#lithium-ion battery systems

Explore tagged Tumblr posts

Text

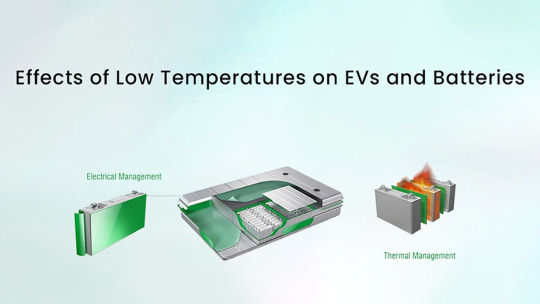

Battery Thermal Management: The Crucial Role of Temperature Control

In modern electric vehicles (EVs), the lithium-ion battery module pack takes center stage, influencing an EV's performance, range, and safety. However, these crucial power sources are sensitive to temperature extremes. Like people, batteries have their comfort zone, typically operating optimally between 15°C and 40°C. Yet, the reality of automotive environments exposes batteries to temperatures ranging from a frigid -20°C to a sweltering 55°C. What's the solution? Give the battery an air conditioner, and you get battery thermal management, which accomplishes three essential functions: heat dissipation, heating, and temperature consistency.

Heat Dissipation

When temperatures soar, batteries can experience a dramatic loss of life (resulting in capacity degradation) and an elevated risk of thermal runaway. Thus, effective heat dissipation is vital when the battery becomes excessively hot.

Heating

Conversely, when temperatures plummet, the battery's capacity may be reduced and performance weakened. Charging the battery in this frigid state can even pose a risk of thermal runaway due to potential internal short circuits. So, it's crucial to warm up or insulate the battery when it gets too cold.

Temperature Consistency

Think back to the old air conditioner in your childhood home. It would blast cold air upon startup and then take a break. Most modern air conditioners now use frequency conversion and even airflow distribution to maintain temperature consistency. Similarly, power batteries strive to minimize spatial temperature differences, ensuring minimal variance in cell temperature. Temperature consistency is paramount to battery performance and safety.

Effects of Low Temperatures on EVs and Batteries

As the heart of an EV, the power battery has a profound impact on its performance, affecting aspects such as range, acceleration, and service life. Safety is also a top priority. Battery performance is deeply intertwined with temperature, and cold climates can significantly hinder an EV's operation.

For instance, electric vehicle owners in colder regions often notice a significant drop in mileage during winter. In some cases, the range can plummet to as low as 70% of its usual capacity. Many drivers resist using cabin heaters to conserve mileage.

Low temperatures not only reduce an EV's battery capacity but also inhibit its discharge capabilities. At extremely low temperatures, the electrolyte inside the battery may freeze, leading to a severe reduction in power output.

Lithium-ion batteries are particularly susceptible to temperature extremes. At lower temperatures, the chemical reactions within the battery slow down, resulting in decreased performance and range. Charging in freezing conditions can also lead to the formation of lithium deposits on the battery's negative electrode, potentially puncturing the battery diaphragm and causing a short circuit. The safety implications of charging batteries at low temperatures are significant.

Battery Thermal Management: A Technological Solution

Battery thermal management is the solution to many of these challenges. This technology aims to maintain battery temperature within the ideal range. The approach includes both heating and cooling, to optimize battery performance.

There are several methods used in battery heating:

Battery Natural Heating: The heat generated during battery operation, discharging, or charging can increase the battery's temperature. However, this method can be slow and is rarely used in modern electric vehicles.

Blower Heating: Blowing hot or cold air into the battery pack through an external air conditioner is another method. This approach demands a carefully designed air duct and can result in uneven temperature distribution within the battery pack.

Heating Elements in the Battery Pack: These are composed of heating elements and circuits. Two common heating elements are the Positive Temperature Coefficient (PTC) and Heating Film. PTC offers advantages like safety, high thermal conversion efficiency, and rapid heating.

Circulating Liquid Heating: Liquid-cooled battery packs have become the mainstream option. This method offers uniform heat distribution, safety, and reliability. It usually features a system to facilitate heat dissipation, ensuring even temperature rises throughout the battery pack.

Conclusion

Battery thermal management is not just a luxury; it's a necessity for modern electric vehicles. In a world of varying climates, maintaining optimal battery temperature is a key factor in enhancing performance, ensuring safety, and prolonging battery life. As technology continues to evolve, battery thermal management will continue to play a crucial role in advancing the electric vehicle industry, offering the promise of efficient and reliable clean energy transportation for the future.

#Battery Cooling Systems#Battery Heating and Cooling Mechanisms#Battery Temperature Control#Battery Thermal Management Systems (BTMS)#electric vehicles#energy storage systems#lithium ion batteries#lithium-ion battery systems#Thermal Management in EV Batteries

0 notes

Text

Harveypower Outer Packaging of Lithium Battery Packs for Solar Systems

youtube

Welcome to the Harveypower video series where we provide you with an inside look into our manufacturing process. In today's video, we will be showcasing the outer packaging of our lithium battery packs designed specifically for solar systems. At Harveypower, we pride ourselves on not only producing high-quality battery packs but also ensuring they are packaged and transported with the utmost care and safety.

In this video, our lithium battery packs are packed in an independent wooden box, which provides excellent protection and stability during transportation. The wooden box is specially designed to fit a single battery pack, and the surface is covered with a film to ensure its airtightness and stability during transportation. This film also prevents any dust or debris from entering the package.

We understand the importance of safe and secure transportation of our products, and we take every step to ensure that our battery packs are packaged properly. Our outer packaging ensures that your battery packs arrive at your doorstep in the same condition as when they left our manufacturing facility.

At Harveypower, we prioritize the safety and satisfaction of our customers. By paying close attention to even the smallest details like packaging, we aim to provide our customers with a seamless and hassle-free experience.

So what are you waiting for, please contact us to start your solar journey!

#lifepo4 battery#lithium iron phosphate battery#lfp battery#lithium battery#solar battery#lithium manufacturer#lithium ion battery#solar battery storage#lithium#solar system#Youtube

1 note

·

View note

Text

You’re right, Mrs, eating batteries is not good for you.

Seriously, though, this is the most obnoxious anti-reality take on medication. People with Bipolar Disorder have reduced GABA neurotransmission, which causes cell death in the brain.

Lithium increases those missing GABA and seratonin levels. Your body already needed those chemicals to function, which is why it doesn’t, hence why you get bipolar disorder in the first place!

Of course you need medication to function, that’s why medication exists. To treat a chemical imbalance in your body. If you can’t handle that, please at least consider not spreading ridiculous misinformation on the internet.

Source: Therapeutic Application of Lithium in Bipolar Disorders: A Brief Review

I like the fact that the two most well-known uses for lithium are treating people who are bipolar, and making batteries, which are also bipolar but in a completely different way.

#also lithium ion batteries can also be bipolar#don’t worry it’s a certain type of lithium ion batteries#system speaks#medical education#bipolar disorder#anti vaxxer warning#shitcraft

75K notes

·

View notes

Text

Why Lithium Ion Batteries for RVs Are a Worthwhile Investment

While they come with a higher blunt cost, their benefits far offset the investment, confirming longer adventures, better efficacy, and a hassle-free experience. Here, we will know why RV fans select lithium-ion batteries. However, if you are searching for the best Lithium Ion Batteries for RVs, regularly choose Sonny Power.

More Info: https://hutchinsonkansasnewspaper.net/why-lithium-ion-batteries-for-rvs-are-a-worthwhile-investment

0 notes

Text

Lithium-Ion BMS Suppliers: Key to Battery Performance

The efficiency and safety of a lithium-ion battery depend on its Battery Management System (BMS). A BMS monitors critical factors like voltage, current, and temperature, protecting batteries from overcharging, over-discharging, and thermal risks.

Lithium-ion BMS suppliers provide advanced systems tailored for applications such as electric vehicles, renewable energy storage, and portable electronics. Companies like Texas Instruments and Analog Devices lead in delivering solutions that enhance battery performance.

As the demand for lithium-ion batteries grows, innovations like solid-state technology and AI-integrated systems from BMS suppliers promise smarter, safer, and more efficient energy storage.

Website - https://jttelectronics.com/

0 notes

Text

The Future of Electric Commuting: DYU's Innovative Electric Commuter Bikes

Greetings, fellow riders! Today, we're thrilled to delve into the exciting world of electric commuter bikes, with a spotlight on the innovative brand DYU. As urban commuting continues to evolve, the demand for sustainable and efficient transportation solutions has skyrocketed, and DYU is at the forefront of this revolution.

DYU's electric commuter bikes are designed to seamlessly blend performance, style, and eco-friendliness. With their sleek and modern designs, these bikes not only turn heads but also offer a smooth and exhilarating riding experience. Powered by cutting-edge lithium-ion batteries and electric motors, DYU's e-bikes provide an effortless and emission-free commute, making them an excellent choice for environmentally conscious individuals.

One of the standout features of DYU's electric commuter bikes is their impressive range. With a single charge, you can confidently tackle your daily commute without worrying about running out of power. Additionally, these bikes boast impressive hill-climbing capabilities, ensuring that even the most challenging inclines are no match for their electric-assisted pedaling.

But DYU's commitment to innovation doesn't stop there. Their bikes are equipped with advanced features such as integrated LED lighting systems, user-friendly digital displays, and intuitive controls, ensuring a safe and enjoyable ride, day or night. Furthermore, the brand's dedication to quality craftsmanship is evident in the durable and lightweight frames, ensuring a long-lasting and reliable riding experience.

As the world embraces sustainable living and seeks eco-friendly transportation alternatives, DYU's electric commuter bikes are poised to revolutionize the way we commute. Imagine gliding through city streets, bypassing traffic congestion, and reducing your carbon footprint – all while enjoying the thrill of an electrifying ride.

So, fellow riders, embrace the future of electric commuting and explore the exceptional offerings from DYU. Join the growing community of eco-conscious commuters and experience the joy of sustainable urban mobility. The future is electric, and DYU is leading the charge!

#electric commuter bikes#DYU#eco-friendly#lithium-ion batteries#electric motors#urban commuting#performance#style#innovative design#impressive range#hill-climbing capabilities#LED lighting systems#digital displays#quality craftsmanship#lightweight frames#sustainable living#carbon footprint#urban mobility

0 notes

Text

Battery Management System: Keeping Lithium-Ion Batteries Running Smoothly

A battery management system, also known as a BMS, is an important component used in lithium-ion battery packs. The primary purpose of a BMS is to protect the battery by regulating voltage, current, and temperature. It does this by continuously monitoring individual cells and the overall battery pack performance. Properly functioning BMS are essential for safety and extending the usable life of lithium-ion batteries used in various applications from electric vehicles to consumer electronics. Monitoring Battery Performance One of the key roles of a BMS is to continuously monitor the voltage, current and temperature of each individual battery cell. Lithium-ion batteries cannot be overcharged or over-discharged as it can cause damage or hazards. The BMS monitors cell voltages and balances charging currents to keep all cells within a safe operating window. It prevents any single cell from charging too much compared to others which could cause issues. Temperature is also closely tracked to avoid operation in temperature extremes that can degrade battery performance over time. Cell Balancing for Extended Life Over time small differences in battery cells can occur due to manufacturing variations or uneven aging characteristics. A good BMS performs active cell balancing to keep all cells at an equal state of charge. This prevents any cells from becoming more drained than others which could lead to early failure or unsafe operation.

Cell balancing helps maximize the usable capacity of lithium-ion battery packs and extends their lifecycle. Constant monitoring and active equalization between cells is an important maintenance function performed by Battery Management System. Thermal Management is Critical Heat generated from high charging currents or discharging rates needs to be carefully controlled by a BMS. Lithium-ion batteries can become damaged if the internal temperature exceeds optimum limits, which is why thermal sensors are included. Cooling systems may need to be activated, and charging/discharging can be slowed or halted altogether if temperatures approach unsafe levels. Overheating issues are addressed with precision in electric vehicles where heat dissipation demands are more complex compared to smaller products like smartphones. Advanced BMS precisely control thermal dynamics for longevity and safety. Detect Faults and Warn Users Proactive fault detection is another role of battery management system technology. It analyzes cells for abnormalities during routine monitoring activities. Early warning signs of potential faults like unexpected voltage or impedance changes can be spotted. Users are alerted to battery issues through status indicators so corrective maintenance can be promptly performed. Serious faults are acted upon automatically by the BMS through isolation procedures that prevent further degradation or hazards to the pack. Fault diagnosis capabilities help maintain high health levels in lithium-ion battery deployments. Data Logging and Telemetry Functions Many BMS are equipped with significant data logging functions to help fine-tune performance over the lifetime of the battery. Parameters like charge cycles completed, cumulative energy throughput, and usage history profiles are stored. This information helps determine remaining useful life estimations and identify factors impacting it sooner. Advanced systems include wireless connectivity for remote battery monitoring as well. Real-time telemetry data and log downloads enable predictive servicing by OEMs and optimize battery second-life reuse opportunities in stationary storage applications. Battery Safety Functions Above everything else, battery safety remains the top priority function for BMS. Overcurrent, overpressure, short circuit detection are all critical hazards addressed. Active protections include current limiting circuitry that engages during fast charging/discharging routines. Pre-charge functions slowly condition cells before high power stages. Thermal shutdown switches off battery operation entirely if cells become imperiled. Internal/external isolation relays prevent fired or damaged cells from impacting others. Strict controls applied by BMS safeguard people and property from battery failures leading to fires or explosions. Get more insights on Battery Management System

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)

#Battery Management System#Energy Storage#Electric Vehicles#EV Batteries#Lithium-Ion Batteries#Battery Safety#Power Management#Battery Monitoring

0 notes

Text

Getsun Power leads India's Lithium Battery manufacturing with advanced technology and a sustainability pledge, crafting top-tier batteries to maximize solar energy utilization.

#lithium ion battery#getsun power#battery manufacturer in india#top telecom battery module#top battery manufacturer in india#energy storage systems#battery suppliers in india#telecom battery bank suppliers in india#lithium ion battery in noida#lithium-ion battery manufacturers in noida

0 notes

Text

Semi-Transparent Perovskite Solar Cells: A Window to the Future of Energy

Introduction In a groundbreaking leap toward sustainable energy, scientists in South Korea have unveiled a remarkable advancement: semi-transparent perovskite solar cells that could revolutionize the way we harness sunlight. Imagine windows that not only let light in but also generate electricity! In this article, we delve into the fascinating world of semi-transparent solar technology,…

View On WordPress

#2d perovskite passivation#building integrated photovoltaics (BIPV)#clear solar panels for windows#energy harvesting windows#lithium ion battery technology#perovskite solar cell cost#perovskite solar cell degradation#perovskite solar cell efficiency#rooftop solar panel system cost#self charging smart glasses#semi transparent solar panels price#smart glass applications#transparent photovoltaic panels#transparent solar cell technology#transparent solar cells

0 notes

Text

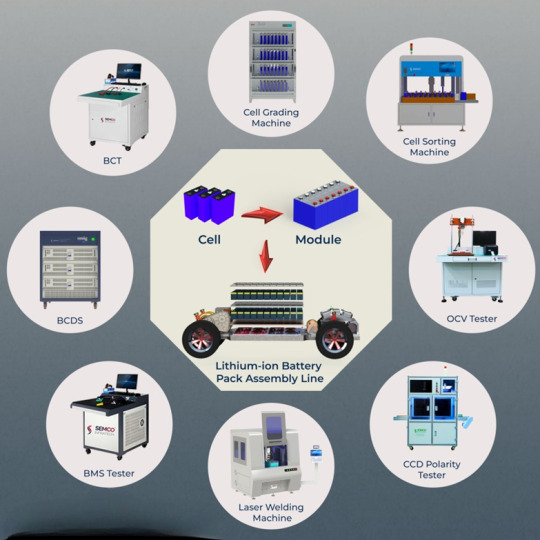

How a Lithium-ion Battery Assembly Line Works?

As the demand for electric vehicles (EVs) and energy storage solutions surges, the efficiency of lithium-ion battery assembly lines plays a crucial role in determining the success of battery manufacturers. A well-optimized assembly line ensures high precision, consistency, and cost-effectiveness. But how does the process work? Let’s dive into the key stages of a lithium-ion battery assembly line.

Cell Grading: The Foundation of Excellence

Cell grading is a crucial first step in the process when each battery cell is carefully examined to ascertain its performance parameters. To produce a thorough "report card" for every cell, capacity, and internal resistance are carefully examined. This methodical procedure guarantees uniformity and groups cells according to their performance attributes, establishing the groundwork for the best possible utilization of a battery pack.

Cell Sorting: Precision in Pairing

After grading, cells are sorted based on their specifications, optimizing the performance of the final battery pack. By ensuring that the batteries in a pack are precisely matched, this precision matching maximizes performance and prolongs battery life. To fully utilize each cell's potential within the battery pack's overall power, this phase must be carefully planned.

OCV Testing Machines

Open Circuit Voltage (OCV) testing machines measure the voltage of cells to ensure they meet the required standards before assembly.

CCD Polarity Tester

This equipment is used for precise alignment and assembly of battery components, enhancing the overall efficiency of the production process.

BMS Testing: The Guardian of Performance

At the heart of the battery pack lies the Battery Management System (BMS), serving as its vigilant guardian. Before integration, the BMS undergoes rigorous testing to validate its functionality and its ability to effectively communicate with the individual cells. This crucial step ensures that the BMS is equipped to monitor and regulate the health and performance of the battery pack with unwavering precision.

Cell Welding: Where Precision Meets Connectivity

As the testing cells await their transformation into a unified force, the delicate process of cell welding takes center stage. Automated robotic arms execute this task with precision, forging strong and reliable electrical connections between the cells. The seamless integration achieved through cell welding forms the foundational framework for the battery pack, ensuring its resilience and efficiency.

Battery Pack Testing or Aging: Trials of Endurance

The culmination of the assembly line journey leads to the final stage – rigorous testing of the complete battery pack. Depending on its intended application, this phase may encompass charging/discharging cycles to simulate real-world usage or accelerated aging tests to evaluate long-term performance and safety. Through these trials of endurance, the battery pack's resilience and reliability are put to the test, ensuring its readiness for the demands of modern life.

Battery Comprehensive Testing

Finally, comprehensive testing machines assess the battery packs' overall functionality, safety, and longevity before they are ready for deployment. The integration of these advanced machines not only streamlines the production process but also ensures that you deliver high-quality, reliable battery packs that power the future of transportation.

Conclusion: Precision, Innovation, and Reliability

From the meticulous grading of individual cells to the comprehensive testing of the assembled battery pack, the cell-to-battery assembly line embodies a fusion of precision, innovation, and reliability. Each step in this intricate process plays a pivotal role in shaping the quality, safety, and performance of the batteries that power our modern world. Behind every seamless charge and every enduring power source lies a journey of expertise and dedication, culminating in the creation of batteries that stand as pillars of energy in our technologically driven lives.

#Lithium-ion battery assembly line#Lithium-ion battery manufacturing process#Battery cell assembly#Lithium-ion battery production#Battery manufacturing equipment#Battery cell grading process#Battery cell sorting techniques#Battery management system testing#Cell welding in battery manufacturing#Battery pack aging tests#Comprehensive battery testing procedures

0 notes

Text

youtube

In this video, we introducing the Harveypower Lithium Battery Pack Aging Test – the solution to extending the lifespan of your battery packs. Our state-of-the-art testing facility combines cutting-edge technology and expert analysis to ensure your batteries perform at their best, even as they age.

Don't let battery degradation impact your business or personal projects. With our aging test, you'll get a comprehensive understanding of how your battery packs are performing and what you can do to extend their lifespan. Our testing process simulates real-world usage scenarios, so you can rest assured that your batteries will perform reliably when you need them most.

At Harveypower, we understand that battery performance is critical in today's fast-paced world. That's why we've made it our mission to provide the most accurate and insightful aging test available. Whether you're a business owner, a hobbyist, or a tech enthusiast, our aging test will give you the confidence to use your batteries to their fullest potential.

Say goodbye to unreliable batteries and wasted resources – with the Harveypower Lithium Battery Pack Aging Test, you can ensure that your battery packs are always performing at their best.

Contact us today to learn more about our battery production process and how we can help you extend the lifespan of your batteries.

#lifepo4 battery#lithium#lfp battery#lithium iron phosphate battery#solar battery storage#solar energy#solar system#solar battery#lithium ion battery#lithium battery#lithium manufacturer#Youtube

1 note

·

View note

Text

Flowing Forward: Nepal's Hydroelectric Future Enhanced by Innovative Energy Storage

Australia’s Hornsdale Power Reserve, a powerhouse in energy storage, boasts one of the country’s largest units, capable of reserving up to 150 MW in its advanced lithium-ion batteries. On the other side of the globe, the Bath County Pumped Storage Station in Virginia, USA, stands as a venerable giant in pumped hydro storage, operating since 1985. This monumental project strategically utilizes two…

View On WordPress

#ADELE#Australia&039;s Hornsdale Power Reserve#Battery Energy Storage Systems (BESS)#Compressed Air Energy Storage (CAES)#energy storage#Energy Storage System (ESS)#Grid Stability#lithium-ion batteries#Nepal&039;s Hydroelectric Challenge#Pumped Hydro Storage#Renewable Energy Integration

0 notes

Text

1 note

·

View note

Text

The Crucial Role of Lithium Battery Management Systems in Modern Technology

Lithium-ion batteries have revolutionized the way we power our devices, from smartphones to electric vehicles and renewable energy systems. Their high energy density and long cycle life make them indispensable in our daily lives. However, to fully realize their potential and ensure safety, Lithium Battery Management Systems (BMS) play a pivotal role. This article explores the importance of Lithium Battery Management Systems in optimizing the performance and safety of lithium-ion batteries.

1. Enhanced Safety: Safety is paramount when it comes to lithium-ion batteries, as they have been known to catch fire or explode when mishandled. BMS serves as a guardian against potential safety hazards by monitoring and controlling critical parameters such as voltage, current, and temperature. It prevents overcharging and over-discharging, which can lead to thermal runaway and catastrophic failures.

2. Prolonged Battery Life: Lithium-ion batteries are an investment, especially in applications like electric vehicles and renewable energy systems. A well-designed BMS helps maximize the lifespan of these batteries. By ensuring that cells are charged and discharged within their safe operating limits, BMS prevents premature degradation. It manages cell balancing, minimizing differences in the state of charge among cells, which can otherwise accelerate ageing.

Website: https://jttelectronics.com/

0 notes

Text

Build a Really Big Lithium Ion Solar Battery

The Really Big Lithium Ion Battery The next upgrade for our Solar Power System was a Really Big Lithium Ion Battery (RBB). When we first installed the system in 2020, I didn’t have a cost-effective solution for Lithium Ion (LiFePo4 chemistry). That came later with the acquisition of a lot of LiFePo4 cells. Since then, I’ve built two small batteries to get used to the technology; one as a portable…

View On WordPress

0 notes

Text

BYD eMAX 7 Superior: The Ultimate Electric MUV for Families

₹29.9 Lakh Overview and General Features The BYD eMAX 7 Superior is an all-electric Multi-Utility Vehicle (MUV) that offers a spacious 7-seater configuration, making it suitable for larger families or anyone requiring a high level of interior space. The model comes in four attractive colors: Quartz Blue, Cosmos Black, Crystal White, and Harbour Grey. It features a 6-year/1.5 lakh kilometers…

#201.15 bhp#310 Nm torque#530 km range#7-seater#AC Permanent Magnet Synchronous Motor#Adaptive cruise control#Advanced Driver Assistance Systems#airbags#automotive technology#BYD eMAX 7 Superior#driving dynamics#eco-friendly#Electric Mobility#Electric Power Steering#Electric Powertrain#Electric vehicle#family vehicle#Fast charging#forward collision warning#high-speed performance#Infotainment System#lane departure warning#Lithium-Ion Battery#Luxury SUV#MUV#Panoramic Sunroof#Performance#regenerative braking#safety features#suspension

0 notes