#Silicone Rubber Manufacturers in India

Explore tagged Tumblr posts

Text

#Silicone Rubber Compound Manufacturers in India#Silicone Rubber Manufacturer#Silicone Rubber Manufacturers in India#Silicone Rubber Manufacturers

0 notes

Text

Reputable Silicone Rubber products and sheet manufacturers in India

Look through the top-rated Silicone Rubber products and sheet manufacturers in India right now to identify solutions that can guarantee effectiveness and long-term success for your company.Due to its exceptional flexibility, temperature resistance, and durability, silicone rubber is the ideal material for a wide range of applications, including medical devices and automotive parts.

#Silicone sheet#silicone rubber products#silicone rubber sheet manufacturers in India#silicone rubber sheet#Silicone Rubber products and sheet manufacturers in India

0 notes

Text

0 notes

Text

Rubber parts supplier - Extrusions & Tubing

Opting for standard rubber part is always the first choice for the machine manufacturers because it cuts down the time required for crafting a custom made one. https://alfarubber.blogspot.com/2024/02/rubber-parts-manufacturer-helping-with.html

#Rubber parts supplier#bush manufacturer#o rings manufacturer#seal manufacturer#grommet manufacturer#rubber industries in india#rubber injection molding#gaskets and seals#silicon rubber products#rubber grommet manufacturer#rubber bush manufacturer

0 notes

Text

Get your Industrial Rubber Products Manufacturing Concept to Reality with Leading Industrial Molded Rubber Products Manufacturers in India & USA.Contact us for your Custom Rubber Molding Requirements.

0 notes

Text

Unraveling the Wonders of Gaurav Industries: Leading Wires and Cable Manufacturing Company in India!

Discover the innovative world of Gaurav Industries, the top wires and cable manufacturing company in India. Delve into their expertise as a renowned solar panel wire harness manufacturer and silicon rubber cables pioneer. Read on to explore their cutting-edge solutions and exceptional products!

#Gaurav Industries#Top Wires and Cable Manufacturing Company#Solar panel Wire harness manufacturer in India#Silicon Rubber Cables manufacturers in India

1 note

·

View note

Text

Azaz Enterprises: Setting the Standard for Silicone Patches Manufacturers

Silicone patches have become an essential component in various industries, from clothing and accessories to military and industrial applications. When it comes to high-quality silicone patches, Azaz Enterprises stands out as a leading manufacturer in India. With their expertise, commitment to quality, and extensive range of products, Azaz Enterprises has set the standard for silicone patch manufacturers.

Expertise and Customization Options

Azaz Enterprises is the largest customized label manufacturer in India, supplying and exporting a wide range of products such as clothes patches, bag labels, jeans patches, and military patches, Silicone Label Manufacturers.

Commitment to Quality

When it comes to silicone patches, durability and quality are of utmost importance. Azaz Enterprises uses high-quality silicone materials that are known for their flexibility, resistance to wear and tear, and longevity.

Technological Advancements

To stay at the forefront of the industry, Azaz Enterprises embraces the latest technologies and innovations in silicone patch manufacturing

Compliance and Certifications

Azaz Enterprises adheres to industry standards and regulations, ensuring that their silicone patches meet the required quality and safety standards.

In conclusion, Azaz Enterprises has established itself as a leading silicone patch manufacturer in India. With their expertise, commitment to quality, extensive customization options, and technological advancements, they have set the standard for silicone patches manufacturers. By partnering with Azaz Enterprises, businesses can be confident in receiving high-quality silicone patches that meet their specific requirements and contribute to their branding success.

#silicone label manufacturers#rubber silicone label manufacturers in india#silicone label manufacturers in india#rubber silicone label manufacturers

0 notes

Text

Key Design Considerations for Pantograph Support Insulators in High-Speed Rail Systems

In the realm of high-speed rail systems, every component plays a crucial role in ensuring safe and efficient operations. Among these components, pantograph support insulators stand out as critical elements that facilitate the seamless transmission of power from overhead lines to the train's electrical system. As a leading pantograph insulator manufacturer in India, Radiant Enterprises recognizes the importance of meticulous design considerations in crafting reliable and durable insulators. In this blog post, we'll explore the key design considerations essential for pantograph support insulators in 25 KV high-speed rail systems, shedding light on Radiant Enterprises' commitment to excellence in manufacturing.

Understanding Pantograph Support Insulators

Pantograph support insulators are integral components of the overhead electrification system in high-speed rail networks. These insulators provide electrical isolation and mechanical support for the pantograph, which is the apparatus mounted on the train's roof responsible for collecting electricity from the overhead wires (catenary). In 25 KV high-speed rail systems, where trains operate at exceptionally high speeds, the performance and reliability of pantograph support insulators are paramount.

Design Considerations for Pantograph Support Insulators

Material Selection: The choice of materials significantly influences the performance and longevity of pantograph support insulators. At Radiant Enterprises, we utilize high-quality, durable materials such as silicone rubber or composite polymers that exhibit excellent electrical insulation properties, mechanical strength, and resistance to environmental factors such as UV radiation, pollution, and temperature variations.

2. Electrical Insulation: Ensuring reliable electrical insulation is paramount to prevent electrical arcing and ensure the safe transmission of power. Our pantograph support insulators are engineered to withstand high voltage levels (25 KV) and exhibit low electrical conductivity to minimize power losses and mitigate the risk of electrical faults.

3. Mechanical Strength: Pantograph support insulators are subjected to mechanical stresses induced by the pantograph's movement and external forces such as wind loads and vibrations. Therefore, our insulators undergo rigorous mechanical testing to ensure they can withstand these forces without deformation or failure, ensuring uninterrupted operation and minimal maintenance requirements.

4. Corrosion Resistance: In outdoor environments exposed to moisture, pollution, and corrosive agents, corrosion resistance is essential to maintain the structural integrity of pantograph support insulators over their operational lifespan. Our insulators are engineered with corrosion-resistant materials and undergo surface treatments to enhance their resistance to rust and degradation, ensuring long-term reliability and performance.

5. Dimensional Accuracy: Precision engineering is critical to ensure proper fit and alignment of pantograph support insulators with the overhead wires and the train's pantograph. Our insulators are manufactured with tight tolerances and undergo strict quality control measures to guarantee dimensional accuracy and compatibility with the rail infrastructure, minimizing installation challenges and optimizing performance.

6. UV Stability: Exposure to ultraviolet (UV) radiation can degrade insulator materials over time, compromising their electrical and mechanical properties. Therefore, our pantograph support insulators are formulated with UV-stabilized materials that withstand prolonged exposure to sunlight without degradation, ensuring reliable performance and longevity in outdoor applications.

Radiant Enterprises: Your Trusted Pantograph Insulator Manufacturer in India

As a leading manufacturer of pantograph support insulators in India, Radiant Enterprises is committed to delivering superior quality products that meet the stringent requirements of high-speed rail systems. Our state-of-the-art manufacturing facilities, coupled with a team of experienced engineers and quality assurance experts, enable us to design and produce pantograph insulators that excel in performance, reliability, and durability.

Conclusion

In the dynamic world of high-speed rail systems, the reliability and performance of pantograph support insulators are critical for ensuring safe and efficient operations. By adhering to meticulous design considerations such as material selection, electrical insulation, mechanical strength, corrosion resistance, dimensional accuracy, and UV stability, manufacturers like Radiant Enterprises can deliver pantograph insulators that meet the demanding requirements of 25 KV high-speed rail systems. As a trusted pantograph insulator manufacturer in India, Radiant Enterprises is committed to providing innovative solutions that contribute to the advancement of railway electrification technology and the seamless operation of high-speed rail networks.

#Customised epoxy insulators manufacturer in India#Pantograph insulator manufacturer in India#25 KV pantograph support insulators manufacturers in India#25 KV roof busbar support insulator manufacturers in India#Solid third rail insulator#Customized Powerrail Epoxy Insulators#Epoxy Insulators#Epoxy insulator manufacturers in India

7 notes

·

View notes

Text

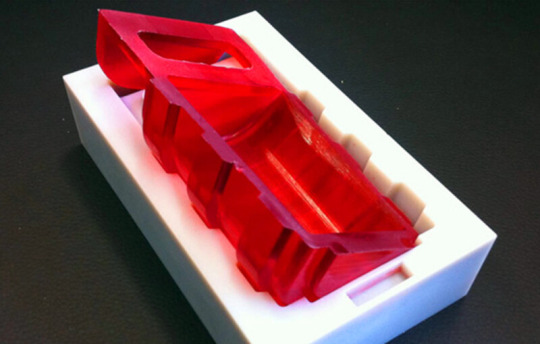

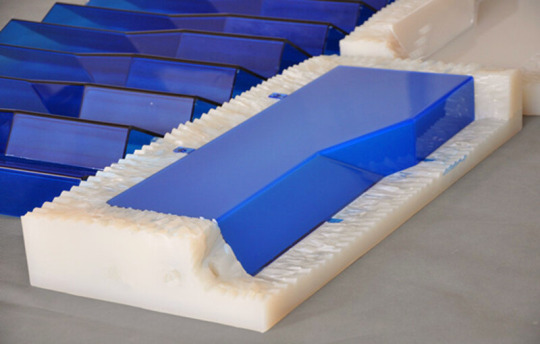

Working of Vacuum Casting and Its Multiple Uses

To make complicated components, a liquid substance is sucked into a silicone mold under vacuum. This method is known as vacuum casting. Rubber and plastic are examples of elastomers that are utilized as liquid materials in vacuum casting.

Since polyurethane resin, a kind of elastomer is employed as the casting medium, vacuum casting is also frequently referred to as polyurethane casting or urethane casting. When producing plastic components, vacuum casting is a more cost-effective method than injection molding because of its reduced manufacturing costs.

For batch manufacturing and other low-volume production tasks, vacuum casting is a great method of production. Vacuum casting is widely utilized in India's manufacturing of industrial electronics, FMCG, and consumer goods.

How do you work with vacuum casting?

Injection molding, in which cast material is poured into molds to create items, and vacuum casting services are very comparable processes. The kinds of molds used in injection molding and vacuum casting differ from one another.

Molds for injection molding might be formed of steel, aluminum, or other materials. Silicone molds are utilized in vacuum casting, nevertheless. This significantly lowers the mold-making cost because silicone is more affordable and has better durability.

Polyurethane is the most often utilized casting material in this procedure. The qualities of various polyurethanes vary, including good shock and temperature resistance, elasticity, flexibility, and structural stiffness. Thus, different polyurethanes may be employed depending on the kind of product being created.

Vacuum casting uses

Making complicated and sophisticated goods may be accomplished more cost-effectively and efficiently with vacuum casting as opposed to the conventional injection molding method.

Due to its efficient production process, vacuum casting finds widespread application in the fabrication of commercial items. The following are a few industries that employ vacuum casting:

Manufacturing of consumer goods

Vacuum casting is a more effective method of producing consumer goods including combs, hair brushes, makeup packaging, sunglasses, pens, and other stationery.

Industry of Food and Beverages

Vacuum casting is used to create food and beverage containers, bottles, cans, mugs, and glasses. Due to the process's great efficiency and ability to produce goods quickly, vacuum casting is widely utilized in various industries where rapid manufacture is essential.

Advanced industry

Excellent heat and shock resistance is a feature of polyurethanes. Therefore, the recommended production procedure for creating electrical device housings is vacuum casting by Vacuum Casting Manufacturer using polyurethanes.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Explore vacuum casting#Vacuum Casting Services China#Vacuum Casting Manufacturer#Vacuum Casting supplier

2 notes

·

View notes

Text

Types of Insulators in Overhead Lines: The Ultimate Guide

Within the realm of electrical power transmission, overhead wires assume a pivotal function in facilitating the effective conveyance of electricity across extensive distances. The aforementioned lines are upheld by a system of towers and poles, and a crucial element that guarantees their dependable functionality is the insulator. Insulators are specifically engineered to impede the transmission of electrical current between the conductive elements and the supporting frameworks, ensuring the safety of the lines and upholding a consistent electrical provision. Strengthen your electrical networks - Trust the expertly crafted Medium Voltage Support Insulators offered by Radiant Enterprises - one of the leading Medium Voltage Support Insulator manufacturers in India!

This comprehensive reference aims to examine the various classifications of insulators utilised in overhead lines, elucidating their distinctive characteristics and practical implementations.

Pin Insulators:

Pin insulators are widely utilised in overhead lines, making them one of the most prevalent types in use. The components are comprised of a body made of either ceramic or glass, including a spindle located at the bottom that is securely attached to the cross-arm of the supporting structure. The conductors are affixed to the upper groove of the insulator, therefore ensuring electrical isolation. Pin insulators are commonly used due to their simplicity, cost-effectiveness, and capacity to endure mechanical and electrical pressures. Distribution lines and low-voltage transmission lines frequently employ these devices.

Suspension Insulators:

Suspension insulators are utilised in high-voltage transmission lines characterised by elevated tension levels. The design of these units involves a serial connection of insulators, resulting in the formation of an elongated chain. Typically, a unit comprises a ceramic or composite disc accompanied by a metallic cover and an insulating cement joint. Suspension insulators are affixed to the cross-arm through the use of an insulating string, so facilitating the suspension of the conductor beneath the tower. These insulators exhibit exceptional mechanical durability and demonstrate remarkable efficacy in environments characterised by substantial levels of pollution, such as industrial zones.

Strain Insulators:

When a transmission line terminates or a sharp turn is made in the line's direction, strain insulators are employed to securely terminate or anchor the conductors. They are built to endure the mechanical tension of the hung conductor as well as the electrical stress. Strain insulators are often constructed of porcelain or toughened glass and have a long, cylindrical shape. Their major function is to disperse mechanical forces while preventing electrical contact.

Shackle Insulators:

Low-voltage distribution lines typically make use of shackle insulators, which are sometimes known as spool or link insulators. Made of porcelain or polymer, they take the form of a spool. Shackle insulators can be fastened to their support structure with a nut and bolt thanks to the centrally located threaded bolt. The shackle eye is then used to secure the conductor. For low-voltage uses, these insulators are a straightforward and inexpensive option. Experience comfort and energy efficiency - Order high-quality Indoor Insulators manufactured and supplied by Radiant Enterprises - one of the renowned Indoor Insulator manufacturers in India!

Composite Insulators:

In recent years, composite insulators have experienced a surge in popularity owing to their advantageous characteristics, including their lightweight nature, superior mechanical strength, and exceptional pollution resistance. Typically, these objects consist of a core made of fibreglass and a housing made of silicone rubber. Composite insulators possess superior resistance to adverse environmental conditions, hence decreasing the necessity for maintenance. Insulators made of alternative materials are employed in both distribution and transmission lines, serving as a practical substitute for conventional porcelain insulators.

Post Insulators:

Post insulators are commonly utilised in substations and various electrical apparatus. These units are specifically engineered to function as a cohesive entity, effectively insulating the conductors from the earth or supporting structures. Post insulators exhibit a diverse range of shapes and sizes, which are contingent upon the particular application and voltage prerequisites. Crucial elements are present in order to guarantee the safety and effectiveness of electrical power networks within substations.

Final Thoughts:

Insulators play a crucial role in overhead lines, serving as essential components that guarantee the dependable and secure transmission of electrical power. This comprehensive resource provides descriptions of numerous types of insulators that are designed to accommodate varying voltage levels, ambient circumstances, and mechanical specifications. Various types of insulators, ranging from old pin and suspension insulators to contemporary composite insulators, possess distinct advantages and find usage in diverse contexts.

When undertaking the design of overhead lines, it is imperative to take into account many elements such as voltage levels, contamination levels, and mechanical loads in order to make an informed decision regarding the appropriate insulator type. The continuous development of insulators, driven by breakthroughs in materials and manufacturing techniques, has resulted in improved efficiency and increased lifespan of power transmission networks on a global scale. With the continuous advancement of technology, it is anticipated that there will be a proliferation of inventive insulator solutions in the future, which will further enhance the efficiency of overhead lines. Ensure continuous power supply with expertly crafted Outdoor Insulators for your infrastructure supplied by Radiant Enterprises - one of the best Outdoor Insulator manufacturers in India!

#Medium Voltage Support Insulator Manufacturers in India#Indoor Insulator Manufacturers in India#Outdoor Insulator Manufacturers in India

7 notes

·

View notes

Text

Bellows, Boots, Rubber Bellows, Manufacturer, Mumbai, India

Bellows, Boots, Rubber Bellows, Rubber Bellows Manufacturer, Anti Vibration Mounts, Rubber Anti Vibration Mounts, Anti Vibration Mounts Manufacturer, Anti Vibration Mount Supplier, Mumbai, India.

Rubber Products, Moulded Rubber Parts, Extruded Rubber Parts, Sponge Moulded Parts, Metal Bonded Parts, Manufacturers Of Rubber Components, Manufacturers Of Moulded Rubber Parts, Manufacturers Of Extruded Rubber Parts, Rubber Moulded Parts, 'O' Rings, Oilseal, U Seal, V Seal, Chevron Packing For Pumps, Hydraulics Seal, Mechanical Seal, Neoprenen Rubber, Nitrile Rubber, Epdm Rubber, Hypalon Rubber, FKM Rubber, Natural Rubber, Polymers, Flourinated Rubber, FKM Rubber, Silicone Rubber, Polyurethane Rubber, Ethylene Propylene Terpolymers, Natural Rubber, Synthetic Rubber, Chemical Resistance, O Rings, U Seals, V Seals, Lip Seals, Wiper Seals, Oil Seals, Diaphragms, Electrical Control Valves, Pneumatic Control Valves, Pressure Regulators, Valve Positioner, Ball & Butterfly Valve, Solenoid Valve With Brass, Stainless Steel Stud, Fabric, Nylon, Canvas, Rayoncord, Wiremess

2 notes

·

View notes

Text

Silicone Hose Manufacturer

Silicone hoses and pipes are flexible tubes made from high-quality silicone rubber, designed for applications that require temperature resistance, flexibility, and durability. Known for their ability to withstand extreme temperatures, silicone hoses are commonly used in automotive, food and beverage processing, pharmaceuticals, and industrial systems. If you are looking for silicon hose manufacturer, contact Shree Rubber Works.

0 notes

Text

Looking for top-quality silicone and industrial rubber sheet manufacturers in India? Discover leading suppliers providing durable, high-performance rubber solutions for various industries. Perfect for sealing, insulation, and vibration control, these manufacturers offer a wide range of products tailored to meet your specific needs. Enhance your projects with reliable materials from the best in the business. Explore now and ensure superior quality for your applications!

#Silicone and Industrial Rubber Sheet Manufacturers in India#Industrial Rubber Sheet Manufacturers in India#Silicone and Industrial Rubber Sheet

0 notes

Text

Dimethylcyclosiloxane Prices, News, Monitor & Demand

North America

During the fourth quarter of 2024, the North American Dimethylcyclosiloxane (DMC) market faced significant downward pressure on prices due to multiple interrelated factors. Weak downstream demand, particularly from the silicone industry, was a primary driver, with sectors such as automotive and construction struggling under the weight of high interest rates and reduced consumer spending. Stable production levels in the domestic market contributed to an oversupply, further straining market dynamics.

Additionally, feedstock costs, especially for dimethyldichlorosilane (DMDC), eased as raw material prices softened, and supply chains improved, reducing overall production expenses. The downward trend accelerated as freight rates stabilized and supply flows remained uninterrupted.

Globally, challenges such as subdued demand for silicone rubber in South Korea and a contracting manufacturing sector in China compounded the situation, with manufacturers facing increased production costs and declining export demand. In India, weak manufacturing activity in key sectors like automotive and construction also hindered global demand. These combined factors underscored a bearish outlook for the DMC market, reflecting broader economic uncertainties.

During the initial months of the fourth quarter of 2024, the Dimethylcyclosiloxane (DMC) market in Asia-Pacific experienced significant price declines, followed by a period of stability in December. The early decline was driven by stable yet subdued downstream demand and easing feedstock costs, particularly for dimethyldichlorosilane (DMDC), as raw material prices softened, and supply chains improved. The silicone market, a key consumer of DMC, maintained consistent demand from sectors like automotive and construction, though these industries were constrained by high interest rates and reduced consumer spending. Oversupply in the domestic market, due to steady production levels, added further pressure on prices. The downward trend was amplified by reduced production costs, smooth supply flow, and stable freight charges. By December, the market showed resilience with balanced supply levels and sufficient inventories, despite subdued performance in the silicone rubber sector and weaker export demand across Asia. Stable domestic consumption and strong demand from the U.S. silicone rubber market provided some support, resulting in a steadying of prices and a cautiously optimistic market outlook.

0 notes

Text

Crucial Steps In Choosing Rubber Parts Supplier

Buying rubber parts from reputed suppliers is crucial for the performance of your finished product. Rubber parts suppliers range from simple garage-type operations to comprehension service providers. The game of choosing a rubber part supplier is not going to be a cakewalk unless you follow these crucial steps:

Choose a specialist: The market is loaded with industrial rubber products like gaskets, caps, grommets, fabricated parts, and more. Each supplier deals with particular products. It is not easy for suppliers to deal with all types of rubber products at a go. Depending on your specifications choose a dealer who masters your type of rubber products. Only a specialist supplier can provide the rubber parts you require without any flaws.

Experience matters: Working with rubber parts requires skill and experience. A good supplier will have the knowledge to understand the properties of the materials and their application. A supplier with an excellent track record should be your choice and anything less will be a compromise on the finished products.

Inventory supply: Always choose a supplier who re-stocks their inventory regularly so that there will be no time wasted between order and delivery. Rubber suppliers with decent stock can deliver on time leaving you without any hassles to meet strict deadlines.

Pricing is vital: Picking the rubber products at the right price is crucial to maintain your profits. Quality cannot be compromised on price. Poor quality rubber parts delivered at cheaper rates can only result in sub-standard products, leading to a loss in clientele. Apart from price, other payment factors do matter. Flexible payment options, credit, and customized solutions are factors to check while choosing a rubber parts supplier.

Alfa Rubber is a name to reckon with when it comes to rubber parts suppliers. With over 35 years of experience and IATF certification what more you could ask for when it comes to buying rubber, foam, and felt products? Call us for a quote!

For More Details:

ALFA RUBBER & SPRINGS PRIVATE LIMITED

A-13/A, SIPCOT INDUSTRIAL COMPLEX,

GUMMIDIPOONDI. TAMILNADU 601 201, INDIA

TELEPHONE – +91-44-27922057

EMAIL – [email protected]

#Rubber parts supplier#bush manufacturer#grommet manufacturer#o rings manufacturer#rubber industries in india#seal manufacturer#rubber injection molding#gaskets and seals#silicon rubber products#rubber grommet manufacturer#rubber bush manufacturer

0 notes

Text

K R Industries is India's Leading Manufacturers of Silicon rubber products specializing in all types of Molded Rubber Parts, Custom Made Rubber Parts and Automotive Rubber Parts in USA. Enquire us for any requirements.

#silicone rubber products manufacturer india#silicone rubber products suppliers india#silicone rubber products manufacturing companies india

0 notes