricity, even. You’ll find plenty of uses for this piece as you chop veggies on it, serve food to friends and family, and display it in your kitchen.

Warning: DIY projects can be dangerous, even for the most experienced makers. Before proceeding with this or any other project on our site, ensure you have all necessary safety gear and know how to use it properly. At minimum, that may include safety glasses, a face mask, and/or ear protection. If you’re using power tools, you must know how to use them safely and correctly. If you do not, or are otherwise uncomfortable with anything described here, don’t attempt this project.

Stats

<b>Time:</b> 4 hours

<b>Material cost:</b> $10 (wood only)

<b>Difficulty:</b> easy

Materials

One piece of hardwood (mine was an 8-by-16-inch piece of live edge cherry)

Paper (for a template)

<a href="https://ift.tt/2A5VGeb" target=_blank>Osmo TopOil</a>

Tools

<a href="https://ift.tt/2WX0XOt" target=_blank>Hand plane</a> (or a <a href="https://ift.tt/3bTUsA9" target=_blank>thickness planer</a>)

<a href="https://ift.tt/2TRPRsV" target=_blank>Coping saw</a> (or a <a href="https://ift.tt/2uAj6WE" target=_blank>bandsaw</a>)

<a href="https://ift.tt/2zpkZbl" target=_blank>Bit brace</a> (or a <a href="https://ift.tt/2NYaTSQ" target=_blank>drill press</a>)

<a href="https://ift.tt/2GjTAY6" target=_blank>Drawknife</a> (or a <a href="https://ift.tt/3c1nVby" target=_blank>spokeshave</a>)

<a href="https://amzn.to/3cSs2I6" target=_blank>Rat tail rasp</a>

<a href="https://ift.tt/2ZuRgZ8" target=_blank>Hand sanding block</a>

<a href="https://amzn.to/3bP1lCQ" target=_blank>Compass</a>

Scissors

Build it

1. Trace a shape onto a piece of wood. I’ve always been attracted to serving boards that embrace the natural qualities of wood. Live edge boards do this well, as each slab features the natural exterior of the tree it came from. I’d recently picked up a piece of live edge cherry that seemed perfect for this project, I let the natural edge of the piece define the shape of the board. Additionally, because I enjoy inviting the wood to make design decisions, I shaped the handle on my charcuterie board to follow the cathedral grain pattern in the wood. I recommend using a hard wood for your project, as it will resist the wear and tear of chopping.

You can freehand a unique shape that you won't find in a store, but feel free to use a compass if you want any precise curves. (Courtney Starr/)

2. Create a template. Cutting a template out of paper can help you get a feel for whether or not you like the shape you’ve drawn. You can hold it in your hand, see if the size feels good, and easily manipulate the shape by slicing off slivers of paper to get the design just right. Additionally, you’ll have the benefit of being able to reproduce the project in the future if you’d like. If you need help making nice curves, consider using a French curve, or even tracing the shape of an existing item in your house that you find attractive.

3. Prepare the wood. You’ll want a nice, flat board, so it doesn’t wobble around on your countertop. I started by removing the bark from my piece with a drawknife, then proceeded to use a hand plane to make both sides of the board perfectly flat.

<b>Note:</b> You can use a power jointer and planer for this step if you have access to them.

<b>Tip:</b> To flatten a board with a hand plane, place the wood on a flat surface and press on each corner to find the high spots on the wood. Then flip the board over and plane them down, checking your work often.

Remove any bark. It doesn't taste very good. (Courtney Starr/)

4. Transfer the template to your board. When your wood is flat and ready to go, trace the final shape onto it.

5. Bore a hole in the handle. If you’re going to make a handmade charcuterie board, you might as well display it. I like when I can hang kitchen accessories, so I recommend boring a hole in the handle of your board around a ¾-inch in diameter. Be sure to leave at least a ½-inch of wood between the hole and the outside edge of the handle.

6. Cut out your board. A simple coping saw will do the job, as its thin blade makes it especially good at cutting along the tight curves of the handle. Don’t fret too much about cutting a perfectly smooth line, as you can correct any mistakes at the next step.

<b>Note:</b> If you have a bandsaw, you can use that for this step.

Use a saw with a thin blade, like a coping saw, to unique designs. (Courtney Starr/)

7. Shape the wood. I prefer to use a drawknife to get the final shape on a charcuterie board. With this basic tool, you can quickly go from heavy stock removal to finessing the smallest details, without missing a beat. I also love the faceted look that drawknives give to the wood since each of the small surfaces left by the blade catch the light in a different way. I figure if I’m making something by hand, you might as well be able to tell! To shape tight corners like the one on the handle, use a round rasp, also called a rat tail rasp.

<b>Tip:</b> If you’re not confident with a rasp or drawknife, try them out on a scrap piece of wood. They’re fairly simple to use with a bit of practice.

You’ll want to round the hole in the handle of your board so it’s easier to hang. (Courtney Starr/)

8. Sand the wood. There’s no need to employ a power sander on such a small project, so sanding by hand will do the trick. I recommend sanding up to 220 grit in order to get a nice, smooth surface that will be easy to clean.

9. Finish the board. Applying finish to a charcuterie board is important, as it will encounter harsh treatment from chopping, serving moist foods, and getting washed after use. I chose Osmo’s TopOil to finish my board because it’s food safe and gives the wood a beautiful look and feel.

<b>Note:</b> It’s imperative to choose a finish that is food safe. Make sure to read the production description carefully to determine whether or not your finish of choice is rated for direct contact with food.

Apply a finish that is food safe and easy to refinish after extended use. (Courtney Starr/)

0 notes

Text

So I gave Curt a mallet, and he liked it, and that was nice, so then I thought tonight I would work on finishing up the other mallet I was making. I marked out how I wanted to shape the handle, and I went at it with a drawknife, just like I did on the other one, which was also hickory, and cut from the exact same board, but this piece is somehow a lot tougher. The drawknife was not doing much, so I had to use a chisel to chop down to the line, then split off the waste, and then grind it down the rest of the way with a rasp and a microplane, after which I could smooth it out with a scraper. I also bevelled the edges in a similar fashion, but at least I could do some of it with a spokeshave, which was a little easier.

But, boy, I am not making another handle out of hickory. It’s ash or oak from here on.

0 notes

Text

RWW Live: Sharpening Bench Redesign

youtube

Let Me Tell You a Story about a Sharpening Journey

I sincerely appreciate everybody who hung out with me live and asked questions. Sharpening is always a topic you can expect people to have confusion. And my tour and subsequent redesign of my sharpening bench is the perfect example of how we as woodworkers can overcomplicate what is actually a very simple topic. We live in a wonderful world now with many fancy gizmos and sharpening aids and when you are unsure they all look like game changers. I hesitate to say I fell into these traps as each method I used only added to my understanding of sharpening and what works for me and what doesn’t. I stress what works “for me” because I feel that it is a personal thing and often times the journey is what is needed to figure out what you need and don’t need. These days my sharpening regimen is very minimal and I look at it not as a task to be performed but merely a breath in the woodworking action. Sharpening is less event and process and often I don’t even realize I’m doing it. That sounds very zen but think about the last time you got into a groove on something and how you don’t realize how much time has passed nor can you clearly remember each individual task that you performed during that time.

Anyway, I’m waxing poetic now. I’m always open to more sharpening questions and stay tuned for the build of my new sharpening bench. If for no other reason than to see me use a track saw and maybe some pocket screws!!

The Questions You Asked

1:40 Sharpening Bench Talk

28:05 Sharpening Narrow Chisels

32:17 Hand Cranked Grinder and the Wheel

33:50 What’s a Good Brand of Rasps & Files

37:14 Would you have been able to understand what sharp is without jigs?

40:30 Why Do my blades go cloudy when changing stones?

43:56 Sharpening a Router Plane blade

46:34 Sharpening a Spokeshave blade

49:43 Scary Sharp?

52:20 Thoughts on Squares?

54:18 Hand Tool School Orientation

54:40 How do I sharpen drill bits?

59:42 Experience with Irwin Auger Bits?

1:01:42 How do I set rake and fleam when saw sharpening?

0 notes

Text

Southern Maine tool-hunting

I live in Downeast Maine, not far from the the Aroostook County border. Southern Maine starts somewhere vaguely around Bangor for me. I just spent a couple days at the Maine Startup and Create Week conference in Portland, and, aside from visiting friends I haven't seen in quite a while, I shopped around for some tools for farm woodworking stuff.

I recently picked up an old Delta Homecraft lathe in Cherryfield, but the tailstock center (the thingy that goes into the tailstock and holds the workpiece from that end) was a weird cupped slug thing. It didn't seem to be working properly, so I went to Rockler and picked up a new "live" center. I also picked up a few EZE-Lap diamond honing paddles to try out Paul Sellers's honing technique with them.

Someone tipped me off about Industrial Hardware in Biddeford, which is a dusty old place that’s only open a couple days a week. The guy working there was elderly, hard of hearing, and shuffled slowly to the back to show me where some chisels. “There are some good sets back behind there, someone stuck some shit in front of them, just move it out of the way.” None of the chisels were, in fact, any good, but there was a section full of new-old-stock Simonds and Nicholson chisels and rasps, 50 years old or more, stuff they don’t make any more. I picked up an auger bit file and a rasp.

Next up was Liberty Tool in Liberty, Maine. They have tons of stuff, but no real deals - everything rare or desirable or fancy gets snapped up quickly as soon as it’s in stock by tool vultures who visit the store often. Since I can only get there once or twice a year, I don’t have a shot. But they do have a ton of interesting old stuff at fair prices, including buckets and buckets of hand saws, piles of braces and bits, dozens of middling hand planes, and stuff like that. They have a display case full of Stanley 45 planes, but they’re priced appropriately, i.e. over a hundred bucks each. I prefer to find stuff like that cheaply at flea markets, yard sales, auctions, etc.

They did have a really neat Wilton vise. It was equipped with woodworking jaws on one side and metalworking jaws on the other, with the appropriate set rotated into place as needed by removing and restoring a locking pin. But it was almost $200 so I skipped it as well. I have a bunch of vises that haven’t been installed yet already.

The final place was a few doors down (past the historic, octagonal Old Post Office), Frapoli’s Place. It’s tiny, compared to Liberty Tool, and it’s also raided regularly for the best stuff, but I did find a nice beechwood spokeshave with the iron in good shape. I couldn’t read the maker’s mark - it was an oval that looked like “... KENT” at the top, “SHEFFIELD” at the bottom, and “... WORKS” in horizontally across the middle. The iron is currently soaking in vinegar so I can remove the rust.

Next steps: rig a motor up for the lathe. I have a 1/3 horsepower Dunlap motor I borrowed from my Craftsman/King Seeley bandsaw, and I hope to rig it up properly to power the lathe.

0 notes