#Packaging Equipment Manufacturer in Faridabad

Explore tagged Tumblr posts

Text

Cup Filler Machines Manufacturer in Haryana

A Cup Filler Machines Manufacturer in Haryana specializes in producing automated machines for filling pre-formed cups with liquids, powders, or granules. These machines ensure precise filling, fast processing speeds, and minimal waste, making them ideal for the food, beverage, and pharmaceutical industries. With a focus on innovation and quality, the manufacturer provides tailored solutions to meet diverse packaging needs.

#Cup Filler Machines Manufacturer in Haryana#Form Fill Seal Machines Manufacturer in Haryana#Auger Filler Machines Manufacturer in Haryana#Automatic Pouch Packaging Machine Manufacturer in Faridabad#Packaging Equipment Manufacturer in Faridabad

2 notes

·

View notes

Text

CRC tubes manufacturer delhi - jagdambaenterprise.in

Delhi’s top CRC tubes manufacturers serve a wide variety of industries. Here's how CRC tubes integrate into specific verticals:

🏎️ Automotive and Transportation

In the automotive sector, precision is everything. CRC tubes are used in:

Steering columns and seat frames

Suspension systems

Exhaust systems and silencers

Two-wheeler frames and luggage carriers

EV chassis and battery trays

Delhi’s manufacturers understand the IATF 16949 requirements and maintain strict quality standards, often supplying directly to OEMs or Tier-1 vendors.

🛋️ Furniture and Interior Solutions

CRC tubes are the backbone of modern steel furniture due to their:

Lightweight yet high-strength profile

Clean, minimalistic aesthetic

Easy-to-finish surface (painted, powder-coated, plated)

Applications include:

Office chairs, modular desks

Bed frames and bookshelves

Partition panels, commercial shelving

Delhi’s vendors often support custom RAL color finishes and bending/forming services for furniture manufacturers.

🏗️ Construction and Structural Engineering

While heavy structural steel dominates in large construction projects, CRC tubes are used in precision structures such as:

False ceilings and curtain walls

Modular housing

Scaffolding and temporary installations

Infrastructure support in interior designs (railings, partition frames)

🏋️ Health, Fitness & Gym Equipment

Delhi-based CRC tubes suppliers support the booming fitness equipment sector with tubing that meets:

High weight-bearing requirements

Ergonomic design flexibility

Scratch- and corrosion-resistant surfaces for gyms

Products include:

Machine frames and benches

Treadmill bases

Adjustable dumbbell frames

⚡ Appliances and Electrical Equipment

CRC tubes are used in:

Washing machine bases

Refrigerator stands and frames

Control panel supports

Solar mounting structures

Manufacturers support appliance makers by offering pre-coated or anti-rust treated tubes that last in high-moisture environments.

Delhi vs. Other Indian Manufacturing Hubs – Why Delhi Leads in CRC Tube Production

India is home to many steel production zones—so what makes Delhi stand out when it comes to CRC tube manufacturing?

Delhi’s unique strengths:

Access to industrial clusters in Faridabad, Noida, Ghaziabad, and Bahadurgarh

Strong supply chain for steel coils, chemicals, and packaging

Better lead times due to central geographic location

Easier transport to North, East, and Central India

This makes Delhi ideal for both MSMEs and export-focused enterprises looking for dependable partners.

What In-House Capabilities Should a Good CRC Tube Manufacturer Have?

When evaluating CRC tube suppliers in Delhi, look beyond product catalogs. A capable manufacturer will offer:

✅ In-House Cold Rolling Mills – Ensures consistent gauge and surface finish ✅ Automated Tube Mills with HF Welding – For precise seam welding and dimensional accuracy ✅ Continuous Annealing Furnaces – Ensures uniform mechanical properties ✅ Online Eddy Current Testing – Detects welding defects in real time ✅ Hydraulic Testing & Chemical Analysis Lab – For mechanical strength and material grade validation ✅ Custom Tooling for Bending/Cutting – For value-added fabrication ✅ In-House Galvanizing/Powder Coating Units – Faster turnaround, uniform finish

Working with such a manufacturer guarantees a one-stop solution, reducing the need for post-processing vendors and saving time.

Long-Term Partnerships and OEM Collaboration Opportunities

For companies looking to establish a stable, long-term supply chain, Delhi’s CRC tubes manufacturers are highly suited for OEM and institutional supply.

Here’s what a partnership model could include:

Annual Rate Contracts (ARCs) with price locking

Just-In-Time (JIT) delivery and buffer stock arrangements

Branding or co-labeling support

Dedicated client servicing teams

Vendor compliance audits and certifications

Participation in design/development of new product lines

This kind of relationship is ideal for:

Automotive tier-1 & tier-2 vendors

Gym equipment brands

Modular furniture OEMs

Government supply contracts

Exporters and traders seeking consistent quality

Streamlined Logistics and PAN India Delivery

Thanks to Delhi’s prime location and transport infrastructure, manufacturers here offer:

Same-day dispatch for stock tubes

PAN India shipping via road and rail

Export container loading from ICD Tughlakabad or Nhava Sheva port

Collaboration with major logistics providers like Delhivery, Gati, and Blue Dart

Most suppliers also integrate real-time shipment tracking and customized packaging (steel strip bundles, HDPE wrapping, or wooden pallets) as per customer needs.

What to Ask When Getting a Quote from a CRC Tubes Manufacturer in Delhi

Here’s a checklist to ensure you get a competitive and comprehensive offer:

✔️ Ask for mill test certificate (MTC) with your quote

✔️ Confirm raw material grade (IS, ASTM, or custom)

✔️ Mention coating requirements (bare, galvanized, painted, etc.)

✔️ Specify any special tolerances or dimensional control

✔️ Ask for packaging options suitable for your industry

✔️ Clarify lead time and shipping terms (FOB, Ex-works, CIF)

Ready to Work with a Trusted CRC Tubes Manufacturer in Delhi?

Whether you need 1 ton or 100 tons, Delhi’s CRC tube manufacturers are ready to deliver quality, reliability, and professionalism. The right supplier doesn’t just ship steel—they become a part of your production story.

🔧 Let’s Build Together – Contact Us Today!

We are a leading CRC tubes manufacturer in Delhi offering:

Premium-grade cold rolled close annealed tubes

Custom sizing, coating, and finishing services

Fast turnaround and dependable logistics

Bulk, retail, and OEM support across industries

0 notes

Text

Top 10 Pouch packing machine Manufacturers in India.

Pouch packing machines are essential equipment used for efficiently packaging products in pouches of various sizes and materials. These machines are widely used across industries like food & beverage, pharmaceuticals, cosmetics, chemicals, and agriculture. They ensure airtight sealing, accurate filling, and consistent packaging—greatly improving production speed and hygiene.

Designed to handle powders, granules, liquids, and semi-liquids, pouch packing machines offer a modern, automated solution for high-volume packaging needs. Their versatility, ease of use, and cost-efficiency make them a must-have for large-scale manufacturers and small businesses alike.

There are the different types Pouch packing machine:

1)Collar type pouch packing machine

2)Ghee pouch packing machine

3)Snacks Kurkure Corn Puff Pouch Packing machine

4)ranule Pouch Packing machine

5)Seal pouch packing machine

6)Trial pouch packing machine

7)FFS pouch packing machine

8)Automatic weight filling pouch packing machine

9)Fruit juice in spout pouch packing machine

10)Multihead Pouch Packaging Machine

Applications of Pouch packing machine:

Pouch packing machines are widely used across industries for their efficiency, versatility, and ability to maintain product integrity. In the pharmaceutical and food sectors, they are essential for packaging powders, liquids, and single-dose items—ensuring accurate filling, hygiene, and extended shelf life. Products like snacks, spices, protein powders, and sauces are securely packed to prevent contamination and spoilage, making them ideal for mass production and retail.

These machines are also valuable in the cosmetic, chemical, and pet food industries. From creams and sample sachets to fertilizers, industrial chemicals, and pet treats, pouch packing ensures safe, moisture-proof, and user-friendly packaging. Their adaptability to different pouch types and materials makes them a smart choice for modern packaging need.

Benefits of Pouch Packing Machines:

Boosts speed and productivity

Ensures accurate filling and sealing

Protects against moisture and contamination

Suitable for various product types

Cuts down labor and material costs

Supports multiple pouch sizes and styles

Enhances product appearance and shelf appeal

Costing of pouch packing machine:

The Multihead Pouch Packaging Machine listed on Indian Trade Bird is priced at approximately ₹14,50,000 (including GST). Designed for automatic operations, this machine efficiently handles a variety of products such as namkeen, chips, dry fruits, rice, pulses, and more. It supports pouch capacities ranging from 10 grams to 5 kilograms and offers versatile sealing options like center seal, three-side, four-side, gusset, standing, and zipper pouches—making it a go-to solution for diverse packaging needs in food and FMCG industries.

For comparison, other manufacturers in Noida offer similar machines in the ₹12,00,000 to ₹12,50,000 range, depending on the machine's capacity, features, and output speed. For instance, Super Engineering Works and S D Food Machinery Industry provide automatic multihead weigher machines that pack 50–60 pouches per minute with excellent accuracy. Pricing may vary based on customization, automation levels, and support services, so it’s recommended to connect with suppliers directly for the most accurate quote based on specific production needs.

Top 10 pouch packing machine Manufacturers In India:

Mauli Packaging Machines, Pune

P K Engineering Works , Noida

Nidan Packaging, Faridabad

G Pack Solutions, New Delhi

A P Pack Solutions, Faridabad

AD Packaging, Ahmedabad

Syam Engineering Food Process, Noida

Pal Baba Industries, Faridabad

Sahil Enterprises, Faridabad

Sara Udyog, Noida

For More Details Contact us: https://www.indiantradebird.com/product/pouch-packing-machine

1 note

·

View note

Text

🍺 Brewery License in India: An Updated Guide to Beer Brewing Permits and Costs & Key conditions by State

Starting your own beer brand is no longer just a dream — it’s a booming opportunity in India’s rapidly growing craft beer industry. But before you start brewing IPAs or wheat ales, you need to crack one major code: the brewery license in India.

Whether you’re setting up a large-scale beer manufacturing plant or a trendy microbrewery, this guide gives you a state-wise breakdown of all beer brewery licenses in India, including estimated costs, rules, and key approvals.

And the best part? You don’t have to go through it alone. Prodeb, India’s №1 brewery equipment manufacturer, offers complete end-to-end brewery setup and brewing support, helping you go from vision to first pour.

What is a Brewery License in India?

A brewery license is a mandatory legal permit issued by the Excise Department of each Indian state. It authorizes individuals or companies to produce, store, and sell alcoholic beverages like beer.

Since alcohol laws are regulated at the state level, the rules and costs vary widely across India. This makes it essential to understand the exact licensing requirements for your target location.

Key Licenses Required to Start a Beer Brewery in India

No matter the state, here are the main licenses and approvals you’ll need:

Excise License Legal right to brew and sell beer (varies by state: CL7, L-11, L-10C, etc.)

FSSAI License Food safety and hygiene compliance

Pollution Control Board (SPCB) Clearance Wastewater and effluent management

Trade/Factory License Local municipal operations permit

Fire NOC Certifies fire safety measures

GST Registration Tax compliance for commercial operations

Trademark Secures your beer brand identity

State-Wise Beer Brewery License in India (2025 Updated List)

Here’s a look at states that currently permit breweries and microbreweries, along with their licensing structure, estimated costs, and rules.

1. Karnataka

License: Microbrewery License

Cost: ₹2 lakh + 15% surcharge + ₹17.5/litre duty

Key Conditions: Only on-premise sales allowed; 14 ft ceiling height mandatory

2. Maharashtra

License: Form BRA

Cost: ₹40,000/year

Key Conditions: Max 2,00,000 litres/year; No bottled beer sales

3. Haryana

License: L-10C (Microbrewery)

Cost: ₹12 lakh/year (Gurugram/Faridabad); ₹8 lakh elsewhere

Key Conditions: Must be part of a restaurant/hotel; No packaging

4. Delhi

License: L-11

Cost: ₹5,000 application + duties

Key Conditions: Draft beer only; environmental NOC mandatory

5. Punjab

License: Microbrewery Excise License

Cost: ₹5–10 lakh/year

Key Conditions: For commercial establishments only; strict equipment guidelines

6. Uttar Pradesh

License: State Excise Brewery License

Cost: ₹2.5 lakh/year

Key Conditions: Max 600 litres/day; approval for renewals every year

7. West Bengal

License: Rule 79 Excise License

Cost: ₹5–7 lakh/year

Key Conditions: Can export beer; packaging allowed under set conditions

8. Assam

License: Microbrewery Permit

Cost: ₹5 lakh/year approx.

Key Conditions: Sustainable brewing encouraged; high scrutiny on waste management

9. Telangana

License: Drafted under Excise Policy

Cost: ₹6–8 lakh/year

Key Conditions: Applicable to hotels/restaurants only

10. Goa

License: Craft Brewery License

Cost: ₹2–4 lakh/year

Key Conditions: Export-friendly state; kegs may be allowed

Estimated Total Setup Cost for a Microbrewery

Component Cost Range

Brewing Equipment (Fermenters, Tanks)₹30–60 lakh

Interiors & Civil Work₹10–20 lakh

Licensing & Legal₹8–15 lakh

Working Capital (Staff, Raw Material)₹5–10 lakh

Branding & Contingency₹5–7 lakh

Estimated Total: ₹60 lakh to ₹1.1 crore+

Why Choose Prodeb to Start Your Brewery?

Setting up a brewery isn’t just about getting the license — it’s about building a reliable, scalable beer business. That’s where Prodeb steps in.

End-to-End Brewery Setup

Complete Licensing Support

Custom-Built Brewing Equipment

On-Site Brewing Assistance & Staff Training

Energy-Efficient Technology & Waste Management

Support from Concept to First Pour

From helping you obtain your beer brewery license in India to designing your space and supplying cutting-edge equipment, Prodeb is your full-service brewery partner.

Final Thoughts

Getting your brewery license in India might seem like a maze, but with the right partner, it becomes a clear path. With the rise in craft beer consumption and state policies evolving in favor of microbreweries, now is the perfect time to start your brewing journey.

Let Prodeb help you brew success — from license paperwork to your first batch of beer.

Want to start your beer brand? 📞 Contact Prodeb today for a complete brewery setup and licensing consultation! visit our website www.prodebbrewery.com or call us on 9384806101

0 notes

Text

Offset Bag printing machine in Delhi NCR

In the competitive world of printing and packaging, efficiency and precision are essential. For businesses in Delhi NCR, Noida, Gurgaon, and Faridabad, finding reliable and high-performing printing equipment can make a significant difference. SBS Machinery, a leading offset bag printing machine manufacturer in Delhi NCR, has been a trusted partner for companies seeking advanced printing solutions that drive productivity and profitability.

Why SBS Machinery’s Offset Bag Printing Machines Stand Out

1. Enhanced Production Efficiency

Our offset bag printing machines are built for speed and precision, ensuring that you can produce bulk orders in less time. This is particularly advantageous for businesses in Patparganj Industrial Area, Okhla Industrial Estate, and Bawana that handle large-scale printing projects. By minimizing downtime and maximizing output, our machines help you maintain deadlines and reduce operational costs.

2. Superior Print Quality

Precision matters in printing, and our offset bag printing machines guarantee sharp, vibrant, and durable prints. This level of quality enhances brand reputation for businesses in Connaught Place, Saket, and Green Park, helping them stand out in the market. Our technology ensures consistency across all print runs, maintaining customer satisfaction and brand loyalty.

3. Versatility in Application

Our offset bag printing machines can handle various types of bags, including paper bags, non-woven bags, and plastic bags. This versatility makes our machines suitable for diverse industries, from retail to manufacturing in Kalkaji, Janakpuri, and Dwarka. Whether you are catering to the fashion industry in South Extension or the food industry in Chandni Chowk, our machines adapt to your needs.

Increasing Profitability with SBS Machinery’s Offset Bag Printing Machines

1. Cost-Effective Solutions

Our offset bag printing machines are engineered to optimize ink usage and reduce wastage, resulting in cost-effective printing. Businesses in Pitampura, Ashok Vihar, and Vikaspuri benefit from reduced material costs, boosting profit margins while maintaining print quality.

2. Quick Return on Investment (ROI)

By enhancing productivity and reducing errors, our machines provide a quicker return on investment for businesses in Shahdara, Shastri Nagar, and Uttam Nagar. The efficiency of our machines means faster order fulfillment, increased sales, and satisfied clients.

3. Expanding Business Opportunities

With our high-quality and versatile printing capabilities, businesses can expand their service offerings, attracting more customers from areas like Narela, Mayapuri, and Ghaziabad. The ability to offer diverse printing solutions opens up new revenue streams, increasing profitability.

Why Partner with SBS Machinery?

Expert Support and Training: Our team offers comprehensive training and support to ensure that businesses in Delhi NCR can operate the machines smoothly and efficiently.

After-Sales Service: We provide dedicated after-sales service and maintenance for companies in Faridabad, Noida, and Gurgaon, ensuring minimal downtime.

Customization Options: We understand the unique requirements of businesses in Punjabi Bagh, Model Town, and Kirti Nagar, offering customized solutions that align with their needs.

Conclusion

SBS Machinery’s offset bag printing machines are transforming the printing industry across Delhi NCR, helping businesses optimize productivity and increase profitability. With our innovative technology, cost-effective solutions, and exceptional customer support, we empower companies to grow and succeed. If you’re seeking the best offset bag printing machine manufacturer in Delhi NCR, SBS Machinery is the partner you can trust.

FAQs – SBS Machinery’s Offset Bag Printing Machines

Q1. What makes SBS Machinery the best offset bag printing machine manufacturer in Delhi NCR?

SBS Machinery stands out due to its advanced technology, commitment to quality, and excellent after-sales support. We serve businesses in Rohini, Dwarka, and Noida with reliable printing solutions.

Q2. Are your offset bag printing machines suitable for large-scale production?

Yes, our machines are built for high-speed, large-scale production, catering to businesses in Okhla Industrial Area, Mayapuri, and Patparganj.

Q3. Can SBS Machinery customize printing machines based on our specific needs?

Absolutely! We provide customized solutions tailored to your business needs in Karol Bagh, Lajpat Nagar, and Rajouri Garden.

Q4. How can I get support for machine installation and training?

We offer on-site installation and comprehensive training for businesses across Delhi NCR, ensuring smooth operations from day one.

Q5. What types of bags can be printed using SBS Machinery’s offset printing machines?

Our machines can print on paper bags, plastic bags, and non-woven bags, suitable for industries in South Extension, Chandni Chowk, and Connaught Place.

Leave a Reply

0 notes

Text

VK Global Digital's new Faridabad plant

In 2018, the leading Faridabad-based textbook publisher, VK Global Publications, got into printing and carton production by acquiring an existing plant in Manesar that had gone into NCLAT insolvency proceedings. The plant, which has extensive book and packaging printing, binding, and converting equipment, along with luxury hard box-making capacity, was renamed VK Global Digital.

The publishing group has taken about five years to learn the commercial print and carton packaging business. The carton and luxury box-making businesses were stabilized and rationalized by producing premium cartons using VK Global’s proprietary metallic hologram and Fresnel lens effects for brand protection and security.

A new Bobst diecutter and a new Bobst folder-gluer were added to the Manesar plant. However, to expand the plant with new printing, postpress, and converting equipment, it was decided to build a purpose-built factory with space for future expansion in Faridabad. Not far from the headquarters building of the publishing house, the elegant purpose-built factory, along with several additional investments in equipment, is humming.

Ambitious from the blueprint stage, the modern work and production spaces are within the elegant 250,000-square-foot load-bearing factory building. On most of the two acres alongside the building is a hydroponic greenhouse where the first horticultural crop of lettuce and kale was just maturing in mid-January.

Apart from the double-height 100,000-square-foot production space and meeting rooms on the ground floor, the 50,000-square-foot mezzanine contains prepress and open-plan management spaces. Another 100,000-square-foot load-bearing floor is not yet populated.

On one side of the ground floor are the sheetfed multicolor presses for printing cartons. Before the plant was complete, a new Heidelberg 6-color plus coater UV press was installed in February-March 2024. The 6-color coater UV press from Manesar was moved subsequently so that no customer deliveries were disrupted.

In the converting section, alongside the multiple die-cutters and folder-gluers, a new Masterwork autoplaten foil stamping machine critical for incorporating the metallic brand security features was installed. The Mecchi equipment for producing two-piece luxury boxes for electronic, personal care, and confectionery products was brought from the Manesar plant and installed in a dedicated area.

By August 2024, all the equipment from Manesar was moved, installed, and recommissioned. Although not without challenges, the entire closely managed process meant the transition to full production was practically seamless – with few or no hitches in the timely shipment of cartons.

In the double-height pressroom, there are 10 Heidelberg presses, including two 6-color coater UV presses for cartons and two 8-color perfectors for commercial and book printing. Apart from improvement in workflow and material movement in the continuous single–level space, the new converting equipment has smoothened and increased production.

Premium visual effects and brand authentication and protection

All the products produced by VK Global – books, monocartons, or luxury boxes tend – to be in the premium category for its select customers. The quality and consistency of design, paper and printing, embellishment, and brand security stand out. The company’s rich experience in security and embellishment using its holographic technology and expertise is formidable. The company uses its own manufactured transfer films to transfer a combination of metallics with holographic diffraction and optically active surface patterns and Fresnel lens effects for application on paper, PET, and BOPP.

The metallic effects are transferred onto paperboard and carton substrates from recyclable films that the company produces for in-house use and also exports. After use, the brand-secure cartons can be pulped along with other paperboard cartons.

Hence, the company is a global pioneer and exporter in creating completely recyclable book covers, cartons, or blister packs integrated with Fresnel lenses and other holography patterns. VK Global’s transfer films have been validated under EU EN 13430 certification, which classifies the products as bio-degradable. In the case of monocartons and other packaging materials such as blister packs, these effects can authenticate consumer products – easily differentiating them from counterfeit packaging and products.

Technology absorption, process, OEE, and human resource optimization

Educated in computer science, Jain, apart from his exploration of the production processes, is one of the few young printers or print businessmen who have taken an interest in the digitally enabled concepts necessary to drive efficiency in printing and packaging businesses today. For instance, he has understood many of the Heidelberg Prinect prepress, workflow, and production monitoring features that are talked about but rarely implemented. This is usually because of the large gap between the educated management and inadequately skilled personnel on the shop floor.

He sees the benefits of investing in an expert printer from Heidelberg to train his team in a sustained three-week program. “This may sound expensive, but it’s trivial compared to the cost of the presses and their complexity. To achieve efficiencies that are closer to the capacity of the individual presses and the entire workflow will require continuous training and skilling,” he says. Moreover, he suggests there are several challenges in the hypercompetitive carton business, and while efficiencies and quality need to improve, so must profitability to sustain the viability of continuous investments in human resources.

Jain has implemented the processes and calculations of overall equipment effectiveness (OEE) using the Heidelberg Prinect spectrum of digital tools. He uses the Prinect imaging engine in prepress, its scheduling features for production, and its ability to produce pallet tags for production tracking and operational material movement.

The entire project of VK Global Digital reflects a perspective of individuals actively finding out, understanding, and implementing what is already well-established and available in the technology that has been paid for. The attitude of breaking down the business challenges and the production processes is the most exciting thing about the new plant and the persistence of the next-generation management. It is heartening to witness a young technocrat aligning technology, production processes, and human resources with his aspiration to excellence without compromise.

0 notes

Text

VK Global commissions greenfield Faridabad plant

In 2018, the leading Faridabad-based textbook publisher VK Global Publications got into printing by acquiring a plant in Manesar comprising book and packaging printing, binding, and converting equipment, along with luxury hard box-making capacity. In the past several years, the group rationalized the VK Global Digital Manesar plant with investments in converting and learned the commercial and carton-making processes. It then decided to build a greenfield plant in Faridabad, not very far from the publishing house. Within 22 months, the elegant purpose-built factory, along with several additional investments in equipment is humming.

The VK Global Digital book printing and packaging project was ambitious from the blueprint stage. The planning embodied the group’s belief in designing modern work and production spaces. The now completed 250,000-square-foot load-bearing factory space has a 1-megawatt solar plant on the roof. Within the plant, on most of the 2 acres alongside the building, is a hydroponic greenhouse where the first horticultural crop of lettuce and Kael is just maturing.

Apart from the double height 100,000 square foot production space and meeting rooms on the ground floor, the 50,000 square-foot mezzanine contains prepress and open plan management spaces. Another 100,000-square-foot load-bearing floor is not yet populated.

The main production floor allocates spaces for commercial and book printing and carton offset presses. The folding and binding sections complete the postpress for book production, while the finishing and converting sections with diecutting, hot foil stamping, and folder gluers complete the cartons. There is a third production process with dedicated equipment for producing two-piece luxury boxes for electronic, personal care, and confectionery products.

The move from Manesar to the new plant nearing completion began with installing a new Heidelberg packaging press in February– March 2024. An 8-color Heidelberg perfector was added for book printing. By August 2024, all the equipment from Manesar was moved, installed, and recommissioned. Although not without challenges, the entire closely managed process meant the transition to full production was practically seamless – with few or no hitches in customer deliveries.

In the double-height pressroom, there are ten Heidelberg presses including two 6-color coater UV presses and two 8-color perfectors. Apart from improvement in workflow and material movement in the continuous space, extensive new equipment has been added for debottlenecking and increasing production output.

For book production, apart from the addition of the 8-color perfector, these include the upgradation of the four Stahl folders, and a new MullerMartini section sewing machine supplementing the two earlier Aster machines. A used Muller Martini Accoro 5000 gathering and perfect binding line complements the earlier binding lines.

Premium visual effects and authentication

All the products produced by VK Global – books, monocartons, or luxury boxes tend to be in the premium category not only because of its select customers and the quality of design, paper, and printing but because of the company’s rich experience in security and embellishment using its holographic technology and expertise. For this, the company uses its own manufactured transfer films which can transfer metallics with holographic diffraction and optically active surface patterns, and Fresnel lens films for application on paper, PET, and BOPP.

Hence, the company is a global pioneer and exporter in creating completely recyclable book covers, cartons, or blister packs integrated with Fresnel lenses and other holography patterns. VK Global’s transfer films have been validated under EU EN 13430 certification which classifies the products as bio-degradable. In the case of textbook cover production, these effects can authenticate books that are legally produced under publishing rights at a nominal cost – easily differentiating them from illegal and pirate editions.

VK Global’s biggest book production customer is still its parent publishing company. However, it has produced excellent quality text, general, coffee table, and children’s books for global publishers. It is also one of the selected printers for the recent government project to triple the production of NCERT textbooks for the 2025-26 academic year, to 150 million.

Technology absorption, process, OEE, and human resource optimization

The most significant aspect of the new Faridabad plant, apparent in its architecture and design, is the keen desire of the management to optimize the production workflow and processes and invest in the skill development of the company’s human resources. Director Namit Jain who manages the plant has acquired a considerable understanding of printing, binding, and converting processes and the technology dynamics in just five years. He sees the benefits of having an expert printer from Heidelberg training his team for a sustained three-week program, which he says may sound expensive but is trivial in comparison to the cost of the presses and their complexity and capacity for quality with efficiency.

Educated in computer science, Jain apart from his exploration of the production processes, is one of the few young printers or print businessmen who have taken an interest in the digitally enabled concepts necessary to drive efficiency in printing and packaging businesses today. For instance, he has understood many of the Heidelberg Prinect prepress, workflow, and production monitoring features that are talked about but rarely implemented. This is usually because of the large gap between the educated management and inadequately skilled personnel on the shop floor.

To improve efficiency, Jain has implemented the processes and calculation of overall equipment effectiveness (OEE) using Prinect’s spectrum of digital tools. He uses Prinect’s imaging engine in prepress, its scheduling features for production, and its ability to produce pallet tags for production tracking and operational material movement. The modern building, its well-lit and decorated environment, and what is happening inside reflect the same perspective. I find this attitude of breaking down the business challenges and the production processes the most exciting thing about the new plant – the aspiration to excellence without compromise.

0 notes

Text

How to Start a Commercial RO Water Plant Business? A Guide by Commercial RO Plant Manufacturers in Faridabad

Starting a commercial RO water plant business can be a lucrative venture, especially as the demand for purified water increases across industries and households. However, it requires careful planning, investment, and understanding of the market and regulations. In this blog, we'll guide you through the essential steps of setting up a commercial RO plant, with insights from leading commercial RO plant manufacturers in Faridabad.

Step 1: Conduct Market Research

The first step in setting up a successful RO water plant business is understanding the demand in your target area. Market research should cover:

Demand for purified water: Industries, institutions, and commercial spaces have a growing need for clean, safe water.

Competition: Identify existing water purification businesses in your region to assess competition and market saturation.

Target audience: Pinpoint potential clients, such as factories, hotels, hospitals, and residential complexes, and understand their specific water purification needs.

Step 2: Create a Business Plan

A solid business plan is the foundation of any successful business. Your plan should outline:

Capital investment: Costs for equipment, installation, operations, and maintenance.

Revenue model: Determine pricing based on water volume, target market, and services (such as regular water delivery or bulk orders).

Scalability: Consider how you can grow your business over time, adding more services or expanding your plant’s capacity.

Step 3: Obtain Necessary Licenses and Approvals

Running a commercial RO plant involves adhering to government regulations, ensuring that the water you produce meets safety standards. In India, you’ll need to:

Apply for permits: Get the required licenses, such as BIS (Bureau of Indian Standards) certification, and NOC (No Objection Certificate) from local authorities for water usage.

Follow health and safety standards: Ensure your plant adheres to local water quality standards set by government bodies to avoid legal complications.

Step 4: Choose the Right RO Plant Equipment

Investing in high-quality, reliable RO plant machinery is crucial to ensuring the efficiency and durability of your business. Consider partnering with top commercial RO plant manufacturers in Faridabad, who offer:

Advanced filtration technology: Ensure the RO system can effectively remove contaminants like heavy metals, chemicals, and microorganisms.

Energy-efficient systems: Look for systems that minimize water wastage and energy consumption to reduce operational costs.

Customizable solutions: Leading manufacturers provide tailored solutions based on the volume and quality of the water being treated.

Step 5: Set Up the RO Plant Infrastructure

Once you’ve selected the equipment, you need to set up the infrastructure:

Location: Choose a strategic location with easy access to water sources and transportation for delivery.

Plant layout: Design an efficient plant layout that facilitates smooth operations, from water treatment to packaging.

Water storage and delivery systems: Ensure you have enough storage capacity for treated water and an efficient delivery system to meet customer demand.

Step 6: Focus on Quality Control and Maintenance

Regular testing and quality checks are essential to ensure the water produced by your plant meets safety standards. You should:

Install water testing systems: Continuously monitor the TDS (Total Dissolved Solids) and other quality parameters to ensure consistency.

Schedule routine maintenance: Maintain RO plant equipment to avoid breakdowns, ensuring uninterrupted water supply to your clients.

Step 7: Develop a Marketing Strategy

To attract customers, you need a strong marketing plan. Highlight the benefits of your purified water, such as its high quality and health safety. Effective marketing strategies include:

Branding and advertising: Create a brand identity and advertise your services through digital marketing, local ads, and business directories.

Targeted outreach: Reach out to industries, institutions, and businesses that require large quantities of clean water.

Partnerships: Build relationships with local businesses and residential complexes that can benefit from your services.

Step 8: Ensure Compliance with Environmental Standards

Water treatment plants need to follow strict environmental guidelines. Be mindful of:

Water conservation: Implement water-saving technologies and recycle water where possible.

Waste disposal: Ensure the safe disposal of waste generated during the water purification process to avoid pollution.

Conclusion

Starting a commercial RO water plant business requires careful planning, significant investment, and a commitment to quality. Partnering with reliable commercial RO plant manufacturers in Faridabad can give you a competitive edge by providing you with advanced equipment and customized solutions. By following the steps outlined above, you can set up a successful business and meet the growing demand for safe, purified water in your region.

0 notes

Text

Bright Steel Bar Suppliers and Company in Faridabad

Guide to know about Bright Bar Suppliers Company

When it comes to the accuracy of industrial procedures used to make components that are the backbone of countless applications, bright bar manufacturers are indispensable. SS Engineering Work stands out among these firms because of the innovative and high-quality products it produces. The great polish, durability, and dependability of stainless-steel bright bars make them highly prized in numerous industries.

Adjustable steel bars, made by trusted Bright Steel Bar Suppliers in Faridabad like SS Engineering Work, are vital in a wide range of sectors. Machine tools, medical equipment, automobiles, and countless more industries rely on them.

What is the exact process for making stainless steel brilliant bars?

Making stainless steel brilliant bars is an exacting process that calls for extreme precision to provide high-quality results. To meet the rigorous requirements of many companies, bright bars are meticulously made. Renowned in the brilliant bar production industry, SS Engineering Work manufactures these versatile components with state-of-the-art machinery and extensive industry experience.

The Role of Bright Bars in the Dynamic Consumer Products Sector

Due to their versatility and outstanding properties, stainless steel brilliant bars find extensive application in the fast-moving consumer goods (FMCG) sector. This business is able to streamline the delivery of high-quality stainless steel bright bars by utilizing superior bright bars. There is evidence that using stainless steel bright bars in the production of FMCG increases output, product quality, and product lifetime. For this reason, they play a pivotal role in this sector of the economy.

Making Machine Parts:

The machinery used to make fast-moving consumer goods relies on brilliant bars manufactured of stainless steel. Pulleys, shafts, and gears are precision components that rely on these bars for their efficient operation in industrial machinery.

Appliances for the Food Industry

Processing equipment for foods and drinks must be extremely hygienic and corrosion-proof. Which is why you may find stainless steel brilliant bars in many different pieces of machinery used for processing food. Conveyor belts, cutting tools, and mixing blades are just a few examples of the many items that fall under this category. This makes them resistant to strong cleaning solutions and makes them suitable for use in areas where food is present.

Tools for packaging:

Stainless steel brilliant bars are the most significant material in the fast-moving consumer goods (FMCG) packaging industry. The bars make the packing gear sturdier and more reliable, which leads to efficient and dependable packaging processes.

Transportation and Storage Methods:

Stainless steel bright bars are indispensable in the fast-moving consumer goods (FMCG) industry for the construction of dependable handling and storage systems. Conveyor systems, sturdy shelves, and racks should be built with these bars in consideration. The instruments from Bright Steel Bar Suppliers and Company in Faridabad can support heavy items for long periods of time without breaking due to this characteristic.

Display Cases and Shelving

Shelving and display units are vital to fast-moving consumer products companies. Stainless steel wonderful bars are the perfect material to work with these tools due to their longevity and resistance to corrosion. These bars can't skimp on style or durability if they want to take their place. Stainless steel is the material of choice for each of these display cases that house FMCG products. Finally, many industries rely on stainless steel brilliant bars, but the FMCG industry in particular is vital. They are crucial to the development of robust storage and handling systems due to their adaptability and durability.

#Bright Bar manufacturer In Punjab#Bright Bar Suppliers Company In Faridabad#Bright Steel Bar suppliers in Sonipat#Bright Steel Bar suppliers In Delhi

0 notes

Text

Heat Shrink Transparent Film

At Modwrap, we specialize in providing high-quality Heat Shrink Transparent Film, the ultimate solution for a wide range of packaging needs. This versatile film is designed to offer superior protection and aesthetic appeal for your products, making it an essential choice for businesses across various industries.

Exceptional Clarity and Presentation

Our Heat Shrink Transparent Film is renowned for its crystal-clear transparency. This feature ensures that your products are showcased in their best light, with no obstruction to their visibility. Whether you’re packaging consumer goods, electronics, or promotional items, the film enhances the product’s appeal, attracting more customers.

Durable and Protective

The film’s durability ensures that your products are well-protected during transit and storage. It provides a strong barrier against dust, dirt, moisture, and other environmental factors, keeping your items pristine. This robust protection extends the shelf life of your products and reduces the risk of damage.

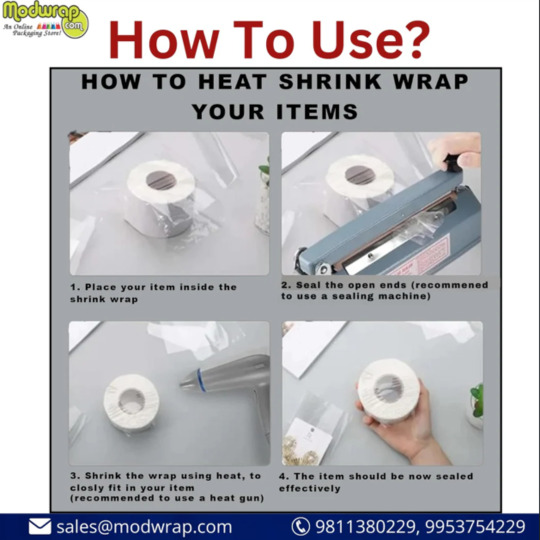

Easy Application and Versatility

Modwrap’s Heat Shrink Transparent Film is easy to apply using standard heat shrink equipment. After applying heat, the film shrinks uniformly around the product, conforming to its shape for a snug and secure fit. This versatility makes it suitable for a wide range of products, from small items to large bulk packages.

Eco-Friendly and Safe

Our Heat Shrink Transparent Film is made from non-toxic materials, ensuring safety for both your products and the end-users. Additionally, it is recyclable, offering an eco-friendly packaging solution that aligns with sustainable business practices.

Cost-Effective

Our Heat Shrink Transparent Film delivers outstanding value for money by providing excellent protection and enhancing product presentation. It helps reduce packaging costs by minimizing the need for additional protective materials.

Choose Modwrap for your heat shrink film needs and experience our packaging solutions' superior quality and reliability. Visit Modwrap — Manufacturer of Eco-Friendly Packaging Material in Faridabad to explore our full range of products and find the perfect packaging solution for your business.

0 notes

Text

Heat Shrink Transparent Film

At Modwrap, we specialize in providing high-quality Heat Shrink Transparent Film, the ultimate solution for a wide range of packaging needs. This versatile film is designed to offer superior protection and aesthetic appeal for your products, making it an essential choice for businesses across various industries.

Exceptional Clarity and Presentation

Our Heat Shrink Transparent Film is renowned for its crystal-clear transparency. This feature ensures that your products are showcased in their best light, with no obstruction to their visibility. Whether you’re packaging consumer goods, electronics, or promotional items, the film enhances the product’s appeal, attracting more customers.

Durable and Protective

The film’s durability ensures that your products are well-protected during transit and storage. It provides a strong barrier against dust, dirt, moisture, and other environmental factors, keeping your items pristine. This robust protection extends the shelf life of your products and reduces the risk of damage.

Easy Application and Versatility

Modwrap’s Heat Shrink Transparent Film is easy to apply using standard heat shrink equipment. After applying heat, the film shrinks uniformly around the product, conforming to its shape for a snug and secure fit. This versatility makes it suitable for a wide range of products, from small items to large bulk packages.

Eco-Friendly and Safe

Our Heat Shrink Transparent Film is made from non-toxic materials, ensuring safety for both your products and the end-users. Additionally, it is recyclable, offering an eco-friendly packaging solution that aligns with sustainable business practices.

Cost-Effective

Our Heat Shrink Transparent Film delivers outstanding value for money by providing excellent protection and enhancing product presentation. It helps reduce packaging costs by minimizing the need for additional protective materials.

Choose Modwrap for your heat shrink film needs and experience our packaging solutions' superior quality and reliability. Visit Modwrap — Manufacturer of Eco-Friendly Packaging Material in Faridabad to explore our full range of products and find the perfect packaging solution for your business.

0 notes

Text

Quality Kits for Screw Compressor Manufacturer in Faridabad

At Perfect Air Compressor, we specialize in providing high-quality kits for screw compressors designed to enhance the performance and longevity of your equipment. Our kits for screw compressors include all essential components required to maintain and optimize your screw compressors, ensuring they operate at peak efficiency. As a leading kits for screw compressor manufacturer, we pride ourselves on offering products that meet the highest standards of quality and reliability. Our comprehensive kits for screw compressors are meticulously assembled, including vital parts such as seals, gaskets, bearings, and more. Each component is crafted with precision and made from premium materials to withstand the rigors of continuous operation and harsh environments. Whether you need to perform routine maintenance or major repairs, our kits are designed to provide you with everything you need in one convenient package. Being a trusted kits for screw compressor manufacturer, we understand the diverse needs of our clients. That’s why we offer a wide range of kits tailored to different models and specifications of screw compressors. Our kits are easy to install, helping you minimize downtime and maintain seamless operations. With Perfect Air Compressor, you can rest assured that you are getting top-tier products backed by exceptional customer service and technical support.

For more details clicks here - https://www.perfectaircompressor.com/faridabad/mpv-kits-for-screw-compressor/ITB-32A837F0

0 notes

Text

Find The Top Commercial RO Plant Manufacturer In Faridabad

The people of Faridabad are highly educated & have become increasingly aware of the need to live in a healthy environment because they realize how important it is to have access to clean & safe drinking water. Purified water is seen as an essential or basic need for every person or manufacturing or for certain operations, whether it be for domestic utilization, cooking, or other commercial infrastructures like hospitals, medical or therapeutic facilities, institutions, workplaces, etc.

In practically every area of the city of Faridabad, reverse osmosis-incorporated water purification plant systems are widely acknowledged as the most efficient water treatment method for obtaining such safe & pure water. The discharge of wastewater in excess due to the growing population has contaminated nearby groundwater systems & waterbodies. Netsol Water is the best commercial ro plant manufacturer in faridabad at best affordable price.

Since, this contamination there has been a rapid increase in the demand for installing cutting-edge technology-based Commercial RO Plant systems in Faridabad. Also, there has been observed an increase in the advanced level Commercial RO Plant manufacturers, among which selecting the best is a very decisive task.

Following are the most influential Commercial RO plant Manufacturers in Faridabad

NETSOL WATER

Because Netsol Water incorporates cutting-edge best technology in its commercial RO plants, it is the brand that most respectable clients in Faridabad choose.

Netsol Water was founded in Greater Noida, & it has a production facility there with state-of-the-art equipment. Since it provides operation & maintenance of its product machinery even after sales, it is a well-liked company in this industry.

It provides industrial RO plant systems ranging from 10,000 to one lakh LPH & commercial RO plants with carrying capacities from 100 LPH to even 10,000 LPH. Being an ISO-accredited company, it readily fulfils the requirements & norms of standards.

Urban RO PLANT

One of the top environmental engineering firms is Urban RO Plant. Through its subsidiary Netsol Water, it provides a large selection of commercial RO plants. Advantages include:

High-purity systems of a framework for power & pharmaceutical applications.

Plug or Play RO plants packaged in containers for easy installation.

Pre or Post as well as post-treatment solutions that are integrated.

Connected to top research & development institutions such as IIT Mumbai.

Urban RO Plant is the leading manufacturer of commercial RO plant systems in Faridabad, however, there are other smaller businesses as well. These firms are distinguished by their size, experience, technological know-how, range of products, & dependability. Corporate companies considering purchasing commercial RO treatment plants are wise to take this reliable brand into account.

Commercial RO Plant

The Commercial RO Plant company was developed & established in 2019 as a branch unit under Netsol Water. Currently, it has installed & set up its base-foundation in Faridabad to provide various solutions for the city's numerous water-borne issues. This business is also well-known for using the most sophisticated, cutting-edge technology in water filtration plant systems, such as reverse osmosis.

To its limited clientele, this company also provides the best technological components, both conventional & state-of-the-art, integrated into the Reverse Osmosis (RO) Plant for treating commercial, municipal, & industrial wastewater.

These businesses have historically built commercial RO facilities, including operations & maintenance, & well-designed, well-engineered automated systems.

Conclusion

After looking at the water situation in Faridabad, larger capacity commercial RO plants must be erected to suit the needs of various companies & the general population.

The top three commercial Reverse Osmosis (RO) plant companies in Faridabad are listed above. Choosing the finest option from the results requires careful consideration. From my side of suggestions, Netsol Water is the best firm among them as well since it is fully satisfying the needs of every individual as well as any specific industry in Faridabad.

0 notes

Text

Revolutionizing Industries: The StripsIndia Advantage

In the bustling world of manufacturing and construction, having access to high-quality tools and components is essential for achieving optimal results. StripsIndia, a renowned name in the industry, has been revolutionizing various sectors with its premium offerings including Coil Nails, Air Compressors, Tie Rods, and Steel Strapping Tools. Let's delve into each of these products to understand how StripsIndia is making a significant impact.

1. Coil Nails: Enhancing Fastening Solutions

Coil Nails are indispensable for professionals in construction and woodworking. StripsIndia's Coil Nails stand out due to their superior grip, durability, and compatibility with coil nailers. These nails streamline the fastening process, saving time and effort on projects of all scales. Crafted with precision, they ensure secure installations, making them a go-to choice for industry experts.

2. Air Compressors: Powering Efficiency

In the realm of pneumatic tools, Air Compressors play a crucial role. StripsIndia's Air Compressors are designed for maximum efficiency and reliability. Whether it's for powering nailers, drills, or other pneumatic equipment, these compressors deliver consistent performance, making them a preferred choice for professionals seeking productivity and durability.

3. Tie Rods: Strength and Stability

Tie Rods are fundamental for providing structural support in various applications, from construction to automotive engineering. StripsIndia's Tie Rods are engineered with precision, ensuring strength, stability, and long-lasting performance. Whether it's for building robust structures or enhancing machinery components, these Tie Rods are designed to meet the highest industry standards.

4. Steel Strapping Tools: Securing Loads with Precision

In industries requiring secure packaging and bundling of goods, Steel Strapping Tools are indispensable. StripsIndia offers a range of Steel Strapping Tools designed for efficiency, precision, and durability. From manual tensioners to pneumatic sealers, these tools ensure reliable strapping solutions, making them a preferred choice for packaging professionals.

The StripsIndia Promise: Quality, Reliability, and Innovation

What sets StripsIndia apart is its unwavering commitment to quality, reliability, and innovation. Each product undergoes rigorous testing to meet stringent standards, ensuring optimal performance and customer satisfaction. With a focus on technological advancements and customer-centric solutions, StripsIndia continues to redefine excellence in the manufacturing and construction sectors.

Conclusion

In a world driven by efficiency and quality, StripsIndia stands as a beacon of excellence. Whether it's Coil Nails for secure fastening, Air Compressors for powering tools, Tie Rods for structural support, or Steel Strapping Tools for secure packaging, StripsIndia's products empower professionals across industries to achieve remarkable results. With a legacy of trust and innovation, StripsIndia remains at the forefront of revolutionizing industries and shaping a brighter future.

contact - E-99, Block E, Sanjay Colony, Sector-23, Welcome Industrial Complex,

Faridabad, Haryana 121005

Phn no- Phn no- +91-9911152476

Web- https://sitplindia.com/air-compressors-manufacturer/

#CoilNail#CableDrumAccessories#Bushplatemanufacturer#BradNailsmanufacturer#CoilNailermanufacturer#CoilNailMakingMachine#CoilNailmachinemanufacturer#Coilnailsmanufacturer#CoilNailssupplier#Aircompressorsmanufacturer#Tierodmanufacturer#SteelStrappingTool

0 notes

Text

HAIR OIL POUCH PACKAGING MACHINE MANUFACTURER

Durag Packing Machine stands out as one of the premier manufacturers and suppliers of Hair Oil Pouch Packaging Machines manufacturer, offering unparalleled quality and efficiency in their products. With a strong commitment to innovation and customer satisfaction, Durag Packing Machine has established itself as a reliable partner in the hair oil packaging industry.

Their machines are designed to meet the specific needs of hair oil manufacturers, ensuring precise filling, sealing, and packaging of pouches. Utilizing advanced technology and high-quality materials, Durag Packing Machine guarantees durability and reliability in their equipment, minimizing downtime and maximizing productivity for their clients.

read morehttps://www.durgapackagingmachine.com/faridabad/hair-oil-pouch-packaging-machine

0 notes

Text

Dashmesh Foils expands with a Nova A5 Flexo Press

Based in Faridabad, Dashmesh Foils, a provider of wrap-around and shrink labels, recently expanded its production portfolio with the installation of a Nova A5 multi-substrate flexo press from Alliance Printech with 450 mm in width. Traditionally a gravure press user, the company provides PVC shrink labels and sleeves, BOPP wrap-around labels, foil lids, laminated pouches, self-adhesive labels, and stickers.

The company, which was established in the year 2000, has a strong grip on the dairy and beverage market, supplying packaging across India, Recently, it has ventured into the export market. Managing director Sandeep Kalra, who is involved in sales and marketing, says competition has grown heavily in the packaging industry.

The company owns two rotogravure printing lines, 8 and 9-color machines, and along with the installation of the flexo press, the company is looking forward to adding another gravure line. It has an in-house blown film extrusion setup from Foursome Industries, Nashik, and foil-cutting equipment from Packline, Ghaziabad.

Dashmesh Foils chose to expand with Alliance’s flexo technology in response to the growing demand for flexible packaging in shrink labels, wrap-around labels, and foil lids that he manufactures for the dairy industry, especially for curd and yogurt. The growth in demand suggests the FMCG market has picked up with the advent of summer.

Packaging manufacturers are growing globally. However, the rate at which packaging was imported into India has decreased. “The packaging industry is being considered the fifth pillar of the economy in India. Our country has seen a bigger spurt in the manufacturing of packaging compared to many other countries. So expansion through technology with production efficiency, with an emphasis on sustainability, is the only way forward.”

“Customer centricity is at the core of Dashmesh Foils,” Kalra said. “We believe an organization survives when its clients are fully satisfied with its products and services. We work to offer our customers a wide range of printed, and non-printed shrink labels and packaging. We are looking forward to acquiring additional production space to properly accommodate customer requirements in flexo-based packaging.”

0 notes