#woven fabric manufacturers

Explore tagged Tumblr posts

Text

Moroccan Made

33 notes

·

View notes

Text

Woven metal interiors

0 notes

Text

SAMI Layer Pavement Fabrics: Boost Road Durability

SAMI Layer Pavement Fabrics: Boost Road Durability

Introduction:

In the ever-evolving landscape of road construction, innovations like SAMI layer pavement fabrics are transforming the way we approach durability and longevity in infrastructure. This blog post explores the key benefits and applications of SAMI layer fabrics, shedding light on how they play a crucial role in enhancing the resilience of our roads.

Understanding SAMI Layer Pavement Fabrics:

How SAMI Layer Fabrics Boost Road Durability

SAMI layer pavement fabrics strengthen the road in multiple ways:

Crack Prevention

Acting as a barrier, the SAMI fabric inhibits cracks from appearing and spreading across the road surface. This adds years to the pavement life. The bonded fabric intercepts cracks at the surface level preventing downward propagation into the base layers.

Enhanced Structural Stability

The integration of the high-modulus SAMI layer evenly distributes traffic loads over a broader pavement area. This reduces concentrated stresses and deformations leading to pavement failures. The outcome is improved stability and strength.

All-Weather Reliability

SAMI fabrics are engineered using polymers like polyester, polyethylene or glass fibers that can withstand diverse environmental conditions from freezing winters to scorching summers. This makes roads more reliable through changing seasons.

Extended Lifespan

The collective impact of crack prevention, load distribution and weather resistance provided by SAMI layers is a significantly extended road lifespan. The surface maintains integrity for longer periods without requiring repairs and rehab.

Sustainable Construction

Applications of SAMI Layer Pavement Fabrics

Some prominent applications that highlight the benefits of SAMI layers include:

Road Rehabilitation

Applying SAMI fabrics provide an economical overlay solution for rehabilitating aged, damaged road surfaces. The fabric strengthens the existing base while providing a new wearing course.

New Road Construction

Integrating a SAMI layer into new road construction leads to more crack-resistant, durable surfacing that extends the period between overlays.

Preventing Reflective Cracking

SAMI layers serve as effective crack retarders at the interface of old and new pavement sections. This addresses reflective cracking, a common issue in road overlays.

Bridge Deck Protection

In conclusion:

SAMI layer pavement fabrics are a game-changer in the realm of road construction, offering a sustainable and effective solution for enhancing the durability of our infrastructure. As we pave the way to the future, these innovative fabrics prove to be an indispensable asset in creating roads that can withstand the test of time.

#geotextile#pavement#non woven fabrics#woven mesh fabric#pp woven bags#woven#woven fabric manufacturers#fabrics

0 notes

Text

Non-woven geotextiles are an important category of geosynthetics used across a wide range of infrastructure and construction applications. This guide provides a deep dive into what non-wovens are, their types, key properties, manufacturing processes, installation methods, advantages, applications, and more.

Introduction to Non-Woven Geotextiles

Geotextiles refer to permeable, polymeric textile materials used in contact with soil or rock in civil engineering applications. They can be woven or non-woven.

Non-woven geotextiles are made by bonding polymeric fibers together through processes like needle punching, heat bonding or resin bonding. The random arrangement of fibres produces a strong, porous and flexible material.

Geotextiles that are non-woven are better than those that are woven. They are better at filtering, draining, and cushioning, and are easier to install. In addition, they are more budget-friendly. These characteristics make non-wovens ideal for many functions like filtration, drainage, separation, and reinforcement.

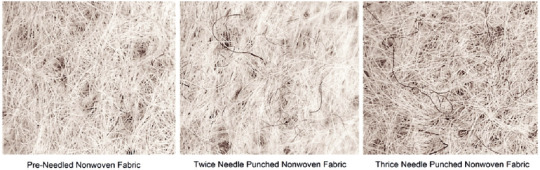

Needle Punched Non-Woven Geotextiles

Needle-punched non-wovens are a major type of non-woven geotextile produced by mechanically orienting and entangling fibers. Hundreds of fine needles repeatedly penetrate a fibre web to tangle the fibres into a strong, porous and stable fabric.

Compared to other non-wovens, needle-punched variants have high permeability and drainage capacity along with good puncture resistance. This makes them ideal for filtration and drainage applications.

Types of Needle-Punched Non-Woven Geotextiles

Needle-punched non-wovens can be categorized into three main types based on weight and fiber thickness:

Lightweight Needle Punched Wovens

Made from fine fibres and low fiber weights between 20-100 gsm. Mainly used in applications that do not require high strength.

Medium Weight Needle Punched Non Wovens

Heavier fibers and medium basis weights of 100-250 gsm. Provides moderate strength for functions like separation.

Heavyweight Needle Punched Non-Wovens

Very coarse, thick fibres and high basis weights above 250 gsm. Imparts maximum strength for reinforcement uses.

Selections depend on the target function. Non-woven fabrics can be categorized into lightweight and heavyweight variants.

Key Functions and Applications of Non-Woven Geotextiles

Non-woven geotextiles perform various functions that make them indispensable for major infrastructure and construction projects:

Filtration Applications

The porous structure allows water to pass through while blocking soil particles. This filtration ability is useful in:

Roadway drainage systems

Retaining walls

Landfill drainage

Water treatment plants

Drainage Applications

Nonwovens have high water flow rates in the principal direction. This makes them excellent for drainage purposes like:

Landfill drainage layers

Sports field drainage

Retaining wall and slope drainage

Separation Applications

The fabric physically separates dissimilar materials. Key applications include:

Roadway base and subbase separation

Railroad bed separation

Foundations separation

https://www.aakarperiwal.com/blogs/wp-content/uploads/2023/09/geotextile-500x500-3.webp

Reinforcement Applications

Non-wovens provide reinforcement for additional strength when wrapped around soil. Uses include:

Embankments over soft soils

Retaining walls with stacked blocks

Slopes requiring improved bearing capacity

Erosion Control Applications

The fabric acts as a permeable layer to protect against wind and water erosion while allowing water passage. Some uses are:

Covering slopes along railways and highways

Coastal embankments erosion control

Riverbanks and canal protection

Transportation Applications

Within road construction, non-wovens assist with filtration, separation, drainage and stabilization. Common applications:

Separation between sub-base and subgrade

Filtration in edge drains alongside pavements

Soil stabilization for improved load-bearing

Construction Applications

Foundations and walls drainage

Vapor barriers in concrete slabs

Flooring reinforcement and crack prevention

This demonstrates the versatility of non-woven geotextiles across diverse functions in C&I projects. Their adaptive properties drive widespread adoption.

Key Properties of Non-Woven Geotextiles

Non-woven geotextiles exhibit unique properties derived from their material composition, manufacturing method and overall structure:

Raw Materials

Most non-wovens use polypropylene as the raw material which is cost-effective and provides required properties. High-end variants use polyester or a polypropylene-polyester blend.

Basis Weight

Basis weight is the mass per unit area measured in g/m2. Heavier basis weights produce stronger fabrics with higher puncture resistance. Typical range is from 20 g/m2 to 300 g/m2.

Thickness

Thickness depends on fiber density and varies from 1mm to 15mm. Affects permeability, cushioning ability and separation effectiveness.

Hydraulic Properties

Non-wovens have high water permeability (normal to the plane) and adequate transmissivity. Allows swift drainage while blocking soil passage.

Mechanical Properties

Tensile strength, tear strength, puncture resistance and burst strength are key mechanical properties. Non woven selection depends on the required load capacity.

Endurance Properties

Long-term resistance against environmental exposure, chemicals, microbes and mechanical stresses comes under endurance properties. Requires proper polymer choice.

These characteristics directly impact the effectiveness and lifespan of the non-woven geotextile for its intended function.

Overview of Manufacturing Processes

Non-woven geotextile production involves specialized processes to achieve the desired fiber arrangement and properties:

Web Formation

The first step is creating a uniform web of fibres laid out in overlapping, random orientations using air, mechanical or wet-laid techniques.

Web Bonding

The fiber web undergoes thermal, chemical or mechanical bonding. This interlocks the fibres to impart strength, stability and thickness.

Finishing

Additional treatments enhance properties - for instance, calendering uses heated rollers to achieve smoothness. Fabric edges are trimmed to create rolls.

Testing and Inspection

Extensive testing under certified labs evaluates parameters like strength, permeability, opening size etc. This ensures compliance with specifications.

Keeping manufacturing consistent and monitoring variabilities is vital for non-woven quality assurance. Automation allows scalable production with minimal defects.

Design and Installation Factors for Non-Woven Geotextiles

Proper design, handling and deployment of non-wovens ensures successful project outcomes:

Site Preparation

The installation site must be graded uniformly and cleared of debris/rocks to avoid damage. Burial depth is determined. Subsurface drainage may be added.

Installation Techniques

Non wovens can be unrolled on site and placed loose or tense. Joints are sewn or bonded. Additional layers can be installed to enhance functioning. Fixings like sandbags or pegs may be used.

Seams and Overlaps

Adjoining rolls are overlapped for continuity. End overlaps depend on joint strength. Edges can be sewn, welded, glued or kept loose. Key consideration for soil retention uses.

Design Factors

Careful specifications of geotextile properties like strength, permeability, and opening size based on engineering requirements and testing. Survivability and performance lifetime also key.

Following recommended practices for non-woven deployment optimizes field performance and prevents failures.

Key Benefits and Advantages of Using Non-Woven Geotextiles

Non-woven geotextiles offer numerous benefits that make them advantageous over traditional materials:

Cost-Effectiveness

Made from polypropylene, non-wovens are an affordable alternative to CMP pipe drains or graded aggregates for drainage. Limited overlap joints also reduce the quantity required.

Rapid Drainage Performance

The high porosity provides greater flow capacity compared to sand filters or gravel layers. Useful in applications like retaining walls.

Good Puncture and Burst Resistance

The entangled fibrous structure provides better resistance against punctures during installation compared to woven geotextiles.

Ease of Installation

Flexible, lightweight non-wovens are simpler to install in field conditions compared to rigid materials. No special equipment needed.

Enhanced Properties

Specialized manufacturing processes like calendering and bonding create improved non-wovens with the right balance of filtration, separation, cushioning and strength.

Wider Widths

The ability to produce up to 5m wide rolls compared to just 1m for wovens leads to faster deployment with fewer joints.

These advantages have positioned non-wovens as a material of choice for major construction activities and geotechnical engineering applications.

Applications and Case Studies Demonstrating Non-Woven Geotextiles in Action

Non-woven geotextiles have delivered value across many real-world projects:

Landfill Construction - Needle-punched non-wovens used in leachate collection systems increased design life while reducing clogging through superior filtration compared to gravel layers.

Retaining Wall Drainage - Heat-bonded non-wovens used as wall wraps maintained water drainage and prevented soil washout, keeping 100km of critical rail walls safely stabilized through extreme weather.

Riverbank Protection - Durable non-woven wraps applied on embankments prevented erosion along highly flood-prone rivers through monsoons. Filtered runoff while retaining soil stability.

Roadway Improvement - Calendered non-wovens beneath motorway overpasses provided vital reinforcement to stabilize compressible soil while facilitating drainage and preventing pumping.

Coastal Reinforcement - Wide-width non-wovens encasing sandy coastal cliffs added shear strength and tensile reinforcement. Protected against collapse from rising sea levels and storm surges.

This demonstrates how non-wovens of different compositions can be adapted for specialized needs in infrastructure projects where performance and longevity are critical.

Industry Trends and Ongoing Innovations in Non-Woven Geotextiles

Several interesting trends, developments and innovations are shaping the non-woven geotextiles sector:

High Growth Potential - The non-wovens market is projected to grow steadily at 6% CAGR driven by major public infrastructure investments and demand from emerging economies.

Raw Material Advances - Enhanced polymers like high-density polypropylene and high-modulus polyester are creating improved non-wovens with greater functionality.

Manufacturing Improvements - Process enhancements and new techniques are allowing more fine-tuned manipulation of fiber properties during production.

Multifunctional Products - Combining non-wovens with drainage nets or reinforcing grids creates single products that provide filtration, separation and reinforcement together.

Application R&D - Ongoing research into novel uses for non-wovens like landfill caps, nuclear waste containment and offshore geotextiles to drive adoption across new domains.

Conclusion

Non-woven geotextiles have become an indispensable resource for civil engineering and infrastructure applications where their high permeability, strength, and versatility can enhance project outcomes and lifespan.

As materials and manufacturing continue evolving, non-wovens are poised to meet more specialized demands. With a thorough understanding of their capabilities, civil engineers can apply these adaptable fabrics for a sustainable future.

0 notes

Text

instagram

Shava 白黒の書道

#black and white#fall 2023#calligraphy#egyptiancotton#knitting#woven fabric manufacturers#cashmere#pashmina#shawls#bespoke#shava#stoles#exclusive#silk#unique#shopping#Instagram

1 note

·

View note

Link

Woven Fabric Manufacturers - Response Fabrics

Woven Fabric Manufacturers

If you want to get the best Woven Fabric Manufacturer in India then Response Fabrics is one of the top well renowned manufacturers of a broad assortment of Woven Fabric, Upholstery Fabric, Mesh Fabric, Blackout Fabric, etc. The offered fabrics are woven at the well-developed manufacturing unit by making use of premium quality yarns, and threads in compliance with defined quality standards. The production department is well-furnished with ultra-modern machines, tools, and equipment to weave these fabrics.

Woven Fabric Manufacturers in india

Response Fabrics has the best solution for the best selective variety of designer Woven fabric that is a delight to those who wear it as well as those who touch, and see it. The collection of woven fabric online gives the best look altogether. The threads used in our woven fabrics are durable, and fade resistant. This brings great joy for all the customers who buy cheap upholstery fabric from our online store & enjoy different benefits from these.

Woven Fabric Suppliers in India

Response Fabrics comes under the top supplier for woven fabrics in India. This produces high quality\ world class products according to customer needs, and wants. The raw materials used are safe for your upholstery fabrics. These fabrics are alluring look, captivating pattern, smooth texture, flawless finish, tear resistant, colorfastness, and longevity.

Woven Fabric Manufacturer in Surat

Response Fabrics is the top designer for woven fabric Manufacturers in Surat that offers the premium quality woven in various ranges that is known for its best quality, and at affordable prices. This is known to be the one of the popular associations occupied with giving brilliant quality material. The offered extent is unequivocally outlined & created utilizing premium quality fundamental material & advanced innovation. Additionally, we offer manufactured leather in various hues, and outlines according to the necessity of the customer at sensible costs.

Polyester Woven Fabric Manufacturers in India

Response Fabric is a manufacturer & exporter of polyester woven fabric in India. We are having all necessary facilities to control the quality, and reliability of our products. We manufacture 100% cotton fabrics, 100% polyester, blended fabrics in various constructions in various weights & widths.

Non Woven Fabric Manufacturer in Uttar Pradesh

Response Fabric is considered as the leading Non Woven Fabric Manufacturers in Uttar Pradesh. This provides for comfortable usage, and maintenance support. These fabrics are a widely popular furnishing fabric choice among the customers. These fabrics are in varieties of finish textures, color options, and designs.

Narrow Woven Fabric Manufacturers in India

Response Fabric offers a premium selection of Narrow Woven Fabric online by the yard. Our vast selection of woven fabric offers an excellent choice for any, and all interior upholstery applications, it just depends on what you’re looking for, included in our selections are very durable, and comfortable casual fabrics for high use areas of your home to very elegant fabrics for a more formal setting. Our Narrow Woven fabrics boast high quality construction, high-ends pattern design, and terrific durability.

READ MORE...Fabric Manufacturers In India - Response Fabrics

#Woven Fabric Manufacturers#Woven Fabric Manufacturers in india#Woven Fabric Suppliers in India#Woven Fabric Manufacturer in Surat

0 notes

Text

How to Choose the Best Fusible Interlining Manufacturer

Fusible interlining plays a crucial role in the textile and garment industry, providing structure, durability, and improved finishing to fabrics. Choosing the proper manufacturer for fusible interlining can significantly impact the quality of your final product. With numerous manufacturers in the market, it is essential to evaluate various factors before making a decision.

This comprehensive guide will help you understand the key aspects of selecting a fusible interlining manufacturer, ensuring that your business benefits from high-quality materials and reliable supply chains.

A. What is Fusible Interlining?

Fusible interlining is a fabric that has an adhesive coating, allowing it to be bonded to another fabric using heat and pressure. It is widely used in the garment industry for:

· Enhancing fabric stability

· Providing additional support and shape

· Improving the longevity of garments

B. Types of Fusible Interlining

Before selecting a manufacturer, it's essential to understand the different types of fusible interlining available:

· Woven Fusible Interlining — Provides strength and stability

· Non-Woven Fusible Interlining — Lightweight and cost-effective

· Knitted Fusible Interlining — Offers flexibility and softness

· Double-Sided Fusible Interlining — Bonds two fabric layers together

Key Factors to Consider When Choosing a Fusible Interlining Manufacturer

Selecting the best manufacturer involves assessing several critical factors. Here’s what you should look for:

A. 2.1 Quality Standards

Quality should be your top priority. Evaluate the manufacturer based on the following:

· Fabric consistency and adhesion quality

· Shrinkage and durability tests

· Certifications such as OEKO-TEX, ISO 9001

· Performance in different fabrics and garment applications

B. 2.2 Material Selection

A good manufacturer should offer a variety of fusible interlining options in different materials:

· Cotton

· Polyester

· Polyamide blends

· Viscose

Ensure the manufacturer provides customized solutions based on your needs.

Manufacturing Process and Technology

Advanced technology ensures higher precision and durability. Consider manufacturers that use:

· State-of-the-art coating machines

· Laser cutting for precise sizing

· Automated quality control systems

Ask for a factory tour or video demonstration of their production process.

Sourcing and Supply Chain Reliability

3.1 Location and Distribution Network

Choose a manufacturer with strategic locations for easier logistics and cost-effective shipping. Evaluate:

· Manufacturing locations

· Global distribution network

· Lead times for production and shipping

3.2 Scalability

Your chosen manufacturer should be able to scale production as your business grows. Consider:

· Their monthly production capacity

· Ability to handle bulk orders

· Whether they provide flexibility for small batches if required

3.3 Cost-Effectiveness

Cost is a significant factor, but compromising on quality can harm your brand. Look for:

· Competitive pricing without sacrificing quality

· Bulk order discounts

· Transparent pricing with no hidden costs

Sustainability and Environmental Responsibility

Eco-friendly manufacturing is a growing concern in the textile industry. Check if the manufacturer:

· Uses non-toxic adhesives

· Follows sustainable production methods

· Has waste reduction policies

· Provides recyclable or biodegradable interlining options

Many brands prefer working with suppliers who align with their sustainability goals.

Customer Support and After-Sales Service

A reliable manufacturer should offer excellent customer support. Key aspects to look for include:

· Technical assistance for product selection

· Fast response times for inquiries and complaints

· Replacement and refund policies

· Training programs for using their products effectively

Case Studies: Successful Partnerships with Leading Manufacturers

Here, we will explore real-world examples of companies that have successfully partnered with top fusible interlining manufacturers. These cases will highlight:

· The selection process they followed

· The benefits they experienced

· Lessons learned from their experiences

Choosing the best fusible interlining manufacturer requires careful research and evaluation. By considering quality, material selection, production capabilities, supply chain reliability, sustainability, and customer service, you can ensure a strong and beneficial partnership.

Would you like a more detailed section on any of these topics? I can expand on specific areas if needed. Let me know how you’d like to proceed!

#non woven interlining#woven interlining#fusible interlining suppliers#china interlining#woven interlining manufacturer#fusible interlining manufacturer#china elastic webbing#china elastic band#down-proof fabric#woven fusible interlining

0 notes

Text

Common Applications of PP Woven Fabric in Agriculture and Farming

PP woven fabrics are a versatile and durable material widely used across industries, particularly in agriculture and farming. These fabrics, crafted by leading PP woven fabric manufacturers in India, are known for their strength, flexibility, and cost-effectiveness. This blog explores the common applications of PP woven fabric bags and PP woven sack bags in the agricultural sector.

What is PP Woven Fabric?

Polypropylene (PP) woven fabric is made by weaving polypropylene threads to create a strong, lightweight material. It is highly resistant to wear and tear, moisture, and chemicals, making it ideal for agricultural and farming applications.

Applications of PP Woven Fabric in Agriculture

1. Packaging of Agricultural Products

Grain Storage: PP woven sack bags are commonly used for storing and transporting grains like wheat, rice, and maize.

Fertilizers and Seeds: PP woven fabric bags provide a reliable solution for packaging fertilizers, seeds, and other agricultural inputs.

Fruits and Vegetables: These bags ensure that fresh produce is safely transported without damage.

2. Erosion Control

PP woven fabrics are used in geotextiles to prevent soil erosion. They act as a barrier to protect soil from water and wind, making them essential in agricultural landscapes and construction.

3. Mulching and Weed Control

PP woven fabric sheets are used as mulch to retain soil moisture and prevent weed growth.

They are particularly useful in controlling weeds without relying on chemicals, ensuring a sustainable farming approach.

4. Shade and Cover Applications

Greenhouse Covers: PP woven fabrics are used as covers for greenhouses to regulate temperature and protect crops from harsh weather.

Crop Protection: These fabrics act as a shield against pests, excessive sunlight, and rain.

5. Storage and Transportation

Bulk Packaging: Farmers and distributors rely on PP woven fabric bags for bulk storage and transportation of goods like animal feed and hay.

Chemical Resistance: The material’s resistance to moisture and chemicals makes it ideal for storing pesticides and other agricultural chemicals.

Why Choose PP Woven Fabric for Agriculture?

Durability: The fabric’s strength ensures long-term use, even under challenging conditions.

Cost-Effective: PP woven fabric bags are affordable, reducing packaging costs for farmers.

Lightweight: Easy to handle and transport, making operations more efficient.

Customizable: PP woven fabric manufacturers in India offer tailored solutions, such as printing logos or product details on the bags.

Role of PP Woven Fabric Manufacturers in India

India is a leading producer of high-quality PP woven fabrics, with manufacturers focusing on innovation and sustainability. PP woven sack bag manufacturers cater to both domestic and international markets, providing solutions tailored to the unique needs of agriculture and farming.

Conclusion

PP woven fabric has revolutionized agriculture and farming with its durability, versatility, and cost-efficiency. From packaging grains to protecting crops, its applications are vast and indispensable. By partnering with reliable PP woven fabric manufacturers in India, farmers can access high-quality products that enhance productivity and sustainability in their operations.

0 notes

Text

Exploring the Elegance of Printed Velvet and Cotton Velvet Fabrics at Sanchi Velvets

Velvet is a fabric synonymous with luxury, and over the years, its versatility and beauty have only increased with the advent of modern fabric innovations. Among these innovations are printed velvet fabrics and cotton velvet fabrics, two styles that combine velvet’s plush texture with contemporary designs and natural materials. At Sanchi Velvets, we offer an exceptional range of both printed and cotton velvet fabrics, each bringing its own unique appeal to the world of fashion, upholstery, and home decor.

Printed Velvet Fabric: The Perfect Fusion of Texture and Design

Printed velvet fabric is a stunning evolution of traditional velvet, offering the perfect combination of luxurious texture and vibrant, detailed designs. Digital and screen printing techniques allow for an endless array of patterns, from rich florals and abstract designs to geometric patterns and even photorealistic imagery. The velvet surface, with its soft pile and deep colors, provides the ideal backdrop for these intricate prints.

Key Features of Printed Velvet Fabric

Vibrant Designs: The printing process results in sharp, bright patterns that truly pop against the plush velvet fabric. Whether you're looking for a traditional floral print or a bold modern pattern, printed velvet offers an unmatched depth of color and visual interest.

Luxurious Feel: Despite the intricate designs, printed velvet retains the signature luxurious feel of velvet, with its soft, rich texture that is perfect for both fashion and home decor.

Versatile Applications: Printed velvet is a perfect choice for creating high-end fashion pieces such as dresses, skirts, blouses, and accessories. It’s equally well-suited for interior design, from statement upholstery and cushions to curtains and bedspreads.

Customizability: At Sanchi Velvets, we offer printed velvet in a range of patterns and colors, allowing for full customization for designers and consumers seeking to make a bold style statement.

With printed velvet, you have the opportunity to create sophisticated garments and furnishings that stand out. The luxurious texture combined with unique designs makes it a go-to fabric for anyone looking to create pieces that are both tactile and visually striking.

Cotton Velvet Fabric: Soft, Breathable Luxury

Cotton velvet is an incredibly popular choice for those seeking the luxury of velvet without the weight and warmth of traditional velvet fabrics. Made from cotton fibers instead of silk or synthetic materials, cotton velvet offers a soft, breathable alternative while still maintaining the rich texture and depth of traditional velvet.

Key Features of Cotton Velvet Fabric

Natural Breathability: One of the main benefits of cotton velvet is its breathability. Unlike synthetic velvet, cotton velvet allows for more airflow, making it a more comfortable option for warmer climates or for designs that require long wear.

Soft, Smooth Texture: Cotton velvet maintains the soft, tactile feel of traditional velvet but is often lighter and less dense, which makes it easier to work with for clothing and upholstery projects.

Eco-friendly Option: As cotton is a natural, renewable resource, cotton velvet can be considered an eco-friendlier option compared to synthetic velvets, offering a more sustainable choice for conscientious designers and consumers.

Versatility in Fashion and Decor: Cotton velvet is highly versatile and can be used for both casual and formal clothing. It is a favorite for fashion pieces like dresses, skirts, and jackets, as well as home decor items such as cushions, bed covers, and upholstery.

At Sanchi Velvets, we offer cotton velvet fabrics in a variety of colors and finishes, perfect for creating both elegant garments and cozy, stylish interiors. Whether you're looking to design a flowy cotton velvet dress or transform your living room with cotton velvet cushions, our fabrics bring soft luxury to any project.

Choosing the Right Velvet for Your Project

When deciding between printed velvet fabric and cotton velvet fabrics, consider the intended use and the specific qualities you're looking for in a fabric.

Printed Velvet Fabric is perfect if you're seeking a fabric with intricate patterns, bold designs, or photorealistic prints. Whether you're designing fashion-forward apparel or want to create a statement piece in your home, printed velvet brings visual impact and luxurious texture to your project.

Cotton Velvet Fabric is ideal for those who want a softer, more breathable fabric that still offers the richness and depth of velvet. It’s a great choice for lightweight clothing, casual wear, or home decor pieces that demand comfort, elegance, and sustainability.

Conclusion: Discover Velvet’s Versatility at Sanchi Velvets

At Sanchi Velvets, we pride ourselves on offering a wide range of premium velvet fabrics, including both printed velvet and cotton velvet. Whether you're designing a high-fashion garment, crafting elegant home decor, or creating a unique, custom piece, our velvets provide the ideal combination of luxury, texture, and design flexibility.

Printed velvet offers the excitement of bold, detailed patterns, while cotton velvet provides soft, breathable comfort for a more laid-back elegance. No matter your project, Sanchi Velvets ensures that you'll find the perfect fabric to bring your creative vision to life.

Explore the luxurious world of printed and cotton velvet fabrics at Sanchi Velvets today and discover how these modern takes on a classic fabric can elevate your next design.

To know more about Sanchi Velvets visit us:

#Sunshine Velvets#Gold Line Velvet#Dispro Print Velvet Fabric#Disperse Print Velvet Fabric#Non Velvet Burnout Fabric#Cotton Slub Velvet#Velvet Manufacturers India#Cotton Viscose Velvet#Ice Velvet fabric#Viscose Rayon Velvet#Woven Velvet Fabric#Light Weight Velvet Fabric#Heavy Weight Velvet Fabric#Polyester Viscose Fabric#Foil Print Velvet Fabric#Digital Print Velvet Fabric#Polyester Velvet Fabric#Printed Velvet Fabric#Cotton Velvet Fabric#Polyester Satin Fabric#Floral Printed Velvet Fabric

0 notes

Text

Learn About The Special Weaves And Dyeing

Explore the best collection of special weaves and dyeing at Svarna. Visit the best organic cotton fabric manufacturers for a detailed insight on organic cotton woven fabric and natural fabrics for clothing.

#organic cotton fabric manufacturers#organic cotton woven fabric#natural fabrics for clothing#cotton fabric for clothing

0 notes

Text

The Complete Guide to Non-Woven Geotextiles

Introduction to Non Woven Geotextiles

Geotextiles refer to permeable, polymeric textile materials used in contact with soil or rock in civil engineering applications. They can be woven or non woven.

Non woven geotextiles are made by bonding polymeric fibers together through processes like needle punching, heat bonding or resin bonding. The random arrangement of fibers produces a strong, porous and flexible material.

Geotextiles that are non-woven are better than those that are woven. They are better at filtering, draining, and cushioning, and are easier to install. In addition, they are more budget-friendly. These characteristics make non-wovens ideal for many functions like filtration, drainage, separation, and reinforcement.

Needle Punched Non Woven Geotextiles

Needle punched non wovens are a major type of non woven geotextile produced by mechanically orienting and entangling fibers. Hundreds of fine needles repeatedly penetrate a fiber web to tangle the fibers into a strong, porous and stable fabric.

Types of Needle-Punched Non-Woven Geotextiles

Needle punched non wovens can be categorized into three main types based on weight and fiber thickness:

Lightweight Needle Punched Non Wovens

Made from fine fibers and low fiber weights between 20–100 gsm. Mainly used in applications that do not require high strength.

Medium Weight Needle Punched Non Wovens

Heavier fibers and medium basis weights of 100–250 gsm. Provides moderate strength for functions like separation.

Heavyweight Needle Punched Non Wovens

Very coarse, thick fibers and high basis weights above 250 gsm. Imparts maximum strength for reinforcement uses.

Selections depends on the target function. Non-woven fabrics can be categorized into lightweight and heavyweight variants.

Key Functions and Applications of Non Woven Geotextiles

Non woven geotextiles perform various functions that make them indispensable for major infrastructure and construction projects:

Filtration Applications

The porous structure allows water to pass through while blocking soil particles. This filtration ability is useful in:

Roadway drainage systems

Retaining walls

Landfill drainage

Water treatment plants

Drainage Applications

Non wovens have high water flow rates in the principal direction. This makes them excellent for drainage purposes like:

Landfill drainage layers

Sports field drainage

Retaining wall and slope drainage

Separation Applications

The fabric physically separates dissimilar materials. Key applications include:

Roadway base and subbase separation

Railroad bed separation

Foundations separation

Reinforcement Applications

Non wovens provide reinforcement for additional strength when wrapped around soil. Uses include:

Embankments over soft soils

Retaining walls with stacked blocks

Slopes requiring improved bearing capacity

Erosion Control Applications

The fabric acts as a permeable layer to protect against wind and water erosion while allowing water passage. Some uses are:

Covering slopes along railways and highways

Coastal embankments erosion control

Riverbanks and canals protection

Transportation Applications

Within road construction, non wovens assist with filtration, separation, drainage and stabilization. Common applications:

Separation between sub-base and subgrade

Filtration in edge drains alongside pavements

Soil stabilization for improved load bearing

Construction Applications

Foundations and walls drainage

Vapor barriers in concrete slabs

Flooring reinforcement and crack prevention

This demonstrates the versatility of non woven geotextiles across diverse functions in C&I projects. Their adaptive properties drive widespread adoption.

Key Properties of Non Woven Geotextiles

Non woven geotextiles exhibit unique properties derived from their material composition, manufacturing method and overall structure:

Raw Materials

Most non wovens use polypropylene as the raw material which is cost-effective and provides required properties. High-end variants use polyester or a polypropylene-polyester blend.

Basis Weight

Basis weight is the mass per unit area measured in g/m2. Heavier basis weights produce stronger fabrics with higher puncture resistance. Typical range is from 20 g/m2 to 300 g/m2.

Thickness

Thickness depends on fiber density and varies from 1mm to 15mm. Affects permeability, cushioning ability and separation effectiveness.

Hydraulic Properties

Non wovens have high water permeability (normal to the plane) and adequate transmissivity. Allows swift drainage while blocking soil passage.

Mechanical Properties

Tensile strength, tear strength, puncture resistance and burst strength are key mechanical properties. Non woven selection depends on required load capacity.

Endurance Properties

Long-term resistance against environmental exposure, chemicals, microbes and mechanical stresses comes under endurance properties. Requires proper polymer choice.

These characteristics directly impact the effectiveness and lifespan of the non woven geotextile for its intended function.

Overview of Manufacturing Processes

Non woven geotextile production involves specialized processes to achieve the desired fiber arrangement and properties:

Web Formation

The first step is creating a uniform web of fibers laid out in overlapping, random orientations using air, mechanical or wet-laid techniques.

Web Bonding

The fiber web undergoes thermal, chemical or mechanical bonding. This interlocks the fibers to impart strength, stability and thickness.

Finishing

Additional treatments enhance properties — for instance, calendering uses heated rollers to achieve smoothness. Fabric edges are trimmed to create rolls.

Testing and Inspection

Extensive testing under certified labs evaluates parametes like strength, permeability, opening size etc. This ensures compliance with specifications.

Keeping manufacturing consistent and monitoring variabilities is vital for non woven quality assurance. Automation allows scalable production with minimal defects.

Design and Installation Factors for Non Woven Geotextiles

Site Preparation

The installation site must be graded uniformly and cleared of debris/rocks to avoid damage. Burial depth is determined. Subsurface drainage may be added.

Installation Techniques

Non wovens can be unrolled on site and placed loose or tense. Joints are sewn or bonded. Additional layers can be installed to enhance functioning. Fixings like sandbags or pegs may be used.

Seams and Overlaps

Adjoining rolls are overlapped for continuity. End overlaps depend on joint strength. Edges can be sewn, welded, glued or kept loose. Key consideration for soil retention uses.

Design Factors

Careful specifications of geotextile properties like strength, permeability, and opening size based on engineering requirements and testing. Survivability and performance lifetime also key.

Following recommended practices for non woven deployment optimizes field performance and prevents failures.

Key Benefits and Advantages of Using Non Woven Geotextiles

Non woven geotextiles offer numerous benefits that make them advantageous over traditional materials:

Cost-Effectiveness

Made from polypropylene, non wovens are an affordable alternative to CMP pipe drains or graded aggregates for drainage. Limited overlap joints also reduce quantity required.

Rapid Drainage Performance

The high porosity provides greater flow capacity compared to sand filters or gravel layers. Useful in applications like retaining walls.

Good Puncture and Burst Resistance

The entangled fibrous structure provides better resistance against punctures during installation compared to woven geotextiles.

Ease of Installation

Flexible, lightweight non wovens are simpler to install in field conditions compared to rigid materials. No special equipment needed.

Enhanced Properties

Specialized manufacturing processes like calendering and bonding creates improved non wovens with the right balance of filtration, separation, cushioning and strength.

Wider Widths

Ability to produce up to 5m wide rolls compared to just 1m for wovens leads to faster deployment with fewer joints.

These advantages have positioned non wovens as a material of choice for major construction activities and geotechnical engineering applications.

Applications and Case Studies Demonstrating Non Woven Geotextiles in Action

Non woven geotextiles have delivered value across many real world projects:

Landfill Construction — Needle punched non wovens used in leachate collection systems increased design life while reducing clogging through superior filtration compared to gravel layers.

Retaining Wall Drainage — Heat bonded non wovens used as wall wraps maintained water drainage and prevented soil washout, keeping 100km of critical rail walls safely stabilized through extreme weather.

Riverbank Protection — Durable non woven wraps applied on embankments prevented erosion along highly flood-prone rivers through monsoons. Filtered runoff while retaining soil stability.

Roadway Improvement — Calendered non wovens beneath motorway overpasses provided vital reinforcement to stabilize compressible soil while facilitating drainage and preventing pumping.

Coastal Reinforcement — Wide width non wovens encasing sandy coastal cliffs added shear strength and tensile reinforcement. Protected against collapse from rising sea levels and storm surge.

This demonstrates how non wovens of different compositions can be adapted for specialized needs in infrastructure projects where performance and longevity are critical.

Industry Trends and Ongoing Innovations in Non Woven Geotextiles

High Growth Potential — The non wovens market is projected to grow steadily at 6% CAGR driven by major public infrastructure investments and demand from emerging economies.

Raw Material Advances — Enhanced polymers like high-density polypropylene and high-modulus polyester are creating improved non wovens with greater functionality.

Manufacturing Improvements — Advancements in processing and techniques now enable precise manipulation of fiber properties during production.

Multifunctional Products — Combining non wovens with drainage nets or reinforcing grids creates single products that provide filtration, separation and reinforcement together.

Application R&D — Ongoing research into novel uses for non wovens like landfill caps, nuclear waste containment and offshore geotextiles to drive adoption across new domains.

Conclusion

Non woven geotextiles have become an indispensable resource for civil engineering and infrastructure applications where their high permeability, strength, and versatility can enhance project outcomes and lifespan.

As materials and manufacturing continue evolving, non wovens are poised to meet more specialized demands. With a thorough understanding of their capabilities, civil engineers can apply these adaptable fabrics for a sustainable future.

1 note

·

View note

Text

A Beginner’s Guide to PP Spunbond Nonwoven Fabric Properties

In the realm of textiles, nonwoven fabrics have become increasingly popular due to their versatility and unique properties. Among the various types of nonwoven fabrics, PP spunbond nonwoven fabric stands out for its impressive characteristics and wide range of applications. This guide aims to provide beginners with an understanding of the properties of PP spunbond nonwoven fabric, its production process, and its uses.

Understanding Nonwoven Fabric

To fully appreciate PP spunbond nonwoven fabric, it’s essential to grasp the concept of nonwoven fabric itself. Non woven fabric are materials made from fibers that are bonded together through various methods, excluding traditional weaving or knitting techniques. This production method allows for a fabric that is both lightweight and durable, making it ideal for numerous applications across different industries.

Characteristics of Nonwoven Fabric

One of the most notable characteristics of nonwoven fabric is its flexibility. This property allows manufacturers to create fabrics that can be tailored to meet specific needs. Nonwoven fabrics can be produced in various weights, thicknesses, and textures, offering a broad spectrum of options for manufacturers and end-users alike. Furthermore, the production process can incorporate additional treatments, enhancing properties like water resistance, flame retardancy, and UV stability.

The Role of PP in Nonwoven Fabric

Polypropylene (PP) is a thermoplastic polymer widely used in the production of nonwoven fabrics. As a nonwoven fabric manufacturer, utilizing PP provides several advantages. First, PP is lightweight and has a low density, contributing to the overall lightness of the finished product. Second, it offers excellent chemical resistance, making it suitable for applications where exposure to various substances is expected. Lastly, PP spunbond nonwoven fabric exhibits good tensile strength and durability, which are crucial for ensuring that the fabric can withstand everyday wear and tear.

Properties of PP Spunbond Nonwoven Fabric

When exploring PP spunbond nonwoven fabric, several properties set it apart from other textiles. Here are some of the key attributes:

1. High Strength

One of the primary reasons for the popularity of PP spunbond nonwoven fabric is its high strength. The process of spinning the fibers and bonding them together creates a robust structure that can endure significant stress and strain. This property is particularly valuable in applications like geotextiles and agricultural coverings, where durability is paramount.

2. Breathability

PP spunbond nonwoven fabric is also known for its breathability. The fabric structure allows air to circulate freely, which is beneficial in applications like hygiene products and medical textiles. This breathability helps to keep moisture away from the skin, reducing the risk of skin irritation and infections.

3. Lightweight Nature

The lightweight nature of PP spunbond nonwoven fabric is another significant advantage. This property makes it easy to handle and transport, reducing shipping costs and simplifying manufacturing processes. It also contributes to the comfort of the final product, whether it’s a disposable garment or an industrial filter.

4. Cost-Effectiveness

From a manufacturing perspective, PP spunbond nonwoven fabric is cost-effective. The production process is efficient, allowing for large quantities of fabric to be produced in a relatively short time. Additionally, the raw materials used in creating PP are often less expensive than those for woven fabrics, resulting in lower production costs.

5. Chemical Resistance

As mentioned earlier, one of the advantages of using polypropylene is its excellent chemical resistance. PP spunbond nonwoven fabric can withstand exposure to various chemicals without degrading, making it suitable for medical and industrial applications where contact with chemicals is common.

6. Versatility

PP spunbond nonwoven fabric is incredibly versatile, allowing for a wide range of applications. From disposable medical gowns and face masks to agricultural fabrics and automotive interiors, the possibilities are nearly endless. This versatility makes it a popular choice among Non woven fabric manufacturer, as they can cater to different markets and customer needs.

Production Process of PP Spunbond Nonwoven Fabric

To fully understand the properties of PP spunbond nonwoven fabric, it's essential to explore its production process. The process involves several key steps:

1. Polymer Extrusion

The first step in creating PP spunbond nonwoven fabric is polymer extrusion. In this process, polypropylene pellets are heated until they melt and are then extruded through a spinneret. The spinneret has multiple holes, creating long continuous filaments of polypropylene.

2. Spinning

After extrusion, the filaments are cooled and drawn to enhance their strength. The drawn filaments are then laid out in a random or oriented manner on a conveyor belt. This step is crucial as it determines the final properties of the nonwoven fabric.

3. Bonding

The next step involves bonding the laid fibers together to form a cohesive fabric. This can be achieved through various methods, including thermal, chemical, or mechanical bonding. In the case of PP spunbond nonwoven fabric, thermal bonding is commonly used, where heat is applied to the fabric to fuse the fibers together.

4. Finishing

Once the fabric is bonded, it may undergo finishing processes to enhance its properties. This can include treatments for water repellency, antimicrobial properties, or dyeing. These finishes allow manufacturers to tailor the fabric to specific applications and customer preferences.

Applications of PP Spunbond Nonwoven Fabric

PP spunbond nonwoven fabric finds use in a wide variety of applications, thanks to its unique properties. Here are some common applications:

1. Medical Textiles

In the medical field, PP spunbond nonwoven fabric is used to create surgical gowns, masks, and drapes. Its breathability and strength make it ideal for disposable medical products, helping to maintain hygiene and reduce the risk of infection.

2. Hygiene Products

This type of nonwoven fabric is also widely used in hygiene products such as diapers, feminine hygiene products, and adult incontinence products. The fabric's soft texture and moisture-wicking properties enhance comfort and performance.

3. Agriculture

In agriculture, PP spunbond nonwoven fabric serves as mulch films, crop covers, and weed control fabrics. Its durability and UV resistance make it suitable for protecting crops and promoting healthy growth.

4. Construction

The construction industry utilizes PP spunbond nonwoven fabric in geotextiles, providing drainage and soil stabilization. Its high strength and resistance to chemicals make it an excellent choice for various construction applications.

Conclusion

In summary, PP spunbond nonwoven fabric offers a unique combination of properties that make it an essential material in various industries. Its strength, breathability, lightweight nature, and cost-effectiveness are key attributes that appeal to manufacturers and end-users alike. As the demand for nonwoven fabrics continues to grow, understanding the properties of Non woven fabric spunbond will help beginners appreciate its significance in the modern textile landscape. Whether you're considering purchasing nonwoven fabric or exploring its applications, this beginner's guide provides a solid foundation for understanding this remarkable material. Frequently Asked Questions (FAQs)

Where is PP spunbond nonwoven fabric used? It is used in a variety of applications, including healthcare (surgical gowns and masks), agriculture (crop covers and mulch), geotextiles (soil stabilization), hygiene products (diapers), and packaging (shopping bags). Is PP spunbond nonwoven fabric recyclable? Yes, PP spunbond nonwoven fabric can be recycled, depending on the local recycling facilities. Many manufacturers are now producing fabrics from recycled materials, promoting sustainability.

Can PP spunbond nonwoven fabric be printed on? Yes, PP spunbond nonwoven fabric can be printed on using various techniques, including screen printing and digital printing. This makes it suitable for branding and promotional items.

0 notes

Text

Tips for Importing Seed Bags from India

When importing seed bags from India, research reliable suppliers and ensure compliance with international regulations. Verify product quality through samples and check packaging standards to avoid damage during transit. Negotiate favorable shipping terms and maintain clear communication to streamline the import process and avoid delays.

0 notes

Link

Woven Fabric Manufacturers - Response Fabrics

Woven Fabric Manufacturers

If you want to get the best Woven Fabric Manufacturer in India then Response Fabrics is one of the top well renowned manufacturers of a broad assortment of Woven Fabric, Upholstery Fabric, Mesh Fabric, Blackout Fabric, etc. The offered fabrics are woven at the well-developed manufacturing unit by making use of premium quality yarns, and threads in compliance with defined quality standards. The production department is well-furnished with ultra-modern machines, tools, and equipment to weave these fabrics.

Woven Fabric Manufacturers in india

Response Fabrics has the best solution for the best selective variety of designer Woven fabric that is a delight to those who wear it as well as those who touch, and see it. The collection of woven fabric online gives the best look altogether. The threads used in our woven fabrics are durable, and fade resistant. This brings great joy for all the customers who buy cheap upholstery fabric from our online store & enjoy different benefits from these.

Woven Fabric Suppliers in India

Response Fabrics comes under the top supplier for woven fabrics in India. This produces high quality\ world class products according to customer needs, and wants. The raw materials used are safe for your upholstery fabrics. These fabrics are alluring look, captivating pattern, smooth texture, flawless finish, tear resistant, colorfastness, and longevity.

Woven Fabric Manufacturer in Surat

Response Fabrics is the top designer for woven fabric Manufacturers in Surat that offers the premium quality woven in various ranges that is known for its best quality, and at affordable prices. This is known to be the one of the popular associations occupied with giving brilliant quality material. The offered extent is unequivocally outlined & created utilizing premium quality fundamental material & advanced innovation. Additionally, we offer manufactured leather in various hues, and outlines according to the necessity of the customer at sensible costs.

Polyester Woven Fabric Manufacturers in India

Response Fabric is a manufacturer & exporter of polyester woven fabric in India. We are having all necessary facilities to control the quality, and reliability of our products. We manufacture 100% cotton fabrics, 100% polyester, blended fabrics in various constructions in various weights & widths.

Non Woven Fabric Manufacturer in Uttar Pradesh

Response Fabric is considered as the leading Non Woven Fabric Manufacturers in Uttar Pradesh. This provides for comfortable usage, and maintenance support. These fabrics are a widely popular furnishing fabric choice among the customers. These fabrics are in varieties of finish textures, color options, and designs.

Narrow Woven Fabric Manufacturers in India

Response Fabric offers a premium selection of Narrow Woven Fabric online by the yard. Our vast selection of woven fabric offers an excellent choice for any, and all interior upholstery applications, it just depends on what you’re looking for, included in our selections are very durable, and comfortable casual fabrics for high use areas of your home to very elegant fabrics for a more formal setting. Our Narrow Woven fabrics boast high quality construction, high-ends pattern design, and terrific durability.

READ MORE...Fabric Manufacturers In India - Response Fabrics

#Woven Fabric Manufacturers#Woven Fabric Manufacturers in india#Woven Fabric Manufacturer in Surat#Polyester Woven Fabric Manufacturers in India

0 notes

Text

The Growing Demand for Non-Woven Interlining in China

Non-woven interlining has become an essential factor in the fabric and apparel industry, particularly in China, which stands as one of the world's biggest producers of garments. The growing call for non-woven interlining is pushed by its fee-effectiveness, ease of utility, and versatility in diverse material packages. This article explores the factors behind the development call for non-woven interlining in China, its packages, manufacturing improvements, and the effect on the worldwide fabric market.

The Rise of China's Textile Industry

China has been a dominant pressure inside the global fabric enterprise for a long time, with its large manufacturing capacity, technological improvements, and competitive pricing. The increasing use of non-woven interlining aligns with the USA's goal of improving fabric exceptional even as maintaining value efficiency. The following elements contribute to the developing demand:

Rapid Growth in Apparel Manufacturing: China remains the biggest manufacturer and exporter of clothes, necessitating green and value-effective materials, including non-woven interlining.

Technological Advancements: Innovations in material bonding and lamination procedures have advanced the performance of non-woven interlining.

Environmental Considerations: The shift closer to sustainable and recyclable substances has made the non-woven fabric more excellent and desirable.

Economic Growth and Urbanization: Rising disposable earnings and converting fashion traits pressure elevated garment production, similarly boosting interlining demand.

Advantages of Non-Woven Interlining

Non-woven interlining gives several benefits that contribute to its significant adoption in China:

Cost Efficiency: Less high priced in comparison to the woven interlining, making it a favoured choice for mass manufacturing.

Easy Application: This can be implemented via warmness pressing, reducing hard work and production time.

Durability and Stability: Provides excellent form retention and structure to garments.

Versatility: Suitable for diverse material sorts, together with cotton, polyester, and blends.

Applications of Non-Woven Interlining in China

The demand for non-woven interlining spans diverse industries past just garb. Some key programs encompass:

Garment Industry: Used in collars, cuffs, waistbands, and linings to provide shape and assist.

Automotive Textiles: Applied in automobile seat covers and insulation substances for stronger durability.

Home Furnishings: Utilized in curtains, upholstery, and bed covers to improve power and longevity.

Medical Textiles: Incorporated into surgical gowns, masks, and disposable clinical put on due to its lightweight and breathable properties.

Key Manufacturers and Suppliers in China

With growing demand, numerous leading producers and suppliers cater to the non-woven interlining marketplace in China. Some distinguished companies consist of:

Freudenberg & Vilene: A global chief in interlining manufacturing, supplying advanced answers.

Wendler Interlining: Known for excellent fusible and non-woven interlining materials.

H&V (Hollingsworth & Vose): Specializes in non-woven fabric solutions for numerous applications.

China Non-Woven Fabric Industry Association (CNFIA): A regulatory frame promoting innovation and best manipulation inside the enterprise.

Challenges and Future Trends

Despite the growing demand, the non-woven interlining marketplace in China faces some challenges:

Environmental Regulations: Stricter sustainability requirements demand eco-friendly manufacturing practices.

Raw Material Fluctuations: Price versions in polyester and different artificial fibres affect manufacturing charges.

Competition from Other Asian Markets: Countries like Vietnam, Bangladesh, and India are rising as robust competition.

However, the destiny of non-woven interlining in China appears promising due to:

Development of Biodegradable Interlining: Innovation in sustainable materials will form the market.

Smart Textiles Integration: Advanced interlining with moisture-wicking and antibacterial properties.

Increased Automation in Manufacturing: AI-pushed manufacturing tactics to beautify efficiency and consistency.

The call for non-woven interlining in China is anticipated to preserve growth as the fabric and garb industries evolve. With technological advancements, sustainability efforts, and increasing packages, non-woven interlining remains a critical fabric inside the global fabric delivery chain. Chinese manufacturers need to adapt to new traits and improvements to maintain their management within the industry even as assembly the growing demand for the best and eco-friendly merchandise.

#non woven interlining#woven interlining#china interlining#fusible interlining suppliers#fusible interlining manufacturer#woven fusible interlining#woven interlining manufacturer#china elastic webbing#down-proof fabric#china elastic band

0 notes

Text

Understanding PP Woven Fabric: A Comprehensive Guide

Polypropylene (PP) woven fabric is a versatile and widely used material in industries ranging from packaging to agriculture. Known for its strength, durability, and adaptability, PP woven fabric plays a vital role in creating reliable and cost-effective solutions. Here’s everything you need to know about this essential material.

What is PP Woven Fabric?

PP woven fabric is a type of textile made from polypropylene strips or threads interwoven to form a durable and strong material. This fabric is lightweight yet capable of withstanding significant stress, making it ideal for various applications.

Key Features of PP Woven Fabric

Strength and Durability: Resistant to wear and tear, it offers excellent load-bearing capabilities.

Lightweight: Easy to transport and handle without compromising sturdiness.

Moisture Resistance: Protects contents from water damage, making it suitable for outdoor use.

Cost-Effective: Provides a high-performance solution at an affordable price.

Customizable: Available in various sizes, colors, and patterns to meet diverse needs.

Applications of PP Woven Fabric

1. Packaging Industry

PP woven fabric is commonly used to create bags for packing grains, seeds, fertilizers, and more. These bags offer excellent durability and keep contents safe from environmental factors.

2. Agriculture

In agriculture, PP woven fabric is used for weed control mats, crop covers, and sacks for transporting produce. Its resistance to moisture and UV rays enhances productivity and reduces waste.

3. Construction

PP woven fabric is utilized in construction projects for creating geotextiles, sandbags, and protective covers. Its high tensile strength ensures reliability in demanding environments.

4. Retail and Shopping Bags

Eco-friendly reusable shopping bags made from PP woven fabric are gaining popularity as a sustainable alternative to single-use plastic bags.

Advantages of PP Woven Fabric

1. Longevity

The durable construction ensures a long lifespan, reducing the need for frequent replacements.

2. Reusability

PP woven fabric can be reused multiple times, making it an eco-friendly option.

3. Versatility

From heavy-duty industrial applications to lightweight consumer goods, the adaptability of PP woven fabric meets diverse requirements.

4. Eco-Friendly Options

Many PP woven products are recyclable, supporting sustainability goals while reducing environmental impact.

How is PP Woven Fabric Made?

Extrusion: Polypropylene granules are melted and formed into flat tapes.

Weaving: These tapes are woven on looms to create the fabric.

Lamination (Optional): A layer of coating is applied to enhance waterproofing and durability.

Finishing: The fabric is cut, printed, and sewn into the desired products.

Conclusion

PP woven fabric is a versatile material that combines strength, functionality, and sustainability. Its widespread applications and cost-effectiveness make it a preferred choice across industries. Whether for packaging, agriculture, or construction, PP woven fabric delivers reliable performance and value. Embracing this innovative material supports a sustainable future while addressing practical needs effectively.

0 notes