#flowability

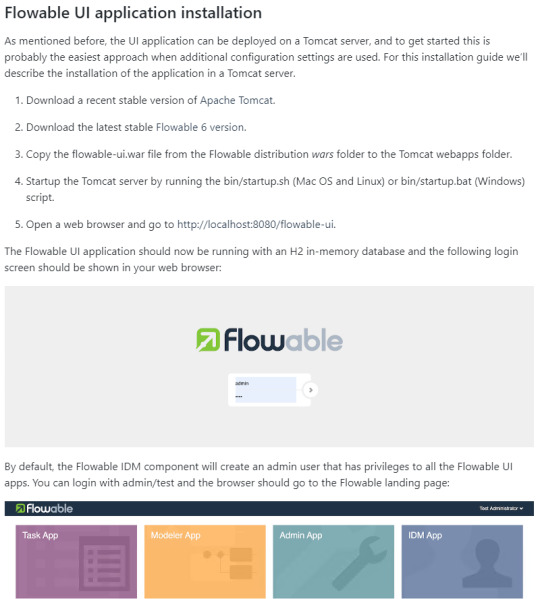

Explore tagged Tumblr posts

Text

Revolutionizing Construction: Unveiling the Latest Breakthroughs in Concrete Admixtures

Introduction:

As the construction industry continues to evolve, innovation plays a crucial role in driving progress and shaping the future. Among the many advancements that have revolutionized the field, concrete admixtures stand out as a game-changer. These additives, when incorporated into cement mixtures, offer enhanced performance, durability, and sustainability, making them indispensable in modern construction practices. In this guest post, we will explore the latest advancements in concrete admixtures and how Ressichem, a leading manufacturer of building and construction materials, is at the forefront of this transformative journey.

Understanding Concrete Admixtures:

Concrete admixtures are chemical formulations added to concrete or cement mixtures to modify their properties and enhance performance. They are primarily used to improve workability, strength, durability, and curing time. By fine-tuning the composition of concrete, admixtures allow for greater flexibility and customization, meeting the diverse demands of various construction projects.

Enhancing Workability and Flowability:

Ressichem has been instrumental in developing cutting-edge concrete admixtures that significantly enhance the workability and flowability of cement mixtures. With the incorporation of high-range water reducers, commonly known as superplasticizers, the viscosity and slump of concrete can be adjusted to suit specific construction requirements. This results in easier placement, reduced labor, and improved finishing, leading to substantial time and cost savings.

Improving Strength and Durability:

Concrete admixtures have opened up new avenues for enhancing the strength and durability of concrete structures. Ressichem's innovative cement admixture solutions, such as high-performance water-reducing agents and pozzolanic materials, enable the production of high-strength concrete with reduced water-cement ratios. This not only improves the compressive strength but also increases resistance to chemical attacks, weathering, and abrasion, resulting in longer-lasting and more resilient structures.

Promoting Sustainability and Environmental Responsibility:

As sustainability becomes a key focus in the construction industry, Ressichem recognizes the importance of eco-friendly solutions. Through extensive research and development, the company has formulated concrete admixtures that contribute to reducing environmental impact. These include admixtures that incorporate industrial by-products like fly ash and slag, which enhance the workability and strength of concrete while reducing the consumption of natural resources and lowering carbon emissions.

Meeting Specialized Construction Needs:

The evolving construction landscape demands specialized solutions to address unique challenges. Ressichem's concrete admixture portfolio includes a range of products designed for specific applications. From self-leveling and self-compacting concrete to underwater concreting and corrosion inhibition, their offerings cater to a wide array of construction requirements, ensuring optimal performance and long-term sustainability.

Conclusion:

Concrete admixtures have ushered in a new era of innovation in the construction industry, offering remarkable advancements in workability, strength, durability, and sustainability. Ressichem, with its state-of-the-art manufacturing facility and commitment to research and development, has emerged as a leading player in this domain. By continuously pushing the boundaries of concrete technology, Ressichem is contributing to the development of safer, more efficient, and environmentally conscious construction practices. As the industry continues to evolve, concrete admixtures will undoubtedly play a pivotal role in shaping a sustainable and resilient future for construction projects worldwide.

#Concrete Admixtures#cement admixture#Ressichem#innovation#construction materials#breakthroughs#workability#flowability#strength#durability#sustainability#eco-friendly solutions#specialized construction needs

0 notes

Text

I wanna have a dragon but like a dog. A dog-dragon? It's a giant dog with wings and it breathes fire. So basically a dragon but not the lizard but a dog....

I can't stop putting my old small toys on my dogs and wonder how cool they would look if these were dog-dragons...

3 notes

·

View notes

Text

i may never get my forklift certification but surely once i get my commercial pesticide applicator's license the women will flock to me in droves

#i have driven a forklift btw. just not certified. osha don't @ me#anyway. ask me abt the difference between wettable powders and dry flowables

3 notes

·

View notes

Link

Discover the brewing game-changer with DynaBoost flowable hop extract no hot water bath! Say goodbye to T-90 pellets and hello to enhanced beer aroma, greater efficiency, and cost savings. Elevate your brewing experience now with this innovative solution. Read more on Brew Scoop. Cheers to better brews!

0 notes

Text

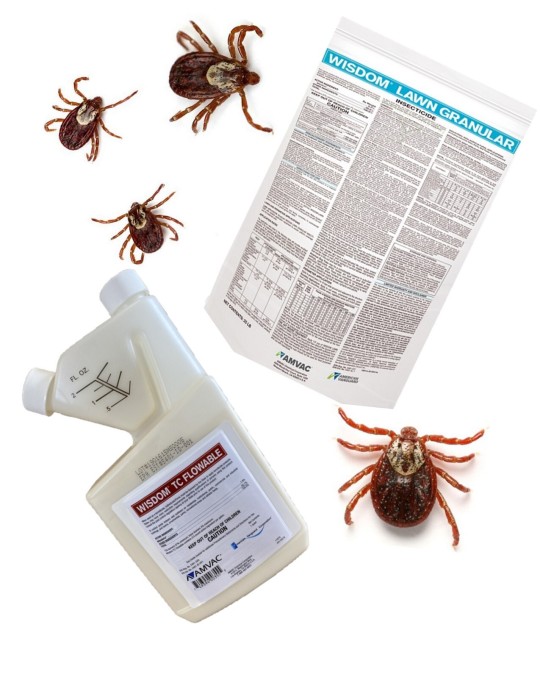

Wisdom TC Insecticide for Effective & Affordable Pest Control

Experience effective pest control with wisdom tc Insecticide. Our potent formula safeguards against pests, ensuring lasting protection. Choose a reliable and affordable solution for a pest-free environment with wisdom tc from OurProSolutions.

0 notes

Text

Inktober 14 the world of Discus Launch Gliders the flowable throwable thermal glidems

©flitetest

youtube

90 notes

·

View notes

Text

oh to engage in the most deepest intellectualest flowable skull-session with a stranger. it's not every day you connect with someone & pick their brain while they do so with yours. i need that, need it respectful & chill to the point where we become acquaintances that ask/pick at the other’s brain whenever we talk. when god, when will it be me ?

#random#conversations#send asks#ask me anything#ask me questions#let’s be friends#4am thoughts#4 am ramblings#i wrote this at 4am#4am posting#be my mutual#be my friend#let’s talk#let’s be mutuals#letsconnect#bored#talk to me#lgbtq community#lgbt nsft#ftm nsft#transmasculine

15 notes

·

View notes

Text

How pour point depressants improve oil flow in cold conditions

The global oil and gas industry faces numerous challenges when operating in extreme weather conditions. One such issue is the formation of wax crystals in crude oil and petroleum products at low temperatures, which hinders flow and transportation. This is where pour point depressants (PPDs) play a crucial role. Designed to enhance oil flow by lowering its pour point, PPDs are an indispensable solution for cold environments.

As a leading pour point depressant manufacturer in India, Imperial Oilfield Chemicals Private Limited specializes in providing high-performance solutions that ensure smooth oil transport even in freezing conditions. This blog explores the importance of pour point depressants, how they work, and why choosing the right supplier is essential for oilfield operations.

Understanding the Role of Pour Point Depressants

Crude oil contains wax molecules that tend to crystallize when exposed to low temperatures. These wax crystals form a network, increasing oil viscosity and obstructing its flow. The pour point is the lowest temperature at which oil remains fluid before becoming solidified.

A pour point depressant modifies the crystallization behavior of wax molecules, preventing them from aggregating into larger clusters. This ensures the oil remains pumpable even in cold conditions, thereby reducing operational downtime and maintenance costs.

How Do Pour Point Depressants Work?

Pour point depressants act as flow improvers by modifying the size and shape of wax crystals in crude oil. Their mechanism involves:

Wax Crystal Modification – PPDs interact with paraffin molecules, disrupting their regular structure and preventing the formation of large, interlocking networks.

Dispersion Effect – They disperse wax molecules evenly throughout the oil, reducing their ability to form solid masses.

Lowering Pour Point – By inhibiting the solidification process, PPDs help lower the temperature at which oil remains fluid, improving flowability.

These mechanisms make PPDs indispensable for regions where temperatures plummet, ensuring a seamless oil supply chain.

Benefits of Using Pour Point Depressants

Companies in the oil and gas sector benefit significantly from using pour point depressants, particularly in extreme weather conditions. Some of the major advantages include:

1. Improved Oil Flowability

PPDs enhance the flow properties of crude oil and refined products, preventing blockages in pipelines and storage tanks.

2. Reduced Operational Costs

By preventing wax deposition, PPDs minimize the need for frequent maintenance, reducing energy consumption and maintenance costs.

3. Enhanced Pipeline Efficiency

Ensuring smooth oil transportation reduces pumping pressure and extends the lifespan of pipelines.

4. Prevention of Equipment Damage

Cold conditions can lead to the accumulation of wax deposits in pumps, valves, and storage tanks, causing mechanical failures. PPDs mitigate this risk, ensuring equipment longevity.

5. Eco-Friendly Solution

Using PPDs reduces the need for thermal heating in pipelines, decreasing energy consumption and carbon emissions.

Industries That Benefit from Pour Point Depressants

Several industries rely on pour point depressants to maintain efficiency in cold environments:

Oil & Gas Exploration – Ensuring crude oil remains pumpable during extraction and transportation.

Petroleum Refining – Enhancing the flow of refined products such as diesel and lubricants.

Pipeline Transportation – Reducing blockages and enhancing efficiency in long-distance oil transport.

Fuel Storage & Distribution – Preventing fuel solidification in storage tanks during winter.

Choosing the Right Pour Point Depressant Supplier in India

Selecting a reliable pour point depressant supplier in India is crucial to ensuring the efficiency and performance of your oilfield operations. Here is why Imperial Oilfield Chemicals Private Limited stands out:

High-Quality Products – As a trusted oilfield chemicals manufacturer and exporter in India, we provide advanced chemical formulations that deliver optimal performance in extreme conditions.

Global Reach – Recognized as a pour point depressant exporter in India, we serve clients worldwide, ensuring smooth and uninterrupted oil flow in different climates.

Customized Solutions – Our team of experts develops tailored solutions to meet the specific requirements of different crude oil compositions.

Commitment to Excellence – As the best oilfield chemicals company in Gujarat, we prioritize quality, innovation, and customer satisfaction.

Why Choose Imperial Oilfield Chemicals Private Limited?

Being the best oilfield chemical products provider in the world, Imperial Oilfield Chemicals Private Limited is dedicated to delivering superior solutions for the oil and gas industry. Here is why clients trust us:

State-of-the-Art Manufacturing – Our advanced production facilities ensure high-purity and effective chemical solutions.

Stringent Quality Control – We adhere to international quality standards, ensuring consistency and reliability.

Strong Customer Support – Our dedicated team offers expert guidance to help clients optimize their oilfield operations.

Conclusion

Pour point depressants are a game-changer in ensuring smooth oil flow in cold conditions. By preventing wax crystallization, they enhance pipeline efficiency, reduce maintenance costs, and improve overall operational efficiency.

As a leading oilfield chemicals exporter Gujarat, Imperial Oilfield Chemicals Private Limited takes pride in offering high-quality pour point depressants that meet global industry standards. Whether you need a reliable pour point depressant manufacturer in India or a pour point depressant supplier in India, we have the expertise and technology to deliver the best solutions for your oilfield needs.

For more information on our products and services, contact us today!

#Pour point depressant manufacturer in India#Pour point depressant exporter in India#Pour point depressant supplier in India

4 notes

·

View notes

Text

Yakima Chief Hops (YCH) and India Hops collaborate to release Strata HyperBoost.

https://bit.ly/4gmoWM9 image courtesy Yakima Chief Hops (YCH) Press Release YAKIMA, WA … Yakima Chief Hops (YCH), a global leader in innovation, has joined forces with Oregon-based Indie Hops to introduce a new offering to brewers: Strata® HyperBoost™. This marks the first collaboration between the two hop suppliers, combining Indie’s well-known and much-loved Strata variety with YCH’s cutting-edge HyperBoost formula, an exclusive flowable hop extract only from YCH. “Indie Hops has always approached customers with a mutual interest in making great beer, so it’s natural that Indie Hops and Yakima Chief Hops have entered into a product collaboration to bring brewers the first Strata HyperBoost,” said Ryan Hopkins, CEO of Yakima Chief Hops. “Indie has been a great partner to the brewing industry in developing hop varieties that bring new and unique flavors to brewers, and they’ve always been a strong advocate for family-owned and operated farms.” Indie Hops CEO Jim Solberg shared his enthusiasm for the project, stating, “Collaboration is a big deal between craft brewers and can be a good thing between hop suppliers as well. We’re stoked to be collaborating with YCH to pair our standout variety Strata with their exciting new cold-side flowable HyperBoost. It’s good for us, good for YCH, and great for brewers!” Strata, celebrated for its unique aroma profile of passion fruit, grapefruit, strawberry, and wafting cannabis, has become a favorite among modern brewers. Now, with HyperBoost’s concentrated oil formula, brewers can effortlessly incorporate Strata’s flavor profile into beer. Designed for maximum efficiency, HyperBoost simplifies the brewing process by allowing brewers to pour the product directly into fermenters, with no additional preparations. YCH’s Research and Development team created HyperBoost in response to brewers' demand to have a highly flowable, concentrated hop product, that would enhance beer flavor and aroma with true-to-style hop attributes. Brewers using HyperBoost have reported significant gains in beer yield, with some achieving increases of up to 10%! HyperBoost can be used to replace a portion of the hop bill or as an addition to amplify the beer’s overall sensory impact. “There is a dizzying number of hop oil extracts in the market now. One key factor that attracted us to YCH HyperBoost for our variety Strata is that HyperBoost is derived solely from hops,” said Solberg. “Real hops grown by real people for brewers to excite customers who really like hoppy beer." Strata HyperBoost is an essential ingredient for brewers at the forefront of innovation, delivering remarkable flavor to beer enthusiasts. Available in limited quantities, Strata HyperBoost comes in 100g easy-to-pour bottles for seamless use, and is available from YCH or Indie Hops. To expand access to Strata’s remarkable characteristics, YCH will also offer Strata T90 pellets. For Strata HyperBoost and pellets, contact Indie Hops, your YCH sales representative, or order through the YCH customer portal. ### Yakima Chief Hops YCH is a 100% grower-owned global hop supplier with a mission to connect brewers with family hop farms. Operating for over 30 years, we have become leaders in innovation, quality, and customer service. We are a resource for brewers, providing industry-leading research and products. We are advocates of sustainability and meaningful social causes, working to support the communities around us. https://www.yakimachief.com/ from Northwest Beer Guide - News - The Northwest Beer Guide https://bit.ly/4gaxVjC

2 notes

·

View notes

Text

does anyone want to fill my wet-well with flowable fill

39 notes

·

View notes

Text

I maybe should've prioritized sorting, folding, & packing clothes before & above knickknacks, books, office supplies. Nailing a nerve so I'll remember next time moving house has to get sequenced into something flowable

7 notes

·

View notes

Text

my favorite bowls to have meals in:

don't be fooled by the "cereal" name, it's good for pastas and stews and soups and anything else that might be a little too flowable for a flat dinner plate. wide surface area lets things cool off quicker but also allows for maximum grated cheese distribution.

and the big bowl, my beloved, for when you want to be able to stir your food without overflowing and/or just want a nice big bowl of whatever.

(28 oz bowl is 6.25" wide, 3.0" high, the flat 15 oz bowl is 8.5" wide, 1.0" high. in comparison the regular 18 oz soup bowl is 6.25" wide, 2.0" high)

i don't know if they've ever been part if a typical set but I had to order them special from the Corelle website. well worth it tbh

I looove when food is in a bowl. Frequently plates are being brought out and I’m thinking this could’ve been a bowl meal but nobody gets it

100K notes

·

View notes

Text

High-Performance Ready Mix Concrete in Karachi: Key Benefits for Builders

In the ever-evolving world of construction, efficiency, durability, and quality are non-negotiable. In a bustling metropolis like Karachi, where infrastructure and real estate development are thriving, Ready Mix Concrete in Karachi has become a vital building material for all types of projects. Allied Materials, a trusted name in the industry, is leading the way in providing top-grade ready mix solutions, helping builders meet the modern demands of construction with ease and confidence.

Understanding Ready Mix Concrete (RMC)

Ready mix concrete (RMC) is a specially manufactured concrete product that is produced in a batching plant under strict quality controls. It is then transported to construction sites using concrete mixer trucks. Unlike traditional site-mixed concrete, RMC ensures consistent quality, saves time, and reduces labor requirements all crucial factors for fast-paced projects in Karachi. Allied Materials provides premium quality Ready Mix Concrete in Karachi to cater to the diverse needs of residential, commercial, and infrastructure projects. Their expertise and dedication ensure that builders receive a product that meets specific strength, durability, and workability standards.

Why Ready Mix Concrete is Gaining Popularity in Karachi

Several factors contribute to the growing preference for ready mix concrete among Karachi’s construction companies:

1. Time Efficiency

Time is money in construction. With RMC, builders no longer have to worry about laboriously mixing materials on-site. Ready mix concrete arrives on-site pre-mixed and ready to pour, saving precious hours and helping projects stay on schedule.

In Karachi’s competitive real estate and infrastructure sectors, this efficiency can make the difference between meeting or missing crucial deadlines.

2. Superior Quality Control

One of the major advantages of using Ready Mix Concrete in Karachi is the consistent quality it offers. Allied Materials uses computerized batching plants where raw materials are carefully weighed and mixed. This reduces human error and ensures a product that consistently meets high-performance standards.

Quality control is particularly critical in Karachi, where extreme weather conditions and heavy usage demand strong, durable structures.

3. Reduction in Material Wastage

Traditional on-site mixing often leads to significant wastage of materials like cement, sand, and gravel. By choosing ready mix concrete, builders can dramatically cut down on wastage, leading to cost savings and a smaller environmental footprint — a priority in today’s eco-conscious world.

4. Customization to Project Needs

Every construction project has unique requirements. Allied Materials offers custom mix designs that can be tailored for specific applications — from high-strength concrete for high-rise buildings to flowable mixes for intricate architectural elements.

Their customizable offerings for Ready Mix Concrete in Karachi make it easy for builders to select the exact product they need, ensuring optimal performance and longevity.

Key Benefits of Choosing Allied Materials for Ready Mix Concrete

Allied Materials has established itself as a reliable and innovative supplier in Karachi. Here are some reasons why partnering with them is a smart move:

1. State-of-the-Art Technology

Allied Materials employs modern batching plants equipped with advanced control systems. This technological edge ensures precise mixing, minimal downtime, and a highly efficient delivery process.

Builders can trust Allied Materials for consistent, high-quality Ready Mix Concrete in Karachi — every single time.

2. Experienced Team and Customer Support

With years of experience in the concrete industry, Allied Materials’ team provides expert advice on selecting the right mix for any project. They work closely with clients to ensure that the delivered product meets all technical and performance requirements.

Additionally, their customer support is responsive and solution-oriented, ensuring a smooth experience from ordering to delivery.

3. On-Time Delivery

In a dynamic city like Karachi, delays can be costly. Allied Materials prides itself on its efficient logistics network, ensuring that concrete reaches construction sites on time. Their fleet of modern transit mixers and pumps facilitates timely deliveries even in the most congested parts of the city.

4. Commitment to Sustainability

Allied Materials is committed to sustainable practices. By minimizing material wastage, optimizing energy use at their plants, and offering eco-friendly concrete options, they contribute to greener construction practices across Karachi.

Applications of Ready Mix Concrete in Karachi’s Projects

Ready mix concrete is versatile and suitable for a wide range of construction projects, including:

Residential Buildings: Villas, apartments, and gated communities benefit from the strength and speed of RMC.

Commercial Complexes: Office towers, malls, and hotels require high-strength concrete for large-scale structures.

Infrastructure Projects: Roads, flyovers, underpasses, and bridges all benefit from the durability of quality RMC.

Industrial Facilities: Factories and warehouses need specialized mixes to withstand heavy equipment and constant use.

Allied Materials understands the diverse demands of Karachi’s builders and offers tailored Ready Mix Concrete in Karachi for every sector.

Challenges in Karachi’s Construction Sector and How RMC Solves Them

Karachi presents unique challenges for builders, including:

Extreme Weather Conditions: High temperatures and humidity can affect the setting time and strength of concrete. Ready mix concrete offers controlled composition and can include additives to counteract environmental stresses.

Traffic and Accessibility Issues: Transporting raw materials to inner-city sites can be complicated. RMC minimizes the need for transporting multiple raw materials, simplifying logistics.

Skilled Labor Shortage: Site-mixed concrete requires skilled workers to measure, mix, and cure correctly. Ready mix eliminates much of this dependency, offering a more consistent and reliable product.

Why Ready Mix Concrete is the Future of Construction in Karachi

The construction industry in Karachi is growing rapidly, with new housing developments, commercial hubs, and mega infrastructure projects constantly emerging. Builders are under increasing pressure to deliver projects faster, more efficiently, and to higher quality standards.

Ready mix concrete answers these demands by offering:

Faster project completion

Improved construction quality

Reduced labor and material costs

Enhanced safety and site cleanliness

By choosing a reputable supplier like Allied Materials, builders not only meet today’s construction challenges but also position themselves for future success. To learn more or to order top-quality Ready Mix Concrete in Karachi, Allied Materials is ready to assist with customized solutions to meet every project’s needs.

Conclusion

High-performance ready mix concrete is transforming the construction landscape in Karachi. Its superior quality, time efficiency, cost-effectiveness, and sustainability benefits make it the preferred choice for modern builders. Allied Materials stands out in delivering premium Ready Mix Concrete in Karachi, offering customized solutions, timely deliveries, and exceptional customer service. Whether you are building a residential villa, a commercial complex, or a large infrastructure project, partnering with Allied Materials ensures your foundation is strong — today and for decades to come.

0 notes

Text

The Invisible Hero in Your Medicine Cabinet: Magnesium Stearate 💊✨

Ever wondered what makes your supplements and medicines so perfectly shaped and consistent? Let me introduce you to the unsung hero of the pharmaceutical world: magnesium stearate powder.

What's This White Powder All About?

Magnesium stearate is that behind-the-scenes ingredient making sure your tablets don't stick to machines during manufacturing. It's like the stage crew of a Broadway show – you never see them, but without them, the whole production falls apart!

Fun fact: It's actually just magnesium combined with stearic acid (which naturally occurs in many foods).

Why Should You Even Care About This?

Because it's in practically EVERYTHING in your medicine cabinet:

Those multivitamins you take? Contains magnesium stearate.

That prescription medication? Yep, probably has it too.

Even some of your favorite powdered makeup products!

The Manufacturing Magic ✨

Here's what this powder actually does:

🔹 Prevents Sticking: Imagine trying to stamp out thousands of tablets per minute and having them constantly stick to the machine. Manufacturing nightmare! Magnesium stearate creates a thin barrier that prevents this.

🔹 Even Distribution: It ensures that all the ingredients mix evenly, so you're not getting a random amount of ingredients in each pill.

🔹 Smooth Operation: During high-speed production, things heat up and create friction. This magical powder reduces that friction, helping maintain the quality of the product.

![Image description: A capsule filled with yellow powder, representing pharmaceutical manufacturing]

The Science-y Bit

Technically speaking, magnesium stearate is a "flow agent" – it makes powders flow better. If you've ever had trouble pouring flour smoothly for baking, you understand the importance of powder flowability. Now imagine that problem but with medicines where exact amounts matter!

Industry Secret

Manufacturers LOVE this stuff because it makes production faster, more efficient, and more reliable. It's like the ultimate industrial lubricant for pharmaceutical production.

In Conclusion...

Next time you easily swallow a perfectly formed tablet or capsule, give a little mental thanks to magnesium stearate – the invisible ingredient making your medicine cabinet more reliable.

#PharmaceuticalScience #BehindTheScenes #SupplementFacts #ManufacturingSecrets #TheMoreYouKnow

0 notes

Text

The Role of Pour Point Depressants in the Oil and Gas Industry

The oil and gas industry relies heavily on chemical additives to optimize production and ensure the smooth flow of crude oil and its derivatives. One such crucial additive is the Pour Point Depressant (PPD), a chemical that significantly impacts the handling and transportation of oil, especially in cold climates. Pour point depressants play a vital role in preventing wax formation and lowering the pour point of crude oil, ensuring that the oil remains fluid even at low temperatures. In this blog, we will explore the importance of PPDs in the oil and gas industry, their function, and why sourcing them from a reliable pour point depressant manufacturer in India is critical for oilfield operations.

Understanding Pour Point and Its Importance

The pour point of a liquid is the lowest temperature at which it remains fluid and pourable. For crude oil and its derivatives, this is a critical property, especially when transporting and storing oil in cold environments. At low temperatures, the waxy components in crude oil begin to crystallize, leading to an increase in viscosity and eventually causing the oil to solidify. This solidification can clog pipelines, damage equipment, and halt oil production altogether.

The introduction of pour point depressants (PPDs) solves this problem. These chemical additives prevent the crystallization of wax in the oil, keeping it fluid and reducing its pour point. By modifying the wax crystals' size and shape, PPDs ensure that the oil remains pumpable even at low temperatures, making them indispensable in the global oil industry.

How Pour Point Depressants Work

Pour point depressants work by interacting with the wax molecules in crude oil, modifying their structure to prevent them from forming large crystals that could impede the flow of oil. The depressants either inhibit the formation of wax crystals or reduce their size, allowing them to stay suspended in the oil without agglomerating. This process helps maintain the oil's viscosity, ensuring it remains flowable at lower temperatures.

In essence, PPDs modify the temperature at which wax crystallization occurs, reducing the likelihood of solidification and blockages. This allows for smoother transportation and processing of oil, particularly in cold weather conditions where oil solidification is a significant concern.

The Benefits of Pour Point Depressants

The use of pour point depressants offers several key benefits to the oil and gas industry. These benefits range from operational efficiency to cost savings, making them an integral part of modern oilfield operations.

1. Ensures Continuous Flow of Oil

The primary advantage of using PPDs is that they ensure the continuous flow of oil through pipelines and storage facilities. By lowering the pour point, PPDs allow oil to remain in a liquid state even in freezing temperatures, preventing blockages and ensuring smooth operations.

2. Reduces Energy Costs

In the absence of PPDs, heating systems are often used to keep oil above its pour point, especially during transportation. This can be energy-intensive and costly. By using pour point depressants, companies can significantly reduce the need for heating, cutting down on energy consumption and lowering operational costs.

3. Prevents Equipment Damage

Solidified oil can cause significant wear and tear on pipelines, pumps, and other oilfield equipment. This leads to expensive repairs and potential downtime. PPDs prevent solidification, reducing the risk of equipment damage and enhancing the longevity of oilfield infrastructure.

4. Improves Storage Efficiency

Storing crude oil in colder climates can be challenging due to the risk of solidification. By incorporating PPDs, storage becomes more efficient as the oil can remain fluid and pumpable, even during extended periods of storage in cold conditions.

5. Facilitates Safe Transportation

The safe transportation of crude oil is a top priority for oil companies. PPDs play a crucial role in ensuring that oil remains fluid during long journeys, particularly when traversing colder regions. By preventing blockages in pipelines and tankers, pour point depressants contribute to safer and more efficient oil transportation.

The Role of Pour Point Depressants in India's Oil and Gas Sector

India, as a major player in the global oil and gas industry, has seen a growing demand for advanced oilfield chemicals to enhance efficiency and safety in oil production and transportation. With its diverse climate and geographical challenges, including cold regions in the north, India requires high-performance pour point depressants to ensure that its oil production and transportation networks remain operational.

Leading PPD Manufacturers in India

India is home to several prominent pour point depressant manufacturers, with a strong presence in key industrial hubs like Gujarat. As a top pour point depressant manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. is committed to providing high-quality PPD solutions that meet the stringent requirements of the oil and gas industry.

Being located in Gujarat, particularly in Vadodara, offers numerous advantages for PPD manufacturing. Vadodara is a significant industrial center with excellent access to raw materials, infrastructure, and skilled labor, making it an ideal base for oilfield chemical production. Imperial Oilfield Chemicals Pvt. Ltd., a leading pour point depressant manufacturer in Vadodara, is well-positioned to meet the needs of oil companies both within India and abroad.

Exporting PPDs to Global Markets

India's oilfield chemicals sector is not just focused on domestic demand but is also an important player in the global market. As a pour point depressant exporter in India, Imperial Oilfield Chemicals Pvt. Ltd. has established a strong presence in international markets, supplying high-performance PPDs to countries across the globe. Our PPDs meet international quality standards and are trusted by oil companies for their effectiveness in extreme weather conditions.

Choosing the Right Pour Point Depressant

Selecting the right pour point depressant for specific oilfield operations is critical. The choice of PPD depends on several factors, including the type of crude oil, operating temperatures, and the specific challenges faced by the oilfield. High-quality PPDs are designed to work across a broad range of crude oils, ensuring flexibility and effectiveness in diverse environments.

At Imperial Oilfield Chemicals Pvt. Ltd., we offer a range of pour point depressants tailored to meet the unique needs of our clients. As a pour point depressant manufacturer in Gujarat, we understand the challenges faced by oil companies operating in varying climates and environments, and our products are designed to provide reliable performance across the board.

The Future of Pour Point Depressants in India

The demand for pour point depressants is expected to grow in India, driven by the expansion of the oil and gas sector and the need for more efficient, cost-effective oil production and transportation methods. As one of the best oilfield chemicals companies in India, Imperial Oilfield Chemicals Pvt. Ltd. is at the forefront of this growth, continuously innovating and improving our products to meet the evolving needs of the industry.

Why Choose Imperial Oilfield Chemicals Pvt. Ltd.?

At Imperial Oilfield Chemicals Pvt. Ltd., we are committed to providing our clients with high-quality pour point depressants that enhance the performance and safety of their oilfield operations. Here are a few reasons why we are considered the best oilfield chemicals company in India:

1. Expertise in Oilfield Chemicals

With years of experience in manufacturing oilfield chemicals, including PPDs, we have developed a deep understanding of the challenges faced by the oil and gas industry. Our expertise allows us to offer innovative solutions that meet the specific needs of our clients.

2. Quality Assurance

We adhere to strict quality control measures at every stage of production to ensure that our PPDs meet the highest standards of performance and reliability. Our commitment to quality has made us a trusted pour point depressant manufacturer in Vadodara and beyond.

3. Global Reach

As a leading pour point depressant exporter in India, we serve clients not only within India but also across the globe. Our ability to meet international standards and deliver high-performance PPDs has earned us a reputation as a reliable partner in the oil and gas industry.

4. Customer-Centric Approach

We understand that every oilfield operation is unique, which is why we work closely with our clients to develop customized PPD solutions that meet their specific requirements. Our customer-centric approach has helped us build long-lasting relationships with oil companies both in India and internationally.

Conclusion

Pour point depressants play a crucial role in ensuring the smooth flow of oil, particularly in cold environments where wax formation can hinder production and transportation. As a trusted pour point depressant manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. is proud to offer high-performance PPDs that help oil companies optimize their operations and reduce costs.

Our commitment to quality, innovation, and customer satisfaction has made us one of the leading pour point depressant manufacturers in Gujarat and a key pour point depressant exporter in India. If you are looking for reliable, high-quality PPDs to enhance your oilfield operations, look no further than Imperial Oilfield Chemicals Pvt. Ltd.

#Best oilfield chemicals company in India#Pour point depressant exporter in India#Pour point depressant manufacturer in Vadodara#Pour point depressant manufacturer in Gujarat#Pour point depressant (PPD)#Pour point depressant manufacturer in India#India#Africa#Kuwait#Bahrain#United Arab emirates#Jordan

4 notes

·

View notes