#plywood sheet sizes

Explore tagged Tumblr posts

Text

What is the actual thickness of half inch plywood?

Plywood is one of the most commonly used materials in construction and woodworking, praised for its versatility, strength, and cost-effectiveness. However, understanding plywood dimensions—especially the thickness—can sometimes be confusing, as the actual thickness of plywood often differs from the nominal, or listed, size. This discrepancy is particularly evident in half-inch plywood, a popular choice for various structural and non-structural projects.

1. What is Half-Inch Plywood?

Half-inch plywood is a type of plywood that is often labeled as 1/2-inch thick. This thickness is widely used in residential and commercial construction and is suitable for applications that require moderate strength without the extra weight and bulk of thicker plywood. However, while this plywood is marketed as half an inch thick, the actual measurement is often slightly less.

2. Understanding Nominal vs. Actual Thickness

Nominal thickness refers to the size that plywood sheets are marketed with, which makes it easy for buyers to identify general sizes. For example, you might see plywood listed as 1/4 inch, 1/2 inch, or 3/4 inch.

Actual thickness, however, is the true measurement of the sheet after it undergoes processing and finishing. The difference between nominal and actual sizes exists because of manufacturing processes like sanding and compression, which remove a small amount of material from the surface, leading to a slight reduction in thickness.

3. The Actual Thickness of Half-Inch Plywood

The nominal thickness of half-inch plywood is 0.5 inches. However, due to the finishing process, the actual thickness is usually around:

15/32 inches, or approximately 0.469 inches in most cases.

This slight reduction may seem minimal, but in construction, even minor variances can affect structural integrity, especially if multiple sheets are being used. It’s essential to measure the actual thickness when precision is required.

Common Thickness Conversions

Nominal ThicknessActual Thickness1/4 inch7/32 inches1/2 inch15/32 inches3/4 inch23/32 inches

Knowing these actual measurements can help ensure better fitting and minimize any adjustments that may be required during installation.

4. Why Does the Thickness Vary?

The difference between nominal and actual thickness in plywood occurs primarily due to the manufacturing processes, which involve:

Sanding: Plywood sheet size are sanded to create a smooth, consistent surface. This process removes a small amount of material from each side, reducing the thickness slightly from the nominal measurement.

Compression and Glue Application: When plywood layers, or plies, are bonded together, pressure is applied to compress the sheets. This compression, along with glue application, also contributes to a minor reduction in thickness.

Manufacturers often follow industry standards set by organizations like the American Plywood Association (APA), ensuring consistency in actual thickness across different brands, but it’s still advisable to confirm these dimensions before purchasing.

5. Common Uses for Half-Inch Plywood

Half-inch plywood is versatile and used for numerous applications that balance strength with weight. Here are some typical uses:

Wall Sheathing: Provides moderate structural support for walls and can be used in both interior and exterior applications.

Roof Decking: Often used in roofing projects where 1/2-inch plywood can support lighter loads and serve as a base for shingles.

Cabinetry and Shelving: Offers enough strength for cabinet backs, shelving, and other lightweight furniture.

Subflooring: Commonly used as an underlayment in flooring, particularly in residential projects where extreme load-bearing isn’t necessary.

For these applications, knowing the actual thickness helps in achieving a proper fit and maintaining structural integrity.

6. Choosing the Right Plywood Thickness for Your Project

Selecting the correct plywood thickness depends on several factors, including:

Load-Bearing Requirements: For projects that require greater strength, such as subflooring or load-bearing walls, consider thicker plywood.

Weight Concerns: Half-inch plywood offers a good balance between strength and weight, making it ideal for projects where excessive weight could be a drawback, like cabinetry and roof decking.

Cost Efficiency: Thicker plywood is generally more expensive. For non-load-bearing applications, thinner plywood can be more cost-effective.

Q1: What is the actual thickness of half-inch plywood? The actual thickness of half-inch plywood is usually around 15/32 inches.

Q2: Why is the actual thickness of plywood less than the nominal size? The reduction in thickness occurs due to sanding and compression during the manufacturing process.

Q3: Can I find half-inch plywood that measures exactly 0.5 inches? Some specialty plywood manufacturers may offer sheets with exact nominal measurements, but most commercially available half-inch plywood measures around 15/32 inches.

Q4: What is half-inch plywood used for? Half-inch plywood is commonly used in wall sheathing, roof decking, cabinetry, and subflooring, providing a balance between strength and manageability.

Q5: Is half-inch plywood strong enough for flooring? While it can be used in subflooring as an underlayment, 1/2-inch plywood may not be suitable for primary load-bearing floors, where thicker sheets like 5/8 or 3/4 inch are often preferred.

9. Conclusion

Understanding the actual thickness of half-inch plywood, which is typically around 15/32 inches, is essential for precision in construction and woodworking projects. The discrepancy between nominal and actual measurements stems from the manufacturing process, particularly sanding and compression, and it affects plywood thickness across all sheet sizes.

Half-inch plywood offers a versatile solution for projects that require moderate strength, such as wall sheathing, cabinetry, and subflooring. When planning a project, consider both the actual plywood sheet size and thickness to ensure it meets the necessary specifications for your intended application. This knowledge can help avoid fitting issues, reduce material waste, and contribute to a higher-quality finished product.

#plywood sheet sizes#What is the actual thickness of 1/2 inch plywood?#What is the actual size of 4x8 plywood?

1 note

·

View note

Text

What is Wood Veneer? Applications of Wood Veneer

Wood Veneer -

Wood Veneer is a thin layer of real wood that is sliced or peeled from a log or a sawn timber, and is typically used as a decorative covering for furniture, cabinetry, doors, paneling, and other interior architectural features.

Veneer is an excellent alternative to solid wood because it is more affordable, more sustainable, and more versatile in terms of design options.

These slices can be as thin as 0.5mm and as thick as 6mm, depending on the intended use.

Largest Collections of Wood Veneer Ever. Buy Now from Uro Veneer World.

Wood Veneer is a thin slice of wood that is typically between 0.5 and 6 millimeters thick. It is cut from a log using a specialized machine called a veneer slicer, and is then used to cover or decorate surfaces such as furniture, doors, walls, and floors.

In this article, we will explore the characteristics, benefits, and applications of wood veneer.

Visit Uro Veneer World Now.

Buy the Largest Collections of Wood Veneer @ Uro Veneer World.

Get in touch with us!!!

Buy your favorite Wood Veneer for your interiors and Home decor @ Uro Veneer World Today.

Characteristics of Wood Veneer -

Wood veneer is available in a variety of species, grades, cuts, and sizes, which can affect its appearance, texture, durability, and cost.

Some of the most popular veneer species include oak, walnut, maple, cherry, mahogany, teak, ash, and birch.

The choice of species depends on the desired color, grain pattern, figure, and texture of the finished product.

For example, oak veneer has a pronounced grain and texture that works well for rustic or traditional designs, while maple veneer has a smoother grain and lighter color that suits modern or minimalist aesthetics.

Veneer grades are based on the quality and uniformity of the wood, and can range from A (highest quality) to D (lowest quality).

A-grade veneer is typically free of defects such as knots, splits, sapwood, and mineral streaks, and has a consistent color and grain pattern. D-grade veneer, on the other hand, may have numerous imperfections and variations in color and grain, and is often used for hidden or low-cost applications.

Veneer cuts refer to the direction and angle of the slicing or peeling process, which can affect the appearance and stability of the veneer.

The three most common cuts are plain-sliced, quarter-sliced, and rift-sliced.

Plain-sliced veneer is produced by slicing a log parallel to its growth rings, resulting in a cathedral-like pattern that is suitable for large surfaces such as doors or tabletops.

Quarter-sliced veneer is produced by quartering a log and then slicing it perpendicular to its growth rings, resulting in a straighter grain and more uniform color that is suitable for high-end furniture or cabinetry.

Rift-sliced veneer is produced by slicing a log at an angle to its growth rings, resulting in a straight grain and narrow figuring that is suitable for modern or contemporary designs.

Veneer sizes can vary depending on the application and the availability of the wood. Standard veneer sheets are typically 4 feet by 8 feet, but can also be 4 feet by 10 feet or 5 feet by 10 feet. Some manufacturers offer custom sizes and shapes to fit specific design requirements.

Buy your favorite and High Quality Wood Veneer Today for your interiors and home decor.

Contact Us for more info!!!

Get Quotes and View Prices.

Download the Wood Veneer Catalog Now.

Benefits of Wood Veneer -

Wood veneer offers several advantages over solid wood and other materials.

First, veneer is more affordable than solid wood because it requires less raw material and less labor to produce.

This makes veneer a viable option for budget-conscious consumers or large-scale projects that require a lot of wood.

Second, veneer is more sustainable than solid wood because it allows for more efficient use of natural resources. By slicing or peeling a log into thin layers, veneer manufacturers can produce several sheets from one log, thereby reducing waste and conserving forests.

Third, veneer is more versatile than solid wood because it can be produced in a wide range of colors, grains, and patterns, and can be applied to a variety of surfaces. This allows designers and architects to create unique and customized looks that are not possible with solid wood or other materials.

Applications of Wood Veneer -

The applications of wood veneer are diverse, and it can be used in both residential and commercial settings.

Some of the most common applications of wood veneer include : -

Furniture: Wood veneer is often used to cover the surfaces of furniture, such as tables, chairs, and cabinets. It can be used to create a variety of looks, from traditional to modern.

Doors: Wood veneer is commonly used to cover the surface of doors, giving them an attractive and natural appearance.

Wall panels: Wood veneer can be used to create decorative wall panels, adding warmth and texture to a room.

Flooring: Wood veneer can be used to create engineered hardwood flooring, which is a more cost-effective and environmentally friendly alternative to solid hardwood flooring.

Architectural millwork: Wood veneer is used in architectural millwork to create decorative elements such as moldings, paneling, and trim.

Musical instruments: Wood veneer is used to create the outer layer of many musical instruments, such as guitars, violins, and pianos. The thin slices of wood are often chosen for their unique grain patterns and colors.

Interior decoration: Wood veneer can be used to decorate walls, ceilings, and other interior surfaces. It can be used to create a rustic or natural look, or to add warmth and character to a space.

Overall, wood veneer offers a cost-effective way to achieve the beauty and durability of solid wood in a variety of applications.

Wood Veneer is a versatile and attractive material that is used in a wide range of applications to add warmth, beauty, and texture to various surfaces.

Visit Uro Veneer World Today.

Get Quotes and View Prices.

Buy your Favorite and Unique Collections of Wood Veneer Today @ Uro Veneer World.

#uro veneer world#laminates#laminates for kitchen cabinets#living room#decor#interior design#home improvement#premium laminates#acrylic laminates#plywood sheets#home decor#interior decorating#home decorators#digital laminates#veneer sheets on display#wood veneer#wood veneer price#wood veneer price bangalore#wood veneer price in bangalore#wood veneer sizes#high quality plywood products in india#high quality#largest collections in bangalore#high quality wood veneer#designer laminates#high pressure laminates#luxury laminates#high gloss#high gloss cabinetry#high gloss laminates

0 notes

Text

In my senior year of high school I did a 5 month co-op in residential construction, specifically framing. I worked on a house like this, worth 1.4 million ish (cad), middle of a brand new subdivision in the city, and let me tell you, not only is it a pain in the ass to build in every possible way (those two extra corners alone would make me kill someone), but these houses are being Mass Produced in order for the contractors to earn as much money as possible

My teacher / supervisor would take my class on tours of the other houses also being built in the subdivision at the same time, and oh my god. The amount of houses that had something wrong with them or were just blatantly not up to code was insane. One house was missing a whole header above a doorway, another was missing an entire load bearing support beam for the second floor. Most of the houses had at least one beam that was falling apart, and almost all had dozens of exposed nails inside the walls because the framers kept missing with their nail guns.

because I'm thinking about sustainability, I'm trying to understand why USAmerican houses are so large

I don't just mean McMansions, I also mean why regular houses and especially newer houses are so huge in proportion to the amount of living space they seem to provide. When I look at the square footage of the house it seems like a lot, but when I look inside at what it has to offer, it seems impossible to get rid of any of the individual things inside without impacting quality of life for the residents, and this is puzzling, since I know there are significantly smaller houses that are perfectly fine to live in.

So I have been looking at floor plans for various houses of various sizes and it seems a major problem is that the design of houses is just terrible.

I hate it so much. At first it doesn't look like there's anything wrong with it. But examine how efficiently the space is being used. From this perspective, it's a cursed and evil garbage fire.

So much space is taken up by doors to things that don't need doors. Why do you have a walk-in pantry with a door on it? Why do you have a laundry room 4 times the size of the washer and dryer with a door on it? A simple curtain would look nicer and doesn't need 10sqft extra to allow the door to swing open.

An additional large amount of space is taken up by awkward hallways that wouldn't need to exist if the arrangement of the rooms had been thought out better. There is a short little hallway to reach the garage because the pantry and half-bathroom are in the way, which branches off from a hallway that exists to reach...the laundry room, which is made 2x as big as necessary so the hallway can connect to it where it is wedged in the depths of the house.

The master bathroom has a tub AND a shower AND two sinks which makes it weird to have a half-bathroom right next to the master bedroom. It's hoarding all the bathroom amenities?? There's also a pretty big room that isn't labeled that is only accessible from the master bathroom. Walk-in closet? Sex dungeon?

(Why do walk-in closets exist? It's just an extra room with shelves in it. You can put shelves in a regular room.)

The other two bedrooms are really small and have another weird hallway to reach them, which could have been part of the bedrooms themselves. The closet labeled "linen" opens directly into the hallway and is on the other side of the house from the laundry room.

My dad remodeled houses for a living when I was a kid and this thing looks like it would be pure evil to run plumbing through...

#figured i cld actually offer my input in this since i have the experience#but yeah id cry if i had to build that house#first of all those dashed lines are support beams for the roof / second floor#u see how the two horizontal ones cut off on the right? yeah. thats not the. best design but anything to make the room layout work right?#the two extra corners? now instead of that whole side of the house being one wall you can build and put up in one go#theres 5 walls you now need to build and put up individually#and nail them to the floor and make sure theyre level and nail the corners together and cut more sheets of plywood to fit the weird sizes#every single one of those unnecessary doors? they need to be double studded with a 10 inch header above them#every single extra closet wall or hallway wall is build individually and stood up and carefully nailed to the others#that pantry would kill a lesser man#also all of those walls have to be thought out because you need the floor space to build them but quickly run out when walls start going up#so the order in which theyre built is very important#anyways#its almost 7am i spent an hour on this#ty for re awakening my special interest in construction at least? lmfao#construction#framing#rambles#edit: the longer i look at the blueprint the worse it gets#i cannot even express how much hatred this fills me with

2K notes

·

View notes

Text

The Igloo Hotel

Located at mile marker 188.7 on the east side of the George Parks Hwy, this abandoned hotel is south of Denali National Park & Preserve and it is truly one of the most odd places in Alaska that you will come across. The nearest town to Igloo City is Cantwell, located about 20 miles away with a population just under 250 year-round residents. The cities of Anchorage and Fairbanks are both over two and a half hours away from this isolated structure in the middle of nowhere. Igloo City was constructed in the late 1970s by Leon Smith. He envisioned it as a hotel, though it was never completed due to code violations. The building suffers from undersized windows which do not meet code. In addition to some other code violation issues, the inadequate window size is the main reason the structure was never operational. Because this building was too big to demolish, it has remained standing for over four decades. The structure is so large in fact that airplanes can see it from over 30,000 feet high in the air. The round structure meant to mimic that of an igloo has four stories and is said to be constructed of 888 sheets of plywood with a urethane outside insulation Those who come from far and wide are urged to use caution. Because of the remote location, predators such as bears and wolves are in the nearby area and have been said to use this giant igloo structure as shelter during times of distress.

359 notes

·

View notes

Text

lustfulpasiphae

What do you mean when you say birch sheets? The cabinets in my apartment are kind of rough inside and I've been trying to find better liners than the kind of rubbery stuff

I hope it's okay that I pulled this out to turn into a post of its own, because I took some photos to share :D When I say "birch sheets" I'm just referring to thin 1/8" (3mm) sheets of birch plywood, cut into planks. Here's what they look like installed:

[ID: Two images of cabinets in my home; one, stocked with toilet paper, the other with a large bin in it. Both have long, thin planks of wood covering the original floors.]

I was having an issue with my bathroom cabinet (on the left) because the bottom of the cabinet was water damaged before I moved in, and wasn't molding or anything but had begun to sag. I wanted some stiff thin boards I could pop into place to make a clean, flat floor without having to replace the entire cabinet. I found these birch sheets that were the perfect length, but I had to order like 10 of them and only needed 3 for the bathroom, so I put the rest in a cabinet in the kitchen that happened to have an ugly-looking floor (and apparently misplaced several, not sure what happened to them). It really spruces up the look of a grotty cabinet.

Anyway, this year I was contemplating re-lining my upper kitchen cabinets; I put paper liners down when I was renovating before I moved in, but those only last so long and that was five years ago. I thought I'd install some birch sheets instead, which wouldn't warp or shred the way the paper liners have. My plan is to cover them in freezer paper, pop them in, and then just pop them out every so often and re-line them, which is easier than trying to put the paper straight into the cupboards (awkwardly located for that kind of work) or trying to remove the shelves.

I ordered the ones for the cabinets from somewhere new to me, so can't vouch for the quality yet; I was able to order them custom-cut to the size I wanted at that page, and while it's slightly more expensive per piece, I also only have to buy as many pieces as I need and they should fit snugly, so it's less expensive overall as a purchase. I'll post up when they arrive and I install them!

91 notes

·

View notes

Note

hello! you very kindly answered an ask of mine recently, and now that i’ve gone through your ball python tag i have a few burning questions!!

1) i’m having a very hard time keeping humidity up for our BP. she’s been doing fine, but she shed recently and it didn’t go as smoothly as it has before. after reading a few of your tips, i think i’m going to try helping her with the last little bits of skin with some reptile shedding spray and a short soak. do you have any other tips here? i know i should keep the water shallow and not try to force off any skin with my fingers.

2) this wasn’t the worst shed ever, but i’d really like to get ahead of it next time and just go ahead and figure out how to get her humidity right. i’m already using coconut substrate, but misting with a sprayer doesn’t seem to be cutting it. i was planning on buying a fancy reptile humidifier, but i haven’t seen that discussed much here. i saw you say somewhere to add water to the substrate itself, but what exactly does that entail/how much should i use? and about how much substrate should actually be down in the tank?

3) for her enclosure itself we’re using exo terra’s 40 gallon tank, which comes with a screen top. we covered a lot of it with a towel (also serving as a privacy curtain) to keep in humidity but i wasn’t sure if that was a good idea or not?

sorry to ask so many questions!! thank you so much for your time!!

(oh, last note! i know 40 gallons isn’t the right size for an adult BP, but she is currently about the same length as the long side. i haven’t had her long enough to know quite how fast they grow, should i be scrambling for a bigger enclosure now?)

Hello hello - these are all good questions, and I really love the care and love you're putting into giving your snake the best!

A soak sounds like a great idea. Make sure the water is lukewarm but not hot - it should feel the tiniest bit chilly on your fingers. Giving your snake a washcloth during their soak is a great idea because that gives them something to hold onto and they'll often be able to rub stuck shed off themselves with it.

I recommend no less than an inch of substrate. How much water you add to rehydrate depends on how big your enclosure is, but a good general rule for a 40 gal is about a cup of water poured into the corners will do nicely. Especially since you've got a screen-top enclosure (which are very difficult to keep humidity in), if you want to spring for a humidifier, it might be a good idea. I don't personally use them (because I'm old and I prefer to limit the number of devices that could malfunction in my snake enclosures), but it might work well for you in this situation. Another trick for raising humidity levels is to make sure you're keeping a deep water dish on the warm side so it'll evaporate into the air (though, again, with screen-top enclosures that'll only do so much).

A towel can help to retain humidity in screen-top enclosures, but there are a few other tricks that might work better. A sheet of plywood or PVC cut to cover most of the enclosure is what I've found to work best; failing that, covering the top with tinfoil you've taped down securely is another good option. Screen-top enclosures can be a bit of a nightmare with humidity-loving snakes like bps, but there are workarounds!

How fast a snake reaches thier adult size depends on how much they eat and individual variation, but in general you can expect most snakes to reach their adult size between 3 and 5 years old. Some will be faster and some slower. If your snake is comfortable in a 40 gallon now, that's fine! I prefer to get snakes in their adult enclosures at around 2 years old, but there's no need to scramble. Just keep in mind what she'll eventually need (I recommend no smaller than a 4x2x2 enclosure), plan for that eventuality, and prepare to have it when she outgrows her current setup.

All the best!!

74 notes

·

View notes

Text

Excerpt from this story from Inside Climate News:

Once a month for nearly two years, Evan Clark, the Waterkeeper at Three Rivers Waterkeeper, a water quality advocacy organization based in Pittsburgh, has traveled by boat along the Ohio River to Shell’s enormous new plastics plant in Beaver County.

This facility is a cracker plant, using ethane from fracked gas to make ethylene and ultimately to manufacture up to 1.6 million tons of plastic per year. In his boat, Clark looks for tiny plastic pellets called nurdles and monitors the plant’s outfalls, the places where its wastewater is discharged into the river.

Since the plant became operational in the fall of 2022, Clark has noticed strong chemical odors at the outfalls—potentially a sign of contaminants like volatile organic compounds, or VOCs—and found many, many nurdles, a feedstock used to make everything from soda bottles to car parts.

This winter, Clark and the team he works with at the Mountain Watershed Association collected samples from 11 square feet of soil from the Ohio’s shorelines both upstream and downstream of the plant. Three Rivers Waterkeeper works to protect the Allegheny, Monongahela and Ohio Rivers, while the Mountain Watershed Association focuses on protecting the Youghiogheny River, a tributary of the Monongahela.

They found more than 700 nurdles, of all different colors, shapes and sizes. “They start to get kind of a white chalky appearance after they’ve been in the water for a long time,” he said, and nurdles also appear different depending on where they were made.

It was an alarming discovery that has implications beyond Shell, Clark said, although recently the team has been seeing more fresh, similar-looking nurdles that seem to have been in the water for a shorter period of time and could be linked to the Beaver County plant. They haven’t yet been able to procure a sample from Shell to match the nurdles definitively.

“That is a tiny area, smaller than half a sheet of plywood, and our preliminary analysis of what we’re looking at there didn’t point directly to a problem at Shell,” he said. “But it pointed to a plastics problem that we have throughout the whole region.”

To Clark, the “incredible” concentration of nurdles was evidence of the industry’s role in contributing to plastic pollution. “If we’re finding that amount of plastic spread through our environment that is the responsibility of manufacturers—these are plastic nurdles, they’re not from consumers—we have a real serious issue with the lack of regulation of plastics manufacturing,” he said.

6 notes

·

View notes

Text

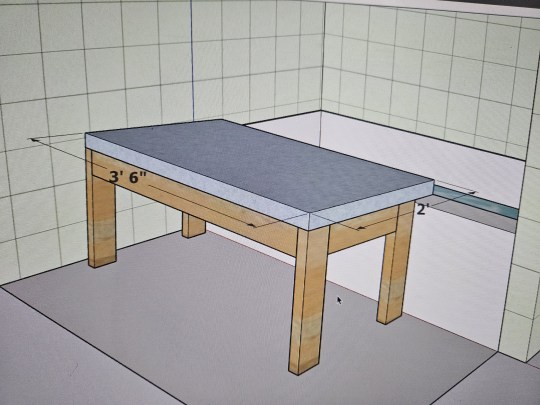

Extremely Strong Shower Bench

I've gotten feedback from the community asking me to share my plans, so here it is. If you want to build your own shower bench, this is how you do it. Make sure to ask a thinno for help, this will not be easy to do!

This is an extremely strong shower bench with a 1000+lb capacity. The floor under you will fail before the bench does! This shower bench is designed to remove you from the shower and basically have you sit on the ledge. You will need a couple feet of clearance away from your tub's ledge for it to work.

The top of my tub's ledge is about 1' 3⅜" up from the ground. If yours is taller/shorter by more than ¼" or so, you will need to make some adjustments to measurements down below.

This is a photo of the materials I used to make this build. I got everything I needed at my local hardware store. My build wasn't perfect though. I would suggest you learn from my mistakes and acquire a slightly different material list though:

1x 2'×4' plywood sheet. Get something pre-sanded and rated for outdoor use. I recommend ¾" thick.

2x 8' 2×4s. Most any wood type will work, so get what you like most. I just got some normal 2×4s and made sure they looked pretty. If you don't want to bother with staining or weatherproofing the structure of your bench, get pressure-treated 2×4s.

4x 2' ½"×½" square dowel.

4x Simpson Strong-Tie RTC2Z. Get the black-powder-coated ones if you can.

2x Simpson Strong-Tie LUS24Z. These will be used for the cross beam.

4x Simpson Strong-Tie FB24Z. These will be the feet.

1x Simpson Strong-Drive SD9112R100 #9×1½" 100ct Connector Screws. You won't use the whole box. It comes with a bit.

4x 3" common nails.

32x 1½" common nails.

35x 1" brad/finish nails.

200-220 grit sandpaper.

Oil-based high-gloss polyurethane.

Small dense-foam roller & roller pan.

If you're applying stain, oil stain & staining brush for oil stain.

Liquid rubber. Get something that will provide grip.

Rubber-foam weather stripping. The thicker and wider, the better. I got 20' of 1¼"×7⁄16" and it worked great for me.

4x paper clips, hair ties, or something to hang the feet from.

A plastic tarp, thickness is more important than size.

As for tools, you really only need two things:

Hammer

Drill, ratchet, or socket screwdriver

OPTIONAL: File or knife

I also highly recommend some PPE. Get some cheap/disposable cleaning gloves, a mask of some type, hair ties for your hair, and an old change of clothes.

If you don't have access to a table saw at home, *don't leave the store yet!* You need to cut your wood at the store. Many home improvement stores will cut your lumber for you, either for free or for a low price.

Ask an employee to cut the two 2×4s like this:

2×4 #1: 38", 38", 17"

2×4 #2: 33½", 33½", 13", 13"

NOTE: If your tub ledge was taller/shorter than mine, then for every 1" difference, lengthen/shorten each 33½" cut by TWO inches.

Then ask them to cut two dowels down to 20½", and two down to 24".

You should also ask them to take 6" off the short side of the plywood, so it's 2'×3½' instead of 2'×4'.

You're not ready to leave yet! You need to make two more cuts, and the store employees will not help you with these. Many home improvement stores will have a DIY handsaw table where you can cut moulding down to length. You'll need to use this to make the last two cuts yourself.

You need to make an ANGLED cut into the 33½" boards. Lay the first 33½" board down flat as shown. On the edge closest to you, mark a point 1' 5⅛" away from the left end of the board. Then on the edge farthest from you, mark a point 1' 5¼" away from the same left end of the board. Position your saw across both points, and cut through the board. You may need to roll the board over to finish the cut.

NOTE: If your tub ledge was taller/shorter than mine, then for every 1" of difference, add/remove 1" from the 1' 5⅛" / 1' 5¼" measurements above.

For the second board, *do not measure!* It is more important that the cuts in the boards be identical than it is for any one cut to have exact dimensions. Lay the second board down, then set one of the cut pieces on top so the ends of the two boards are aligned, then use the existing angle in the cut piece to start the cut in the second board.

When you are done, you will have four boards, two slightly taller than the others, with the exact same angle cut in all of them. In the above photo, the boards are resting on their angled ends. These pieces will be your long and short legs.

NOW you can bring everything home.

First, lay down your tarp somewhere. Ideally you'll have access to a 5'×10' flat area outside.

Then you need to sand *everything* (except the big faces of the plywood, and the pressure-treated wood if you went that route). Pay special attention to the corners and cuts in the wood.

Now you need to attach the square dowels to the outside of the plywood board. Choose a face of the board to be the "up" face, the one you'll sit on. Put the 24" dowels on top, right along the short edges. Choose a long edge to be the back, and squeeze the two shorter dowels in along it between the side dowels. Nail everything down with the finish nails.

Next is staining, if you chose to stain. Apply according to the directions on the tin. You will likely have to do multiple coats.

Now the truly hard part, applying polyeurethane. I recommend using the foam roller for this and applying many coats. You can prop up the plywood sheet using the 2×4s if you like so you can get all the way around the edges in one pass. You'll still need to flip it over and do three more passes when done with the top, so you can protect the underside from warping.

While waiting for your polyethylene to dry, you may as well make the rubber feet. Grab your four FB24Zs and tie something through one of the holes in the end. Open your can of liquid rubber and follow the instructions to fully submerge each one before leaving it out to dry. One coat should be enough. Once dry, try to remove excess rubber from the inside using a file or knife.

When everything's had a good long dry (at least a day after final coat), it's time for assembly.

Grab your two 38" boards, your two 13" boards, all four of your legs, and your four RTC2Zs — everything except what's highlighted red in the first photo above. Set the 38" boards down on their narrow side along the long edges of the board, and the 13" boards down on their narrow side along the short edges of the board. Bring them together to form a rectangle, then set the RTC2Zs upside-down on the corners. Each RTC2Z has an L-shaped hole in its bottom; the top/bottom of each L-shaped hole will be filled by the ends of the 38" boards, while the center and left/right of each hole will be filled by the legs. The ends of each 38" board will butt against the wide side of the legs, while the ends of each 13" board will butt against the narrow side of the legs. Now make sure everything is pressed firmly together as you use the Strong-Drive screws to attach the RTC2Zs to the 38" & 13" boards. For each corner, four screws go into the 38" board and two screws go into the 13" board. *DO NOT ATTACH THE LEGS YET!* The legs are just here for spacing right now. Remove the legs when everything is attached.

Grab your 17" board and your LUS24Zs. The 17" board should squeeze in nicely right in the middle, turning your blocky 0 into a blocky 8. Straighten out your LUS24Zs if needed (mine were bowed outwards too much), set them down over the ends of the 17" board, and use 4 screws each to attach them to the sides of the 38" boards. Now grab your long 3" nails and use two on each LUS24Z, installing them at a 45° angle into the remaining holes. They'll nail at an angle into the 17" board and go straight through into the 38" board.

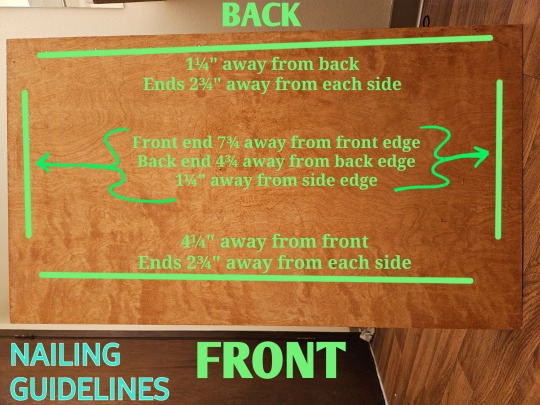

Flip everything over such that the plywood board is now resting good-side-up on top of the mostly-complete frame, with the whole thing resting on the rounded bottoms of the RTC2Zs. Center the frame between the left and right sides of the plywood (should be ½" overhang on each side); let the plywood's back overhang ½" off the back of the frame, and its front overhang 3½" off the front. Now use the 1½" common nails to nail in the plywood into the frame. I used four lines of nails, one for each outer board; measurements are in the second photo above.

OPTIONAL: Apply a final polyurethane coat over the nail heads. This will need a day or two to dry.

Screw the feet into the ends of the legs. See the third photo above for a reference. Try to make the feet as straight and snug as you can get them.

Insert the legs into the holes left from step 1. The short legs go in on the front side, and the long legs go in on the back side. You should have a bench that tilts slightly forward, to allow for water to drain into the tub. Use some sort of material as a spacer as necessary to adjust each leg to level out the bench. Don't be afraid to introduce gaps between the legs and the plywood; the metal connectors are what hold the weight. Once everything is nice and level, use six screws on each leg to attach then to the RTC2Zs.

Apply your rubber-foam stripping. I applied stripping all along the length of my tub's ledge AND along the underside of my bench.

And you're done! Your bench will look different than the photo above, I hadn't yet added the stripping, the wooden dowel siding, or the feet. And perhaps you chose a different stain color, or made your legs out of pressure-treated wood! In any case, this thing is built like a tank (made with actual home framing materials) and shouldn't break easily. I hope it serves you well!

17 notes

·

View notes

Text

Gaz finds out a couple of weeks after Price.

It's a complete accident and not even a fault on Soap's part really, unless you count getting the wrong type of bin.

It's some time in the middle of the night, Gaz doesn't know, Gaz can't be bothered to say. What he does know is that there's an intruder in his room ruffling around on the floor. "Ye wee foockin son of a bitch yer gonna wish ye were nae foockin born" ....Fucking Soap?

He doesn't even bother getting up. "Soap what the bloody fuck are you doin in here mate??"

The cursing on his floor goes silent. He's about to ask more when he feels a slight pressure on his calf, ready at this point to accept that Soap just wants cuddles and drag him on to the bed he's nowhere near prepared for the sharp pinch that clamps down on his leg.

"Jesus Mary and Joseph Soap what the hell??" He squeals at the same time Soap declares "I've got ye wee bastard!"

He looks down just in time for Soap to rip his covers and grab a... thing that had been attached to his leg, cradling it in his palms with a stern look.

"You gonna explain what the fuck just happened to me?" Soap, now looking appropriately sheepish holds up his palms like an offering. In them, cradled delicately in calloused hands is a baby turtle the size of a golfball. Little bugger is fucking cute too.

"I ah had them in ma closet...they wernae sposed to get out but the bin locks are shit. Think he could hear the water from your tanks or somethin, slipped right under the door."

Gaz, properly awake now, is taken to Soap's room with the little snapping turtle. He realizes for as good of friends as he is with the man he'd never actually been in his room, now he knows why.

"Mate there's no fucking room in here!"

"Ach ah know, I donnae have a space for turtles but they just hatched a couple days ago."

Gaz laughs. "Soap I meant for you ya fuckin muppet!"

Soap blinks. "Well I can get to the bathroom, and if I get chilly I can just curl on up in there with Wee Man."

Gaz takes it in, he admittedly doesn't know the first thing about reptiles but everything looks pretty fucking mint, fake and real plants all over, big sticks and caves to hide in, not to mention the size of the things. They don't look like much on the outside, sheets of blank plywood that look just the slightest bit slap glued. But the fronts have well installed sliding glass doors and the insides are all painted with hand drawn jungle and desert scenes and sealed expertly with silicone.

"You make this?" Gaz asks, gesturing to the enclosures.

Soap looks up from where he's contorted himself to get into his closet, fiddling with the bin that the baby turtles had escaped from where it sits on a heat pad.

"Oh aye, nothing much to look at but it gets the job done."

"Fuckin mint."

#some jackasses were fucking with a snappjng turtle nest after the mom got hit by a car so Soap got called in#he incubated the eggs while the Laswell's got a baby tank set up#if Soap had an inch of spare space he would but he is literally parkouring around his bedroom with a mildly venomous snake in his bathroom#Gaz likes turtles and hes thought about doing a turtle tank before but his real love is and always will be fish#not seen:Price sprinting around the base trying to find the other turtles while Soap's infiltrating Gaz's room#Soap loves drawing his little scale children and he does a portrait of each of the ones hes rescued#cod mw2#fish person gaz#john soap mactavish#kyle gaz garrick#john price#reptile person soap

41 notes

·

View notes

Text

I went down to the makerspace to cut some styrofoam sheeting and some plywood, and I managed to use a table saw without cutting off both of my hands.

(Which has been a long-term dream of mine; I've even been examining doing big woodworking with CNC routers in large part because I've been worried about cutting sheets of plywood to size.)

2 notes

·

View notes

Text

Ukiyoe Reproducing ー "Asakusa Ricefields and Torinomachi Festival, from the series One Hundred Famous Views of Edo".

I thesedays done a work. It's ukiyoe reproducing from a Hiroshige's work, "Asakusa Ricefields and Torinomachi Festival, from the series One Hundred Famous Views of Edo".

The concept this time reproducing was to ``make as quickly as possible at the lowest possible cost, and with the highest possible quality.'' This work was made for wholesale sale to various vendors. However, there may be some individuals who want it, so I'm also selling it on my webshop.

I used the original image from the National Diet Library Digital Collection as a reference, but my colors and lines are quite different. However, such matter is generally not uncommon in ukiyoe reproductions. Also, even if the carving and printing are somewhat rough, it does not impede the appreciation of the print, which is particularly evident in the original prints from the Edo period. Thinking the producing status and skill standards of Edo period ukiyo-e prints, and comparing the originals and nowadays ukiyoe reproductions, it seems that the rougher carvings and printing take even more reality. Nowadays, ukiyo-e is commonly viewed as art , but on the other hand, it also has originally aspects of commercial prints made quickly and cheaply and printing techniques for that. Although it from my experience seems that carvers and printers in the past placed more emphasis on speed, but I think it comes from that. Alternatively, from the Meiji period to the present day, ukiyo-e may have changed from a ``commercial print'' to an ``work of art,'' and its technique changed from a ``printing technique'' to an ``artistic expression technique.'' One old printer once said, ``There is something "play" in the print by a master.'' In my personal interpretation, it seems to me like the work of a master , that is not made with perfect care and attention to detail, but rather work that is basically done well but still retains imperfection with a sense of speed. However, note this time my reproducing is far from such that level.

This time, I re-sharpened the previously used wild cherry woodblock with a plane and reused it. Such technique is also important in reducing production costs.

The keyblock done to carve. It's been 10 days since I started carving. Then, the necessary number of sheets are printed from this keyblock to make a manuscript for the color block, and each color block is carved based on that. I this time used woodblocks of plywood of japanese lime for that.

The all color blocks done to carve. Up to this point, 18 days have passed since I first started carving the keyblock.

I then prepared the paper for printing. It's hand-made japanese washi of all mulberry. The sizing was not drawn on this time paper, so I drew it myself. Once the blocks and paper are ready, I first do a test printing and check the blocks. Sometimes I forget to carve a part in the color blocks , so I must check it at this stage. After making a test print and checking the blocks, the final printing begins.

The total color impression is 17. I printed to make 120 sheets in 5 days. After this, l do some inspection work.

This time, I applied an aged color to only the front side of the paper since I thought that giving it an aged look would give it a better feel.

This time, the work took about a month in total, including holidays. When vendors purchase it all, this 120 sheet brings about 150,000 yen as my income. So I have to make it such quickly. Just to be clear, this is not a work of carver and printer, in terms of remuneration.

I mentioned that I made it for wholesale, but there may be people who want it personally, so I also sell on my webshop. In addition, my friend gave me the advice, ``I want one color ink line print of the keyblock since it's interesting. There might be other people who want it, so why not sell it?'' I thought that's a good idea, so I decided to sell a print of only ink line of keyblock this time.(This keyblock one not done aged process.)

4 notes

·

View notes

Text

What Size Do Plywood Sheets Come In?

Plywood is one of the most versatile materials used across various industries, including construction, furniture-making, and DIY projects. It’s valued for its strength, flexibility, and affordability. Knowing the sizes of plywood sheets can help with efficient project planning, reducing waste and optimizing resources.

1. Introduction to Plywood Sheet Sizes

Plywood sheet size are made by layering thin sheets of wood veneer, called plies, which are glued together with the grain direction rotated at each layer. This cross-grain pattern gives plywood its strength and dimensional stability. Plywood sheets come in a range of sizes to meet various project requirements, from large construction jobs to smaller furniture builds.

Understanding the available plywood sheet sizes can help you make the right choice, ensuring that the sheet size fits your specific application and reduces the need for extensive cutting or joining.

2. Standard Plywood Sheet Sizes

The most common plywood sheet size is 4 feet by 8 feet (48 inches by 96 inches). This size is often used in general construction projects, as it aligns well with standard wall and flooring dimensions. However, plywood sheets are also available in other sizes to cater to different needs.

Here are the most widely available plywood sheet sizes:

4 feet by 8 feet (48 inches by 96 inches): The standard plywood sheet size, frequently used for walls, flooring, and roofing.

5 feet by 5 feet (60 inches by 60 inches): Common in specialty plywood, like Baltic birch, often used in cabinetry and furniture making.

4 feet by 10 feet (48 inches by 120 inches): Used for larger projects like wall paneling, allowing fewer seams.

4 feet by 12 feet (48 inches by 144 inches): Ideal for large-scale applications, such as commercial construction or long wall panels, as it reduces visible seams.

Benefits of Using Standard Sizes

Standard plywood sheet size are often more cost-effective and easier to find in most hardware stores. These sizes are also easier to work with as they align with standard building practices, making construction projects more efficient.

3. Oversized and Specialty Plywood Sheets

In addition to standard sizes, plywood sheets are available in oversized dimensions, especially for industrial or commercial uses. Oversized plywood sheets reduce the need for additional joints and are often used in large construction projects. Some common oversized plywood sheet sizes include:

4 feet by 10 feet: Useful for applications that require fewer visible seams, such as long wall panels.

4 feet by 12 feet: Often used for extended wall sections or larger surfaces that need to be covered with minimal joins.

5 feet by 10 feet and 5 feet by 12 feet: Larger, custom-sized sheets for more specific construction needs, such as wide wall panels.

These oversized sheets provide additional flexibility for contractors working on large projects or when aiming to minimize the appearance of seams. However, due to their size, they can be more challenging to handle and may require specialized transportation and cutting tools.

4. Plywood Thickness Options

Plywood sheets come in a variety of thicknesses, each suitable for different applications. The most common thicknesses available include:

1/8 inch: Very thin plywood often used in lightweight projects, crafting, or decorative work.

1/4 inch: Commonly used in cabinets, paneling, and furniture backings.

3/8 inch: Ideal for applications requiring slightly more strength, such as cabinetry and certain furniture pieces.

1/2 inch: Popular for interior wall sheathing, flooring underlayment, and other structural applications.

5/8 inch: Used in subflooring, roof decking, and other construction projects where additional strength is necessary.

3/4 inch: A sturdy thickness used in heavy-duty furniture, countertops, and load-bearing applications.

1 inch (or greater): Typically used for industrial applications requiring extra durability and load-bearing capacity, such as industrial flooring.

5. Choosing the Right Plywood Sheet Size for Your Project

Selecting the right plywood sheet size depends on several factors, including the type of project, desired durability, and ease of handling. Here are some guidelines for common applications:

Walls and Ceilings: Standard 4x8-foot sheets with a thickness of 1/2 inch or 5/8 inch are popular for wall and ceiling sheathing. Larger sheets (4x10 feet or 4x12 feet) reduce the need for joins, resulting in a smoother finish.

Flooring and Subflooring: For subflooring, thicker sheets (5/8 inch to 3/4 inch) in 4x8-foot dimensions are generally recommended for durability and stability. This thickness offers resistance to flexing and supports heavier loads.

Furniture and Cabinetry: Depending on the project, 1/4-inch, 1/2-inch, or 3/4-inch plywood in 4x8 or 5x5-foot sheets work well for furniture and cabinets, providing both strength and aesthetic appeal.

Roofing: Roofing projects typically require 4x8-foot sheets in either 1/2-inch or 5/8-inch thickness, ensuring structural integrity and ease of installation.

Q1: What is the standard size of a plywood sheet?The most common standard size for plywood sheets is 4 feet by 8 feet (48 inches by 96 inches).

Q2: Are there oversized plywood sheets available?Yes, oversized sheets, such as 4 feet by 10 feet and 4 feet by 12 feet, are available for projects requiring fewer seams or larger coverage areas.

Q3: What is the actual size of a 4x8 sheet of plywood?A 4x8 plywood sheet typically measures slightly smaller than its nominal size, around 47 7/8 inches by 95 7/8 inches, due to the finishing process.

Q4: What thicknesses are available for plywood?Plywood is available in a range of thicknesses, including 1/8 inch, 1/4 inch, 3/8 inch, 1/2 inch, 5/8 inch, 3/4 inch, and 1 inch or greater.

Q5: What size plywood is best for furniture?For furniture, common sizes include 4x8 feet and 5x5 feet, with thicknesses ranging from 1/4 inch to 3/4 inch, depending on the project requirements.

Q6: Can plywood sheets be custom cut?Yes, many suppliers offer custom cutting services to achieve specific dimensions for unique project needs.

Q7: What size plywood should I use for flooring?Flooring projects generally use 4x8-foot sheets with a thickness of 3/4 inch for strength and durability.

8. Conclusion

Understanding plywood sheet sizes is essential for successful project planning, whether in construction, furniture making, or DIY work. The most commonly used plywood sheet size is 4x8 feet, which fits well with standard building practices and provides an affordable option for various applications. Specialty sizes, such as oversized sheets and smaller panels, are also available to accommodate specific project requirements.

Choosing the correct plywood sheet size and thickness ensures that your project has the strength, durability, and aesthetic appeal you desire. By considering factors like project dimensions, handling needs, and structural demands, you can select the plywood that best fits your needs, optimizing resources and achieving professional results.

#plywoodsheetsizes#What is the standard size of plywood sheets?#What are the list of plywood sizes?#How big is a 4x8 sheet of plywood?

1 note

·

View note

Text

Different types of plywood sheets and their Applications

Plywood Sheets is a type of engineered wood made from thin sheets of wood veneer that are glued together. It is versatile and can be used in a variety of applications, including construction, furniture making, and decorative purposes.

Plywood is a widely used building material made from thin layers or "plies" of wood veneer that are glued together. These plies are usually laid in alternating directions to provide strength and stability.

There are several different types of plywood sheets, each with its own characteristics and uses.

Visit Uro Veneer World Now and Buy your favorite Plywood sheets Today.

Contact Us for more info!!!

Here are some of the most common types of plywood and their uses : -

Structural plywood: This type of plywood is designed for use in construction, particularly in roofing, flooring, and wall sheathing.

It is made with strong and durable veneers, and has a high load-bearing capacity. It is made with a thicker veneer and has a higher density than other types of plywood to provide greater strength and durability.

Marine plywood: This type of plywood is designed for use in wet environments. This type of plywood is designed for use in marine environments, such as boats and docks. It is made with waterproof glue and has a high resistance to water and moisture.

Exterior plywood: This type of plywood is designed for use in outdoor applications where it will be exposed to the elements. This type of plywood is suitable for use in outdoor applications, such as outdoor furniture, exterior walls, and soffits. It is made with water-resistant glue and has a high resistance to moisture and weather.

Interior plywood: This type of plywood is designed for use in indoor applications, such as cabinets, furniture, and paneling. It is not as water-resistant as exterior plywood and should not be used in areas with high humidity or moisture.

Decorative plywood: This type of plywood is used for decorative purposes, such as wall paneling, ceilings, and furniture. It is available in a variety of finishes, including veneer, laminate, and paint-grade.

Fire-resistant plywood: This type of plywood is designed to meet fire-resistant standards and is used in applications where fire safety is a concern, such as in commercial buildings and high-rise structures.

Flexible plywood: This type of plywood is designed to be flexible and is used in applications such as curved furniture and decorative elements.

Softwood plywood: This type of plywood is made from softwood trees such as pine or spruce. It is lightweight and relatively inexpensive, making it ideal for construction projects such as walls, roofs, and floors.

Hardwood plywood: This type of plywood is made from hardwood trees such as oak, maple, or birch. It is more expensive than softwood plywood and is often used in furniture-making, cabinetry, and decorative applications.

Buy the Best and High-Quality Plywood Sheets from Uro Veneer World.

Applications of Plywood Sheets -

Here are some common applications of plywood sheets : -

Furniture: Plywood is commonly used to make furniture such as chairs, tables, and cabinets. It is a strong and durable material that can be easily cut and shaped.

Flooring: Plywood sheets can be used as a subflooring material for hardwood, tile, and carpeted floors. It provides a stable base that helps prevent movement and cracking.

Walls and ceilings: Plywood sheets can be used as an alternative to drywall for walls and ceilings. They provide a smooth surface for painting or wallpapering.

Roofing: Plywood sheets can be used as sheathing for roofing. It provides a strong base for the roof covering and helps protect against weather damage.

Exterior siding: Plywood can be used as exterior siding for homes and other buildings. It can be painted or stained to match the surrounding architecture.

Boat building: Plywood is commonly used in boat building. It is strong, lightweight, and can be easily shaped to fit the contours of the boat.

Packaging: Plywood sheets can be used to create crates and boxes for shipping and storage. It is a strong and durable material that helps protect the contents from damage.

Overall, plywood sheets are a versatile building material that can be used in a wide range of applications.

Buy the Largest Collections of Plywood Sheets Now @ Uro Veneer World.

Get Quotes and View Prices.

Conclusion -

In conclusion, plywood sheets are a versatile and widely-used building material that offer numerous benefits over other types of wood and composite materials. They are made by gluing together multiple thin layers of wood veneer, creating a strong and durable sheet that is resistant to warping, cracking, and splitting.

Plywood is available in a variety of grades, thicknesses, and sizes, making it suitable for a wide range of applications in construction, furniture-making, and other industries. Some of the key advantages of plywood include its strength and durability, its resistance to moisture and rot, and its ability to be easily cut and shaped to fit a variety of purposes.

The type of plywood you choose will depend on your specific application and the conditions it will be exposed to. It's important to choose the right type of plywood to ensure it performs as intended and lasts for as long as possible.

Visit Uro Veneer World Now!

Get in touch with us!!!

#uro veneer world#interior design#home improvement#living room#decor#plywood sheets#plywood sheets price#plywood price in bangalore#plywood#plywood manufacturers#plywood dealers#cabinets#dining table#plywood sheets price in bangalore#plywood sheets for interiors#plywood sheets for home decor#plywood sheets cost#plywood sheets size#plywood sheets brands#plywood sheets catalogue#plywood sheets catalogue pdf

0 notes

Text

Off to the races

Chapter 7: He doesn't mind

Somehow, both John and Lilith understood this, it wasn’t enough.

master list

price x oc, series.

a03: pricescigar, Off to the races is posted in full.

sexi taglist: @deadbranch , @jxvipike, @smoggyfogbottom

warnings: angst, mentions of blood.

His comfort faded as quickly as his smile did, having corralled Lilith inside the Captain seemed to have moved on from her distress. Set on checking off another task on his ever-long list, his presence coursing through halls as he passed through, the dampened woman trailing after him. Soldiers pressed against the walls to make room for his bearish gait, reputation cloaked upon his broad frame, tripling his size. He moved in silence, thoughts ticking over in time with his steps, a steady beat in which his subconscious could growl too, mull over the thrum of his anger. Wet echos of her borrowed footwear sounded as she hurried herself in order to remain in his shadow, scornful eyes burning holes into the back of his khaki shirt, occasionally flickering around to then glare at a stray soldier.

The flip-flops were slowing her down considerably, slipping and sliding on the shiny linoleum floors. Lilith slid her foot out of one mid-step, letting it remain in their wake. She soon ditched the other, now able to somewhat keep in step with Price as he led her through the maze of buildings. Words clattered against the cage of her teeth, hurdling around her shut mouth with such force she could barely contain herself, desperate to stir up something other than the heavy atmosphere that the man ahead of her carried. This whole situation had uprooted her life completely and yet it felt like he was the one on a quiet rampage. She could feel it slamming against her, the need to crack the weighted silence, break the dam. The pink of her lips now slowly burst into a deep red as the capillaries broke, teeth wrenched down into the soft flesh, hesitantly released in preparation to speak, cage steadily shattering.

“This’ll be your room.”

Her mouth hung open, brows furrowed as his tones filled the air instead of hers. So focused on projecting her angered gaze on him, entangled with finding the right words, blinded to her surroundings as he had thrown open a locked door. She faltered, blinking away the burning resentment in her eyes and letting them carry across the space. It almost reminded her of a dorm room, simplistic plywood furniture, desk, shelves, all of one eggshell colour that carried an impersonal air. The bed tucked into the corner, deep blue sheets that matched the colour of the curtains which were drawn over the window that presided just over. The light overhead flickered, he loomed beside the doorframe, inspecting her reaction, waiting.

Lilith stepped across the threshold, bare feet scratched by the rough-cut carpet, an off-blue that almost looked dirty. Maybe it was. She shivered involuntarily, sucking in a deep breath, cringing at the overwhelming smell of bleach.

“Garrick prepped it for you weeks ago,” Price had watched him do it, unsure as to why one of his best men was hell-bent on freeing someone who could have been the undoing of them all. Back and forth debate all the way as the Captain witnessed him scrub the place clean, skirting boards and all.

“What’s going to happen to those men?” She faced away from the other, cheek turned and body held in place. Lilith felt as if one more step further would come across as acceptance, a willing participant in her fate, no doubt he’d want to seal her in this astringent-smelling room. Practically a storage closet with a bed and a window, it was just missing the bloody body. Somehow this felt familiar.

She wanted some course of judgement, some trial, some punishment. His anger felt futile, an enraged Captain meant little to a woman trapped within his den of predators, a bleeding bunny led deeper into the bowls of this haunt, those pictures had only just rung the dinner bell.

The question riled his wrath further, calloused hands down dragging down the length of his visage, pulling at the course hairs on his chin, eyes clenched shut. Blood lay behind them, the vision of red so potent he could barely see past it. Not that he wanted to, it felt right in this situation, morals askew when it came to upholding the dignity of a woman, one supposedly in his protection. The red swirled on, protection or investigation? Who knew at this point, lines continued to blur as the weeks went on, now standing in a soldier's room and asking for damnation. He had answered before, he was going to fire them. The answer felt weak now, frail in the kingdom of his rage, barely able to keep upright as it offered itself before him. Somehow, both John and Lilith understood this, it wasn’t enough.

It felt wrong, wanting to inflict lasting hurt on men who were supposedly on his side, slept in his barracks, ate beside him at mess. And for what? A stranger who had saved Simon from a stab wound? Seen his face?

Saved.

He could make out her frame through the maroon mirage, peering out back at him, barefoot and shivering.

“They won’t be an issue.”

Lily inhaled once more, almost as if his reassurance had permitted her to breathe again. She nodded, eyes closing with the movement, lips drawn tight. She didn’t doubt that it would be handled, it seemed now, that the other's anger had grown so large it consumed her own, elevating the burden of action, swallowing the responsibility down as his to herald. His anger alone may have issued uncertainty but theirs together, it morphed into an odious thing. And by god was it beautiful.

The four walls surrounding her felt oppressive without Price’s presence pushing them back, focusing her thoughts. Having left Lilith to herself long ago with a gruff command to ‘remain’. At first, she spent the time in riled dismay, jeering out mock impressions of the Captain and his demands.

“Remain!” She’d bark, soon following it with a deeply sardonic laugh, then a stretch of pitying quiet as the room stayed the same, the carpet still scratched and she was still very much alone. With no clock to watch, an hour had stretched on to feel like an eternity. Wet clothes clad to her skin as she circled the small space, soon resorting to flinging open all the cabinets and drawers to relieve some modicum of her boredom.

Upon opening the inside of her desk, Lily stood pleasantly surprised. A small sticky note clung to the wrapper of a chocolate bar, messy handwriting scrawled out in black alongside a badly drawn smiley face wearing sunglasses.

‘Peace offering from your new neighbour, I introduce to you, the Gaz-laxy bar’

She removed the note to reveal a Galaxy bar with a ‘z’ crudely shoved between letters with what looked like black permanent marker. Lily huffed softly, a humorous swirl of air leaving her as she tried not to chuckle, it was so stupid. She loved it.

“See, told you guys it was funny.”

“Fucking hell!” With a gargled yelp, Lily spun toward the voice, now finding Kyle poking his head around the open doorway, Soap and Ghost beside him, all peering in. A strained silence fell upon the four as they seemed to stare at one another, she clutched the chocolate bar in her hands with a suspicious look, scowl now forming.

“How long have you been there?”

“Not long, just came back, meant to show yer’ round lass” Soap pushed past the two other men crowding her doorway, awkwardly stumbling into one of the open closet doors in the process. A bundle of clothing in his hands messily clutched with great difficulty as he took a moment to situate himself, now dumping them onto her bed. Lilith picked through the pile, all standard-issue military uniform, on first inspection most of the items seemed normal though as the woman started to look properly-

“Where are the laces for the boots?” She held up a black boot, its leather tongue flopping out without the lace holding it steady.

Soap rocked back and forth on his own shoes, which very evidently had laces, lips pursed as he let out an elongated ‘err’, decidedly looking away and distracting himself by opening and closing the door he’d just fallen into. Lily persisted, now ever more suspicious, shoving the boot towards Gaz, waving it in his direction with a raise of her brow.

“How am I supposed to walk properly in them without laces?”

“Not allowed laces.” Deep, voice awash with general distaste, like he’d chewed up stone and spat it right out at her.

Lilith faltered slightly, not expecting Ghost to have addressed her, it was unusual, the man hadn’t spoken to her directly after the whole needle incident in the hospital. She chucked the boot back onto the pile, hand now situated on her hip as she returned his sour answer.

“Any particular reason?”

Both Soap and Gaz looked uncomfortable, even more so as the towering menace crossed the threshold and loomed over her, even with a good stride between them Lilith felt dwarfed by the other, things fell into Ghost’s orbit and never came back out, a black hole of a man sucking out all the energy in the room, all the oxygen.

“Could hang yourself with them.”

The sharp pinch of a shiver scraped down her spine, her hand fell to her side, shoulders slumping forward slightly, and the urge to make herself smaller overcame her.

“No belt, no laces, no drawstrings.”

She moved back toward the bed, picking up a long-sleeved shirt before casting an overly pointed look back towards the three.

“No underwear either? What am I gonna do with those? Seduce someone into lending me their laces so I can finally fucking hang myself?”

Soap let out a snort, throaty laugh leaving the shorter male as he petted Simon on the shoulder.

“Ask the Cap’n about personal items and whatever’s not there” He rocked back and forth once again before Simon shrugged off Soap’s hand and crowded the man out of the room, grumbling something toward Johnny as they left Gaz waiting in the doorway.

“C’mon Lil’ go commando and get changed for now, wanna show you the place before its dark”

She reluctantly complied with Kyle, only because of his stupid chocolate bar. Dawned with her ill-fitting hand-me-downs the woman looked like she’d been playing dress up. The dark green shirt hanging from her frame unflatteringly as well as the camo patterned cargos, which she had rolled up around her waist to accommodate for the material slipping down every two steps. The tour was short as her world had, oh so graciously, been opened up from the small hospital room to the section of the barracks which the team occupied. Shared bathrooms, a shabby common room and a hallway of half-empty dorms.

“What a thrilling tour Garrick, I must thank you from the bottom of my heart for the ten minutes you took out of the busy, busy day to show me your bountiful kingdom.” Lily stood, arms crossed over one another, sarcasm spread thickly over her demeanour.

“I haven’t even shown you the best part yet lil’ miss commando, get yourself ready, it’s the best your life in captivity is gonna’ get.” He grinned wickedly, beckoning Lily over to him as he raised himself up on his toes, stretching out to grab ahold of a cardboard box that sat on top of the row of kitchen cupboards within the common room. She watched curiously, inching closer as Gaz shook the box, the sound of packaging filled the air with each jolt.

“Oh yes”

“Oh yes indeed.” He hummed, chuckling now as the black-haired girl dove her hands into the mess of food. A whole box packed full of snacks, the feeling of the different plastics scratching her hand made her smile widen, childish pangs of excitement escaping her as she rummaged through the contents.

“Suddenly I love it here.” She grasped onto a packet of crisps and laid them along her forearms like she was cradling a newborn, rocking the plastic and shushing it comically.

“What’s her name?” Kyle cooed, now picking up his own packet and copying Lilith as they tended to the children. Laughter intermingled, he was indulging her for sure, or maybe just tired and happy that someone was willing to endorse his tendency to play stupid. Someone other than Soap that is. She circled the box and planted herself next to the other, pushing her packet towards his own when something seemed to halt the girl, her smile fading as she soon pointed at Kyle’s hands.

“Was it..” She started, glancing over the red ridges in his knuckles, the beginnings of a bruise covering the flesh around the welts. A heavy sigh heaved from his lips as he let his packet drop back into the box, stretching out his fingers, he spread the digits wide in order to grant the other a good look. Garrick had decided the moment his hand had collided with the face of one of those tech boys, that he’d tell Lilith. This had gone beyond the usual, it felt less like duty and more like defending a friend. Even more so when Price had come back to the room, Gaz was sure he’d be hearing the Captain call them off, but no, John stood seething, soon joining in. Even Ghost had thrown his weight about a bit.

“I doubt they’ll be finding any reputable jobs with faces like balloons” He scoffed, head tilted down slightly, trying to catch her gaze as she stared at his hands. Lily hesitated for a moment before she sucked in a sharp breath, already feeling the rush of blood circle through her head, the worry starting to build with every pump of her heart.

“I wish-“ Voice fell flat, not as strong as she wanted it to be, betrayed by the air in her lungs. “I wish I could’ve done something yanno? I feel like, well, I don’t know” She sighed, closing her eyes as she pinched the bridge of her nose.

“What happened, how it was dealt with, I think everyone involved wished they could’ve done something more” He was whispering now, lowering his voice to meet hers, outstretched hand now moving to gently grasp her shoulder, a gentle hold as they fell into quiet conversation. He inched closer, body turning to face her, eyes flickering around the place before he continued on. “I’ll be honest Lil’, never seen the Captain hit another soldier, not like that.” Hushed, eyes a little wide as he recounted Price, the look in his eye, the man seemed far from his sense, lost in whatever had taken hold. “Think we all crossed some lines today, if I’m honest-“

“What are you two hens clucking about?” The Scotsman smashed through the delicate exchange, rounding the corner to the common room with a loud whistle at the sight of Gaz and Lilly crowded over the snack box. “Price ain’t gon’ be chuffed about that” He hollered, clearly pitching the call up an octave or two, wanting to attract attention.

“Shut up man!” Gaz was quick to snatch the packet of crisps from Lily’s hands and scurry to shove the box back above the cupboards, leaving the girl to stand confused.

“Caught red-handed in the reward box Gazza, I canny remember you getting any permission for tha’”

Lilith watched as the two dropped into some petty back and forth, soon gathering that the snack box was indeed not a free-for-all but a coveted reward. One that king Price seemed to dangle over their heads. The notion made her curl inwards with a dubious sort of humour, disbelief evident at the childish nature of it all.

“Would you two shut up.” Ghost soon came into sight, notably, the man had changed into what looked like an attempt at loungewear. Dropping down onto the worn sofa he drew an exaggerated breath, taking out a phone from his pocket and holding it out before him. “Price said to go ahead and order.”

#cod price#captain john price#john price#captain price#price#captain john price x you#captain john price x reader#john price x reader#captain john price x oc#cod price x reader#kyle gaz garrick#kyle garrick#soap mctavish#soap call of duty#simon ghost riley#cod#mw2 x reader#mw2 price#modern warfare#off to the races#lana del rey#john price x y/n

22 notes

·

View notes

Text

Packard Patricia pickup

Chris Coleman

Former Test Driver & Mechanic at Automotive Industry (2007–2008

What were the original reasons for Chevrolet coming out with the El Camino?

The El Camino, and other similar vehicles, like the Ford Ranchero, Subaru BRAT, Dodge Rampage and others, were designed to offer car-like comfort, performance and convenience, with the cargo capability of a light truck. Three of the forerunners to this were the Packard Patrician pickup, the Chevrolet Cameo and the Dodge Sweptline pickups.

1957 Dodge Sweptline with tailfins

Chevrolet Cameo Fleetside

The El Camino was based on the full-sized Impala originally, and was enormous. The low ground clearance and hefty weight made it a poor choice as a pickup. Most owners purchased them for styling reasons, especially with the cat eye taillights and horizontal tail fins.

1959 Chevrolet El Camino

Later, Chevrolet downsized the El Camino and based it on the Chevelle/Malibu, where it remained until it was discontinued.

1968 El Camino SS

With nothing in the rear, other than an empty bed, it was difficult to make it competitive as a muscle car, since the weight distribution was heavily biased towards the front.

Also, the bed used curved sheet metal in many places, to accommodate the rounded body panels, and this wasn’t a good fit with common pickup cargo, like plywood, hay bales and crates.

With the passenger compartment realistically holding two people, it was worthless as a family car, while a station wagon version of the Chevelle would be perfect. These things made it an odd fit with a very limited customer base.

Holden Ute, from Australia

Paradoxically, in Australia, cars like these, called Utes (short for utility) were and are extremely popular. Australia has a more rural environment and remote ranches and homes, which make this type of vehicle perfect for them. However in a more suburban setting, like the U.S., the El Camino was always an odd choice.

1972 Ford Ranchero - Based on the Torino

Dodge Rampage

Dodge Rampage, built on the K-car platform

Subaru Baja

Today, no one makes a ute for the American market, but that doesn’t mean these may not resurface from time to time. As kids grow up and nests are emptied, we may once again see a demand for the ubiquitous El Camino, Ford Ranchero and others.

17 notes

·

View notes

Text

DIY Stenciled Floors

Project by AshleyAnn: