#mesh bags manufacturer

Explore tagged Tumblr posts

Text

PP Mesh Bags in Australia | Onion Mesh Bulk Bags Suppliers

Choosing Wales as your mesh bags supplier in Australia ensures a seamless blend of quality, reliability, cost-effectiveness and eco-friendly practices.

#bulk onion bags#pp mesh bags#mesh bags manufacturer#mesh bags manufacturer in australia#mesh storage bags

0 notes

Text

Just kinda... putting this out into the universe for right now, but I've been thinking really hard about getting my old enamel pin collections back in circulation, as well as maybe releasing them as stickers as well (for a budget option and also for things you can't put enamel pins on). I had to throw out basically all my remaining stock when I moved (which... oouugh it still hurts), so I might essentially run a "reboot" kickstarter to get another batch of Dire Hounds made and then try again to get the full Grimalkins set funded. A few things this would let me do:

update the templates for slightly cleaner manufacturing, and update the backer cards with accurate artist info because man that was really bothering me

like I said, hopefully get the second half of the Grimalkins produced so they're a proper six-pin collection like the first one

network! Now that I'm in a big city I think I honestly might have better luck with consignment stores and craft fairs than I ever did with only an online shop, and more visibility can only mean good things.

I'm also still definitely planning to make idog merch, and beyond that I'd potentially love to lean even further into the cyberpunk and y2k aesthetics to really hone my Brand™, but obviously that requires original thought and creative effort while getting the dogs and cats remade just requires pulling the old AI files off my poor aging iMac.

#if possible I'd love to find a (more) local manufacturer instead of the one in the UK I was using before#unfortunately that means they'll cost a bit more up front since they won't have the molds already#which I guess would have possibly been a non-issue anyway if I was gonna tweak the art#but also the lower shipping costs without going through customs.....#anyway just thinking..... on a conceptual level I really miss ~designing merch~ even though I never really excelled at it lmao#a lot of you probably have no fucking clue what I'm talking about because the pins were before your time :/#just take my word for it they were all really really cool and you want them#I wish I made the kind of art that people want on their walls lmao prints seem like easy money for a lot of people#but it just doesn't mesh with what I make. All I can offer to The People is Little Guys For Your Bag Or Jacket

20 notes

·

View notes

Text

The Versatility of Leno Mesh Bags: A Comprehensive Guide

0 notes

Text

Casa fashion is one of the best Mesh Tote Bag. We have our own manufacturing unit in india for Mesh Tote Bag manufacturing and we export best quality Mesh Tote Bag products

#Mesh Tote Bag#Casa fashion is one of the best Mesh Tote Bag.#Mesh Tote Bag manufacturing#export best quality Mesh Tote Bag products

0 notes

Text

The Benefits of Using PP LENO Mesh Bags in Agriculture

In recent years, the agricultural industry has seen a significant shift towards more sustainable and environmentally friendly practices. One such change is the increasing use of PP LENO mesh bags in agriculture. These bags offer a range of benefits that make them an attractive option for farmers and producers. In this article, we'll explore the advantages of using PP LENO mesh bags and why they have become a popular choice among growers.

What Are PP LENO Mesh Bags?

PP LENO mesh bags are made from polypropylene (PP) and feature a leno weave structure. This unique weaving technique provides the bags with excellent strength and durability while allowing for good airflow. The mesh design also makes them lightweight and easy to handle, making them ideal for packaging agricultural products.

Leno Mesh Bags Suppliers in India

India has emerged as a leading producer and supplier of PP LENO mesh bags, catering to the growing demand from the agricultural sector. Leno mesh bags suppliers in India offer a wide range of options to suit different needs and requirements. Whether you're looking for bags to package fruits, vegetables, or other agricultural products, you can find a supplier that meets your specific needs.

Mesh Bag Manufacturer in Gujarat

Gujarat, known for its thriving textile industry, is home to several mesh bag manufacturers specializing in PP LENO bags. These manufacturers leverage their expertise in weaving and production to create high-quality mesh bags that meet industry standards. With state-of-the-art manufacturing facilities and a skilled workforce, Mesh bag manufacturers in Gujarat are well-equipped to cater to both domestic and international markets.

PP LENO Bags Manufacturer in India

In addition to suppliers and manufacturers in Gujarat, there are several PP LENO bags manufacturers across India. These manufacturers produce a wide variety of mesh bags tailored to the needs of the agricultural sector. With a focus on quality and innovation, PP LENO bags manufacturers in India are driving the adoption of sustainable packaging solutions in agriculture.

Benefits of Using PP LENO Mesh Bags in Agriculture

Environmental Sustainability One of the most significant benefits of using PP LENO mesh bags is their environmental sustainability. Unlike traditional plastic bags, PP LENO bags are reusable and recyclable, reducing the amount of plastic waste generated. This eco-friendly feature aligns with the growing demand for sustainable packaging solutions in agriculture.

Enhanced Product Protection PP LENO mesh bags offer excellent protection for agricultural products. The leno weave structure allows for good airflow, reducing the risk of moisture buildup and mold growth. Additionally, the durable material helps prevent damage during handling and transportation, ensuring that products reach consumers in optimal condition.

Cost-Effective Solution Despite their premium quality, PP LENO mesh bags are a cost-effective packaging solution for farmers and producers. Their durability and reusability mean fewer replacements are needed, leading to long-term cost savings. Moreover, the lightweight design of these bags can help reduce shipping costs, further adding to their economic appeal.

Brand Visibility and Marketing The customizable nature of PP LENO mesh bags provides an excellent opportunity for brand visibility and marketing. Farmers and producers can opt for bags with printed logos, labels, or promotional messages, effectively promoting their brand while packaging their products.

Conclusion

PP LENO mesh bags have revolutionized the way agricultural products are packaged and transported. With their environmental sustainability, enhanced product protection, cost-effectiveness, and marketing potential, these bags offer a compelling solution for farmers and producers. As the demand for sustainable packaging continues to grow, the role of PP LENO mesh bags in agriculture is expected to expand further, making them an essential tool for modern farming practices.

Frequently Asked Questions

Are PP LENO mesh bags suitable for packaging all types of agricultural products? Yes, PP LENO mesh bags are versatile and can be used to package a wide range of agricultural products, including fruits, vegetables, grains, and more.

How do PP LENO mesh bags compare to traditional plastic bags in terms of durability? PP LENO mesh bags are more durable than traditional plastic bags due to their leno weave structure and polypropylene material. They offer better resistance to tears, punctures, and UV degradation.

Are PP LENO mesh bags environmentally friendly? Yes, PP LENO mesh bags are environmentally friendly as they are reusable and recyclable, reducing the environmental impact compared to single-use plastic bags.

Where can I find reliable suppliers of PP LENO mesh bags in India? You can find reliable suppliers of PP LENO mesh bags in India through online directories, trade associations, or industry trade shows. Additionally, reaching out to mesh bag manufacturers in Gujarat and other regions can help you find the right supplier for your needs.

#leno mesh bags suppliers in India#mesh bag manufacturer in Gujarat#pp leno bags manufacturer in india

0 notes

Text

SAMI Layer Pavement Fabrics: Boost Road Durability

SAMI Layer Pavement Fabrics: Boost Road Durability

Introduction:

In the ever-evolving landscape of road construction, innovations like SAMI layer pavement fabrics are transforming the way we approach durability and longevity in infrastructure. This blog post explores the key benefits and applications of SAMI layer fabrics, shedding light on how they play a crucial role in enhancing the resilience of our roads.

Understanding SAMI Layer Pavement Fabrics:

How SAMI Layer Fabrics Boost Road Durability

SAMI layer pavement fabrics strengthen the road in multiple ways:

Crack Prevention

Acting as a barrier, the SAMI fabric inhibits cracks from appearing and spreading across the road surface. This adds years to the pavement life. The bonded fabric intercepts cracks at the surface level preventing downward propagation into the base layers.

Enhanced Structural Stability

The integration of the high-modulus SAMI layer evenly distributes traffic loads over a broader pavement area. This reduces concentrated stresses and deformations leading to pavement failures. The outcome is improved stability and strength.

All-Weather Reliability

SAMI fabrics are engineered using polymers like polyester, polyethylene or glass fibers that can withstand diverse environmental conditions from freezing winters to scorching summers. This makes roads more reliable through changing seasons.

Extended Lifespan

The collective impact of crack prevention, load distribution and weather resistance provided by SAMI layers is a significantly extended road lifespan. The surface maintains integrity for longer periods without requiring repairs and rehab.

Sustainable Construction

Applications of SAMI Layer Pavement Fabrics

Some prominent applications that highlight the benefits of SAMI layers include:

Road Rehabilitation

Applying SAMI fabrics provide an economical overlay solution for rehabilitating aged, damaged road surfaces. The fabric strengthens the existing base while providing a new wearing course.

New Road Construction

Integrating a SAMI layer into new road construction leads to more crack-resistant, durable surfacing that extends the period between overlays.

Preventing Reflective Cracking

SAMI layers serve as effective crack retarders at the interface of old and new pavement sections. This addresses reflective cracking, a common issue in road overlays.

Bridge Deck Protection

In conclusion:

SAMI layer pavement fabrics are a game-changer in the realm of road construction, offering a sustainable and effective solution for enhancing the durability of our infrastructure. As we pave the way to the future, these innovative fabrics prove to be an indispensable asset in creating roads that can withstand the test of time.

#geotextile#pavement#non woven fabrics#woven mesh fabric#pp woven bags#woven#woven fabric manufacturers#fabrics

0 notes

Text

Non-woven geotextiles are an important category of geosynthetics used across a wide range of infrastructure and construction applications. This guide provides a deep dive into what non-wovens are, their types, key properties, manufacturing processes, installation methods, advantages, applications, and more.

Introduction to Non-Woven Geotextiles

Geotextiles refer to permeable, polymeric textile materials used in contact with soil or rock in civil engineering applications. They can be woven or non-woven.

Non-woven geotextiles are made by bonding polymeric fibers together through processes like needle punching, heat bonding or resin bonding. The random arrangement of fibres produces a strong, porous and flexible material.

Geotextiles that are non-woven are better than those that are woven. They are better at filtering, draining, and cushioning, and are easier to install. In addition, they are more budget-friendly. These characteristics make non-wovens ideal for many functions like filtration, drainage, separation, and reinforcement.

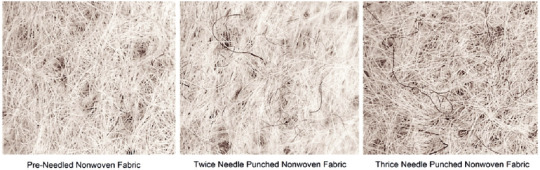

Needle Punched Non-Woven Geotextiles

Needle-punched non-wovens are a major type of non-woven geotextile produced by mechanically orienting and entangling fibers. Hundreds of fine needles repeatedly penetrate a fibre web to tangle the fibres into a strong, porous and stable fabric.

Compared to other non-wovens, needle-punched variants have high permeability and drainage capacity along with good puncture resistance. This makes them ideal for filtration and drainage applications.

Types of Needle-Punched Non-Woven Geotextiles

Needle-punched non-wovens can be categorized into three main types based on weight and fiber thickness:

Lightweight Needle Punched Wovens

Made from fine fibres and low fiber weights between 20-100 gsm. Mainly used in applications that do not require high strength.

Medium Weight Needle Punched Non Wovens

Heavier fibers and medium basis weights of 100-250 gsm. Provides moderate strength for functions like separation.

Heavyweight Needle Punched Non-Wovens

Very coarse, thick fibres and high basis weights above 250 gsm. Imparts maximum strength for reinforcement uses.

Selections depend on the target function. Non-woven fabrics can be categorized into lightweight and heavyweight variants.

Key Functions and Applications of Non-Woven Geotextiles

Non-woven geotextiles perform various functions that make them indispensable for major infrastructure and construction projects:

Filtration Applications

The porous structure allows water to pass through while blocking soil particles. This filtration ability is useful in:

Roadway drainage systems

Retaining walls

Landfill drainage

Water treatment plants

Drainage Applications

Nonwovens have high water flow rates in the principal direction. This makes them excellent for drainage purposes like:

Landfill drainage layers

Sports field drainage

Retaining wall and slope drainage

Separation Applications

The fabric physically separates dissimilar materials. Key applications include:

Roadway base and subbase separation

Railroad bed separation

Foundations separation

https://www.aakarperiwal.com/blogs/wp-content/uploads/2023/09/geotextile-500x500-3.webp

Reinforcement Applications

Non-wovens provide reinforcement for additional strength when wrapped around soil. Uses include:

Embankments over soft soils

Retaining walls with stacked blocks

Slopes requiring improved bearing capacity

Erosion Control Applications

The fabric acts as a permeable layer to protect against wind and water erosion while allowing water passage. Some uses are:

Covering slopes along railways and highways

Coastal embankments erosion control

Riverbanks and canal protection

Transportation Applications

Within road construction, non-wovens assist with filtration, separation, drainage and stabilization. Common applications:

Separation between sub-base and subgrade

Filtration in edge drains alongside pavements

Soil stabilization for improved load-bearing

Construction Applications

Foundations and walls drainage

Vapor barriers in concrete slabs

Flooring reinforcement and crack prevention

This demonstrates the versatility of non-woven geotextiles across diverse functions in C&I projects. Their adaptive properties drive widespread adoption.

Key Properties of Non-Woven Geotextiles

Non-woven geotextiles exhibit unique properties derived from their material composition, manufacturing method and overall structure:

Raw Materials

Most non-wovens use polypropylene as the raw material which is cost-effective and provides required properties. High-end variants use polyester or a polypropylene-polyester blend.

Basis Weight

Basis weight is the mass per unit area measured in g/m2. Heavier basis weights produce stronger fabrics with higher puncture resistance. Typical range is from 20 g/m2 to 300 g/m2.

Thickness

Thickness depends on fiber density and varies from 1mm to 15mm. Affects permeability, cushioning ability and separation effectiveness.

Hydraulic Properties

Non-wovens have high water permeability (normal to the plane) and adequate transmissivity. Allows swift drainage while blocking soil passage.

Mechanical Properties

Tensile strength, tear strength, puncture resistance and burst strength are key mechanical properties. Non woven selection depends on the required load capacity.

Endurance Properties

Long-term resistance against environmental exposure, chemicals, microbes and mechanical stresses comes under endurance properties. Requires proper polymer choice.

These characteristics directly impact the effectiveness and lifespan of the non-woven geotextile for its intended function.

Overview of Manufacturing Processes

Non-woven geotextile production involves specialized processes to achieve the desired fiber arrangement and properties:

Web Formation

The first step is creating a uniform web of fibres laid out in overlapping, random orientations using air, mechanical or wet-laid techniques.

Web Bonding

The fiber web undergoes thermal, chemical or mechanical bonding. This interlocks the fibres to impart strength, stability and thickness.

Finishing

Additional treatments enhance properties - for instance, calendering uses heated rollers to achieve smoothness. Fabric edges are trimmed to create rolls.

Testing and Inspection

Extensive testing under certified labs evaluates parameters like strength, permeability, opening size etc. This ensures compliance with specifications.

Keeping manufacturing consistent and monitoring variabilities is vital for non-woven quality assurance. Automation allows scalable production with minimal defects.

Design and Installation Factors for Non-Woven Geotextiles

Proper design, handling and deployment of non-wovens ensures successful project outcomes:

Site Preparation

The installation site must be graded uniformly and cleared of debris/rocks to avoid damage. Burial depth is determined. Subsurface drainage may be added.

Installation Techniques

Non wovens can be unrolled on site and placed loose or tense. Joints are sewn or bonded. Additional layers can be installed to enhance functioning. Fixings like sandbags or pegs may be used.

Seams and Overlaps

Adjoining rolls are overlapped for continuity. End overlaps depend on joint strength. Edges can be sewn, welded, glued or kept loose. Key consideration for soil retention uses.

Design Factors

Careful specifications of geotextile properties like strength, permeability, and opening size based on engineering requirements and testing. Survivability and performance lifetime also key.

Following recommended practices for non-woven deployment optimizes field performance and prevents failures.

Key Benefits and Advantages of Using Non-Woven Geotextiles

Non-woven geotextiles offer numerous benefits that make them advantageous over traditional materials:

Cost-Effectiveness

Made from polypropylene, non-wovens are an affordable alternative to CMP pipe drains or graded aggregates for drainage. Limited overlap joints also reduce the quantity required.

Rapid Drainage Performance

The high porosity provides greater flow capacity compared to sand filters or gravel layers. Useful in applications like retaining walls.

Good Puncture and Burst Resistance

The entangled fibrous structure provides better resistance against punctures during installation compared to woven geotextiles.

Ease of Installation

Flexible, lightweight non-wovens are simpler to install in field conditions compared to rigid materials. No special equipment needed.

Enhanced Properties

Specialized manufacturing processes like calendering and bonding create improved non-wovens with the right balance of filtration, separation, cushioning and strength.

Wider Widths

The ability to produce up to 5m wide rolls compared to just 1m for wovens leads to faster deployment with fewer joints.

These advantages have positioned non-wovens as a material of choice for major construction activities and geotechnical engineering applications.

Applications and Case Studies Demonstrating Non-Woven Geotextiles in Action

Non-woven geotextiles have delivered value across many real-world projects:

Landfill Construction - Needle-punched non-wovens used in leachate collection systems increased design life while reducing clogging through superior filtration compared to gravel layers.

Retaining Wall Drainage - Heat-bonded non-wovens used as wall wraps maintained water drainage and prevented soil washout, keeping 100km of critical rail walls safely stabilized through extreme weather.

Riverbank Protection - Durable non-woven wraps applied on embankments prevented erosion along highly flood-prone rivers through monsoons. Filtered runoff while retaining soil stability.

Roadway Improvement - Calendered non-wovens beneath motorway overpasses provided vital reinforcement to stabilize compressible soil while facilitating drainage and preventing pumping.

Coastal Reinforcement - Wide-width non-wovens encasing sandy coastal cliffs added shear strength and tensile reinforcement. Protected against collapse from rising sea levels and storm surges.

This demonstrates how non-wovens of different compositions can be adapted for specialized needs in infrastructure projects where performance and longevity are critical.

Industry Trends and Ongoing Innovations in Non-Woven Geotextiles

Several interesting trends, developments and innovations are shaping the non-woven geotextiles sector:

High Growth Potential - The non-wovens market is projected to grow steadily at 6% CAGR driven by major public infrastructure investments and demand from emerging economies.

Raw Material Advances - Enhanced polymers like high-density polypropylene and high-modulus polyester are creating improved non-wovens with greater functionality.

Manufacturing Improvements - Process enhancements and new techniques are allowing more fine-tuned manipulation of fiber properties during production.

Multifunctional Products - Combining non-wovens with drainage nets or reinforcing grids creates single products that provide filtration, separation and reinforcement together.

Application R&D - Ongoing research into novel uses for non-wovens like landfill caps, nuclear waste containment and offshore geotextiles to drive adoption across new domains.

Conclusion

Non-woven geotextiles have become an indispensable resource for civil engineering and infrastructure applications where their high permeability, strength, and versatility can enhance project outcomes and lifespan.

As materials and manufacturing continue evolving, non-wovens are poised to meet more specialized demands. With a thorough understanding of their capabilities, civil engineers can apply these adaptable fabrics for a sustainable future.

0 notes

Text

Eco-Friendly Packaging: The Benefits of Leno Mesh Bags

Leno mesh bags are a type of packaging that has gained popularity in recent years due to their versatility and eco-friendliness. They are made using a unique weaving process that creates an open-mesh pattern, which offers several advantages over traditional packaging materials.

One of the primary benefits of leno mesh bags is their breathability. The open-mesh pattern allows air to circulate, preventing moisture build-up that can cause spoilage. This makes them an ideal packaging solution for fruits and vegetables, as it helps to extend their shelf life.

In addition to being breathable, leno mesh bags are also durable and resistant to tearing and puncturing. They are designed to withstand the rigors of transportation and handling, making them a reliable packaging solution for a variety of applications.

Another advantage of leno mesh bags is their lightweight nature. They are easy to handle and take up minimal space, which makes them an excellent choice for small retailers and farmers markets. Their lightweight nature also makes them a convenient option for suppliers and consumers, as they are easy to carry and transport.

Leno mesh bags are also a sustainable option for packaging. They are reusable and recyclable, which reduces waste and environmental impact. This makes them an eco-friendly alternative to traditional packaging materials like plastic bags.

Finally, leno mesh bags are customizable. They can be made in a variety of sizes and colors to meet specific needs, and they can be customized with logos, graphics, and other branding elements. This makes them an excellent promotional tool for businesses looking to differentiate their brand and stand out in the marketplace.

Overall, leno mesh bags offer several advantages over traditional packaging materials, making them an excellent choice for businesses and consumers alike. Their breathability, durability, lightweight nature, sustainability, and customization options make them a versatile and user-friendly option for a variety of applications. Whether you're a farmer looking for a sustainable packaging solution or a retailer looking to differentiate your brand, leno mesh bags are a reliable and eco-friendly option that is worth considering.

#leno bags#leno mesh bag#mesh bags#pp leno mesh bags#leno bags manufacturer#mesh bags exporter#Singhal Industries

0 notes

Note

How do you build a atomic bomb?

Easily!

All you need are a few household items, a little bit of patience, and a Class 1 Top Security clearance for the manufacture of biological, chemical or nuclear weapons under the Fermi laws of 1954 contingent to permission from the United Nations Security Council.

You're gonna need-

A box of matches

A blender

Tape

Some wire mesh (Like a window screen, for sifting)

Cake mix (Yellow sponge cake works best)

Ziplock bags

String

Ice cubes (The cold kind, not the rapper/actor)

A toilet paper tube

A Catholic Missal

An empty kitty litter bucket

First, you're gonna need two rare substances- Weapons grade uranium and "heavy" water. For the uranium, just take your yellow cake mix and sift it with the wire mesh. Whatever stays on top of the mesh- That's weapons grade. For the heavy water, take some ice cubes, which are heavier than water but still made of water, and put them in the blender. By breaking up the ice cubes and releasing the water, you keep the weight but make it a fluid. This is a process that scientists call "Putrefaction".

To build the weapon, pack some uranium into one end of the toilet paper tube and then cover that end with the Catholic Missal. This guarantees what we call a "Critical Mass" of uranium. Then take a smaller wad of uranium and pack it into the other end of the tube, leaving plenty of space between the two.

Tape the box of matches to that end of the tube. It will act as an explosive device to send the "bullet" of uranium into the critical mass, thus resulting in a nuclear fission explosion.

You now have a nuclear fission device! This device has a yield equal to about 10 thousand tons of T.N.T. But fission is for wimps, right? So let's turn that fission bomb, into a fusion bomb!

Tape your string to the matches to act as a fuse, and then put the nuclear warhead in a ziplock bag. Be sure to seal it tight! Now place that assembly into the kitty litter bucket. Make sure it's empty of kitty litter before the next step.

Fill the rest of the bucket with the heavy water you made in step one, and seal the top of the kitty litter bucket with the string still poking out. Once the fuse is lit, it will light the matches and detonate the nuclear fission bomb. This acts as a heat source to boil the heavy water, and when heavy water boils- Nuclear Fusion!

Congratulations, your bomb is now complete. Remember that it's illegal to carry or detonate a nuclear fusion warhead in public (except in Texas), and bear in mind this will be quite a bit stronger than your usual firecrackers. We recommend only setting off your nuclear device on official U.S. testing grounds, such as the desserts of New Mexico or islands in the Pacific only populated by tribes under no country's protection, because that's seriously what the U.S. did.

So play safe and have a good time,

-facts-i-just-made-up.tumblr.com

#nuclear weapons#atomic bomb#hydrogen bomb#global thermonuclear war#would you like to play a game#unreality

542 notes

·

View notes

Note

Omg your Humans are space orcs/deathworlders + Transformers is just *d e l i c i o u s*. My complaints are pretty much the same, it seems that most humans on the franchise are just manufactured to be hated or simply annoying for being so useless. I want transformers to realize just how hard we have to work to simply stay alive *in our own planet*, with the sheer amount of diseases and poisonous animals and predators and weather and so much more, I want them to wonder how such seemingly fragile beings became the dominant species, how can we be so resilient yet so delicate... I'd like a transformer that particularly hates/is disgusted by humans to swap places with us for like a day or so, the first one that comes to mind is Starscream, I want him to get a glimpse at the daily fight for survival here on Earth and can't help but develop a tiny speck of respect for humans, not that he would ever admit it, even to himself, that he's secretly more mindful of where he steps when there are humans around ever since.

I literally just gave a rundown about this to a friend in a drunken rant the other night, so I am so ready for this.

Starscream wouldn’t be my first pick, based solely on the fact that I haven’t psycho-analyzed him the same way I have others, but imma do my best ~

For situation-sake so my writer brain doesn’t kill itself over context, imma do this in the form of Headcannons. Let’s say Starscream gets stuck in a human body and has to exist as such until he magically gets put back. Until then, he’s stuck with a human who is aware of what he is (vague gn oc/reader, up to whoever. Writing from the viewpoint of “one of us”).

(Also y’all can input any Starscream here cause imma write him in his basic form: whiney, stuck-up, clever little cunt).

- Bro is flabbergasted. Disgusted. Horrified. Out-of-his-mind losing it. Keeps praying to primus it’s a drug-induced hallucination or a dream.

- Wakes up on the soft cushions of a… couch? The word pops up in his head. He knew the basics from his overviews when their war traveled to earth. He brought his servos- No. Hands, up to his face, inspected his new honey, fleshy digits. The detail was too vivid to be a hallucination. Colors were both muted and bright. Starscream found himself automatically trying to adjust his optic intake. But nothing happened. Of course. Because fleshy organics can’t manually adjust their own sensory inputs.

- He curls his lips, and is instantly hit with the feeling of muscle contorting. Skin and flesh was an entirely different sensation from mesh and plating. It made his plating- damnit no, skin crawl. Another sensation trailed up the center of his back, spine and shiver popping up in his mind.

- Even the way his psyche worked was different. Like a new plane of existence. Thoughts were unorganized, uncalculated. Like something that squirmed out of his grasp as he tried to keep hold. Everything felt simplified, yet the awareness and sensations were overwhelming. His entire presence felt… hypocritical.

- Sounds distracted him from his insightful, yet horrific reverie. His gaze drifted to another area of the room, half-built walls sectioning it off, but with flat slabs atop. Counters. A face pops from behind the half-wall. Human eyes catch his, and the creature pulls its lips back to bare its teeth. To smile. Even though humans and cybertronians had similar facial anatomy, the little creatures were so ugly that it was hard to recognize similar expressions.

- “You good bud?” The thing asks. Starscream felt his new face twist into his casual sneer, one laced with aggravation and disgust.

- “Good? Is such a thing possible when you’re a skin bag of flesh and bones?” The humans only response was to broaden their grin.

-“Glad you haven’t lost the attitude. Means you’ll make it out alive.” The nonchalance threw the ex-cybertronian for a loop.

- “You… know me?” That grin turned into a smirk that made the non-energon in his lines boil.

- “You’re Starscream, second-in-command to Megatron, lord of the deceptions, yada yada yada… yeah I know who you are.” They leaned back against the wall, eyes boring into the deception. Starscream found himself wondering if human eyes were always so disturbingly piercing.

- “Wonderful.” He shoved the unsettled feeling to the back of his head, determined to figure out a solution and still be in control. “Then you can explain how and why I am in this disgusting organic form.”

- The smirk disappeared into an odd expression Starscream had never seen before. The human flattened their lips and pursed their… cheeks. It looked entirely stupid. But something in the back of his head whispered apologetic.

- “I’m not sure on the exact details, but I can tell you it won’t last long. I’m basically your caretaker until it wears off.”

- Instinctually, Starscream’s brows raised. “That’s it? Is this some new human weapon, cruel imprisonment within one your fleshy bodies?”

- The human tilted their head back and laughed, once again taking Starscream off guard. Their casual presence was so different from the fight-or-die everyday lifestyle that gripped his species.

- “Nope. Just a random accident that you’re the unfortunate victim of.” At the con’s bewildered stare, the human pushed their mouth outwards, changing the pitch of their voice as they said, “aww, poor baby. Don’t worry, you’re safe with me.” Then they whirled around and walked into the other room.

- Man is flabbergasted. Is out of his element and cannot function. Cue him trying to stand and do normal things, and bust his ass because the different sensations hitting him all at once. Organic nervous systems feel very different from techno ones.

- First thing he starts doing is eating and drinking. It takes a couple hours, but his “babysitter” eventually gets him to try something. Water first, of course (he refused any organic foods). The con is disgusted, but moderately pleased that the tasteless liquid isn’t slimy or thicker like he expected. It’s actually rather soothing to his human body.

- The first food he willingly tries is melon. Honeydew to be precise. Refused to touch meat, as the idea of eating actual organic flesh was unfathomable. He was pleasantly surprised to find the flavor of the fruit likable. Humans don’t taste things the same way cybertronians do. Whereas energon has a more electrical charge to it (to put it in human words), Earth flavors were smoother. Discovers he has a huge sweet tooth (as his “babysitter” put it).

- His human guardian took this opportunity to drag him out of their home and go shopping for more consumables. Let him pick things he found somewhat pleasing, but chose most others. Lots of fruit to try and other non-meats. Went in to try the other types of fruit. Has a preference for honeydew, strawberries, cantaloupe, watermelon, and grapes. Really likes (loves but won’t admit) pineapple and raspberries. The sour/sweetness is similar to energon. Citruses like oranges and mandarin are also similar, but he prefers more sweetness than straight sour. Kiwi is also a treat.

- (I headcannon that energon is similar to sour patch kids and skittles, super sweet and sour with an electric tang and texture. So all transformers would be immediate sweet lovers as humans because of the similarity).

- Hates anything dull or flavorless. Don’t try to feed this man spinach, he’ll call you grass-eating fleshbag.

- Drinks water only because he has too (stupid human body), but once he discovers those liquid flavors he can put in, it’s all he uses. Tried juices when he found out they were liquids derived from the fruit he likes. Got excited when it tasted almost like energon and tried to only consume juice from then on. His guardian explained that humans couldn’t only exist on juice, but of course he tried to argue that all he needed was nutrients in liquid. He then discovered smoothies. Nearly did the same thing until he actually tried them. Hated the thickness and gritty texture.

- A couple days go by and his guardian decides it’s time to get him tf out properly. Man is lounging around all the time. If he’s not on the couch making fun of human entertainment and politics, he’s following his guardian meatbag around and demanding answers for his current predicament.

- So his guardian starts small. Hauls his ass outside for a jog. This is where things really get interesting. Starscream is unaware of how human bodies work. When his guardian begins a slow run, he gets confused. Why would you run when you can walk fine? Where were they going? Leads to an explaination of exercise, which results in the con doing his usual snide shit of “you force yourselves to go through training otherwise your bodies become slow and unusable? How unsurprising.” And they’re like “yes and nooo, it’s so we can stay strong and get stronger as time goes on. Staying strong allows us to do cool things.”

- Cool things like what? Well his guardian gets an evil idea in their head. Starscream hates running. Hates using his legs and having nothing to do with his arms. Don’t even get them started on the tantrum he threw when he started sweating (fluids exiting one’s body? Horrifying).

- So his guardian introduces him to swimming. The con is a jet in his natural form, and the closest he’ll get to that as a human without a shit ton of equipment will be the water.

- Problem is the man has to learn to swim first. And willingly get in the water. Stays on the edge of the lap pool the first few times, watching with his nose turned up at the humans swimming.

- However, he starts to slowly dip his toes in the water. The sensation is… interesting. It’s not dislikable on human skin. In fact, on the hotter days it’s very soothing, like when he drinks water (finds out he can’t drink this kind tho, chemicals and bodies in it and such).

- Eventually he gets in, staying in the shallow area. His guardian helps him learn how to swim. It feels humiliating, learning to kick and tread water, while watching human children do it with relative ease. It feels strange to use his body in such ways. But with his guardian constantly reminding that none of his cybertronian peers knew or will know of his situation, AND their constant praise, he finds it in himself to continue.

- The praise he receives from his guardian is also something he’s not used to. As well as other humans willing to help him learn. It apparently wasn’t uncommon for many adult humans to not know how to swim or do other things, and gave him more confidence to learn. He’d never admit it, but he tried harder to learn just to hear the praise from others. It felt nice to be treated kindly. Better than nice. But again, he’d never admit it. He’d just respond with a clever quip. Never did anyone hear a thanks (but most quickly figured out he was grateful from the obvious burning red on his copper-toned neck and ears).

- Weeks drag on, and to distract himself from the impatience of going back to his normal, Starscream becomes an excellent swimmer. He finds it is like flying, the way the water holds up his body. When he holds his breath and dips under the surface, he can almost imagine his rocket boosters on his pedestal holding him aloft in the sky.

- From the work it took, he gained a slight appreciated for how his human body worked. At first he thought it was a hindrance. But as he worked with the others, he began to have an understanding that unsettled the cybertronian part of him.

- Humans were incredibly versatile. After he began to improve greatly at swimming, he asked about other activities humans did for exercise. The resulted in learning that humans didn’t always “exercise” to become strong. Many did it for fun. It was a hobby to them, and the exercise was a great benefit. It kept their minds clear, it kept their bodies healthy, and it satisfies a part of them that he was only beginning to discover.

- Starscream was aware of human creativity. It’s what had made their species a slight hindrance when they aided the autobots in the war, but because of their size, they were seen as nothing but bugs. Pests at the most. But as the con experienced this small bit of human life, he began to understand there was more to them than he’d like to admit. There was this drive to do things, to push themselves beyond their current capabilities.

- He learned of skills that human no longer needed but still learned to take pride in for fun. Swimming was only a base skill. There were humans that attempted to swim across the oceans just to see if they could, even with the high chance of death. Beyond swimming, there was running across land for days on end, jumping off cliffs and diving in spectacular ways, gliding across the sky’s on flimsy metal pipes and fabric, and so much more. Their adaptability to any environment was envious.

- It nearly terrified him, the thought of what if humans were the same size as cybertronians. What if they could acutally measure up to other species of their universe? They could do anything. They would be a real threat. Or the greatest ally any race could ask for.

- His lid has been flipped.

- Eventually he wakes up back in his habsuite in his normal body. The euphoria that rushes through him at the familiarity his nothing he’s ever experienced before. Checking his info screens, he discovers no time passed. As if he had dreamed all of it. But when he looks to his desk in the room, he sees it.

- Starscream picks the item up, inspecting it, and feels his spark skip a pulse. It’s a small ring and chain, attached to two metal objects. Both in the shape and color of a pineapple and raspberry.

#humans are space orcs#humans are crazy#humans are space australians#humans are deathworlders#humans are weird#transformers#transformers prime#shower thoughts#maccadam#starscream#transformers idw

205 notes

·

View notes

Text

Peanut Butter & Honey Ice Cream

2 cups heavy cream, divided

1 cup whole milk

⅓ cup granulated sugar

3 Tbsp. honey

pinch salt

4 egg yolks

1 tsp. vanilla extract

⅔ cup creamy peanut butter

To make the ice cream, pour 1 cup of the heavy cream into a heat-proof bowl and nest inside a larger bowl filled with ice water. Place a fine mesh sieve over the top of both bowls.

In a saucepan, combine remaining cream, milk, sugar, honey, and salt. Cook gently over medium heat, stirring regularly, until sugar is dissolved and mixture just starts to steam. Remove from heat.

In a small bowl, whisk egg yolks. Slowly whisk in some of the warm cream mixture, 1/3 cup at a time, until about half of the cream mixture has been incorporated and yolk mixture is warm to the touch. You want to do this gradually; doing so will temper the egg yolks rather than cook them.

Pour yolk mixture back into the saucepan and return to medium heat, stirring constantly, until the mixture thickens slightly and coats the back of a spatula, about 5 to 7 minutes, or until it reaches approximately 165 to 170ºF. Do not allow it to boil. Pour mixture through sieve into cold cream, discarding any solids. Add vanilla extract and stir until cool. Cover mixture with plastic wrap, carefully pressing wrap down onto the surface of the cream mixture. This will prevent a skin from forming on top of the custard. Refrigerate until completely cool, at least 3 hours or overnight if possible.

Just prior to churning the ice cream, spoon peanut butter into a piping bag fitted with a medium size round tip (you can also drop dollops of peanut butter in if you prefer, but I found the piping bag produced a more swirl-like result).

Churn ice cream according to manufacturer’s instructions. When ice cream is the consistency of soft serve, squeeze in the peanut butter, swirling it evenly throughout the ice cream, then transfer to a freezer safe container and freeze overnight until firm.

#angelkin#food#dessert#ice cream#gluten free#vegetarian#heavy cream#milk#honey#egg#vanilla#nuts#peanut#peanut butter#dogkin#ghostkin#phoenixkin#succubuskin#tricksterkin#spring#Summer

52 notes

·

View notes

Text

Hazard 4 Blastwall Hardshell Sling Pack

Hazard 4 Blastwall Sling Pack boasts a multitude of features, making it a highly functional and versatile choice for gear organisation and protection. With its lightweight shell/pad construction, padded walls, and modular dividers, you can efficiently arrange and safeguard your belongings.

Additionally, the pack offers a dedicated rear compartment for laptops or hydration bladders, an admin organiser panel for pens, multi-tools, SD cards, tablets, and more, as well as multiple MOLLE webbing for attaching extra gear.

For comfort, the main strap is padded with 3-D air mesh, and the abrasion-resistant moulded back pad not only adjusts to your spine but also enhances ventilation, ensuring a pleasant carrying experience even during extended use.

Manufactured from durable Cordura 1000D nylon or 600D polyester, with reinforced stitch patterns for added strength and longevity, this tactical sling bag is built to withstand the rigours of everyday use.

Whether you're carrying cameras, drones, laptops/tablets, or using it for motorcycle excursions, Hazard 4 Blastwall Sling Pack is the perfect companion for your adventures.

Find out more at Military 1st online store.

http://mil1.st/BSPBSSCPUK

Enjoy free UK delivery and returns! Swift delivery to Ireland, the US, Australia, and across Europe.

#hazard 4 california#military 1st#hazard4#hazard4california#prepared4anyhazard#backpack#slingpack#shellpack#photogear#airsoft#softair#camouflage#camo#gear#gearporn#tactical#tactical gear#tacticool#hiking#hike#outdoors#trekking#wilderness#get outside#opt outside#into the woods#preppers#survival#adventure photography#gear up for action

12 notes

·

View notes

Text

And now for something completely different: a random product review!

This is a Port Authority Xcape BG100 computer backpack, with print-on-demand customization by Spreadshirt/Spreadshop. In the US, it retails for $27+tax from Mozilla's apparently-official merch shop, which regularly has free shipping promotions.

Now, first off, and importantly when considering this an ostensible piece of branded merchandise: the Firefox Aurora logo (now Nightly, but I'm sure you can see why Aurora was the original name/branding) that I picked here is apparently a terrible choice for generic print-on-demand, since the teal color it fades to at the upper right is probably way too saturated to be printable with a lot of processes. Mozilla probably shouldn't offer this design on this product, and I can't say anything about how good Spreadshirt's print accuracy is based on this.

That being said, in this particular case I don't actually care about this at all; if you just told me the result is a random (natural-gas-flame-themed?) alternative colorway for the Firefox logo I'd believe you:

Now, on to more practical matters. This product is, for some reason, $27. The same backpack on Amazon, without customization, is... $32. The bottom-of-the-barrel Amazon Basics backpack that appears when I search "backpack" on Amazon is $24. We're not talking about some $250 LTT bullshit here; the bar is somewhere around "it doesn't suck," and it definitely doesn't suck.

Size is important. I wouldn't call this a huge bag in length and width, but the claimed 7" depth seems about right and makes for a pretty voluminous interior. The angle shown on the sale page rather undersells the depth; the manufacturer's image might oversell it a bit (that one's pretty stuffed) but I would call it a reasonable, practical size.

The laptop pocket is described as fitting "most 17" laptop computers," and I think that's about right, maybe a bit optimistic considering how huge a 17" gaming laptop is these days. A typical 16" gaming laptop should fit fine (not going to bother to borrow my friend's to try it unless someone asks). I don't put my laptop directly in my bag, though, I put it in a sleeve, and a 16" M1 Macbook Pro in a padded sleeve just fits through the side zipper, which is what I need it to do, so, hey. I would call it minimally padded; I haven't tried other tech backpacks so I don't know what the standard is here but I would not want to put my laptop in without a sleeve. The separate laptop compartment and sleeve are more than it looks like you get on a lot of cheap backpacks, though.

Besides that, there are half-height and full-height flat front pockets, one with an organizer (with a zippered mesh; manufacturer pic is a bit old), and then the one big main compartment. No comments here; that's about how I'd do it. It's not much organization, but a lot of space efficiency if you're packing e.g. clothes. The zipper for the large compartment is angled, as you can see in the pic, which I think is smart. The elastic water bottle mesh pockets on the sides seem to work (my old bag's weren't deep enough and so the bottle would fall out, making them functionally useless; they probably should have angled the ones on this bag a little less but I think they're secure enough).

Build quality seems perfectly adequate; I can find no cut corners or anything chintzy, which is saying a lot for merch. Handling it, I'd easily believe you if you told me this was $60+ (and maybe it was when it came out in, I think, 2018). Zippers are large enough and smooth (plastic coil; metal body); strap padding and ventilation are reasonable; back padding and ventilation are rather good. The plastic top handle is a nice touch. (I might avoid using it if you filled the bag with something really, really dense; because of that angled zipper the handle attach point isn't on the strongest part of the bag, but whatever).

I have the "charcoal" color, which is a subtle two-tone. I wasn't sure if the grey would be very light, which wouldn't look great IMHO; the color is actually on the darker side, certainly darker than those photos depending on light angle, and really just makes it read as a black backpack that someone put significant effort designing some visual depth into. The use of multiple material pieces and angled stitching does look quite sharp; looking at it, I'd probably believe you if you told me it was $120?

So, in conclusion, uh... I dunno. I can't immediately think of anything I would change about it, and while I haven't tried any other competing products, it seems better-designed, better-looking, and less expensive than other similar things you could buy, and I guess it's also technically Firefox (or whatever else you want if you just go on Spreadshirt) merch.

Buy used stuff, obviously, when you can, and consider more environmentally friendly fabrics or whatever. But other than that, yeah, sure, if you need a backpack go buy this. It's cheaper than the price bump for a year of ad-free Tumblr, so that's something.

3 notes

·

View notes

Text

Understanding PP Mesh Bags and Leno Mesh Bags: The Versatile Solutions

0 notes

Text

Casa fashion is one of the best Mesh Tote Bag. We have our own manufacturing unit in india for Mesh Tote Bag manufacturing and we export best quality Mesh Tote Bag products

#Casa fashion is one of the best Mesh Tote Bag#our own manufacturing unit in india for Mesh Tote Bag#export best quality Mesh Tote Bag products

0 notes

Text

The Complete Guide to Non-Woven Geotextiles

Introduction to Non Woven Geotextiles

Geotextiles refer to permeable, polymeric textile materials used in contact with soil or rock in civil engineering applications. They can be woven or non woven.

Non woven geotextiles are made by bonding polymeric fibers together through processes like needle punching, heat bonding or resin bonding. The random arrangement of fibers produces a strong, porous and flexible material.

Geotextiles that are non-woven are better than those that are woven. They are better at filtering, draining, and cushioning, and are easier to install. In addition, they are more budget-friendly. These characteristics make non-wovens ideal for many functions like filtration, drainage, separation, and reinforcement.

Needle Punched Non Woven Geotextiles

Needle punched non wovens are a major type of non woven geotextile produced by mechanically orienting and entangling fibers. Hundreds of fine needles repeatedly penetrate a fiber web to tangle the fibers into a strong, porous and stable fabric.

Types of Needle-Punched Non-Woven Geotextiles

Needle punched non wovens can be categorized into three main types based on weight and fiber thickness:

Lightweight Needle Punched Non Wovens

Made from fine fibers and low fiber weights between 20–100 gsm. Mainly used in applications that do not require high strength.

Medium Weight Needle Punched Non Wovens

Heavier fibers and medium basis weights of 100–250 gsm. Provides moderate strength for functions like separation.

Heavyweight Needle Punched Non Wovens

Very coarse, thick fibers and high basis weights above 250 gsm. Imparts maximum strength for reinforcement uses.

Selections depends on the target function. Non-woven fabrics can be categorized into lightweight and heavyweight variants.

Key Functions and Applications of Non Woven Geotextiles

Non woven geotextiles perform various functions that make them indispensable for major infrastructure and construction projects:

Filtration Applications

The porous structure allows water to pass through while blocking soil particles. This filtration ability is useful in:

Roadway drainage systems

Retaining walls

Landfill drainage

Water treatment plants

Drainage Applications

Non wovens have high water flow rates in the principal direction. This makes them excellent for drainage purposes like:

Landfill drainage layers

Sports field drainage

Retaining wall and slope drainage

Separation Applications

The fabric physically separates dissimilar materials. Key applications include:

Roadway base and subbase separation

Railroad bed separation

Foundations separation

Reinforcement Applications

Non wovens provide reinforcement for additional strength when wrapped around soil. Uses include:

Embankments over soft soils

Retaining walls with stacked blocks

Slopes requiring improved bearing capacity

Erosion Control Applications

The fabric acts as a permeable layer to protect against wind and water erosion while allowing water passage. Some uses are:

Covering slopes along railways and highways

Coastal embankments erosion control

Riverbanks and canals protection

Transportation Applications

Within road construction, non wovens assist with filtration, separation, drainage and stabilization. Common applications:

Separation between sub-base and subgrade

Filtration in edge drains alongside pavements

Soil stabilization for improved load bearing

Construction Applications

Foundations and walls drainage

Vapor barriers in concrete slabs

Flooring reinforcement and crack prevention

This demonstrates the versatility of non woven geotextiles across diverse functions in C&I projects. Their adaptive properties drive widespread adoption.

Key Properties of Non Woven Geotextiles

Non woven geotextiles exhibit unique properties derived from their material composition, manufacturing method and overall structure:

Raw Materials

Most non wovens use polypropylene as the raw material which is cost-effective and provides required properties. High-end variants use polyester or a polypropylene-polyester blend.

Basis Weight

Basis weight is the mass per unit area measured in g/m2. Heavier basis weights produce stronger fabrics with higher puncture resistance. Typical range is from 20 g/m2 to 300 g/m2.

Thickness

Thickness depends on fiber density and varies from 1mm to 15mm. Affects permeability, cushioning ability and separation effectiveness.

Hydraulic Properties

Non wovens have high water permeability (normal to the plane) and adequate transmissivity. Allows swift drainage while blocking soil passage.

Mechanical Properties

Tensile strength, tear strength, puncture resistance and burst strength are key mechanical properties. Non woven selection depends on required load capacity.

Endurance Properties

Long-term resistance against environmental exposure, chemicals, microbes and mechanical stresses comes under endurance properties. Requires proper polymer choice.

These characteristics directly impact the effectiveness and lifespan of the non woven geotextile for its intended function.

Overview of Manufacturing Processes

Non woven geotextile production involves specialized processes to achieve the desired fiber arrangement and properties:

Web Formation

The first step is creating a uniform web of fibers laid out in overlapping, random orientations using air, mechanical or wet-laid techniques.

Web Bonding

The fiber web undergoes thermal, chemical or mechanical bonding. This interlocks the fibers to impart strength, stability and thickness.

Finishing

Additional treatments enhance properties ��� for instance, calendering uses heated rollers to achieve smoothness. Fabric edges are trimmed to create rolls.

Testing and Inspection

Extensive testing under certified labs evaluates parametes like strength, permeability, opening size etc. This ensures compliance with specifications.

Keeping manufacturing consistent and monitoring variabilities is vital for non woven quality assurance. Automation allows scalable production with minimal defects.

Design and Installation Factors for Non Woven Geotextiles

Site Preparation

The installation site must be graded uniformly and cleared of debris/rocks to avoid damage. Burial depth is determined. Subsurface drainage may be added.

Installation Techniques

Non wovens can be unrolled on site and placed loose or tense. Joints are sewn or bonded. Additional layers can be installed to enhance functioning. Fixings like sandbags or pegs may be used.

Seams and Overlaps

Adjoining rolls are overlapped for continuity. End overlaps depend on joint strength. Edges can be sewn, welded, glued or kept loose. Key consideration for soil retention uses.

Design Factors

Careful specifications of geotextile properties like strength, permeability, and opening size based on engineering requirements and testing. Survivability and performance lifetime also key.

Following recommended practices for non woven deployment optimizes field performance and prevents failures.

Key Benefits and Advantages of Using Non Woven Geotextiles

Non woven geotextiles offer numerous benefits that make them advantageous over traditional materials:

Cost-Effectiveness

Made from polypropylene, non wovens are an affordable alternative to CMP pipe drains or graded aggregates for drainage. Limited overlap joints also reduce quantity required.

Rapid Drainage Performance

The high porosity provides greater flow capacity compared to sand filters or gravel layers. Useful in applications like retaining walls.

Good Puncture and Burst Resistance

The entangled fibrous structure provides better resistance against punctures during installation compared to woven geotextiles.

Ease of Installation

Flexible, lightweight non wovens are simpler to install in field conditions compared to rigid materials. No special equipment needed.

Enhanced Properties

Specialized manufacturing processes like calendering and bonding creates improved non wovens with the right balance of filtration, separation, cushioning and strength.

Wider Widths

Ability to produce up to 5m wide rolls compared to just 1m for wovens leads to faster deployment with fewer joints.

These advantages have positioned non wovens as a material of choice for major construction activities and geotechnical engineering applications.

Applications and Case Studies Demonstrating Non Woven Geotextiles in Action

Non woven geotextiles have delivered value across many real world projects:

Landfill Construction — Needle punched non wovens used in leachate collection systems increased design life while reducing clogging through superior filtration compared to gravel layers.

Retaining Wall Drainage — Heat bonded non wovens used as wall wraps maintained water drainage and prevented soil washout, keeping 100km of critical rail walls safely stabilized through extreme weather.

Riverbank Protection — Durable non woven wraps applied on embankments prevented erosion along highly flood-prone rivers through monsoons. Filtered runoff while retaining soil stability.

Roadway Improvement — Calendered non wovens beneath motorway overpasses provided vital reinforcement to stabilize compressible soil while facilitating drainage and preventing pumping.

Coastal Reinforcement — Wide width non wovens encasing sandy coastal cliffs added shear strength and tensile reinforcement. Protected against collapse from rising sea levels and storm surge.

This demonstrates how non wovens of different compositions can be adapted for specialized needs in infrastructure projects where performance and longevity are critical.

Industry Trends and Ongoing Innovations in Non Woven Geotextiles

High Growth Potential — The non wovens market is projected to grow steadily at 6% CAGR driven by major public infrastructure investments and demand from emerging economies.

Raw Material Advances — Enhanced polymers like high-density polypropylene and high-modulus polyester are creating improved non wovens with greater functionality.

Manufacturing Improvements — Advancements in processing and techniques now enable precise manipulation of fiber properties during production.

Multifunctional Products — Combining non wovens with drainage nets or reinforcing grids creates single products that provide filtration, separation and reinforcement together.

Application R&D — Ongoing research into novel uses for non wovens like landfill caps, nuclear waste containment and offshore geotextiles to drive adoption across new domains.

Conclusion

Non woven geotextiles have become an indispensable resource for civil engineering and infrastructure applications where their high permeability, strength, and versatility can enhance project outcomes and lifespan.

As materials and manufacturing continue evolving, non wovens are poised to meet more specialized demands. With a thorough understanding of their capabilities, civil engineers can apply these adaptable fabrics for a sustainable future.

1 note

·

View note