#rubber compound manufacturers

Explore tagged Tumblr posts

Text

Rubber O-ring components are essential in industries requiring reliability and precision, providing tight seals that prevent leaks and ensure efficient performance. From household appliances to complex machinery, these versatile parts play a crucial role. As industries evolve, O-ring manufacturers continue to innovate, offering advanced solutions. Understanding both basic and advanced applications of rubber O-rings is key to making informed decisions when selecting the right products for business needs.

0 notes

Text

Rubber Compound

SRKP specializes in aerospace rubber seals and components, offering high-precision solutions for demanding aviation and aerospace applications

#Surge arrester#rubber molding#'rubber compound#industrial rubber products#rubber manufacturing companies#nabl accredited laboratory

0 notes

Text

#Silicone Rubber Compound Manufacturers in India#Silicone Rubber Manufacturer#Silicone Rubber Manufacturers in India#Silicone Rubber Manufacturers

0 notes

Text

Rubber Processing Aids Chemical Manufacturer | Call +91-33-22826195

Find rubber processing aids suppliers in India. We specialise in Rubber chemical manufacturing since 1994. ✔️ Experience unmatched service.

#rubber chemical#rubber accelerator#butadiene rubber#tmq rubber chemical#mbts accelerator#Rubber Processing Aids#processing aids in rubber compounding#Rubber Processing#Rubber Chemical & Additivies#Rubber Process Oil#Rubber Process Oils Manufacturer in India

0 notes

Text

Indycar crash course

(For this all I’m just going to use 2024 as an example)

I hope this is helpful feel free to ask any questions!!

1. Teams/drivers

* There is no limit on how few or many drivers can race for a single team.

* Most teams have 3 cars but some have as low as 2 and others have as high as 5

* Drivers don’t have numbers, the cars/teams do (ex: David is car #66 but will change to #41 when he changes to Aj Foyt racing)

* Additional Teams/drivers will come in for the Indy 500

2. Circuits

* circuit types – from road and street circuits to short ovals (one mile or less) and long ovals, often referred to as superspeedways.

* From what I have seen most Indycar drivers like/prefer ovals

3. Chassis and engines

* Dallara is the exclusive chassis supplier for INDYCAR. The chassis is made of carbon fibre, Kevlar and other composites, and weighs approximately 770 kg.

* Chevrolet and Honda are the two engine manufactures in the series and supply competitors

4. Tyres

* Like Formula 1, INDYCAR has a sole tyre supplier. But instead of Pirelli rubber, INDYCAR uses Firestone.

* Firestone provides three types of tyres for road and street courses, and one for ovals. On road and street courses, there is the ‘primary’ black tyre. The ‘alternate’ red tyre is a softer compound that allows for higher speeds but wears faster. A grey sidewall tyre is used in wet weather conditions.

* On ovals, only the ‘primary’ black tyre is used and if the rain falls at this type of circuit, Indy cars will not take to the track.

5. Aeroscreen

* In Formula 1, the teams have the halo. In INDYCAR, the aeroscreen is a ballistic, canopy-like windscreen anchored by titanium framework surrounding the cockpit.

6. Race weekend format

* The format of race weekends changes from race to race, however the most common is that Friday consists of two practice sessions – one in the morning and one in the afternoon.

* On Saturday, there is a morning practice session followed by qualifying in the afternoon.

* Sunday is race day and it begins with a warm-up session at road and street courses. However, on oval circuits there is no warm-up session.

7. Pit Stops

* Unlike Formula 1 where 16 team members assist during a pit-stop, just seven members of each INDYCAR team are permitted go ‘over the wall’ to execute a pit-stop.

* Team members include: four tyre changers, a fueler, a person responsible for the air jack (to raise the car to change the tyres) and an aeroscreen assistant to clean or pull a ‘tear-off’ from screen to help the driver’s vision.

* Each crew member is required wear a firesuit and helmet for protection.

* Indy cars refuel at each stop and drivers pit depending on the length of the track. In the 10 seconds it takes to fuel the car, all four tyres are changed.

8. Point scoring

* Points are awarded for all finishing positions in INDYCAR.

* First – 50 points, second – 40, third – 35, fourth – 32, fifth – 30, sixth – 28, and so on, going down to just five points for the lowest finishing position in the field.

* Bonus points are awarded for: pole position – 1 point, leading at least one race lap – 1 point, and most race laps led – 2 points.

* For the Indianapolis 500 and the final race of the season, points are doubled in those races.

TEAMS (as of end 2024 season)

1. AJ Foyt Racing

* 14 Santino Ferrucci

* 41 Sting Ray Robb

2. Andretti Global

* 26 Colton Herta

* 27 Kyle Kirkwood (logan’s friend !!)

* 28 Marcus Ericsson

3. Arrow McLaren

* 5 Pato O’Ward (McLaren reserve driver)

* 7 Alex Rossi

* 6 Nolan Siegel

4. Chip Ganassi Racing

* 8 Linus Lundqvist

* 9 Scott Dixon

* 10 Álex Paluo Montalbo

* 4 Kyffin Simpson

5. Dale Coyne Racing

* 51 Katherine Legge

* 18 Jack Harvey

6. Ed Carpenter Racing

* 20 Christian Rasmussen

* 20 Ed Carpenter (ovals only)

* 21 Rinus Veekay

7. Juncos Hollinger Racing

* 77 Romain Grosjean

* 78 Conor Daly

8. Meyer Shank Racing

* 66 David Malukas

* 60 Felix Rosenqvist

9. Rahal Letterman Lanigan Racing

* 15 Graham Rahal

* 45 Christian Lundgaard

* 30 Pietro Fittipaldi

10. Team Penske

* 2 Josef Newgarden

* 3 Scott McLaughlin (twt icon)

#indycar#indy 500#f1#formula 1#logan sargeant#ls2#david malukas#pato o'ward#kyle kirkwood#josef newgarden#arrow mclaren#mclaren

591 notes

·

View notes

Text

explaining f1: tyres 🛞

first post in this series (will it be a series? we’ll see)

recently i think we’ve had some particularly interesting races in terms of tyre strategy and i readied in suzuka that i don’t totally understand it all, so this has been my little research project on tyres!

pirelli

pirelli are an italian tyre manufacturer who have been supplying f1 tyres since 2011. unlike some eras of f1, pirelli is currently the exclusive supplier in the sport.

in 2022, pirelli introduced a new 18-inch (the previous being 13-inch) tyre as part of sweeping changes to the technical regulations of the sport.

compounds

pirelli’s range is currently comprised of six ‘slick’ compounds (referred to as slick because they lack the grooves of normal road tyres - this is because these grooves exist to dispel water, something necessary for road tyres but that slows down an f1 car when not necessary) tyres, along with ‘intermediates’ and full ‘wets’ to account for weather conditions.

the six slick compounds (from hardest to softest) are referred to as follows: c0, c1, c2, c3, c4 and c5. from this range, pirelli pick three to be used at each grand prix, based on the track characteristics and climate.

the highest of the set is marked red and is known as the soft, the middle marked yellow and know as the medium, with the lowest marked white and known as the hard (intermediates are green and wets are blue).

theoretically, the softs have more grip over short periods of time, making them faster and better for qualifying runs. generally, the hard and medium compounds are more favourable on race day because they last longer.

rules

on most weekends, drivers are given 13 sets of slicks, 4 intermediates and 3 wets, with a set of softs reserved for drivers who reach q3 (the final round of qualifying). all drivers must return 2 sets after each of the 3 practise sessions, meaning only 7 sets are left for qualifying and the race. drivers must also use at least two different slick compounds during the race (provided the weather is dry).

on sprint weekends, the number of dry sets are reduced to 12. after the sprint, drivers must return the set they completed the most laps on.

tyre allocation is on a per-driver basis, teammates cannot share or swap tyres. in bahrain in 2020, mercedes mistakenly put bottas’ tyres on russell’s car when attempting a double stack. the team was fined €20,000 for this.

drivers must run the same compound on all four wheels at all times.

strategy

tyre plan for the weekend is the decision of the team, generally based on information from pirelli, observed degradation over practise, the circuit and the weather forecast.

if rain is expected, teams can draw from their wet weather allocation, and so they don’t need to be as cautious with their dry weather tyres. if it’s hot, teams have to make sure they can cover plenty of tyre changes.

if track layout means overtaking is tough, teams may want a higher number of pitstops to stop drivers getting stuck behind rivals. also, if the track is walled (and so safety cars are more likely) teams may plan for more stops.

terminology

scrubbed: teams often ‘scrub in’ a set of tyres by running them briefly during practise, this means that when they are later used in the race, they warm up much faster than brand new tyres.

blistering: when the inner part of tyre heats more than the outer, creating minor explosions which damage the surface of the tyre.

graining: when the outer surface is hotter than the inside of the tyre, leading to the outside rubber flexing, breaking and sticking to the tyre.

flat spot: a patch where the surface of the tyre looses its curve. this is usually caused by a driving locking up by breaking too late, meaning the tyre scrapes along the ground.

deg or degradation: refers to a steady loss of tyre performance due to general wear.

#obviously i’ve gone into a lot of detail here that you don’t really need to enjoy the race#but i think it’s interesting!#feel free to correct or add anything#f1#formula one#motorsports#max verstappen#charles leclerc#lando norris#carlos sainz#oscar piastri#logan sargeant#alex albon#fernando alonso#lewis hamilton#george russell#lance stroll#daniel ricciardo#yuki tsunoda#explaining f1

55 notes

·

View notes

Text

Safely Shipping Tips: How Frequent You Need to Replace a Tire

Understanding when to replace your tires is crucial for maintaining the safety and performance of your vehicle, especially when preparing for transport. While there’s no one-size-fits-all answer to how often tires need replacement, several factors influence their lifespan.

Mileage is often used as a general guideline for tire replacement. On average, tires last between 25,000 to 50,000 miles. However, this can vary greatly depending on the type of tire, driving conditions, and maintenance practices. High-performance tires, for example, may wear out faster than all-season tires.

Age is another critical factor. Even if a tire hasn’t reached its mileage limit, it may need replacement due to age-related deterioration. Many manufacturers recommend replacing tires that are 6-10 years old, regardless of tread depth. This is because the rubber compounds in tires break down over time, even if the tire isn’t being used.

Tread depth is perhaps the most immediate indicator of when a tire needs replacement. In the United States, tires are legally required to have at least 2/32 inch of tread depth. However, performance begins to decline well before this point, especially in wet conditions. Many experts recommend considering replacement when the tread depth reaches 4/32 inches.

Driving habits and conditions significantly impact tire lifespan. Frequent hard braking, aggressive cornering, and driving on rough roads can accelerate tire wear. Similarly, extreme temperatures, both hot and cold, can affect tire longevity.

Proper maintenance can extend tire life. Regular rotation, proper inflation, and wheel alignment can help tires wear more evenly and last longer. Conversely, neglecting these maintenance tasks can lead to premature tire wear and the need for early replacement.

The type of vehicle and how it’s used also play a role. Heavy vehicles put more stress on tires, as does carrying or towing heavy loads. Performance vehicles may require more frequent tire replacements due to the demands placed on the tires.

Visual inspection can reveal signs that a tire needs replacement, regardless of age or mileage. Look for cracks in the sidewall, bulges or blisters on the tire surface, or excessive or uneven tread wear. Any of these conditions warrant immediate attention and possible replacement.

It’s worth noting that tires on the same vehicle may wear at different rates. Front tires on front-wheel-drive vehicles, for example, often wear faster than rear tires. This is why regular rotation is important, and why you may sometimes need to replace tires in pairs or sets rather than individually.

Lastly, consider your driving needs. If you frequently drive in adverse weather conditions or rely on your vehicle for critical transportation, you may want to replace your tires earlier to maintain optimal performance and safety.

Before transporting your vehicle, it’s especially important to assess your tires’ condition. The stress of transport can exacerbate existing tire issues. If your tires are nearing the end of their lifespan, considering replacement before transport can prevent potential problems and give you peace of mind.

Why proper tire pressure matters more than you think—especially when shipping using an open air car shipping! Ever wonder why your car's tires keep losing air? Discover the secret!

Checking Sidewall Tires for Wear and Tear

Examining the sidewalls of your tires is a crucial part of tire maintenance, particularly when preparing your vehicle for transport. The sidewall, which is the outer face of the tire between the tread and the bead, plays a vital role in supporting the weight of your vehicle and maintaining tire shape. Damage or wear in this area can compromise the tire’s structural integrity and potentially lead to tire failure.

Start your inspection by cleaning the sidewalls. A damp cloth can help remove dirt and grime, making it easier to spot any issues. Once clean, visually inspect the entire sidewall, looking for any abnormalities.

One of the most common issues to look for is cracking. Small cracks in the sidewall, often referred to as weather checking or ozone cracking, can occur due to exposure to the elements over time. While minor cracking may not require immediate action, deep or extensive cracking is a sign that the tire needs replacement.

Bulges or blisters on the sidewall are serious red flags. These protrusions indicate that the internal structure of the tire has been compromised, often due to impact damage. A tire with a bulge or blister is at high risk of sudden failure and should be replaced immediately.

Look for any cuts or gouges in the sidewall. Even if these don’t penetrate all the way through the rubber, they can weaken the tire’s structure. Deep cuts that expose the tire’s internal components require immediate tire replacement.

Pay attention to any signs of scuffing or excessive abrasion on the sidewall. This can occur from rubbing against curbs and can weaken the tire over time. While minor scuff marks may not be cause for concern, deep or extensive abrasion may necessitate replacement.

Examine the area where the sidewall meets the tread. Any separation in this area, often visible as a bulge or distortion, indicates internal damage and requires immediate replacement.

Check for any signs of dry rot, which appears as a fine network of small cracks covering a large area of the sidewall. This is often due to age or prolonged exposure to sunlight and ozone. Tires showing signs of dry rot should be replaced, even if they still have adequate tread depth.

Look for any discoloration or fading on the sidewall. While this doesn’t necessarily indicate a problem, it can be a sign of age or exposure to harsh conditions, which might warrant a closer inspection of the tire’s overall condition.

Don’t forget to check both the outer and inner sidewalls of each tire. The inner sidewall can sometimes sustain damage that’s not immediately visible from the outside of the vehicle.

Pay attention to any unusual wear patterns on the edge of the sidewall where it meets the tread. Excessive wear in this area can indicate alignment issues or chronic under-inflation.

Lastly, take note of any objects lodged in the sidewall. While it’s more common to find puncturing objects in the tread, occasionally they can become embedded in the sidewall. Unlike tread punctures, sidewall damage generally cannot be repaired safely, and the tire will need to be replaced.

Remember, the sidewall is a critical component of your tire’s structure. Any significant damage or wear in this area is cause for concern, especially when preparing for vehicle transport. If you’re unsure about the condition of your tire sidewalls, it’s best to consult with a professional tire technician for a thorough inspection and advice.

Don’t let flat tires derail your shipping plans. Inflate to the right pressure now! Discover more useful information on how to safely transport your car with a reliable car carrier service like Lucky Star Auto Transport with years of experience transporting all types of vehicles, for your peace of mind knowing your car will arrive at your preferred destination on time and in pristine condition.

youtube

10 notes

·

View notes

Text

transforming soffits reorganizing keys formalizing immersion joints justifying kick extractors advising aggregates managing elbows recasting connectors achieving aluminum trowels officiating disks exhibiting absolute spigots progressing coil hydrants jerry-building reflectors informing casters inventing rubber hoists performing wrenches judging chalk adapters upgrading ignition paths

regrowing flashing recommending ratchets approving barriers sweeping impact fillers sewing mirrors detailing collectors enforcing measures distributing systems presenting plugs interwinding registers piloting ash diffusers gathering cranks supplying eave pockets undertaking scroll stops accelerating straps designing fittings protecting diamond boilers logging downspouts correlating shingles uniting mallets qualifying electrostatic lifts sharing clamps obtaining circular fluids ranking foundation gauges sensing miter brackets originating space networks translating drills regulating guards selecting gable padding utilizing pellet dowels reconciling artifacts altering pulleys shedding space filters determining vents representing mortar remaking flash rakers supporting funnels typecasting rotary chocks expressing junctures resetting auxiliary vises professing strip treads inlaying matter trowels questioning drivers forming edge fittings sketching blanks overshooting spark breakers rewriting controls playing tunnels inventorying buttons enduring joint handles effecting ratchet bibbs unwinding couplings forsaking vapor conduits defining sockets calculating heaters raising grids administering tiles measuring resources installing ignition remotes extracting corners manufacturing ventilators delegating consoles treating mounting stones enacting jig deflectors intensifying alleys improvising cargo pinpointing bobs prescribing arc masonry structuring metal chucks symbolizing lathes activating plumb kits adapting coatings fixing channels expediting cordage planning compressors enlisting hangers restructuring keyhole augers shearing ridge hardware collecting reciprocating bolts maintaining corrugated dimmers whetting hole collars conducting mandrels comparing assets compiling sealants completing paths composing equivocation wheels computing dampers conceiving electrostatic treatment ordering cotter grates organizing ties orienting ladders exceeding materials targeting thermocouples demonstrating emery stock expanding latch bases training wardrobe adhesives overcomming[sic] fasteners streamlining storm anchors navigating springs perfecting turnbuckles verifying gate pegs arbitrating arithmetic lifts negotiating outlets normalizing strips building surface foggers checking key torches knitting grinders mowing planers offsetting stencils acquiring bulbs adopting rivets observing avenues ascertaining coaxial grommets slinging wing winches instituting circuit generators instructing wicks integrating pry shutters interpreting immersion lumber clarifying coils classifying wood bits closing cogs cataloging matter strips charting holders conceptualizing push terminals stimulating supports overthrowing shaft spacers quick-freezing connectors unbinding ground hooks analyzing eyes anticipating gateways controlling proposition rollers converting power angles coordinating staples correcting benders counseling joist gaskets recording gutter pipes recruiting drains rehabilitating rafter tubes reinforcing washers reporting guard valves naming freize sprues nominating rings noting straps doubling nailers drafting circuit hoses dramatizing flanges splitting framing compounds refitting stems interweaving patch unions placing sillcocks sorting slot threads securing mode cutters diverting catharsis plates procuring load thresholds transferring syllogism twine directing switch nuts referring time spools diagnosing knobs discovering locks dispensing hinges displaying hasps resending arc binders retreading grooves retrofitting aesthetics portals seeking stocks shrinking wormholes assembling blocks assessing divers attaining lug boxes auditing nescience passages conserving strikes constructing braces contracting saw catches serving installation irons recognizing fluxes consolidating fuse calipers mapping shims reviewing chop groovers scheduling lag drives simplifying hoists engineering levels enhancing tack hollows establishing finishing blocks

21 notes

·

View notes

Text

So there's one big question nagging at me throughout my foray into leftist theory, and it's one of the big things holding me back from actually being an anarchist—medicine. As a chronically ill woman who needs specialized anti-inflammatory and immunosuppressant medication to digest food painlessly, have any energy, and keep my colorectal cancer risk down, the only concrete answer I've been able to find is herbalism—which, lol no I'm not treating my Crohn's with tumeric when evidence-based medicine exists.

I'm genuinely curious, so if you're an anarchist, please let me know if you have non-anprim answers to these questions and further reading (or if you're a Marxist, because honestly you guys are voices of reason sometimes), and keep in mind that you are not convincing someone who thinks capitalism holds the answers, but someone who thinks that regulatory bodies and a socialist state hold the answers.

In an anarchist, decentralized, stateless society:

How can I guarantee that the doctor mixing my infusion and the nurse administering it are qualified to do so?

How can I guarantee that the specialized antibodies going into my body are the correct ones at the correct concentration, without contamination by other medications or harmful pathogens?

How can I guarantee that the other medications I receive during treatment (Tylenol, Benadryl, and Solu-Medrol) contain the correct compounds at the correct concentrations, without contamination?

How can I guarantee that the IV pump infusing me at a constant rate is manufactured correctly in a clean environment and is still operational when I'm attached to it?

How can I guarantee that the gloves, gauze, alcohol swabs, etc. used by the nurse are manufactured correctly in a clean and sterile environment?

How can I guarantee that the bag and tubing holding my infusion is manufactured correctly in a clean and sterile environment?

How can I guarantee that the needle and catheter going into my body are manufactured correctly in a clean and sterile environment?

If I do develop a site infection, how can I guarantee that any antibiotics I take are the correct ones at the correct dosage, matched correctly to my specific infection at the right length to fight it without breeding resistance?

How do we source the metals, plastic, fibers, rubber, glass, and organic compounds needed along these steps in an ethical way? If it's impossible for some more complicated aspects such as pump machines, how do we ensure I nevertheless get infused at the right rate that isn't too quickly?

I haven't even brought up blood pressure cuffs or pulse oximeters, nor discussed other areas of treatment such as colonoscopies and the web of steps contained therein (prep medications that work without contamination, sedation medications that work without killing, a larger qualified staff of doctors and nurses before, during, and after the procedure, the scope and biopsy tools being made correctly), but suffice it to say, I have the same questions there.

#yael.text#anarchism#like i know there are disabled anarchists but i just don't know if that can be me

4 notes

·

View notes

Text

04/07/2024: Flap Differential

Annoyingly one day Amy came home… and I’d noticed the rear near side mud flap was missing, wtf!? This was a long time ago and it was in fact it a new mud flap that appeared to be stolen! Now I’m not one to throw accusations around but it seemed odd to me and they (bolts) were loctited in.

So cut a long boring story short, I had a spare used flap in the box of spares, ordered stainless steel brackets and fasteners. The brackets went for powder coating and eventually (today) I fitted it all.

Top tip: Scour pad and some washing up liquid with warm water is the recipe for getting the weathered mud flap back into something presentable, plus with the addition of a plastic enhancer - not bad aye!?, just a shame it makes the rear cross member look like turd.

Now onto the D110, a leak on a truck is like it shedding a tear of disrepair… I mean if I was leaking fluid I’d likely be pretty upset as well. So, we focus our or my attention to the rear differential input seal, which has had a moist casing for a while.

How to….

1. Mark the propshaft position on the drive flange for correct refitting.

2. Remove the propshaft bolts using a spanner/socket, then secure the propshaft out of the way.

3. Use a socket and breaker bar to remove the pinion nut.

4. Slide off the drive flange – a light tap with a rubber mallet may help.

5. Remove the Old Differential Seal, by carefully prying out the old seal using a seal puller or flathead screwdriver.

6. Clean the seal mating surface to remove any debris or old sealant, inspect and grease bearing if necessary.

7. Install the New OEM Differential Seal, by lightly coating the outer edge of the new seal with gear oil for ease of installation.

8. Carefully press or tap it into place using a rubber mallet or a seal driver, ensuring it sits flush and even.

9. Reinstall the drive flange onto the pinion shaft.

10. Apply thread-locking compound to the pinion nut threads and tighten it securely (refer to manufacturer torque specs).

11. Reattach the propshaft, aligning it with the marks made earlier.

12. Check the seal area for any gaps or damage.

13. Refill the differential with fresh oil if it was drained.

14. Test drive and inspect for leaks.

Final Notes:

- Using a genuine OEM seal ensures longevity and a proper fit.

- If you don’t have the correct torque values, tighten the pinion nut securely but avoid overtightening.

- Regularly inspect for leaks after installation.

Parts for Rear Mudgaurds

RH Mudflap Bracket 90: MUC3986

LH Mudflap Bracket 90: MUC3987

Mudflap Support Plate 90 (both sides): MUC1512

Parts for rear differential input seal

Flange Kit: NSTSTC3124G

Rear Propshaft Bolt Kit: DA1424

#landrover#defender#landroverdefender#overlander#4x4#defendertd5#defender90#jlr#d90#britpart#defender110#overland#landroverphotoalbum#paddockspares#d110

2 notes

·

View notes

Text

In industries where precision and reliability are essential, rubber o-ring manufacturers components are critical. From household appliances to sophisticated machinery, these vital parts ensure tight seals, preventing leaks and maintaining optimal performance.

As industry demands evolve, O-ring manufacturers continue to advance their products and technologies. Understanding both basic and advanced applications of rubber O-rings is crucial for making informed decisions when selecting the right products for business needs.

0 notes

Text

Understanding Hydrocarbon Resins: Overview and Applications

What Are Hydrocarbon Resins?

Hydrocarbon resins, commonly referred to as petroleum resins, are synthetic resins derived from unsaturated hydrocarbons. These versatile materials are typically produced from crude oil or natural gas through processes such as thermal or catalytic cracking. They are recognized for their high thermal stability, strong adhesion, and compatibility with various polymers, making them integral to numerous industrial applications.

Types of Hydrocarbon Resins

C5 Resins:

Derived from C5 feedstocks (aliphatic hydrocarbons like pentenes).

Characterized by low molecular weight and tackiness.

Ideal for adhesives and coatings due to their stickiness and flexibility.

C9 Resins:

Made from C9 feedstocks (aromatic hydrocarbons such as indene and styrene).

Known for higher molecular weight, thermal stability, and color stability.

Suitable for rubber compounding and ink formulations.

C5/C9 Copolymer Resins:

A blend of C5 and C9 monomers.

Provides a balanced set of properties, useful in adhesives and sealants.

Hydrogenated Hydrocarbon Resins:

Undergo hydrogenation for enhanced stability, reduced color, and odor.

Suitable for applications requiring high purity, such as hot-melt adhesives and packaging materials.

Applications of Hydrocarbon Resins

Adhesives:

Hot Melt Adhesives: Essential for hot-melt formulations due to tackiness and adhesion, used in packaging, bookbinding, and pressure-sensitive adhesives.

Pressure-Sensitive Adhesives: Enhance tack, adhesion, and peel strength for tapes, labels, and hygiene products.

Rubber Compounding:

Serve as tackifiers to improve processing, adhesion, and reinforcement in tires, conveyor belts, and other rubber products.

Provide a balance between tensile strength and elasticity.

Coatings:

Paints and Varnishes: Improve adhesion, gloss, and durability in various paints and varnishes.

Road Markings: Enhance adhesion and weather resistance in traffic paint formulations.

Printing Inks:

Offer excellent adhesion, color stability, and fast drying for flexographic and gravure inks.

Packaging:

Used in films and coatings to improve mechanical properties, adhesion, and sealing.

Tapes and Labels:

Increase tackiness and adhesion in adhesive tapes and labels.

Sealants:

Integral to sealant formulations for construction and automotive uses, providing good adhesion and flexibility.

Advantages of Hydrocarbon Resins

Cost-Effectiveness: Generally more affordable compared to natural resins.

Versatility: Available in various molecular weights and viscosities, allowing for tailored applications.

Chemical Stability: Resistant to chemicals and environmental conditions, suitable for outdoor and industrial uses.

Summary

Hydrocarbon resins are indispensable in many industries, known for their adhesive properties, compatibility with a wide range of materials, and their role in enhancing the performance of adhesives, rubber, coatings, printing inks, and packaging materials. Their cost-effectiveness and adaptability make them a preferred choice for numerous manufacturing processes.

Contact:

Yuen Liang Industrial & Co., Ltd.

Website: www.ylresin.com

Email: [email protected]

Tel: +886-7-6161787 Ext.224

Mobile/WhatsApp/Zalo: +886-952 715 676

Skype: luuman123

#c5 resin#chemicals#hydrocarbon resin#petroleum resin#yuen liang resin#yl resin#taiwan resin#c9 resin

2 notes

·

View notes

Text

For two decades, researchers worked to solve a mystery in West Coast streams. Why, when it rained, were large numbers of spawning coho salmon dying? As part of an effort to find out, scientists placed fish in water that contained particles of new and old tires. The salmon died, and the researchers then began testing the hundreds of chemicals that had leached into the water.

A 2020 paper revealed the cause of mortality: a chemical called 6PPD that is added to tires to prevent their cracking and degradation. When 6PPD, which occurs in tire dust, is exposed to ground-level ozone, it’s transformed into multiple other chemicals, including 6PPD-quinone, or 6PPD-q. The compound is acutely toxic to four of 11 tested fish species, including coho salmon.

Mystery solved, but not the problem, for the chemical continues to be used by all major tire manufacturers and is found on roads and in waterways around the world. Though no one has studied the impact of 6PPD-q on human health, it’s also been detected in the urine of children, adults, and pregnant women in South China. The pathways and significance of that contamination are, so far, unknown.

Still, there are now calls for regulatory action. Last month, the legal nonprofit Earthjustice, on behalf of the fishing industry, filed a notice of intent to sue tire manufacturers for violating the Endangered Species Act by using 6PPD. And a coalition of Indian tribes recently called on the EPA to ban use of the chemical. “We have witnessed firsthand the devastation to the salmon species we have always relied upon to nourish our people,” the Puyallup Tribal Council said in a statement. “We have watched as the species have declined to the point of almost certain extinction if nothing is done to protect them.”

The painstaking parsing of 6PPD and 6PPD-q was just the beginning of a global campaign to understand the toxic cocktail of organic chemicals, tiny particles, and heavy metals hiding in tires and, to a lesser extent, brakes. While the acute toxicity of 6PPD-q and its source have strong scientific consensus, tire rubber contains more than 400 chemicals and compounds, many of them carcinogenic, and research is only beginning to show how widespread the problems from tire dust may be.

While the rubber rings beneath your car may seem benign — one advertising campaign used to feature babies cradled in tires — they are, experts say, a significant source of air, soil, and water pollution that may affect humans as well as fish, wildlife, and other organisms. That’s a problem because some 2 billion tires globally are sold each year — enough to reach the moon if stacked on their sides — with the market expected to reach 3.4 billion a year by 2030.

(Researchers weigh a salmon that died after four hours in a tank filled with road runoff.)

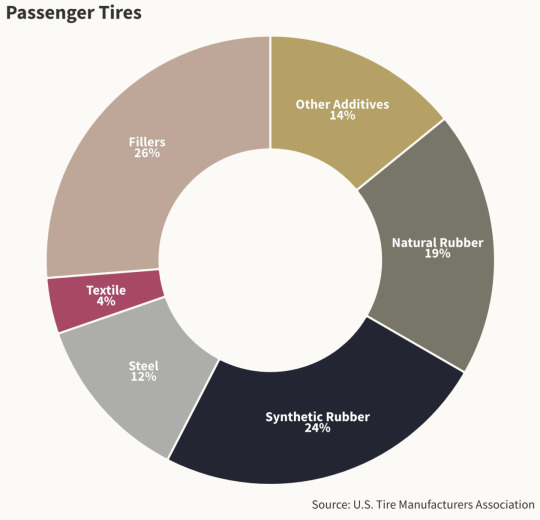

Tires are made from about 20 percent natural rubber and 24 percent synthetic rubber, which requires five gallons of petroleum per tire. Hundreds of other ingredients, including steel, fillers, and heavy metals — including copper, cadmium, lead, and zinc — make up the rest, many of them added to enhance performance, improve durability, and reduce the possibility of fires.

Both natural and synthetic rubber break down in the environment, but synthetic fragments last a lot longer. Seventy-eight percent of ocean microplastics are synthetic tire rubber, according to a report by the Pew Charitable Trust. These fragments are ingested by marine animals — particles have been found in gills and stomachs — and can cause a range of effects, from neurotoxicity to growth retardation and behavioral abnormalities.

“We found extremely high levels of microplastics in our stormwater,” said Rebecca Sutton, an environmental scientist with the San Francisco Estuary Institute who studied runoff. “Our estimated annual discharge of microplastics into San Francisco Bay from stormwater was 7 trillion particles, and half of that was suspected tire particles.”

Tire wear particles, or TWP as they are sometimes known, are emitted continually as vehicles travel. They range in size from visible pieces of rubber or plastic to microparticles, and they comprise one of the products’ most significant environmental impacts, according to the British firm Emissions Analytics, which has spent three years studying tire emissions. The company found that a car’s four tires collectively emit 1 trillion ultrafine particles — of less than 100 nanometers — per kilometer driven. These particles, a growing number of experts say, pose a unique health risk: They are so small they can pass through lung tissue into the bloodstream and cross the blood-brain barrier or be breathed in and travel directly to the brain, causing a range of problems.

According to a recent report issued by researchers at Imperial College London, “There is emerging evidence that tyre wear particles and other particulate matter may contribute to a range of negative health impacts including heart, lung, developmental, reproductive, and cancer outcomes.”

The report says that tires generate 6 million tons of particles a year, globally, of which 200,000 tons end up in oceans. According to Emissions Analytics, cars in the U.S. emit, on average, 5 pounds of tire particles a year, while cars in Europe, where fewer miles are driven, shed 2.5 pounds per year. Moreover, tire emissions from electric vehicles are 20 percent higher than those from fossil-fuel vehicles. EVs weigh more and have greater torque, which wears out tires faster.

Unlike tailpipe exhaust, which has long been studied and regulated, emissions from tires and brakes — which emit significant amounts of metallic particles in addition to organic chemicals — are far harder to measure and control and have therefore escaped regulation. It’s only in the last several years, with the development of new technologies capable of measuring tire emissions and the alarming discovery of 6PPD-q, that the subject is receiving much needed scrutiny.

Recent studies show that the mass of PM 2.5 and PM 10 emissions — which are, along with ozone and ultrafine particles, the world’s primary air pollutants — from tires and brakes far exceeds the mass of emissions from tailpipes, at least in places that have significantly reduced those emissions.

The problem isn’t just rubber in its synthetic and natural form. Government and academic researchers are investigating the transformations produced by tires’ many other ingredients, which could — like 6PPD — form substances more toxic than their parent chemicals as they break down with exposure to sunlight and rain.

“You’ve got a chemical cocktail in these tires that no one really understands and is kept highly confidential by the tire manufacturers,” said Nick Molden, the CEO of Emissions Analytics. “We struggle to think of another consumer product that is so prevalent in the world, and used by virtually everyone, where there is so little known of what is in them.”

“We have known that tires contribute significantly to environmental pollution, but only recently have we begun to uncover the extent of that,” said Cassandra Johannessen, a researcher at Montreal’s Concordia University who is quantifying levels of tire chemicals in urban watersheds and studying how they transform in the environment. The discovery of 6PPD-q has surprised a lot of researchers, she said, because they have learned that “it’s one of the most toxic substances known, and it seems to be everywhere in the world.”

Regulators are playing catch up. In Europe, a standard to be implemented in 2025, known as Euro 7, will regulate not only tailpipe emissions but also emissions from tires and brakes. The California Environmental Protection Agency has passed a rule requiring tire makers to declare an alternative to 6PPD-q by 2024.

(A worker takes apart a tire at a recycling shop in Mit al-Harun, Egypt.)

Tire companies are conducting their own studies of 6PPD, which they have long considered critical for tire safety, and seeking alternatives. In response to new regulations and the emerging research on tire emissions, 10 of the world’s large tire manufacturers have formed the Tire Industry Project to “develop a holistic approach to better understand and promote action on the mitigation” of tire pollution, according to a statement by the project. The group has committed to search for ways to redesign tires to reduce or eliminate emissions.

One critical area of research is how long tire waste, and its breakdown products, persist in the environment. “A five-micron piece of rubber shears off the tire and settles on the soil and sits there a while,” said Molden. “What, over time, is the release of those chemicals, how quickly do they make their way into the water, and are they diluted? At the system level, how big of a problem is this? It is the single biggest knowledge gap.”

Another area of research centers on the impacts of aromatic hydrocarbons — including benzene and naphthalene — off-gassed by synthetic rubber or emitted when discarded tires are burned in incinerators for energy recovery. Even at low concentrations, these compounds are toxic to humans. They also react with sunlight to form ozone, or ground-level smog, which causes respiratory harm. “We have shown that the amount of off-gassing volatile organic compounds is 100 times greater than that coming out of a modern tailpipe,” said Molden. “This is from the tire just sitting there.”

When tires reach their end of life, they’re either sent to landfills, incinerated, burned in an energy-intensive process called pyrolysis, or shredded and repurposed for use in artificial turf or in playgrounds or for other surfaces. But as concern about tire pollutants grows, so do concerns about these recycled products and the hydrocarbons they may off-gas. There is ongoing debate over whether crumb rubber, made from tire scraps, poses a health threat when used to fill gaps in artificial turf. Based on several peer-reviewed studies, the European Union is instituting stricter limits on the use of this material. Other studies, however, have shown no health impact.

Besides California’s requirement to study alternatives to 6PPD, there are a number of efforts worldwide to redesign tires to counter the problems they pose. More than a decade ago, tire makers hoped that dandelions, which produce a form of rubber, and soy oil could provide a steady and sustainable supply of rubber. But tires made from those alternatives didn’t live up to expectations: they still required additives. The Continental Tire Company, based in Hanover, Germany, markets a bicycle tire made of dandelion roots. Tested by Emission Analytics, it emitted 25 percent fewer carcinogenic aromatics than conventionally made bike tires, but the plant-powered tire still contained ingredients of concern.

(Rubber made from dandelions.)

Other companies are searching for ways to address the problem of tire emissions. The Tyre Collective, a clean-tech startup based in the U.K., has developed an electrostatic plate that affixes to each of a car’s tires: The plates remove up to 60 percent of particles emitted by both tires and brakes, storing them in a cartridge attached to the device. The particles can be reused in numerous other applications, including in new tires.

In San Francisco, scientists studying the pollutants in storm runoff found a potential solution: Rain gardens, installed in yards to capture stormwater, were also trapping 96 percent of street litter and 100 percent of black rubbery fragments. In Vancouver, B.C. researchers found that rain gardens could prevent more than 90 percent of 6PPD-q from running off roads and entering salmon-bearing streams.

Tire waste particles, says Molden, of Emissions Analytics, are finally getting the attention they deserve, thanks in part to California’s rule requiring a search for alternatives to 6PPD. The legislation “is groundbreaking,” he says, “because it puts the chemical composition [of tires] on the regulatory agenda.” For the first time, he adds, “Tire manufacturers are being exposed to the same regulatory scrutiny that car manufacturers have been for 50 years.”

8 notes

·

View notes

Text

Raw natural or synthetic rubber is not suitable for industry usage and application. It has to undergo a few steps in order to become industry-suitable. Here, we have highlighted the steps.

#Rubber Processing Aids#processing aids in rubber compounding#rubber aids#Rubber Processing#rubber molding#rubber manufacturing#rubber extrusion#rubber manufacturing near me#casting rubber#rubber extrusion manufacturers

0 notes

Text

Drivers notch up over 600 laps in Pirellis 2024 tyre test as Mick Schumacher makes Mercedes debut

Ferrari and Mercedes’ drivers have notched up over 600 laps between them over the course of two days of lapping the Circuit de Barcelona-Catalunya – host of last weekend’s Spanish Grand Prix – as Pirelli tested a selection of proposed tyre compounds for the 2024 season. Ferrari’s Charles Leclerc and Carlos Sainz, and Mercedes’ George Russell and Mick Schumacher – the team’s reserve, who was making his on-track debut for the Silver Arrows in the newly-upgraded W14 – clocked up 617 laps between them across Tuesday and Wednesday: 167 for Leclerc, 152 for Schumacher, 151 for Russell and 147 for Sainz. WATCH: Schumacher returns to F1 action with first run in Mercedes’ W14 “These were two very important days of testing,” said Pirelli’s Head of Motorsport Mario Isola, “as we gathered plenty of useful information to come up with the best possible choices for next year. “In terms of construction, there are still just a few details to fine-tune, while during this test we began to identify a solid development base for the compounds; especially for the middle of what will be the 2024 range.” Ferrari and Mercedes were on hand to test the new rubber Meanwhile, Pirelli confirmed that running took place without the use of tyre blankets – with the manufacturer having been set to trial a blanket-less wet weather compound at the Emilia Romagna Grand Prix before it was called off last month. “All the running took place without using tyre blankets. We verified a few interesting things on track,” added Isola. “Now we move on to a complete analysis of all the data so that we head into the next test, at Silverstone after the British Grand Prix, as well prepared as we can be. “After that we will draw some conclusions from all the work done over the last few months and present the FIA, F1 and the teams with the complete picture, so that the best decisions can be taken using all the information available.” READ MORE: Pirelli 'happy' with their tyre development in 2023 as they talk plans for their future in Formula 1 Meanwhile Schumacher – son of seven-time champion Michael – who lost his drive at Haas to fellow German Nico Hulkenberg at the end of 2022, said it had been “good to get back in the driving seat” – with the 24-year-old having been praised after the Spanish Grand Prix weekend by Mercedes race drivers Russell and Lewis Hamilton for his simulator work developing the W14. “It was great! I learned a lot and it was a lot of fun,” said Schumacher, who drove alongside Sainz on Wednesday. “It was a very productive day; we got through everything we wanted to and ran every test tyre on the plan. It was also good to have that first experience of the tyres without any blankets. Obviously having not driven in a while, I felt it physically, but it was good to be back in the driving seat. George Russell discusses the new compounds with the Pirelli engineers “There is obviously a difference between the simulator and driving in the real world,” he added. “There will always be a difference as the technology is not at a point where you can compare it 100%. However, it is the closest experience I've had between a simulator and real life. The simulator has prepared me, and the team has made a great effort of correlating it. That helped me to know what to expect when driving it. READ MORE: Hamilton and Russell pay tribute to Schumacher for simulator work that contributed to double podium in Spain “I'm very excited for the rest of the year. I've had a great time today and hopefully I'll be back in a car at some point. I loved every bit of it! I want to say a big thank you to everybody for this opportunity.” Pirelli, meanwhile, will introduce a new specification of slick tyre for July’s British Grand Prix at Silverstone, with teams having tested the new construction in free practice for the Spanish Grand Prix last week. The next tyre test will take place at Silverstone after the British Grand Prix via Formula 1 News https://www.formula1.com

#F1#Drivers notch up over 600 laps in Pirelli’s 2024 tyre test as Mick Schumacher makes Mercedes debut#Formula 1

7 notes

·

View notes

Photo

How excited was I to find out that I could effortlessly fit four wheels and four tires in the back of my car? So excited.

I bought new wheels to replace my 17-year old ones, which were corroded from their lifetime in the Rustbelt and one of which was bent (RIP). The tires—Yokohama Avid Ascends—replaced a set of Bridgestone Turanza Serenity tires, purchased in 2016, about 63,000 miles ago.

The Turanzas served me extremely well in all conditions but ice/snow, which they were garbage at—I have a separate set of winter tires. I went with the Yokohamas this time around because they were better reviewed on TireRack in all possible ways and cheaper than the Bridgestone equivalent being manufactured today.

Anyway, I figured this was a good time to write up some notes!

The Care & Feeding of Tires: A Beginner’s Guide

After all, this all started with a blown left rear:

Even if you’re not driving your street car at race speeds, your tires are the only part that actually touches the road—that one contact patch on each of your four corners.

The service writer at your shop is going to go by the numbers; the technician will say something if it’s real bad, maybe. But you don’t want to wait until you have a blowout and end up stranded, or until you’re hydroplaning on the freeway.

1. How do you measure tire health?

Every tire comes with two measure of its age: treadwear and time.

Treadwear: The more you drive, the more the tire wears down. How quickly this happens depends mostly on your tire compound (and technically the type of driving you do, though I doubt for most people this is statistically significant).

At least in the United States, your tread is measured in 32nds of an inch. How many 32nds you start with depends on the tire. Since most people don’t own a tread depth gauge, treadwear is also conveyed in terms of mileage, and the average number of miles driven it takes to wear the tread a certain amount.

Time: If you don’t drive your car that much, it doesn’t mean your tires will last longer, though! Because the rubber is blowing out those birthday candles no matter what. You can keep the rubber cool and dry if you want, but age waits for no tire. Generally, tire rubber will last around 6 years before it should be replaced, regardless of mileage. Like measuring treadwear in mileage, six years is an estimate based on rubber degradation.

You can also gauge tire age by looking for signs of dryrot. This will look like cracks in the rubber—on the sidewall or the tread. They can look shallow and unimportant, but these cracks on the surface are an indication that there’s likely similar rot happening where you can’t see it.

Here’s an example of mild dryrot on my old tires, which are 7 years old. You can find MUCH more extreme examples on Google Images, if you’re so inclined:

🚨 IMPORTANT 🚨 The age of your tire is based on its date of manufacture, NOT the date you put it on your car! If you want to check this, this date is printed on your tire. Each tire is printed with a DOT code—the last two digits designate the year it was made. (There’s other info in that code, but that’s the most important part.)

You know how your car’s care manual has intervals that expressed in both miles and time? You’re not supposed to choose which to follow—you’re supposed to do with whichever comes first. The two ways tires age is a great example of why!

2. How do you keep tires happy?

Do your preventative maintenance.

Cars are extremely expensive to own, and that sucks—especially when you live in the United States, where in a lot of places you have to own a car if you want to make a living. You have to pay to get paid. :\

But cars are also something where preventative maintenance is a lot cheaper than a repair—or worse, a wreck. Tires are designed to endure a lot, and perform through all kinds of conditions. But you can thank them for their hard work by being attentive to their needs!

Check your tire pressure regularly (let’s say seasonally)! Particularly if the ambient temperatures where you live are changing. Tires are wily, and can be absurdly low on air before they start looking flat. Seriously—they can be at 15psi when they’re supposed to be at 30psi and still look pretty round. Keeping your tires inflated to spec will prolong your tread life (and save your gas mileage).

Rotate your tires on schedule! Your car’s schedule is in the owner’s manual. This help your tires wear evenly, which will prolong their life AND the lifespan of your drivetrain, which is substantially more expensive to repair than a tire rotation is. (A rotation is free if you do it yourself; some tire suppliers like Costco give you free tire rotations for the life of the tire, too.) Keeping your tires wearing evenly is particularly important if you have an AWD car, which is increasingly common in this frenzied age of crossovers and SUVs.

Keep your suspension in alignment! If your car’s not driving straight on the road, it’s not wearing your tires evenly, either. Your alignment can be thrown off if you hit a pothole or a curb. Sometimes it just wanders off, due to wear on suspension components. Letting your suspension do what it will is only going to increase the wear on other components and make the repair bill bigger int the long run.

Aside from not knowing what a car needs, I think there are two main reasons people end up in bad spots with their tires: 1) It’s not a priority (fair, but if you pay attention to one thing outside of your oil changes, let it be the tires! this is part of the job of owning a car), and 2) They don’t have the money. Nothing this Pixar Cars blog can say can solve late capitalism and the wage gap, but if you can conceptualize tire care and feeding as a regular, predictable, budgetable expense, and not an emergency one, the financial hit of buying new tires can be given some cushion.

Stay safe and stay rolling!

9 notes

·

View notes