#die manufacturing company

Explore tagged Tumblr posts

Text

4 Ways Satellite Metal Helps You Reduce Metal Part Manufacturing Costs

Metal parts are necessary components in many different industries, and the price of their manufacture can have a significant effect on a project’s total costs. Things like process complexity, accuracy, and material choice impact these expenses. Finding methods to cut these costs without sacrificing quality is essential in a market that is always very competitive. With nearly fifty years of experience, Satellite Metal provides clients with cutting-edge methods and creative solutions to successfully reduce their metal part production costs. Let’s understand four ways how it can help your business.

Modern Die Manufacturing and Design

Metal part manufacture depends heavily on die design, directly affecting part quality and production efficiency. Satellite Metal is a die manufacturing company that produces exact and effective die designs using cutting-edge CAD/CAM technology. Through investments in cutting-edge software and precise machinery, they guarantee that dies are made to reduce material waste and maximize production cycles. With time, these cost savings are substantial since die production precision lowers the requirement for frequent modifications and reworks.

Superior Stamping Techniques

Stamping is one of the least expensive ways to make metal components, particularly in large quantities. Satellite Metal’s stamping operations are designed to be as waste-free and efficient as possible. Tight checks can produce constant quality with modern stamping equipment. Custom metal stamping services cut the time and workforce needed for every batch of parts, reducing overall production costs.

Electric Erosion Cutting Precision

Reducing material waste and guaranteeing the integrity of the finished product need precise cutting of metal components. Modern electro-erosion technology used by Satellite Metal allows for unmatched precision in the cutting of complex shapes and adds minute details. This approach lowers the quantity of scrap material produced during the cutting process while yet guaranteeing great precision. Customers can save time and money by achieving intricate designs with EDM without the need for extra finishing procedures. Less wastage of materials and higher accuracy bring down production costs for the clients at metal stamping company.

Deburring and Finishing Processes

Metal parts can be made smooth, useful, and visually appealing when they are finished and deburred. Satellite Metal’s deburring and finishing procedures are made to be incredibly effective and yield excellent results fast. Significant cost savings are achieved through time savings brought about by streamlining these procedures. Their finishing experience also guarantees parts are of the best quality, which lowers the possibility of expensive reworks or replacements.

For more information, visit https://www.satellitemetal.com/

Original Source: https://bit.ly/45UF6ZH

0 notes

Text

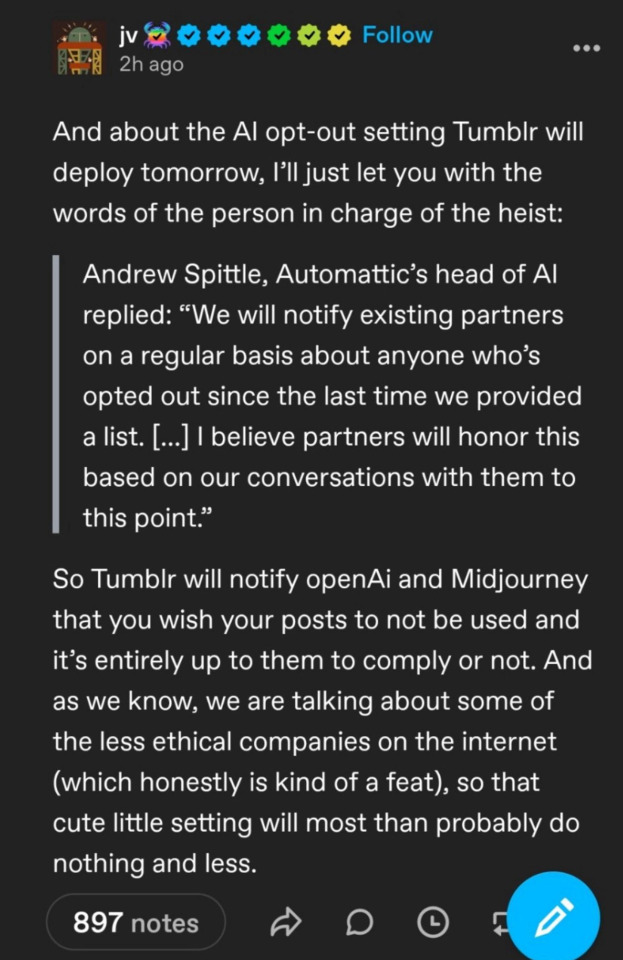

Honest to god fuck Apple, fuck the government officials who created FOSTA/SESTA over 5 years ago, fuck every single person who bought this site off the original creators and proceeded to spend the rest of the previous decade making all the wrong decisions, but more importantly, fuck Matt Mullenweg and Automattic.

Man deadass took a site that was, once upon a time back in the 2010s the best, most welcoming, most educational, social blogging site on the internet, and turned it into a fucking data mine for techbros to plunder, all while driving off queer users and staff.

It is depressing seeing the place I grew up on turn out this way.

As always though if you wanna find me I mostly use Discord, but my new socials are... My Bluesky here:

and my Cohost here:

#Contemplating deleting both my blogs#But I'm patient#I know the AI hype is nothing more than a manufactured scam and a fad that'll eventually die out#If not#then the legal battles calling it out as theft of people's hard work if successful will definitely hasten it's death#But I'm def still not gonna use this place as religiously as I once did#Not until matt the transphobe-at-CEO-level is ousted from the company#god I wish this trend of manbabies being given high level jobs in the tech industry over those who are qualified would fucking die already#What happened to this place between then and now?

4 notes

·

View notes

Text

0 notes

Text

Top Closed Die Forging Manufacturers in India - Elmex Electric Pvt. Ltd.

Elmex Electric Pvt. Ltd. ranks among the top 10 forging companies in India, specializing in closed die forging solutions. As trusted closed die forging manufacturers in India, we deliver precision-engineered components that meet the highest industry standards for strength and durability. Contact us for tailored forging solutions. Closed die forging manufacturers in india, Top 10 forging companies in india.

Elmex Electric Pvt. Ltd. Add : 12, GIDC Estate, Makarpura, Vadodara -390010, Gujarat, India. Ph : 02652642021 / 23 Mo : (+91)8905403006 Fax : 02652638646 mail : [email protected] Visit us at : https://elmex.net/ (+91)8905403006, (+91)8905902016

Facebook : https://www.facebook.com/ElmexControls/ Twitter : https://twitter.com/elmexcontrols LinkedIn : https://www.linkedin.com/company/elmex-controls-pvt.-ltd. Youtube : https://youtu.be/LOooD_SvEMo

#Closed die forging manufacturers in india#Top 10 forging companies in india#Terminal blocks in India

0 notes

Text

Automotive Injection Molding - Precision Manufacturing for High-Quality Auto Parts

Automotive Injection Molding by Keiteq offers advanced solutions for producing precise and durable automotive components. This process ensures high efficiency and consistency, making it ideal for creating complex parts like dashboards, bumpers, and interior panels.

#electronics manufacturing services#automotive mold manufacturers#electronic manufacturing services#aluminium die casting#automotive molding#plastic injection molding supplier#plastic injection molding company

0 notes

Text

Advantages and Disadvantages of Die Cutting in Jackets Manufacturing

visit:

As a business owner selling jackets, know about the advantages and disadvantages of die cutting in jacket manufacturing.

#Guides For Die Cutting#Jacket Manufacturers#Jacket Manufacturing Companies#Jacket Supplier#Jackets In Bulk#Wholesale Jackets#Wholesale Jackets In Bulk#Wholesale Jackets Manufacturer#Wholesale Jackets Supplier

0 notes

Text

How Indian Die Casting Companies Are Transforming the Automotive Industry

The automotive industry is undergoing a profound transformation, and Indian die casting companies are at the forefront of this evolution. Among these, Taural India stands out as a key player, leveraging advanced technologies and innovative processes to drive significant changes. This blog explores how die casting companies in India, with a particular focus on Taural India, are reshaping the automotive landscape, emphasizing the role of aluminum die casting.

The Rise of Die Casting Companies in India

Die casting, a metal casting process characterized by forcing molten metal under high pressure into a mold cavity is crucial in manufacturing lightweight and high-strength components. India, with its burgeoning industrial base and skilled workforce, has become a hub for die casting activities, particularly aluminum die casting. This growth is fueled by the demand for more efficient, lightweight, and environmentally friendly automotive components.

Taural India: A Leader in Aluminum Die Casting

Taural India exemplifies the strides made by Indian die casting companies. Specializing in aluminum die casting, Taural India has established itself as a leader by focusing on quality, innovation, and customer satisfaction. The company's advanced facilities and commitment to excellence have made it a preferred supplier for many automotive giants.

Lightweight Components: Enhancing Fuel Efficiency and Performance

One of the primary ways Indian die casting companies are transforming the automotive industry is by producing lightweight components. Aluminum die casting is particularly beneficial in this regard. Aluminum, being lighter than steel, reduces the overall weight of vehicles. This reduction in weight leads to better fuel efficiency and improved performance, addressing the industry's growing need for sustainability and cost-effectiveness.

Taural India has mastered the art of creating lightweight aluminum components without compromising on strength and durability. By supplying parts that contribute to lower fuel consumption and emissions, Taural India is helping automotive manufacturers meet stringent environmental regulations and consumer demands for greener vehicles.

High Precision and Superior Quality

In the competitive automotive sector, precision and quality are paramount. Die casting companies in India, such as Taural India, employ state-of-the-art technologies to ensure the highest levels of accuracy in their products. The use of advanced die casting machines, computerized control systems, and rigorous quality checks enable these companies to produce components that meet exact specifications and standards.

Taural India's focus on precision ensures that each component fits perfectly within the larger assembly, reducing the need for additional machining and minimizing production costs. This level of precision not only enhances the performance of automotive parts but also extends their lifespan, offering better value to automotive manufacturers and end consumers.

Innovation in Die Casting Processes

Innovation is a key driver of the transformation seen in the automotive industry. Die casting companies in India are continually investing in research and development to improve their processes and products. Taural India is no exception. By adopting innovative techniques such as vacuum die casting, squeeze casting, and the use of advanced alloys, Taural India has been able to produce components with superior mechanical properties and minimal defects.

These innovations have led to the production of parts that can withstand higher stress and temperatures, making them ideal for modern automotive applications. The ability to produce complex geometries with high repeatability also allows for more design flexibility, enabling automotive manufacturers to create more efficient and aesthetically pleasing vehicles.

Cost-Effective Solutions

Cost efficiency is another area where Indian die casting companies are making a significant impact. By streamlining production processes and optimizing resource utilization, companies like Taural India can offer high-quality components at competitive prices. This cost advantage is critical in the automotive industry, where manufacturers are constantly looking to reduce production costs without sacrificing quality.

Taural India's efficient production methods, combined with its strategic location and access to a skilled labor force, enable it to provide cost-effective solutions to automotive manufacturers worldwide. This cost efficiency, coupled with high quality, makes Taural India an attractive partner for both domestic and international clients.

Commitment to Sustainability

Sustainability is no longer a buzzword but a necessity in today's industrial landscape. Die casting companies in India are increasingly focusing on sustainable practices, and Taural India is leading by example. By using recyclable materials like aluminum and implementing energy-efficient manufacturing processes, Taural India minimizes its environmental footprint.

Moreover, the company invests in waste reduction technologies and adheres to strict environmental regulations. This commitment to sustainability not only enhances the company's reputation but also helps its clients achieve their sustainability goals, thereby contributing to a greener automotive industry.

Strategic Partnerships and Collaborations

The transformation of the automotive industry is also facilitated by strategic partnerships and collaborations. Die casting companies in India, including Taural India, actively collaborate with automotive manufacturers, research institutions, and technology providers to stay ahead of the curve. These partnerships enable the exchange of knowledge and expertise, leading to the development of better products and processes.

Taural India's collaborations have resulted in several successful projects, showcasing its ability to adapt to changing market demands and technological advancements. By working closely with its partners, Taural India ensures that it remains at the cutting edge of innovation, providing its clients with the best possible solutions.

Future Prospects

The future looks promising for die casting companies in India. With the increasing adoption of electric vehicles (EVs) and the ongoing demand for lightweight and high-performance components, the role of aluminum die casting is set to become even more significant. Taural India is well-positioned to capitalize on these opportunities, thanks to its strong foundation in quality, innovation, and sustainability.

As the automotive industry continues to evolve, Indian die-casting companies will play a crucial role in shaping its future. By providing advanced solutions that meet the changing needs of the market, companies like Taural India are transforming the industry and contributing to a more sustainable and efficient automotive ecosystem.

Conclusion

Die casting companies in India, particularly those specializing in aluminum die casting like Taural India, are making a substantial impact on the automotive industry. These companies are driving significant changes through their focus on lightweight, high-precision, and cost-effective components, coupled with a commitment to innovation and sustainability. As the industry continues to evolve, the contributions of Indian die casting companies will be instrumental in shaping the future of automotive manufacturing.

#Die casting companies in India#aluminum die casting manufacturers#aluminium die casting manufacturers in india#aluminum die casting

0 notes

Text

Reasons to Use Aluminum for Die-Casting

There are various popular processes you can use to form aluminum; however, one of the most common processes that a designer considers is aluminum die casting.

Nowadays, Aluminium Die Casting Companies use the method for many automotive, industrial, and telecommunication products. In fact, it is also utilized to create electrical hydraulic, and lighting components.

Overview of Aluminum Die Casting

To put it simply, it is a metal-forming process that enables the design of intricate aluminum parts. To initiate the process aluminum alloys are heated to excessively high temperatures until they are molten.

Furthermore, under high pressure, liquid aluminum is inserted into the hole of the steel die. Since the die is made up of two halves, the solid molten aluminum gets separated and displays the aluminum part. The product is developed explicitly with a soft texture and usually needs the tiniest and no machining process.

The Advantages of Aluminum Die-Casting

Its Weight

Aluminum is hugely favored for its lightweight quality. Since it is the lightest metal, it is no great surprise that Aluminum Die-Cast parts are highly sought after in the aviation and motor industries.

Flexibility

Are you looking for a metal that’s easy to work? Aluminium is the answer! Since it is the second malleable metal and ductile – it is hard to beat in terms of flexibility.

Conductivity

Aluminum is a great electrical and thermal conductor. Though copper is even more conductive – it is heavier which can often be a disadvantage. It is only a third of the weight of copper. Adding to the fact, that aluminum is non-sparking – it is the chosen metal for various applications including electrical products, computer parts, and LED lighting.

Resistance to Corrosion

Thanks to the strong oxide film – it forms on the surface of aluminum when it is exposed to air or water. It is highly resistant to corrosion. The coat of aluminum oxide hardens the surface and keeps the metal free from corrosion.

Bottom Line

Aluminium is 100% recyclable. Aluminum can be melted down and reused without its favorable quality. Apart from the topmost quality – there are more advantages to using aluminum in die casting.

#precision manufacturing#precision machining companies#cnc machining service#die casting companies#die cast metal#aluminium die casting#aluminum alloy die casting#medical device companies#machining medical devices#medical equipment parts#medical component supplier#optical manufacturing#medical parts supplier

1 note

·

View note

Text

Casting Manufacturer Industry in Rajkot, Gujarat, India, Die Casting Manufacturer,

Aluminium die casting industry in Rajkot,Gujarat, India,

Our company offers a comprehensive suite of manufacturing solutions, including die casting services. With a focus on precision, efficiency, and quality, we cater to diverse industries and provide tailored solutions to meet specific project needs. Casting Manufacturer Industry in Rajkot, Gujarat, India,

Milling Die Casting Services From the Aluminium Gravity Die Casting Manufacturing Industries In Rajkot

Our Milling Alluminium Gravity Die Casting Manufacturing services leverage state-of-the-art equipment and advanced technology to deliver high-precision parts with tight tolerances. Key highlights of our machining services include:

Advanced Equipment: We utilize modern Die casting Service material machines with multi-axis capabilities, enabling us to perform a wide range of machining operations with speed and accuracy.

Die Casting Manufacturer,

Aluminium die casting industry in Rajkot,Gujarat, India,

#india#gujarat#aluminium die casting industry in rajkot#aluminium casting manufacturer company in rajkot#aluminium gravity die casting industry in rajkot#diecasting#Diecastingmanufacturer#Diecastingmanufacturerindustryinrajkotgujarat#manufacturer

0 notes

Text

Top Casting Manufacturers in Howrah, West Bengal | Call 9163221666

✔️ Strictly follow quality control regime ✔️ Products at competitive prices ✔️ Consider the latest market demands ���️ Maintain prompt and scheduled delivery ✔️ Encourage suggestions and feedback from customers

#Casting Manufacturer in West Bengal#aluminium die casting factory kolkata west bengal#casting manufacturer in west bengal#casting manufacturer#injection moulding companies#investment casting companies#zinc die casting#stainless steel casting companies#die casting companies near me#aluminum die casting manufacturer

0 notes

Text

#die cast manufacturer#casting company in india#die casting company in india#casting manufacturers#die casting manufacturer

0 notes

Text

"The story of 'John Doe 1' of the Democratic Republic of the Congo is tucked in a lawsuit filed five years ago against several U.S. tech companies, including Tesla, the world’s largest electric vehicle producer. In a country where the earth hides its treasures beneath its surface, those who chip away at its bounty pay an unfair price. As a pre-teen, his family could no longer afford to pay his $6 monthly school fee, leaving him with one option: a life working underground in a tunnel, digging for cobalt rocks. But soon after he began working for roughly two U.S. dollars per day, the child was buried alive under the rubble of a collapsed mine tunnel. His body was never recovered.

The nation, fractured by war, disease, and famine, has seen more than 6 million people die since the mid-1990s, making the conflict the deadliest since World War II. But, in recent years, the death and destruction have been aided by the growing number of electric vehicles humming down American streets. In 2022, the U.S., the world’s third-largest importer of cobalt, spent nearly $525 million on the mineral, much of which came from the Congo.

As America’s dependence on the Congo has grown, Black-led labor and environmental organizers here in the U.S. have worked to build a transnational solidarity movement. Activists also say that the inequities faced in the Congo relate to those that Black Americans experience. And thanks in part to social media, the desire to better understand what’s happening in the Congo has grown in the past 10 years. In some ways, the Black Lives Matter movement first took root in the Congo after the uprising in Ferguson in 2014, advocates say. And since the murder of George Floyd and the outrage over the Gaza war, there has been an uptick in Congolese and Black American groups working on solidarity campaigns.

Throughout it all, the inequities faced by Congolese people and Black Americans show how the supply chain highlights similar patterns of exploitation and disenfranchisement. ... While the American South has picked up about two-thirds of the electric vehicle production jobs, Black workers there are more likely to work in non-unionized warehouses, receiving less pay and protections. The White House has also failed to share data that definitively proves whether Black workers are receiving these jobs, rather than them just being placed near Black communities. 'Automakers are moving their EV manufacturing and operations to the South in hopes of exploiting low labor costs and making higher profits,' explained Yterenickia Bell, an at-large council member in Clarkston, Georgia, last year. While Georgia has been targeted for investment by the Biden administration, workers are 'refusing to stand idly by and let them repeat a cycle that harms Black communities and working families.'

... Of the 255,000 Congolese mining for cobalt, 40,000 are children. They are not only exposed to physical threats but environmental ones. Cobalt mining pollutes critical water sources, plus the air and land. It is linked to respiratory illnesses, food insecurity, and violence. Still, in March, a U.S. court ruled on the case, finding that American companies could not be held liable for child labor in the Congo, even as they helped intensify the prevalence. ... Recently, the push for mining in the Congo has reached new heights because of a rift in China-U.S. relations regarding EV production. Earlier this month, the Biden administration issued a 100% tariff on Chinese-produced EVs to deter their purchase in the U.S. Currently, China owns about 80% of the legal mines in the Congo, but tens of thousands of Congolese work in 'artisanal' mines outside these facilities, where there are no rules or regulations, and where the U.S. gets much of its cobalt imports. 'Cobalt mining is the slave farm perfected,' wrote Siddharth Kara last year in the award-winning investigative book Cobalt Red: How The Blood of the Congo Powers Our Lives. 'It is a system of absolute exploitation for absolute profit.' While it is the world’s richest country in terms of wealth from natural resources, Congo is among the poorest in terms of life outcomes. Of the 201 countries recognized by the World Bank Group, it has the 191st lowest life expectancy."

3K notes

·

View notes

Text

#aluminum-die-casting-companies#die-casting-companies#aluminum-die-casting-manufacturers#custom-die-maker

0 notes

Text

Did You Know?

Steel is resistant to scratches, stains and overall porosity issues, providing lasting beauty and durability.

➡️ Visit our website: https://sandeepenterprises.com ➡️Follow us on Instagram: https://www.instagram.com/sandeep_enterprises/ ➡️Follow us on Facebook: https://www.facebook.com/SandeepEnterprisesSE/ ➡️Follow us on LinkedIn: https://www.linkedin.com/company/28695826/admin/feed/posts/ ➡️Follow our Pinterest: https://in.pinterest.com/sandeep_enterprises/ ➡️Follow our Tumblr: https://www.tumblr.com/sandeepenterprises ➡️Subscribe our YouTube Channel: https://www.youtube.com/channel/UCj8046i0M6dYO62TOK0gQUw ➡️Visit our Google Map Sonipat Location: https://goo.gl/maps/tT9ar8dfKgbBssBn6 ➡️Visit our Google Map Delhi Location: https://goo.gl/maps/kNJdAc5LA1SUTMzeA 📧Mail us: [email protected] 📞Call us: +91-9654956890

#steel#manufacturing#plastic mould steel#die and tool steel#plastic moulding company#plastic#manufacturer#manufacturingindustry#manufacturers

0 notes

Text

Precision Press: Mastering the Art of Stamping Die Design

Precision Press: Mastering the Art of Stamping Die Design" is an essential guide for professionals and enthusiasts in the field of stamping die design. This comprehensive book delves into the intricate world of precision stamping and offers valuable insights into the design and manufacturing of high-quality stamping dies.

Authored by industry experts, this book provides a step-by-step approach to mastering the art of stamping die design. It covers a wide range of topics, including die material selection, die component design, tooling considerations, die layout, and die manufacturing processes. With detailed explanations and illustrations, readers gain a deep understanding of the principles and techniques involved in designing precision stamping dies.

The book also addresses advanced concepts such as progressive die design, formability analysis, die simulation, and optimization techniques, catering to the needs of experienced die designers. Furthermore, it explores emerging trends and technologies in the field, keeping readers up to date with the latest advancements.

Whether you are a novice or a seasoned professional, "Precision Press" equips you with the knowledge and skills necessary to create efficient and accurate stamping dies. It serves as an indispensable resource for anyone seeking to enhance their expertise in the art of stamping die design.

1 note

·

View note

Text

Precision Plastic Injection Molding company | Keiteq

Plastic Injection Molding Company specializing in molding. The basic process includes creating the product design and making a tooling mold to fit the product. we deliver top-quality molds and exceptional services to meet your unique needs. Trust Keiteq, the experts in plastic injection mold company solutions, for your next project. Visit us to learn more!

#plastic injection molding supplier#electronics manufacturing services#aluminium die casting#electronic manufacturing services#plastic injection molding company

0 notes