#motor v12

Explore tagged Tumblr posts

Text

UNMUTE! 🔊😱

#video#sfw#lamborghini#v12#v12 engine#motor#motor v12#engine#sound#sonido#audio#unmute#epic#coche#coches#car#cars#supercar#wow

32 notes

·

View notes

Link

#Toyota#Century#motor V12#Toyota Century#Toyota Century V12#Sakichi Toyoda#Toyoda#Fascinace#Pojízdný obývák#Luxus#Luxusní auta#Luxusní vozy#Fuji#Limuzína#Made in Japan#Rolls-Royce#VVT-i 1GZ-FE#Phoenix#Fénix#Japonská císařská rodina#Život v luxusu#DriveZone#DriveZoneCZ#Pro bohaté#youngtimer

0 notes

Text

Ferrari 250 GT Passo Corto, 1962, by Bertone. Designed by 24-year-old Giorgetto Giugiaro when he was working at Bertone, a one-off for Nuccio Bertone himself. It was presented at the Geneva Motor Show

#Ferrari#Ferrari 250 GT Passo Corto#short wheelbase#Bertone#Giorgetto Giugiaro#1962#Nuccio Bertone#one-off#Geneva Motor Show#V12#Ferrari 250 GT

565 notes

·

View notes

Text

Jaguar XJS V12

#Jaguar#Jaguar XJS#Jaguar XJS V12#British#England#English#UK#Classic Cars#Vintage Cars#Cool Cars#Old Cars#Oldtimer#Cars#Autos#Motors#Culture#Style

180 notes

·

View notes

Text

Ferrari 643

#Ferrari#643#F1#Formula One#Jean Alesi#motor racing#open wheel racing cars#Scuderia Ferrari#1991 F1 season#v12 engine

14 notes

·

View notes

Photo

V12 by Maranello.

Acuarela sur papier 300 gr A3. jrG Motor

B-1080

2023

4 notes

·

View notes

Text

Lamborghini Aventador SVJ: Prestazioni Eccezionali

La Lamborghini Aventador SVJ è una supercar straordinaria. Offre prestazioni mozzafiato grazie al suo motore V12 aspirato da 770 CV. Questo motore permette di raggiungere velocità elevate e accelerazioni fulminanti. Il suo design è aggressivo e aerodinamico. Questo lo rende non solo estremamente performante, ma anche unico nel suo genere. La Lamborghini Aventador SVJ è l’epitome del lusso e della…

#Aerodinamica Perfetta#Classe e Potenza#Design Sperimentale#Modello Esclusivo#Motore V12#Prestazioni da Corsa#Prestazioni Sportive#Supercar italiana#Tecnologia avanzata#Velocità estrema

0 notes

Text

In addition to powering U.S. aircraft in WWI, the Liberty V-12 helped create the Lincoln Motor Co - Mike McNessor @Hemmings

In addition to powering U.S. aircraft in WWI, the Liberty V-12 helped create the Lincoln Motor Co – Mike McNessor @Hemmings

Advanced engine design used overhead cams, an aluminum crankcase, liquid cooling Aerial combat advanced at an astonishing rate during World War I, and though it seems unimaginable today, there were no American-designed aircraft deemed suitable for battle in the skies over Europe. There was a U.S.-designed engine in the fight however: the Liberty V-12 or L-12. The L-12 engine was America’s…

View On WordPress

0 notes

Text

1962 Ferrari 330 LM / 250 GTO by Scaglietti

With just 36 in existence, the 250 GTO is a coveted motorcar. However, this example is even more special, thanks to its 4.0-liter engine.

It's the only example initially fitted with the larger displacement motor, unlike the 3.0-liter found in the other cars. However, the original engine made way for a 3.0-liter Colombo V12, which remains under the hood today.

This car placed second overall in the 1962 Nurburgring 1000km race, and competed in the 24 Hours of Le Mans in the same year, surviving 56 laps before a crash ended the car's race.

Courtesy: RM Sotheby’s

#art#design#luxury cars#luxury lifestyle#supercars#sport cars#luxurycars#luxurylifestyle#supercar#luxurycar#ferrari#1962#ferrari 330LM/250GTO#scaglietti#sportcars#sportcar#nurburgring#racecars#racecar#250GTO#collector's#rmsothebys

853 notes

·

View notes

Text

1938 Mercedes-Benz W154

In September 1936, the AIACR (Association Internationale des Automobile Clubs Reconnus), the governing body of motor racing, set the new Grand Prix regulations effective from 1938. Key stipulations included a maximum engine displacement of three liters for supercharged engines and 4.5 liters for naturally aspirated engines, with a minimum car weight ranging from 400 to 850 kilograms, depending on engine size.

By the end of the 1937 season, Mercedes-Benz engineers were already hard at work developing the new W154, exploring various ideas, including a naturally aspirated engine with a W24 configuration, a rear-mounted engine, direct fuel injection, and fully streamlined bodies. Ultimately, due to heat management considerations, they opted for an in-house developed 60-degree V12 engine designed by Albert Heess. This engine mirrored the displacement characteristics of the 1924 supercharged two-liter M 2 L 8 engine, with each of its 12 cylinders displacing 250 cc. Using glycol as a coolant allowed temperatures to reach up to 125°C. The engine featured four overhead camshafts operating 48 valves via forked rocker arms, with three cylinders combined under welded coolant jackets, and non-removable heads. It had a high-capacity lubrication system, circulating 100 liters of oil per minute, and initially utilized two single-stage superchargers, later replaced by a more efficient two-stage supercharger in 1939.

The first prototype engine ran on the test bench in January 1938, and by February 7, it had achieved a nearly trouble-free test run, producing 427 hp (314 kW) at 8,000 rpm. During the first half of the season, drivers such as Caracciola, Lang, von Brauchitsch, and Seaman had access to 430 hp (316 kW), which later increased to over 468 hp (344 kW). At the Reims circuit, Hermann Lang's W154 was equipped with the most powerful version, delivering 474 hp (349 kW) and reaching 283 km/h (176 mph) on the straights. Notably, the W154 was the first Mercedes-Benz racing car to feature a five-speed gearbox.

Max Wagner, tasked with designing the suspension, had an easier job than his counterparts working on the engine. He retained much of the advanced chassis architecture from the previous year's W125 but enhanced the torsional rigidity of the frame by 30 percent. The V12 engine was mounted low and at an angle, with the carburetor air intakes extending through the expanded radiator grille.

The driver sat to the right of the propeller shaft, and the W154's sleek body sat close to the ground, lower than the tops of its tires. This design gave the car a dynamic appearance and a low center of gravity. Both Manfred von Brauchitsch and Richard Seaman, whose technical insights were highly valued by Chief Engineer Rudolf Uhlenhaut, praised the car's excellent handling.

The W154 became the most successful Silver Arrow of its era. Rudolf Caracciola secured the 1938 European Championship title (as the World Championship did not yet exist), and the W154 won three of the four Grand Prix races that counted towards the championship.

To ensure proper weight distribution, a saddle tank was installed above the driver's legs. In 1939, the addition of a two-stage supercharger boosted the V12 engine, now named the M163, to 483 hp (355 kW) at 7,800 rpm. Despite the AIACR's efforts to curb the speed of Grand Prix cars, the new three-liter formula cars matched the lap times of the 1937 750-kg formula cars, demonstrating that their attempt was largely unsuccessful. Over the winter of 1938-39, the W154 saw several refinements, including a higher cowl line around the cockpit for improved driver safety and a small, streamlined instrument panel mounted to the saddle tank. As per Uhlenhaut’s philosophy, only essential information was displayed, centered around a large tachometer flanked by water and oil temperature gauges, ensuring the driver wasn't overwhelmed by unnecessary data.

97 notes

·

View notes

Text

1932 Bucciali TAV 12 "Golden Arrow" by Saoutchik

Paul-Albert Bucciali built only six cars between 1926 and 1932. They were built to display the front-wheel-drive system Bucciali invented. Bucciali received an American patent and licensed his technology to Peerless Motor Car Company of Cleveland, Ohio. Unfortunately for Bucciali, Peerless never used the license.

This Bucciali features a specially designed Voisin V12 sleeve-valve engine with four carburetors. Drive to the front axle is through a four-speed transaxle. The huge wheels, fabricated from steel, have integral brake drums. The coachwork is by the French Carrozzeria Saoutchik. The distinctive stork on each hood side is made from German silver, phosphor bronze, and gold-plated brass. This stork was the insignia of Bucciali's WWII fighter squadron. The original chassis price was an incredible 130,000 Francs, and the coachwork was an additional 85,630 Francs. Only one Bucciali was sold to the public. This is it!

The original owner, George Roure, displayed his Bucciali at the 1932 Paris Auto Show. Subsequently, he sold it to Count de Rivaud, who later mounted the body on a more maneuverable Bugatti chassis. In the 1970s, the body was reunited with what remained of the Bucciali chassis and drivetrain, and after a long, challenging restoration, the Bucciali was returned to its original state. The work was begun in Detroit by the noted collector Raymond Jones. In addition to using many factory blueprints, Paul Albert Bucciali was consulted for special detail as to the colors and design of the interior. The car now appears exactly as displayed at the Paris show in 1932.

Starring at the 1932 Paris Auto Show, the front-wheel drive, twelve-cylinder, sleeve-valve engined Bucciali stunned show-goers. Cloaked in one-off coachwork by Saoutchik, the car received acclaim as the most advanced and modern French automobile.

The Bucciali was sold originally to a Paris banker, who drove it for three years. The coachwork was then removed and fitted to a Type 47 Bugatti chassis. The Bugatti fitted with the Bucciali's coachwork was sold and brought stateside after World War II. The original chassis remained behind in France.

In the 1970s, the Bucciali body was reunited with the original chassis, which was purchased from a French collector. With the assistance of Paul Albert Bucciali, the car was restored to the original, spectacular state that it is today.

73 notes

·

View notes

Text

¿Sabías que Aston Martin también fabrica motocicletas?

Esta es la Aston Martin AMB001 solo para pista. Una de solo 100 fabricadas para todo el mundo. Esta es la número 93. Esta también está personalizada para coincidir con el V12 Vantage del propietario en un trabajo de pintura Lamborghini Verde Ermes único en su tipo. ¡Cuerpo completo de carbono con un motor turboalimentado de 997 cc! Eso son 180 caballos de fuerza en un cuerpo que pesa poco menos de 400 libras en seco.

83 notes

·

View notes

Link

#BMW#BMW7#7er#BMW 760i F01#760i#dvanáctiválec#V12#Velký motor#Bimmer#BMW gang#BMW club#BMW recenze#BMW zkušenosti#BMW poradna#BMW fórum#Limuzína#BMW sedan#BMW limo#DriveZone#DriveZoneCZ#Auto klub#Auto magazín#Auto blog#Auto fórum#Auto komunita#Petrolheadi#Autíčkáři

6 notes

·

View notes

Text

Lamborghini Countach LP500 Turbo S Prototipo, 1984. Lamborghini built 2 turbocharged Countach prototypes, commissioned by Max Bobnar, the official Lamborghini distributor in Switzerland. One was presented at the 1984 Geneva Motor Show but Turbo Countach went no further

#Lamborghini#Lamborghini Countach#Lamborghini Countach LP500#Lamborghini Countach LP500 Turbo S#prototype#twin turbo#V12#1984#Geneva Motor Show#one of two

1K notes

·

View notes

Text

Jaguar XJS V12

#Jaguar#Jaguar XJS V12#British#English#England#UK#Classic Cars#Vintage Cars#Cool Cars#Old Cars#Oldtimer#Cars#Autos#Motors#Culture#Style

47 notes

·

View notes

Text

Flying Scotsman in 2004 - A Comedy of Errors and Owners:

Ok - so this is something I've been sitting on for a while now, but I feel like with 'The World Famous Engine' now being uploaded to Ao3, now is the right time to cover this rather insane topic. See, we all know the story of Flying Scotsman and the NRM: the NRM bought the engine for the nation, and then sent it into the Works for 1 years' worth of work in 2006... One year of work that ended up spiralling into ten years and £4.2 million.

But behind that story is a rather more shocking story, and one that really needs more recognition to help people understand just how absolutely shockingly Flying Scotsman had been treated before that overhaul.

Sir William McAlpine:

Our story most likely begins under Alan Peglar, but I have a rather sneaking suspicion it actually gets interesting under McAlpine. Sir William McAlpine bought 4472 Flying Scotsman in 1972 to save the engine after Alan Peglar went bankrupt in San Francisco, leaving the engine on a US Military Base.

He brought Scotsman and had the engine restored at Derby Works in England, and then successfully owned and ran the engine for another 23 years, making him the longest-lasting and most successful of all Scotsman's owners.

Pretty good achievement!

But, during this era, Flying Scotsman visited Australia, broke the record for the longest non-stop run by a steam locomotive, pulled the Royal Train, ran on a multitude of heritage railways and mainline excursions, got an overhaul three times - including one at Barrow-in-Furness (story idea, anyone?). This is not where the worst of the issues arose from, but it does give you a good idea of the kind of work this engine was being tasked with.

And then in 1995, it was involved in an accident at Llangollen Railway. When put back into steam, smoke emerged from a crack separating the boiler and the front cab. It was deemed a total failure and immediately withdrawn from service immediately - and that's what did McAlpine in. He sold the engine off to cover some debts, and Tony Marchington

What do I think went wrong here? I have a feeling that Scotsman was run pretty haggard in Australia (which, fair - it's not always a very nice country to machines) and when refitted to his BR livery, several... shortcuts were made to get the engine back in service. All the same, this isn't where the trouble came from.

Tony Marchington:

And here's where things went south. Fast. Flying Scotsman was bought, went through a three-year long overhaul worth £1 million and then was set to work. Thing is, that overhaul had a number of red flags surrounding it - perhaps most notable being the fitting of an A4 boiler working at 250psi. Now, for those unaware - the original A1 class ran at 180psi, and the upgraded A3 class ran at 225psi. The engine was being run at a pressure it was extremely unfit to operate with.

It would be a bit like fitting a massive V12 motor to a Honda Accord. Yes, the car will move extremely fast and look impressive and move for a while, but every other piece of that car will deteriorate rapidly due to the pressure it's all under. Now transfer that to a steam locomotive - one where to reach that pressure, the firebox is under a lot of strain.

Flying Scotsman failed a lot during the Marchington era, and it's not surprising why. The poor engine was literally falling to pieces - as one NRM staffmember noted: "On our first inspection, the rear drivers had been removed to deal with bearing problems. The visiting NRM team was most unimpressed with the quality of work being done on the bearings. Other examples of poor workmanship (of which I cannot remember the detail) were evident on inspection.”

Please note, the bearings and valves had all recently been replaced.

Also note, Tony Marchington was under pressure from the shareholders of Flying Scotsman PLC - a company he set up - to make money, and so many of the fitters working on the engine may have been given far, far too many constraints in time and budget to properly overhaul the engine, in essence needing to just 'do the bare minimum to get it back in service'...

And this is the condition the NRM bought 4472 Flying Scotsman in.

The National Railway Museum:

All of the above is an indication of the condition that Flying Scotsman was in when bought in 2004 - but that only tells about half of the story. The other half is a bunch of issues surrounding the purchase, certification and understanding of just how bad things were. And make no mistake, the NRM is not blameless in this circus - it just managed to inherit a bad situation and then fumble with it until they sat down and figured out what had happened.

Let's take a moment to look at the AEAT report that the NRM got, then compare it to reality:

The AEAT report stated that:

"Whilst it was not possible to complete a thorough examination of the locomotive, or to witness it in steam, the condition of the locomotive has been monitored regularly as part of the VAB audit process. Taking this into consideration, it is considered that the general mechanical condition is satisfactory for continued operation, subject to effective maintenance, until the next General Overhaul in 2006. The scope of mechanical overhaul is not anticipated to be extensive but will involve strip down of the motion and axleboxes to gauge wear and remedial action. The cylinders all require re-lining and boring to nominal diameter."

The reality of the condition of the engine was far from this rather rosy portrayal given by AEAT. For starters, the engine was not properly examined, and several areas of testing were 'not possibly to be checked adequately' for a variety of reasons, including:

the locomotive was being prepared for a test run

equipment failure

4472 Flying Scotsman not being in steam

Anyone notice something off? Why exactly can the company not see how the engine is when in steam if the engine is being prepared for a test run?

Furthermore, AEAT had been the VAB (Vehicle Acceptance Body) for Flying Scotsman for 14 years by this point and finding a huge number of faults at this point very much would have raised questions about their work. More probably, the company had grown accustomed to the engine working, and simply assumed everything was satisfactory unless demonstratable to the contrary. Like the NRM admitted:

"[T]he previous owner’s VAB may not have been the best choice of inspector."

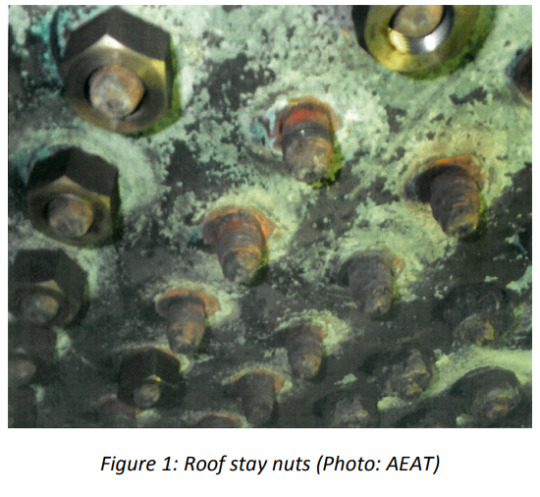

Thing is, AEAT included pictures in their report, but most of these were of the air brake compressor, locomotive air brake, tender air brake cylinders, TPWS antenna selection switch and the TPWS antenna mounting arrangements, which while critical to obtaining permission to operate on Network Rail, don't say much about the actual condition of the engine. And the photos that were of the actual mechanical parts of the engine were... telling.

The Stay Nuts in the firebox are rusting, melting and missing. And that wasn't the only major issue with the engine - several of which were extremely dangerous:

the Robinson superheater header doors had been seal welded;

other inspection doors had also been seal welded;

Repairs to defective studs on the superheater header were needed;

the smokebox door locking mechanism was broken;

the firebox stays needed caulking;

the boiler mountings and pipework in the cab was considered dangerous;

the air brake reservoirs were overdue re-certification;

two tender springs needed replacing;

Re-metalling one crosshead was needed, which resulted in having to remove the bogie, and led to the discovery that the piston rods were incorrectly fitted to the crossheads and required extensive repairs in order to make them fit properly;

Removal of the 'belly' access door in the bottom of the boiler barrel in order to remove a build-up of some 6 inches of sludge;

one of the tender wheel tyres was flat;

the air pump needed repairs;

the vital axlebox oil pads which were long overdue for replacement;

the tender handbrake just didn't work and needed repairs;

121 boiler tubes needed replacement (2004);

the boiler itself needed replacement (2006);

Foundation ring heavily corroded and cracked;

a large number of latent fractures throughout the whole of the locomotive's frame assembly;

the valves and bearings were faulty or broken;

there was a serious crack in the right-hand cylinder;

the entire firebox itself was in desperate need of replacement;

the boiler washout plugs had been fitted with domestic gas plugs;

the wheels are all in need of re-turning;

the frame hornblocks are all cracked;

one of the driving wheels was bent;

the frame stretchers were all cracked and beyond repair;

The centre-cylinder motion bracket also had cracks;

The frames were wrongly aligned;

And the frame's horn ties were scrap, and needed to be remade.

That is thirty separate issues that the NRM discovered between 2004 and 2012 restoring the Flying Scotsman. The Flying Scotsman needed such a complete overhaul to be restored that some people argued that it would cheaper to just build an entirely new engine.

A completely new version of this engine:

And remember, AEAT certified this engine to run on the mainline. The Flying Scotsman had turned into a literal moving death trap under its various owners, and I am not surprised it cost the NRM £4.2 million to rebuild Flying Scotsman.

In summary, 4472 Flying Scotsman was about as sick as an engine could get when it arrived at the NRM. The amount of work required to fix the poor engine was extensive - and some may argue unjustified. Personally, I disagree. Yes, Flying Scotsman cost a ridiculous amount of money to save and rebuild - but this is not an engine who would ever accept living on a plinth in a museum. This is an engine with a fascinating history filled with trials, tribulations and triumphs; and in my opinion the Flying Scotsman's place is on the mainline. Will there be a day when the old engine has to be withdrawn and placed in the NRM? Probably - it's the oldest mainline certified engine in the UK already, and it's not getting any younger. But by that same token, Flying Scotsman went through a massive, extensive overhaul to ensure that generations to come could see the majestic A3 doing what it always did best, and there's something truly inspiring about that.

A big thank you to the NRM for saving Flying Scotsman, and an even bigger 'what the hell?' to the people who almost destroyed it by being careless.

The pictures used in this post do not belong to me. All pictures belong to their owners. If you wish to read the NRM Flying Scotsman report yourself, this is the URL, and a hyperlink to its archived form on the Wayback Machine:

#weirdowithaquill#railways#real railway stuff#Flying Scotsman#4472 Flying Scotsman#NRM#The National Railway Museum#Flying Scotsman very nearly didn't get his happy ending#There was a lot wrong#this stuff is crazy#long reads#very long post#lner a3#wayback machine

135 notes

·

View notes