#seal manufacturer

Explore tagged Tumblr posts

Text

Get to know more about the industry's best seal manufacturer Alfa Rubber is widely accredited as the most sort-after seal manufacturer. We have long years of experience in producing and distributing silicon rubber products. https://alfarubber.com/application-engineering/

0 notes

Text

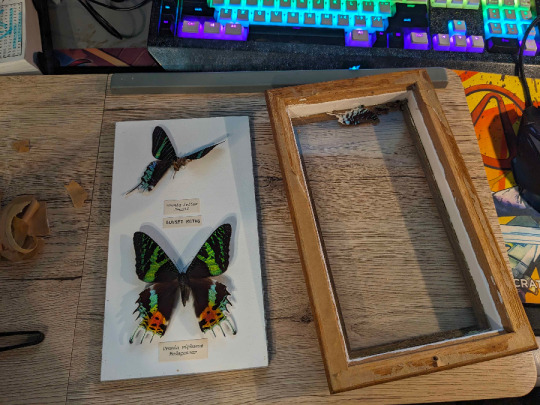

i had to open up and repair some of my butterflies because the ancient glue holding the glass gave in, and i figured while it's open, might as well take some close ups of the sunset moth

#jj stuff#the collectors stamp on the back said it was closed in 1969 so the person who sealed it did a GREAT job#it was just the frame manufacturing that gave way rip 😔#crushed 1/4 of the top one so i had to make due :'(#i got soo many of these from a Weird Old Local Guy (<- said fondly) who did them himself. miss u mr. warren <3

25 notes

·

View notes

Text

it's kirby's birthday 🤑🤑🤑

you would think confetti would make for a nice fancy birthday dinner but it absolutely was not

bonus cleanup . doing glitter next year because the confetti was coming out of any unsealed area it could . took forever to get it off of him

#objectum#my husband#kirbyposting#he was manufactured in 1965#loave him#I now dislike confetti#a reminder to seal his fan case eventually

8 notes

·

View notes

Text

Burned my shrimp after 2 already failed attempts at making food

#stovetop wont light for one attempt#the second attempt there was a manufacturing error and the seal was punctured so the food was no food

10 notes

·

View notes

Text

Cup Filler Machines Manufacturer in Haryana

A Cup Filler Machines Manufacturer in Haryana specializes in producing automated machines for filling pre-formed cups with liquids, powders, or granules. These machines ensure precise filling, fast processing speeds, and minimal waste, making them ideal for the food, beverage, and pharmaceutical industries. With a focus on innovation and quality, the manufacturer provides tailored solutions to meet diverse packaging needs.

#Cup Filler Machines Manufacturer in Haryana#Form Fill Seal Machines Manufacturer in Haryana#Auger Filler Machines Manufacturer in Haryana#Automatic Pouch Packaging Machine Manufacturer in Faridabad#Packaging Equipment Manufacturer in Faridabad

2 notes

·

View notes

Text

my sibling heard me saying i really like the new base set draculaura doll and got me one for christmas :) (which they could just do because they’re widely and conveniently available at major retailers and on sale prices for the holidays, hasbro). it’s fun having a modern doll in my collection but also trying to open her box without damaging it makes me feel like i’m in a saw trap. are they all like this now.

#she’s actually my first doll that’s newer than probably 2006-2008 not counting ponies#ponies were extremely easy to open#she’s so new and seems to have been manufactured in high enough quantities that i think it’s fine not leaving her MIB. i think#i could always put her back in her box even if it’s not sealed#switch speaks

9 notes

·

View notes

Text

What Are EPDM Extrusion Profiles Used For?

Recently, the extrusion generation has been advanced with the tool of Ethylene Propylene Diene Monomer (EPDM) profiles. High quality EPDM extrusion profiles are an example of advancement and development that promoted a wide range of uses in car, production, industrial, and other areas.

Enhanced Durability: These profiles are acknowledged to be environment friendly within the stability of the financial system. They proudly for the confrontation resistance of negative consequences from rather severe types of climate, high temperatures, chemicals, and UV radiation, thus maintaining durability.

Versatile Applications: The elastomeric-characterized EPDM extrusion profiles entails that the profile can be developed in a host of varied and specialized profile designs. This factor makes them suitable for use in window seals, door seals, gaskets and hoses in many industries.

Economic Viability: EPDM profiles strike a perfect balance of sturdiness and fee-effectiveness. They offer an excessive-overall performance, reliable answer without breaking the financial institution.

Advancements in EPDM extrusion profiles generation are yielding sturdy, adaptable, and least expensive profiles which might be enhancing myriad commercial programs.

Leading the Way: Stature of EPDM Rubber Profile Manufacturers in Today's Industry

In the commercial global, producers of ethylene propylene diene monomer or epdm rubber profiles are laying the foundations for increased great and tremendous durability. Industrial, automotive as well as production industries could not have a more remarkable indispensable contribution from them.

Unparalleled Quality: These manufacturers are synonymous with integrity and fine. Using superior era, those producers make sure the EPDM profiles have vast strength, UV resistance, and advanced weather ability that render lengthy-lasting overall performance.

Extensive Application: The versatility of the EPDM rubber profiles sees its wide application in car door and window sealing, cable and conduit installations and the insulation of windows and doors in residential and commercial homes.

EPDM rubber profile manufacturers play a paramount role in bolstering the economic realm with notable, versatile, and eco-friendly rubber answers.

Unmasking the Power of Extruded Rubber Seal Profiles

These profiles are the unsung heroes in a lot of sectors. Working seamlessly to make sure tight seals in applications starting from automotive, business equipment, to home appliances, those subtle components make our lives less difficult and more secure without a great deal fanfare.

Versatility: The innate strength that defines extruded rubber seal profiles is flexibility. In a customizable size and design it finds its uses in many places ranging from simply as barriers to doorways/ window to shielding gears/systems in highly chemical reactive places like industries.

Durability: These profiles are produced from first-class rubber material and thus they stand great stresses such as wear and tear, high temperature and unfavorable environment thus implying longevity.

Cost-Effectiveness: However, being a crucial component, the cost of these profiles is not heaped mainly on conventional mission charges. They are durable hence reducing the costs of replacement which makes them a capital power tool when considering the long-term.

It proves the adage that the seal is sealed tight when your packages are secure with those sturdy extruded rubber seal profiles.

Unraveling the Intricacies of Rubber Seal Profiles

Silent heroes are the rubber seals that seem to be unimportant all too often and are actually the backbones of many business plans. These tiny elements undertake the critical task of closing up a tight, airtight connection between different components of a machine; this prevents fluid or gases from leaking out and guarantees optimum rated machines’ performance.

Versatile Utility: Rubber seal profiles locations its software’s within various segments such as automobile, aerospace, electronics and upper. In the combustion chamber of a car engine or the hydraulic device of an aero plane, these seals perform a critical role of smooth running of machines.

Material Matters: The sort of rubber used in seal profiles, then, depends on the utility fully. The everyday materials include Silicone, Nitrile and EPDM, each of them has been selected for particular attributes such as temperature endurance, oil-progression, or elasticity.

Therefore, notwithstanding their unobtrusive presence, these profiles are unsung heroes in numerous industrial packages, warranting deeper expertise and appreciation.

Enhanced Home Security through Custom Door Seals

Each house deserves an add-on stage of safety and ease that can be easily attained through these seals. The differences between a basic door security and a personalized one are innumerable when you opt for the later.

Enhanced Security: Their design also ensures a better fit since they are made to order to be off the capacity access factors for the intruders. It does the same for your own home, thereby protecting you and those you care about.

Energy Efficiency: Custom Door Seals prevent air leakage, improving the power performance of your property. During winter, a terrific seal continues the cold air out; in the course of summer season, it keeps the conditioned air in.

Noise Reduction: Door seals can also lessen any undesirable noise from the out of doors, developing a nonviolent environment in the domestic.

Revolutionizing Sealing Solutions with T-Profile Rubber Seals

These Rubber seals are transforming the present day enterprise sealing requirements due to their precise layout and first-rate features.

Flexible Yet Robust: These seals are made from excessive-energy, strong rubber that makes them resilient to intense situations, but rather bendy to make sure a really perfect healthy.

Efficient Sealant: The T-Profile design gives remarkable sealing performance, stopping any ingress of liquids or dirt particles, surpassing traditional sealing strategies.

Versatile Use: Suitable for numerous industrial programs, those seals may be utilized in diverse regions along with automotive, aerospace, production and many extra.

T-Profile Rubber Seals combine durability with fantastic sealing performance. They can resist severe climate situations, resist chemical substances, and provide a green seal as a result making them a choicest choice throughout numerous industries requiring robust sealing answers. Explore the seal of the future with T-Profile rubber seals for a stable, leak-proof revel in!

Conclusion

Ethylene Propylene Diene Monomer (EPDM) profiles are a key component in the manufacturing of premium extrusion profiles, which find use in a variety of sectors, including automotive, manufacturing, and industrial. These profiles are renowned for their improved economic viability, durability, and adaptability. EPDM rubber profile producers are renowned for their dependability, excellence, and broad range of uses. Additionally, they are utilized in a number of industries, including household appliances, commercial equipment, and automobiles. Extruded rubber seal profiles are strong and adaptable, making them ideal for a range of uses, including insulation, cable and conduit installations, and door and window sealing. They are affordable and offer a long-term fix without going over budget. Custom door seals are a popular option for many businesses because they provide increased security, energy efficiency, and noise reduction.

Custom Rubber Extrusions offers specialised rubber extrusion solutions, designed to fit your precise wishes on your region. We interact with all involved stakeholders and verify the go back on investment to deliver most cost. Along with customizable capabilities, our offerings are aimed toward enhancing your business performance and industry effect.

Contact us nowadays at [email protected] or (213)-426-1030 to time table a session or speak your desire

#EPDM-extrusion-profiles#EPDM-rubber-profile-manufacturers#extruded-rubber-seal-profiles#Custom-Door-Seals

0 notes

Text

Understanding Security Seals: Types, Usage, and Need in Modern Business Organizations

Of course, security seals alone play the most critical role in security for such goods as commodities and documents and even other essential items in the same industries, like in transportation, banking, and various others. As items are relatively more compact, they justify tamper-evident security, bringing much to hold accountable operations related to transport and industries as well as those regarding banks. In this blog, we shall discuss the various types of security seals, their applications, and why they are indispensable in today's world. We will also discuss a prominent security seal manufacturer and exporter from India—Azoliya.

What Are Security Seals?

Security seals are tamper-evident devices that indicate tampering or unauthorized access. They are made of plastic, metal, and other strong materials to prevent theft and tampering. Once they are placed, they cannot be removed except through deliberate action. Thus, sealed items remain protected during transportation, storage, and other critical processes.

Types of Security Seals

Knowing these types of security seals will help businesses choose a specific solution for their needs. Here are some common ones:

Plastic Seals

Lightweight and affordable.

Suits bags, containers, and meters.

Metal Seals

Extremely durable, tamper-resistant, and ideal for use in high-security applications like shipping containers.

Cable Seals

The variety allows them to vary in length. They are occasionally used in the logistics and transport industries.

Bolt Seals

Bolt seals can be used for heavy-duty applications. They can seal trucks and shipping containers.

Indicative Seals

These provide visual proof of any tampering.

These are generally used for low-risk applications.

Applications of Security Seals

Security seals are applied in a variety of industries such as:

Transportation and Logistics: To protect cargo during transportation and prevent illegal access.

Retail: To safeguard goods in warehouses and during delivery.

Banking: To secure cash, documents, and ATM cassettes.

Healthcare: To guarantee the integrity of medical equipment and pharmaceuticals.

Why Security Seals Are Important

Security seals are a necessity to ensure trust and accountability in operations. Here are some reasons why they are indispensable:

Tamper Evidence: Security seals provide clear evidence of tampering, which can be acted upon quickly.

Deterrence: Their presence alone can deter unauthorized access.

Compliance: Many industries require the use of security seals to meet regulatory standards.

They offer cost-effective protection by means of a simple but effective way of securing assets without considerable investment.

Azoliya: Security Seal Manufacturer and Exporter from India

Be it for any industrial requirements of excellent quality security seals, the name to glance at is Azoliya. This being one of the most reliable security seal manufacturers in India, they offer a variety of innovative sealing solutions for many different kinds of industries. They come with seals of precision designed into prime material so that the seals get the prime protective cover it needs.

Why Choose Azoliya?

Years of experience have made Azoliya the market leader in the market for many decades.

Innovative Designs: The seals are designed in a manner that would merge functionality with advanced features, thus delivering high security.

Custom Solutions: It caters to specific client requirements and delivers customized solutions.

Global Reach: Being one of the well-known security seal exporter in India, it caters to clients worldwide with timely delivery and quality.

Whether it is plastic seals for retail purposes or high-duty bolt seals for shipping, the products by Azoliya ensure the safety and security of your belongings.

Conclusion

Security seals have assumed significant importance in the present-day industry that protects the merchandise and provides tamper-evident protection for the product. With such a pivotal security seal, enormous applications exist; now it becomes the back support for the industrial operational security system. The Azoliya group is an Indian security seal manufacturer and exporter providing incomparable solutions for businesses across the globe. Therefore, by availing yourself of the right kind of security seal, you may be able to increase trust and accountability and work efficiency.

Frequently Asked Questions

1. What are security seals used for?

Security seals prevent tampering and unauthorized access to goods, documents, and other valuable assets. These are normally used in the transport, retail, and banking industries.

2. How do I choose the right security seal?

The right seal to be chosen depends on some requirements, which are the level of security needed, the application, and the environment where the security seal is used.

3. Why are security seals important in the supply chain?

Keeping up, the contents are intact while sending the goods, which reach the end without any variation. They also achieve some security compliant to the various industry codes

4. What makes Azoliya a genuine security seal-making company in India?

Azoliya has set up its name with being an old hand in the game for decades as well as novel designs and excellence. As one of the leading exporting security seal manufacturers in India, it really seems authentic.

5. Are there environmentally friendly security seal options?

Yes, there are many such manufacturers, not to forget including Azoliya, who have come up with environmentally friendly security seal options, which are recyclable to make them more sustainable.

About the Author

She has experience in content creation for more than five years through interesting and informative blogs about tools and equipment, modern heritage, and much more. With more than 3,000 blogs under her belt, she manages to create creativity intertwined with research in all those pieces, making them insightful stories readers will love. And because Ritika focuses on trust and dependability in her work, she ensures that every single blog she has meets the highest of standards.

0 notes

Text

High-Quality rubber bellows dust boot for Long-Lasting Protection

When hardworking machinery and delicate, sensitive equipment are given protection from dust, dirt, and other elements, rubber bellows dust boots have an essential role to play. These are high-quality products that ensure peak possible performance, low wear and tear, and long life for vital systems. This certainly is a good tip for investing one's resources in addition to having engineering types in other industry sectors, such as automotive and aerospace industrial fields. The right selection can save you time and cost, whereas wasting such. This blog will talk about the features, advantages, and applications of and what to look out for when buying the right rubber bellow manufacturer for your operations.

What Are rubber bellows dust boots?

Rubber bellows Dust boots are specifically designed protective enclosures keeping machinery parts such as shafts, joints, and actuators protected from most harmful elements. A boot of dust is built of tough materials such as nitrile rubber, EPDM, or silicone, so it is flexible while enduring cold and the hardest things it can be found near. That is what channels these protective devices are doing.

Key

The most striking point about them is its unique qualities.

It is long-lasting, it can handle heavy loads, and its wear against wear and tear is commendably high.

Very high elasticity of movement is enabled in users who have some character in their application process.

Operates through a sealed closure, a good seal about contaminants, one can use even in a very contaminated working environment.

The diversity in the material is available in nitrile, EPDM, and silicone, mainly because it possesses diverse properties.

Design variants can be added to accommodate almost all sizes and functions.

Applications

Rubber bellows dust boots are the kind of versatile footwear that is used in a river of industries. These include the following:

Automotive Sector : Guard against dust and moisture in steering systems, suspension parts, and gearboxes, so that everything can run trouble-free.

Industrial Machinery : Protects from dust and corrosive particles to the moving elements of industrial apparatuses, thus promoting the efficiency of the operation.

Aerospace Industry: Protective measures of critical systems aboard aircraft to maintain accuracy and reliability.

Medical Equipment : Prevents contamination of crucial devices and enhances their longevity.

How to Select the Right Rubber Bellows Manufacturer

Choosing the rubber bellows is just as important as choosing the right manufacturer for it. Here are some points that can assist in making a decision:

Experience and Expertise: Seek out a rubber bellow manufacturer that has been in the business for years and has remarkable experience in manufacturing bellows.

Customization Options: A credible industrial bellows manufacturer will provide fully customizable options of different dimensions, shapes, and materials.

Quality Standards: Look for a manufacturer that is up to mark in standard compliance and has the necessary certification for their products.

Innovation and Technology: Many fast advanced manufacturing technologies are used in the production of various products to satisfy most requirements and needs.

Customer Support: Always ensure that the manufacturer has excellent support and assistance for their products.

If there is a well-chosen manufacturer, then a suitable product will be obtained. No more return on such investment.

Advantages of Using High-Quality

Investing in high-quality comes with several advantages:

Enhanced Protection: Seals off contaminants to minimize the chances of spoiling the efficiency of the machines in operation.

Longevity: Saves the cost of replacement, and maintenance, as well as the cost of spare parts for vital machinery and equipment.

Cost Efficiency: Reduces maintenance cost and time spent on fixing damaged components in a production line.

Versatility: Versatile, which makes them useful not only in a certain field but also in a certain use.

Eco-Friendly Options: Most producers incorporate environmentally friendly production materials into their products in support of the green agenda.

Customizable Features: In other words, customized designs mean the absence of a loose fit and, therefore, superior performance. Thus, by putting on rubber bellow seals, you are protecting your equipment against possible harm, which in the long run translates to dispensing with repair and purchase costs.

Customization: Tailored to Fit Your Needs

rubber bellows dust boots are not universal pieces of equipment. The main manufacturers of industrial bellows provide information on different possibilities of customization, which can guarantee a perfect match of the product to its usage.

Material Selection: There is the choice of nitrile, EPDM, silicone, and many others depending on the conditions in which the equipment operates.

Design Modifications: It comes in flanged, tapered, and cylindrical styles for configuration according to the type of setup required.

Size and Thickness: Choose the precise sizes and thicknesses for the best performance. Customization makes it possible to meet the necessary safety, ruggedness, and mobility needed from the dust boots.

Conclusion

Rubber bellows dust boots are a must-have for industries that require a piece of machinery or equipment to run for a very long time without wearing out due to contamination. This versatility and elasticity give them the attribute of impressive resilience and durability, which make them the quintessential primary solution to the goal of long-term optimization of the effectiveness and cost-effectiveness of the processes in the needs. As an Industrial Bellows Manufacturer, we strive to develop high-quality dust boots for the industry that serve various needs. Policies that promote business success, professionalism, creativity, and consumer contentment enable a guarantee of reliability in product performance.

Want to safeguard your equipment? Please contact us today to discuss the complete line of rubber dust boots and our complete line of products to find which will be perfect for your needs.

#rubber-bellows-dust-boot#rubber-bellow-manufacturer#industrial-bellows-manufacturer#rubber-bellow-seal

0 notes

Text

O-ring seals play a vital role in industrial equipment by creating reliable, pressure-resistant seals in various applications. Available in materials like Nitrile, Viton, Silicone, and PTFE, they offer versatility, durability, and resistance to extreme conditions. Discover how these affordable, durable components enhance performance and longevity. For quality O-rings, trust Horiaki India Private Limited for your sealing needs!

0 notes

Text

RUBBER PARTS MANUFACTURER - HELPING WITH CUSTOM MADE RUBBER PARTS

Various types of rubber parts are absolutely essential for any kind of machine. But at times it is not possible for the machine manufacturers to access the exact kinds of rubber parts that they are seeking. In such cases, they either have to accommodate the available parts or have to opt for custom made rubber parts.

Custom made rubber parts used to be expensive earlier, but off late thanks to the effort of every rubber parts manufacturer these have become affordable and easy use. There is no denying that standard rubber parts are cheaper than custom made ones, any day. But incase getting a particular type and dimension of rubber part is extremely crucial to the process then getting it custom made albeit at a little higher price, would be the right decision. Also because in general rubber parts being inexpensive, going in for custom made parts for a machine manufacturer is not be a problem.

The Types of Custom Made Rubber Parts Offered By Rubber Parts Manufacturer

There are several types of rubber parts that can be custom made by the rubber parts manufacturer. Some of these are:

Seals

O-rings

Flanged Stem Bushings

Grommets

Bumpers

Anti-vibration Pads

Tips & Caps

Extrusions & Tubing

Opting for standard rubber part is always the first choice for the machine manufacturers because it cuts down the time required for crafting a custom made one. But in instances wherein the standard rubber parts are very difficult to fit in, the manufacturers have to opt for the custom made ones. Generally in case of custom made rubber parts, the clients draft the design for the part themselves. But it is for the Rubber parts manufacturer to choose the right kind of rubber and factor in noise dampening and vibration isolation in the given design.

Contact Us

Alfa rubber & Springs Private Limited

TELEPHONE – +91-44-27922057

EMAIL – [email protected]

Website: https://alfarubber.com/

#Rubber parts supplier#bush manufacturer#o rings manufacturer#seal manufacturer#grommet manufacturer#rubber industries in india#rubber injection molding

0 notes

Text

Mumbai’s Leading Manufacturer of Square Chemical Seal Container - SinghEnterprises

Singh Enterprises, based in Mumbai, is a prominent manufacturer of square chemical seal containers, catering to various industries with high-quality packaging solutions. Our square seal chemical containers are crafted from high-density polyethylene (HDPE) plastic, known for its superior strength and durability. We manufactures both the seals and the container bodies in-house, ensuring a design that evenly distributes heat, pressure, and weight of the contained substances. Singh Enterprises' commitment to quality and customer satisfaction has made them a trusted name in the plastic packaging industry, providing reliable solutions for chemical storage and repackaging needs.

0 notes

Text

Automatic ROPP Cap Sealing Machine Manufacturers, Suppliers in Mumbai, India

Our precision engineered 12 Automatic ROPP Cap Sealing Machine is meticulously designed and is ideal for effective and reliable sealing of bottles and containers with aluminum caps of different sizes All the contact parts are fabricated using stainless steel and conforming to the latest GMP norms.

Automatic ROPP Cap Sealing Machine Manufacturers, Suppliers in Mumbai, India.

0 notes

Text

The Essential Role of Rubber Seals and Gaskets in Enhancing Vehicle Performance

Importance of Rubber Seals in Vehicle Performance

Rubber seals are crucial in automotive operations, acting as the first line of defense against system failures. They ensure that essential fluids like oil, coolant, and fuel stay within their designated paths, preventing leaks that could lead to inefficiencies or mechanical damage. Gaskets and seals from reputable seals and gaskets suppliers play a vital role in creating airtight, leak-proof barriers for these critical components.

For example, rubber seals prevent oil leaks in the engine, which could cause insufficient lubrication, overheating, or even engine failure. Similarly, coolant seals maintain the vehicle's temperature control, preventing overheating. Without these essential components, vehicles would experience a range of issues, from minor inefficiencies to major mechanical breakdowns.

Types of Rubber Seals Used in Automobiles

Not all rubber seals are the same. Automotive applications require various types of seals, each designed for specific pressures and environments. Some common types include:

O-rings: These circular seals ensure fluid or gas-tight connections between components, commonly used in automotive systems.

Gaskets: Crucial in sealing joints, especially in engine and exhaust systems, gaskets manufacturers in India provide rubber gaskets that withstand high pressures and extreme temperatures.

Rubber Grommets: Primarily used for protecting electrical wiring, rubber grommets prevent cable damage by providing a buffer between metal components and delicate wires.

Key Applications in the Automotive Industry

Rubber seals are essential in maintaining vehicle functionality across various critical systems:

Engine Seals: Multiple engine seals control the flow of air, oil, and coolant. For example, the head gasket endures extreme heat and pressure, preventing gas leaks while keeping fluids separate. A failed head gasket can cause catastrophic engine damage.

Electrical Insulation: High-quality seals from rubber seal manufacturers in India protect electrical systems from moisture and dirt, insulating spark plugs and other components to prevent shorts and ensure optimal functioning.

Cooling Systems: Rubber seals are vital for preventing coolant leakage in vehicle cooling systems, ensuring it circulates properly through the engine and radiator to prevent overheating.

Transmission and Suspension Systems: Rubber seals protect transmission and suspension components, keeping dirt, water, and debris out and extending the lifespan of sensitive parts, ensuring smooth vehicle performance.

For more information on our range of sealing components, please visit our website or contact our experts now.

Conclusion:

Rubber seals and gaskets are indispensable components in maintaining the efficiency and reliability of automotive systems. From preventing fluid leaks in engines to protecting electrical systems and enhancing cooling efficiency, these components are crucial for vehicle longevity and performance. By choosing high-quality seals from trusted gaskets manufacturers in India and seals and gaskets suppliers, automotive manufacturers and repair services can ensure optimal functionality, safeguard critical systems, and ultimately provide a smoother, more reliable driving experience.

0 notes

Text

How Can Cup Filler Machines from Ambika Packaging Solution Streamline Your Packaging Process?

In today’s competitive market, packaging plays a crucial role in ensuring the safety, quality, and presentation of products. Whether you're in the food, pharmaceutical, or industrial sector, choosing the right packaging machine is essential to maintain product integrity and streamline production processes. Ambika Packaging Solution is a leading name in the packaging industry, offering a diverse range of high-quality packaging solutions. As a renowned Packaging Machine Manufacturer, we specialize in providing top-of-the-line equipment to meet the unique demands of various industries.

Why Choose Ambika Packaging Solution?

At Ambika Packaging Solution, we focus on delivering reliable, efficient, and cost-effective packaging machines. With years of experience and expertise in the field, we offer a comprehensive range of packaging equipment that can help businesses enhance their production efficiency and product presentation. Our machines are engineered with precision and advanced technology to ensure that each product is packed with care and perfection.

Wide Range of Packaging Solutions

Features of Our Pouch Packaging Machines

Our Automatic Pouch Packaging Machine Manufacturer equipment boasts advanced features like automatic feeding, high-speed filling, and precise sealing capabilities. These features ensure that each pouch is securely packed with the right amount of product. With minimal downtime and maximum efficiency, our machines help you scale your production effortlessly.

In addition to our standard pouch packaging solutions, we also offer customizable options to suit your unique packaging requirements. Whether you need specialized pouch sizes, unique sealing types, or multi-lane packaging, we have the perfect solution for your business.

We understand that businesses require diverse packaging solutions to meet specific demands. That’s why Ambika Packaging Solution provides a variety of packaging machinery, including Form Fill Seal Machines Manufacturer solutions that are highly adaptable. Our Form Fill Seal Machines Manufacturer are designed to work with multiple packaging materials and formats, making them perfect for industries ranging from food and beverages to pharmaceuticals and household products.

These machines allow you to create a wide variety of pack styles, from stand-up pouches to flat bags. With our Packaging Equipment Manufacturer expertise, we ensure that each machine is easy to operate, maintain, and adjust for different production requirements.

As a Food Packaging Machine Manufacturer, we understand the importance of packaging in the food industry. Packaging not only protects food items from contamination but also extends their shelf life. Our food packaging machines are designed with food safety and hygiene standards in mind, ensuring that each product is sealed and preserved properly.

We provide Liquid Packaging Machines Manufacturer solutions that are capable of efficiently handling liquids like juices, sauces, and oils. Our machines are equipped with precise measuring systems, ensuring that every package contains the correct volume of product. From juice packaging to liquid soap filling, our solutions are engineered for high performance and durability.

For businesses dealing with powders and granular products, our Auger Filler Machines Manufacturer offers a perfect solution. These machines are ideal for packaging powders such as spices, coffee, flour, and more. Our Auger Filler Machines Manufacturer equipment ensures precise, accurate filling with minimal waste, helping businesses maintain consistency in their products.

Custom Packaging Equipment to Meet Your Needs

At Ambika Packaging Solution, we are committed to delivering tailored solutions to meet the specific needs of our clients. As a leading Packaging Equipment Manufacturer, we offer a wide array of machines that can be customized based on your production requirements, product type, and packaging goals.

Whether you need a simple pouch packaging machine or a complex automated system, we work closely with our clients to understand their unique needs. Our engineers and technicians design packaging systems that not only meet industry standards but also provide efficiency and cost savings.

Why Choose Us?

Quality Assurance: As a prominent Packaging Machine Manufacturer, we ensure that all our machines are built to the highest quality standards. Each machine undergoes rigorous testing to guarantee reliability and performance.

Customization: We understand that one size does not fit all. Our team works with clients to develop bespoke packaging machines that perfectly align with their needs.

Innovation: We are always at the forefront of technological advancements. As a leading Pouch Packaging Machine Manufacturer, we incorporate the latest technologies into our machines, helping businesses stay competitive.

Affordable Solutions: We believe in offering high-quality packaging solutions at competitive prices. Whether you're a small business or a large enterprise, we offer cost-effective solutions without compromising on quality.

After-Sales Support: Our commitment to client satisfaction doesn’t end with the sale. We provide exceptional after-sales support to ensure that your machines continue to operate at peak performance.

Packaging Machines for Every Industry

Our comprehensive range of packaging machines is designed to cater to a variety of industries. From food and beverages to pharmaceuticals, cosmetics, and chemicals, Ambika Packaging Solution provides specialized equipment that ensures efficiency, consistency, and quality in your packaging process.

Whether you're looking for a Food Packaging Machine Manufacturer, a Liquid Packaging Machines Manufacturer, or an Auger Filler Machines Manufacturer, we have you covered. Our machines are designed for high-speed production, minimal downtime, and maximum output.

Conclusion

Packaging is a vital part of every production process, and having the right machinery can make all the difference. At Ambika Packaging Solution, we are proud to be a trusted Packaging Machine Manufacturer offering innovative and reliable packaging solutions. From Pouch Packaging Machine Manufacturer equipment to Auger Filler Machines Manufacturer, our comprehensive product line ensures that businesses across industries have access to the best packaging technology available.

If you’re searching for Packaging Solutions Near Me, look no further than Ambika Packaging Solution. We are here to provide cutting-edge packaging equipment that enhances productivity and product quality. Reach out to us today to learn more about how we can help you achieve your packaging goals.

#Packaging Machine Manufacturer#Pouch Packaging Machine Manufacturer#Automatic Pouch Packaging Machine Manufacturer#Packaging Solutions Near Me#Form Fill Seal Machines Manufacturer#Food Packaging Machine Manufacturer#Liquid Packaging Machines Manufacturer#Auger Filler Machines Manufacturer#Packaging Equipment Manufacturer#Cup Filler Machines Manufacturer

0 notes