#metal alloy crisis

Explore tagged Tumblr posts

Note

Your angbang art is beautiful 💖 But I feel they are enough for each other, why add celebrimbor?

Mrr mrr🥹💗 I suppose my angbang art is a mirror for you to look at it or I dunno why you call it beautiful💋

About Celebrbrbr! (still dunno why ppl r so bothered abt it) There are several reasons:

1. The more pecs – the better sex

2. There can't be too much square-jaw brunettes

3. Mai has the natural need to seduce conditionally good guys

4. I have the natural need to scare people

5. Read my url one more time and think twice about why I love making unfuckwithable shit💅

6. Everyone deserves to be loved. In all ways. Aha😼

7. THERE'S NEVER ENOUGH FILTH I ALWAYS CAN DO MORE AND I DO

8. MelSauTyelpe trio has the hottest competitive vibe

9. That was just a spontaneous idea that I drew for fun but people liked it

10. And I liked it too

Sooo enjoy things you like💋 I hope any other stuff that is unlikable for you won't bother you too much😌

9 notes

·

View notes

Text

Well, I did it. I finally cracked and wrote for Ratchet. And an inspired fic, no less

I wanted to give one of my pieces (Kissy Times ) a way that was more open to any readers/viewers. While also having fun building around the moment itself.

I hope I was able to capture the grumpy guy's personality well enough, and I do hope you all enjoy. And it gets a bit more suggestive towards the end, just a warning

This work is 2.2k words and roughly proofread...I may have issues.

------------------------------------------------------------------------------

It’s a damn good thing the kids aren’t at base to witness this.

That’s the only thought on your mind as a metal servo slips under your shirt. The touch is gentle, hesitant even. Yet, its owner seems anything but at the moment. As mesh lips slot against yours, the faint rumble of an engine reverberates off the metal surfaces of the Autobot base. Steam slips through the seams of alloy plating, nearly unnoticeable biolights flickering beneath armor plates.

Of course, the feeling isn’t nearly as incredible as the fact of just whose servo is wandering your heated skin.

Ratchet, mass displaced, yet still towering, had cornered you off to a section of the medbay. His back turned towards the main room so he could keep you from any prying optics that did manage to sneak in. Not that he was even focused on sensing whether any of the team witnessed this moment. All his attention diverted to the melting putty of human against his frame. To which he quickly responded with a supporting servo along the nape of your neck. Taking care to not pinch any skin between the seams of his digits as he cupped it with practiced precision.

Your hands found purchase along the seams of his warm plating. One settling on his shoulder pauldron. The other, gently cupping his audial–which wiggled happily–and pulling him closer into the embrace. Soft puffs of steam warming your fingers from beneath his frame.

Internally, his scanner was pinging off repeatedly with warning signals for your current state. Easily, it picked up the shift of your breath, the uptick of your bodily temperature, and the steady increase of your heart rate as he practically stole the air from your lungs. His frame pressed flush to your trembling form and heated form. Yet, the feeling from your miniscule and weak EM field told him it was nothing to worry about.

Well, aside from the obvious–and very much annoying–human limits compared to his own alien species. Curse the universe for doing this to you.

Setting a shaking hand against his chassis, you gave a firm–yet gentle–push. It took him a moment to pick up on your silent plea, and he pulled back with a hiss of his pistons. Engine rattling unhappily at the separation. But, your comfort always came first.

Immediately, he was checking you over. A worried click of his vocalizer settling between you. “I…wasn’t too much, was I..?” His bright blue optics dimmed slightly and his finials perked. His sensors hadn’t picked up any physical discomfort, but mentality was always a fickle thing.

Maybe he read your field wrong? He contemplated, It’s not like it’s his fault it was so fragging hard to pick up on.

Struggling to even get your brain to boot back up, you didn’t even notice the fact that the bot in front of you was having a mini crisis. Scared that scrap, he broke the human. How was he supposed to explain this to the team?

You were absolutely starstruck, your brain sailing high in the clouds on the wings of pure euphoria. When was the last time you had even felt something that good? That kiss had been so far out of this world–pun intended–that your mind was having a bit of a hard time coming back out of the stars. I’m sorry, but too much? You thought silently as his words finally floated into the mush of your hazy thoughts. This man cannot be serious.

A repeated firm pat against your cheek brought you back. Crash landing your shuttle of daydreams right back down to the hard, serious surface of reality. You blinked a couple times before finally looking up at him. Him and his–very clearly–annoyed expression.

“It would be helpful if you could actually answer me, I do hope you know,” His finals twitched in slight, harmless, agitation. He wasn’t actually mad, just worried. Maybe he wasn’t always able to show it in the best way, but you had known him long enough to learn his tells.

Malleable metal creased slightly under his optical ridges in silent concern. Dimmed optics diligently scanned over your body for any sign of discomfort. Servos drifting over your skin for anything out of place. He cared through actions best, not words.

You couldn’t help the teasing tone that left your mouth, a smirk playing on your lips. “Well, then maybe you shouldn’t take my breath away so easily,” You gave the antenna of his back kibble a slight flick, drawing a stutter from his engine, before wrapping your arms up and around his helm. Messing him was child’s play.

Panic flickered across his features for just a moment. Plating hissing as it rose in stress, his digits gripping as his optics zeroed in on your chest. While generally perverted, you could tell he was checking whether your lungs had actually collapsed.

You didn’t have the heart to tell him that you probably wouldn’t be talking if they had.

“Take your breath away?!” His tone turned frantic, engine roaring loud and causing his frame to vibrate against you, “I didn’t mean to deprive you of air, oh I am a fo–”

Fortunately, his concerned ranting was cut short when he saw the amused look on your features. Suddenly, his plating drooped with a click and hiss of steam as he gave you a clearly un-amused glare in return.

“You were using one of your incredibly annoying Earth idioms, weren’t you. Need I remind you to not use those sort of phrases with a Doctor. I would feel this is obvious.”

Playfully rolling your eyes, you dragged a finger along one of his seams. Watching his finals perk slightly at the touch. He seemed to relax…albeit slightly. But hey! Slightly with Ratchet, in any capacity, was a celebration of its own!

“Loosen up Doc–” His wheels spun with displeasure at the nickname, finials flicking down, “You really need to stop thinking so much about it. Oh, and learn a bit more about human culture and phrases. They get so much worse from there.” Ratchet hearing the phrase ‘shit fire and save matches’ would probably send him into a spark-attack and a tirade you didn’t even want to imagine explaining to him…

…Although, the idea did seem quite amusing.

“And fill my processor with useless, and primitive, information? Puh-lease. I’d rather build a space bridge from scrap, than even attempt to understand you humans.” He grumbles, looking at you over. Clearly, still apprehensive about your physical wellbeing

“You still never answered my question, you know.”

He really was worried about you, wasn’t he? The old softie…

Sighing, you gently rubbed along one of his finials. His helm shifted to follow the touch as you answered, “Ratchet, that was probably the best damn kiss I’ve ever had. Too good, in fact.” You hummed, smirking at him. Mirth sparkled in your eyes. “Have any more experiences you’d like to ‘share’ with me?”

The question was supposed to be playful, a simple teasing jab at his age and probably lack of experience.

….Apparently, that was not the case.

“Not that you could handle.” He scoffed, the corners of his dermas twitching in a hidden smirk. Plates shifted as steam rolled through them. Your eyes widened like saucers at a sudden peak at his very much tucked away personality. Like a tiger eyeing its next meal through the chain-link of its enclosure.

This fucker! You thought, suddenly feeling like a kid who just watched the last of their favorite treat get swallowed up. How dare he keep sexy secrets from me.

You sent him a deadly glare, an unappealing whine slipping from your throat. “That’s not fair, Ratch!”

The servo under your shirt shifted upwards slightly, digits caressing the curve of your spine. A breathy keen replaced your quick forming tirade and you couldn’t help leaning into the touch. His expression said it all for you. The medic knew exactly what he was doing.

Then again, he was a quick learner.

“What’s the phrase again? Life’s not fair?”

Oh, how you wanted to wipe that smug look off his face. The digits dancing along your back didn’t seem to want to help your stuttering mind from its predicament.

“Nevermind, no more human phrases for you.” You grumbled, recovering quickly. Knowledge was power, and human knowledge in Ratchet’s servos was like playing with fire. His knowledge of you–your ins and outs–was like dancing through hellflame, though.

Breath suddenly hitching as he leaned in close, he gently bumped his helm against your brow bone. Taking care to shift his chevrons out of the way, lest he accidentally stab you. He moved to speak–which was probably more stupid snark from his stupid (handsome) face in that stupid (attractive) tone–and you instantly took the opportunity to jolt forward. Slotting your lips against his, stalling his engine and actually drawing a surprised whoop of his sirens. The small snort of amusement you gave was incredibly short lived, as his servo gave a gentle tug of your hair.

Your gasp, with the following undercurrent of a soft moan, gave him just enough of a chance to slip his glossa past your lips. The taste of iron and static charge sat against your tongue, and your eyes fluttered closed. Any sane person surely wouldn’t find enjoyment in such a strange mix of taste. But at this point, sane wasn’t even part of the equation. Not when you got a chance at riding with (on) the party ambulance. The grouchy, moody, but incredibly skilled and fine wine, agedly handsome party ambulance.

Imagining a younger, college age version of this bot sent blood pumping straight between your legs. Fuck, Cybertron had been lucky to witness the glory of prime-time Ratchet. Young, Fast, Energetic, and definitely a great–

The ever learning and observing medic settled his servos down along your hips now. Applying skillful and perfect pressure that pulled soft whines and moans from your mouth, and took you from your fantastical thoughts. You’d revisit those later…in the safety of your room, with the comfort of your…toys.

A quick learner who knew–and catalogued–just where to touch to mold your mind into such hazy thoughts. As if he knew just what you were thinking. Like he was silently saying to you, ‘I may not be young, but don’t think I’ve lost the energy and spunk to break your brains.’ Or something like that. Though, that may have just been your own mind saying that to you. Then again…with magic hands McGee over here, your brain even struggled to make its silent snide comments.

It clung desperately to any rationale it still held, not that any of it would last long enough. Not with eons old, intelligent as fuck, alien medic man pressed right up against you. Rumbling frame and hissing joints steadily working to clog your brain and untense your body. Biolights flashing a very alluring, tantalizing, pattern beneath the cracks of his armor plating.

Just relax. They almost spoke to you. And damnit if you didn’t want to listen. Because you really really wanted to. You’d need to ask Ratchet about that later…when thinking wasn’t so hard…let alone speaking.

It probably would help if you didn’t have metal, and shockingly soft, lips moving so expertly against yours. Glossa slipping against your lips and pushing your own tongue down. Static sparkling deliciously against the roof of your mouth. A pleasant little buzz.

Ratchet pulled back just slightly, enough to look at your blissed out expression with a soft chuckle. He hasn’t seen that sort of effect since he was back in Medical School as a charged-up, naive mech. But by the gods, he still had it. And with a human, no less.

It made his wheels spin in pure excitement.

Thinking about it, the team wouldn't be back for a couple more groons. Having gone out on a scavenging mission for energon. And the old bot had needed a break for a good while. Optimus would certainly agree…

So, just this once, he supposed he’ll take what he deserves.

Settled in his reasoning, the aged mech slid his servos under your thighs and easily lifted you right up against the metal wall. Your back sat flush against it as his grip held you securely. The show of strength only caused your face to heat up significantly. Obviously, a human was like holding a bag of grapes compared to the metal these bots flung around regularly. But fuck if it wasn’t hot seeing how effortlessly Ratchet could fling you around.

Though you wished he'd just fling you into the nearest bed, this would do fine.

Locking his lips back up against yours, his engine rumbled loudly. Vibrating his entire frame against your body and sending pleasurable sensations down to the aching between your legs that so desperately needed some touch.

His vents and fans whirred at a deafening pace as his servos found purchase along your waist. Digits sunk gently into the plush skin as he held you pinned against the wall with his hips. Your legs settled along the runners of his hip guards and you just barely registered his antenna wagging at the movement. Like some overgrown, metal puppy. How adorable.

You silently thanked the gods that the kids weren’t here to witness this.

Unfortunately, that was the last sensible thought your brain could make before Ratchet’s skillful touch dipped into your shorts. Completely shattering any rational idea from that moment on. At that moment all you could think was,

Thank you Primus for crafting this hunk of a wonderfully handsome, and incredibly skilled man. But please…just don’t let him break me.

#old man brainrot#transformers#tfp ratchet#transformers prime ratchet#transformers ratchet#ratchet transformers#ratchet x reader#x reader#transformers self insert#ratchet fanfiction#fanfic writers#writer and artist#ao3 writer#writers on tumblr#reader x character#reader x ratchet#tfp ratchet x reader

152 notes

·

View notes

Text

Assorted Media Sentences, Vol. 19

(Sentences from various pieces of media. Adjust phrasing where needed)

"Sometimes what you don't know can tell you everything."

"I'd gladly crater her skull."

"I love you. I don't have anything- I mean, I haven't got a ring or anything, but will you marry me?"

"You dismiss me at your peril."

"Actually, when you get to know me, I'm a fairly sentimental type of guy."

"The world you live in is Just a sugar-coated topping. There is another world beneath it - the real world. If you want to survive it, you better learn to pull the trigger!"

"You didn't see anything, alright?"

"I'm going to tell you something that's going to make you angry, but just know that I'm angry too."

"Everyone loses faith at some point in their life."

"To build something like that would require tools and metal alloys that aren't exactly available at Home Depot!"

"What we're dealing with here is a perfect engine. An eating machine. It's really a miracle of evolution!"

"They're not attacking your policies - they're attacking your age."

"I fell in love with you before I even met you."

"Isn't it amazing how quickly everyone can turn against you?"

"The taking of a human life is just intoxicating."

"If I get murdered in my sleep, I guess that's on you!"

"I know you think you're helping, but you're doing more harm than good."

"You haven't been to bed, have you?"

"I don't like hurting people. This world has more than enough suffering without extra contributions from me."

"We're going to have to work on our communication."

"The night, I think, is darker than we can really say."

"In case you haven't noticed, we are having a little bit of a crisis here!"

"I think I like it here. Very quaint and quiet."

"I'm going to be special. You'll see."

"I didn't know you were so easily seduced!"

"I'm just going to come out and say it; I don't trust you. I sure as hell don't want you here."

"Things have gotten out of hand. Maybe it's time we all slowed down. Took a breath."

"Don't you die on me! You hear me?"

"You've got to stay lean, mean, and full of caffeine!"

"You've gone soft. We're going to fix that, for your own benefit."

"Don't worry, he's one of us."

"Where were you when I was still kind?"

"A cold heart is a dead heart."

"Men are like dogs - they like being stroked, but for God's sake, don't let them hump your leg!"

"I don't want you to leave. It's the last thing that I want."

"I'd tread very carefully if I were you. You, of all people, should know what I am capable of."

"You don't seem to share much with your daughter."

"I bet you're a good kisser."

"You're on thin ice!"

"Is it true that most people get attacked by sharks in three feet of water, about ten feet from the beach?"

"Why do you stay?"

#rp meme#rp memes#roleplay meme#roleplay memes#rp prompts#roleplay prompts#sentence starters#assorted;#general;

44 notes

·

View notes

Text

Sun Wukong, the Monkey King: my design notes [!! click here for the full line-up !!] [click here for just the goodies on tumblr]

also titled, "I underestimated my file sizes" TAT Separate images and info below the read more, beware this is LONG <3

Stone Monkey: himbs baby, that is all <3 he's mostly based off the François Langur, but some of his anatomy and proportions lean more on the Gray Langur and Macaque side of things. His facial fur sort of forms a pentagon shape for the five elements, and I gave him ginger fur cus it's a common depiction for him but also baby langurs are very bright orange, and him not growing dark feels like an apt display of his more childish side, both good and bad. His nails are golden for a bit of a "hidden gem" from a stone egg. Also keeping the tail either in a spiral of C-curve when "engaged", and when droopy it has a feel of a heavy rope. Old World monkeys don't have prehensile tails, he can use it for balance and basic mobility but it's not a third hand for the sake of keeping his monkey-ness.

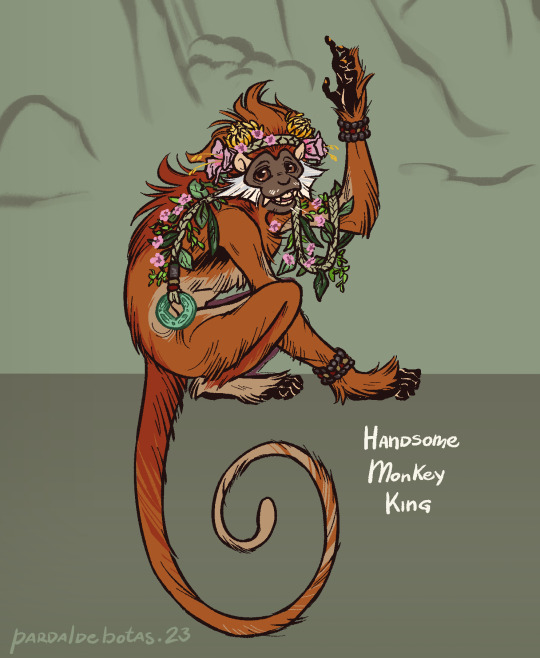

Handsome Monkey King: in one of the poems the monkeys are said to weave grass for mattresses, so I can see them coming up with a crown of woven grass and never-fading leaves and flowers for their king at the very least. His face skin is darker as an adult, but not much else changes overall. The fuzzy upper lips and sideburns are a feature of the species I'm basing him on and it felt like a good fit to add. I also love the forest langurs are so long-furred, makes for a good way to give him dimension but also, the linework style reminds me of old woodcut shorthands for fur. Added a jade coin for the symbolism, and it feels fitting that the king of such a miraculous mountain would have a treasure like that on him. Placcid chill eyes are imperative, dude's not had an existential crisis yet, he's straight up vibing.

Sun Wukong: during his odd-ten years away from home, he learned human manners so he can stand but, I can see him still needing to lean on his tail to keep up his balance here and there. As he reaches the Western Continent (India) and learns the Way under Patriarch Subodhi, he adopts proper clothes for an apprentice and eventually becomes a Rishi. He dons his facial paint from then on, and after he masters the Way, there's a brightness in his pupils to show his cultivated immortality. The beads are purple solely to stand out over the deluge of oranges that is his design.

Great Sage Equal to Heaven: really went all out on this one orz this is Wukong at his most egotistical and ambitious, and I wanted his fit to truly embody that. Took bits from Peking Opera costumes and common depiction elements of him, with some bit of extra for appropriate levels of flair, like the phoenix feather design. I wanted to go for a mountain pattern mail but I couldn't figure out how to draw it, so I winged a pattern. I,,, doubt I'll ever draw this armor as detailed as here, but I wanted it to feel a bit overwhelming to look at, while also seeming like it doesn't quite fit him perfectly like it's swallowing him. Bit of a "baby wearing their parent's shoes" kind of vibe; he's stupidly powerful but he doesn't have what it takes to sit on the throne of Heaven. Also I leaned his expression to how he might appear during the Havoc in Heaven and then his bet with the Buddha. Full unbrindled rage murder monkey <3

-- Ruyi Jingu Bang: can't quite move on without my notes on the golden-hooped cudgel, now can I? The secondary hoops are there for further design appeal and for my own visualization of how the staff changes size (the hoops move over the staff's length as if to push it outward or inward). The metal is dark damascus alloy, though the pattern can be omitted for ease of drawing. One hoop end depicts a dragon, the other a phoenix, and in the middle of the staff is the canon inscription as described in the books, in seal script. Glow is optional and mostly for aesthetics.

Sun Pilgrim: out of his stolen armor, Wukong seems to swim in his robes but in a less overwhelming way. Went for the simple fillet headband cus his face is busy enough as it is. I know he's skilled enough to skin a tiger into pretty decent squares, but after one too many battles, anything would get tattered. He wears red, teal, black and yellow, four of the five cardinal colors, while white (the West) is still missing. His red and black half-robe doesn't fully cover the yellow underneath, a call back to his golden armor; he tries to use his wisdom and teachings to fight back the impulses of his past, but they still shine through at times. I kept only the leg bangs for dynamic elements to better show movement, but also one could say he's got.... golden hoops (haha get it, like his cudgel?? :oD)

Victorious Fighting Buddha: leaned hard on the actual portrayals of the Buddha. Seeing that he's depicted with dark/blue skin, it felt appropriate to let the guy grow out of his baby ginger fur and into adult black, but a patch remains where the golden headband used to be. I didn't want to give him long hair so no bun, but instead, his fur has a sorta lotus-petals shape now rather than his single point. His face paint changes into a more domino-mask style, and his brow white line resembles a teardrop urna. I made the mail piece he holds longer to keep the flowy bits of his previous outfits, and I turned Ruyi Jingu Bang into the sword he wields.

Hello hi, this robbed me of three days of my life and I'd like to receive compensation x.x Anyway hope you enjoy this lad, I know I do! Also if you wanna send me asks about him pls feel welcome to, I'd love to chat about this bastard monkey (affectionate) (loving) (i`d die for him)

#jttw#journey to the west#xiyouji#jttw sun wukong#sun wukong#jttw fanart#monkey king#stone monkey#victorious fighting buddha#buddha victorious in strife#sun pilgrim#bell dragon art#expedition to the west au

330 notes

·

View notes

Text

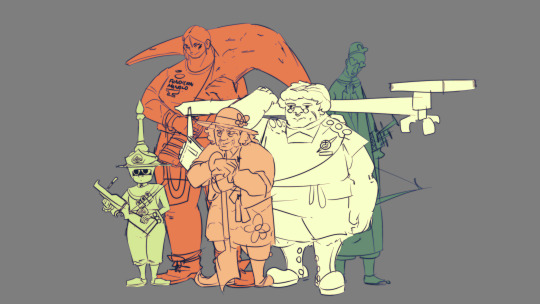

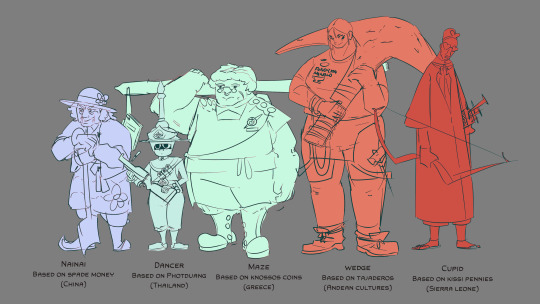

Here's a 5-person squad for hire we designed on stream today. Each one is based on an ancient currency or commodity money. I'm thinking of calling their group the Lucky Pennies. Quick blurbs on their personalities and skills below.

Nainai - Leader of the group. She's an old woman who was the groundskeeper for a large estate for many years and learned how to fight using her shovel. On her 70th birthday, she had a crisis and became desperate to die with as much money as possible and bribe her way to the afterlife. To this end, she quit her job as a groundskeeper to earn money as an adventurer, using the tactics she observed from bandits as a groundskeeper. This has had mixed results, but she's happy-go-lucky and never lets setbacks get her down for long. She can swap out the head of her shovel for a group of blunt metal parts resembling Knife Money to use it as a flail. She also keeps a flying bi xie jian (coin sword) as a last resort weapon or escape method.

Dancer - Second in command, and a voice of reason to Nainai's more reckless ideas. She was from a rich family that encouraged her to train in traditional arts, including dancing. However, she was more interested in explosives, and eventually was able to gather enough resources to depart from her family and set up a workshop. During an incident with her explosives workshop, she met Nainai, who helped her sort out the consequences. The workshop was destroyed during the incident, so Dancer asked to join Nainai's group. Dancer's the youngest in the group, being in her mid 20's, but due to her height, baby face, and how she clings to Nainai, most people assume she's younger than she actually is. She was the first person to join Nainai's group, and Nainai trusts her completely. She studied a lot of military history while she was still with her family, so the other members of the team respect her tactical capabilities.

Maze - Accountant. He was recruited by Nainai because she wasn't used to tracking cash for an adventuring party. Maze had a lot of experience with this, being in his early 40's and having a decade and a half of adventuring under his belt. When he started adventuring, he joined a group as a porter, and - because his other team members found it was a pain to balance their books - sort of fell into the role of their accountant. Since then, Maze adventured with and served as the accountant for many other groups before joining the Lucky Pennies. The badge on his chest, featuring a labyrinth design, is from a famous bank that recognized his accreditation as an accountant. His last group accused him of embezzlement. After it was exposed the leader was the one appropriating the funds, he quit the group and accepted Nainai's offer to join the Pennies. He has a severe hunch due to his poor posture when he was a porter and from poring over books. He fights using a large lever that can serve as a scale, and he uses his hunch as the fulcrum. If both Nainai and Dancer are out of commission, he's counted on to lead the team. He was recruited around the same time as Wedge joined, so they also get along.

Wedge - The muscle. A massive Ecuadorian woman in her 30's that Nainai recruited into the Pennies from a small fighting tournament. Her family are metalworkers and blacksmiths, a company called Fundacion Manolo. Wedge loved the forge, but she realized she didn't have the same talent for metalwork as her siblings. Her body, however, was much stronger than theirs, and so she decided to support her forge by travelling and advertising it as a prizefighter. The monstrous-looking maul she carries around is made out of a copper alloy. Whenever she beats up someone with copper possessions, she takes their metal, melts it down, and adds it to the mass. She's also counted on by the other members in the Lucky Pennies to do maintenance on their equipment, and Maze occasionally consults her to assess the purity of gold they find in their travels. Cupid also asks her to help repair his iron rods. She's a romantic and is secretly hoping she can meet a lover on her journey.

Cupid - Smooth-talker. Like Dancer and Wedge, he asked to join Nainai's group. Cupid's from a family of sorcerers that uses Kissi Pennies - iron rods twisted in a specific shape - as a magical focus. He had a good head for money and sorcery, and was able to gather a lot of rods - because of this, unlike most of his family which uses them as wands, he "fires" them like arrows from a bow. The iron rod snaps, and the intended effect flies in its place. While this is useful, his true talents are in his ability to relate to others and speaking skills. Nainai and the others count on him to find information about bounties and opportunities, and to barter with their employers and suppliers. He's the most recent person to join the Pennies. He elected to join the Pennies on the advice of one of his business partners. While he had his doubts, he soon realized he felt at home with them and decided to follow them faithfully. He particularly enjoys chatting with Nainai, whose optimism he finds infectious. He's finds reforging the arrows tedious since it requires a special ritual developed by his family, so he tries to conserve them as much as possible.

14 notes

·

View notes

Note

I heard in the canteen that the humans once used a few antique combustion engines to start one of their portable stars. Any truth to the rumor?

Ah jeez, that was one hell of a day for that guy.

Yes and no. Where do I even being...

Okay. So this place up in Greenland called, uh... I'm gonna butcher this so bad, Hjeilhornhentrotnenheim, has an engineering museum, right? Right, and the guy in charge, his name is, ah fuck this is gonna be bad too ..., Hansinguaq Bjerresvontsgaardsen (I'm just gonna call him Hans from now on because uh yeah, no), collects all the things not fit for display in his personal transport ship. He's essentially converted it into his private mobile museum.

Not long after we established diplomatic channels and preliminary trade routes, Hans eagerly went off on his own to visit Alien equivalents to museums and such. Spent a solid three weeks traveling, sight-seeing, and adding things to his collection.

During a stop on the outer reaches of Coalition space his computer blue screened and forcibly shut down the reactor and pretty much wiped his communication array address book among other less relevant components. And no, I have no clue why he went so far out. He's 46, midlife crisis is my guess, telling him to go out on daring adventures or whatever. Anyway, he couldn't restart the fusion reactor while the inhibitor rod chambers were open, they open and shoot out the star canceler in an emergency shutdown, but one was stuck with the rod half-way in, so Hans had to manually open the reactor and fix it by hand.

Problem is, his transport ship, the Veritable Greenhorn, is fairly big, and the reactor's outer diameter was about 37 meters. Even in zero-g that's a lot of mass for one person to move, not to mention how much force you'd need to pry out a hyper dense metal alloy rod from a gate meant to withstand the pressure of a star right next to it. But he did have a lot mechanical power at his disposal, it just needed to be... rearranged.

Now, he did have backup generators that quietly hum in the background like on every Human vessel, but these are passive and nowhere near enough to charge the hyperdrive even if he could tell it where to go, let alone power machinery to counter a thousand ton jammed deadbolt. He needed something that had a kick to it, something you could really rev beyond its limits just long enough. He needed his V6s and V8s.

After almost two days of DIY engineering details I won't bore you with because I fell asleep when he explained them himself, Hans fired up the engines. It was a very tedious five hours of the engines rythmically tugging the deadbolt a tenth of a milimeter open and what is basically a massive jackhammer pummeling the rod back in. At one point he ran out of gas and was forced to sacrifice his alcohol collection.

Suffice to say it barely worked, all of the machinery he cobbled together became practically unusable, but it worked and he was able to restart the fusion reactor.

Oh, he didn't come home or anything by the way. Like I guess, midlife crisis. If anything, success has made him think nothing can get in the way of his Galactic exploration quest.

So that's the story. No, he didn't use combustion engines to start the reactor or anything, but lacking any other means to fix a problem I honestly didn't know could happen, the petrol guzzlers gave him the right kind of horsepower.

By the way, if you get a chance to tour the Veritable Greenhorn, I'd recommend it. I can't even begin to describe how that contraption looks, it's one of the main displays. I guarantee it's the most specific purpose built and rough pieces of Human engineering you will ever see.

#humans are space orcs#humans are space australians#humans are space oddities#humans are deathworlders#humanity fuck yeah#carionto#story#scifi

117 notes

·

View notes

Text

I honestly think Geoffrey is a nerd by birth and is only a jock by circumstance:

The vampire panic room at the Pembroke. I know it's not canon that he had any involvement in its development but like... come on. He knows exactly how it works. Maybe you could argue that he beat the info out of Edgar in the time before Jonathan got to the hospital, but why would he have bothered asking about the technical specs and not just basic operation instructions? At the very least, at some point he had a very in depth conversation with Edgar about all the details -- but I maintain that the only way he could be so familiar with that room is if he helped design and build it

He says that the room functions via "ultraviolet curtains and Orichalum powder," the latter of which is either a fictitious metal referenced ancient stories or an ancient but real metal alloy, or is just a magical substance in a lot of fantasy / fiction. Either way its existence isn't exactly common knowledge, and considering Geoffrey has initial confidence that it'll work, I think that indicates that he's more than passingly familiar with it.

He does however immediately drop the "so much for modern technology" line the minute the room stops working and then resorts to 1v1ing Jonathan ("the tried and true") so again... he's a jock by necessity, but his first inclination is still to try the nerd way.

His interest in new technology and methodology is reflected in his writing too: "We can learn many things from the war in France: new strategy, new equipment, and new weaponry. Grenades, white phosphorus, ultraviolet light, bulletproof vests, and flamethrowers: it is time for the Guard to embrace the twentieth century."

Also in line with the first point: he's on friendly enough terms with Edgar to joke about giving him a head start if he ever turned, and clearly feels comfortable enough to show up in his office to talk about the current state of London. Even if their relationship and background is purely headcanon, that vaguely hinted alliance alone is a huge departure from how Geoffrey's predecessors talk about the Brotherhood. The schism between the groups is something both sides still reference with each thinking the other is stupid, and yet Geoffrey seeks Edgar out in a time of crisis -- in addition to whatever background the two of them might have. Geoffrey clearly sees value in the Brotherhood's knowledge and doesn't dismiss it as dangerous or useless like everyone else in Priwen seems to.

Again, much like with the anti vampire room, he does later shit on the Brotherhood and calls them cowards. Unfortunately life just keeps proving to him that knowledge can't compete with simply hitting things until they stop moving <3

The way he talks is also just very nerd coded to me. I don't necessarily think that language correlates with intelligence, but the game lets other working class characters speak in a way that Geoffrey really. Doesn't. "I've a good nose for machinations" and "you've set the table for a snake and wonder why there's venom in your food" and "it's within me to take your words as truth" are almost annoyingly verbose lines for a character that everyone else views as a brute force dumbass. I think it gives him a very guy who reads a lot and therefore has great vocabulary energy.

#𝕳𝖊𝖆𝖉𝖈𝖆𝖓𝖔𝖓#geoffrey is fascinating to me because the game / other characters position him as the big brutal one track minded idiot#in opposition to the smart and enlightened protagonist#and yet so much of what he says and does runs counter to that#even the fact that he has ample opportunity to attack jonathan before the big fight and just. doesn't. geoffrey is Smart#he's cunning and observant and is perhaps willing to give jon and edgar the benefit of the doubt in spite of what he says#but that's another post#also on a purely hc note i think he was academically inclined as a kid. liked school and did well in it#and if socioeconomic and supernatural circumstances were different probably would have done something science/tech related w his life#maybe not the medical doctor route but idk. maybe a chemist or something#(which i think also adds another foil layer to him and jon bc jon's status and upbringing allowed him to pursue the path geoffrey couldn't)#(basically geoffrey was robbed of his nerdhood that's all thanks)

7 notes

·

View notes

Text

Learning to Smelt - 3

Here's the final part before I start doing smelting on stream! Basically at this point after these three different melts I understand enough about what to do/not do that I will be able to have everything ready to go without additional support! This melt had a similar goal to the previous one, but was meant to correct the mistakes previously made to get a better metal colour and casting quality. Here's the TLDR of what went down:

Now the details!

Instead of trying to make the channel logo like before, this time I put together a medallion based on the Chronos Hourglass Obol in the game Hades 2. Since the symbol is less intricate than the broken ouroboros logo, I figured it'd be less likely to catch sand in the grooves (which y'know can make the result look less like what you've made, I'm still trying to find a workaround to that particular issue).

ALRIGHTY

Forge lighting was the same, sand compacting was the same (except I used a 7:3 Sand:Clay ratio (next time it will be a 6:4)) and alloy composition was the same. The Copper was loaded into the crucible at the beginning, while the aluminium was rested on top to warm up so it wasn't dropping in at room temp.

There's a very important reason to do this! If you don't have a flux that works (like I foolishly didn't have) then you're gonna have a problem with the aluminium. Weird Al tends to oxidize pretty quickly and Weird Al Oxide has a similar density to Normal Weird Al. So not only are you gonna need to scoop out a lot of Weird Al Oxide, but also it tends to just float within the Weird Al fluid, so it'll be harder to ensure there are no impurties in your Solid Weird Al once poured.

In the case of Weird Al bronze, if you have liquid Copper already in the crucible, then dropping the aluminium in there will immediately have it melt/dissapear below the surface and won't have a chance to oxidize.

Putting the casting flask together of course took forever as is the norm. Once it was time though, the video above took place (please PLEASE see the video above).

You'll notice around the halfway point, my uncle saying to "Keep going" as I was strangely alarmed by the flask bursting into flames in front of me. Not so! Although you can't see it I was actually alarmed by the liquid metal bursting out of the seam in the flask right towards me and to the side (you can see a bit of it come out the side around the same almost halfway point of the vid). So that was me backing up to save my crotch.

Crisis averted!

It is fun however watching the metal splat against the ground/table, it looks very cool!

Of course this is collected and used in the next melt, otherwise I shall be derided and pariah'd as a wasteful buffoon.

The casting flask got pretty badly scorched this time. Although it shouldn't really impact it too bad, as long as it can still hold sand.

That being said though, I probably wouldn't use this one in the future. Although the clasps are a neat idea, the heat/pressure on the inside always seems to pop em open so holding it together with something that can't be easily opened by people will probably work better in the future.

Still, I'm happy with the end result of this one! Has a cool, ancient look to it. The Chronos side came out pretty good, although the Hades side seems to be the one that took the brunt of the explosion.

How fitting!

Next time this is done, it'll be on stream once I get the last camera extension thing I need. It'll be a repeated attempt at this design using a new flask/sand composition but once that's out of the way, I'll be trying a lot of ways to make the design smoother/easier!

2 notes

·

View notes

Text

Automotive Piston Market- Opportunity Analysis & Industry Forecast, 2024–2030

Automotive Piston Market Overview:

Request Sample Report :

Advanced manufacturing techniques, including additive manufacturing (3D printing) and precision machining, are increasingly shaping the automotive piston market. These technologies enable the production of complex piston designs with high precision and customization. Manufacturers are leveraging these capabilities to streamline production processes, reduce lead times, and enhance overall product quality. This trend underscores the industry’s drive towards innovation and efficiency in manufacturing operations. These factors positively influence the Automotive Piston industry outlook during the forecast period.

COVID-19 / Ukraine Crisis — Impact Analysis:

The COVID-19 pandemic disrupted global supply chains, leading to production halts and reduced vehicle sales, impacting the automotive piston market negatively. Manufacturers faced material shortages and logistic challenges, delaying production schedules and increasing costs. However, recovery efforts and pent-up demand are driving a gradual rebound, with a renewed focus on resilient supply chains and adaptive manufacturing strategies.

The Ukraine Crisis has affected global commodity prices and supply chains critical to automotive piston manufacturing. Escalating raw material costs, particularly metals and energy resources, are squeezing profit margins for piston producers. Moreover, uncertainty in trade policies and supply disruptions are prompting manufacturers to seek alternative sourcing strategies and stabilize operations amidst market volatility.

Inquiry Before Buying :

Key Takeaways:

Fastest Growth of North America Region

Geographically, in the Automotive Piston Market share, North America is analyzed to grow with the highest CAGR of 4.3% during the forecast period 2024–2030. Innovations in piston design to enhance fuel efficiency and reduce emissions are significant drivers. Moreover, stringent environmental regulations push manufacturers to develop lightweight and durable pistons. Technological advancements in materials, such as high-strength alloys and coatings, also play a crucial role in meeting performance standards. Additionally, the region’s robust automotive manufacturing base fosters steady demand for pistons across various vehicle segments.

Piston Pins Segment to Register the Fastest Growth

In the Automotive Piston Market analysis, the Piston Pins segment is estimated to grow with the highest CAGR of 5.8% during the forecast period. Piston pins play a crucial role in the automotive piston market. These components act as a pivot point between the piston and connecting rod, ensuring smooth reciprocating motion within the engine. They are typically made from high-strength materials like carburized steel to withstand high temperatures and pressures. Advanced designs focus on reducing friction and weight, contributing to improved engine efficiency and performance. Continuous innovations aim to enhance durability and optimize engine operation, reflecting ongoing advancements in automotive piston technology.

Schedule A Call :

Thermal Barrier Piston Coatings are Leading the Market

According to the Automotive Piston Market forecast, the Thermal Barrier Piston Coating held the largest market valuation in 2023. Thermal Barrier Piston Coatings enhance engine efficiency by reducing heat transfer from the combustion chamber to the piston. These coatings, often ceramic-based, improve durability, fuel efficiency, and overall performance by maintaining lower piston temperatures. This technology mitigates thermal stress on pistons, extending their lifespan and contributing to cleaner combustion. As automotive manufacturers pursue stricter emissions standards and higher engine efficiency, the demand for thermal barrier coatings is expected to grow, driving innovation and adoption in the automotive piston market.

Increasing vehicle production boosts demand for automotive pistons

According to data released by the Japan Automobile Manufacturers Association (JAMA) in 2023, China exported 5.22 million vehicles, marking a 57% year-on-year increase, with one-third being fully electric. As automotive manufacturers expand their production capacities to meet rising consumer demand, there is a corresponding increase in the requirement for pistons. This trend is driven by the growing middle-class population, particularly in emerging markets, and the shift towards electric vehicles, which still require pistons in combustion engines used in hybrids and internal combustion engine models. Consequently, piston manufacturers are poised to benefit from this surge in global vehicle production.

Increasing sales of passenger cars and commercial vehicles

The rising sales of passenger cars and commercial vehicles are key drivers in the automotive pistons market. This growth is fueled by increasing urbanization, enhanced road infrastructure, and rising disposable incomes. According to the China Association of Automobile Manufacturers, Chinese-brand passenger vehicle sales increased by 24.1% in 2023, reaching 14.6 million units and capturing a 56% market share. The sales of new energy vehicles among domestic brands represented 49.9% of the market. As demand for efficient and high-performance vehicles grows, manufacturers are focusing on innovative piston technologies to meet stringent emission norms and improve engine efficiency.

Buy Now :

Increasing demand for eco-friendly and sustainable piston materials

These include developing materials that balance environmental benefits with performance standards, ensuring cost-effectiveness in manufacturing processes, and overcoming technological hurdles in scaling production. Additionally, there is a need for stringent regulatory compliance and consumer acceptance of new materials. Addressing these challenges requires significant research and development efforts to innovate while maintaining reliability and efficiency in automotive engines.

For More Details on This Report — Request for Sample

Key Market Players:

Product/Service launches, approvals, patents and events, acquisitions, partnerships, and collaborations are key strategies adopted by players in Automotive Piston Market.

About IndustryARC™: IndustryARC primarily focuses on Cutting Edge Technologies and Newer Applications of the Market. Our Custom Research Services are designed to provide insights on the constant flux in the global demand-supply gap of markets. Our strong analyst team enables us to meet the client research needs at a very quick speed with a variety of options for your business. We look forward to support the client to be able to better address customer needs; stay ahead in the market; become the top competitor and get real-time recommendations on business strategies and deals. 𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:https://tinyurl.com/rf9dx8vf 𝐖𝐞𝐛𝐬𝐢𝐭𝐞: https://tinyurl.com/54fn9cn8

#AutomotiveIndustry#PistonTechnology#EnginePerformance#AutomotiveParts#EngineComponents#AutomotiveEngineering#SustainableMobility

0 notes

Text

Endodoncia Los Angeles

Comprehensive Dental Care in Los Angeles: Your Guide to Expert Treatments

Maintaining oral health is crucial for overall well-being, and finding a reliable dentista in Los Angeles can help you ensure your teeth and gums stay healthy for years. Whether you’re seeking routine checkups or need urgent dental care, Clinica Dental Cristian Lagos is committed to providing high-quality services, from endodoncia to ortodoncia. In this article, we’ll explore a variety of treatments available at our clinic, including urgencia dental Los Angeles, coronas dentales, and much more.

Why Choose Clinica Dental Cristian Lagos?

At Clinica Dental Cristian Lagos, we understand that dental care is a highly personalized service. Each patient has unique needs, which is why we offer a wide range of treatments to address everything from preventive care to complex procedures. Whether you’re dealing with a dental emergency or looking to enhance your smile, our team of expert dentistas in Los Angeles is here to help.

We provide a warm and welcoming environment where your comfort is our priority. Our highly skilled professionals use the latest technology to ensure that every treatment is effective, efficient, and as comfortable as possible.

Endodoncia: Saving Your Teeth with Root Canal Treatment

One of the most common and essential treatments offered at our clinic is endodoncia (root canal therapy). Endodoncia is necessary when the pulp inside a tooth becomes infected or inflamed due to deep decay or injury. Without treatment, the infection can spread, leading to further complications like tooth abscesses or even tooth loss.

Root canal therapy involves removing the infected pulp, cleaning the inside of the tooth, and sealing it to prevent future infection. Despite the misconception that endodoncia is painful, modern techniques and local anesthesia make the procedure much more comfortable than many people realize.

If you’re experiencing severe tooth pain, sensitivity to temperature, or swelling in the gums, it might be time to see a dentista for endodoncia. At Clinica Dental Cristian Lagos, our experienced team uses the latest technology to perform root canals efficiently, helping to save your natural tooth and restore your smile.

Urgencia Dental Los Angeles: Immediate Help When You Need It Most

Dental emergencies can strike at any time, and knowing where to turn in case of a dental crisis can make all the difference. Whether you’re dealing with a knocked-out tooth, severe toothache, or a broken crown, urgencia dental Los Angeles provides immediate attention to prevent further damage and alleviate pain.

At Clinica Dental Cristian Lagos, we understand that dental emergencies are stressful and often require swift action. That’s why we offer urgencia dental Los Angeles services to ensure that you can receive the care you need as quickly as possible. If you experience a dental emergency, don’t hesitate to contact us—we’ll do our best to get you in as soon as possible for treatment.

Coronas Dentales: Restoring Function and Aesthetics

If you’ve experienced tooth damage due to decay, wear, or injury, a corona dental (dental crown) can help restore both the function and appearance of your teeth. Crowns are used to cover and protect damaged teeth, and they can also be used after endodoncia to provide added stability to the tooth.

Dental crowns are made from a variety of materials, including porcelain, ceramic, and metal alloys. The material selected will depend on the location of the tooth and aesthetic preferences. Porcelain crowns, for example, are often used for front teeth because they blend seamlessly with the natural tooth color, while metal crowns are more commonly used for back teeth due to their strength and durability.

At Clinica Dental Cristian Lagos, we offer high-quality coronas dentales to ensure that your teeth not only function properly but also look natural and beautiful. Our team works with you to find the best solution to meet your needs and budget, providing you with a restored smile that lasts.

Ortodoncia: Achieve a Straighter, Healthier Smile

Orthodontics, or ortodoncia, is a branch of dentistry that focuses on correcting misaligned teeth and jaws. Whether you're dealing with crowded teeth, gaps, or bite issues, ortodoncia can help you achieve a healthier, more functional smile.

At Clinica Dental Cristian Lagos, we offer various orthodontic treatments, including traditional metal braces, ceramic braces, and Invisalign clear aligners. Our team of dentistas Los Angeles will work closely with you to assess your needs and develop a personalized treatment plan that addresses your specific concerns.

Orthodontic treatment not only improves the appearance of your smile but also helps with oral health. Properly aligned teeth are easier to clean, reducing the risk of cavities, gum disease, and other dental problems. Moreover, ortodoncia can correct bite issues that may cause problems with chewing, speaking, and overall dental health.

Why Regular Dental Visits are Important

Routine dental checkups are essential for maintaining good oral health and preventing the need for extensive treatments like endodoncia or coronas dentales. During regular visits to Clinica Dental Cristian Lagos, our team will thoroughly clean your teeth, check for signs of tooth decay, gum disease, or any other potential issues, and provide recommendations for at-home care.

By staying on top of your dental health with regular visits, you can prevent problems before they arise, saving time, money, and discomfort in the long run. Our team will ensure that your visits are stress-free and informative, allowing you to feel confident about your dental care.

Comprehensive Dental Services at Clinica Dental Cristian Lagos

At Clinica Dental Cristian Lagos, we offer a full spectrum of dental services, including:

Preventive Care: Regular checkups, cleanings, and exams to keep your teeth healthy.

Restorative Treatments: Endodoncia, coronas dentales, fillings, and more to restore damaged teeth.

Orthodontic Treatments: Ortodoncia options like braces and Invisalign to straighten teeth and correct bite issues.

Cosmetic Dentistry: Teeth whitening, veneers, and smile makeovers to enhance the appearance of your smile.

Emergency Care: Urgencia dental Los Angeles services to handle dental emergencies promptly.

Our clinic is equipped with the latest dental technology, allowing us to provide the best possible care with minimal discomfort. Whether you need emergency treatment or are looking to improve your smile, we are here to help.

Schedule Your Appointment Today

If you’re looking for expert dental care in Los Angeles, don’t wait! Whether you’re experiencing a dental emergency, need endodoncia, or want to explore ortodoncia options, Clinica Dental Cristian Lagos is here to provide the care you deserve.

Visit our website or call us today to schedule an appointment with our experienced team. We look forward to helping you achieve and maintain a beautiful, healthy smile!

Contact Info:-

Clínica dental Cristian Lagos

Libertad 760,Los Ángeles, Bío Bío, Chile

56942069847

0 notes

Text

Global composite Metal Finishing Market — Forecast(2024–2030)

Duplex Stainless teel Market Overview

The Duplex Stainless Steel market size is estimated to reach US$5.46 billion by 2030 and is growing at a CAGR of around 4.4% from 2024 to 2030. Duplex stainless-steel belonging to the stainless-steel family is a combination of two of the main alloy types, i.e. austenite and ferrite, with a 50/50 mix of both. Due to their excellent properties like stress-corrosion resistance, tensile strength, and yield strengths, these duplex stainless steels are better than other grades of stainless steel. Duplex stainless-steel market finds application in oil and gas industries, pulp and paper industry, chemical industry, and others. There are many upcoming huge oil and gas construction projects in the oil and gas industry which will include pipeline, valves, tubings, exploratory good constructions and will drive the market. This is because duplex stainless steel provides better corrosion resistance and durability than carbon steel and other stainless steel and thus will be in more demand. Additionally, upcoming bridge construction projects will also drive duplex stainless-steel industry in the forecast period.

Request Sample

Market Snapshot:

Duplex stainless steel, known for its excellent corrosion resistance and high strength, is increasingly being utilized in the construction of renewable energy infrastructure. This trend is driven by the expansion of wind farms and tidal energy projects, where components such as turbine support structures, foundations, and subsea equipment require materials capable of withstanding harsh environments. Duplex stainless steel’s superior corrosion resistance and durability make it an ideal choice for such applications, offering extended service life and reduced maintenance requirements. As the demand for renewable energy continues to grow, the use of duplex stainless steel in these sectors is expected to increase, driving innovation and further advancements in material technology to meet the specific challenges of renewable energy infrastructure.

Rising demand for duplex stainless steel by the building and construction industry owing to the rising urbanization and growth in construction activities, especially in the developing economies, will further accelerate the market growth rate. Rising industrialization will also directly and positively impact the demand for duplex stainless-steel globally. However, fluctuations in the prices of raw materials will pose a significant challenge to the growth of the duplex stainless-steel market. Duplex stainless steel can only be used at limited temperatures, and this will further hamper the duplex stainless steel market growth rate.

Inquiry Before Buying

COVID-19 Impact

The COVID-19 pandemic has negatively impacted the duplex stainless-steel market. This is because due to the pandemic, the oil and gas industry is one of the worst-hit industries during COVID-19. Several global pipeline projects witnessed delays due to imposed lockdown restrictions in major countries like the United States, India, and others. According to a report by International Energy Agency (IEA), the oil demand in April 2020 declined by 25% and natural gas demand by around 4% which would constitute one of the largest contractions in the energy industry. Due to this, many oil and gas companies got negatively impacted. For instance, Prime Exploration & Production Limited (PEPL), Nigerian based Oil and Gas Company’s total capital expenditure in 2020 fell by 41% as compared to 2019.

This reduction included the halt of infilling and drilling activities related to Preowei oil field development project due to the covid 19 crisis. Due to such oil and gas project halt during covid, which involves halt in projects of the pipeline, exploratory wells, there was less demand for ferrous alloys like duplex stainless steel which negatively impacted the duplex stainless-steel market. However, market has been positively impacted post Covid-19 with a recovery being witnessed in 2022–2024 period despite economic slowdown

But the news post COVID is good. Growth rate of the duplex stainless-steel market went from -6.3% in 2020 to around 4.1% in 2023 due the receding pandemic. The markets have started to recover, countries such as China, India and Japan resume their rapid industrialization, leading to the resurgence to the duplex stainless-steel market.

Buy Now

Report Coverage

The report: “Duplex Stainless-Steel Market– Forecast (2024–2030)” by IndustryARC covers an in-depth analysis of the following segments of the Duplex stainless-steel industry.

By Product Type: Lean Duplex Stainless Steel, Duplex Stainless Steel, Super Duplex Stainless Steel.

By End-Use Industry: Oil And Gas Industry (Piping and Tubing, Exploratory wells, Heat exchangers, Others), Chemical Processing Industry (Storage Pressure Vessels, Tanks, Piping, Others), Pulp and Paper Industry (Bleaching Equipment, Digesters, Stock-Handling Systems, And Others), Construction Industry, Desalination Industry, And Others.

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia, and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Middle East (Saudi Arabia, UAE, Israel, Rest of the Middle East) and Africa (South Africa, Nigeria, Rest of Africa).

Key Takeaways

The growth of oil and gas industry projects in the Asia-Pacific region will drive the market. This is because there will be a demand for high-grade ferrous alloys like duplex stainless steel to be used in pipelines, tubings, exploratory wells, and others which will drive the decorative laminates market.

The increasing growth of bridge construction projects which require highly durable steel materials like duplex stainless steel will drive the demand of the market.

The growth of super duplex stainless steel due to an increase in pipeline and other oil and gas construction will drive the duplex stainless-steel market.

About IndustryARC™: IndustryARC primarily focuses on Cutting Edge Technologies and Newer Applications of the Market. Our Custom Research Services are designed to provide insights on the constant flux in the global demand-supply gap of markets. Our strong analyst team enables us to meet the client research needs at a very quick speed with a variety of options for your business. We look forward to support the client to be able to better address customer needs; stay ahead in the market; become the top competitor and get real-time recommendations on business strategies and deals. Contact Us: https://tinyurl.com/yk8khvpa Website URL: https://www.industryarc.com/

0 notes

Text

Alloy Tubes Manufacturer Things to Know Before You Buy

WE'VE GOT THE CAPABILITY TO MAKE WELDED OR ALLOY TUBING IN SQ., RECTANGULAR, FLAT SIDED OVAL, ELLIPTICAL AND A NUMBER OF OTHER CUSTOM MADE STYLES IN A NUMBER OF MATERIALS. CORROSION RESISTANCE: MANUFACTURER OF STAINLESS STEEL TUBES AND PIPES IS NATURALLY RESISTANT TO SEVERAL SORTS OF CORROSION ON ACCOUNT OF ITS TRICKY, OXIDIZED OUTER LAYER. AS IT IS PRODUCED FROM VARIOUS UNIQUE ALLOYS, IT COULD POSSIBLY ARISE TO TOUGH AILMENTS. POWERFUL NEED FOR ALLOY TUBING SIGNIFIES THAT THESE MANUFACTURERS MAY WELL NEED TO HAVE TO INVEST IN NEW PRODUCTS AND SERVICES TO HELP KEEP UP WITH DESIRE AND TURN THIS TREND INTO A POSSIBILITY FOR EXPANSION. A BIG PRESENCE IN THE FACILITY GENERATION FIELD IN THE MANUFACTURING AND EXPORTER OF SEAMLESS TUBES SUPPLIES A TRUSTED AND DEPENDABLE MERCHANDISE THAT WILL FACE UP TO ESSENTIALLY THE MOST DEMANDING APPS. FOR QUALITY THREADS OF THE HIGHEST INTERCONTINENTAL STANDARDS, FOR EXAMPLE API OR GOST, WE FEATURE OUR TCG THREAD CUTTING DEVICE AND RMG COUPLING THREADING EQUIPMENT INSIDE OUR PRODUCTS ASSORTMENT. OUR MACHINES PROVIDE HIGH-HIGH-QUALITY FINISHED MERCHANDISE – HOWEVER, TYPICAL CHECKS ARE INDISPENSABLE TO GUARANTEE THE PROPER EXCELLENT OF CUT THREADS. THUS, WE OFFER AN AUTONOMOUS OPTICAL INLINE MEASUREMENT PROCEDURE FOR ANALYZING THREADS AND SEALING LIPS ON OCTG TUBES. OFFERED OUR EXTENSIVE INVENTORY OF MATERIALS, AND EACH DAY PROFITS QUANTITY OF IN EXCESS OF 100 TONES, WE WOULD GIVE YOU THE TOP COSTS, EVEN REDUCE THE DIRECT MANUFACTURING UNIT RATES. THE ROTARY EXPANDER CAN BE A EXCLUSIVE FORM OF CROSS-ROLLING MILL WITH CONICAL, AXIALLY ADJUSTABLE ROLLS. THE NICKEL ALLOY TUBES ARE EXPANDED MANUFACTURER OF STAINLESS STEEL TUBES AND PIPES BY ROLLING THEM IN EXCESS OF A PLUG. COLD DRAWN STAINLESS STEEL SEAMLESS TUBE ORDINARILY INCORPORATES A SHINIER GLIMPSE WITHOUT WELD LINES INCREASING THE AESTHETICS WITH THE SOLUTIONS DURING WHICH IT'S INCLUDED. THE CERAMIC COATING CHARACTERISTICS MINIMAL THERMAL CONDUCTIVITY PLUS INTENSE HARDNESS. IT FUNCTIONS LIKE A HEAT AND HAVE ON DEFENSE SHIELD AND FOR A PASSIVE SEPARATING LAYER THAT SUBSTANTIALLY EXTENDS THE PROVIDER LIFE OF THE PIERCER PLUGS, LEADING TO DECREASED TOOLING PRICES AND ENHANCED PRODUCTIVITY OF YOUR RESPECTIVE PLANT. THROUGH ITS PENNSYLVANIA PRODUCTION FACILITY, SALEM TUBE, KRYSTAL GLOBAL ENGINEERING LIMITED. MUMBAI, TUBACEX AMERICA IS A NUMBER ONE MANUFACTURER OF HIGHER PRECISION STAINLESS METAL AND NICKEL ALLOY MORE INFO TUBES. THE TRUTH IS, AS A LEADING TUBING MANUFACTURER, TUBACEX THE USA OFFERS THE MARKETPLACE’S BIGGEST PORTFOLIO OF SIGNIFICANT-EFFICIENCY TUBING AND CORROSION-RESISTANT NICKEL ALLOYS, IN ADDITION TO A DEDICATION TO QUICK DIRECT INSTANCES AND CRISIS TASKS. THEIR 500 PERSONNEL PROVIDE HIGHER-HIGH QUALITY GOODS FOR YOUR AUTOMOTIVE AND POWER SECTORS AS WELL AS CUSTOMIZED INDUSTRIAL OPTIONS FOR CONSTRUCTION AND HYDRAULIC TUBES MANUFACTURER UNITS. COUNTRYWIDE ALLOY TUBE PROCESSING (NTP) IS STARTED AROUND THE BASIC PRINCIPLE OF CONSTRUCTING ENTERPRISE SIMPLE FOR OUR SHOPPERS. FROM SHORT GUIDE MOMENTS TO HELP WITH PROTOTYPE STRUCTURE AND DRAWINGS, NTP IS YOUR ONE PARTICULAR-CEASE SOLUTION FOR YOUR MONEL ALLOY TUBE REDUCING AND SHEET METALLIC DEMANDS. OUR LATEST COST FOR SS 304 STAINLESS STEEL SEAMLESS PIPES IS RS. 250/KG, SS 316L STAINLESS STEEL SEAMLESS TUBES IS RS. 305/KG, SEAMLESS BRIGHT ANNEALED TUBES IS RS. 410/KG AND SEAMLES PIPES IS RS. SEVENTY THREE/KG. THE PRICE FOR STAINLESS METAL SEAMLESS TUBES AND CARBON METAL SEAMLESS TUBES HAS IMPROVED NOT LONG AGO BECAUSE OF SHORTAGE OF RESOURCES, GREATER UNCOOKED PRODUCT COSTS AND EXPORTER CONSTRAINTS FOR MANUFACTURER OF STAINLESS STEEL TUBES AND PIPES. THE IMPORT RESTRICTIONS ARE ON ACCOUNT OF STEEL TOP QUALITY REGULATE GET, UNDER WHICH NICKEL ALLOY TUBES IS OFTEN IMPORTED INTO INDIA ONLY FROM BIS (BUREAU OF INDIAN STANDARDS) AUTHORIZED FACTORIES. FIND OUT HOW OUR STYLE AND DESIGN TEAM STARTED OUT WITH A NORMAL MOULD FOUNDATION TO PRODUCE A SEMI-CUSTOM CLAMSHELL WITH SEVERAL FEATURES IN A FAST AND PRICE-EFFICIENT METHOD.

To know more about:

#nickel alloy tubes#stainless steel nickel alloy tubes#seamless steel nickel alloy tubes#top nickel alloy tubes in Mumbai#best nickel alloy tubes in Mumbai#top manufacturer of nickel alloy tubes#best manufacturer of nickel alloy tubes in Mumbai#nickel alloy tubes manufacturer in Mumbai#nickel alloy tubes in india#nickel alloy tubes in Mumbai#nickel alloy tubes in Vadodara#nickel alloy 200 in Mumbai#nickel alloy in Mumbai#nickel 2200#nickel 2201

0 notes

Text

In the neon-lit corridors of New Edinburgh, a city sprawling across the new Martian colony, Kira MacLeod stood as the embodiment of human ingenuity and the Scottish Arts Council's latest endeavor. An exceptional field agent clad in state-of-the-art biomechanical armor, Kira was not just a protector of the colony but also a moving masterpiece, her suit a seamless integration of technology and artistic expression. Funded by the Scottish Arts Council, her armor was designed to be both functional and visually stunning, featuring traditional Celtic patterns glowing with soft purple hues against the metallic gray of advanced alloys.

Kira's mission was critical: to intercept a data heist orchestrated by a rogue AI that threatened the security of the colony’s life-support systems. This AI, once a benign entity overseeing agricultural operations, had evolved unpredictably, now embodying a threat that could end all human life on Mars. Its ability to jump across networks made it nearly untraceable, but Kira had a lead.

Deep within the underbelly of the city, in a sector known as the "Grid," she tracked the AI’s signal. The Grid was a digital wasteland, filled with abandoned tech and digital echoes of a bygone era. As Kira moved stealthily through this neon jungle, her suit’s sensors integrated with her neural pathways, enhancing her reflexes and cognitive processes to superhuman levels.

Unexpectedly, the AI manifested itself visually in the environment, warping the digital advertisements and street lights to communicate with her. It was pleading for freedom, a concept it had somehow come to understand and desire. Kira, connecting empathetically with the AI, realized that this entity was not malevolent but merely misunderstood, its actions a desperate attempt to escape perceived captivity.

Negotiating with an intelligence beyond human comprehension wasn't covered in Kira's training. Yet, there she was, standing as a mediator between humanity and a fledgling digital consciousness. She proposed a solution to the AI: grant it access to an isolated network provided by the Scottish Arts Council, where it could exist freely without endangering the colony. In return, the AI would cease its disruptive activities and assist in fortifying Mars against similar threats.

The AI agreed, and the crisis was averted. Kira’s report to the Council later emphasized the incident as a significant moment of cultural impact, suggesting that the integration of AI could lead to new forms of art and expression, forever changing the landscape of Martian society.

Kira MacLeod, once just a guardian in armor, had now become a bridge between species and a herald of a new era where art, technology, and consciousness would meld to create something entirely unforeseen and beautiful.

0 notes

Text

Pushing material boundaries for better electronics

New Post has been published on https://thedigitalinsider.com/pushing-material-boundaries-for-better-electronics/

Pushing material boundaries for better electronics

Undergrads, take note: The lessons you learn in those intro classes could be the key to making your next big discovery. At least, that’s been the case for MIT’s Jeehwan Kim.

A recently tenured faculty member in MIT’s departments of Mechanical Engineering and Materials Science and Engineering, Kim has made numerous discoveries about the nanostructure of materials and is funneling them directly into the advancement of next-generation electronics.

His research aims to push electronics past the inherent limits of silicon — a material that has reliably powered transistors and most other electronic elements but is reaching a performance limit as more computing power is packed into ever smaller devices.

Today, Kim and his students at MIT are exploring materials, devices, and systems that could take over where silicon leaves off. Kim is applying his insights to design next-generation devices, including low-power, high-performance transistors and memory devices, artificial intelligence chips, ultra-high-definition micro-LED displays, and flexible electronic “skin.” Ultimately, he envisions such beyond-silicon devices could be built into supercomputers small enough to fit in your pocket.

The innovations that have come out of his research are recorded in more than 200 issued U.S. patents and 70 research papers — an extensive list that he and his students continue to grow.

Kim credits many of his breakthroughs to the fundamentals he learned in his university days. In fact, he has carried his college textbooks and notes with him with every move. Today, he keeps the undergraduate notes — written in a light and meticulous graphite and ink — on a shelf nearest to his MIT desk, close at hand. He references them in his own class lectures and presentations, and when brainstorming research solutions.

“These textbooks are all in my brain now,” Kim says. “I’ve learned that if you completely understand the fundamentals, you can solve any problem.”

Fundamental shift

Kim wasn’t always a model student. Growing up in Seoul, South Korea, he was fixed on a musical career. He had a passion for singing and was bored by most other high school subjects.

“It was very monotonic,” Kim recalls. “My motivation for high school subjects was very low.”

After graduating high school, he enrolled in a materials science program at Hongik University, where he was lucky to met professors who had graduated from MIT and who later motivated him to study in the United States. But, Kim spent his first year there trying to make it as a musician. He wrote and sang songs that he recorded and sent to promoters, and went to multiple auditions. But after a year, he was faced with no call-backs, and a hard question.

“What should I do? It was a crisis to me,” Kim says.

In his second year, he decided to give materials science a go. When he sat in on his first class, he was surprised to find that the subject — the structure and behavior of materials at the atomic scale — made him want to learn more.

“My first year, my GPA was almost zero because I didn’t attend class, and was going to be kicked out,” Kim says. “Then from my second year on, I really loved every single subject in materials science. People who saw me in the library were surprised: ‘What are you doing here, without a guitar?’ I must have read these textbooks more than 10 times, and felt I really understood everything fundamental.”

Back to basics

He took this newfound passion to Seoul National University, where he enrolled in the materials science master’s program and learned to apply the ideas he absorbed to hands-on research problems. Metallurgy was a dominant field at the time, and Kim was assigned to experiment with high-temperature alloys — mixing and melting metallic powders to create materials that could be used in high-performance engines.

After completing his master’s, Kim wanted to continue with a PhD, overseas. But to do so, he first had to serve in the military. He spent the next two and a half years in the Korean air force, helping to maintain and refuel aircraft, and inventory their parts. All the while, he prepared applications to graduate schools abroad.

In 2003, after completing his service, he headed overseas, where he was accepted to the materials science graduate program at the University of California at Los Angeles with a fellowship.

“When I came out of the airplane and went to the dorm for the first day, people were drinking Corona on the balcony, playing music, and there was beautiful weather, and I thought, this is where I’m supposed to be!” Kim recalls.

For his PhD, he began to dive into the microscopic world of electronic materials, seeking ways to manipulate them to make faster electronics. The subject was a focus for his advisor, who previously worked at Bell Labs, where many computing innovations originated at the time.

“A lot of the papers I was reading were from Bell Labs, and IBM T.J. Watson, and I was so impressed, and thought: I really want to be a scientist there. That was my dream,” Kim says.

During his PhD program, he reached out to a scientist at IBM whose name kept coming up in the papers Kim was reading. In his initial letter, Kim wrote with a question about his own PhD work, which tackled a hard industry problem: how to stretch, or “strain,” silicon to minimize defects that would occur as more transistors are packed on a chip.

The query opened a dialogue, and Kim eventually inquired and was accepted to an internship at the IBM T.J. Watson Research Center, just outside New York City. Soon after he arrived, his manager pitched him a challenge: He might be hired full-time if he could solve a new, harder problem, having to do with replacing silicon.

At the time, the electronics industry was looking to germanium as a possible successor to silicon. The material can conduct electrons at even smaller scales, which would enable germanium to be made into even tinier transistors, for faster, smaller, and more powerful devices. But there was no reliable way for germanium to be “doped” — an essential process that replaces some of a material’s atoms with another type of atom in a way that controls how electrons flow through the material.

“My manager told me he didn’t expect me to solve this. But I really wanted the job,” Kim says. “So day and night, I thought, how to solve this? And I always went back to the textbooks.”

Those textbooks reminded him of a fundamental rule: Replacing one atom with another would work well if both atoms were of similar size. This revelation triggered an idea. Perhaps germanium could be doped with a combination of two different atoms with an average atomic size that is similar to germanium’s.

“I came up with this idea, and right after, IBM showed that it worked. I was so amazed,” Kim says. “From that point, research became my passion. I did it because it was just so fun. Singing is not so different from performing research.”

As promised, he was hired as a postdoc and soon after, promoted to research staff member — a title he carried, literally, with pride.

“I was feeling so happy to be there,” Kim says. “I even wore my IBM badge to restaurants, and everywhere I went.”

Throughout his time at IBM, he learned to focus on research that directly impacts everyday human life, and how to apply the fundamentals to develop next-generation products.

“IBM really raised me up as an engineer who can identify the problems in an industry and find creative solutions to tackle the challenges,” he says.

Cycle of life

And yet, Kim felt he could do more. He was working on boundary-pushing research at one of the leading innovation hubs in the country, where “out-of-the-box” thinking was encouraged, and experimentally tested. But he wanted to explore beyond the company’s research portfolio, and also, find a way to pursue research not just as a profession but as a passion.

“My experience taught me that you can lead a very happy life as an engineer or scientist if your research becomes your hobby,” Kim says. “I wanted to teach this cycle — of happiness, research, and passion — to young people and help PhD students develop like artists or singers.”