#forging companies in India

Explore tagged Tumblr posts

Text

Forging Company in Faridabad, Forging Manufacturer in Faridabad – CD Industries – Forging Companies in India, Ghaziabad, Mumbai, Gujarat, Forging Manufacturers

Forging Company in Faridabad are traditionally considered as the backbone of the manufacturing industry. It is a major input to the sectors which support economic growth of the nation, such as, Automobile, Industrial Machinery, Power, Construction & Mining Equipment, Railways and General...

#cd industries#cdind#Forging Company in Gujarat#Forging Company in Noida#Forging Manufacturers#forgingcompany#forgingcompanyingurgaon#Gujarat#Careers#Forging Companies in India#Ghaziabad#Manufacturing Capabilities#mumbai

3 notes

·

View notes

Text

Forging Manufacturer in India: A Hub for Excellence and Quality

India has emerged as a global leader in the forging business, known for its cutting-edge technology, trained workforce, and strong production capabilities. The country is home to various forging firms that serve a variety of industries, including automotive, aerospace, oil & gas, construction, and agricultural. Among them, many are regarded as India's best forging companies, producing remarkable products and services that meet worldwide standards.

The Growth of Forging Companies in India

The forging business in India has grown dramatically during the last few decades. This expansion is being driven by the rising demand for high-quality forged components, both domestically and internationally. India's forging industries have seized on this need by investing in powerful gear, cutting-edge technology, and innovative procedures.

Indian forging firms are well-known for their capacity to produce a wide range of goods, including small precision components and massive industrial parts. These include automobile parts, gears, shafts, crankshafts, and flanges. With a strong emphasis on quality, efficiency, and sustainability, India's forging sector has set the standard for others to follow.

Anandmayee Forgings Pvt. Ltd: A Leading Forging Company

Among the noteworthy forging firms in India, Anandmayee Forgings Pvt. Ltd is a well-known name in the sector. With years of experience and a commitment to perfection, the company has established itself as one of India's leading forging enterprises. Anandmayee Forgings Pvt. Ltd specializes in producing high-quality forged components, such as industrial flanges, for a number of industries.

Why Choose an Indian Forging Company?

1. Modern Manufacturing Capabilities: Anandmayee Forgings Pvt. Ltd, an Indian forging company, uses modern procedures to make precise components. These methods guarantee dimensional correctness, a higher surface polish, and improved mechanical qualities.

2. Global Standards: Indian forging manufacturers follow international standards like ISO, ASTM, and ASME, making their products appropriate for global markets. Anandmayee Forgings Pvt. Ltd complies with these criteria, ensuring high quality.

3. Cost-Effectiveness: India's cost-competitive production methodology delivers high-quality forged components at competitive costs without sacrificing quality.

4. Skilled Workforce: Indian forging firms, such as Anandmayee Forgings Pvt. Ltd, have a large pool of skilled engineers and technicians who continually provide creative solutions to meet client needs.

Flanges Manufacturer in India

Flange manufacture is a notable segment of the forging industry. Anandmayee Forgings Pvt. Ltd, a prominent flange producer, serves sectors like oil and gas, petrochemicals, and power generation. They manufacture a variety of flanges, including socket weld, threaded, blind, and slip-on flanges.

Flange manufacturers in India, such as Anandmayee Forgings Pvt. Ltd, prioritize quality by employing high-quality raw materials and adhering to stringent quality control procedures. Their products are engineered to withstand high pressures, temperatures, and climatic conditions, ensuring dependability and longevity.

Best Forging Companies in India

Several forging firms in India are known for their competence in manufacturing and innovation. Anandmayee Forgings Pvt. Ltd has built a reputation as one of India's best forging enterprises by constantly delivering high-quality products and keeping good client relations. They have a global presence, exporting to countries in Asia, Europe, the Americas, and the Middle East.

Some of the key attributes that define the best forging companies include:

• State-of-the-art manufacturing facilities.

• Continuous investment in research and development.

• A commitment to sustainability and eco-friendly practices.

• Comprehensive quality assurance programs.

Conclusion

India's forging industry is a pillar of the country's industrial sector, fueled by innovation, quality, and a dedication to excellence. Whether you're seeking for automotive components, industrial parts, or high-quality flanges, Anandmayee Forgings Pvt. Ltd. provides unparalleled experience and value. With a reputation for being both cost-effective and quality-driven, India is unquestionably the preferred destination for all forging requirements. If you're looking for the top forging company in India, Anandmayee Forgings Pvt. Ltd is a reliable partner who will produce amazing products that exceed your expectations. Contact: 9315902761 or email:[email protected].

Website: https://www.afpl.in/

0 notes

Text

CDIND: Leading the Forging Industry in Gujarat

Gujarat, known for its robust industrial base, is home to numerous manufacturing giants. Among them, CDIND stands out as a premier forging company, renowned for its commitment to quality, innovation, and customer satisfaction. With decades of experience and a forward-thinking approach, CDIND has established itself as a leader in the forging industry not only in Gujarat but also across India.

Excellence in Forging

CDIND specializes in producing high-quality forged components that cater to various industries, including automotive, aerospace, oil and gas, and heavy engineering. The company's state-of-the-art manufacturing facility is equipped with the latest technology and machinery, ensuring precision and efficiency in every product they forge. CDIND's expertise covers a wide range of materials, from carbon and alloy steels to stainless steel and non-ferrous metals, allowing them to meet diverse industry requirements.

Cutting-Edge Technology and Innovation

At the heart of CDIND's success is its unwavering focus on technological advancement and innovation. The company continuously invests in modernizing its production processes and adopting new technologies to enhance product quality and reduce production time. This commitment to innovation enables CDIND to offer custom solutions tailored to the specific needs of its clients, ensuring that each component meets the highest standards of durability and performance.

Quality Assurance

Quality is the cornerstone of CDIND's operations. The company adheres to stringent quality control measures at every stage of the forging process, from raw material selection to final inspection. CDIND's quality management system is ISO 9001 certified, reflecting its dedication to maintaining the highest quality standards. The company's in-house testing laboratory is equipped with advanced testing equipment, enabling thorough inspection and validation of every forged component.

Customer-Centric Approach

CDIND's success is deeply rooted in its customer-centric approach. The company believes in building long-term relationships with its clients by providing exceptional service and support. From the initial consultation to after-sales service, CDIND's team of experts works closely with customers to understand their requirements and deliver solutions that exceed their expectations. This dedication to customer satisfaction has earned CDIND a reputation for reliability and trustworthiness in the forging industry.

Sustainable Practices

In addition to its focus on quality and innovation, CDIND is committed to sustainable manufacturing practices. The company employs eco-friendly processes and strives to minimize its environmental impact through efficient resource management and waste reduction initiatives. CDIND's sustainability efforts are integral to its business strategy, ensuring that it contributes positively to the environment and the community.

Conclusion

CDIND has firmly established itself as a top forging company in Gujarat, driven by its commitment to quality, innovation, and customer satisfaction. With its advanced manufacturing capabilities, rigorous quality control, and customer-focused approach, CDIND continues to lead the way in the forging industry, setting new benchmarks for excellence. Whether you are in the automotive, aerospace, or any other sector requiring high-quality forged components, CDIND is the partner you can trust for reliable and superior solutions.

READ MORE...Forging Companies in India Ghaziabad Mumbai Gujarat Forging Manufacturers CD Industries

0 notes

Text

When one doesn't believe in assholes . . .

#hand-forged ales#alesmith brewing company#ipa#west coast-style india pale ale#san diego#california#columbus#citra

5 notes

·

View notes

Text

#tool and die manufacturing company#forging manufacturers in india#Tool Design and Manufacturing Solutions#die and tool designing services#tool manufacturing company in india#tool & die manufacturing services

0 notes

Text

youtube

Indolift, established in 2010 by M/S. PDS Trading & Warehousing Co Pvt Ltd, specializes in material handling equipment, notably Chain Pulley Blocks. They collaborate with Hangzhou Jentan Machinery Co Ltd, a leading Chinese manufacturer, to offer high-quality products at competitive prices. Their product range includes Chain Pulley Blocks, Ratchet Lever Hoists, Webbing Slings, D-Shackles, Plate Lifting Clamps, Steel Wire Ropes, Forged Clamps, Pallet Trucks, and Alloy Steel Chains. Indolift is committed to delivering efficient solutions and maintaining high-quality standards.

#forged clamps#alloy steel chain#d shackles#wire rope company in india#webbing slings#chainpulley#construction materials#infrastructure#material handling equipment#equipment#rigging#steel#wire rope#industry#Youtube

0 notes

Text

Leading Steel Forging Units in India

India is one of the global leaders in forging manufacturing, thanks to its robust industrial base, skilled workforce, and access to raw materials. Forging is a key process in the manufacturing sector, involving shaping metal through compressive forces to create high-strength components. This process is critical for industries such as automotive, aerospace, railways, oil and gas, construction, and defines. Let’s explore the landscape of forging manufacturing companies and leading steel forging units in India.

Key Highlights of Forging Manufacturing in India

India ranks as the third-largest forging producer globally, supported by over 400 forging companies, including small, medium, and large enterprises. The industry employs over 300,000 skilled professionals and is known for its innovation, quality, and export potential. Forging manufacturers in India utilize state-of-the-art technology, including precision forging, closed-die forging, and advanced heat treatment processes, ensuring superior product quality.

Leading Steel Forging Companies in India

Bharat Forge Limited Bharat Forge is a globally renowned player in the forging sector. Headquartered in Pune, this company specializes in high-performance forgings for automotive, aerospace, power, and oil and gas sectors. Bharat Forge’s advanced forging technologies and strong R&D capabilities make it a leader in the field.

Ramkrishna Forgings Based in Kolkata, Ramkrishna Forgings is a prominent name in steel forging. The company caters to diverse sectors, including railways, mining, automotive, and heavy engineering. With a focus on export markets, Ramkrishna Forgings is a key contributor to India’s forging exports.

Amtek Auto Limited Amtek Auto is a major supplier of forged components to the automotive and non-automotive industries. Known for its extensive manufacturing facilities, the company delivers world-class forged products across the globe.

Larsen & Toubro (L&T) Forgings L&T Forgings specializes in heavy forging solutions for the oil and gas, power, and aerospace industries. The company is renowned for its ability to handle complex and large-scale forgings.

GNA Axles A leader in axle shaft manufacturing, GNA Axles serves the global automotive industry. Its advanced forging capabilities and export-oriented approach make it a significant player.

Conclusion

India’s forging manufacturing companies are setting global benchmarks in innovation, quality, and sustainability. With a strong focus on technological advancement and market expansion, these leading steel forging units contribute significantly to India’s industrial and economic growth. The sector’s continuous evolution ensures a bright future for forging in India.

#Forging Manufacturing Companies in India#Leading Steel Forging Units in India#Manufacture Forging Quality Ingots

0 notes

Text

Top Closed Die Forging Manufacturers in India - Elmex Electric Pvt. Ltd.

Elmex Electric Pvt. Ltd. ranks among the top 10 forging companies in India, specializing in closed die forging solutions. As trusted closed die forging manufacturers in India, we deliver precision-engineered components that meet the highest industry standards for strength and durability. Contact us for tailored forging solutions. Closed die forging manufacturers in india, Top 10 forging companies in india.

Elmex Electric Pvt. Ltd. Add : 12, GIDC Estate, Makarpura, Vadodara -390010, Gujarat, India. Ph : 02652642021 / 23 Mo : (+91)8905403006 Fax : 02652638646 mail : [email protected] Visit us at : https://elmex.net/ (+91)8905403006, (+91)8905902016

Facebook : https://www.facebook.com/ElmexControls/ Twitter : https://twitter.com/elmexcontrols LinkedIn : https://www.linkedin.com/company/elmex-controls-pvt.-ltd. Youtube : https://youtu.be/LOooD_SvEMo

#Closed die forging manufacturers in india#Top 10 forging companies in india#Terminal blocks in India

0 notes

Text

Railway Parts Manufacturer in India: A Detailed Analysis

Introduction to Railway Parts Manufacturing Industry in India

The railway parts manufacturing industry in India plays a crucial role in supporting the country's vast railway network. India has one of the largest rail networks in the world, making the demand for railway parts consistently high. This industry includes the production of components such as wheels, axles, bearings, and various other essential parts needed to keep trains running smoothly and safely.

The railway sector in India is driven by both the Indian Railways and various private players, ensuring a steady flow of orders for manufacturers. Companies in this sector range from small-scale industries to large, established firms, all contributing to the robust supply chain necessary for the operation and maintenance of the railway network.

Importance of Railway Parts Manufacturing

Railway parts manufacturing is essential for several reasons:

Safety: High-quality parts ensure the safety of trains, passengers, and goods. Faulty components can lead to accidents, causing loss of life and property.

Efficiency: Well-manufactured parts help in the smooth operation of trains, reducing downtime and delays. This efficiency is critical for both passenger and freight services.

Economic Impact: The railway industry is a significant contributor to the Indian economy. The manufacturing of railway parts provides employment to thousands and supports numerous ancillary industries.

Innovation and Growth: Continuous innovation in railway parts manufacturing leads to improved performance and new technologies, contributing to the overall growth of the railways.

However, the industry faces challenges such as fluctuating raw material prices and the need for constant technological upgrades to meet global standards.

Manufacturing Capabilities and Technologies

India's railway parts manufacturing sector boasts a wide range of capabilities and uses advanced technologies to meet the needs of modern railways:

Precision Engineering: Companies use state-of-the-art machinery to produce components with high precision. This ensures that parts meet strict quality standards.

Automation: Many manufacturers employ automated processes to enhance production speed and reduce human error. This includes the use of robotics and computer-controlled machinery.

Material Science: Advanced materials like high-strength alloys and composites are used to manufacture durable and lightweight parts, improving the performance and lifespan of railway components.

Quality Control: Rigorous quality control measures, including non-destructive testing and computerized inspection systems, ensure that only the best parts reach the market.

Despite these advancements, some manufacturers struggle with the high cost of technology adoption and maintaining skilled labor.

Market Trends and Growth Opportunities

The railway parts manufacturing industry in India is evolving with several key trends and opportunities:

Government Initiatives: The Indian government has launched various initiatives, such as "Make in India," to boost local manufacturing. This provides significant opportunities for railway parts manufacturers to expand their operations.

Global Market: Indian manufacturers are increasingly exporting railway parts to international markets, taking advantage of competitive pricing and quality.

Technological Advancements: The adoption of new technologies like 3D printing and IoT (Internet of Things) is creating new opportunities for innovation and efficiency in manufacturing processes.

Sustainability: There is a growing focus on sustainable manufacturing practices, with companies investing in eco-friendly materials and processes.

However, the industry must navigate challenges such as stiff global competition and the need for continuous investment in research and development to stay ahead

Challenges Facing the Industry

Technological Advancements

Staying abreast of technological advancements is crucial for forgings companies in India to maintain competitiveness. Investments in research and development are essential to meet evolving safety and efficiency standards in railway operations.

Infrastructure and Logistics

Logistical challenges can impact the timely delivery of railway components. Improved infrastructure and streamlined logistics processes are necessary to support the industry's growth aspirations.

Government Initiatives and Policies

Make in India Initiative

The Indian government's Make in India initiative has provided a significant impetus to the manufacturing sector, including railway parts manufacturing. Incentives and policies aimed at promoting domestic production have encouraged investments in modernizing manufacturing facilities and adopting sustainable practices.

Regulatory Framework

Adherence to stringent regulatory standards is paramount in the railway industry. Manufacturers must comply with safety and quality regulations set by authorities to ensure the reliability and durability of railway components.

Future Outlook

Emerging Technologies

The adoption of digital technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) is poised to revolutionize the railway parts manufacturing landscape. Predictive maintenance and real-time monitoring solutions will enhance operational efficiencies and reduce downtime.

Sustainable Practices

There is a growing emphasis on sustainability in manufacturing processes. Companies are increasingly adopting eco-friendly practices and materials to minimize their environmental footprint while meeting the demands of a greener future.

Conclusion In conclusion, the railway parts manufacturer in India industry is poised for robust growth driven by technological advancements, export opportunities, and government support. Companies like Bharat Forge Limited, Ramkrishna Forgings Limited, and Happy Forging continue to innovate and excel in producing high-quality components that support the safe and efficient functioning of railway networks globally.

#forging#forging services in india#steel forging services in india#technology#railway parts manufacturing#forgings companies in India

0 notes

Text

AceForge: Pioneering Excellence Among Metal Forging Companies in India

In the vibrant landscape of India's manufacturing sector, metal forging companies play a pivotal role in shaping industries ranging from automotive and aerospace to infrastructure and energy. Among these companies, AceForge stands out as a beacon of innovation, precision, and reliability, setting the benchmark for excellence in the field of metal forging.

Metal forging is a time-honored manufacturing process that involves shaping metal through the application of compressive force. This process enhances the mechanical properties of metals, resulting in components that exhibit exceptional strength, durability, and reliability. As one of the leading metal forging companies in India, AceForge leverages cutting-edge technology and decades of expertise to deliver forged components that meet the diverse needs of its clients across various industries.

One of AceForge's key strengths lies in its extensive capabilities across a wide range of metals and alloys. Whether it's carbon steel, stainless steel, aluminum, or exotic alloys, AceForge has the expertise and infrastructure to forge components with precision and consistency. From simple shapes to complex geometries, AceForge's versatile manufacturing facilities can accommodate diverse requirements, catering to the unique needs of each client.

Moreover, AceForge's commitment to quality is unparalleled. The company adheres to stringent quality control measures at every stage of the manufacturing process, from raw material inspection to final product testing. By maintaining the highest standards of quality assurance, AceForge ensures that its forged components meet or exceed the expectations of its clients, both in terms of performance and reliability.

In addition to its focus on quality, AceForge places a strong emphasis on innovation and continuous improvement. The company invests in research and development to explore new materials, processes, and technologies that enhance the efficiency and capabilities of its forging operations. This culture of innovation enables AceForge to stay ahead of the curve and address emerging trends and challenges in the dynamic landscape of metal forging.

Furthermore, AceForge is committed to sustainability and environmental responsibility. The company employs energy-efficient practices and waste reduction strategies to minimize its environmental footprint. By prioritizing sustainability in its operations, AceForge not only contributes to environmental conservation but also aligns with the growing demand for eco-friendly manufacturing solutions.

As India's economy continues to grow and diversify, the demand for high-quality forged components across various industries is expected to rise. AceForge, with its proven track record of excellence and commitment to customer satisfaction, is well-positioned to capitalize on these opportunities and further strengthen its position as a leading player in the metal forging industry.

In conclusion, AceForge exemplifies the best of Indian manufacturing prowess among metal forging companies. With its relentless focus on quality, innovation, and sustainability, AceForge continues to set new standards of excellence in the field of metal forging, driving progress and prosperity in India's manufacturing sector and beyond.

0 notes

Text

Forging Company in Gujarat, Forging Manufacturer in Gujarat – CD Industries – Forging Companies in India, Ghaziabad, Mumbai, Gujarat, Forging Manufacturers

Forging Company in Gujarat are traditionally considered as the backbone of the manufacturing industry. It is a major input to the sectors which support economic growth of the nation, such as, Automobile, Industrial Machinery, Power, Construction & Mining Equipment, Railways and General...

#cd industries#cdind#Forging Company in Noida#Forging Manufacturers#forgingcompany#forgingcompanyingurgaon#Gujarat#industries#Kolkata#Mumbai#Careers#Forging Companies in India#Ghaziabad#Manufacturing Capabilities

2 notes

·

View notes

Photo

Second Anglo-Sikh War

The Second Anglo-Sikh War (1848-9) once again saw the British East India Company defeat the Sikh Empire in northern India. The war, which started off as a rebellion against British colonial rule, included the high-casualty Battle of Chillianwala, but the conflict was finally won by the EIC with a decisive victory at the Battle of Gujrat in February 1849.

The EIC & the Sikh Empire

The British East India Company had been grabbing territory since its victories at the 1757 Battle of Plassey and the 1764 Battle of Buxar, which gave the British a vast and regular income in local taxes, besides other riches. The EIC kept on expanding and defeated the southern Kingdom of Mysore in the three Anglo-Mysore Wars (1767-1799) and the Maratha Confederacy of Hindu princes in central and northern India in the three Anglo-Maratha Wars (1775-1819). Next came expansion in the far northeast and more victories in the Anglo-Nepalese War (1814-1815) and the three Anglo-Burmese Wars (1824-1885). The next and final target of the EIC was northwest India and the Punjab, the heartland of the Sikh Empire.

The Punjab, located in the northwest of the Indian subcontinent, is an area which today covers parts of Pakistan and India. The Sikh Empire had risen due to the gradual decline of the Mughal Empire (1526-1857). Sikh territories were divided between 12 misls or armies, each led by a chief who collectively formed a loose confederation. The greatest of Sikh leaders was Ranjit Singh (1780-1839), the 'Lion of Lahore'. He forged the Sikh Empire by modernising the army and conquering Multan and Kashmir (1819), Ladakh (1833), and Peshawar (1834). This expansion rang alarm bells in the offices of the East India Company, especially after their failure in the First Anglo-Afghan War (1838-42) to the north.

In 1839, the Sikhs, Afghans, and British signed a treaty to protect existing borders. Ranjit Singh died in June 1839, and political turmoil weakened the Sikh government's control over its own army. Rajit Singh's youngest son, Duleep Singh (l. 1838-1893), was selected as the new Sikh ruler in 1843, but as he was but a child, his mother, Jind Kaur (aka Rani Jindan, d. 1863), ruled as regent. Jind Kaur supported a military escapade against the British since, even if the Sikhs lost, this would cut the army down to size, perhaps ending the interference of the generals in government affairs and certainly reducing the threat of a military coup.

The EIC exploited the turmoil and conquered the Sindh province (southwest of the Punjab) in 1843. Confident that some of the Sikh misls in the east supported closer ties with the EIC, the British prepared for war in the Punjab and amassed an army of 40,000 men to the southeast of the Sikh state. In the wider world of empires, the British no longer considered the Sikh Empire a useful buffer zone in case of expansion of the Russian Empire into Afghanistan and northern India – the so-called Great Game. The Sikhs would now have to fight the seemingly unstoppable armies of the East India Company.

Continue reading...

20 notes

·

View notes

Text

Established in the year 1966 as a Flange Manufacturer in India, CD Industries has immensely contributed to the industry for more than five Decades. Technological advancement achieved by CD Industries within a short span of time is what has kept us on top in this fiercely competitive market

0 notes

Text

Arctic Poi coming this winter . . .

#hand-forged ales#alesmith brewing company#tropical marmalade#hazy ipa#hazy india pale ale#aloha#sabro#san diego#california

4 notes

·

View notes

Text

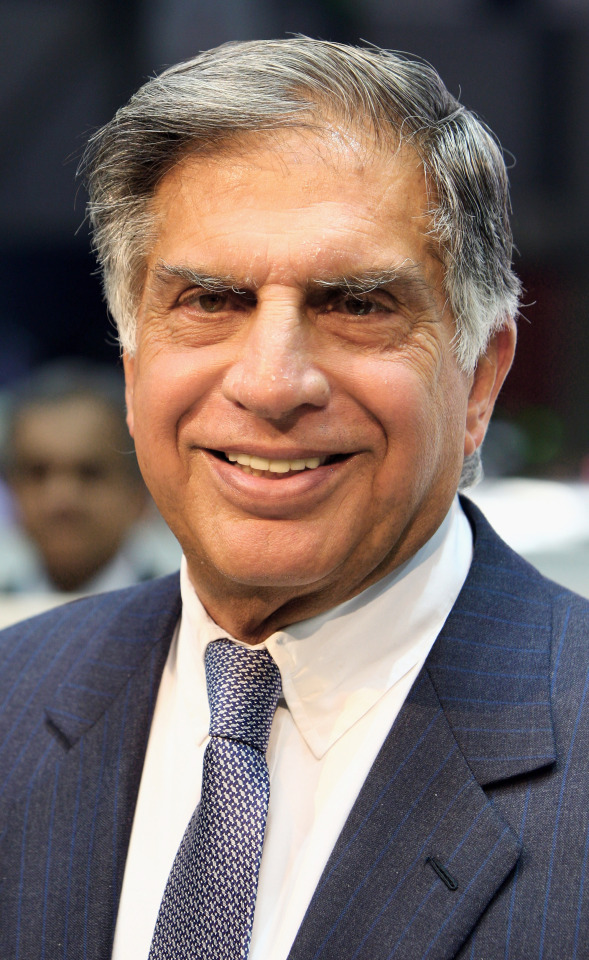

Ratan Tata

Indian business tycoon who turned his family’s Tata Group into a global player, and invested heavily in British industry

Ratan Tata, who has died aged 86, was India’s most celebrated industrialist. He modernised the unwieldy business empire founded by his great grandfather in the 19th century and internationalised it. In the process he spread his interests into western countries, with mixed results.

For the UK, that included the £271m purchase of the Tetley Group in 2000, followed more controversially by the acquisition of the steel company Corus for £6.2bn in 2007. Then, in 2008, Tata, himself a car enthusiast, added the troubled Jaguar Land Rover motor business for a further £1.75bn.

He joined the family firm, Tata Steel, in 1962. Educated in the US, and newly qualified as an architect, the young Tata had, he said, no intention of returning to India. But family ties won out. When his ailing grandmother, Navajbai, who had raised him, asked him to return he did so. He was soon promoted, building his reputation with tough reorganisation, followed by more troubleshooting at the electronics and textile companies.

In 1981, he was made chairman of Tata Industries, and found himself confronting an assortment of separate businesses, with different ownership patterns over which there was little formal control. He made a blueprint for reorganisation, having spent time at the Harvard Business School, but it was rejected after opposition from semi-autonomous bosses.

However, in 1991, the 81-year-old patriarch of the group, JRD Tata, chose him as his successor as the overall chairman. Asked why, he replied: “He has a modern mind.”

Tata soon demonstrated it with a tough programme of reshaping that, against continuing opposition, brought closures, job reductions, and the departure of the heads of the steel, hotel and chemical businesses.

He began to focus more on brands and less on heavy industry, and he benefited from the deregulation of Indian industry championed by Rajiv Gandhi. As part of it, he took the company more heavily into the motor industry. Tata lorries already dominated Indian highways, but now he moved into the car business in line with his own enthusiasms. While always seen as a man of modest habits, he had his own lovingly maintained collection of high-powered and classic cars, and delighted in driving them along Mumbai’s Marine Drive most Sundays.

Tata produced what was called “the first Indian car”, designed by and for Indians, in 1998. Ratan did some of the first drawings himself. The Tata Indica was a success. But when he went further a decade later, and the company conceived the Nano, a tiny saloon described as the world’s most affordable car at a price of about £2,000, the project failed. Such a cheap car was not enticing even to those “on two wheels” whom he hoped to attract.

In 1999 Tata had travelled to Detroit to discuss the sale of the motor business to Ford, only to be asked why his firm had gone into the passenger car business when it clearly knew nothing about it. Later he would turn the tables, buying underperforming Jaguar Land Rover from Ford and reviving it.

With sell-offs and cutbacks, Tata reorganised the group into 98 operating companies from more than 250, reducing the labour force by more than a third. He forged alliances with foreign companies and went into information technology.

He stepped down in 2012, observing the compulsory retirement rule he had himself introduced, but was still regarded as “chairman emeritus” and was brought back unhappily for a few months when his successor was sacked four years later.

His most shocking day came in 2008, when terrorists took over the Tatas’ Taj Mahal hotel on the front at Mumbai with great loss of life. The company has continued to support staff affected and the families of those who died.

Ratan was born in Mumbai, into the large Parsi Tata family, whose wealth came from a scattered collection of businesses including textiles, hotels, engineering, steel and tea. His father, Naval, had been adopted by the son of the founder, Jamsetji Tata. After Naval and his wife, Soonoo, separated when Ratan was seven, the child was brought up with his younger brother, Jimmy, by his grandmother in a grand Tata mansion in central Mumbai.

Aged 17 he was sent to the US to attend Riverdale Country school in New York City, from where he entered Cornell University in Ithaca, New York. He studied engineering before switching to architecture, graduating in 1959. He worked as an architect for a while in Los Angeles before returning to India, and Tata Steel.

In his 20 years at the helm, Tata’s sales grew by 22% annually and its international revenues rose from a quarter to 58% of the total, while Tata Consultancy Services became Asia’s largest software company.

His British investments have been among his less successful. Corus was bought for an over-the-top £6bn just before the global financial crash devastated the industry. Tata claimed it as “the first big step that Indian industry has taken as a global player”. It was later described by a senior Tata executive as “worthless”. The firm is currently negotiating terms of new investment at Port Talbot, which would be accompanied by hundreds of redundancies, while huge plants on Teesside and Scunthorpe have already been closed or sold for a nominal sum.

Jaguar Land Rover was initially a happier story. Tata’s major investment, including in research and development, made the company for a while the largest foreign investor in British industry. But eight years of profits have been followed by losses since 2018.

Surveying the British scene in 2011, Tata told the Times: “Nobody seems to want to exert the effort to make the UK truly competitive. It’s a work ethic issue. In my experience in both Corus and JLR, nobody is willing to go the extra mile.”

He was a major figure in the international business community, close to US politicians as well as the Indian government, advising the former prime ministers Gordon Brown and David Cameron, and sitting on the boards of multinational institutions.

He was also known as a major philanthropist. Many of the Tata companies were owned through trusts he chaired, and huge sums were provided for medical research and university projects both in India and abroad, particularly in the US, where a number of campuses have buildings bearing his name.

A softly spoken man, renowned for his courtesy, he never married, although he described himself as having come close four times. He was known for living modestly, although his recreations included flying his private jet and driving his collection of expensive cars, as well as a speedboat. He was noted for his love of dogs. The Tata headquarters in Mumbai had kennels and made provision for street dogs, and he was a donor to canine charities. In 2014 he was made GBE.

He is survived by Jimmy, by his stepmother, Simone, a half brother, Noel, and two half sisters, Shireen and Deanna.

🔔 Ratan Tata, businessman, born 28 December 1937; died 9 October 2024

Daily inspiration. Discover more photos at Just for Books…?

6 notes

·

View notes

Text

Material handling equipment plays a pivotal role in the overall success of a manufacturing unit by boosting productivity, ensuring safety, improving product quality, and enabling efficient use of resources.

Indolift offers a broad range of material handling solutions designed to cater to manufacturing units.

#chainpulleyblocks

#webbingsling

#steelwireropemanufacturers

0 notes